Patents

Literature

34 results about "Tolerance optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

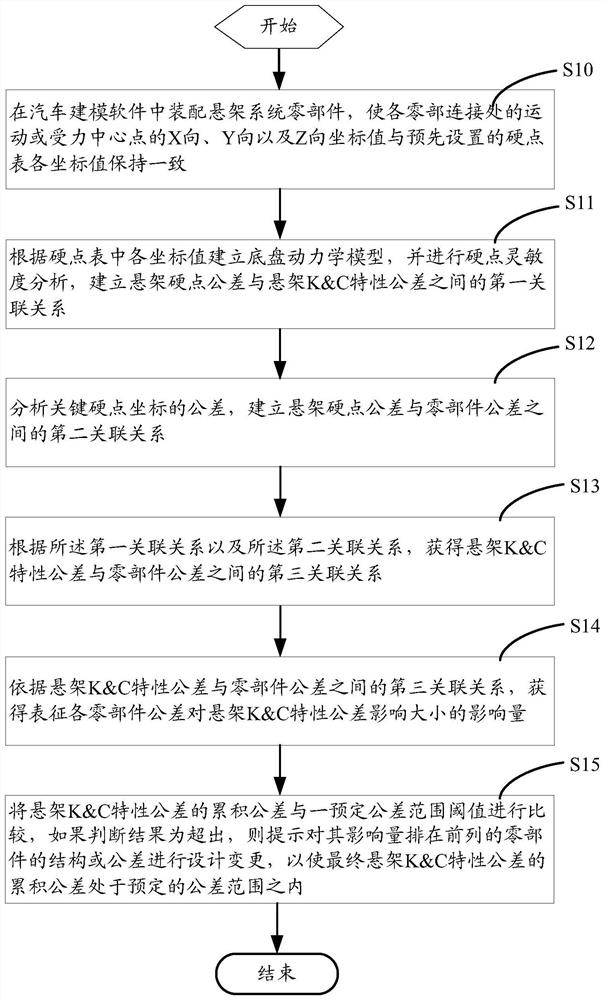

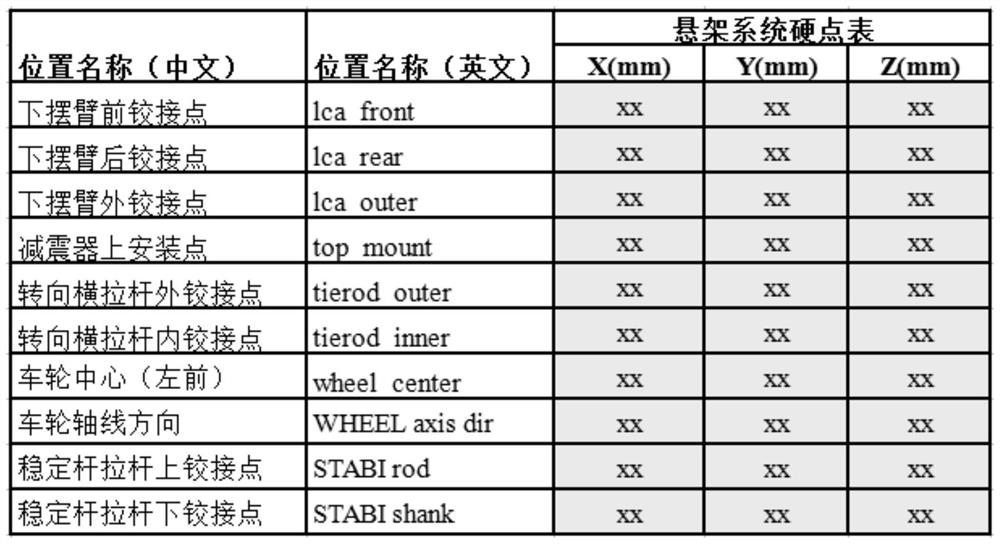

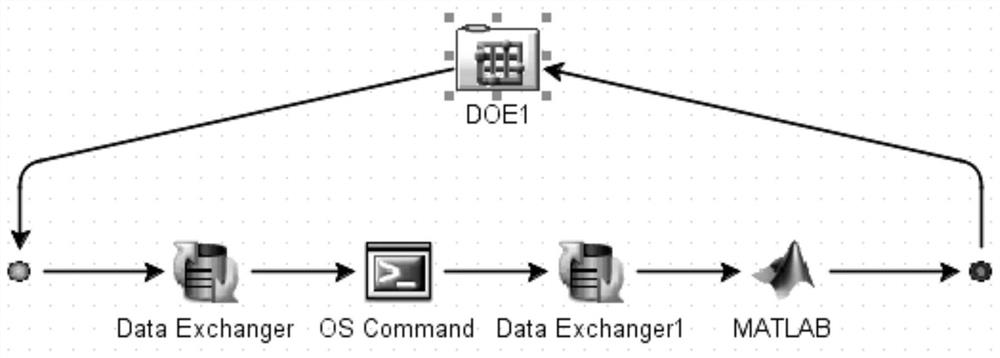

Automobile suspension K&C characteristic tolerance optimization method and system

ActiveCN107247830AShorten development timeLow costGeometric CADSpecial data processing applicationsEngineeringKinetic model

