Patents

Literature

165 results about "Selection principle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, a selection principle is a rule asserting the possibility of obtaining mathematically significant objects by selecting elements from given sequences of sets. The theory of selection principles studies these principles and their relations to other mathematical properties. Selection principles mainly describe covering properties, measure- and category-theoretic properties, and local properties in topological spaces, especially function spaces. Often, the characterization of a mathematical property using a selection principle is a nontrivial task leading to new insights on the characterized property.

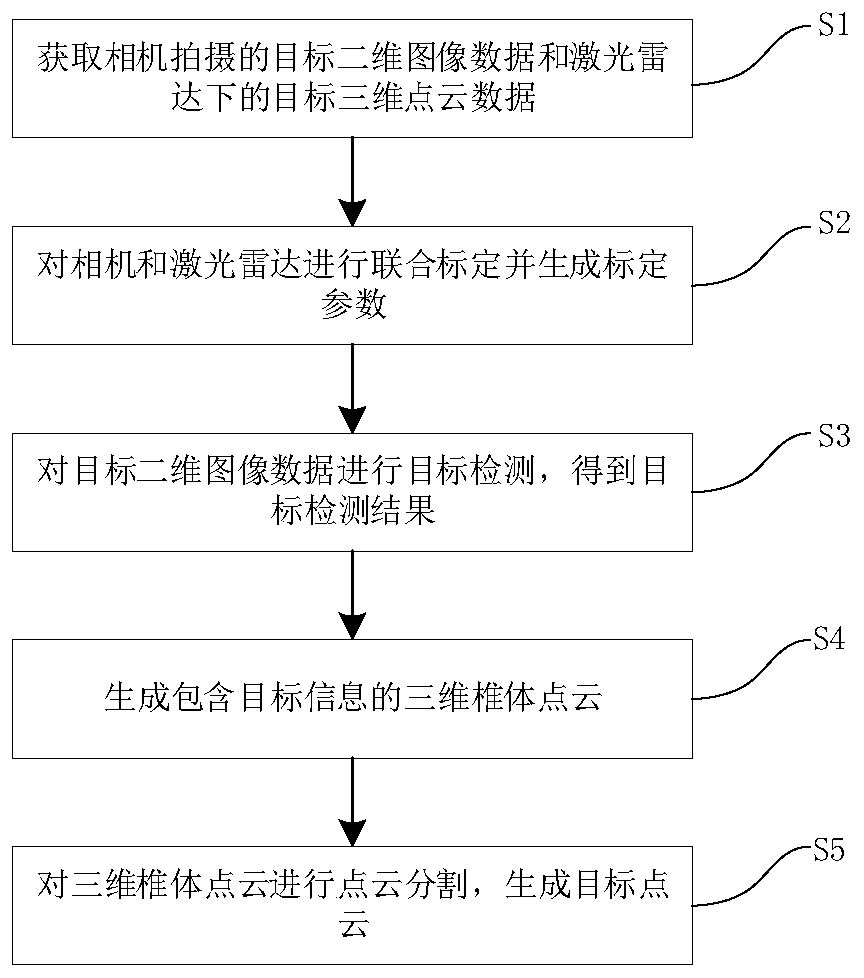

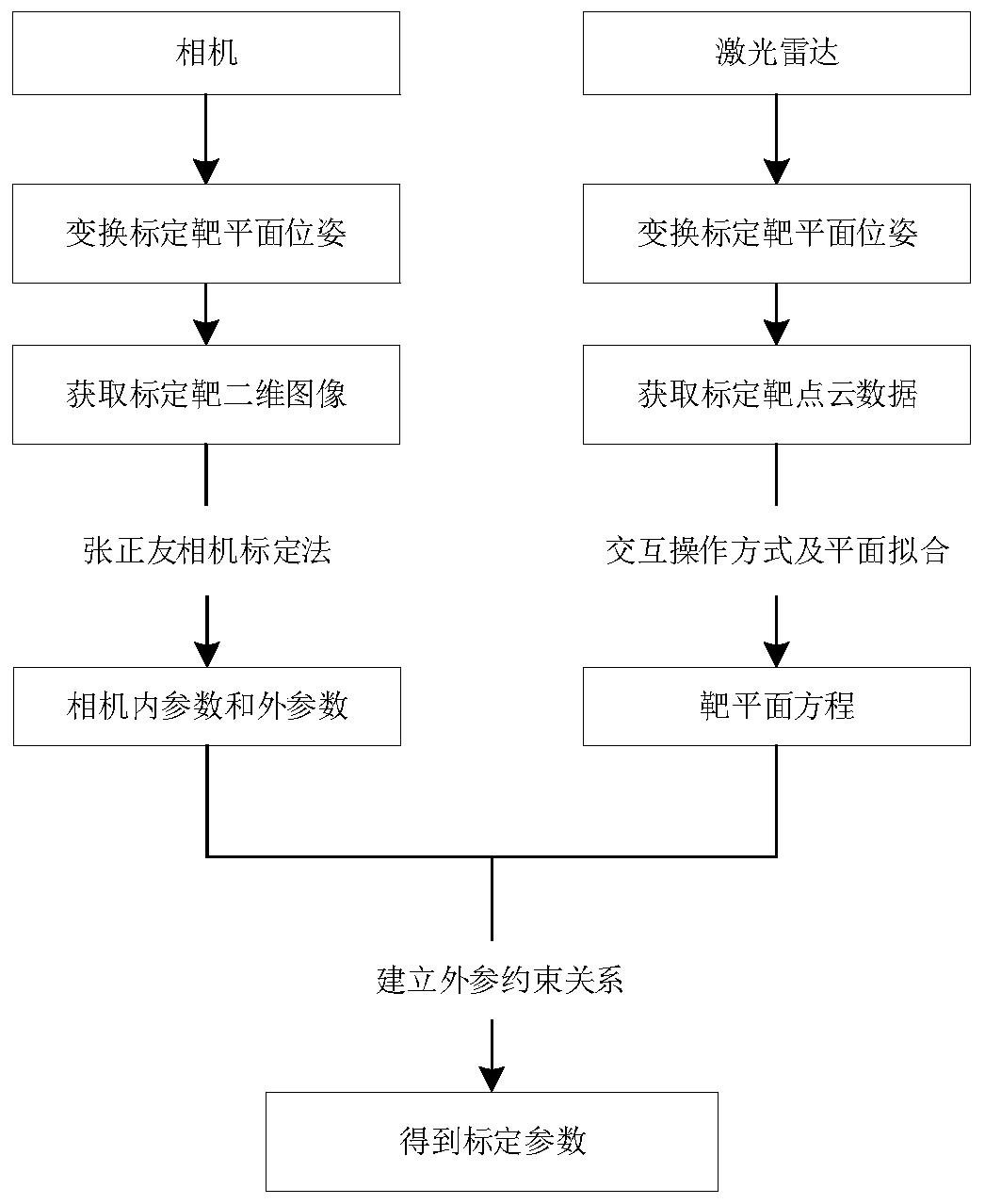

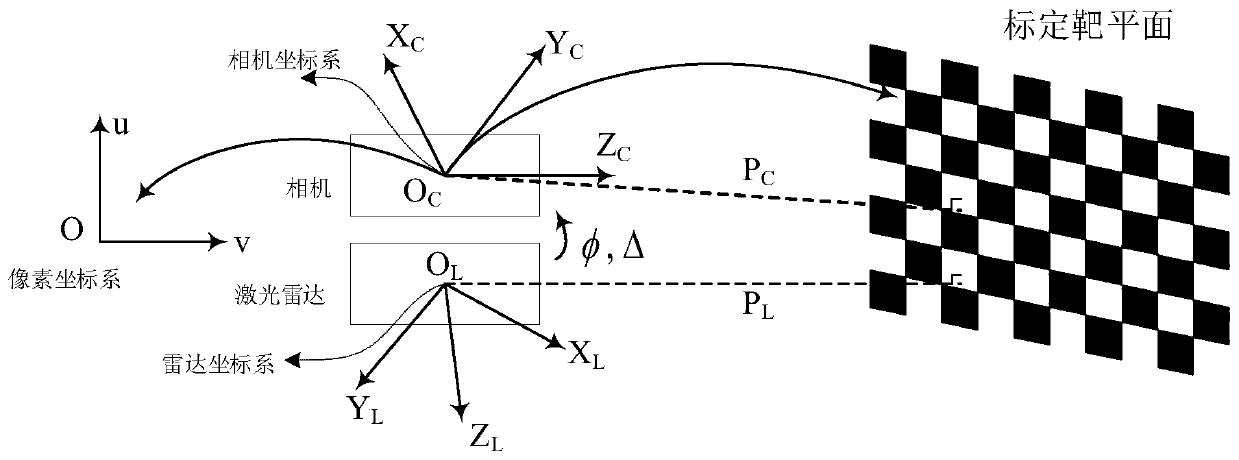

Sparse point cloud segmentation method and device

ActiveCN110264416AHigh precisionImprove efficiencyImage enhancementImage analysisImaging processingRadar

The invention discloses a sparse point cloud segmentation method and device. Relating to the field of image processing, the method comprises the following steps of: obtaining a target object, acquiring target two-dimensional image data shot by a camera and target three-dimensional point cloud data under the laser radar; performing joint calibration on the camera and the laser radar, generating calibration parameters, performing target detection on target two-dimensional image data, extracting three-dimensional points which can be converted to a target two-dimensional boundary frame according to a target detection result and a selection principle, generating three-dimensional cone point cloud containing target information, and finally performing point cloud segmentation to generate target point cloud. In the prior art, a laser radar combination fusion mode is used to carry out point cloud segmentation. According to the method, the equipment cost is reduced, the three-dimensional cone point cloud containing the target information is obtained according to the selection principle, then point cloud segmentation is carried out to remove the noise point cloud, the point cloud segmentation precision and efficiency are improved, and the method has a good practical application value.

Owner:SHENZHEN UNIV

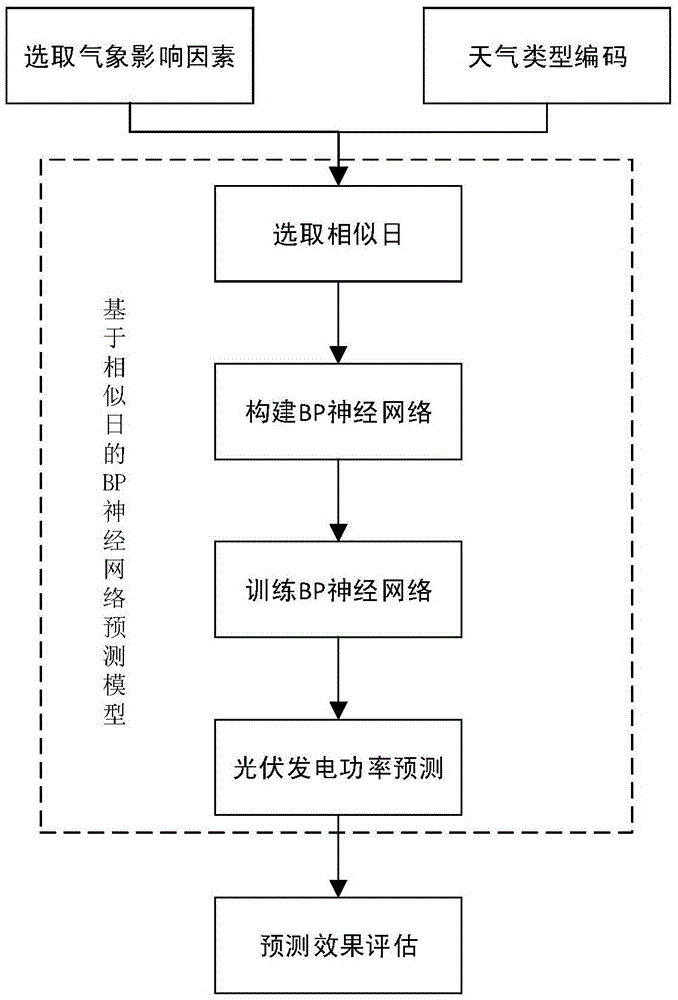

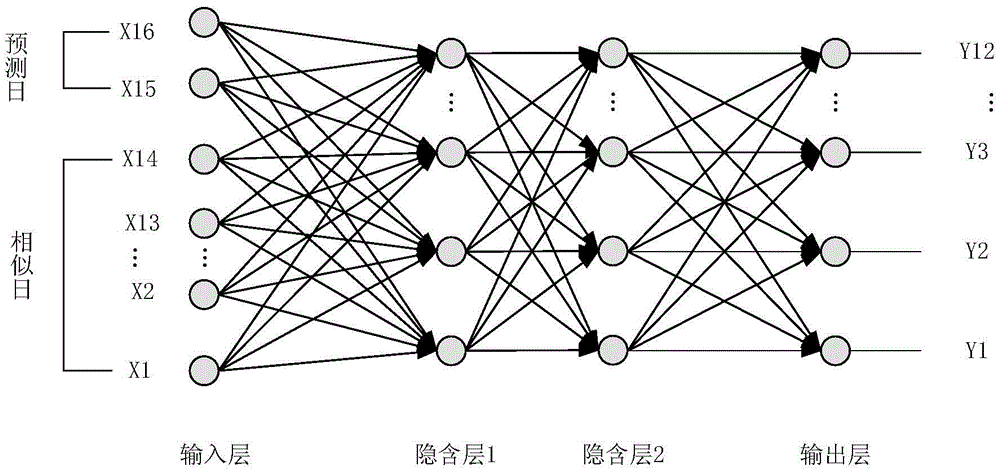

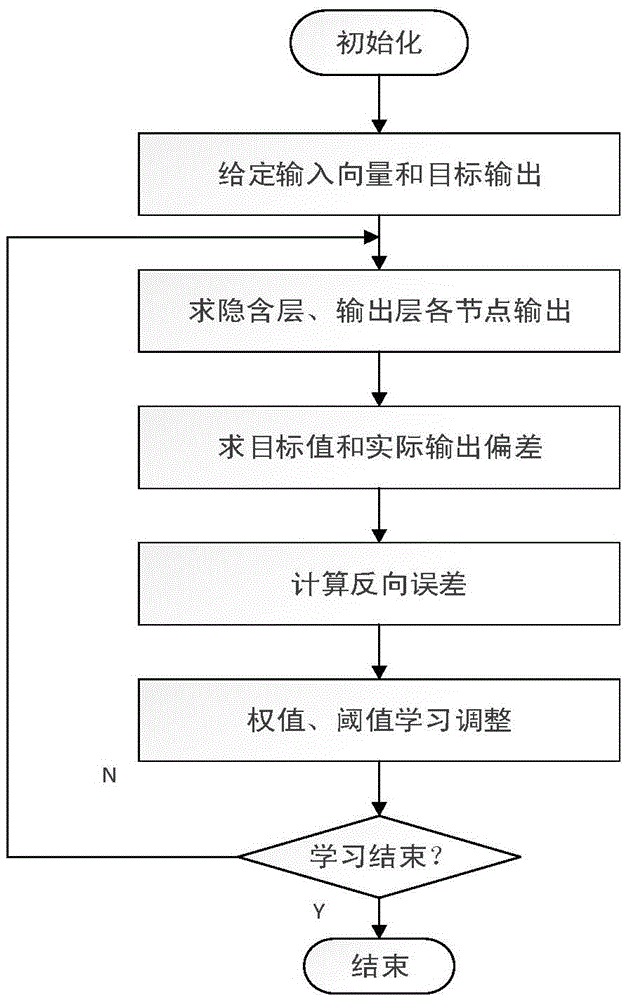

BP neural network photovoltaic power generation system power prediction method based on similar day

InactiveCN105631558AGuaranteed accuracyGuaranteed stabilityForecastingWeight adjustmentPredictive methods

The invention discloses a BP neural network photovoltaic power generation system power prediction method based on a similar day. After quantization coding of weather influence factors, a historical day, which has higher similarity with a prediction day, is selected according to a similar day selection principle; through power generation data and weather data of the similar historical day, and with meteorological data of the prediction day being combined, a training sample set is formed to carry out training on a BP neural network; and during training, a weight adjustment algorithm adopts a gradient correction method with additional momentum and variable learning rate being combined, thereby improving model convergence speed, reducing the probability that a model falls into locally optimal solution and ensuring prediction model precision and stability.

Owner:STATE GRID CORP OF CHINA +5

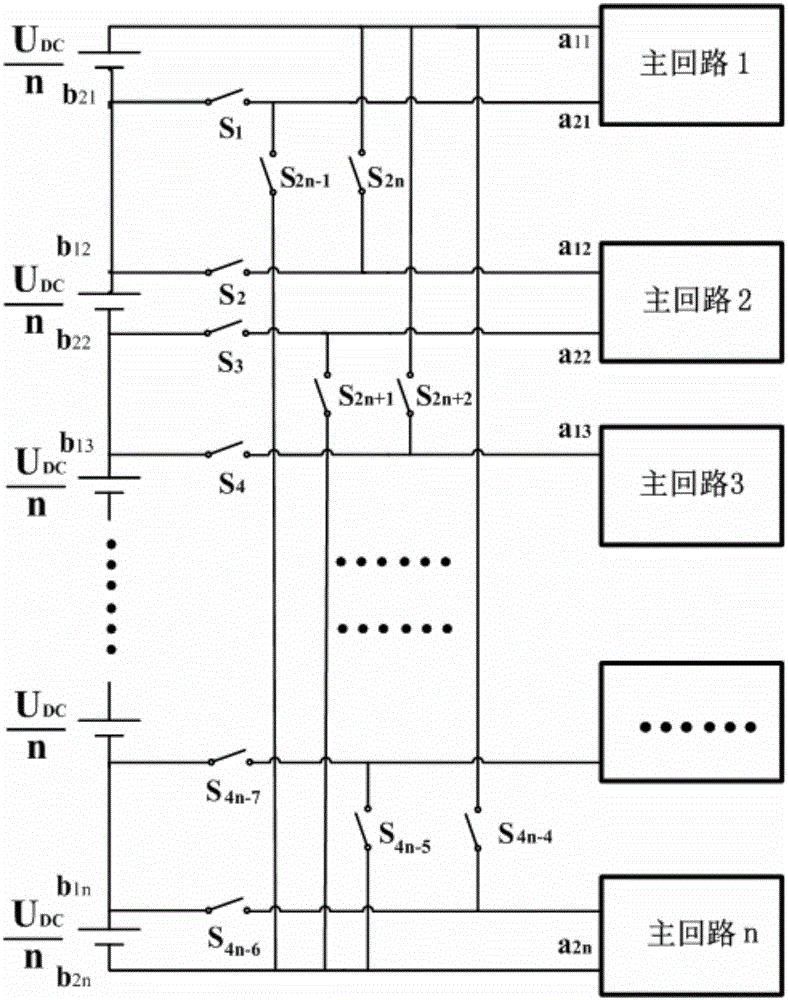

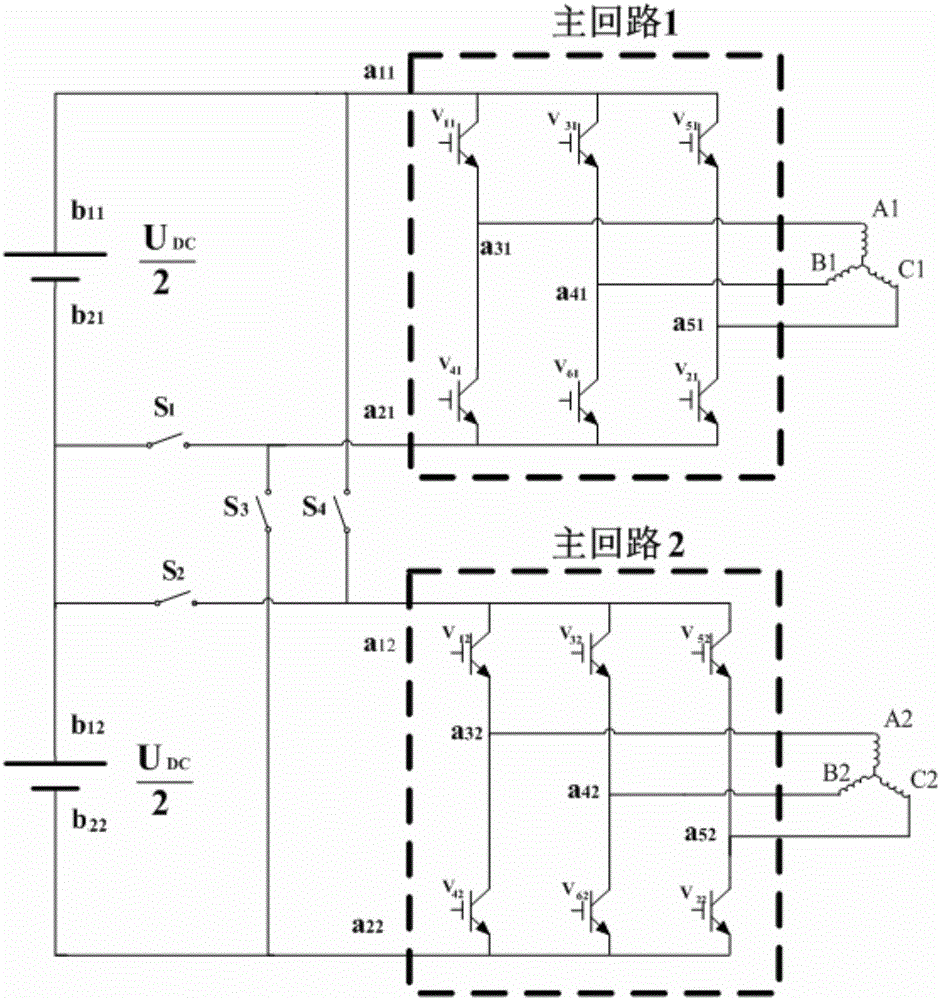

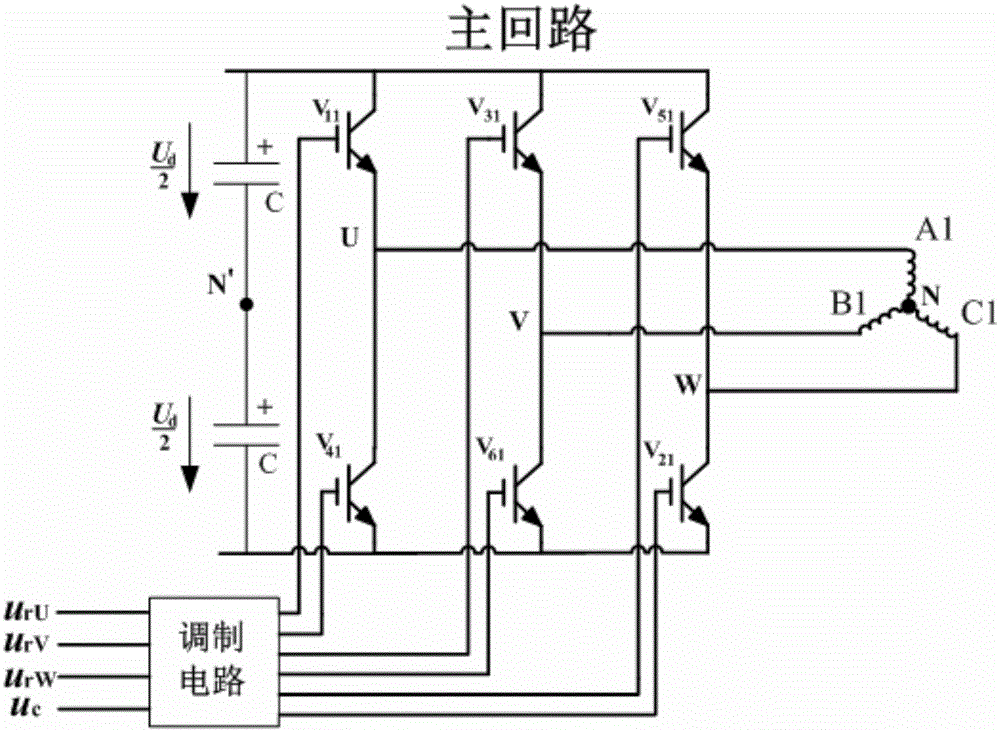

Switching device of permanent magnet synchronous motor windings

InactiveCN105048888ALow costImprove reliabilityElectronic commutation motor controlTransient statePower flow

The invention provides a switching device of permanent magnet synchronous motor windings. The switching device has n sets of windings corresponding to n main loop units; and with the joint effort of (4n-4) switches, switching of series connection and parallel connection of the n sets of windings is realized. The switching device has the following characteristics: the cost of the switching system is lowered and reliability of the switching system is improved; the motor operation efficiency is improved, the speed regulation range of the motor is expanded, and the demand of the main loop capacity is reduced; the selection principle of the switching rotation speed is provided; and a switching strategy for reducing the transient impulse current during the switching process is also brought forward.

