Parallel APF DC side voltage control method based on sliding mode PI compound control algorithm

A DC side voltage, compound control technology, applied in the direction of AC network circuits, electrical components, circuit devices, etc., can solve problems such as poor control accuracy, slow voltage response speed, and complex implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

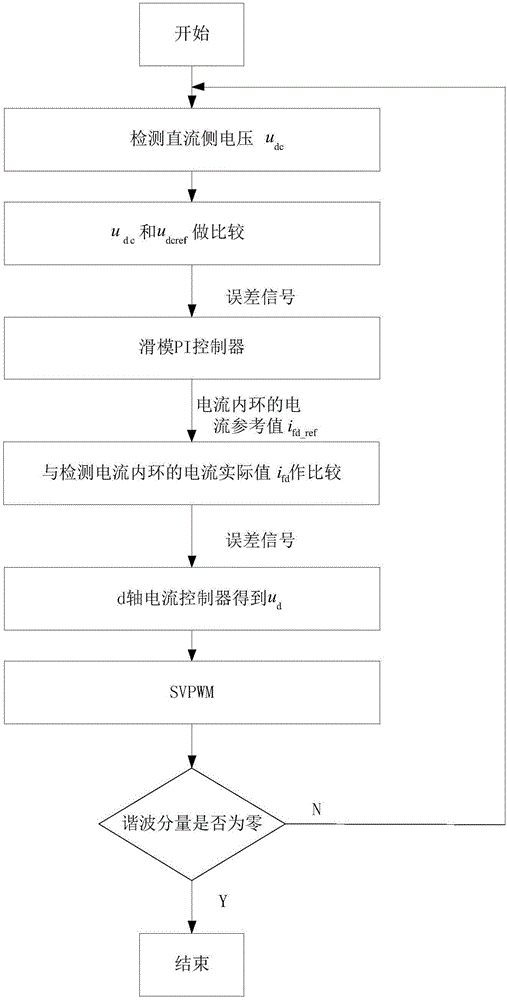

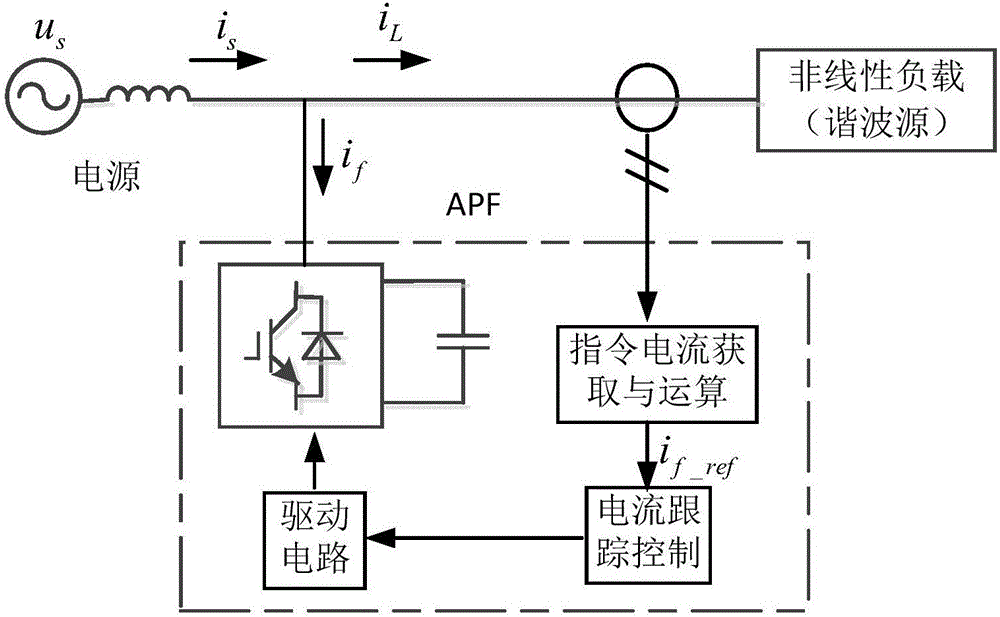

[0059] figure 1 It is a block diagram of the parallel APF DC side voltage control based on the sliding mode PI compound control algorithm, and the specific steps of the parallel APF DC side voltage control method based on the sliding mode PI compound control algorithm:

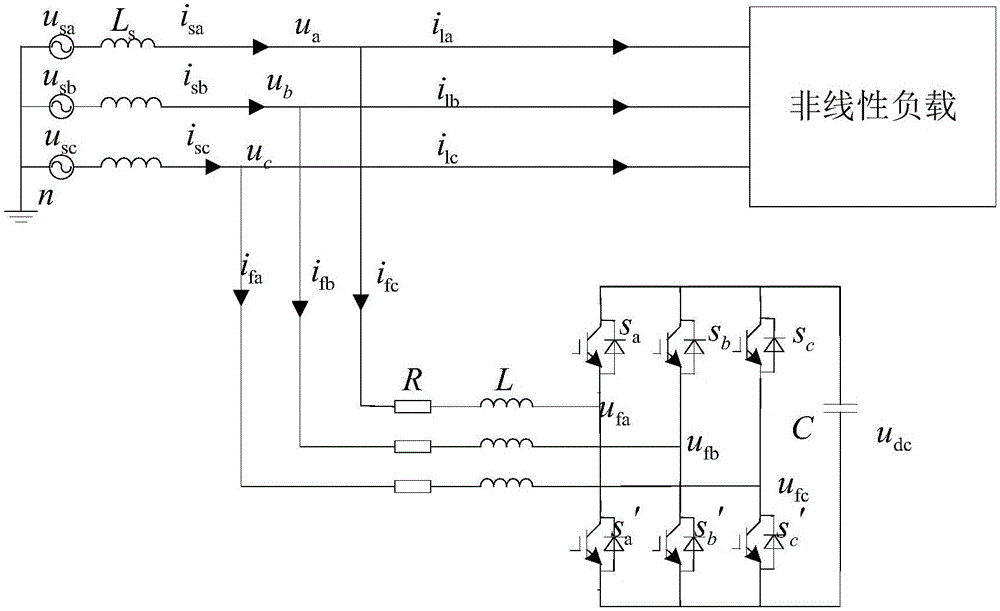

[0060] (1) Establish a low-order system model of the parallel APF in the dq coordinate system;

[0061]

[0062] (2) Detect DC side capacitor voltage u dc , compare it with the DC side reference voltage value u dcref For comparison, the error signal is obtained, and the error signal is passed through the sliding mode PI controller to obtain the current reference value i of the current inner loop fd_ref , by checking the current actual value i of the current inner loop fd , put i fd_ref with i fd Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com