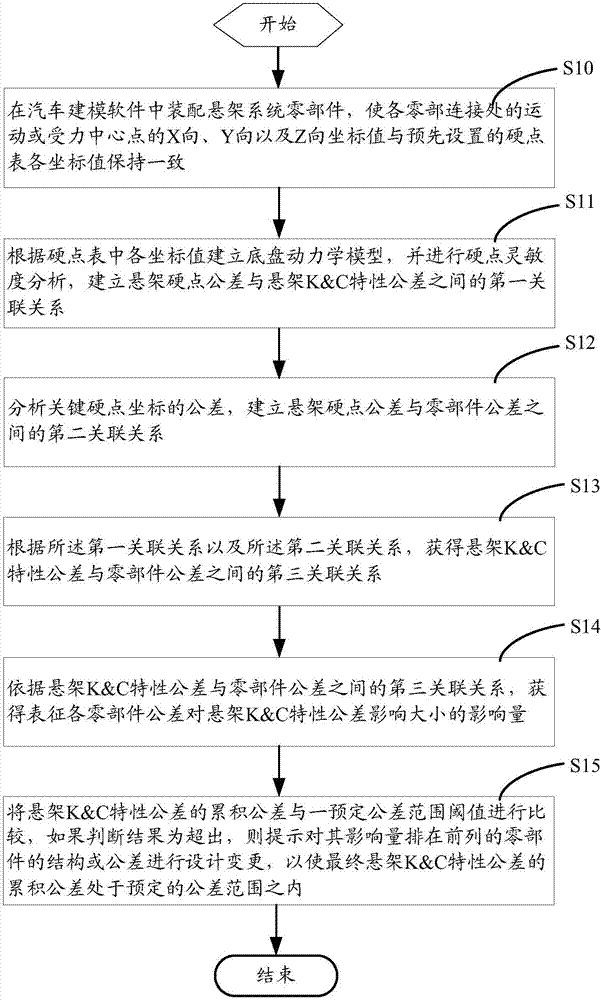

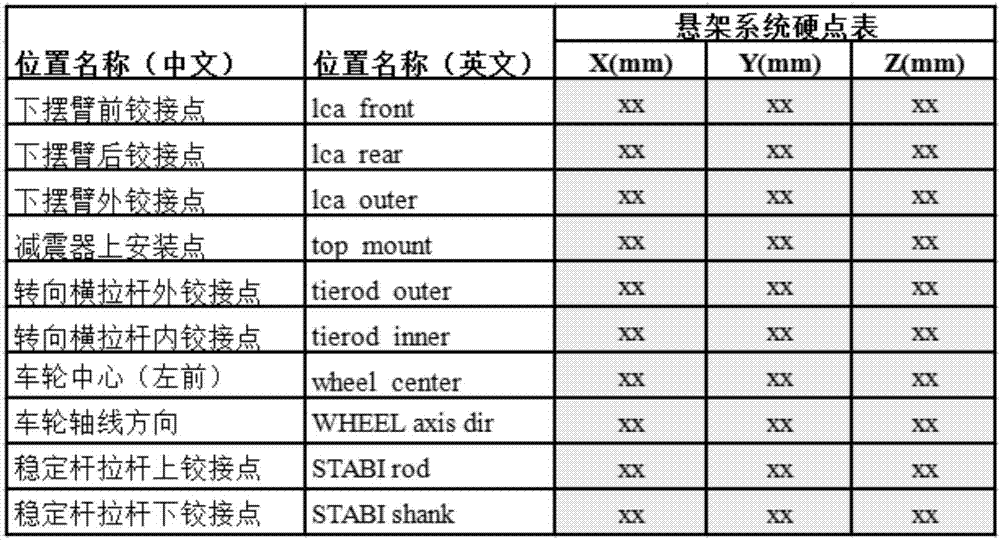

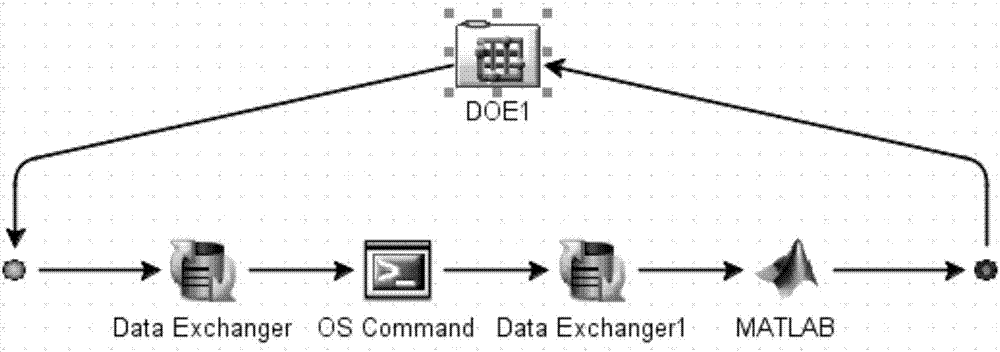

The invention provides an automobile suspension K&C characteristic tolerance optimization method. The method includes: building a chassis kinetic model according to each coordinate in a hard spot table, and building a first correlation between suspension hard spot tolerance and suspension K&C characteristic tolerance; analyzing the tolerance of the coordinates of key hard spots, and building a second correlation between the suspension hard spot tolerance and part tolerance; according to the first correlation and the second correlation, acquiring the third correlation between the suspension K&C characteristic tolerance and the part tolerance, and acquiring the influence quantity representing the influence of each part tolerance on the suspension K&C characteristic tolerance; when the accumulated tolerance of the suspension K&C characteristic tolerance exceeds a preset tolerance range threshold, prompting that design alteration needs to be performed on part structures or tolerance with high influence quantity so as to allow the final accumulated tolerance to be located within the preset tolerance range threshold. The invention further provides a corresponding system. By the automobile suspension K&C characteristic tolerance optimization method, development time can be shortened evidently, and cost can be saved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