Owner:CHONGQING UNIV

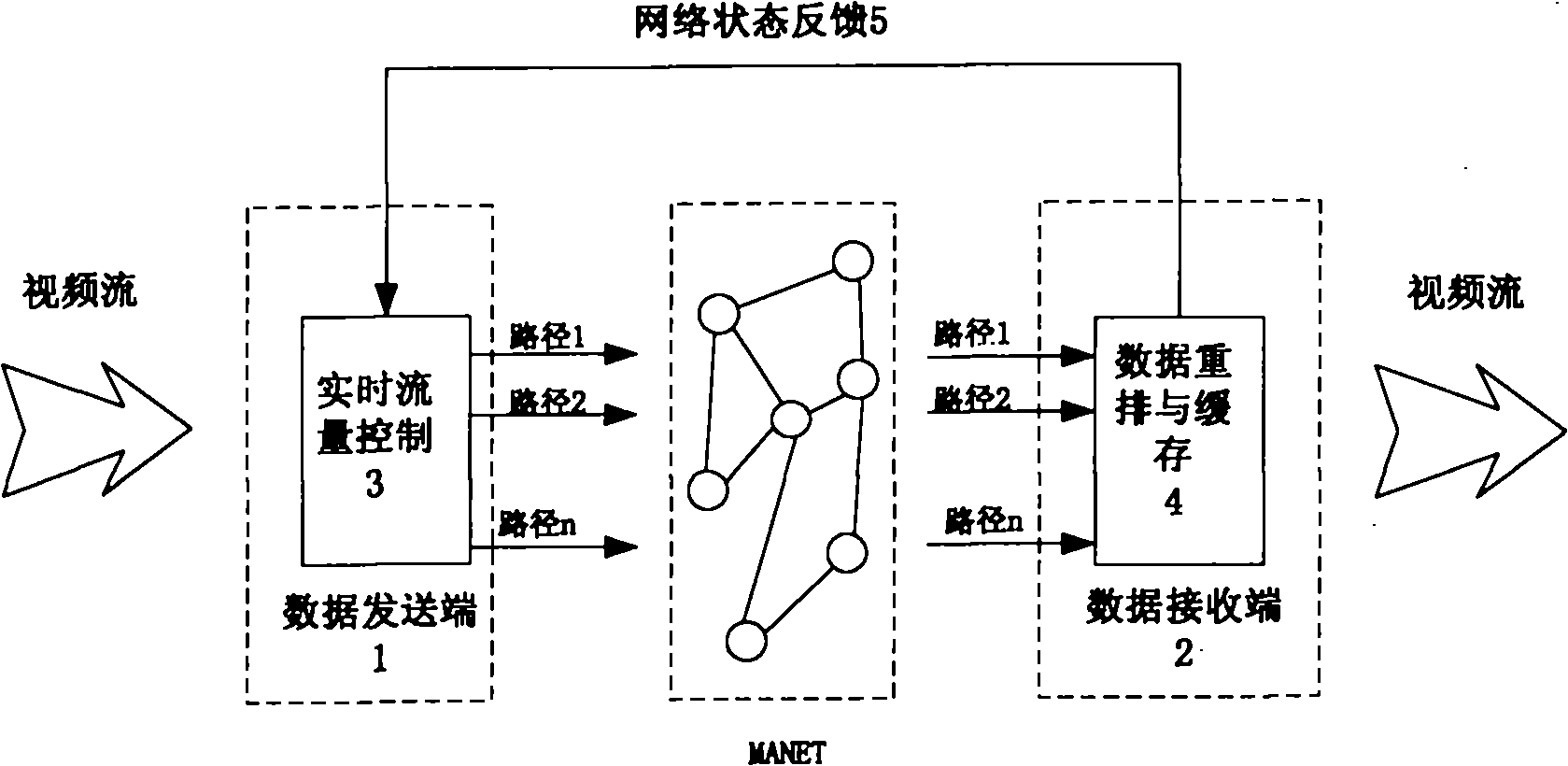

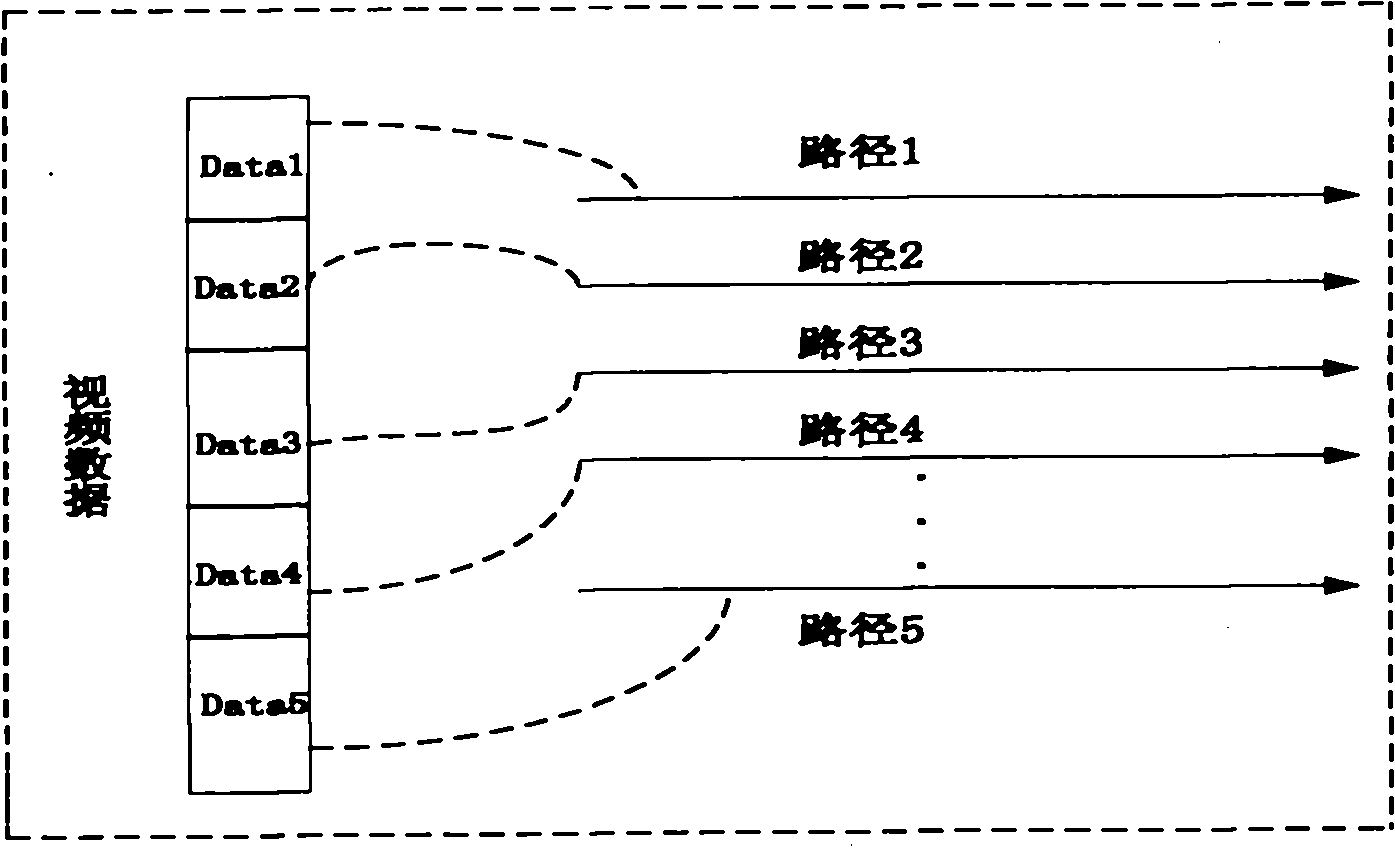

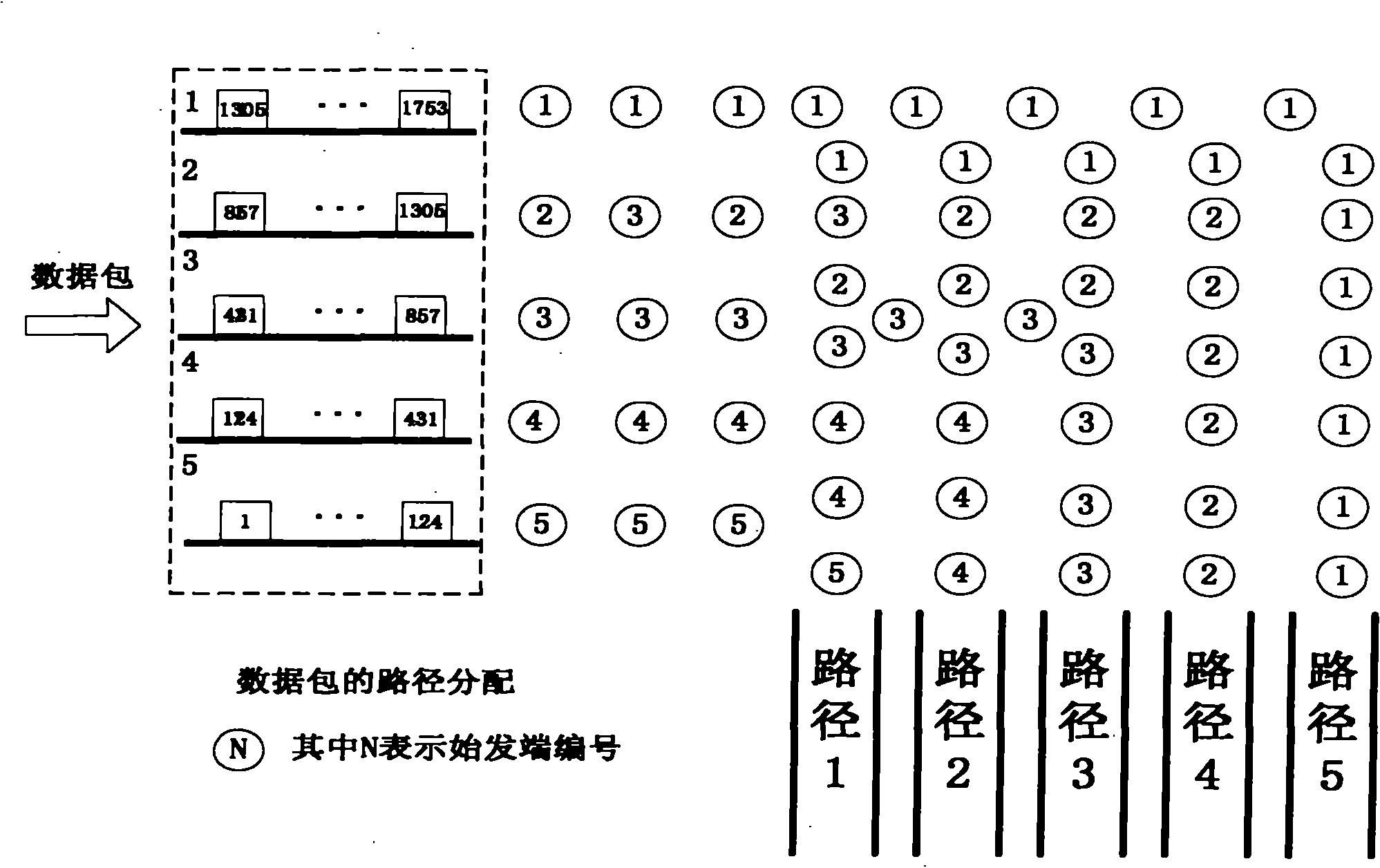

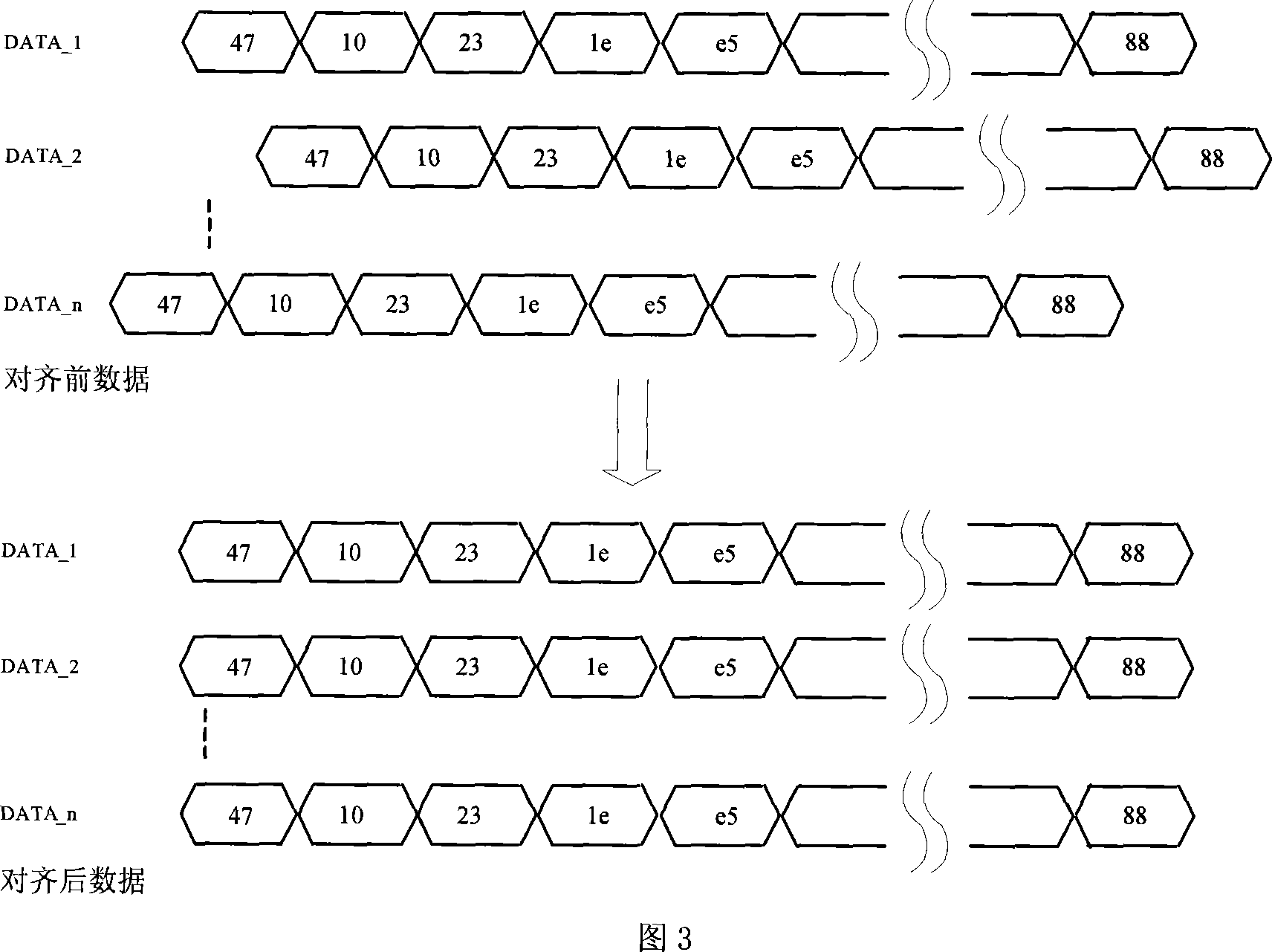

Video multi-path parallel transfer method in wireless self-organization network

InactiveCN101888664ASmooth displayAvoid blockingNetwork traffic/resource managementNetwork topologiesTime delaysMaximal flow

The invention discloses a video multi-path parallel transfer method is a wireless self-organization network, video data is distributed to optimal multiple paths for simultaneous transmission on the whole, and a data sending end is used for selecting the path with the minimal time delay for transmitting a data packet which constitutes the video data according to the situations of time delay and data packet sending rate of the multiple paths partially. The selection principle of the optimal multiple paths is to select a shortest path set in all the paths of the data sending end and a data receiving end, and then seek a maximal flow path set in the shortest path set, wherein the maximal flow path set which meets the requirements on video data transmission bandwidth comprises the multiple paths for simultaneously transmitting the video data. The sending end and the receiving end further comprise network state feedback and real-time flow control functions, the receiving end can calculate the time delay of a link according to the received data packet, the time delay of the link is fed back to the receiving end, and then the receiving end can dynamically adjust the data packet sending rate of all the paths according to the time delay of the link of the paths.

Owner:陶洋

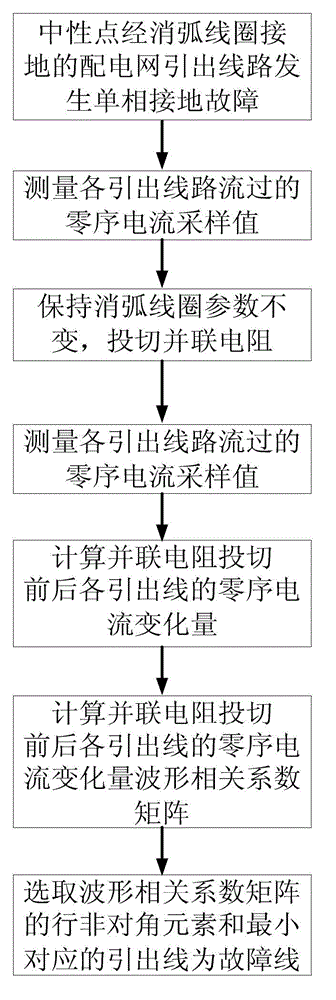

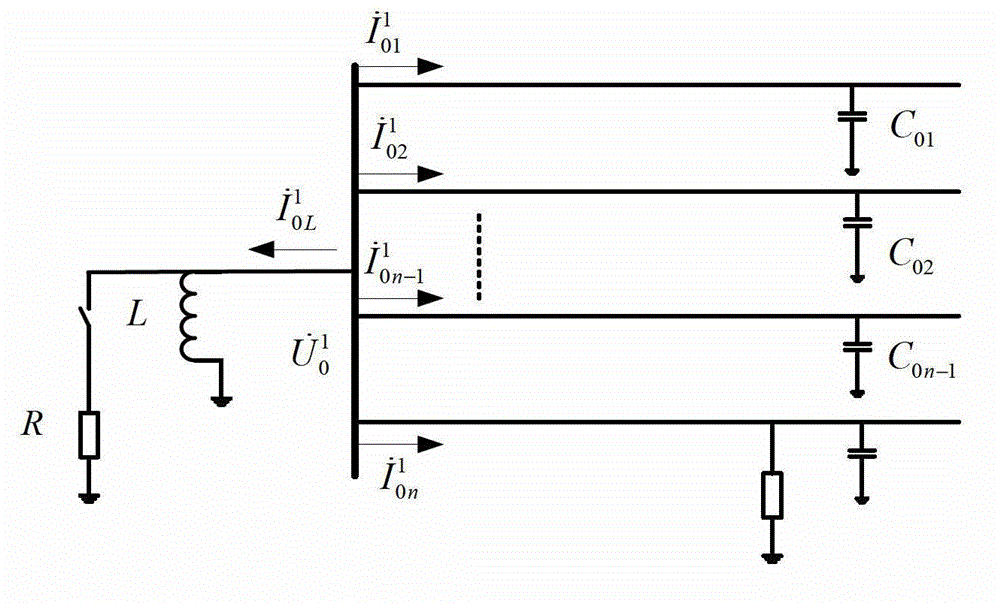

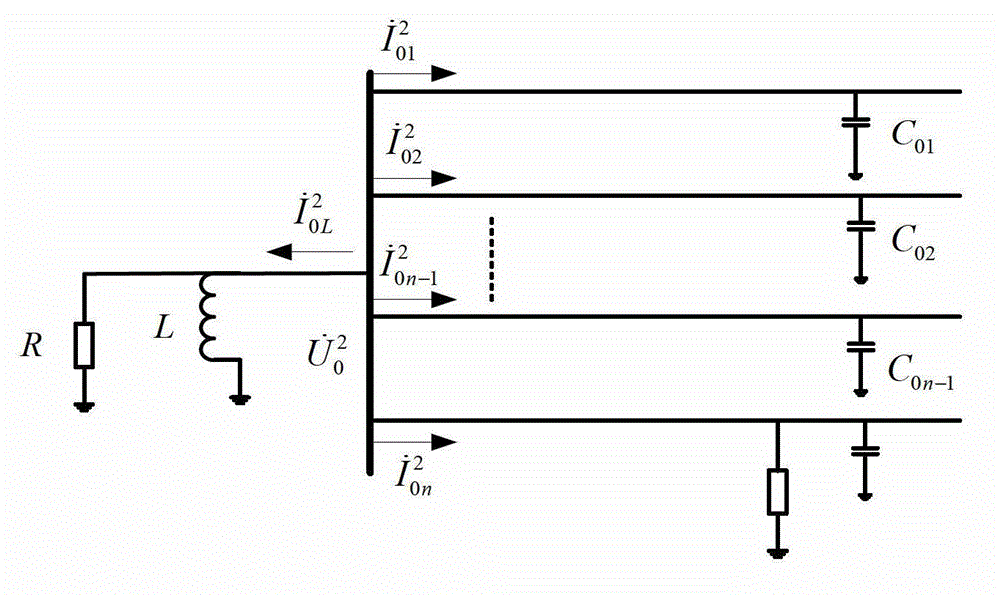

Distribution network fault line selection method based on zero sequence current variable quantity waveform correlation coefficient matrix

The invention discloses a distribution network fault line selection method based on a zero sequence current variable quantity waveform correlation coefficient matrix. According to the distribution network fault line selection method disclosed by the invention, a row off-diagonal element of each feeder zero sequence current variable quantity waveform correlation coefficient matrix and feeders in minimum corresponding before and after switching of a parallel resistance are utilized to carry out line selection for a fault line principle; and zero sequence voltage of a distribution network bus is larger than 15% phase voltage, the parallel resistance is switched by keeping arc suppression coil parameters invariable, a zero sequence current sampling value of each feeder flowing before and after switching of the parallel resistance is measured, the zero sequence current variable quantity waveform correlation coefficient matrix is further calculated, and the row off-diagonal element of each feeder zero sequence current variable quantity waveform correlation coefficient matrix and the feeders in minimum corresponding are selected as fault lines. With the adoption of the method, a line selection result is not influenced by factors such as transition resistance, line parameters, line length, distribution network running mode and fault position, the line selection principle is simple, and the line selection result is high in reliability and strong in practicability.

Owner:STATE GRID CORP OF CHINA +2

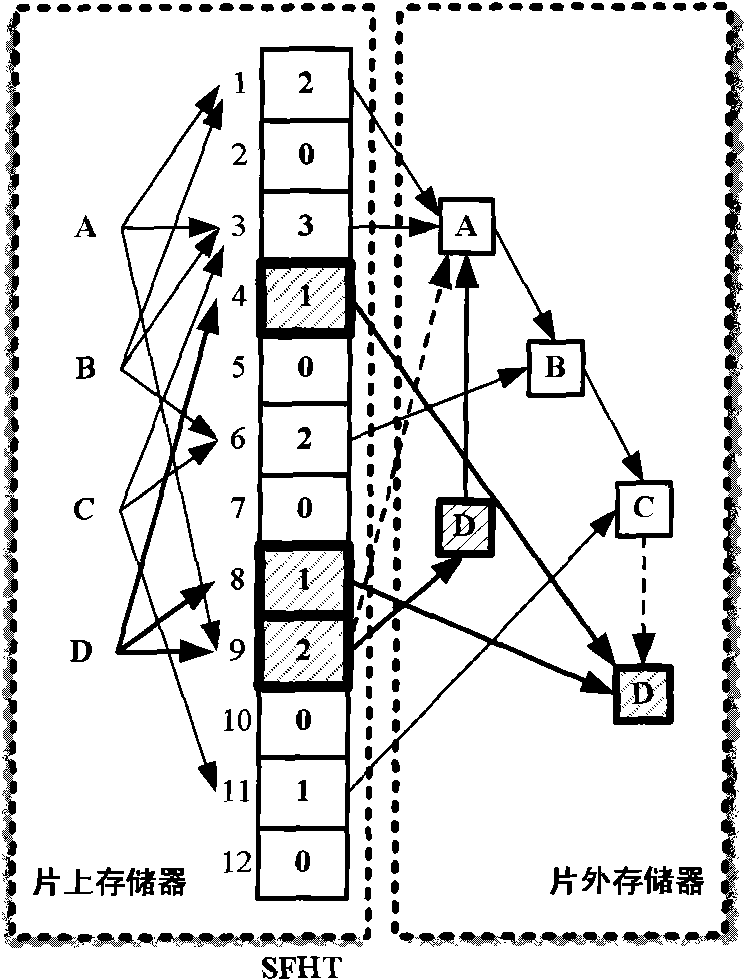

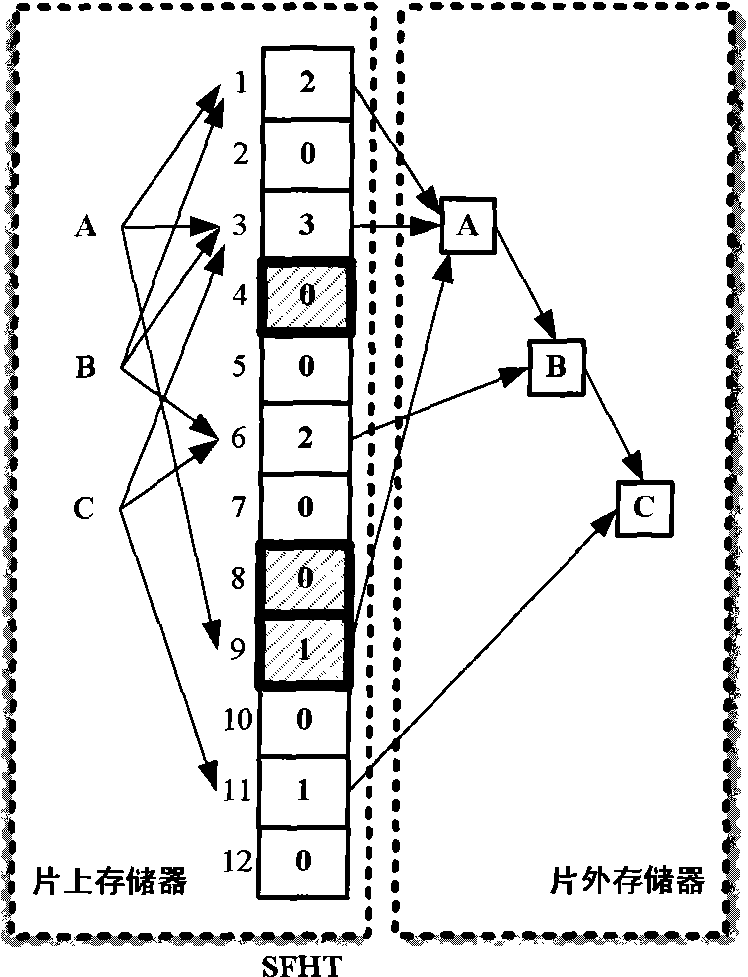

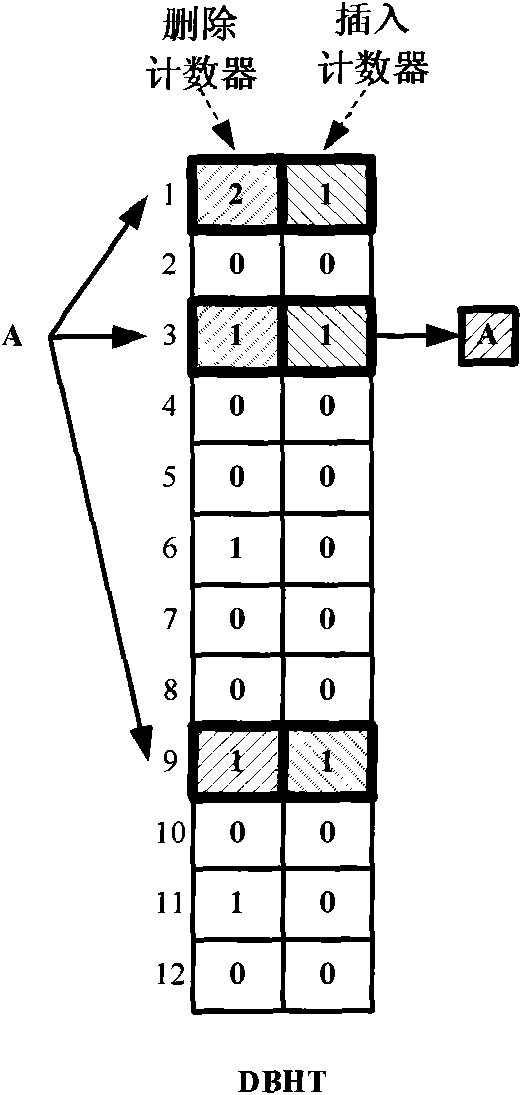

Hashing method based on double-counting bloom filter and hashing device

ActiveCN101655861AReduce update overheadReduce demandMemory adressing/allocation/relocationSpecial data processing applicationsBloom filterSelection principle

The invention provides a hashing method for realizing hashing insert operation on a hash table; the hash table comprises a plurality of buckets, the bucket comprises an insert counter and a delete counter, the insert counter is used for recording the number of insert elements in the bucket, and the delete counter is used for recording the number of the delete elements in the bucket; the method comprises the following steps: the element to be operated is mapped to at least one bucket of the hash table according to hash function, and the bucket is called as a candidate bucket; a target bucket isfound from the candidate buckets according to selection principle of the target bucket; the elements to be inserted are inserted in the target bucket; weather the inserted elements have effect on thestorage position of the stored elements in the candidate bucket is judged, if the storage positions of the stored elements can not meet the selection principle of the target bucket, the storage positions of the stored elements are re-adjusted; the hashing method also comprises the step of accumulating the value of the insert counter of the bucket.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

