Method for manufacturing selective texturing heterojunction solar cell

A technology of solar cells and manufacturing methods, applied in the direction of final product manufacturing, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems such as high defect state density, open circuit voltage drop, and increase the recombination probability of photogenerated carriers. Achieve the effects of cost reduction, enhanced anti-reflection effect, and reduced production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

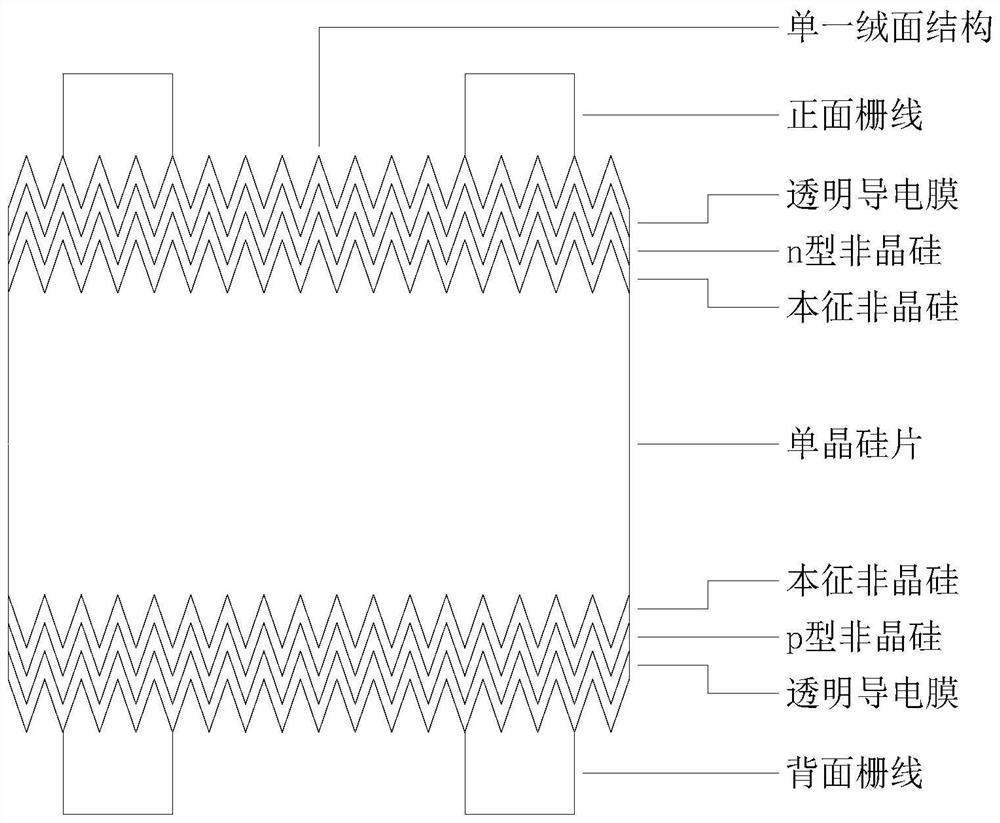

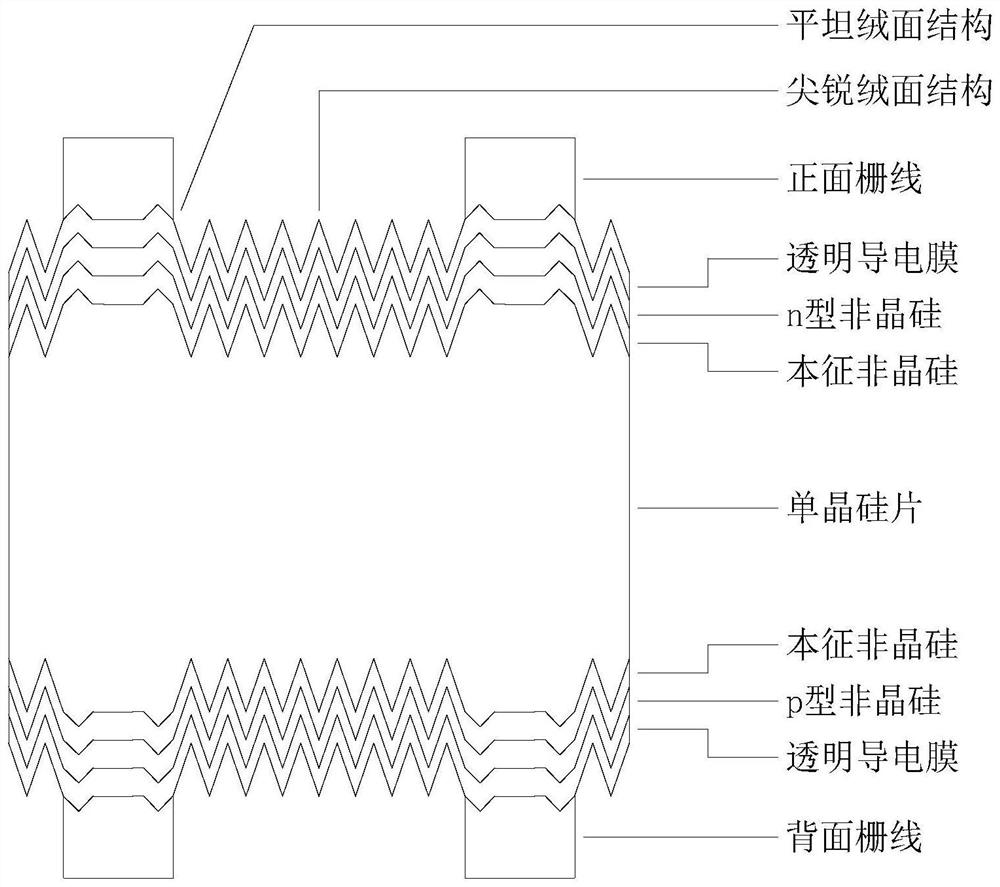

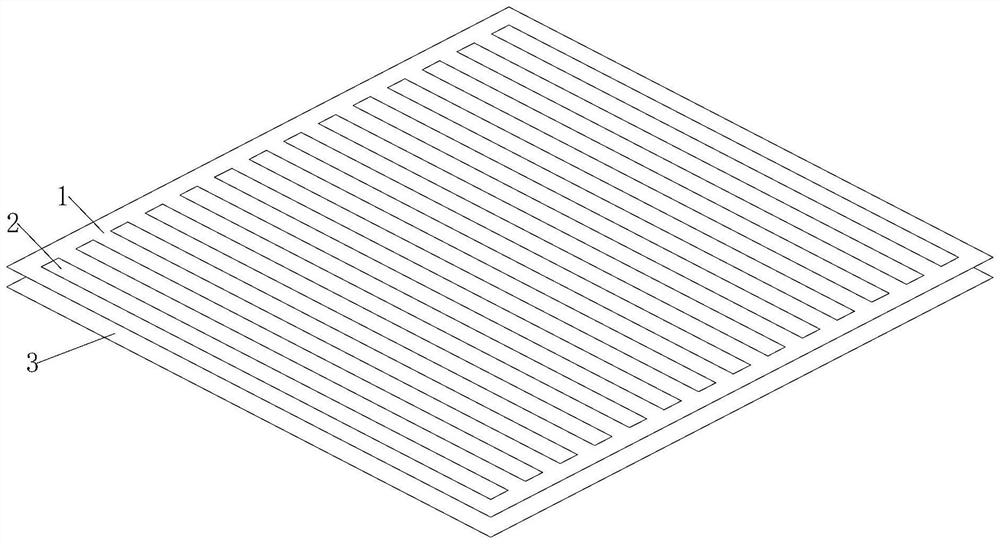

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

[0025] A method for selectively making textured heterojunction solar cells, combining the attached Figure 8 shown, including the following steps:

[0026] Step 1: Clean the monocrystalline silicon wafer with a cleaning solution at 60-85° C. for 60-300 seconds. The cleaning solution is a mixture of potassium hydroxide, hydrogen peroxide and water at a volume ratio of 1:1:6.

[0027] Step 2: Alkali etching the monocrystalline silicon wafer treated in Step 1 with 60-85° C., 5-25 wt % potassium hydroxide solution for 60-300 seconds, and the etching depth is greater than 5 μm to remove cutting damage.

[0028] Step 3: The single crystal silicon wafer treated in Step 2 is used to make a retardation layer on the required selective texturing area on the surface of the retardation material.

[0029] The selection principle of delaying material: it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com