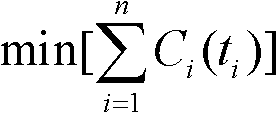

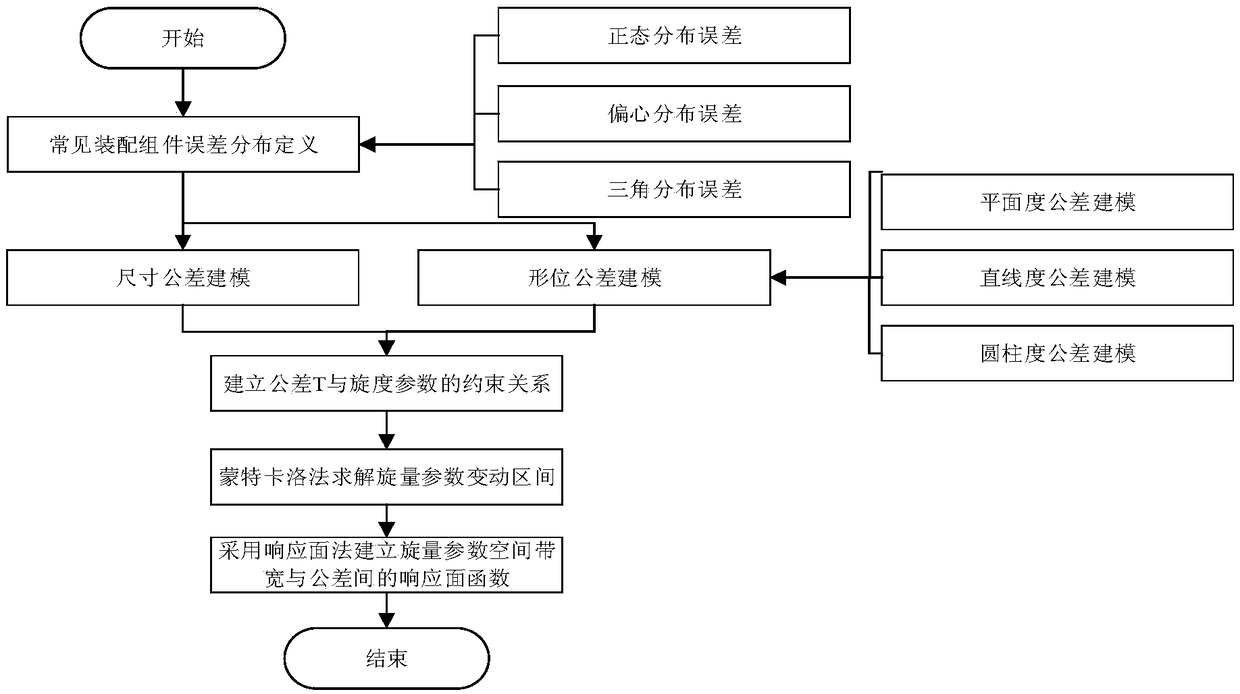

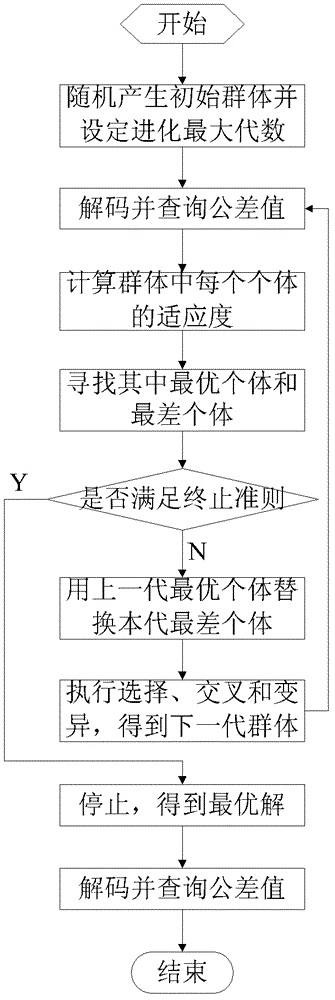

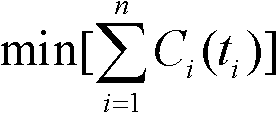

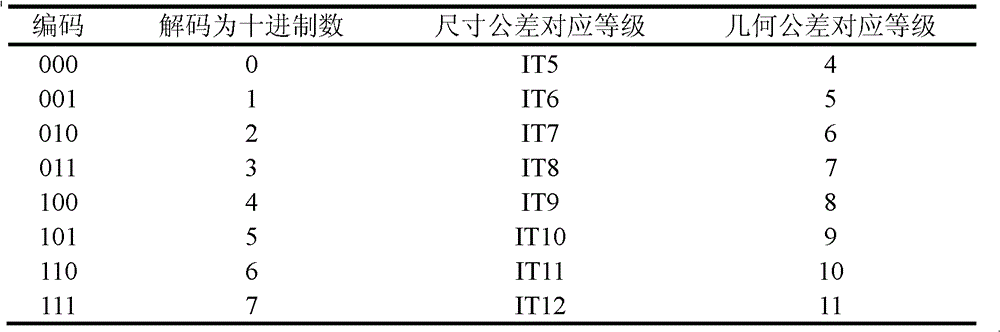

Tolerance optimization allocation method based on tolerance grade and genetic algorithm

ActiveCN102622495AImprove execution efficiencyImprove efficiencyBiological neural network modelsSpecial data processing applicationsMathematical modelComputer-aided