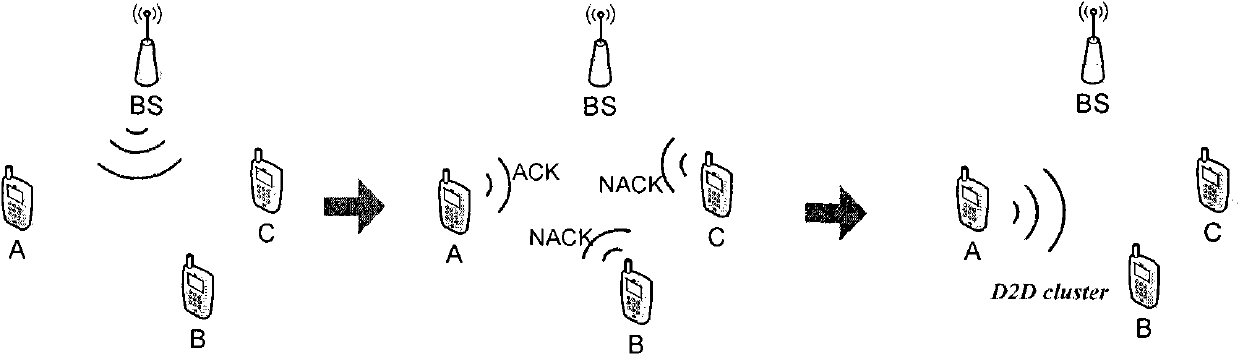

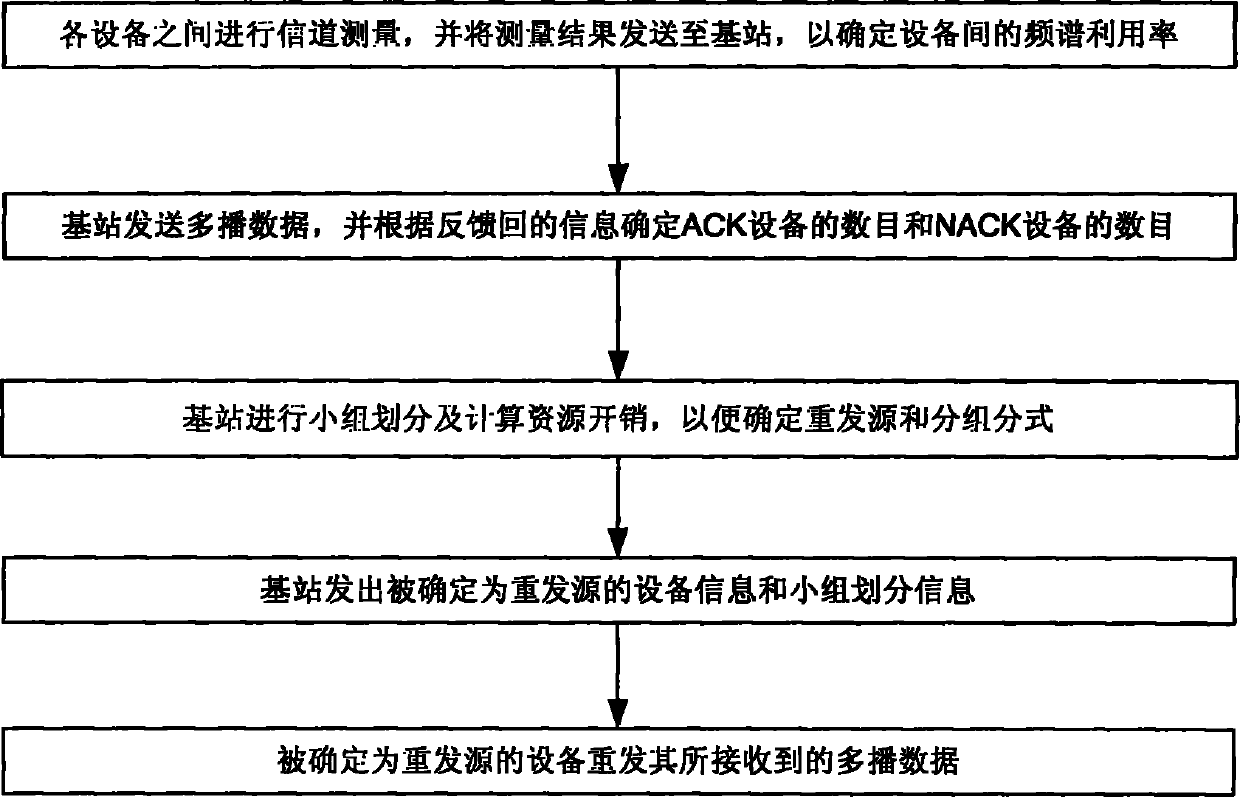

Information retransmitting method for improving multicast efficiency of cellular system

InactiveCN102118692AImprove multicast efficiencyImprove transmission efficiencyError prevention/detection by using return channelNetwork traffic/resource managementFrequency spectrumSelection principle

The invention provides an information retransmitting method for improving the multicast efficiency of a cellular system. The method comprises the following steps: the channel measurement is performed between every two devices for determining the frequency spectrum utilization ratio between the two devices; a base station sends multicast data for determining the number of devices which successfully receive the multicast data or fail to receive the multicast data; the devices are grouped, and the resource cost is calculated according to the frequency spectrum utilization ratio, the number of the devices which successfully receive the multicast data, the number of the devices which fail to receive the multicast data and the selection principle of a retransmission source set in advance; the corresponding device with the lowest resource cost is selected as the retransmission source of multicast data, meanwhile, the corresponding grouping method is recorded; the base station transmits the information of the device determined as the retransmission source as well as the group division information to all devices in the jurisdiction area; and the device selected as the retransmission source retransmits the received multicast date through an orthogonal resource. Therefore, the purpose of improving the multicast efficiency is achieved.

Owner:SHANGHAI RES CENT FOR WIRELESS COMM

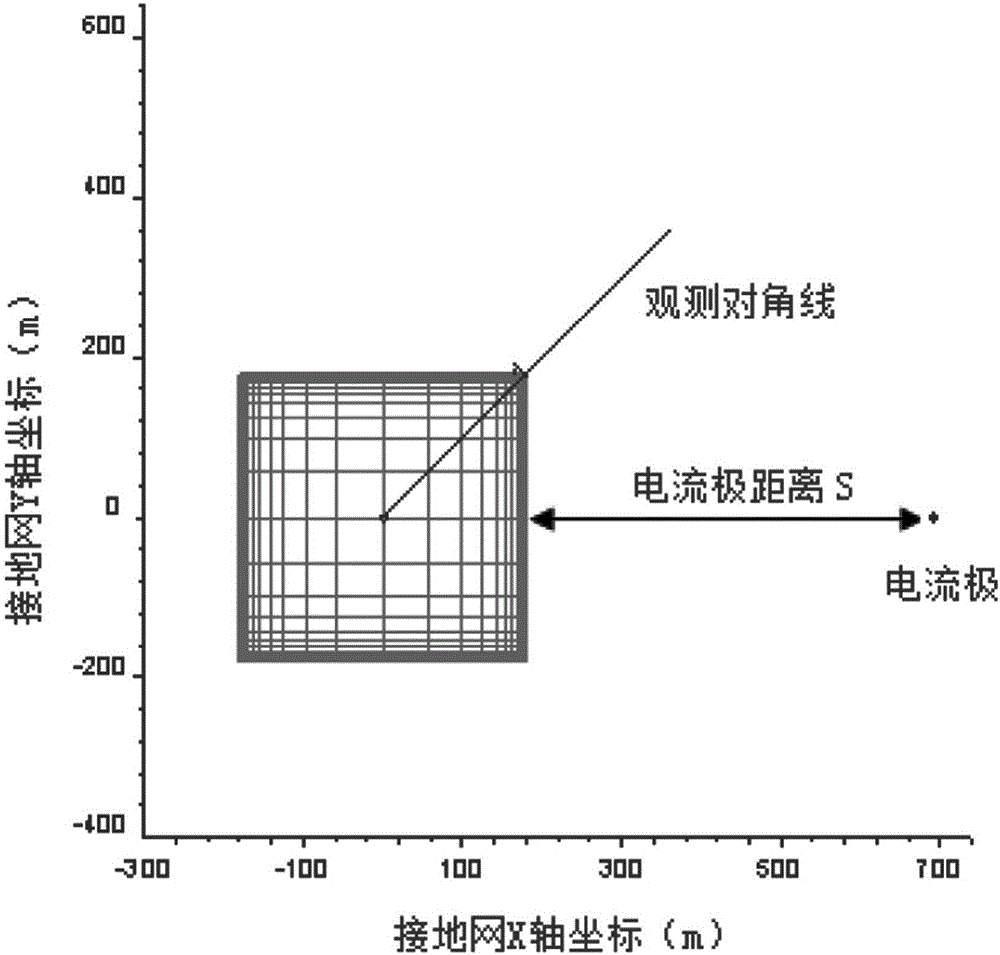

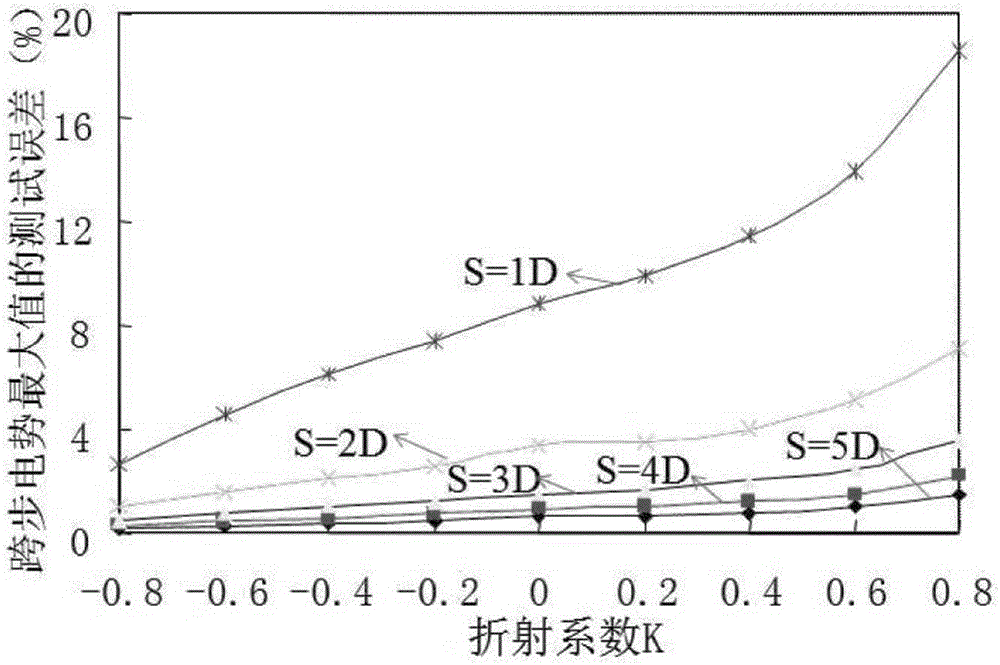

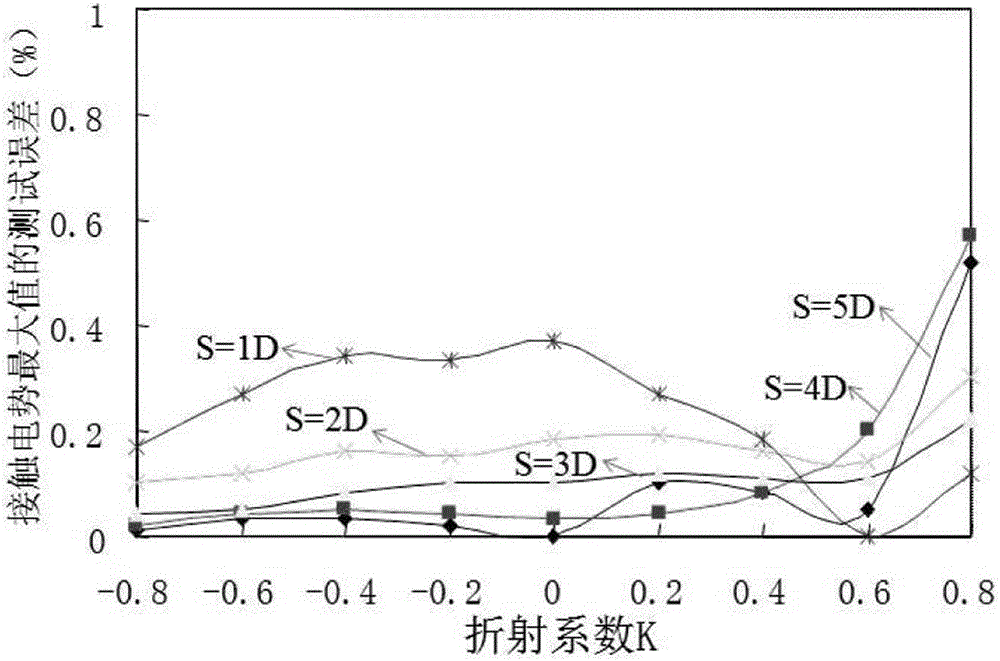

Method for testing step voltage and touch voltage of grounding grid

InactiveCN106093534AAvoid measurement errorsGuaranteed measurement accuracyCurrent/voltage measurementTest efficiencyGrounding grid

The invention relates to a method for testing a step voltage and a touch voltage of a grounding grid, and especially relates to a short current electrode method for testing a step voltage and a touch voltage of a grounding grid. The test cost can be significantly reduced and the test efficiency is improved by proper reduction of a lay out of route distance of the current electrode under the premise of assurance of the test accuracy. The method for testing the step voltage and the touch voltage of the grounding grid influences step voltage and touch voltage test errors, and provides a selection principle of the current electrode lay out of route distance in a large grounding grid test. The selection principle is verified in the test of a super high voltage transformer station grounding grid, and test results well verify the accuracy and high efficiency of the short current electrode testing method provided by the invention.

Owner:CHINA THREE GORGES UNIV

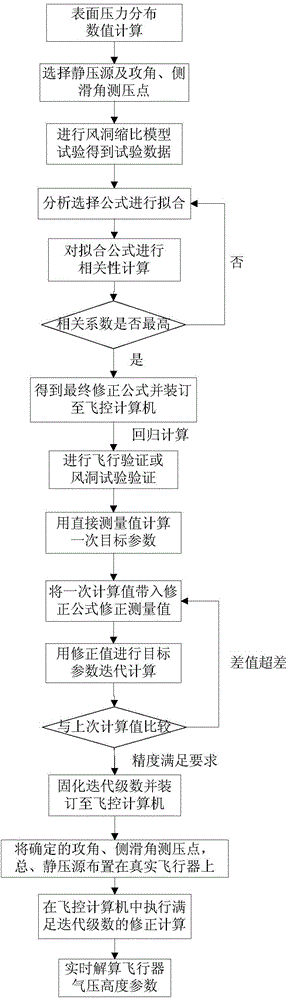

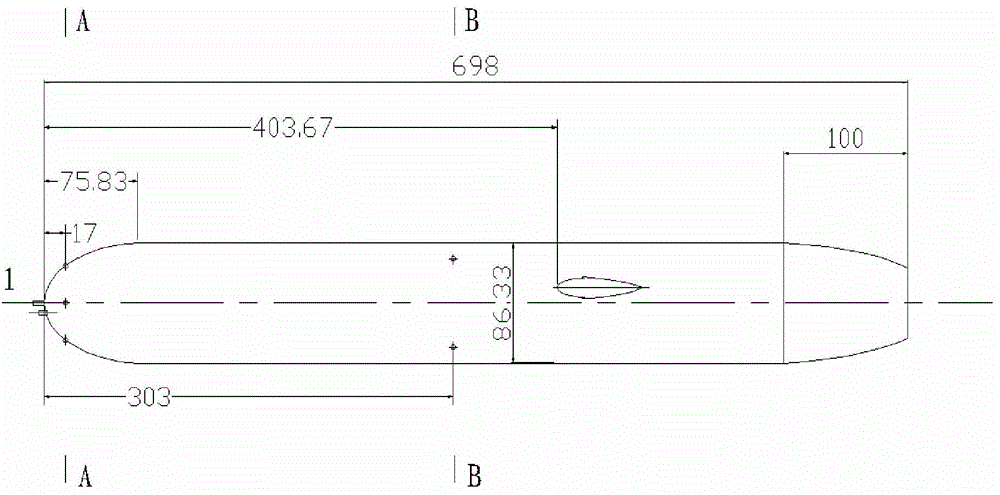

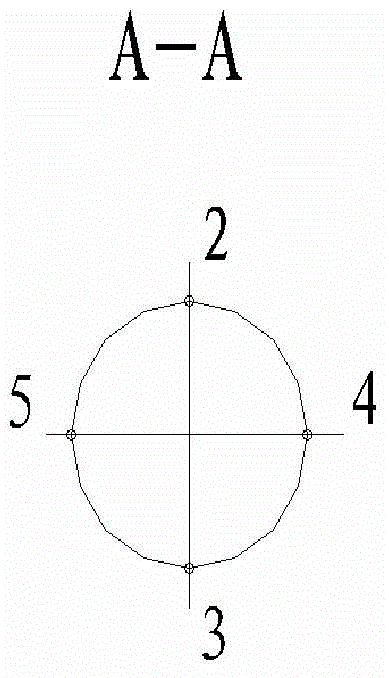

Determination method for pressure altitude parameters on subsonic vehicle body

ActiveCN104061960AConducive to stealth designReduce protrusionMeasurement devicesFlight vehicleObjective variables

The invention discloses a determination method for pressure altitude parameters on a subsonic vehicle body. The determination method comprises a selection principle of a pressure source on the subsonic vehicle body and a data processing method for measuring pressure based on a selected pressure source, wherein the selection principle of the pressure source on the subsonic vehicle body is used for selecting and locating the pressure source; the data processing method for measuring pressure based on the selected pressure source comprises a correction formula fitting and measured value returning and calculating method, wherein the correction formula comprises [alpha] correction, [beta] correction and static pressure correction, and the returning and calculating method is a method that objective variables are obtained according to the iteration of pressure measuring values. Test results show that the corrected data has very high reducibility, the objective variables including a flying attitude angle, a speed and the like of a subsonic vehicle with higher precision can be obtained by combining the returning and calculating method, therefore, a new method is provided for the subsonic flying speed measurement of the subsonic vehicle.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

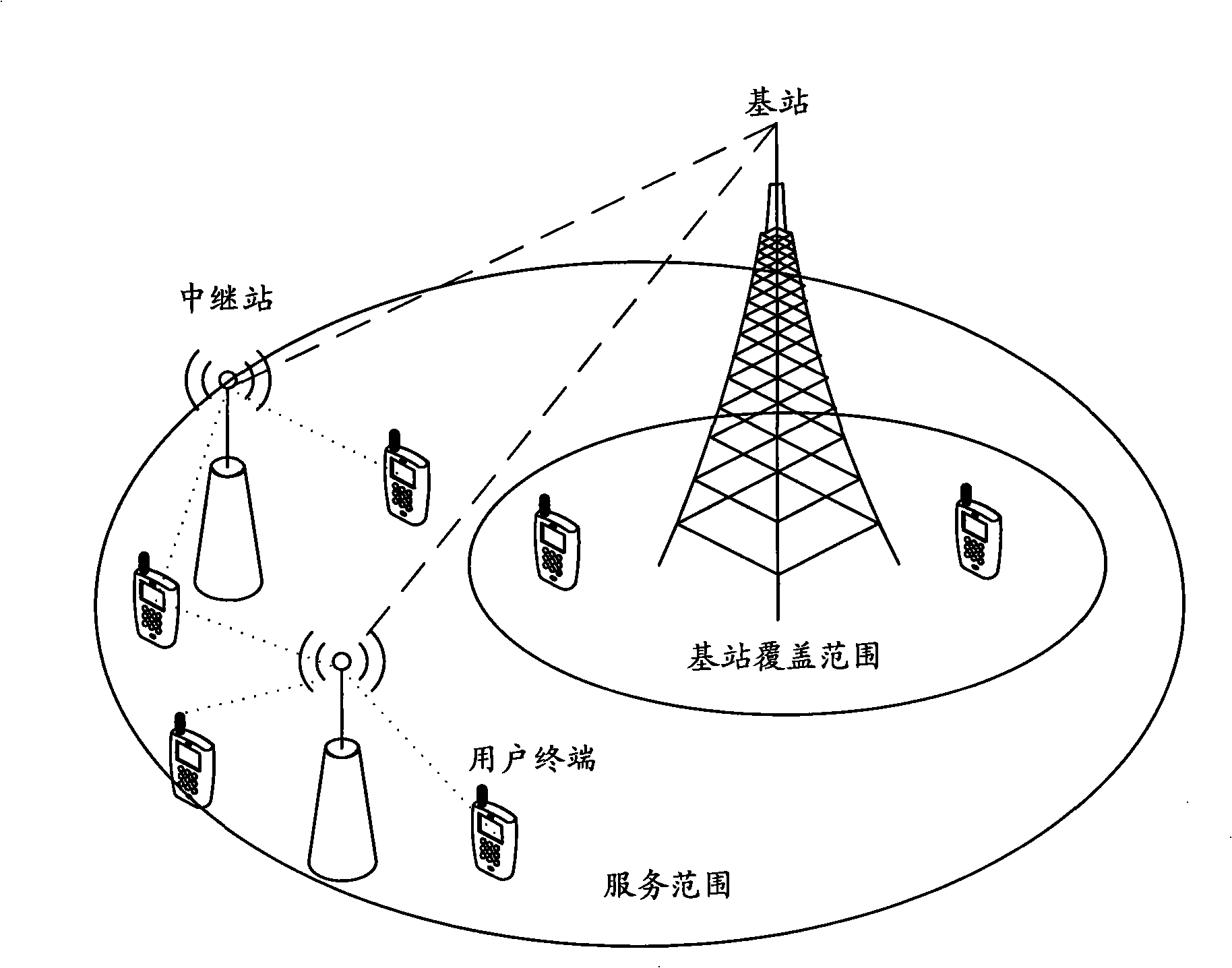

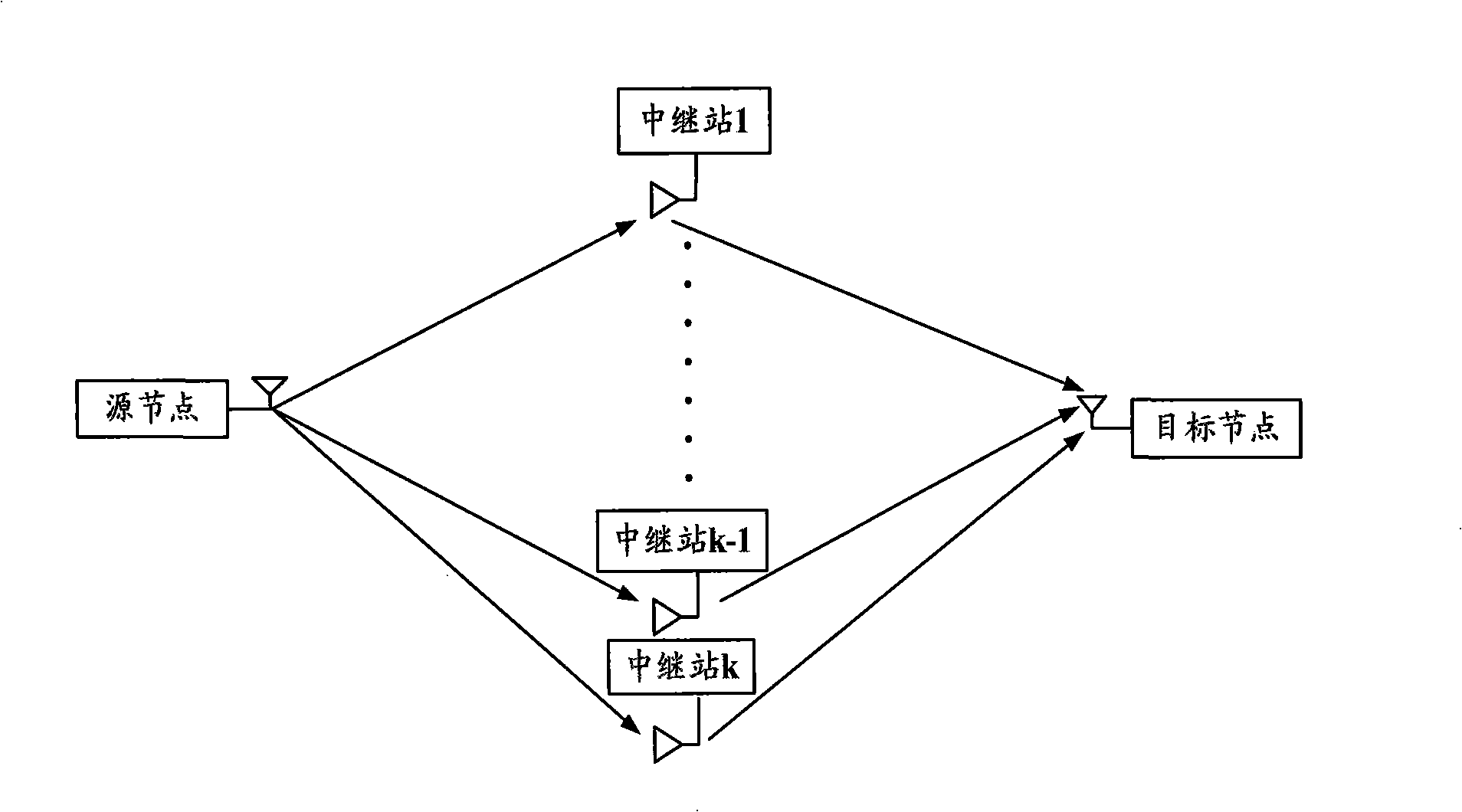

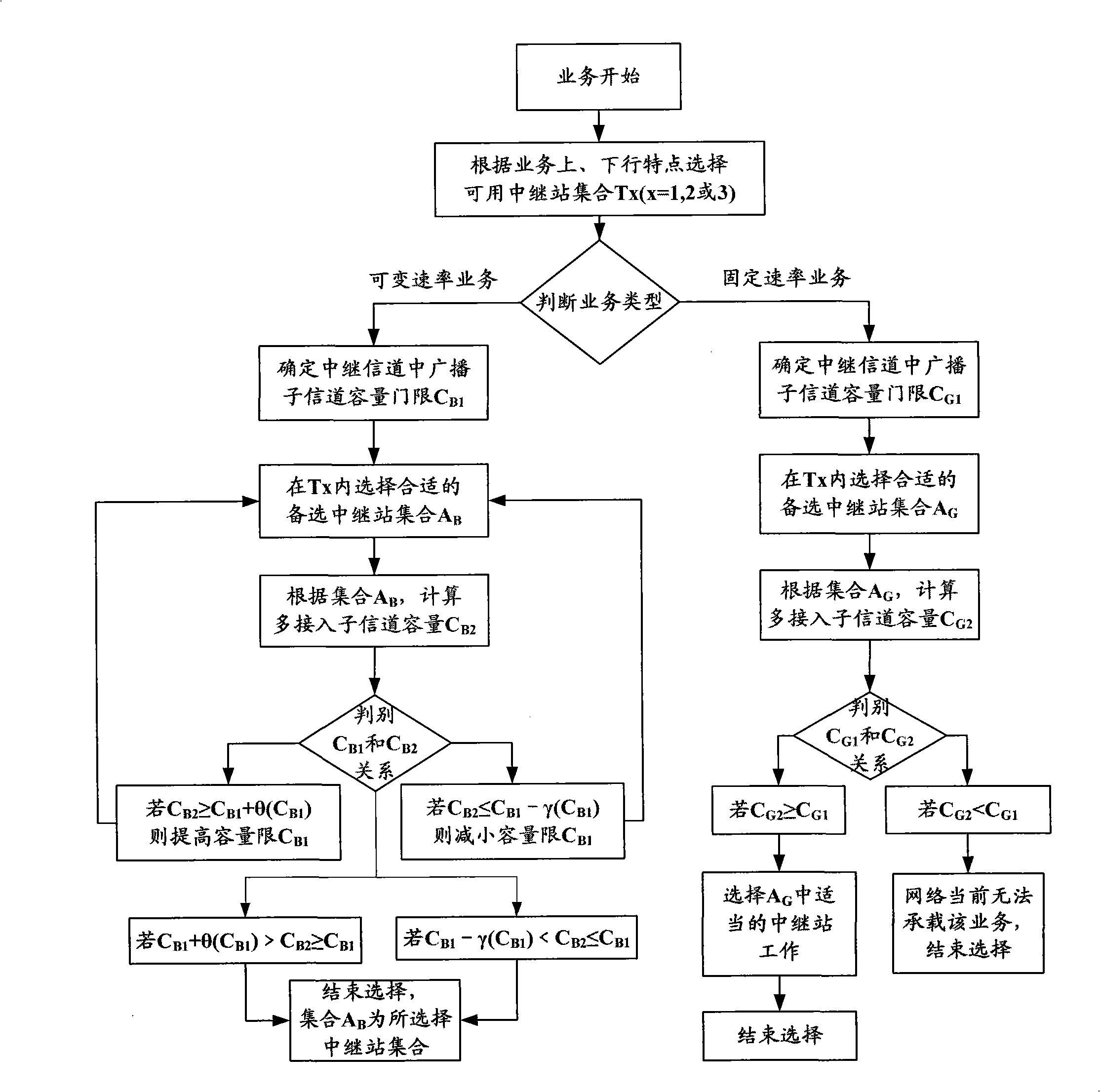

Selection method of wireless relay station

ActiveCN101291169AImprove satisfaction rateImprove throughputActive radio relay systemsRadio/inductive link selection arrangementsUplink transmissionSelection criterion

The invention discloses a method for selecting wireless relay stations. The operation steps are as follows: (1) the relay stations are selected according to business uplink and downlink features and different states of various relay stations among all relay stations in a cell, three basic selection criteria at this time are as follows: comprehensively considering states of uplink and downlink channels to select the appropriate relay stations to perform uplink communication and downlink communication, separately considering the states of the uplink channel to select the appropriate uplink transmission relay stations, or separately considering the states of the downlink channel to select the appropriate downlink transmission relay stations; (2) business type is judged according to business features of variable speed and fixed speed and the corresponding selection principle, respectively selecting one or a plurality of appropriate relay stations, and the capacity access thresholds of the relay stations are self-adaptively and flexible set. Therefore the selection method for the wireless relay stations can select the relay stations efficiently and rapidly, reduce signaling overhead and improve utilization rate of radio resources.

