Method for preparing a-Si: H thin film based on hydrogen plasma treatment

A plasma, a-si technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as affecting passivation effect, epitaxial growth, reducing silane decomposition rate, etc., to improve passivation quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First, the substrate is cleaned. A 250um thick (100) oriented phosphorus-doped N-type double-polished CZ silicon wafer (resistivity 5-10Ωcm) was used as the substrate, and a simplified RCA method was used before the deposition of the amorphous silicon film (Wang Nan, Zhang Yu, Zhou Yuqin. Research on the key process of interface treatment of silicon heterojunction cells [J]. Journal of Synthetic Crystals, 2013, 42(2): 000235-239.) Removal of organic contamination and metal impurities on the surface of silicon wafers.

[0024] Then, the chemical pretreatment of the substrate is carried out. The silicon wafer cleaned by the simplified RCA method was immersed in a dilute HF solution (concentration: 3%), and then the silicon wafer was placed in a deionized water (80°C) water bath for 60 minutes; before a-Si:H thin film deposition, the The cleaned silicon wafer was immersed in dilute HF solution (concentration: 3%) again and blown dry with nitrogen gas.

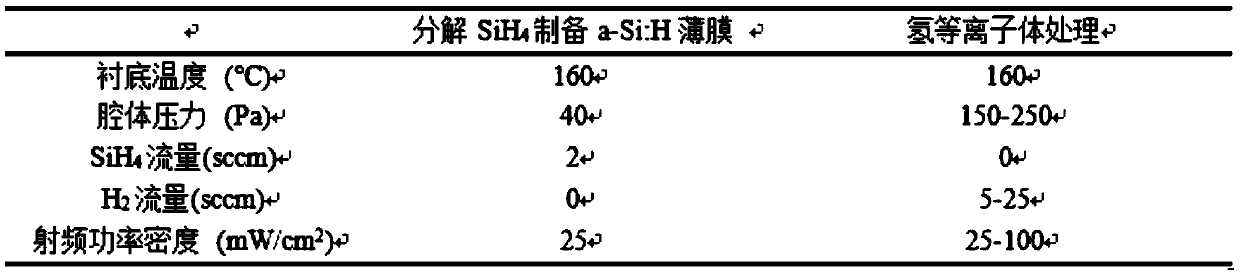

[0025] Table 1. D...

Embodiment 2

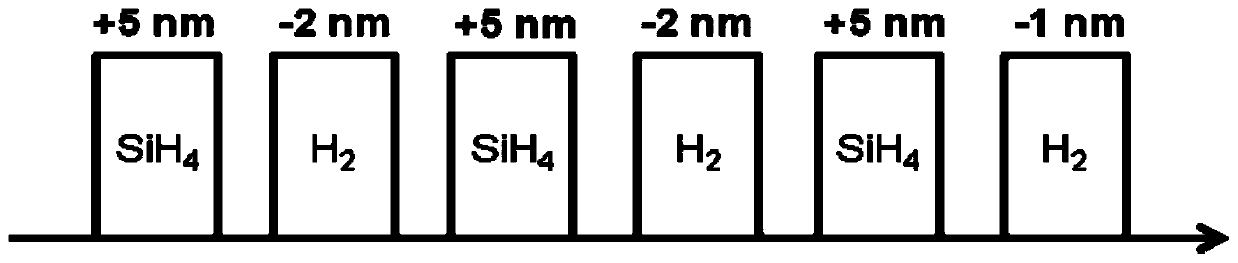

[0031] On the one hand, the hydrogen plasma treatment process can interrupt the deposition process of a-Si:H film to avoid the generation of low-order silicon-hydrogen units, and on the other hand, it can also inject the atomic hydrogen produced by decomposition into the a-Si:H film. Fill the electrical defects in the a-Si:H film and the dangling bond states on the saturated c-Si surface to improve the passivation effect of the a-Si:H / c-Si interface.

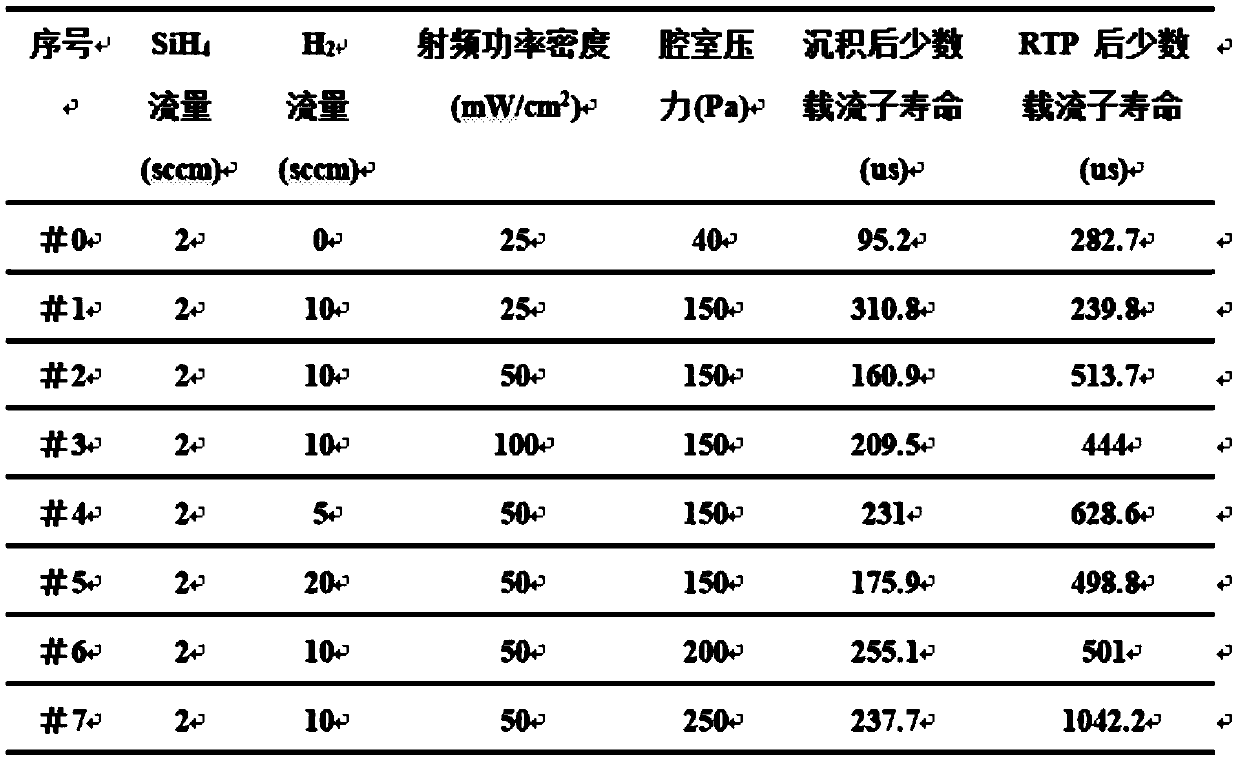

[0032] Table 2. Embodiment 2 experimental data

[0033]

[0034] See Table 2, where the samples numbered #0 are a-Si:H film deposition for the decomposition of pure SiH4, and the samples numbered #1-#7 are a-Si prepared by periodically interrupting the decomposition of pure SiH4 by hydrogen plasma : Deposition process of H film and hydrogen plasma treatment of the film. Microwave photoconductivity decay method was used to measure the minority carrier lifetime of thin film samples after deposition and rapid thermal annealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com