Anti-Reflection Film, Manufacturing Method Thereof, Polarizing Plate and Transmission Type LCD

a technology of anti-reflection film and manufacturing method, which is applied in the direction of identification means, instruments, polarising elements, etc., can solve the problems of low productivity and decrease in display quality, and achieve excellent optical properties and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

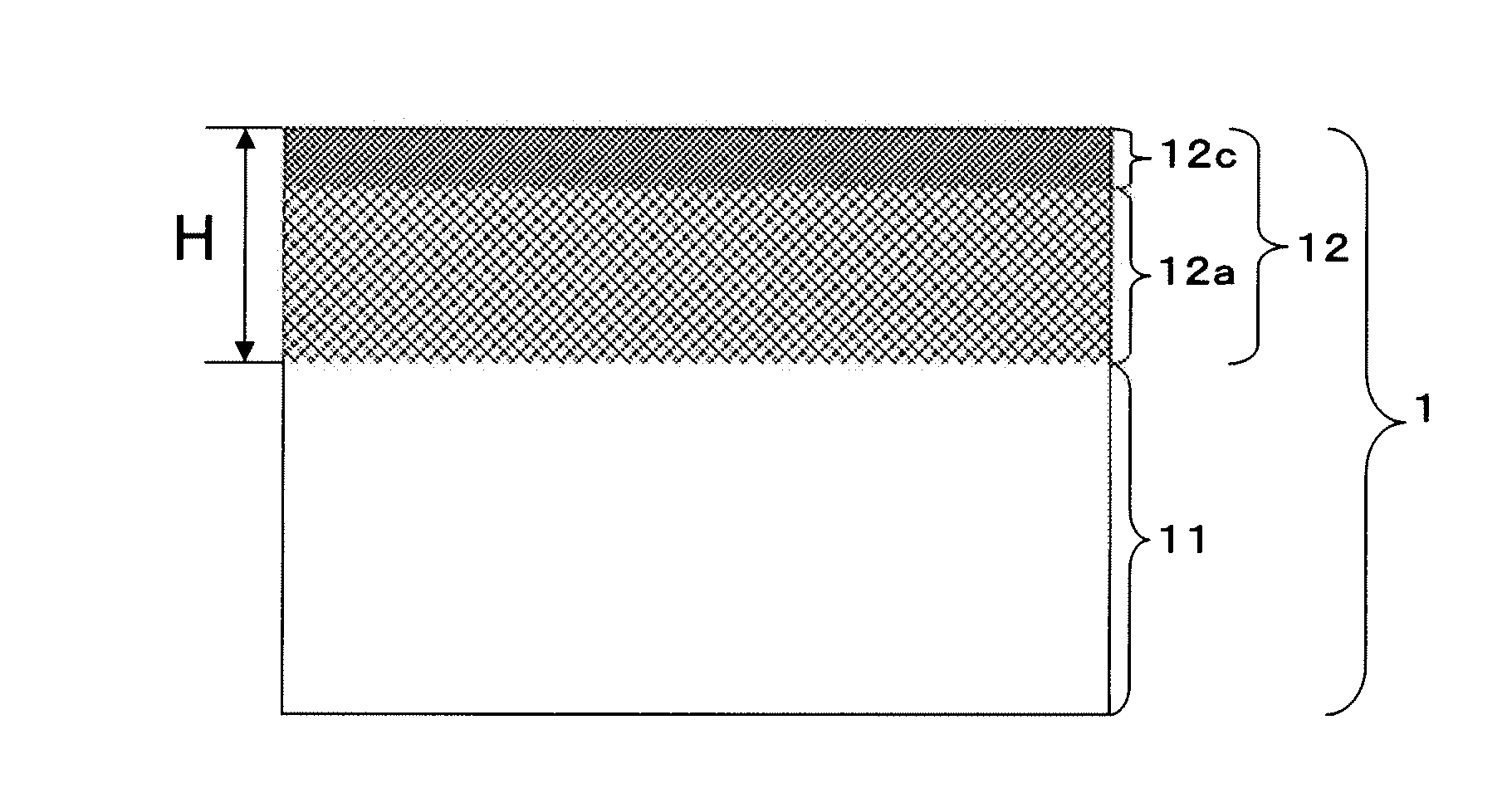

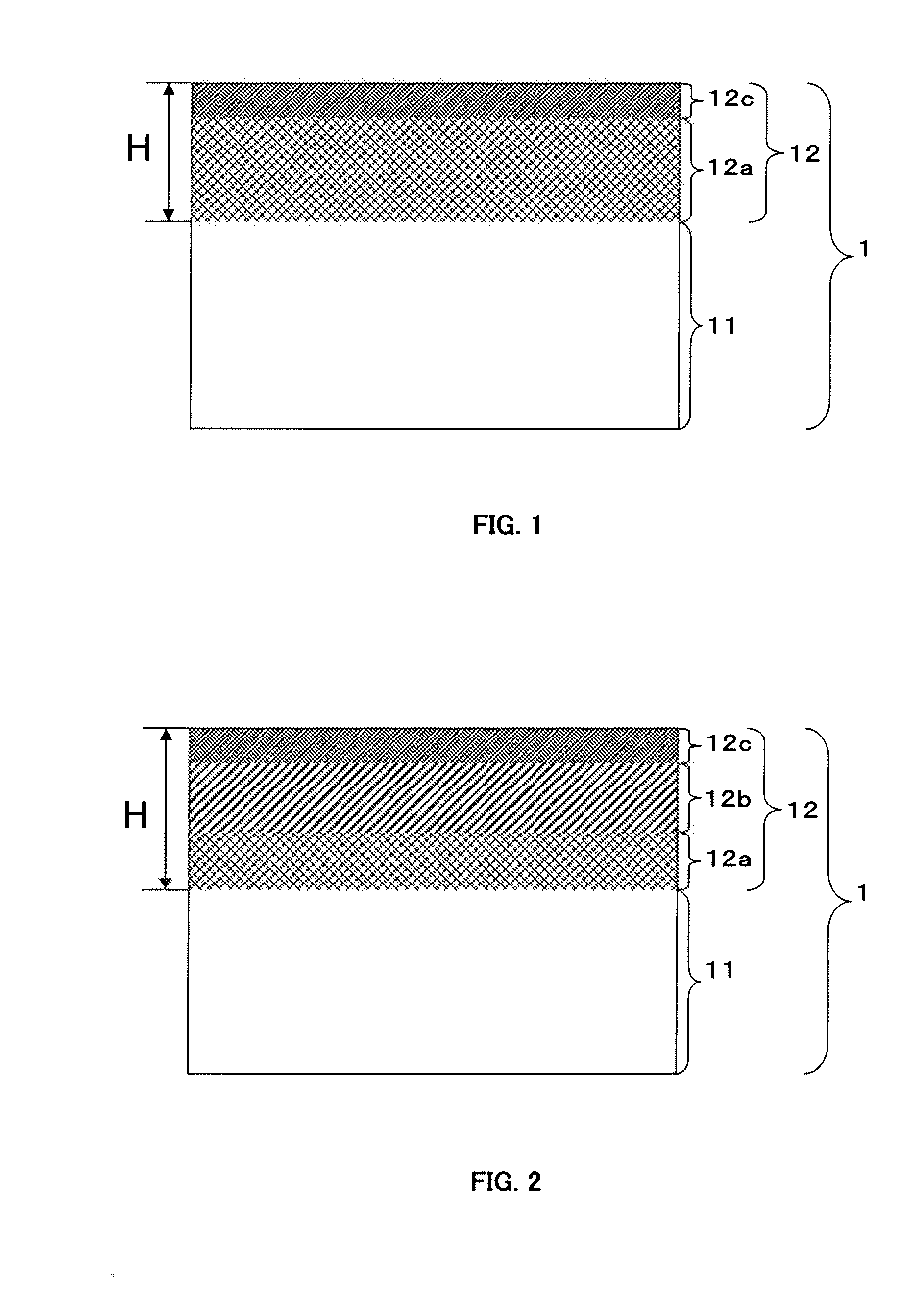

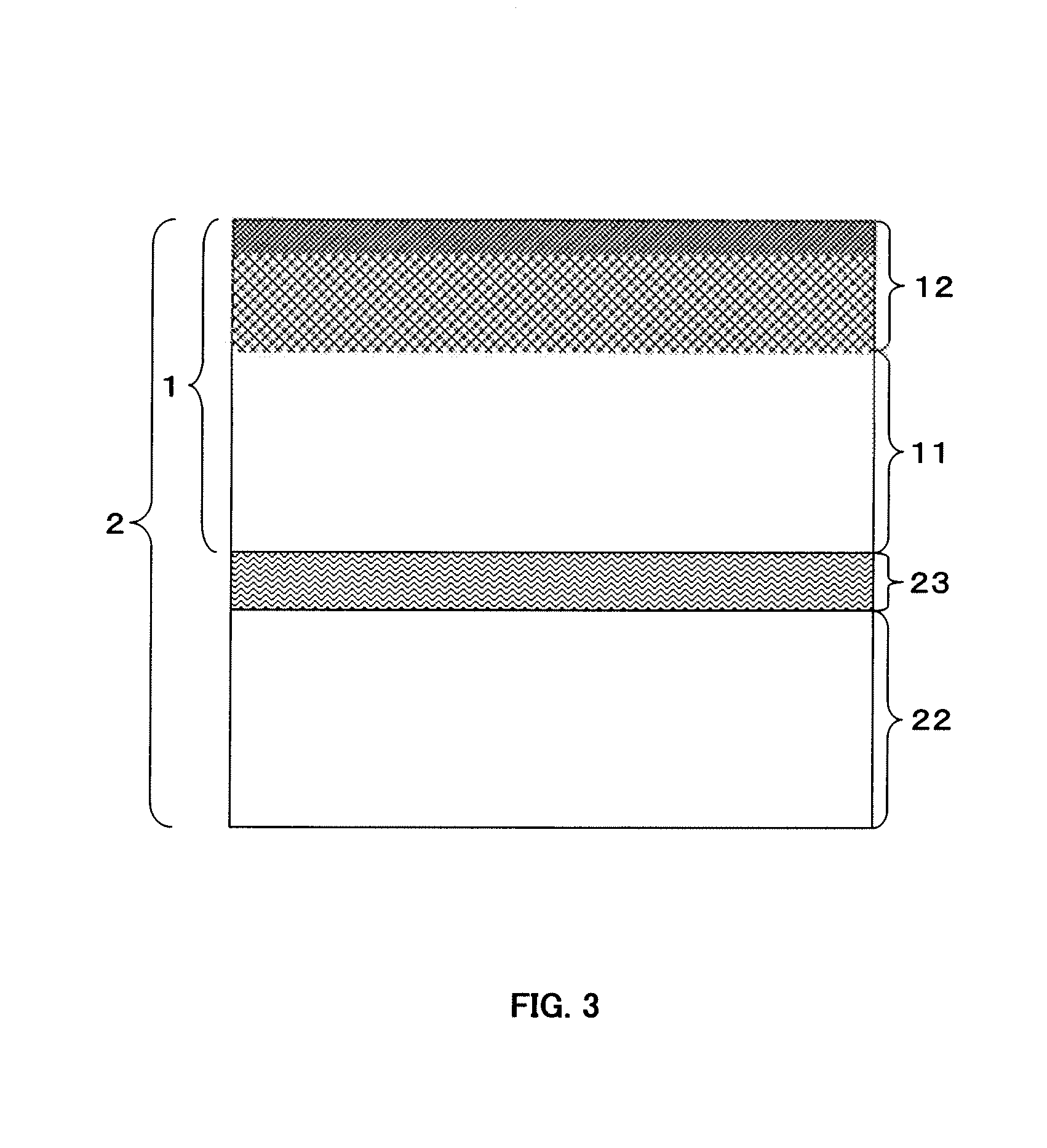

Image

Examples

example 1

Transparent Substrate

[0162]An 80 μm thick triacetyl cellulose film (refractive index: 1.49) was prepared as the transparent substrate.

[0163]6.0 parts by weight of a dispersion liquid of low refractive index silica particles having pores therein (primary particle diameter: 30 nm, solid content ratio: 20 wt %, dispersion solvent: isopropyl alcohol), 7.8 parts by weight of dipentaerythritol hexaacrylate (DPHA), 23.3 parts by weight of pentaerythritol tetraacrylate (PETA) and 7.8 parts by weight of urethane acrylate UA-306T (made by Kyoeisha chemical Co., Ltd.) as the ionizing radiation curable material, 2.0 parts by weight of Irgacure 184 (by Ciba Japan) as the