Sintering method for reducing PERC battery aluminum cavities

A sintering method, aluminum void technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of improving battery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

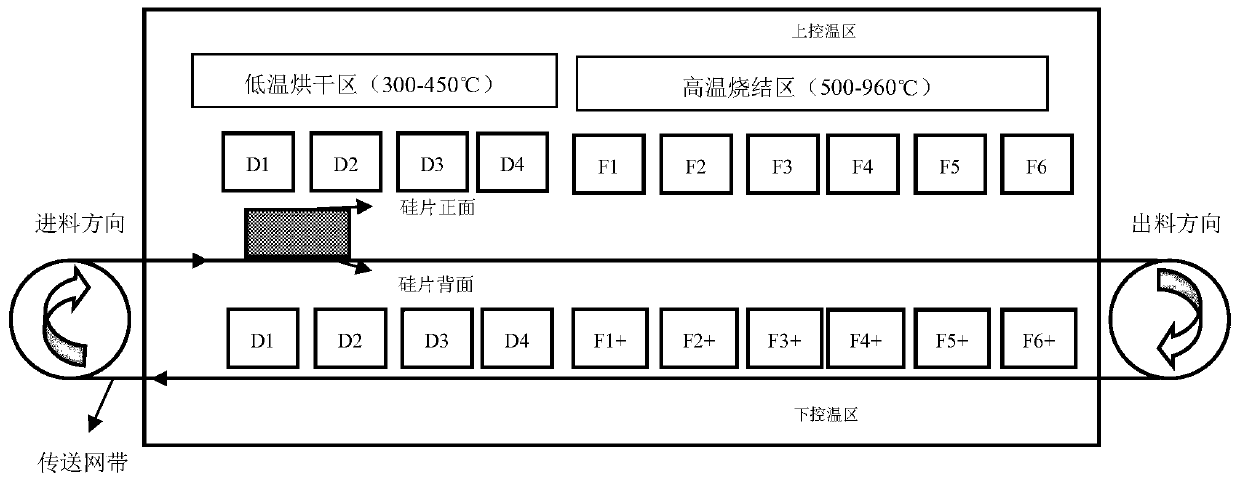

[0028] Such as figure 1 and Figure 3-4 As shown, a sintering method for improving PERC battery aluminum voids in this embodiment includes the following steps:

[0029] Step 1: According to the battery process, the original silicon wafer is cleaned and textured from one time to the back plated with passivation and anti-reflection film and front anti-reflection film, and then the back is grooved by laser equipment, and the corresponding power is selected according to the requirements of the PERC process for different graphics ( Dot / Dash / Line, etc.) slotting.

[0030] Step 2: The grooved silicon wafers are printed with back silver back aluminum front silver paste in the screen printing equipment, and the printed silicon wafers are fed to the sintering equipment (Despatch) with the blue film face up and the aluminum paste face down That is, sintering is carried out in the sintering furnace tube. The sintering equipment includes a low-temperature drying zone and a high-temperatu...

