Compartment type passivation device used for threaded carding tool edges

A thread comb, thread comb technology, applied in machine tools suitable for grinding workpiece edges, surface polishing machine tools, grinders, etc. Friction damage and other problems, to achieve the effect of improving passivation quality, prolonging service life and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

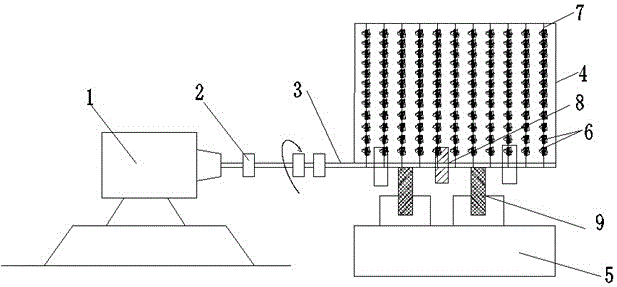

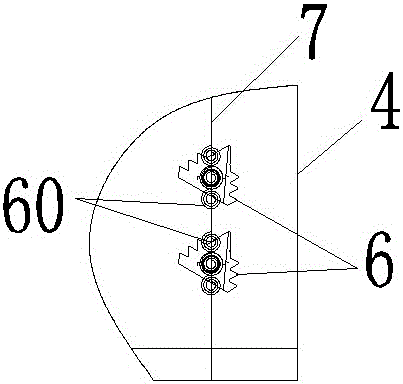

[0012] see figure 1 and 2 , the embodiment of the present invention includes: a box-type passivation device for the edge of a threaded comb, including: a motor 1, a continuously variable transmission 2, a transmission shaft 3, a passivation container 4 and a base 5, and the motor 1 passes without The stage transmission 2 is connected to the transmission shaft 3, and the passivation container 4 is provided with a plurality of installation shafts 7 for fixing the comb cutter 6, and the installation shaft 7 is covered with a plurality of thread comb cutters 6, and every two thread comb cutters The knives 6 are isolated by a spring 60, the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com