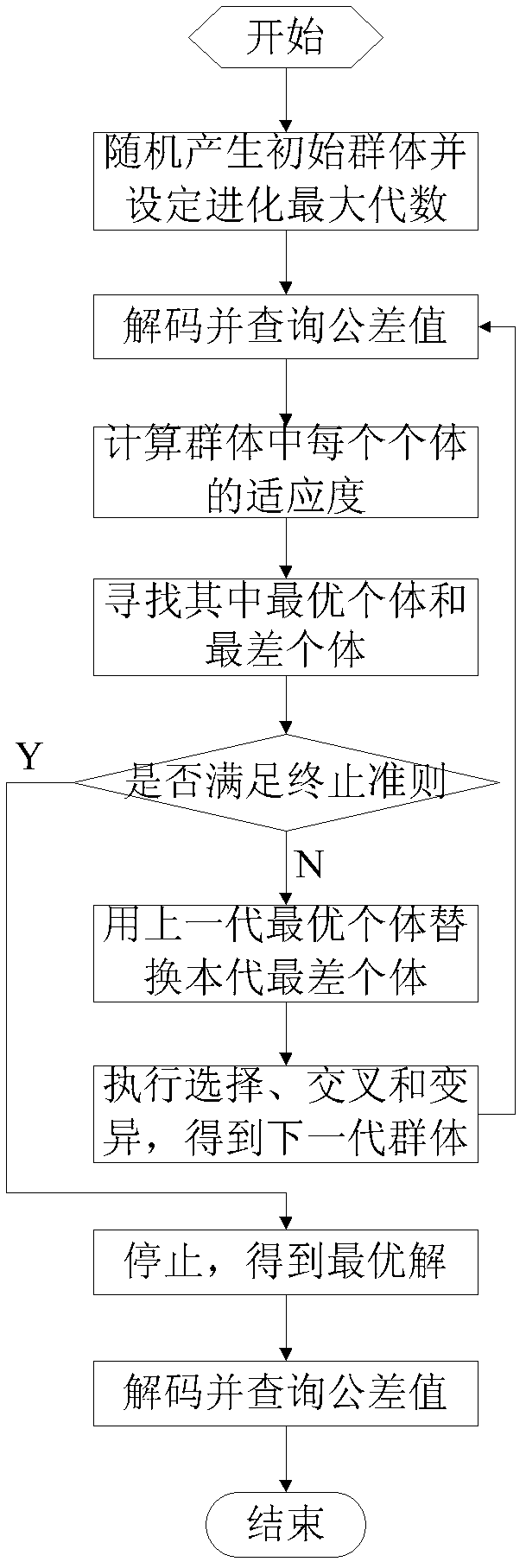

The invention discloses a tolerance optimization allocation method based on a tolerance grade and a genetic algorithm, comprising the following steps: (1) creating a tolerance optimization mathematical model; (2) creating a standard tolerance database; (3) encoding based on the tolerance grade; (4) determining an adaptability function of the genetic algorithm; (5) setting a genetic operator; (6) performing genetic evolution; and (7) decoding to obtain a corresponding tolerance grade and inquiring a corresponding tolerance value. The method disclosed by the invention realizes the tolerance optimization allocation in the product design by using a computer, thereby replacing the manual distribution, improving the efficiency and saving the time; meanwhile, the method performs the optimization allocation through the genetic algorithm, serves the minimum processing cost as an optimization target and reduces the processing cost of products. Therefore, the method has good practical value and extensive application prospect in the technical field of computer aided tolerance design.