photopolymerization initiator, and 55.2 parts by weight of a solvent mixture of methyl ethyl ketone, isopropyl alcohol and diacetone alcohol having a blend ratio of 6:2:2 as the solvent were blended together to prepare a coating liquid for forming a low refractive index hard coat layer with a solid content ratio of 40 wt % by we...

example 2

Transparent Substrate

[0165]An 80 μm thick triacetyl cellulose film (refractive index: 1.49) was prepared as the transparent substrate.

[0166]2.0 parts by weight of a dispersion liquid of low refractive index silica particles having pores therein (primary particle diameter: 30 nm, solid content ratio: 20 wt %, dispersion solvent: isopropyl alcohol), 4.9 parts by weight of dipentaerythritol hexaacrylate (DPHA), 14.7 parts by weight of pentaerythritol tetraacrylate (PETA) and 4.9 parts by weight of urethane acrylate UA-306T (made by Kyoeisha chemical Co., Ltd.) as the ionizing radiation curable material, 2.0 parts by weight of Irgacure 184 (by Ciba Japan) as the photopolymerization initiator, 16.7 parts by weight of conductive polymer Baytron P CH 8000 (solid content ratio: 3%), 0.5 parts by weight of modified silicone oil TSF44 (made by GE Toshiba silicone Ltd.), and 56.6 parts by weight of a solvent mixture of methyl ethyl ketone, isopropyl alcohol and diacetone alcohol having a blend...

example 3

Transparent Substrate

[0168]An 80 μm thick triacetyl cellulose film (refractive index: 1.49) was prepared as the transparent substrate.

[0169]6.0 parts by weight of a dispersion liquid of magnesium fluoride (MgF2) (primary particle diameter: 20 nm, solid content ratio: 20 wt %, dispersion solvent: isopropyl alcohol), 7.8 parts by weight of dipentaerythritol hexaacrylate (DPHA), 23.3 parts by weight of pentaerythritol tetraacrylate (PETA) and 7.8 parts by weight of urethane acrylate UA-306T (made by Kyoeisha chemical Co., Ltd.) as the ionizing radiation curable material, 2.0 parts by weight of Irgacure 184 (by Ciba Japan) as the photopolymerization initiator, and 55.2 parts by weight of a solvent mixture of methyl ethyl ketone, N-methylpyrrolidone and diacetone alcohol having a blend ratio of 5:2:3 as the solvent were blended together to prepare a coating liquid for forming a low refractive index hard coat layer with a solid content ratio of 40 wt % by weight.

[0170]The resultant coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical thickness | aaaaa | aaaaa |

| optical thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com