Owner:COMBA TELECOM SYST CHINA LTD

Power distribution network single-phase earth fault line selection method based on line double-terminal negative sequence current

InactiveCN103063984ACorrectly selectedSensitive selectionFault locationElectric power systemEngineering

The invention belongs to the field of power system relay protection technology, and provides a power distribution network single-phase earth fault line selection method based on line double-terminal negative sequence current. The power distribution network single-phase earth fault line selection method is characterized in that the method includes the steps of firstly carrying out synchronous sampling to three-phase current of head ends and tail ends of all circuits to be judged in a power distribution network, and then calculating negative sequence current components at the head ends and the tail ends of the circuits according to sampling results; the negative sequence current components at the head ends and the tail ends of normal circuits are equal, while the negative sequence current components at the head ends and the tail ends of the circuits with a single-phase earth fault are different, so that a criterion for fault line selection is formed. The calculation and analysis to a representative 35-kilovolt multi-branch power distribution network single-phase earth fault indicates that the power distribution network single-phase earth fault line selection method can be used for choosing the faulty circuits accurately in a sensitive mode, and can be widely applied to the power distribution network with various earthing methods, and the line selection principle is not influenced by arc suppression coils.

Owner:BEIJING JIAOTONG UNIV

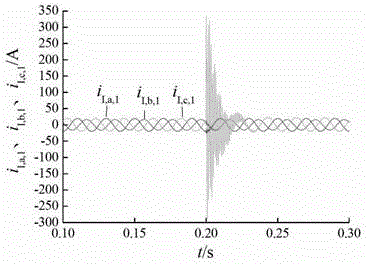

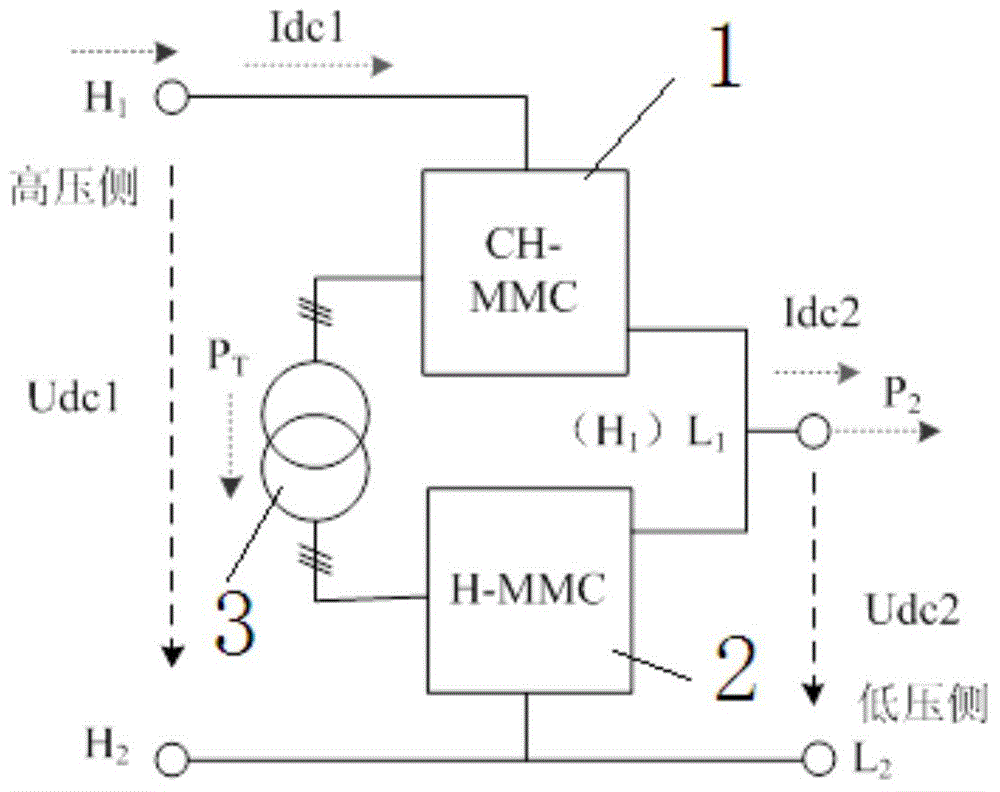

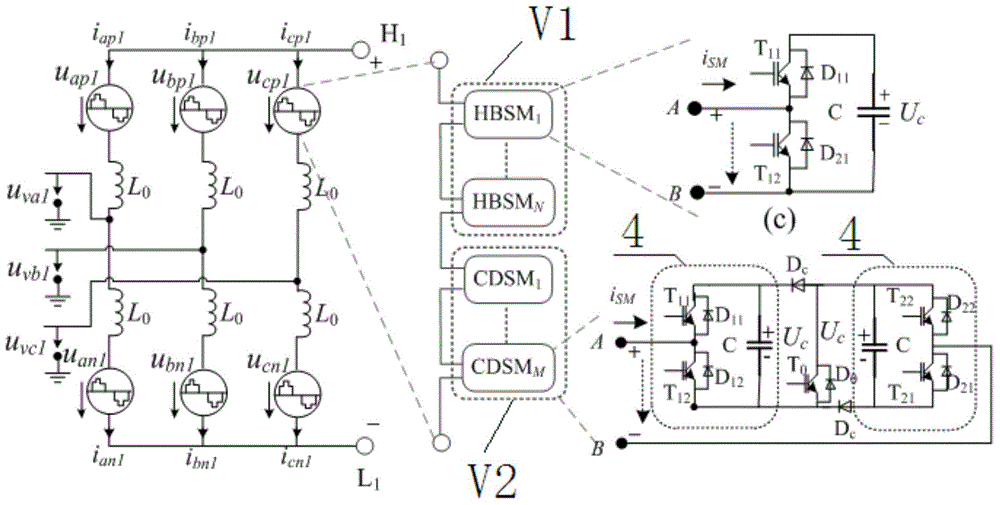

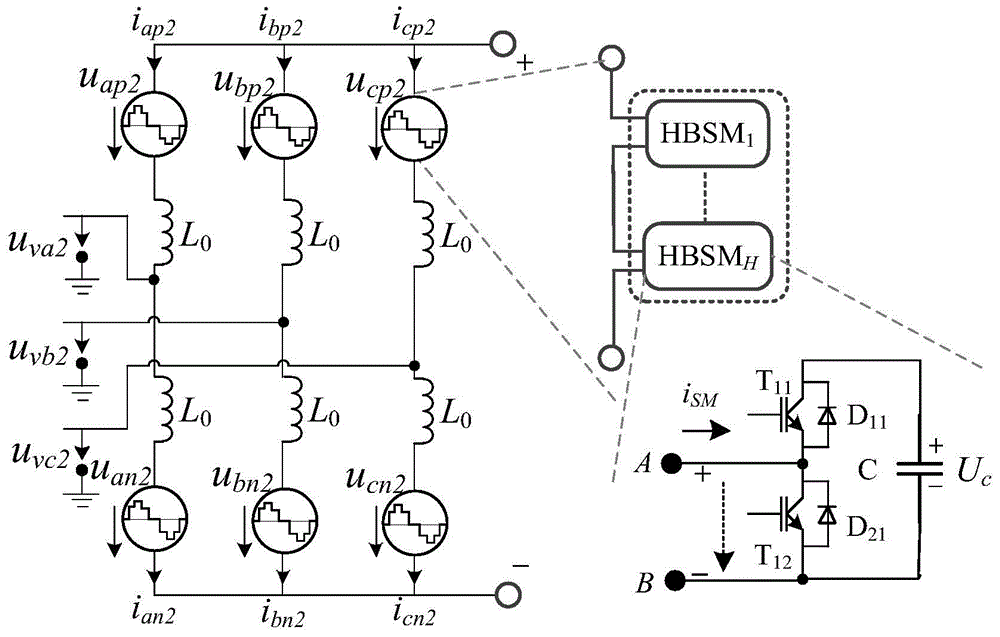

Self coupled modular multilevel high-voltage DC-DC transformer and control method thereof

ActiveCN104600997AReduce manufacturing costReduce volumeDc-dc conversionElectric variable regulationHybrid typeLinear control

The invention relates to a self coupled modular multilevel high-voltage DC-DC transformer and a control method thereof. An upper portion converter of the transformer adopts a full bridge sub module and half bridge sub module mixed modular multilevel one, a lower portion converter is a half bridge sub module type modular multilevel one, and energy interaction of the upper and lower portion converters is implemented in a self coupling manner. According to the determined alternate current transformer optimal rated transformation ratio and sub module selection principle, on the premise of maintaining the direct current failure isolating capability, the component requirements are lowered to the utmost extent, and the cost is reduced accordingly; on the basis of the precision feedback linear control strategy, the characteristics that the alternate current portion of a direct current transformer is free of power grid interference and system parameters can be measured accurately can be utilized completely, and the fine control performance is provided; by means of the fast direct current failure isolation, the direct current failure transmission and expansion of two direct current power grids can be prevented effectively; the transformer has the advantages that the transmission capacity is large, the direct current voltage level is high, and the transformer is adaptive to a high-voltage large capacity direct current power grid power conduction occasions.

Owner:STATE GRID CORP OF CHINA +1

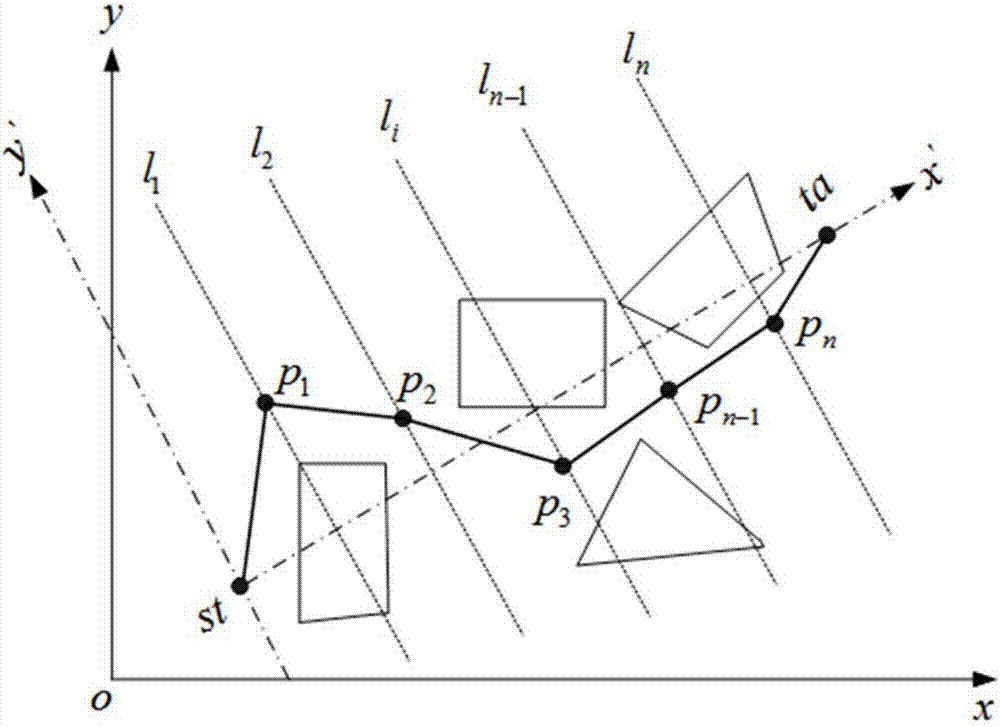

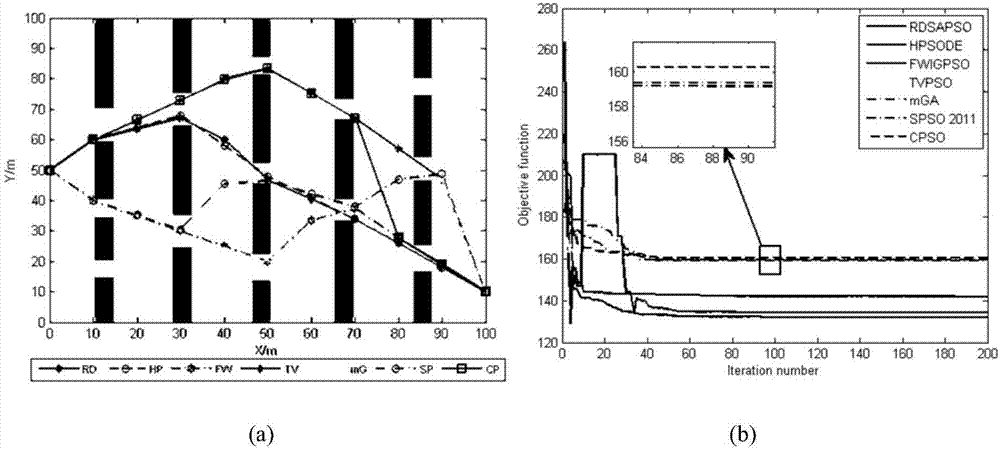

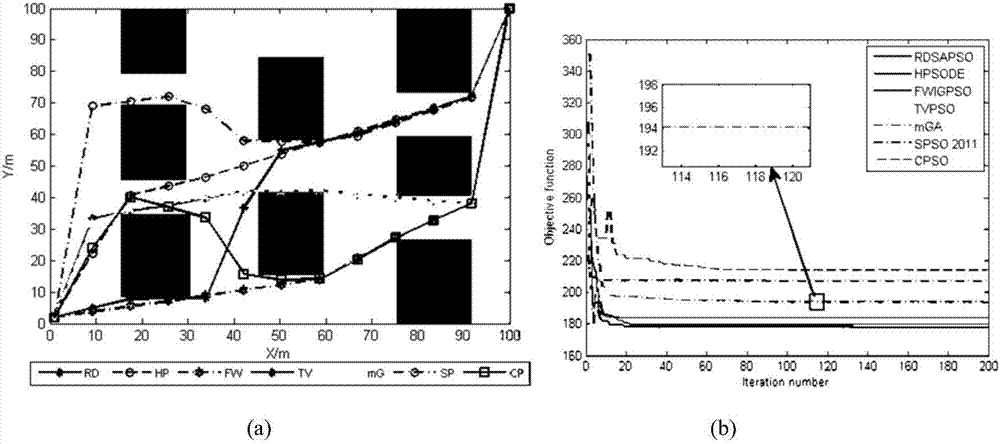

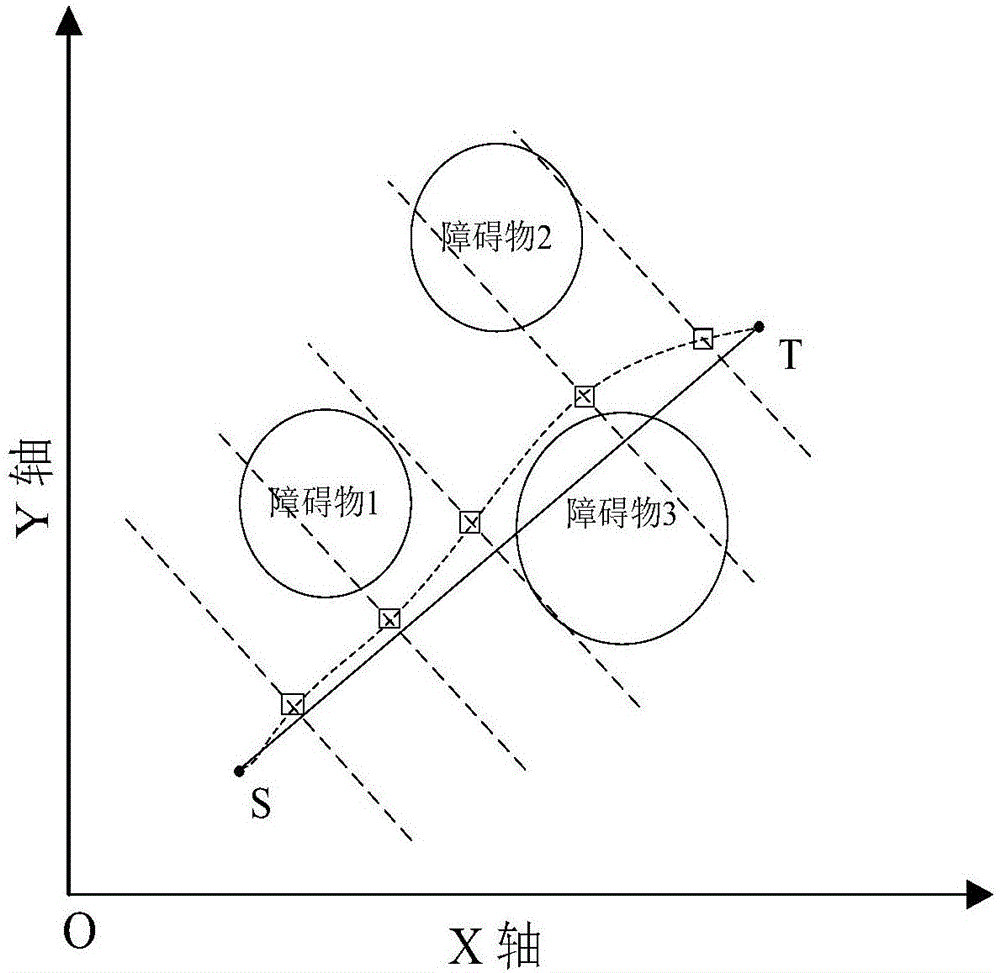

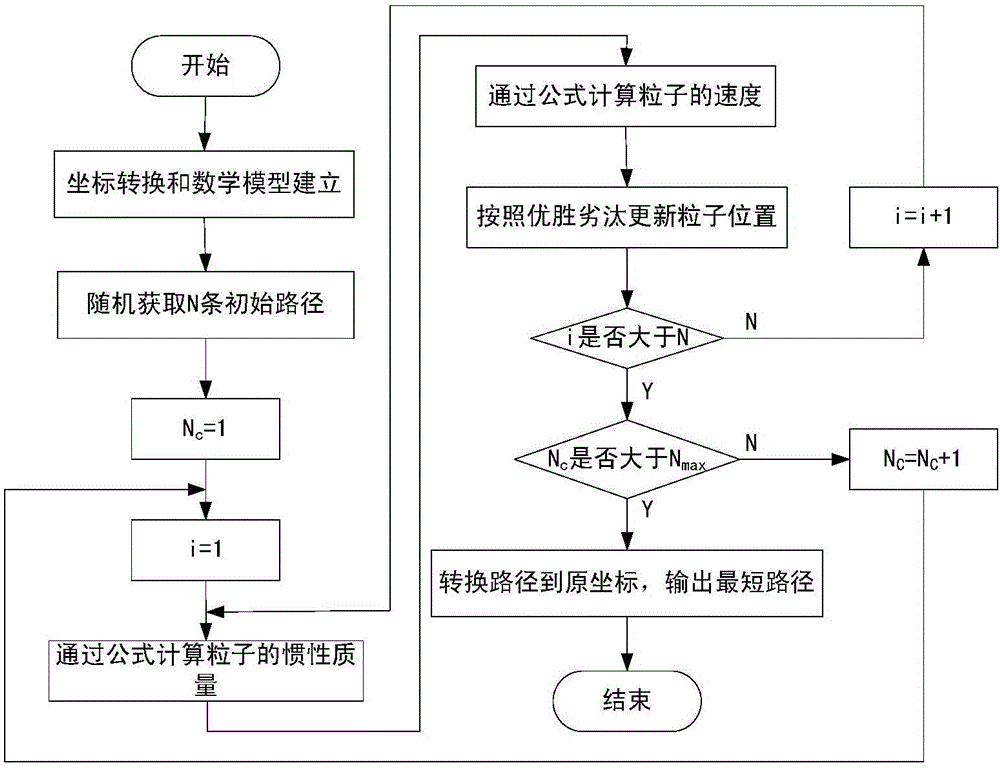

Improved particle swarm optimization-based mobile robot path planning method

InactiveCN107065876AIncrease diversityAvoid stagnationArtificial lifePosition/course control in two dimensionsArtificial intelligencePlanning method

The invention discloses an improved particle swarm optimization-based mobile robot path planning method. According to the method, a global optimal update strategy of disturbance is implemented in RDSAPSO (random-disturbance self-adaptive particle swarm optimization), small random disturbance is added to a global optimal position in a population, so that non-stagnation attributes in the RDSAPSO are obtained; an adaptive strategy is adopted to finely adjust three control parameters of particles in the RDSAPSO, so that global search capability and local search capability can be better balanced in the RDSAPSO, and a convergence guarantee parameter selection principle is provided for the RDSAPSO; and the constraint conditions of a path planning problem are solved through using a feasibility rule, and therefore, optimization difficulty can be decreased, and diversity can be decreased; and the developed RDSAPSO is utilized, so that an RDSAPSO-based path planning method framework is completed. With the method of the invention adopted, an effective method is provided for the path planning problem of a mobile robot.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