Owner:BEIHANG UNIV

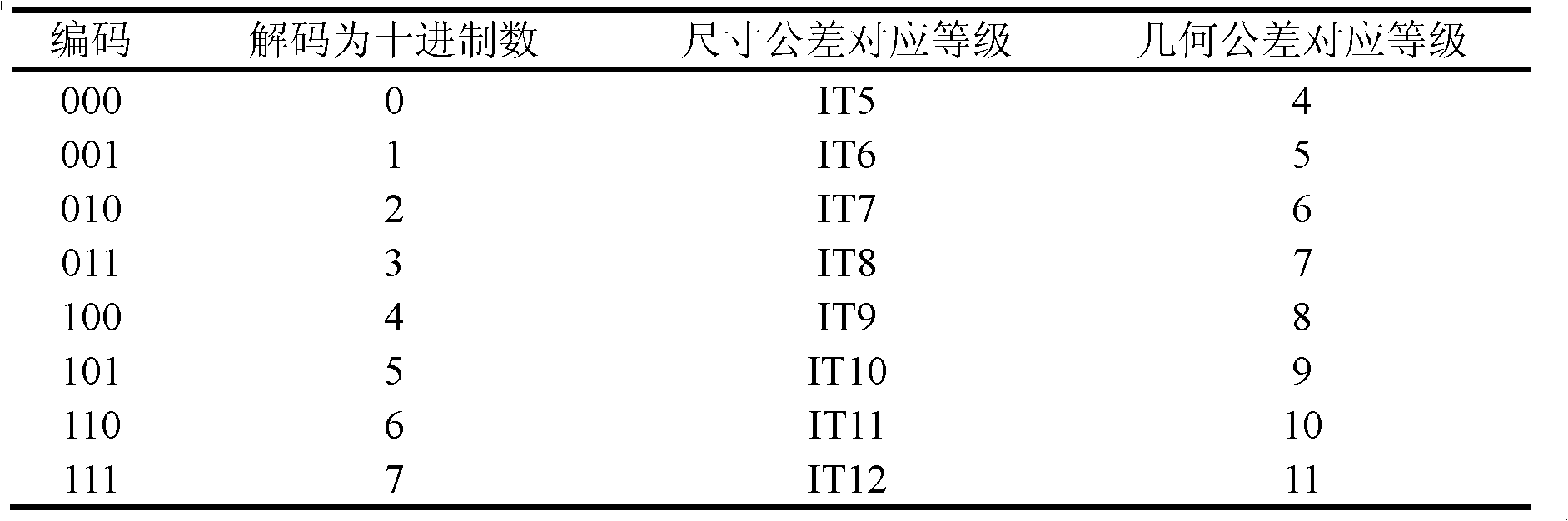

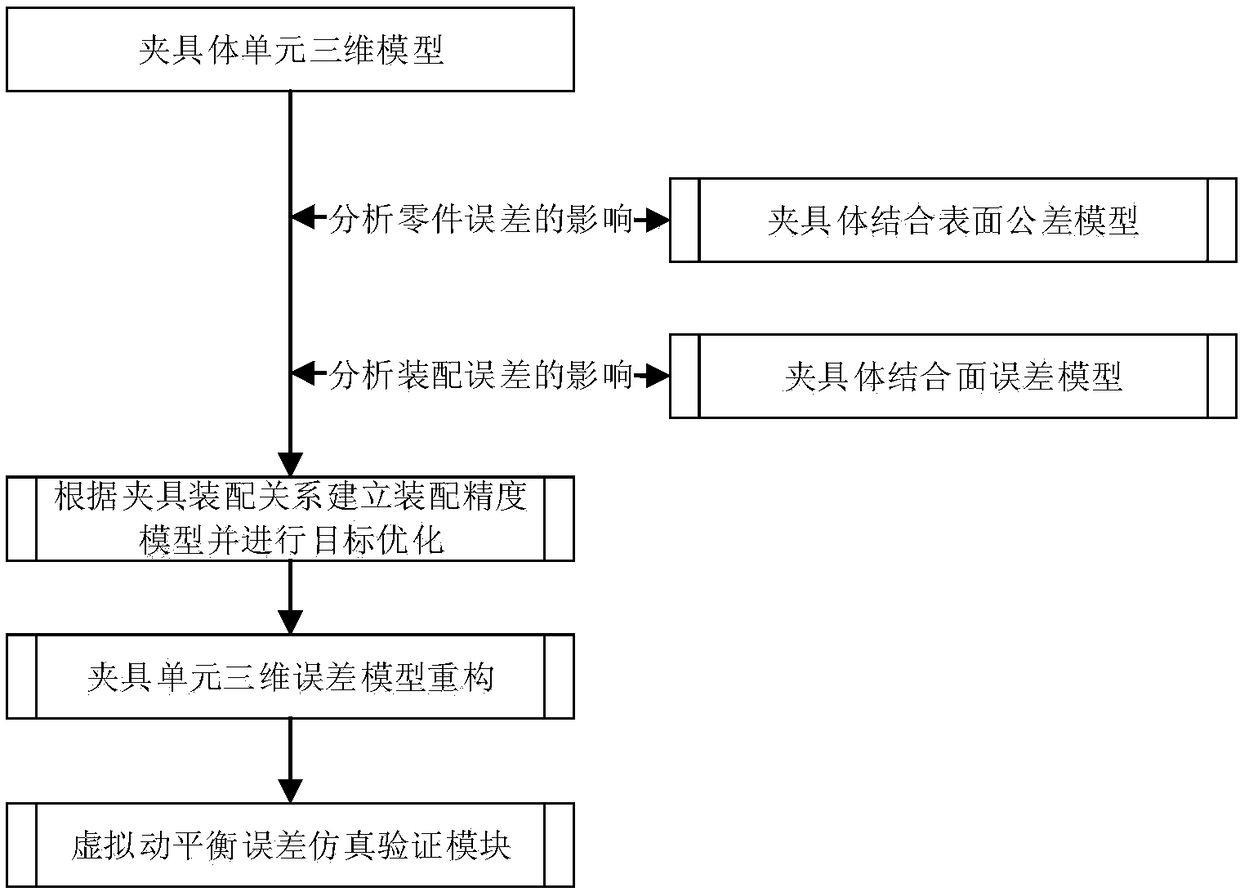

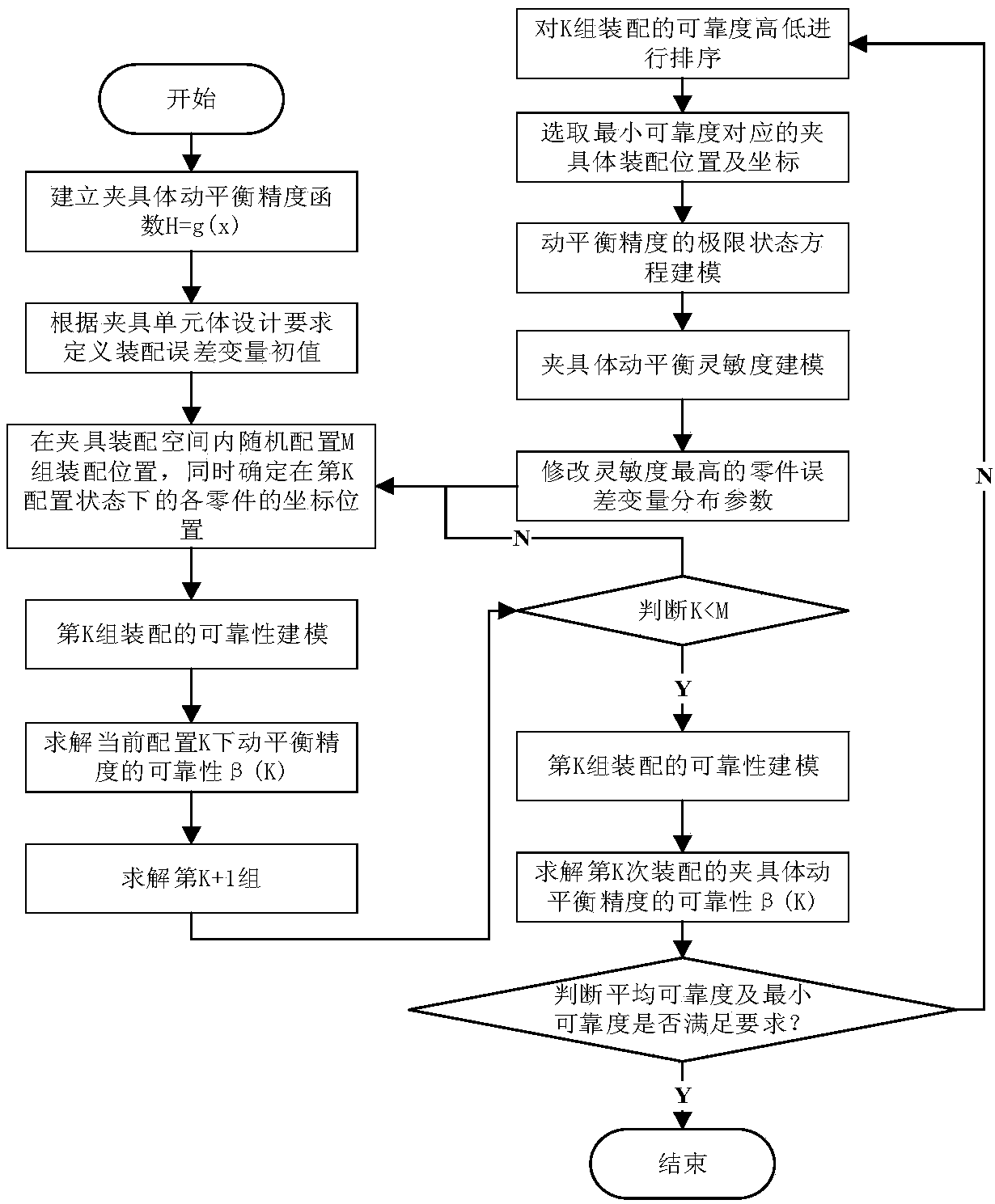

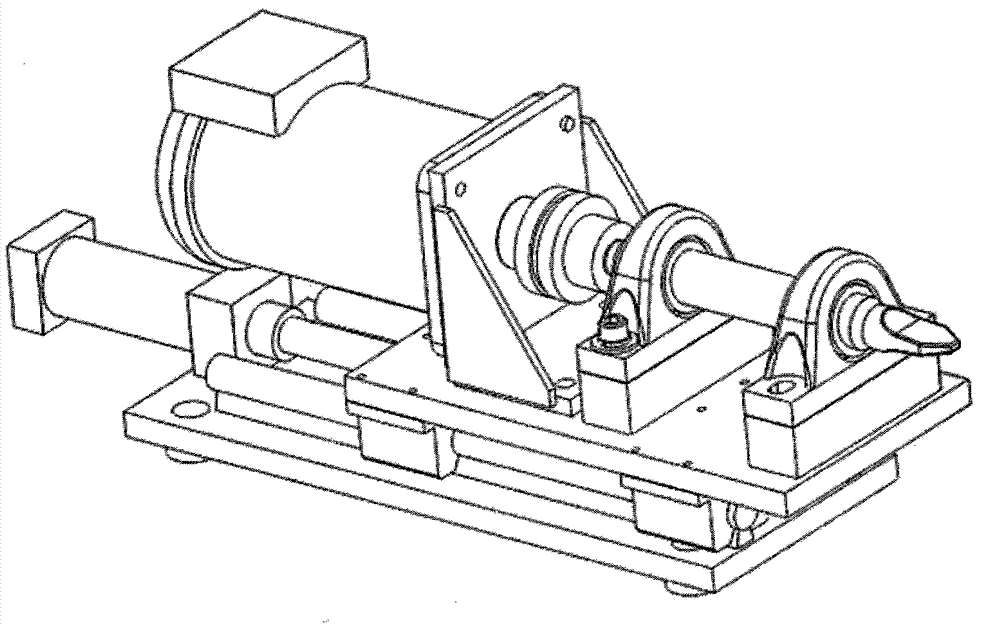

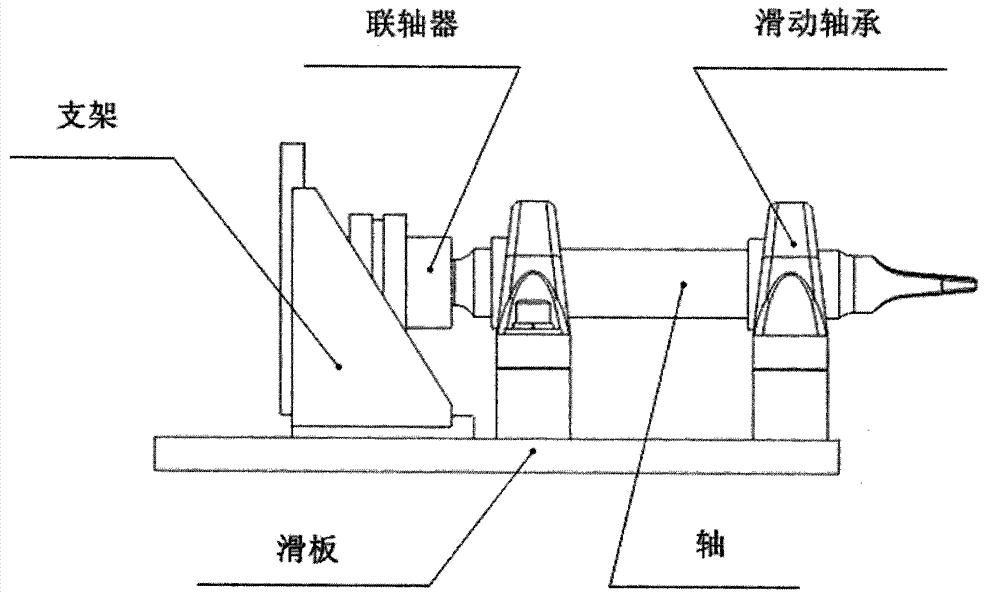

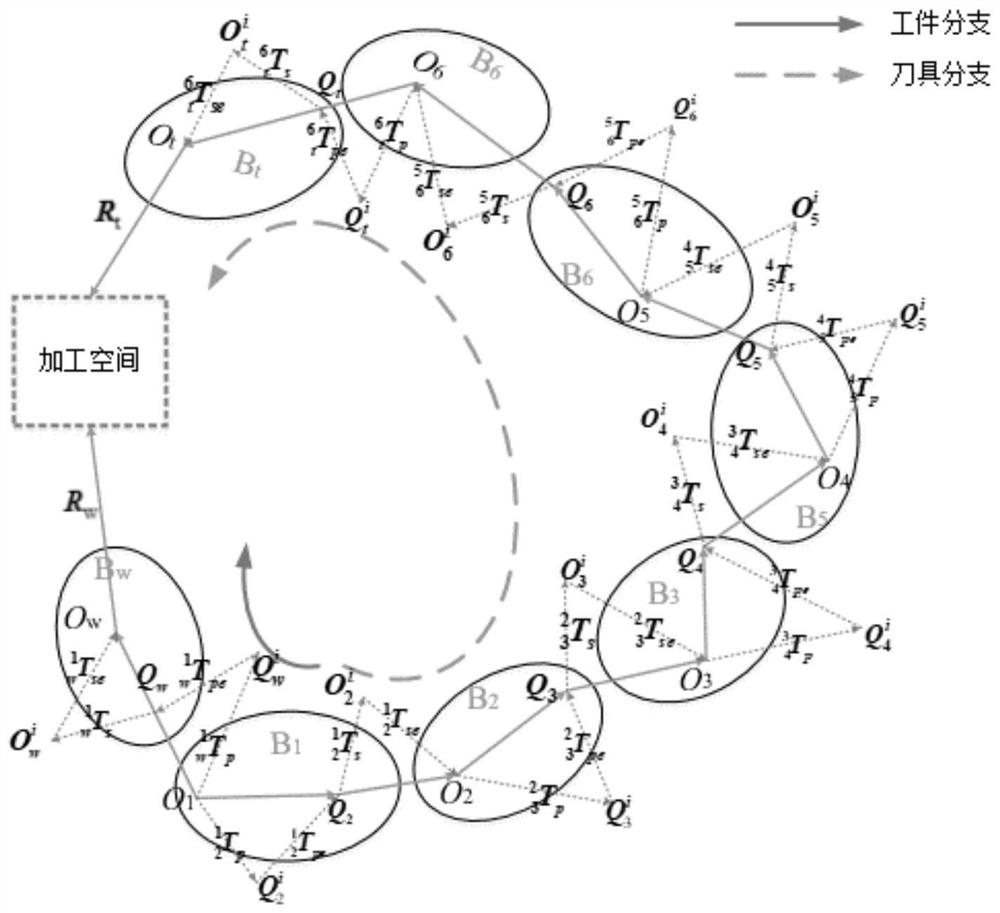

Joint surface error and joint surface tolerance optimization method for machine tool fixture component

InactiveCN108268010ARealize the clamping functionCancel or reduce the passive trim processProgramme controlComputer controlGeometric errorDynamic balance

