Semiconductor apparatus and method of fabrication for a semiconductor apparatus

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., to achieve the effects of improving stability, improving passivation quality, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

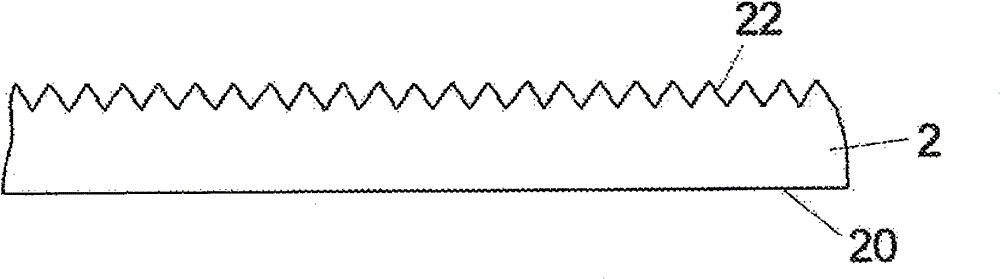

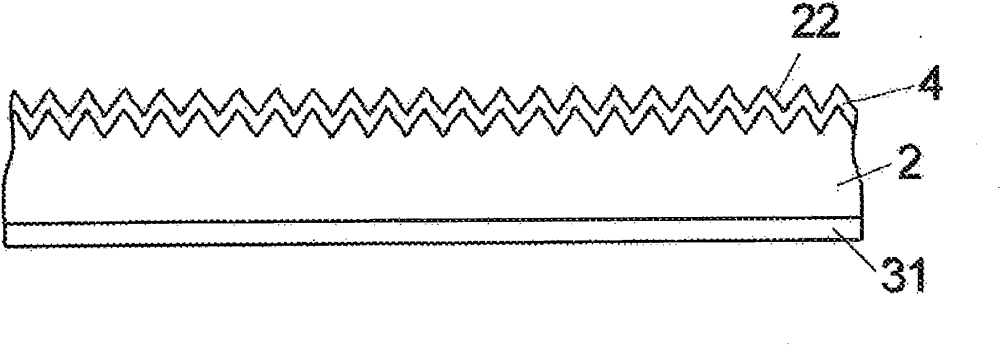

[0045] The manufacture of a solar cell 1 with surface passivation on both sides according to a possible embodiment is described below with reference to FIGS. 1a-1e. As noted in the background section of this specification, these considerations apply equally to other semiconductor devices than solar cells. 1 a shows a cross-section of a semiconductor layer 2 , wherein the semiconductor layer 2 comprises a semiconductor layer surface 20 forming a solar cell rear 20 facing backlight and a further semiconductor layer surface 22 forming a solar cell front 22 facing light. The surface 20 of the semiconductor layer is preferably textured (shown as a zigzag pattern in the figure) to improve efficiency.

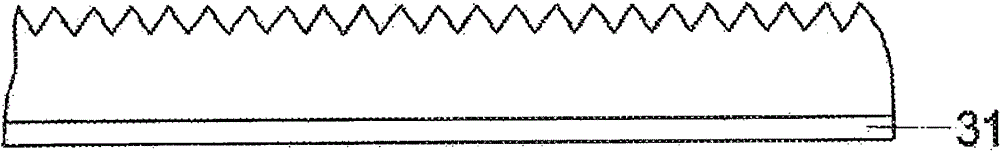

[0046] According to FIG. 1 b, a passivation sublayer 31 is applied to the semiconductor layer surface 20 for chemical passivation, wherein this sublayer can also serve as a diffusion barrier in a subsequent doping step of the further semiconductor layer surface 22 layer. After this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com