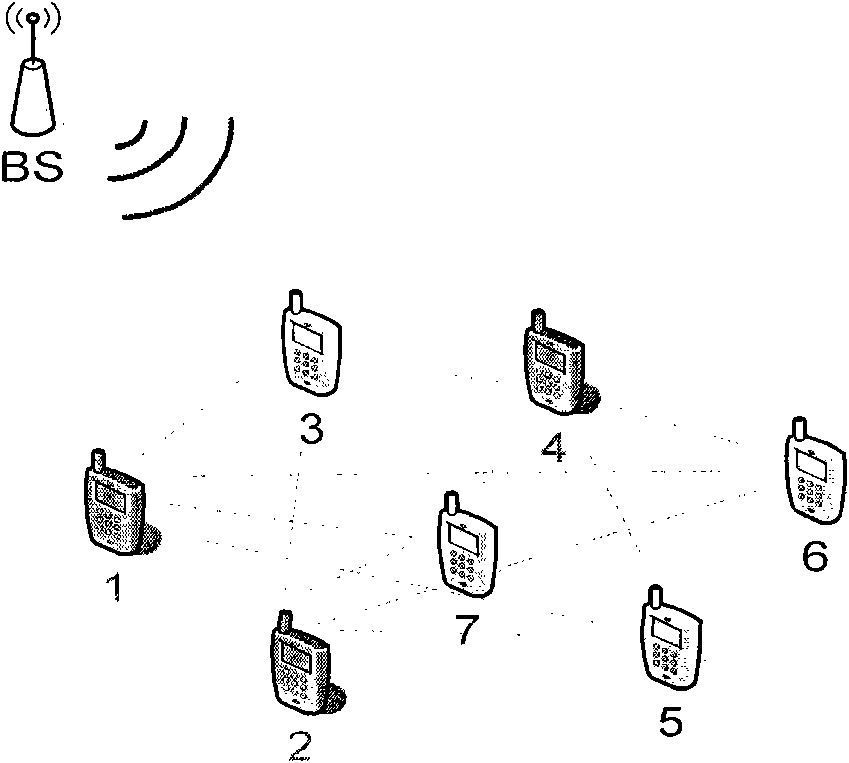

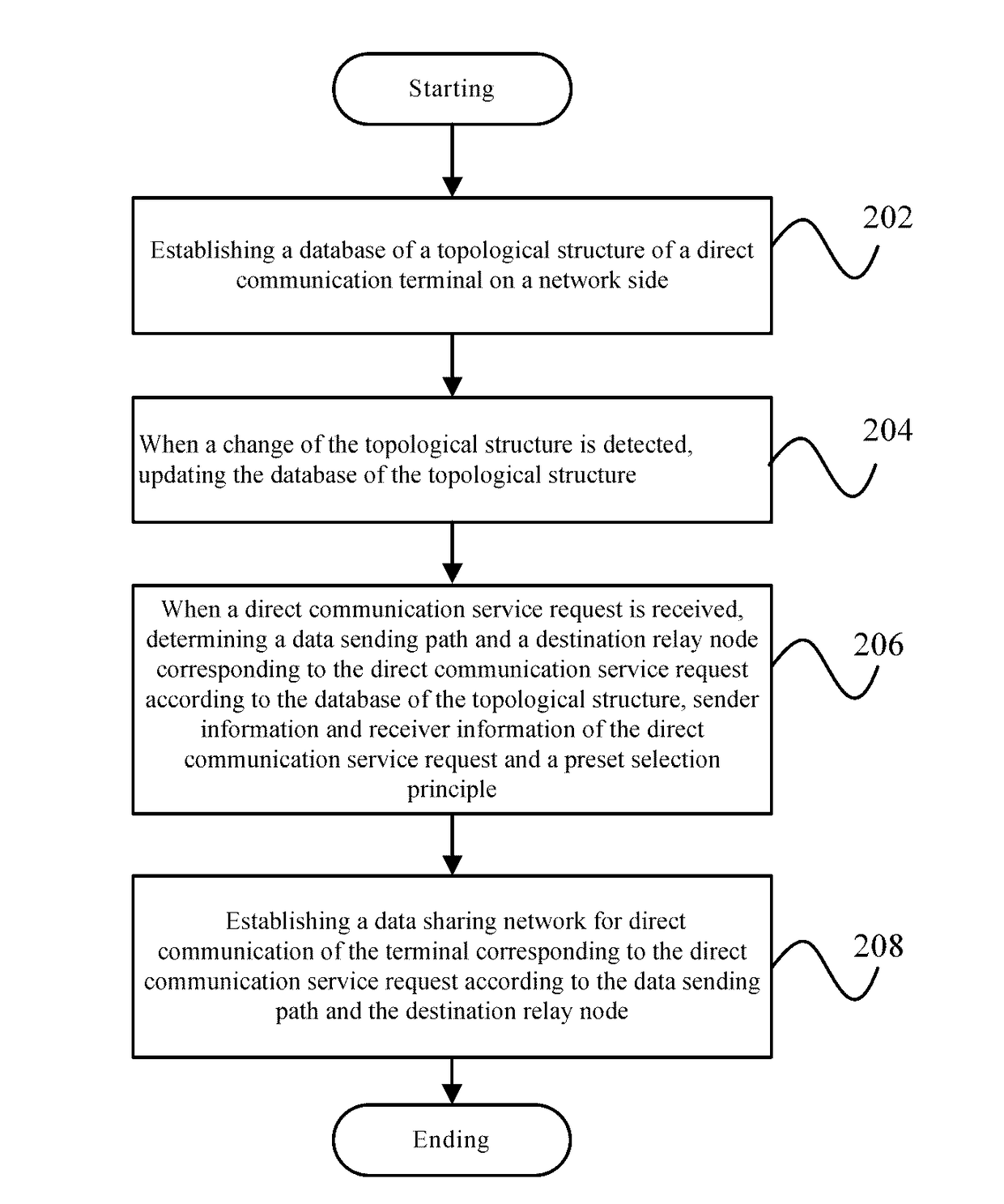

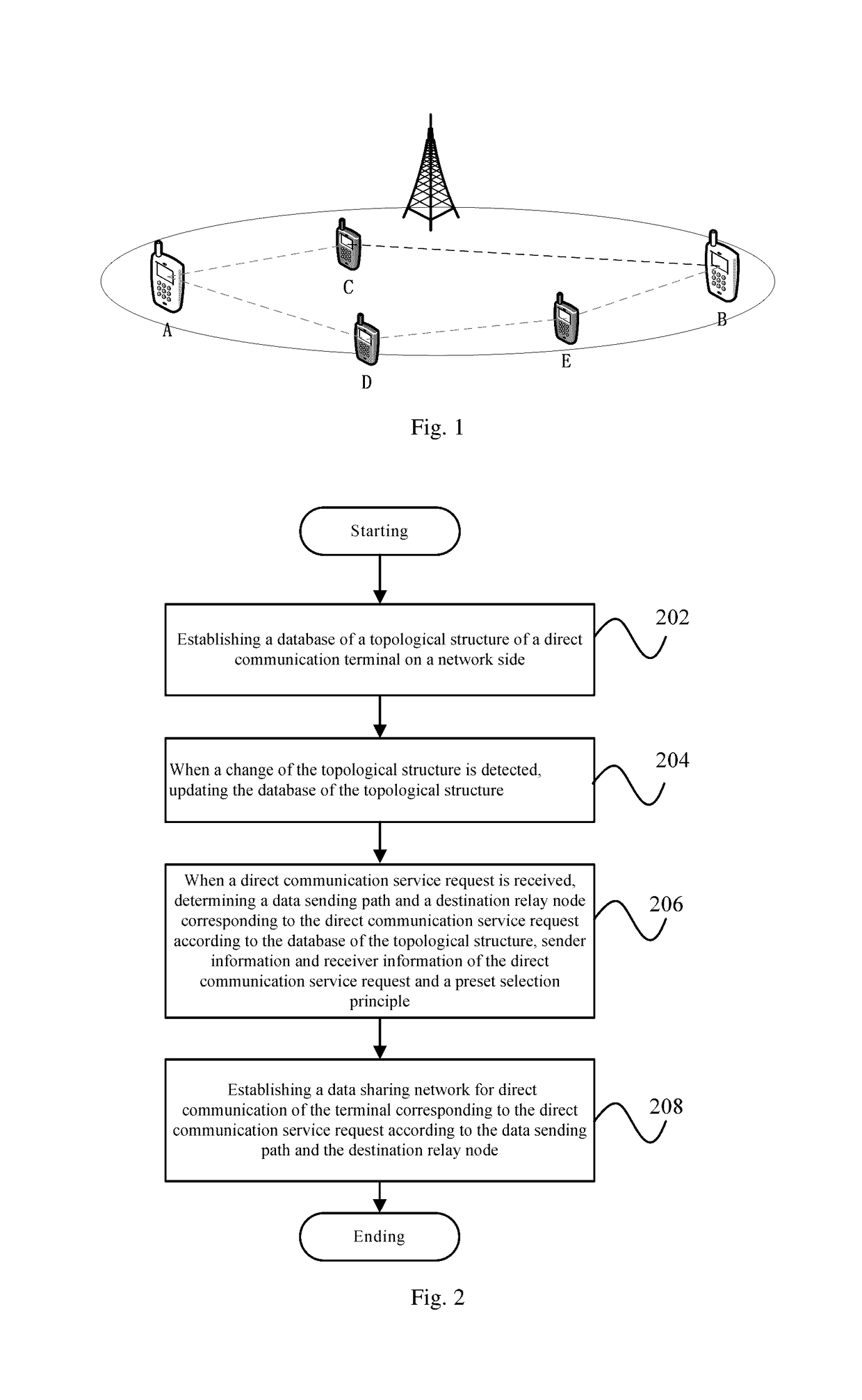

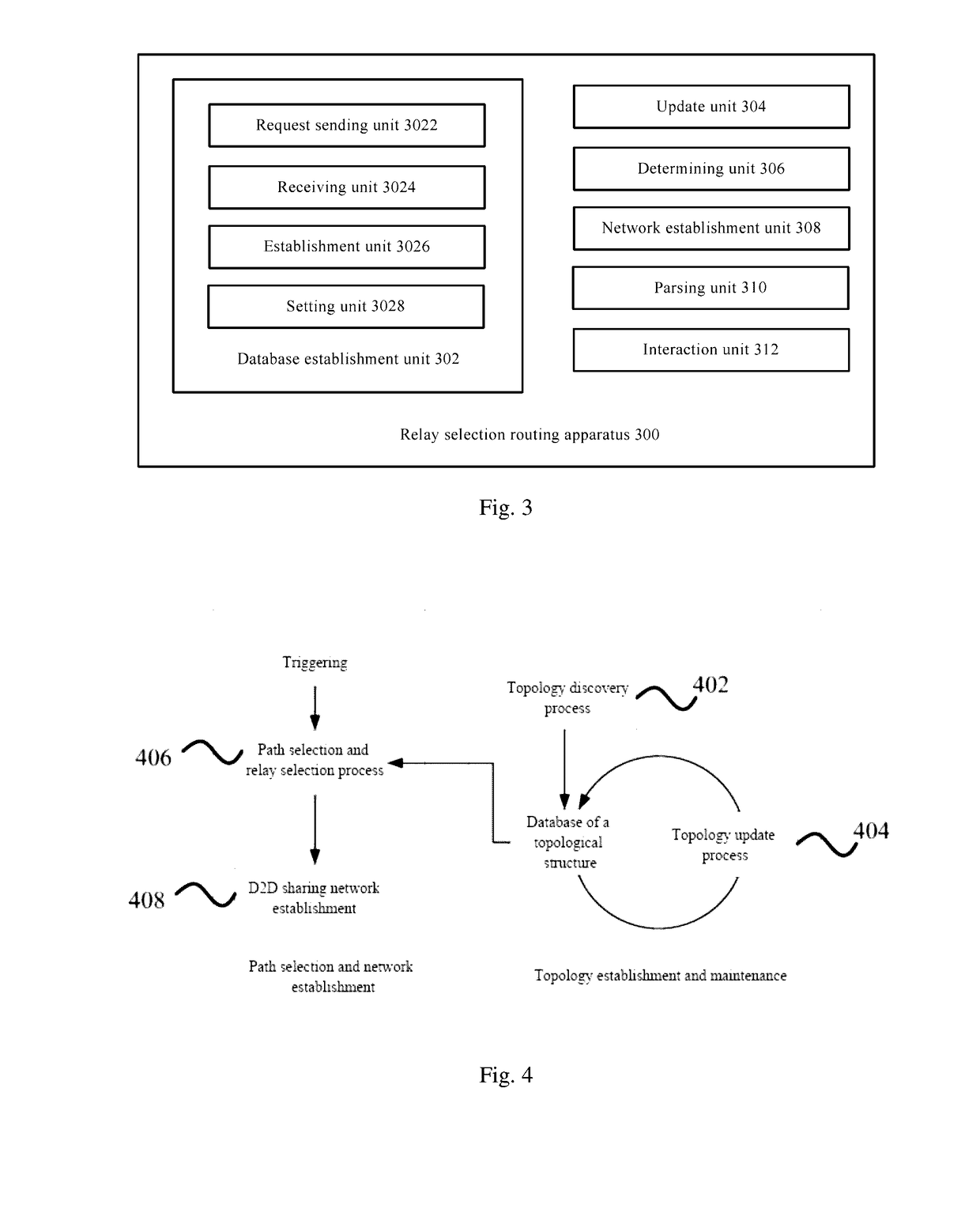

Relay Selection Routing Method and Relay Selection Routing Apparatus Based on Direct Communication of Terminal

ActiveUS20170142594A1Smooth data sharingAvoid a lotNetwork topologiesConnection managementStructure of Management InformationDirect communication

The present invention provides a relay selection routing method based on direct communication of a terminal, applied to a base station, including: establishing a database of a topological structure of a direct communication terminal on a network side; when a change of the topological structure is detected, updating the database of the topological structure; when a direct communication service request is received, determining a data sending path and a destination relay node corresponding to the direct communication service request according to the database of the topological structure, sender information and receiver information of the direct communication service request and a preset selection principle; and establishing a direct communication data sharing network corresponding to the direct communication service request according to the data sending path and the destination relay node. Correspondingly, the present invention further provides a relay selection router based on direct communication of a terminal.

Owner:NANCHANG COOLPAD INTELLIGENT TECH CO LTD

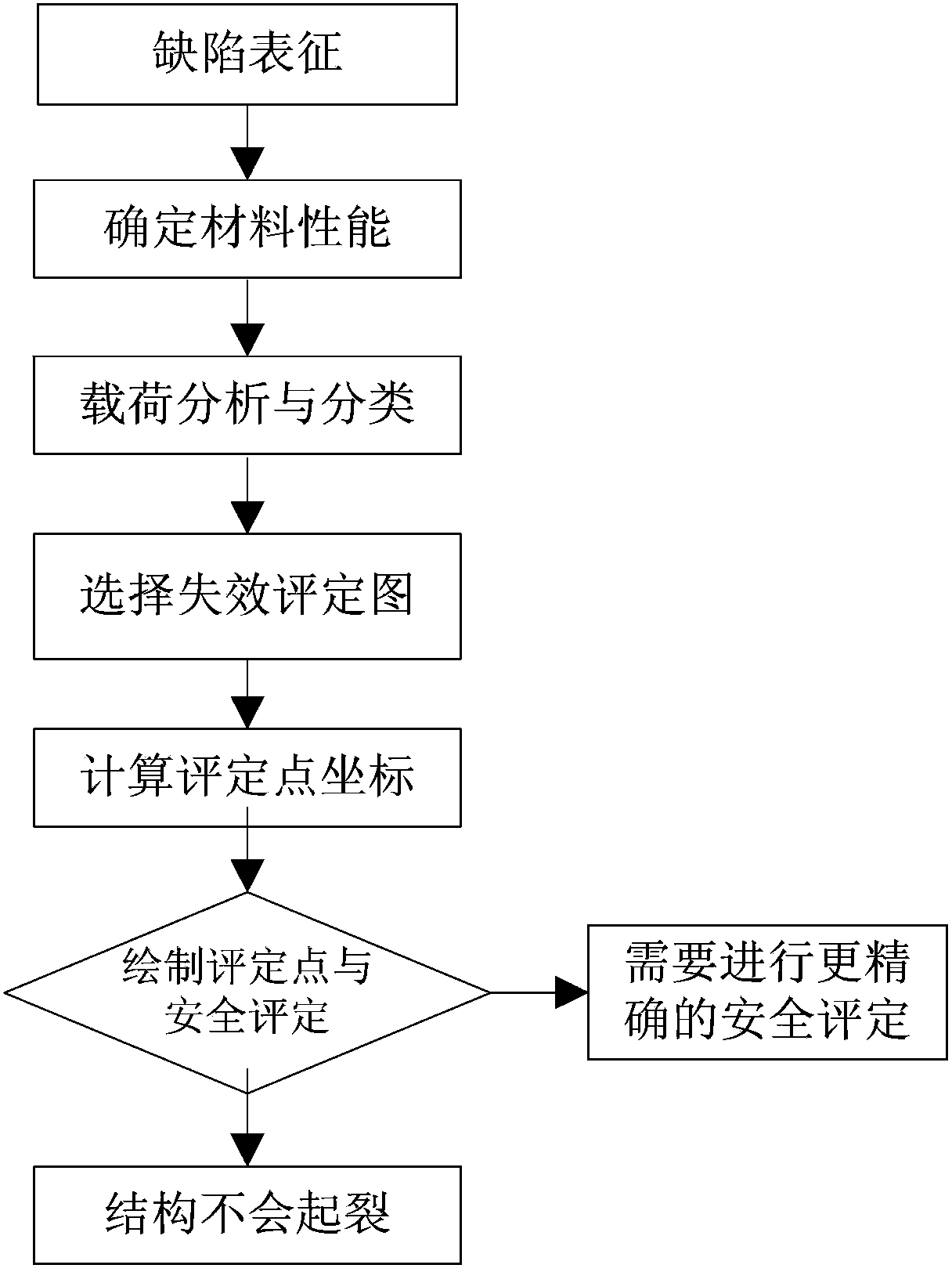

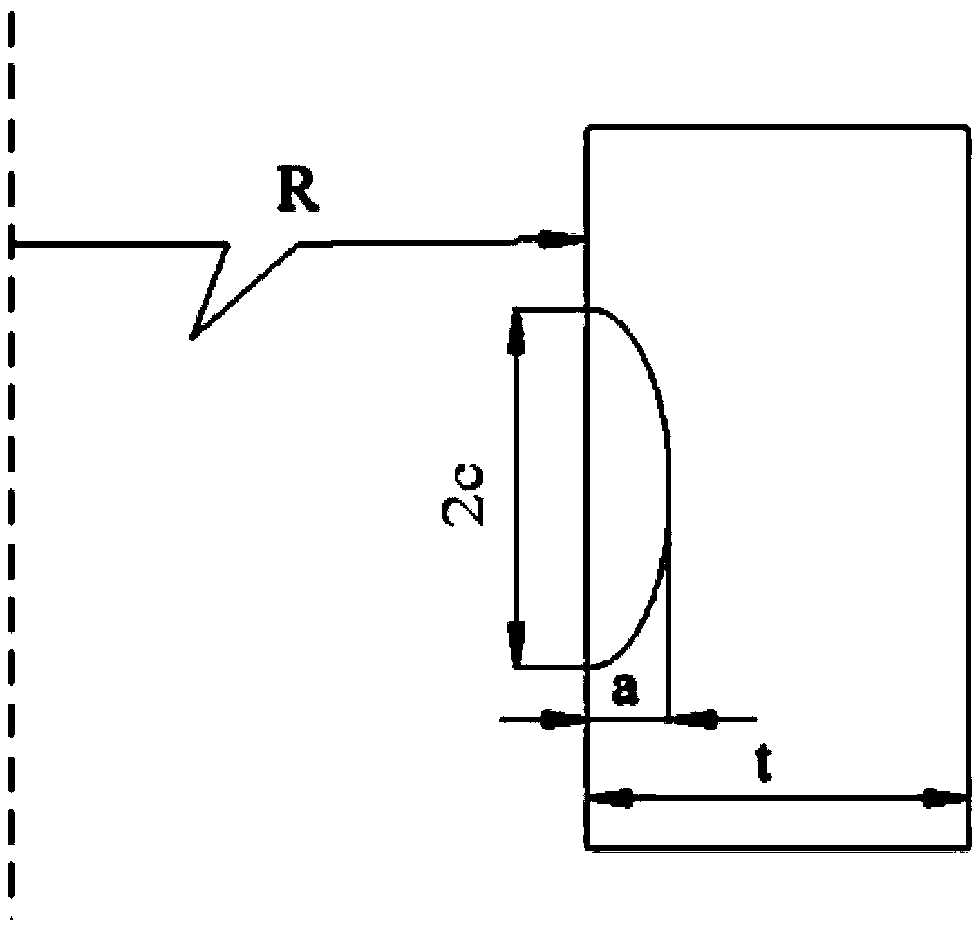

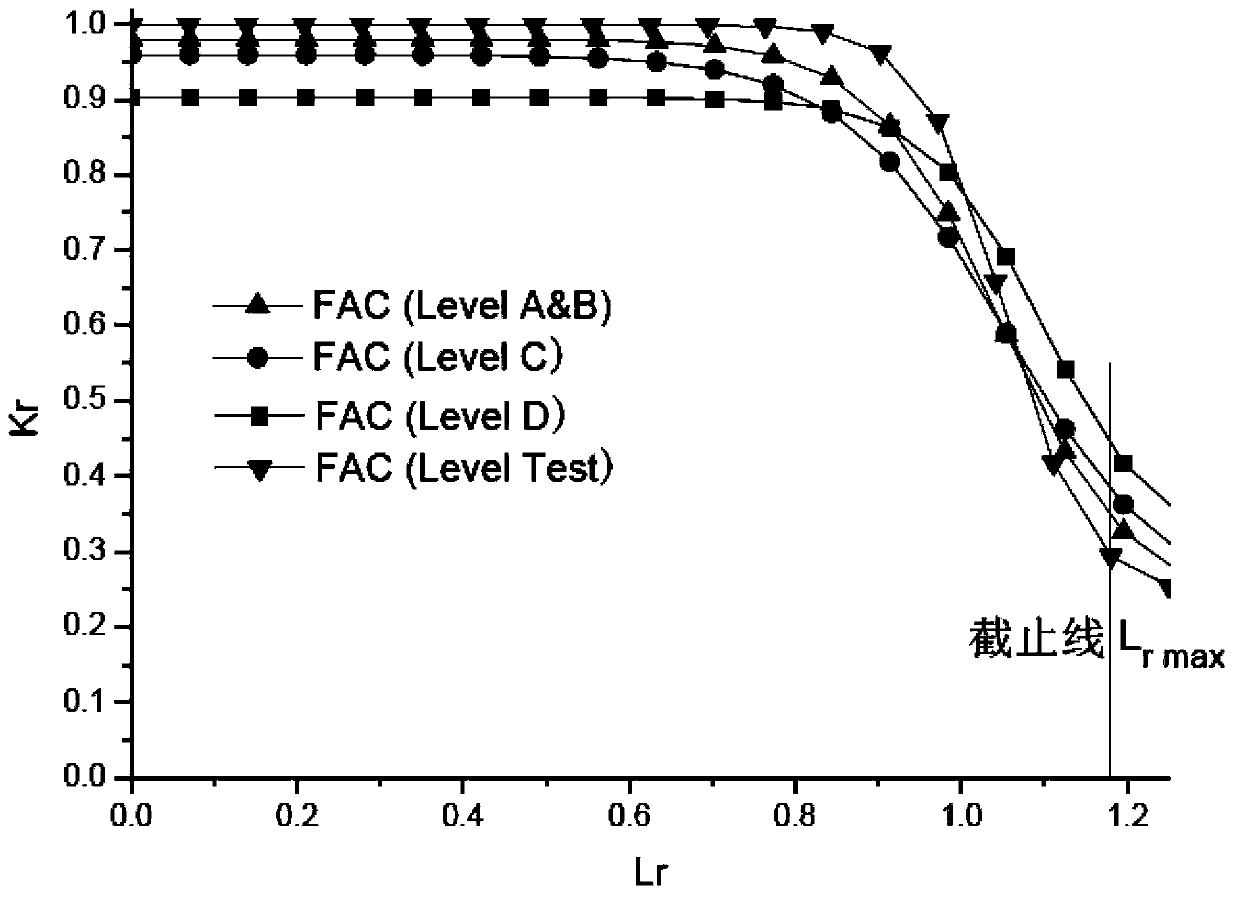

Evaluation method for defects of CPR1000 unit reactor pressure vessel core cylindrical shell zones

The invention provides an evaluation method for defects of CPR1000 unit reactor pressure vessel core cylindrical shell zones. The method comprises steps of (1) characterizing defects; (2) acquiring physical property parameters and breaking property parameters of a material; (3) analyzing and classifying loads; (4) selecting a failure evaluation curve; (5) calculating evaluation point coordinates; (6) drawing evaluation points and evaluating safety; and (7) evaluating a structure safety allowance and analyzing parameter sensitivity. The method has advantages comprising higher precision, lower calculation cost and capability of giving selection principles of the safety allowance in the evaluation over the prior art, and therefore the method has practical significance for safety evaluation of defects of core cylindrical shell zones.

Owner:SUZHOU NUCLEAR POWER RES INST +1

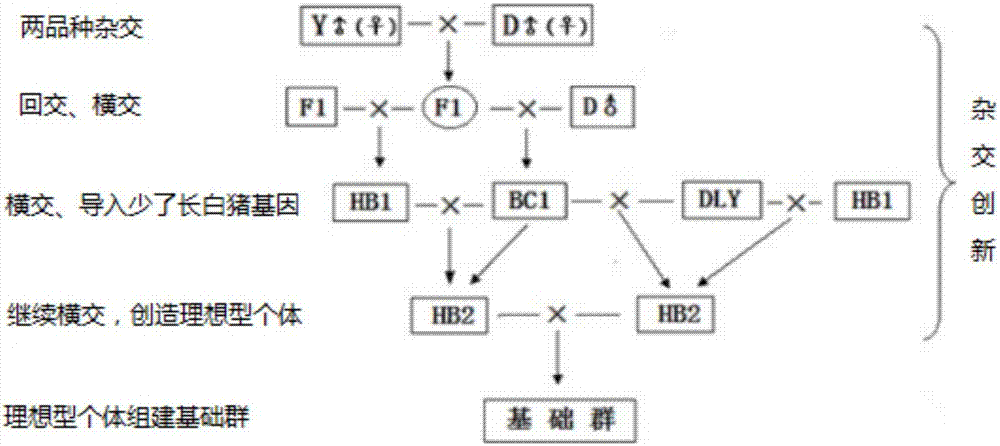

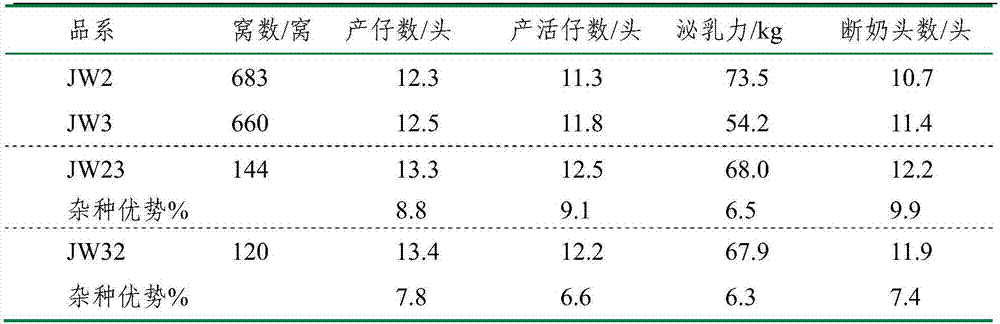

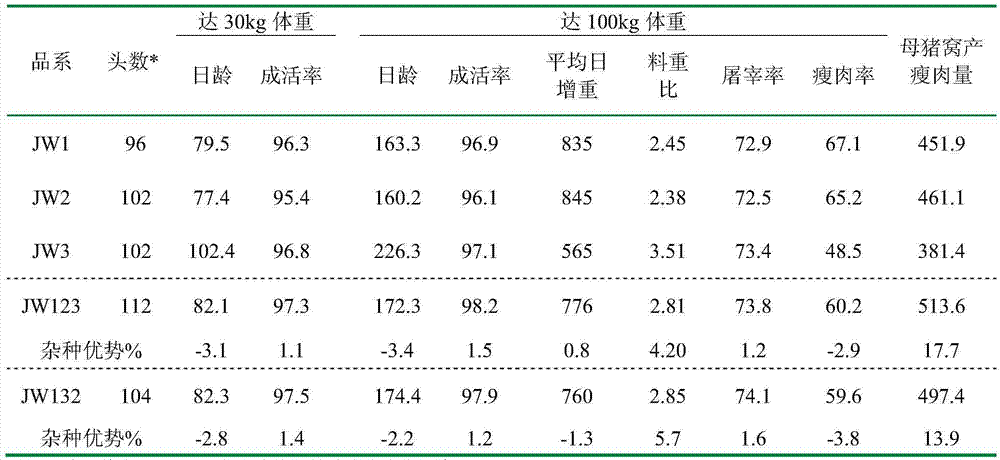

Breeding method of high-quality synthetic white pig line

ActiveCN107182927AImprove adaptabilityStrong breeding abilityAnimal husbandryLean meatSelection principle

The invention relates to the technical field of animal breeding and particularly provides a breeding method of a high-quality synthetic white pig line. The method utilizes existing domestic and overseas pig breed resources, a specialized line is bred according to a trait differentiation and selection principle, thus commercial pigs quicker to grow, higher in lean meat percentage, good in meat quality, strong in resistance and high in slaughtering weight uniformity are obtained through hybrid breeding of the specialized line, the problem existing in 'inner binary' and 'inner ternary' breeding systems can be solved, meanwhile local pig breed resources can be also effectively protected and utilized, high-quality pig breeds are provided for industrial large-scale breeding, and the heavy demands for high-quality pork of masses of consumers are met.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

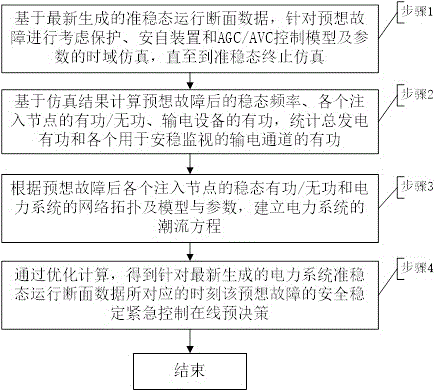

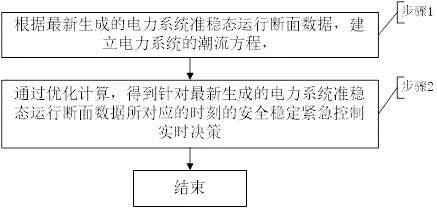

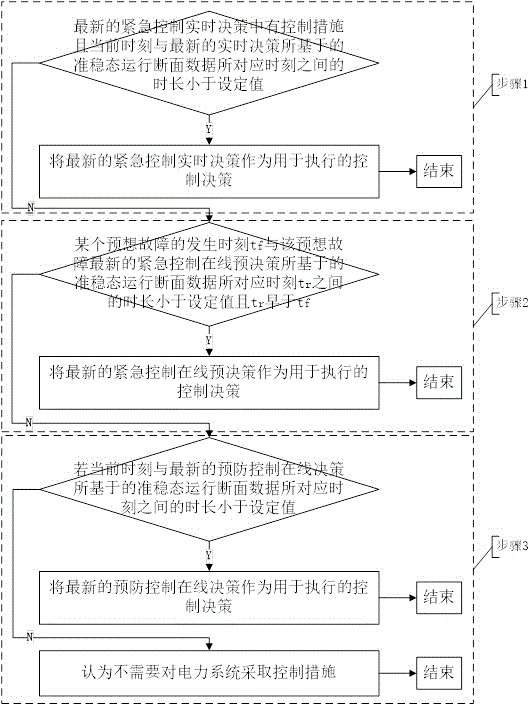

Safe and stable online comprehensive defense method for electric power system

ActiveCN106099906AAvoid safety and stability risksOvercoming the Unreasonable Online Pre-decision of Emergency ControlContigency dealing ac circuit arrangementsEngineeringSelection principle

The invention discloses a safe and stable online comprehensive defense method for an electric power system, and belongs to the safe and stable control technical field of the electric power system. When the electric power system is in a quasi-steady-state operational state, a safe and stable prevention control online strategic decision specific to a preconceiving fault set, a safe and stable emergency control online pre-strategic decision specific to each preconceiving fault, and a safe and stable emergency control real-time strategic decision specific to the actual operational state of the electric power system are calculated separately; whether the duration between the operational moment and the current moment of the electric power system under the three kinds of control strategic decisions exceeds a corresponding constant value or not is taken as the effective criterion for each type of the control strategic decision; a to-be-executed control measure is determined by combination with the control strategic decision selection principle that the safe and stable emergency control real-time strategic decision is adopted firstly, the safe and stable emergency control online pre-strategic decision is adopted secondly, and the safe and stable prevention control online strategic decision is adopted finally in sequence; and therefore, a practical and effective method is supplied to the safe and stable online comprehensive defense of the electric power system.