The invention relates to a joint surface error and joint surface tolerance optimization method for a machine tool fixture component. According to the prior art, the quality characteristics of a machine tool fixture component cannot truly reflect the quality distribution condition of the machine tool fixture component, which can influence calculation accuracy and trimming precision and make automation hard to realize, and therefore, the invention provides the method to solve the problems in the prior art. The method of the invention includes the following steps that: 1, surface tolerance is represented by a homogeneous matrix; 2, joint surface error is represented by a homogeneous matrix; 3, a geometric error transfer model of assembly is constructed; 4, the surface tolerance and joint surface error are optimized according to the nature of error terms; 5, sensitivity is analyzed; 6, a part surface error or surface tolerance parameter optimization method is established with the processing cost of the fixture component adopted as an objective and assembly precision reliability and tolerance selection principles adopted as constraints; and 7, the distribution rule and parameter of theimbalance of a fixture component assembly body are obtained through a simulation experiment after the optimization result of the spinor parameter of the assembly body is obtained, and therefore, the dynamic balance optimization design of the assembly body is realized.

Owner:XIAN TECHNOLOGICAL UNIV

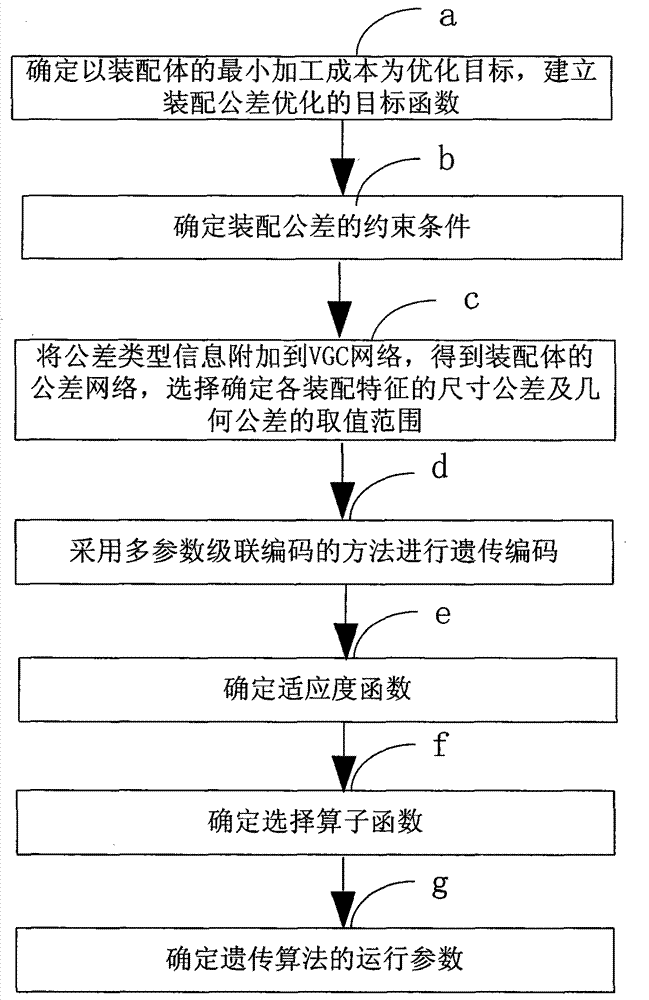

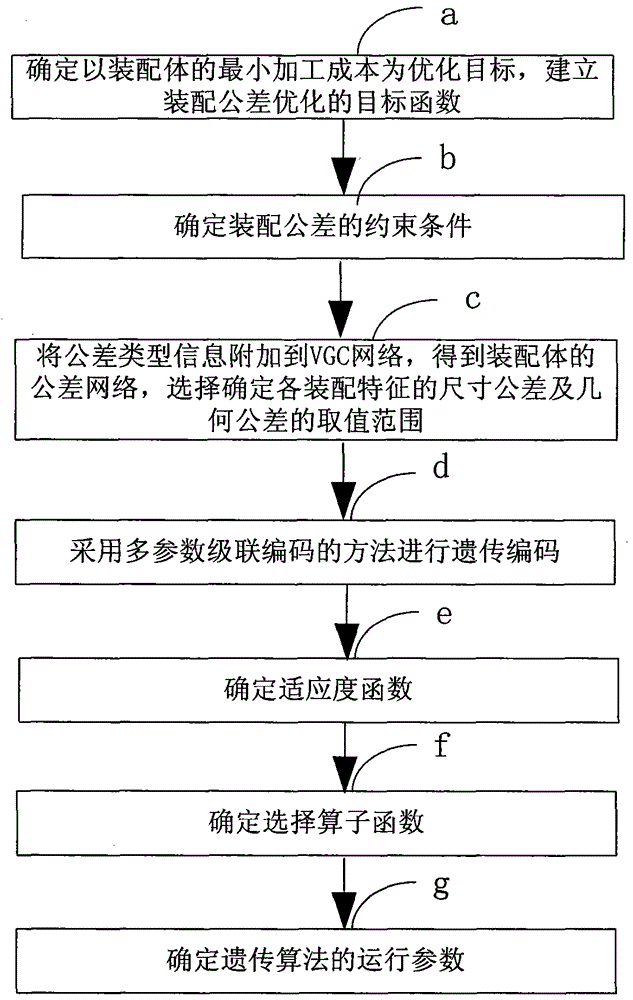

Assembly tolerance optimization designing method based on genetic algorithm

InactiveCN103902759AImprove robustnessStrong application potentialGenetic modelsSpecial data processing applicationsRobustificationAlgorithm