Embodiment 2

[0037] Embodiment 2 result and discussion

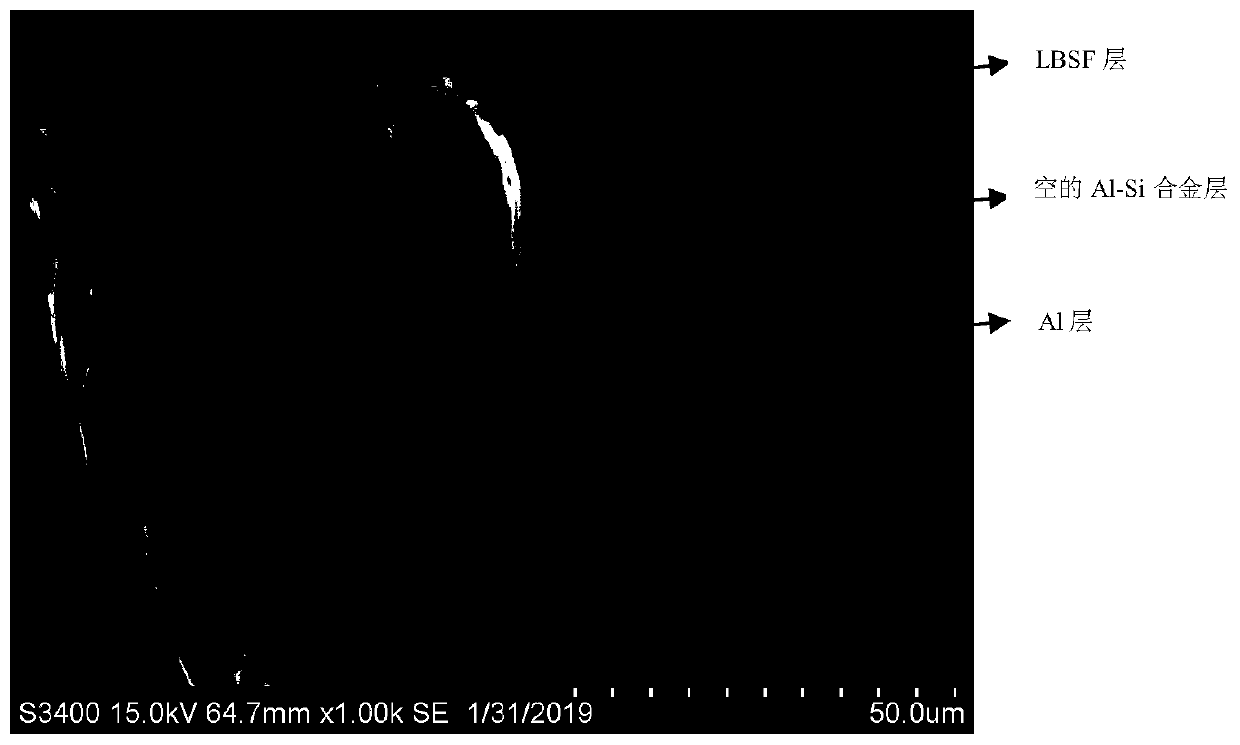

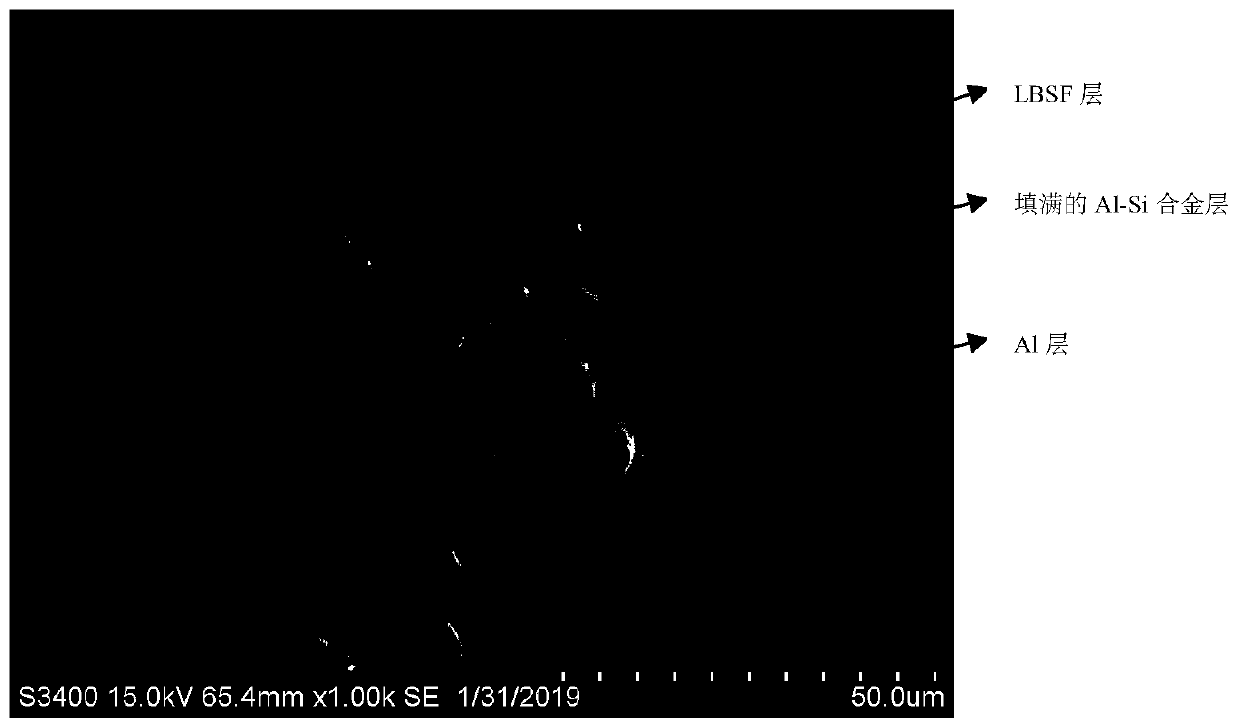

[0038] (1) The detection of the battery sheet produced by using Example 1 and the battery sheet produced by the traditional process of Comparative Example 1 is carried out, and the SEM section is analyzed for aluminum voids and LBSF. The results are shown in Figure 2-4 .

[0039] figure 2 The results show that the LBSF layer of the battery sheet prepared by the traditional sintering method is thin and uneven, and the Al-Si alloy layer has aluminum voids.

[0040] image 3 The results show that using the sintering method with temperature difference in Example 1 can obtain aluminum-free voids and a thicker and uniform LBSF, further improving the efficiency of solar cells.

[0041] Figure 4 The aluminum-silicon phase diagram shows that the aluminum-silicon phase undergoes liquid-solid transition along the solidus line according to F (960 ° C) → E (577 ° C), and the aluminum-silicon LBSF → aluminum-silicon alloy → aluminum layer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com