Owner:NARI TECH CO LTD +4

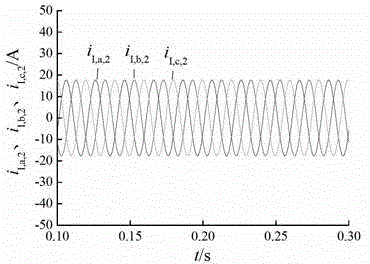

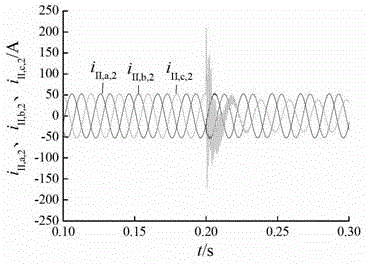

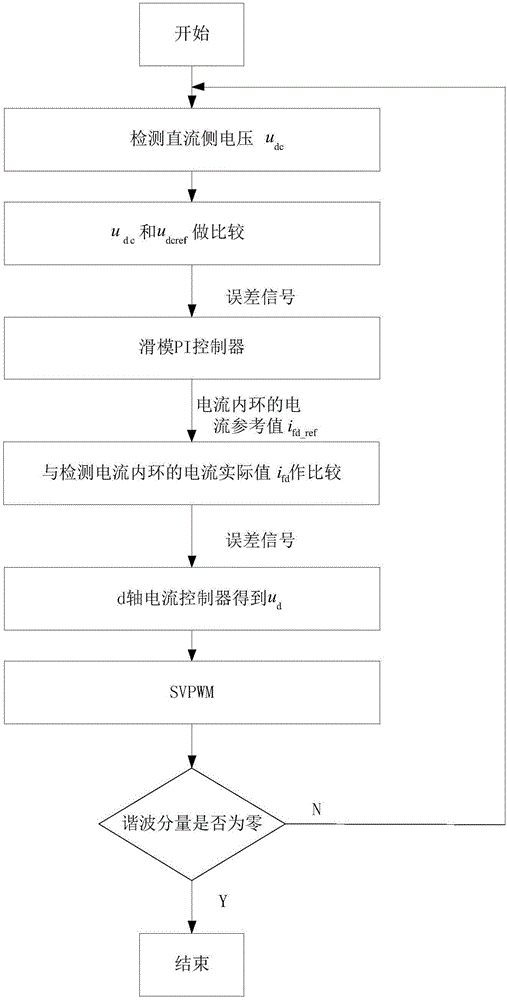

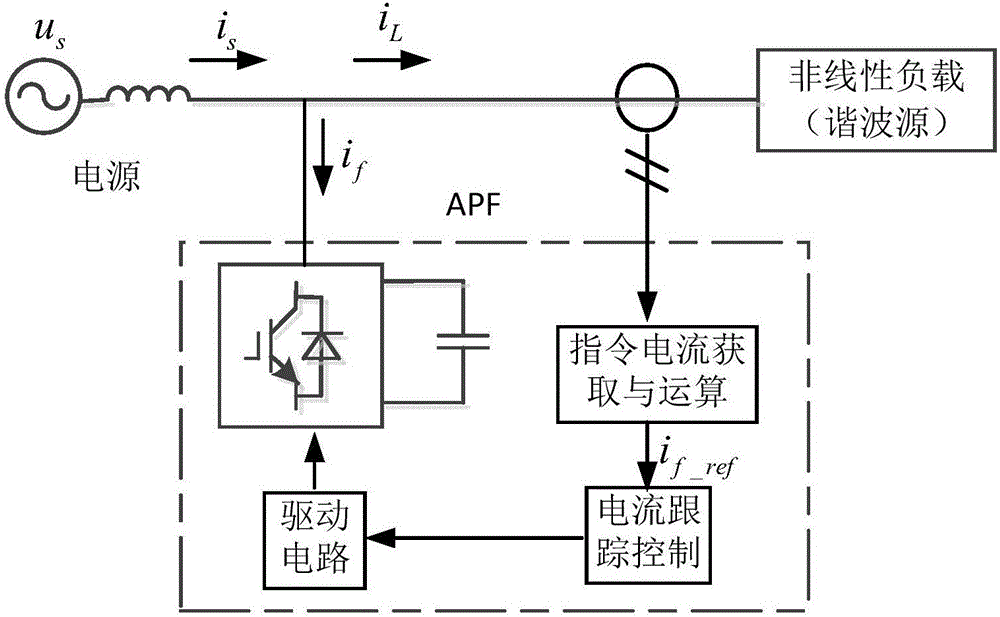

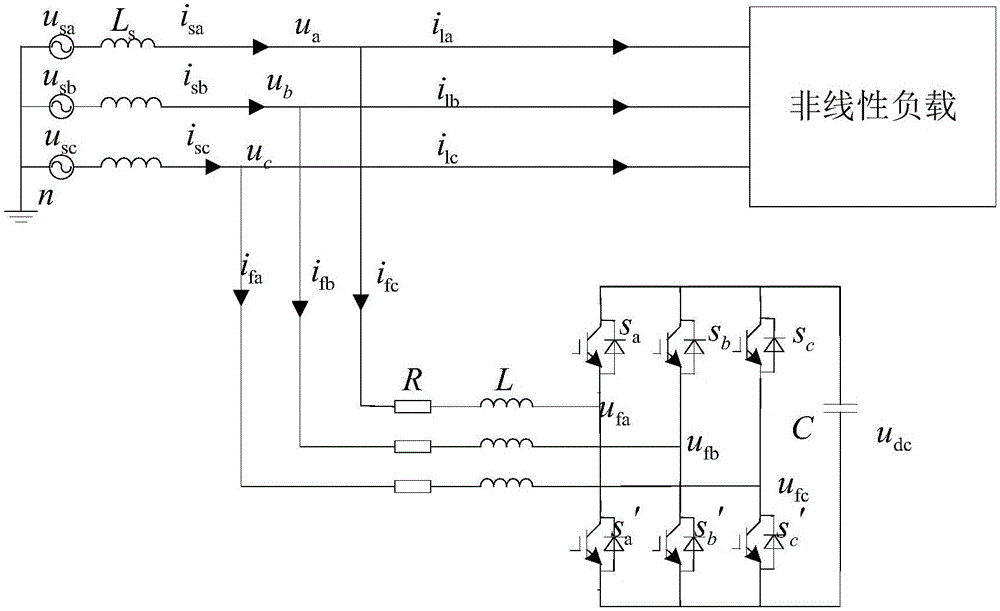

Parallel APF DC side voltage control method based on sliding mode PI compound control algorithm

ActiveCN106549399AReduce lossHigh steady state accuracyActive power filteringReactive power adjustment/elimination/compensationVoltage referenceVoltage control

The invention discloses a parallel APF DC side voltage control method based on a sliding mode PI compound control algorithm. The method comprises the following steps: firstly establishing a low-order system model of a dq coordinate system by using synchronous rotating coordinate transformation; determining the sliding mode switching function of the DC side voltage according to the selection principle of sliding mode surfaces; and finally designing the control parameter output function of a PI controller according to the switching function of the sliding mode surfaces. By adopting the control method disclosed by the invention, the steady state performance and response speed of the DC side voltage can be improved, and the voltage fluctuation can also be effectively reduced; and a parallel APF control system based on the sliding mode PI compound control algorithm has good robust performance and dynamic performance. According to the parallel APF DC side voltage control method based on the sliding mode PI compound control algorithm disclosed by the invention, the parameter of the PI controller is determined through the sliding mode controller, the steady state accuracy and response speed during load sudden change and reference voltage jump can be increased, the power loss at the DC side can be reduced, and thus the compensation ability of the parallel APF (active power filter) can be ensured.

Owner:CHONGQING CHUANYI AUTOMATION

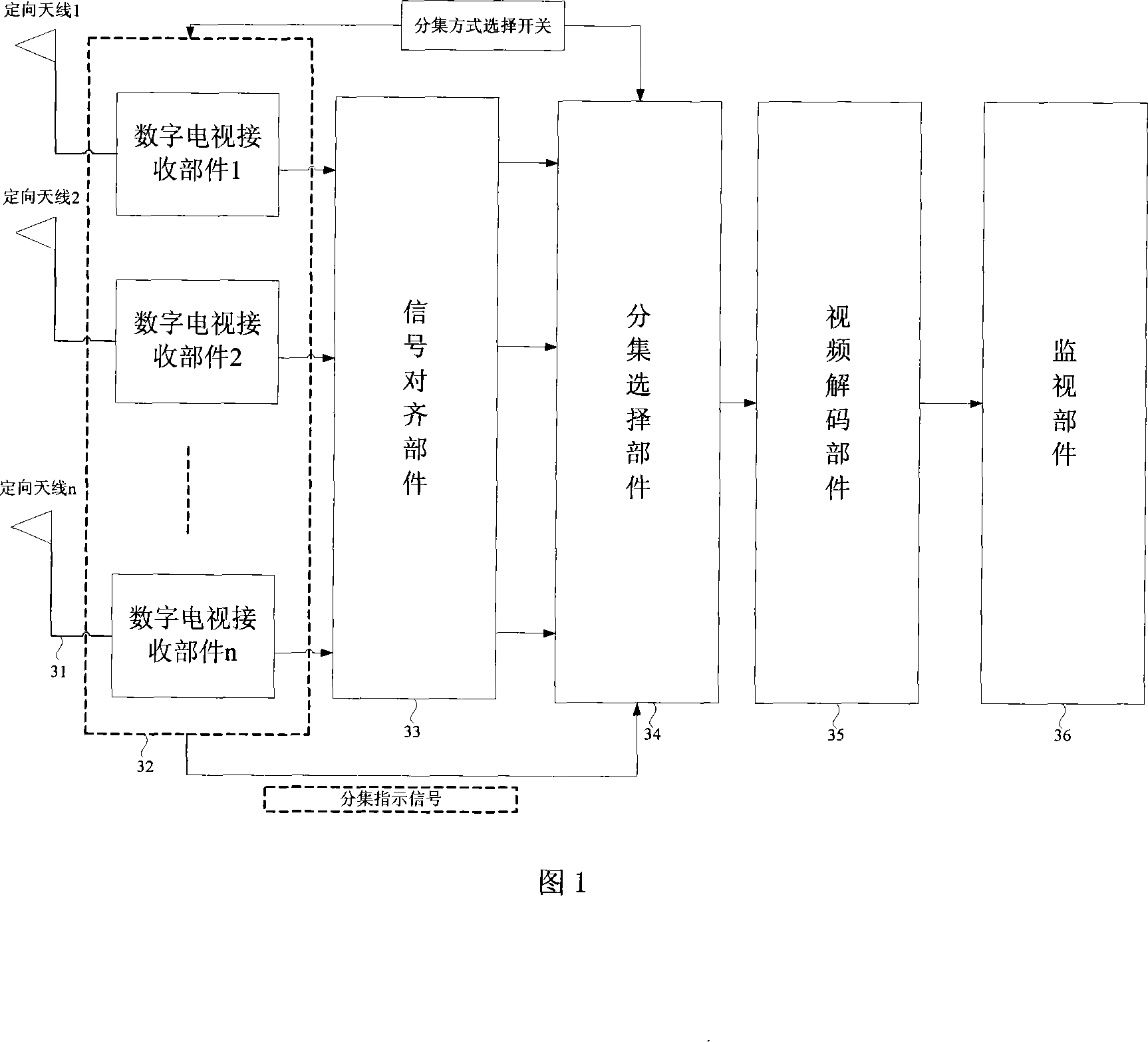

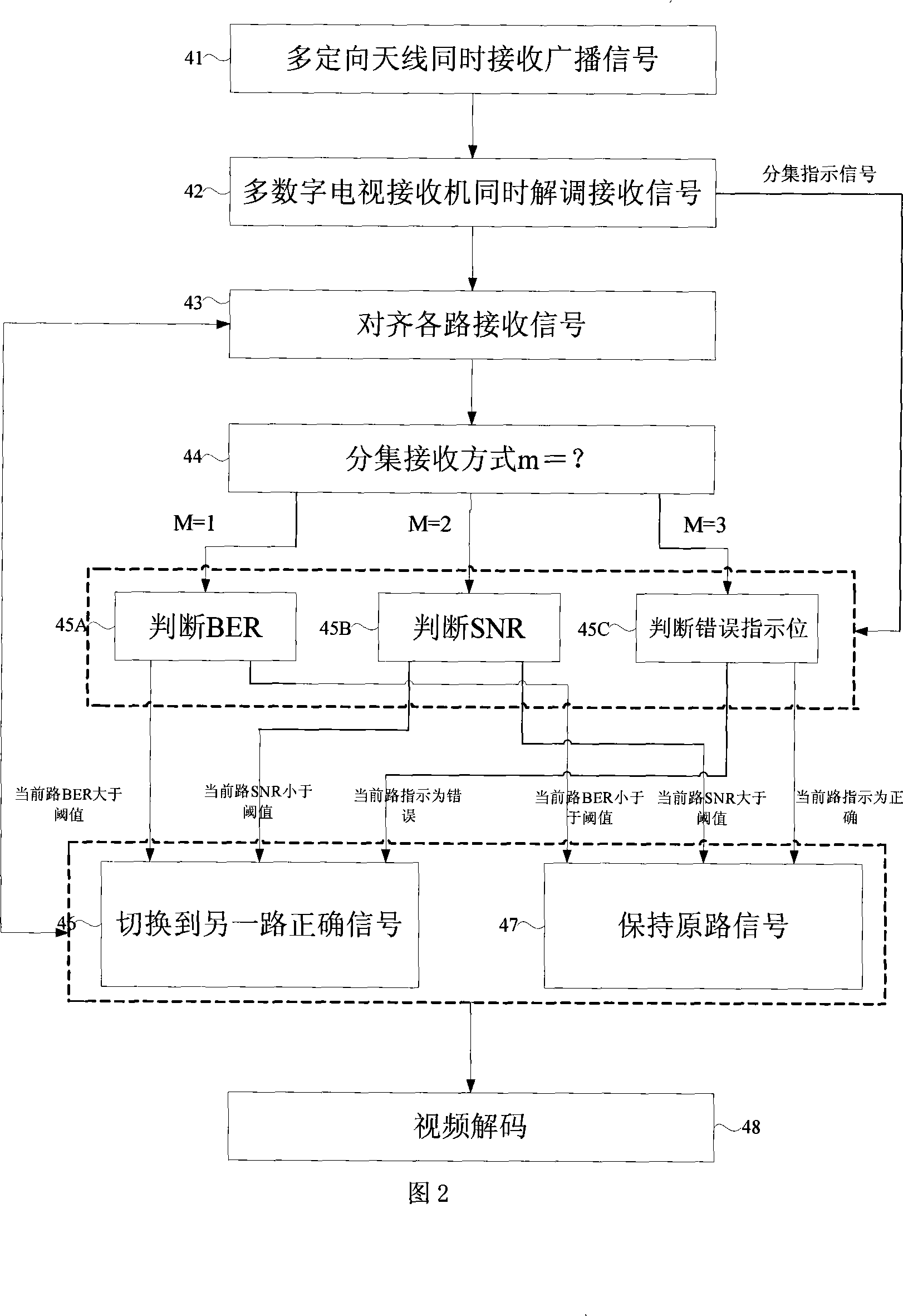

Diversity receiving terminal and receiving method for digital television single frequency network

InactiveCN101068316AOvercoming multipath interferenceImprove receiver sensitivityTelevision system detailsTelevision system scanning detailsDirectional antennaDiversity scheme

A diversity-receiving terminal of digital TV single-frequency network consists of multiple directional antenna enabling to receive TV broadcast band signal, multiple receiving-component enabling to independently receive TV broadcast signal and enabling to generate different diversity indication signal according to different diversity selection principle, a diversity selection component for carrying out diversity selection according to different diversity combination algorithm and a video decoding component.

Owner:SHANGHAI JIAO TONG UNIV

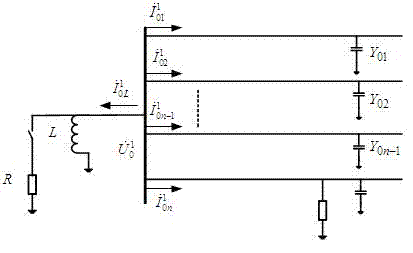

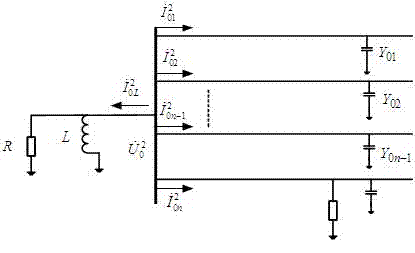

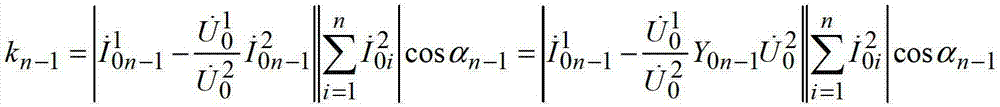

Maximum line selection coefficient principle based single-phase earth fault line selection method for power distribution network

The invention discloses a maximum line selection coefficient principle based a single-phase earth fault line selection method for a power distribution network. The method comprises the steps of measuring a zero-sequence voltage of a bus and zero-sequence currents of all feeder lines of the power distribution network when the single-phase earth fault of the feeder line of the power distribution network occurs; switching a parallel resistor with parameters of an arc suppression coil unchanged, and measuring the zero-sequence voltage of the bus and zero-sequence currents of all feeder lines of the power distribution network again; and calculating line selection coefficients of all feeder lines to conduct fault line selection according to the maximum line selection coefficient principle corresponding to the fault feeder line. According to the method, the line selection principle is simple, line selection results are not affected by factors such as feeder line types, fault positions, line parameters, transition resistors, earth fault types and line lengths, the requirements for the reliability of hardware and algorithms are low, and the method is suitable for complex operation environments of the power distribution network and good in practicability.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

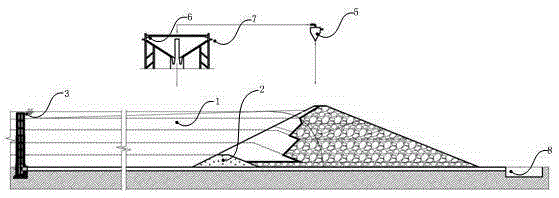

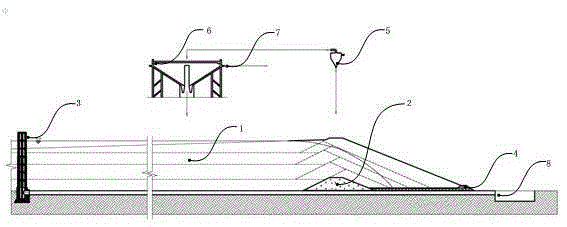

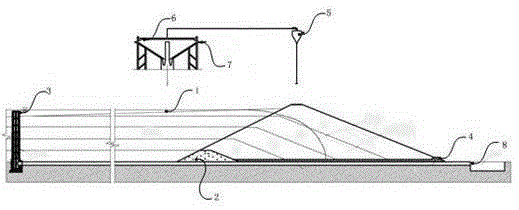

Water-saving tailing discharge method

ActiveCN105350498AEmission buildup is easy to controlImprove stabilityVortex flow apparatusSoil drainageTerrainWater saving

The invention belongs to the field of metallurgical mines, and particularly relates to a water-saving tailing discharge method. A place is selected according to the tailing pond address selection principle. A tailing pond, a primary dam, a floodwater drainage system, a seepage drainage system, a tailing conveying system, a tailing classification and condensation system, a water return system and other matched facilities are reasonably arranged according to terrain and geological conditions. The tailing conveying system comprises a section from a dressing plant to a hydrocyclone, a section from the hydrocyclone to a thickener, and a section form the underflow of the thickener to the tailing pond. Pumping or self-flowing conveying can be adopted for the conveying process of each section. The tailing classification and concentration involves the steps that ore pulp coming from the dressing plant is classified through the hydrocyclone; and overflow tailing ore pulp of the hydrocyclone is concentrated through the thickener. The water return system comprises a thickener overflow water return system and a tailing pond water return system. Return water can be conveyed to the mineral processing process to be recycled in a pumping or self-flowing conveying manner. The tailing pond formed through the method is good in anti-seismic property, high in return water utilization rate, low in dam body seepage line, large in anti-slide buckling safety factor, wide in application range and low in operation and management expense.

Owner:金建工程设计有限公司

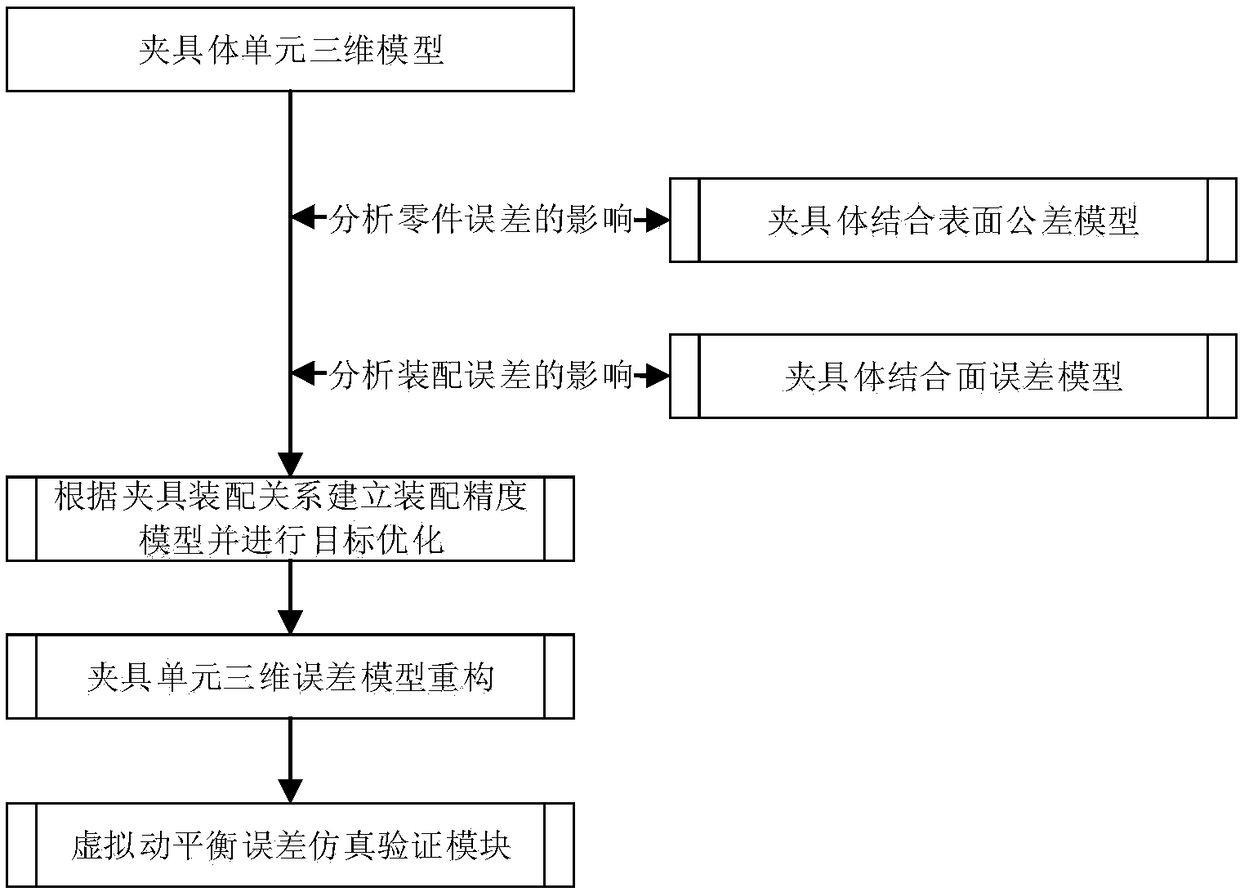

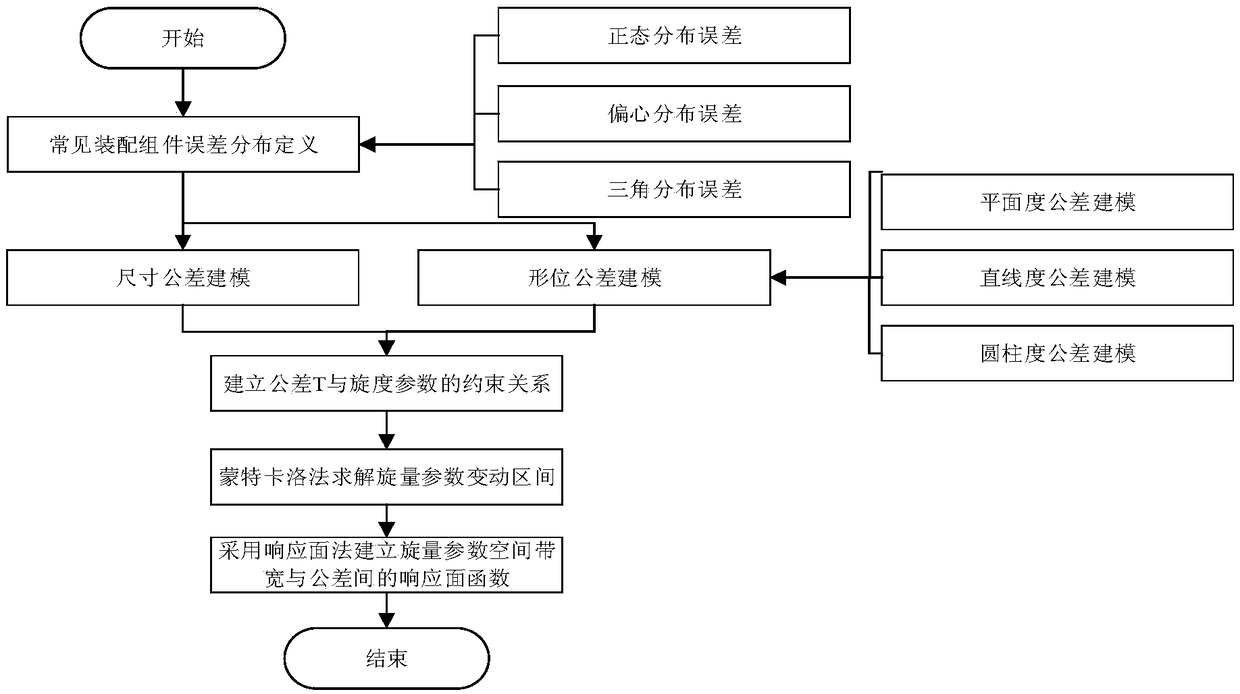

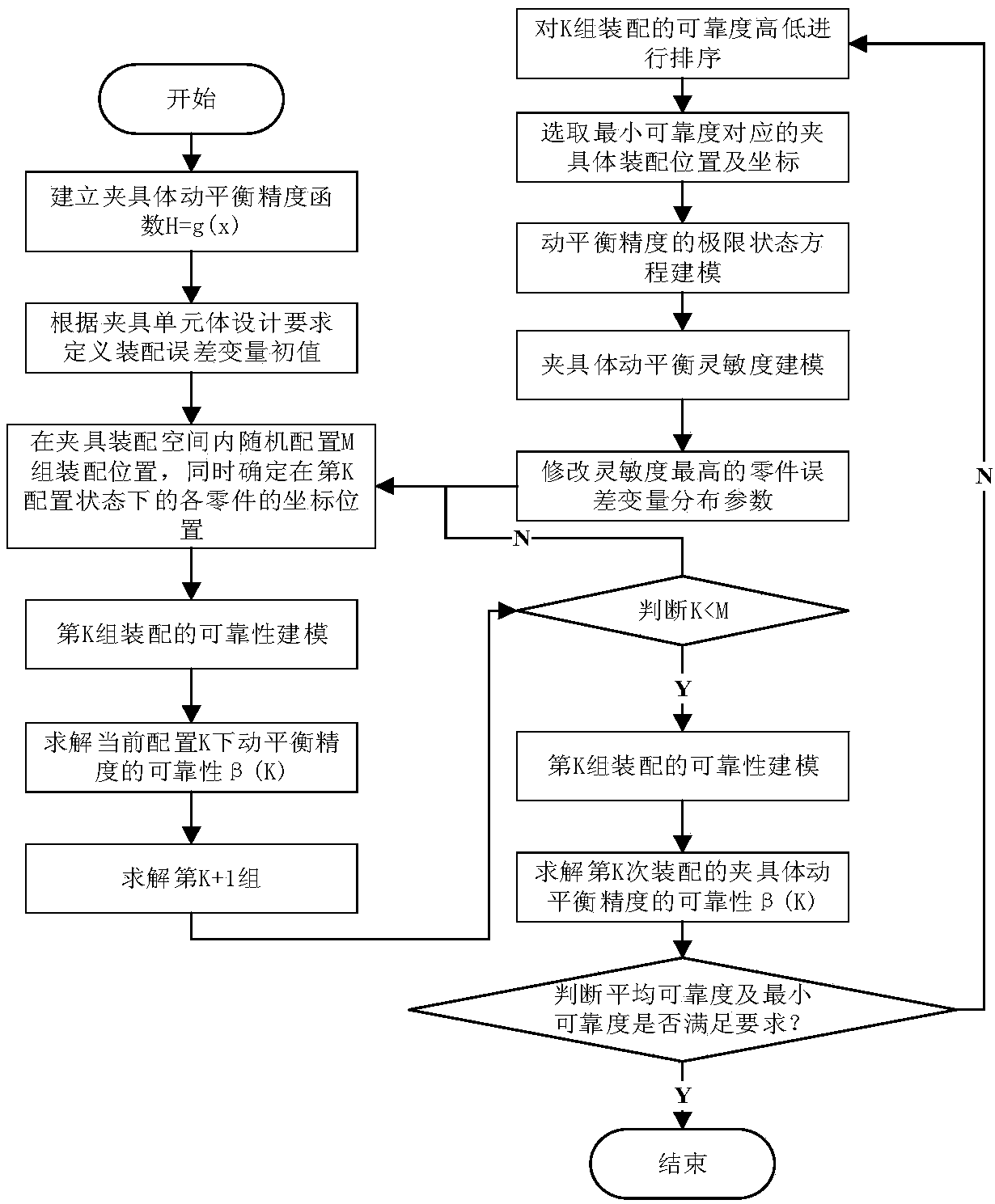

Joint surface error and joint surface tolerance optimization method for machine tool fixture component

InactiveCN108268010ARealize the clamping functionCancel or reduce the passive trim processProgramme controlComputer controlGeometric errorDynamic balance

The invention relates to a joint surface error and joint surface tolerance optimization method for a machine tool fixture component. According to the prior art, the quality characteristics of a machine tool fixture component cannot truly reflect the quality distribution condition of the machine tool fixture component, which can influence calculation accuracy and trimming precision and make automation hard to realize, and therefore, the invention provides the method to solve the problems in the prior art. The method of the invention includes the following steps that: 1, surface tolerance is represented by a homogeneous matrix; 2, joint surface error is represented by a homogeneous matrix; 3, a geometric error transfer model of assembly is constructed; 4, the surface tolerance and joint surface error are optimized according to the nature of error terms; 5, sensitivity is analyzed; 6, a part surface error or surface tolerance parameter optimization method is established with the processing cost of the fixture component adopted as an objective and assembly precision reliability and tolerance selection principles adopted as constraints; and 7, the distribution rule and parameter of theimbalance of a fixture component assembly body are obtained through a simulation experiment after the optimization result of the spinor parameter of the assembly body is obtained, and therefore, the dynamic balance optimization design of the assembly body is realized.

Owner:XIAN TECHNOLOGICAL UNIV

Transformer substation grounding grid fault corrosion monitoring method and system

InactiveCN105652155AImprove securityImprove stabilityWeather/light/corrosion resistanceFault locationGrounding gridTransformer

The invention discloses a transformer substation grounding grid fault corrosion monitoring method and system. The monitoring method can monitor the fault corrosion condition of a transformer substation grounding grid, has certain reliability and accuracy and can reduce error and improve precision of point selection according to a measuring point selection principle and a measuring point selection rule. By means of monitoring on the transformer substation grounding grid, the running safety and stability of the grounding grid are improved, and safety production of an electrical power system is facilitated. Potential safety hazards existing in the grounding grid can be found in time, and normal running of a power supply system is guaranteed. For maintenance of the grounding grid, due to the fact that local breakpoints of the grounding grid can be positioned precisely, damage to the substation environment can be greatly reduced, and meanwhile the labor intensity is reduced.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Spacecraft close-distance safe operation control method based on equal collision probability line method

ActiveCN109765919AEasy to chooseSmall amount of calculationAttitude controlSimulationGradient estimation

The invention discloses a spacecraft close-distance safe operation control method based on an equal collision probability line method. The method is used for realizing autonomous obstacle avoidance and safe approach of a target spacecraft and a tracking spacecraft, and comprises the following steps: establishing a coordinate system and a relative kinetic equation, performing uncertainty propagation analysis, calculating collision probability, establishing an equal collision probability line method, calculating and analyzing obstacle avoidance control force, determining parameter selection standards, calculating tracking control force and total control force. Taking uncertain factors into consideration, the spacecraft close-distance safe operation control method based on the equal collisionprobability line method still has the advantages of small calculated amount and guaranteed real-time performance; a set of parameter selection principle of an equal collision probability line gradient estimation method is established, so that the parameters in the potential function can be conveniently selected; and meanwhile, by improving the LQR controller, higher control precision and robustness can be obtained.

Owner:NAT INNOVATION INST OF DEFENSE TECH PLA ACAD OF MILITARY SCI

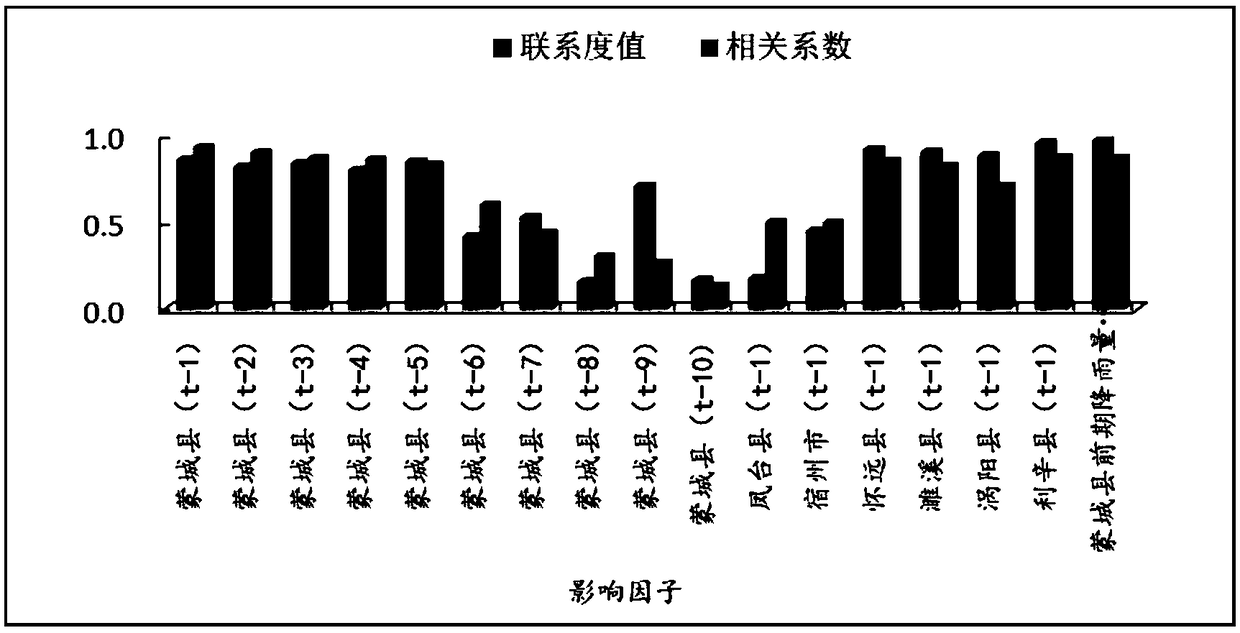

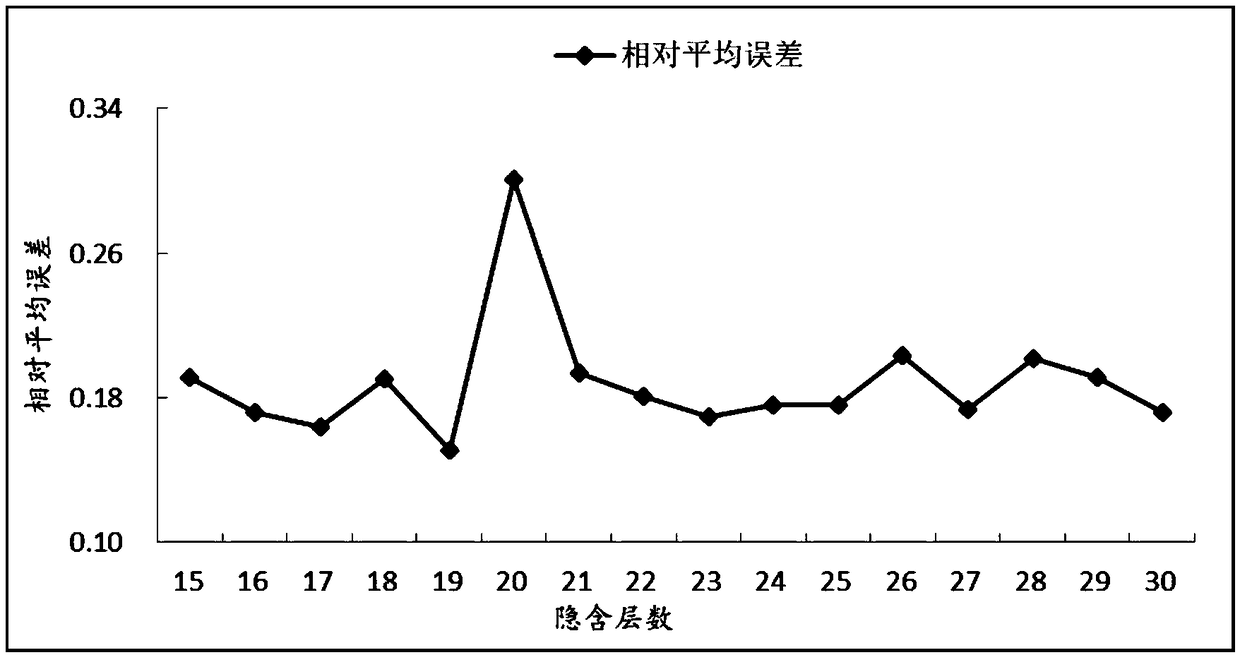

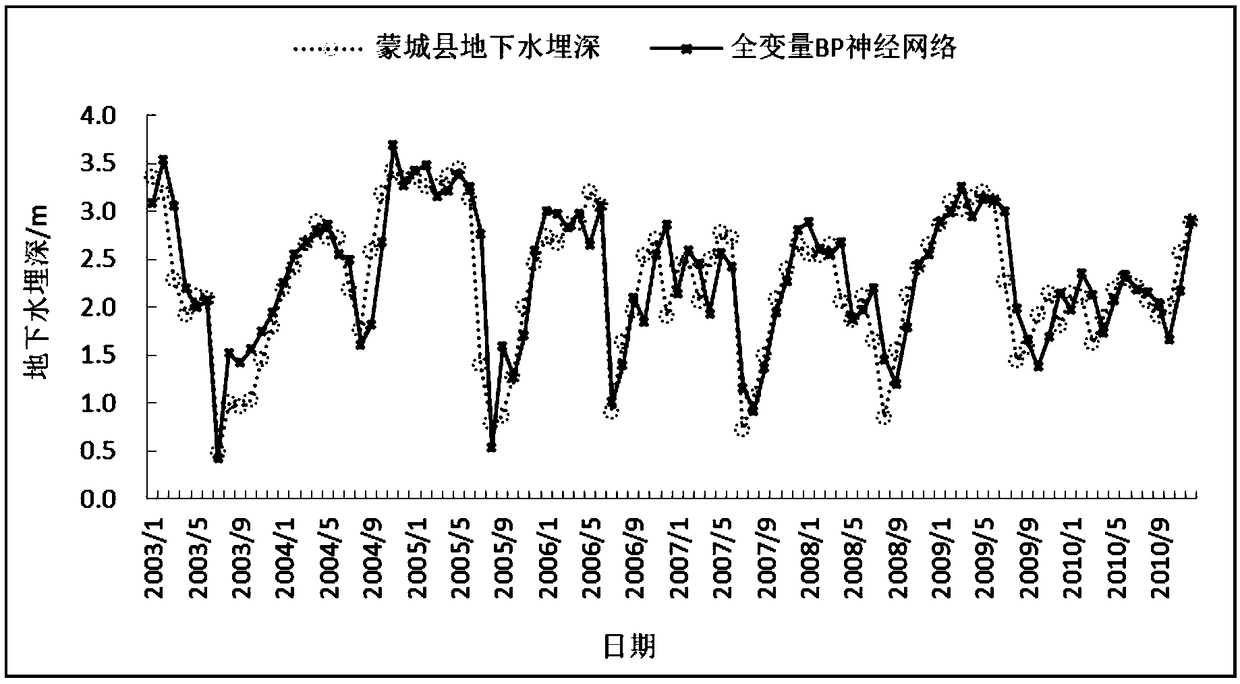

A method for optimizing groundwater depth of BP neural network based on genetic algorithm

InactiveCN109409568AImprove relevanceImprove forecast accuracyForecastingNeural learning methodsAlgorithmPredictive methods

A method for optimizing groundwater depth of BP neural network based on genetic algorithm includes collecting data, analyzing and screening independent variable by set pair, and taking samples corresponding to said target independent variable; the output result of BP neural network is obtained by setting BP neural network; setting initial parameters of genetic algorithm; individual selection operation: In the old population, the preset probability is used to select the individual to produce the next generation. The selection principle is as follows: selecting according to the fitness value ofthe individual from large to small; crossover: the generation of new individuals through the crossover of chromosomes; mutation: An individual selected from a population to mutate a segment of a chromosome to produce a new individual; the fitness is calculated and compared with the original population when the number of evolution reached the upper limit. The chromosome corresponding to the fitnessoptimal solution is the threshold value and weight value corresponding to BP neural network. The application of the embodiment of the invention can improve the accuracy of the groundwater burial depth.

Owner:ANHUI AGRICULTURAL UNIVERSITY

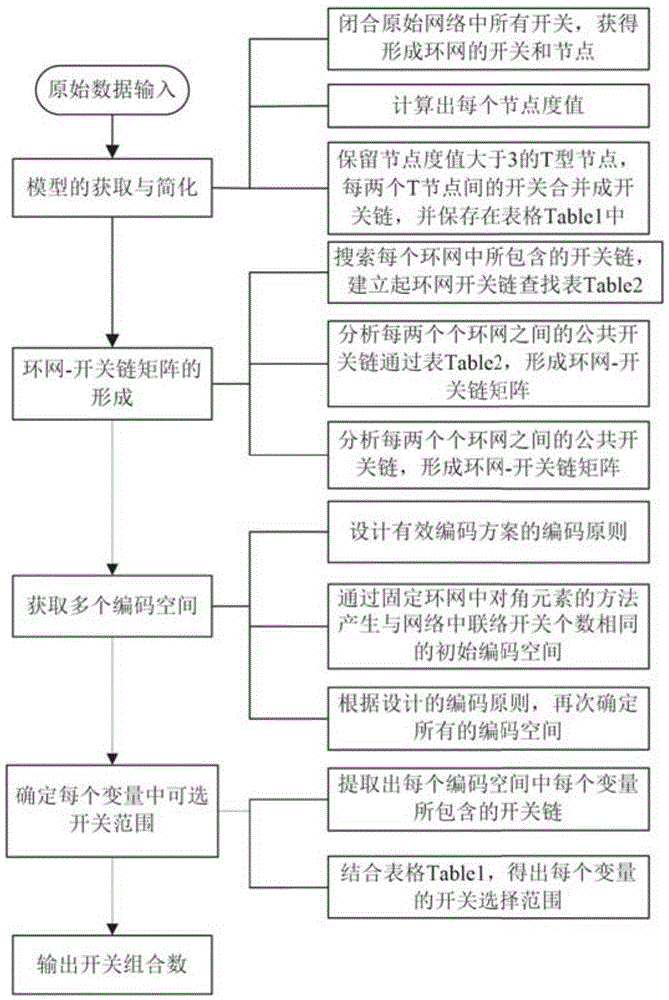

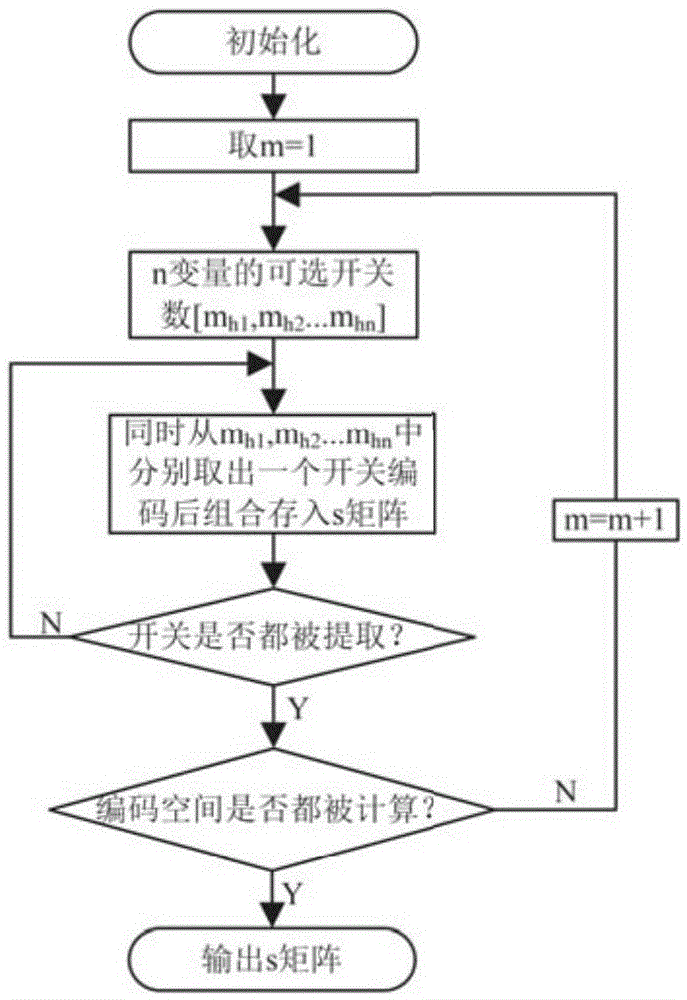

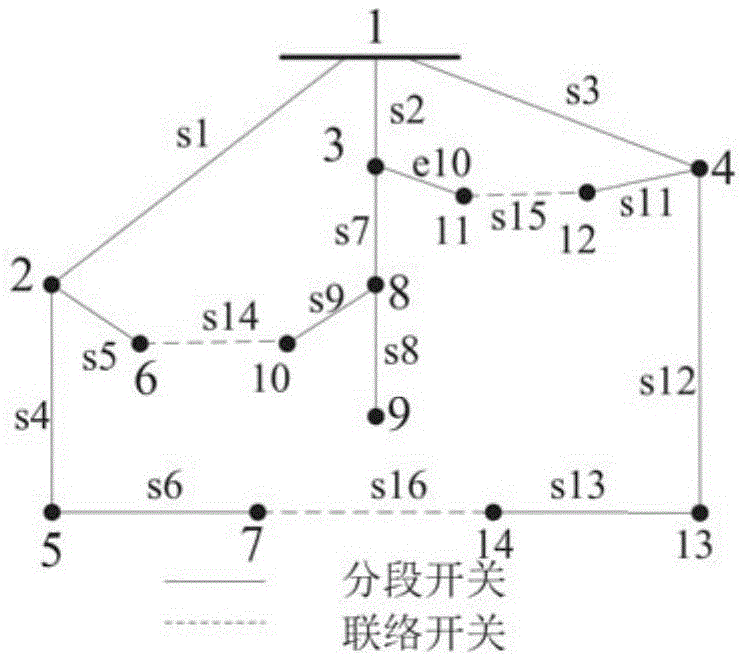

Coding method of fast acquisition of radiation topology structure in ring power distribution network

ActiveCN105631768ASmall scaleSimple topologyData processing applicationsAc network circuit arrangementsNetwork sizeCode space

The invention relates to a coding method of fast acquisition of a radiation topology structure in a ring power distribution network. The coding method is characterized in that 1) ring network switches can be acquired, and are all of the switches of the ring network of the closed power distribution network, comprise section switches and interconnection switches, and disconnected switch variables can be used to represent feasible topology structures in the power distribution network; 2) the ring network can be simplified; 3) a loop-switch matrix can be formed according to the ring network determination principle; 4) variables in a coding space can be determined according to the variable selection principle of the designed effective coding method; 5) diagonal elements in the matrix can be fixed, and according to the switch selection principle, disaggregation spaces of a plurality of feasible topology structures can be acquired; 6) the related switch number of every variable can be analyzed, and the switch combination number of every disaggregation space can be determined. By adopting the above mentioned method, the topology structure can be simplified, the network scale can be reduced, the coding length can be shortened, the number of the parameters can be reduced, and the calculation can be simple.

Owner:HUNAN UNIV

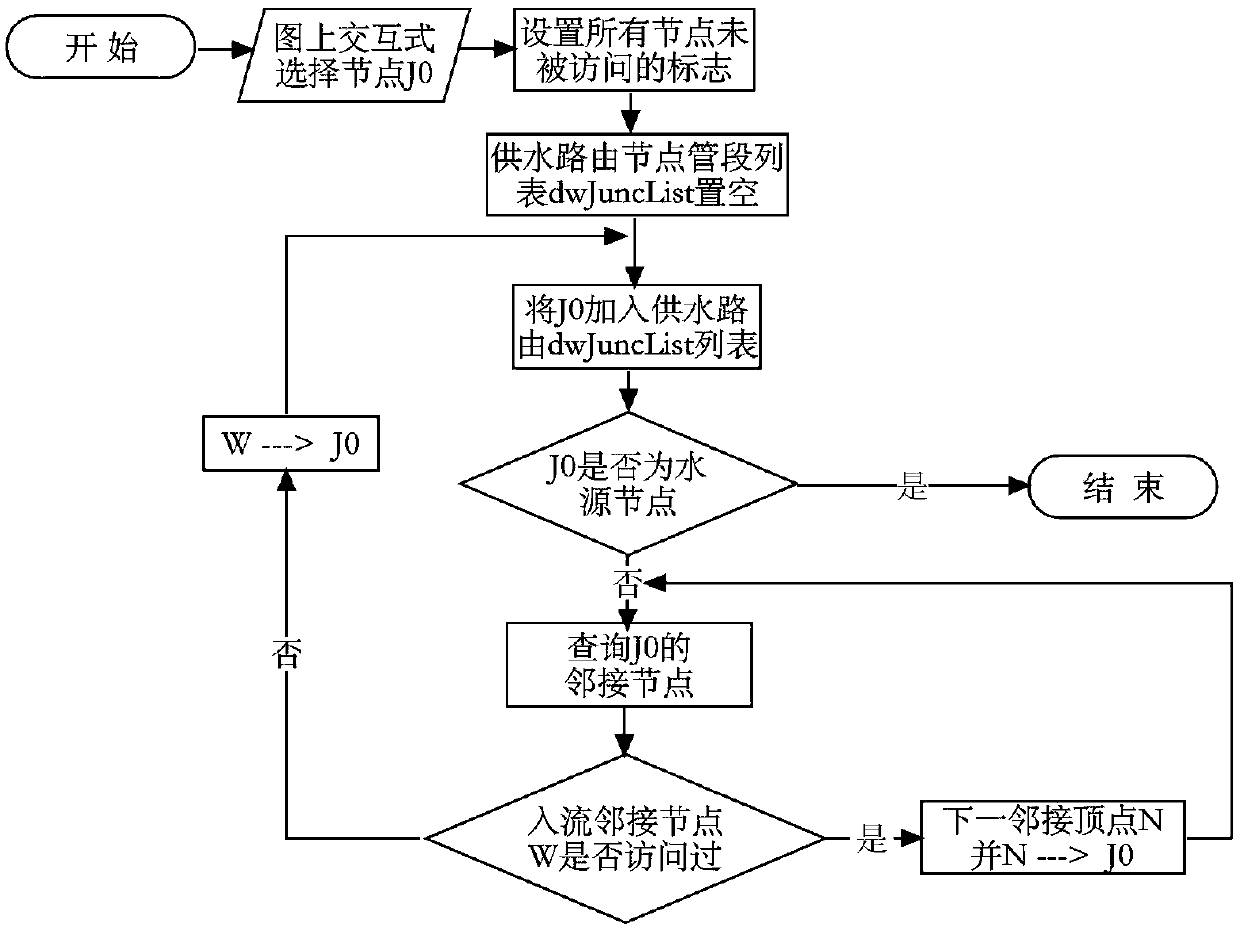

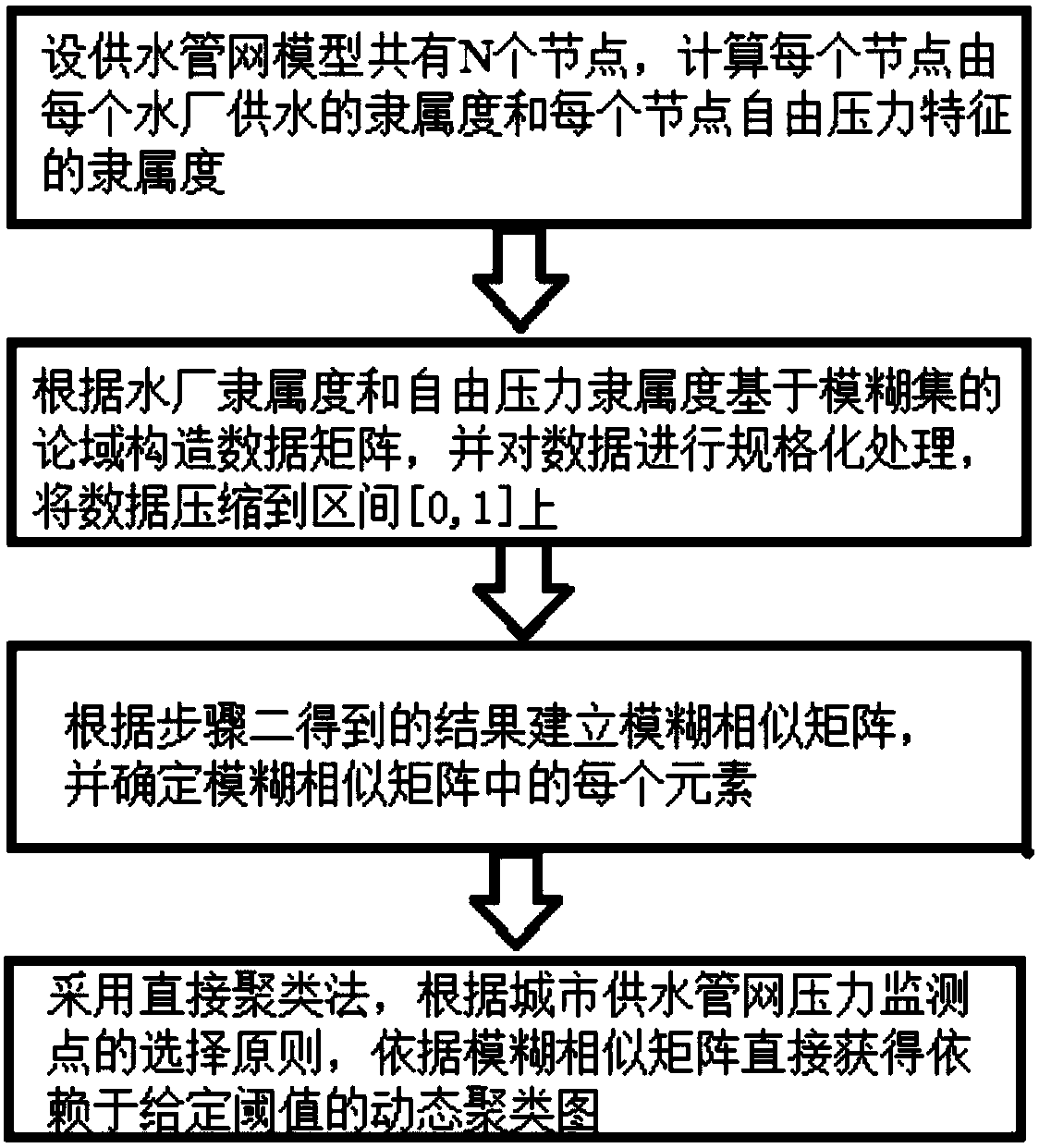

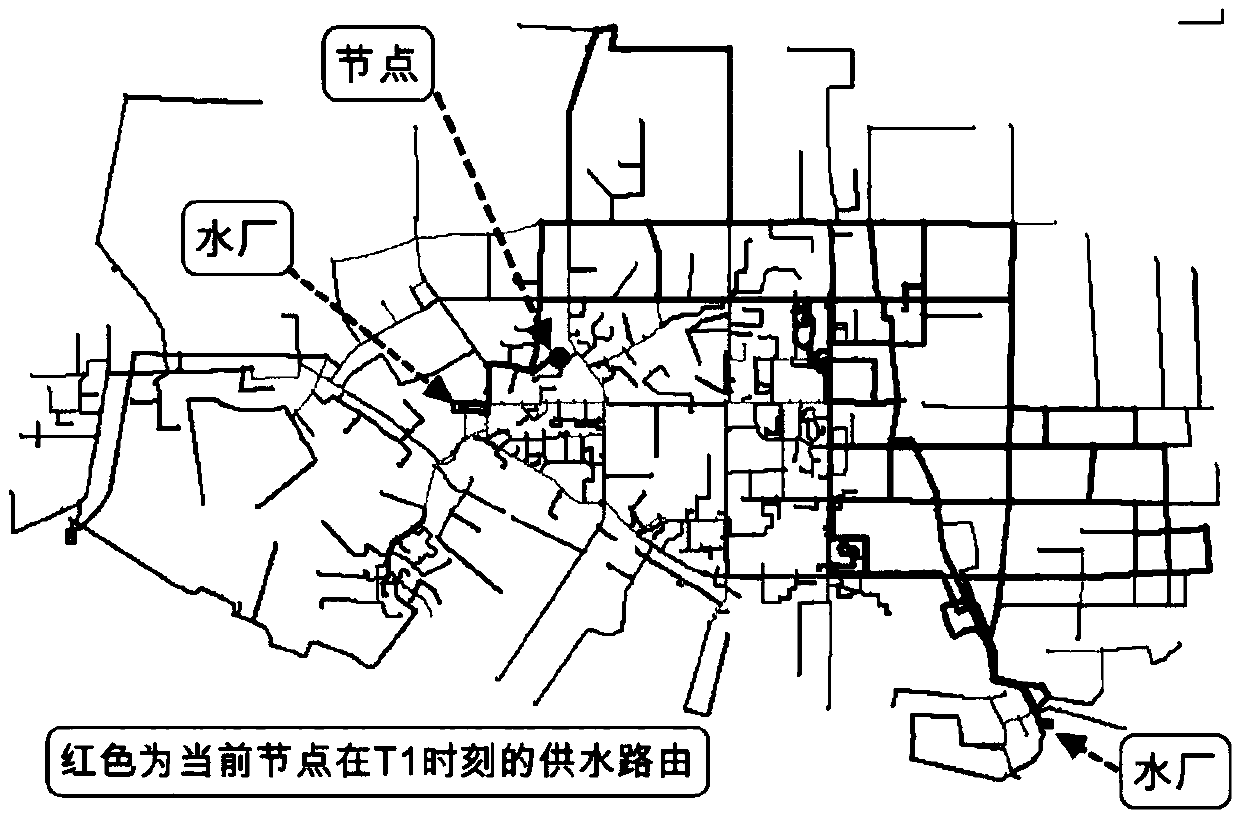

Location selection method for pressure monitoring point of water supply network based on fuzzy set

The invention relates to a location selection method for a pressure monitoring point of a water supply network based on a fuzzy set. The method comprises the steps that first, N nodes are set on a water supply network model, and the membership degree of each node of the water supply of each waterworks and the membership degree of the free pressure characteristic of each node are calculated; second, a data matrix is constructed based on the domain of discourse of the fuzzy set according to the membership degree and the membership degree of the free pressure, the data is normalized, and the datais compressed within the interval [0,1]; third, a fuzzy similarity matrix is established according to the results obtained in the second step, and each element in the fuzzy similarity matrix is determined; and fourth, a direct clustering method is adopted, according to the selection principle of the pressure monitoring point of the urban water supply network, a dynamic clustering diagram relyingon the given threshold is obtained directly according to the fuzzy similarity matrix. The method is low in calculation, and the location selection method is feasible based on the evaluation method proving of the F statistics.

Owner:HARBIN UNIV

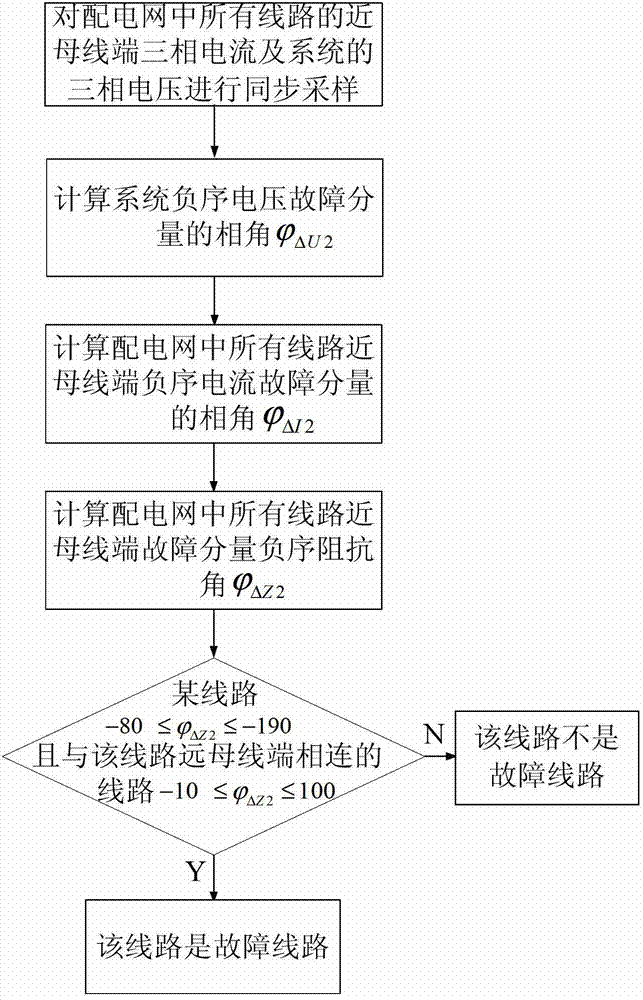

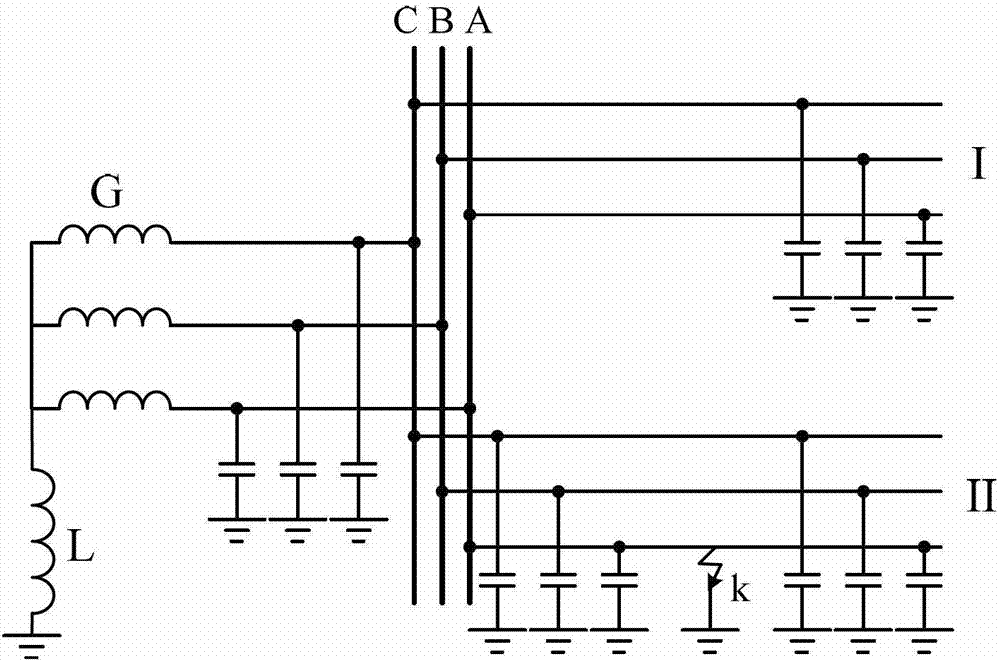

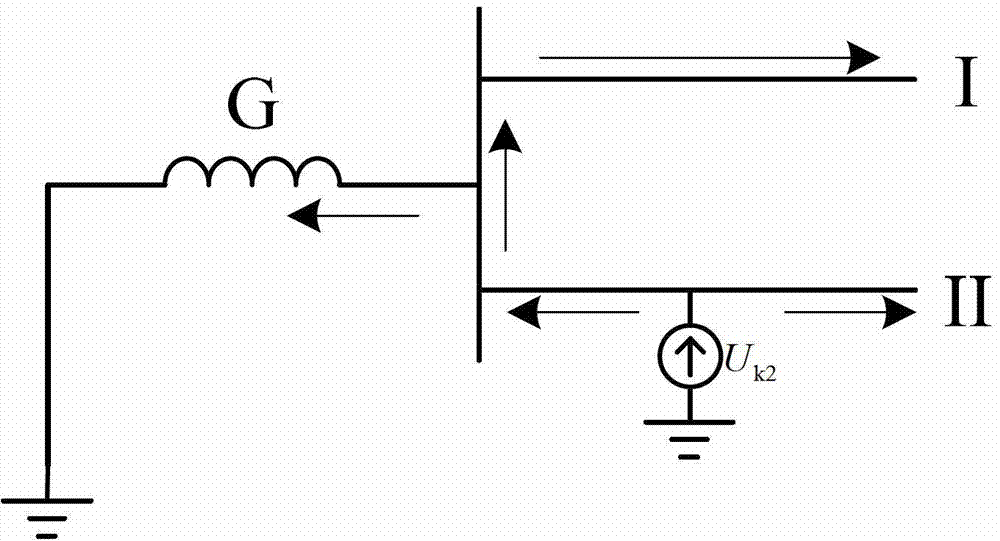

Distribution network single-phase earth fault line selection method based on negative sequence impedance angles

InactiveCN103048582ACorrectly selectedSensitive selectionFault locationElectric power systemElectrical impedance

A distribution network single-phase earth fault line selection method based on negative sequence impedance angles belongs to the technical field of power system relay protection. The method is characterized by comprising the following steps of: first, synchronously sampling the three-phase currents of the near power ends of all lines in a distribution network and the three-phase voltage of a system; calculating the negative sequence voltage fault component phase angle of the system and the negative sequence current fault component phase angles of the near power ends of all the lines according to a sampling result, and furthermore, obtaining the fault component negative sequence impedance angles of the near power ends of all the lines; and if the fault component negative sequence impedance angle of the near power end of a certain line is between minus 80 degrees and minus 190 degrees and the negative sequence impedance angles of the near power ends of all the lines which are connected with a far power end of the line are between minus 10 degrees and 100 degrees, determining the line to be a fault line, and otherwise, determining the line to be a normal line. The single-phase earth fault calculation of a typical 35kV multi-branch complicated distribution network shows that the method provided by the invention can accurately and flexibly select the fault line, moreover, a line selection principle is not influenced by an arc suppression coil, and the method can be applied to the distribution networks with various earthing modes.

Owner:BEIJING JIAOTONG UNIV

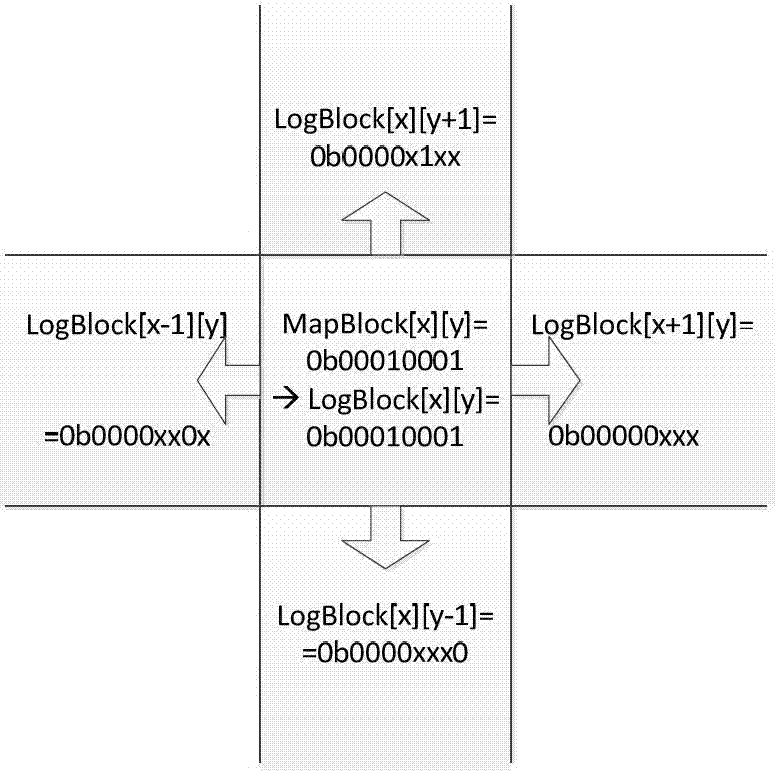

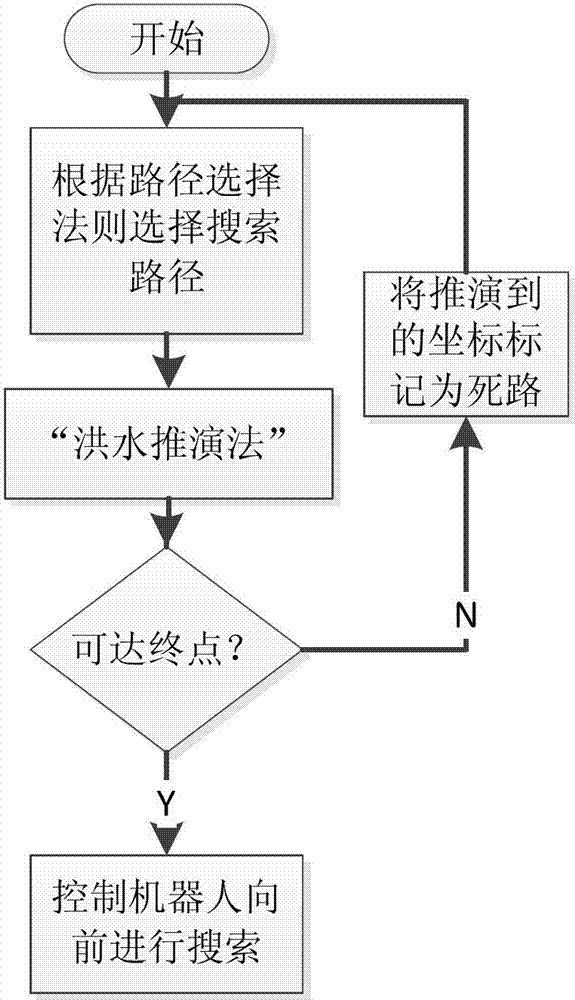

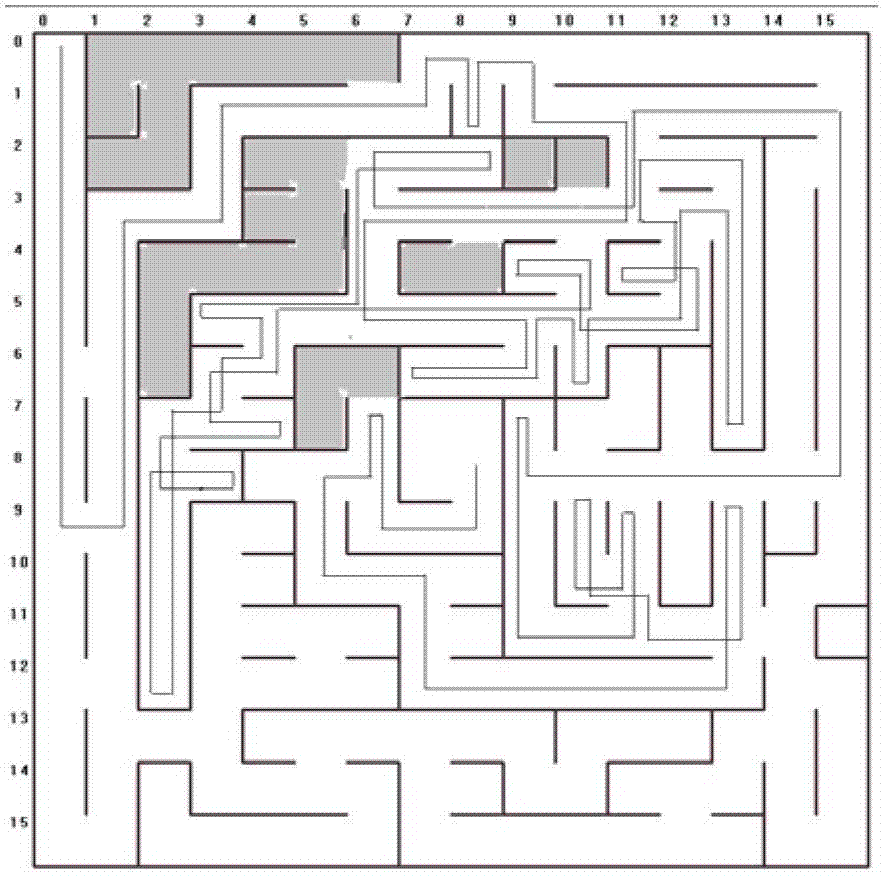

Robot maze search method

InactiveCN103092207AAccurate selectivityAccurate judgmentPosition/course control in two dimensionsAlgorithmSimulation

The invention relates to a robot maze search method. When the robot searches a maze, metope information explored by the robot is expanded, and search path which is selected out through path selection principle is pre-deducted by a flood deduction method. The aim of the pre-deduction is that a plurality of paths which are unreachable to destination are eliminated before the robot walks, and so search time of the robot is reduced from two angels of eliminating invalid search paths and increasing effective information. According to the robot maze search method, mechanical operation speed of a robot with relative low speed is replaced by operation speed of a micro controller with high speed, and maze search efficiency is improved.

Owner:DONGHUA UNIV

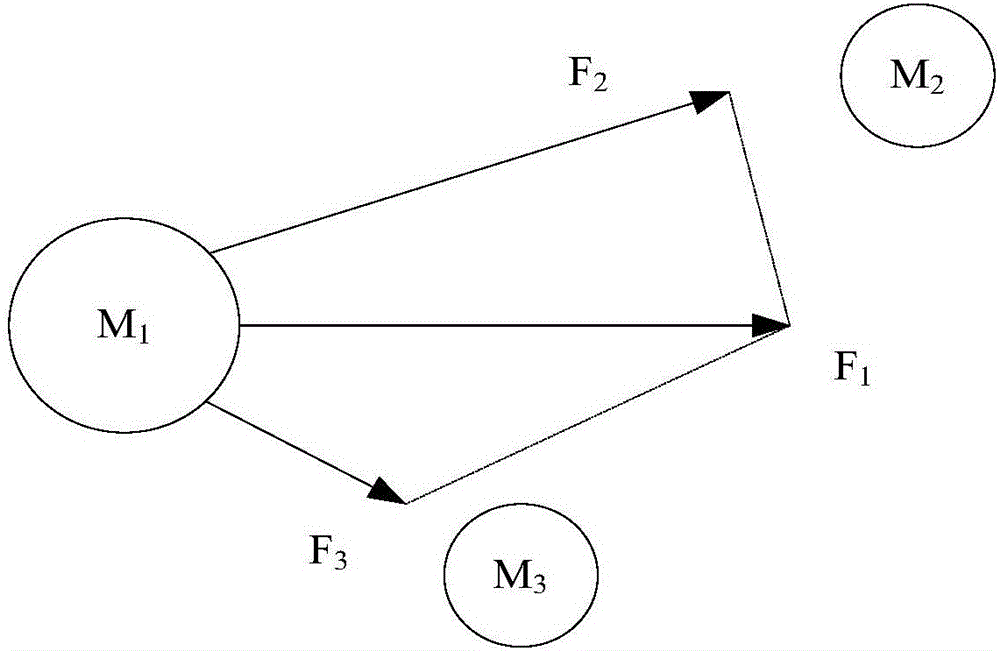

Method for planning route of unmanned surface vehicle based on universal gravitation search

InactiveCN106705975AImprove accuracyShorten the timeNavigational calculation instrumentsPosition/course control in two dimensionsMathematical modelSimulation

The invention discloses a method for planning route of an unmanned surface vehicle based on universal gravitation search. The method comprises the following steps: firstly, establishing a mathematical model of the surface unmanned vehicle, and initializing parameters of the method; secondly, randomizing a plurality of paths and an initial position and an accelerated speed of each particle, and establishing a rotating coordinate system; thirdly, updating inertia mass of each particle according to a rule of dynamic inertia weight, and updating the speed of each particle according to an improved universal gravitation method; finally, updating the position of each particle according to an updated speed of the particle and a selection principle of survival of the fittest; if the number of iterations is greater than the maximum number of iterations, exiting a loop; otherwise, returning to the previous step for entering into the next iteration; performing coordinate inverse-transformation on the obtained optical path coordinate, and outputting results.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com