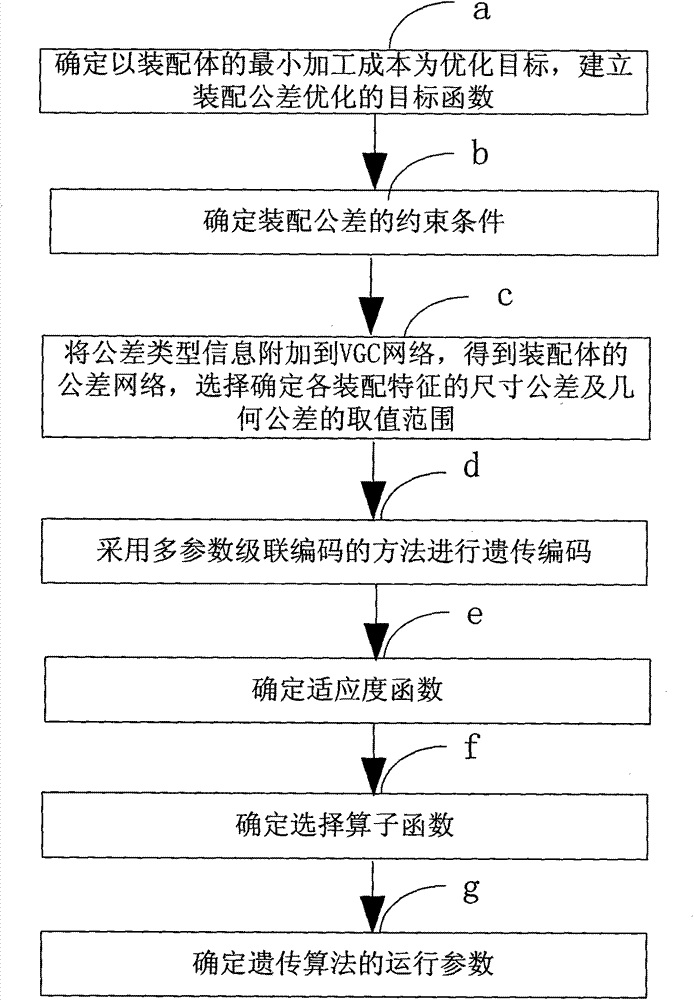

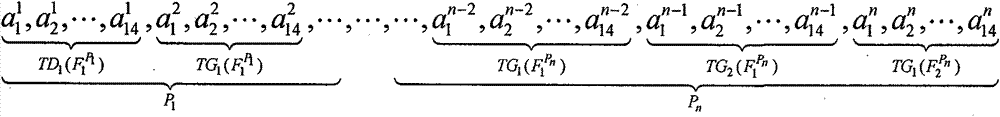

The invention relates to an assembly tolerance optimization designing method based on the genetic algorithm. The method comprises the steps that a target function for assembly tolerance optimization is established with the minimum processing cost of an assembly body as the optimization target; the constraint conditions of assembly tolerance are determined; tolerance type information is added to a VGC network to obtain a tolerance network of the assembly body and the value range of dimensional tolerance of various assembly features and the value range of geometric tolerance of the assembly features are selected and determined; genetic coding is conducted by the adoption of a multi-parameter cascade coding method; a fitness function is determined; an operator function is selected and determined; operating parameters of the genetic algorithm are determined. According to the assembly tolerance optimization designing method based on the genetic algorithm, the genetic algorithm shows great application potential through the global searching capacity, the high robustness and the calculation parallelism.

Owner:XIJING UNIV

Assembly tolerance optimization method based on quality loss and cost minimization

InactiveCN106960101AFew basic parametersCalculation results are stableGeometric CADDesign optimisation/simulationPareto rankingMathematical model

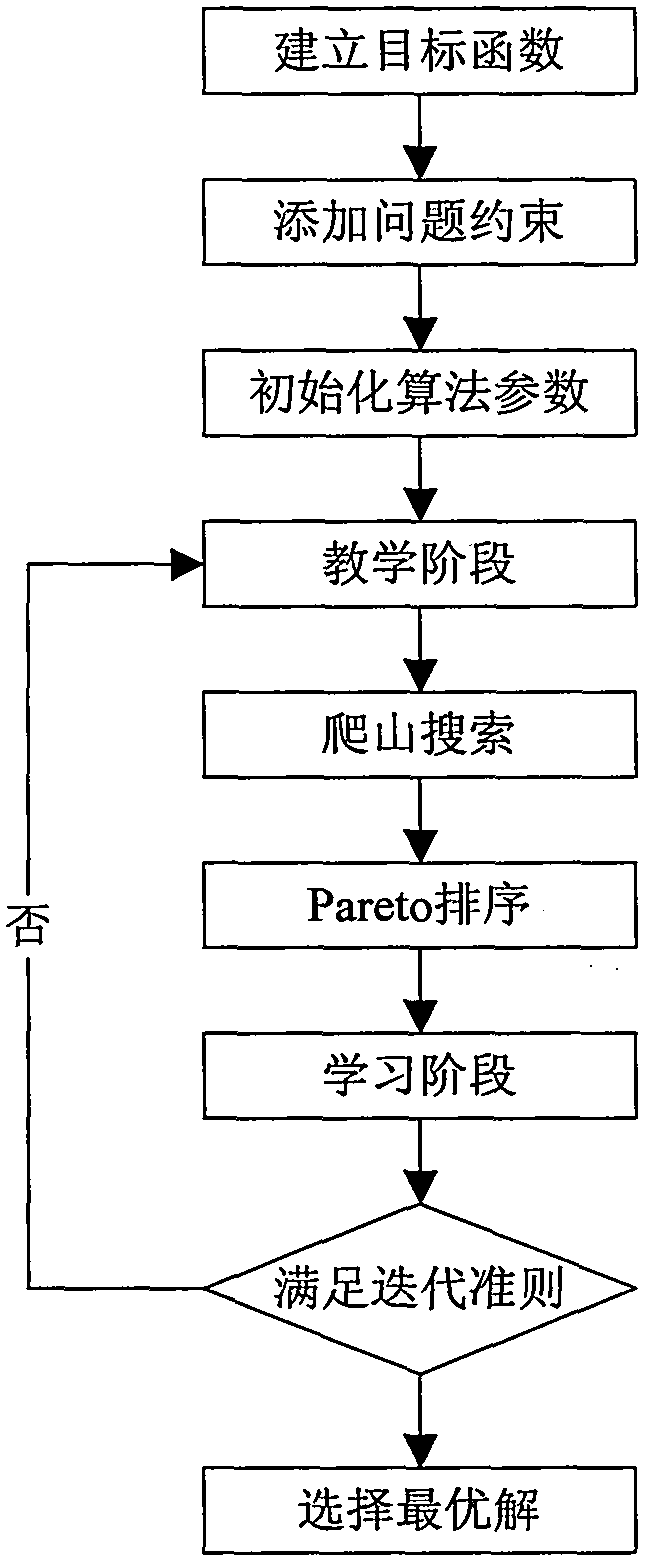

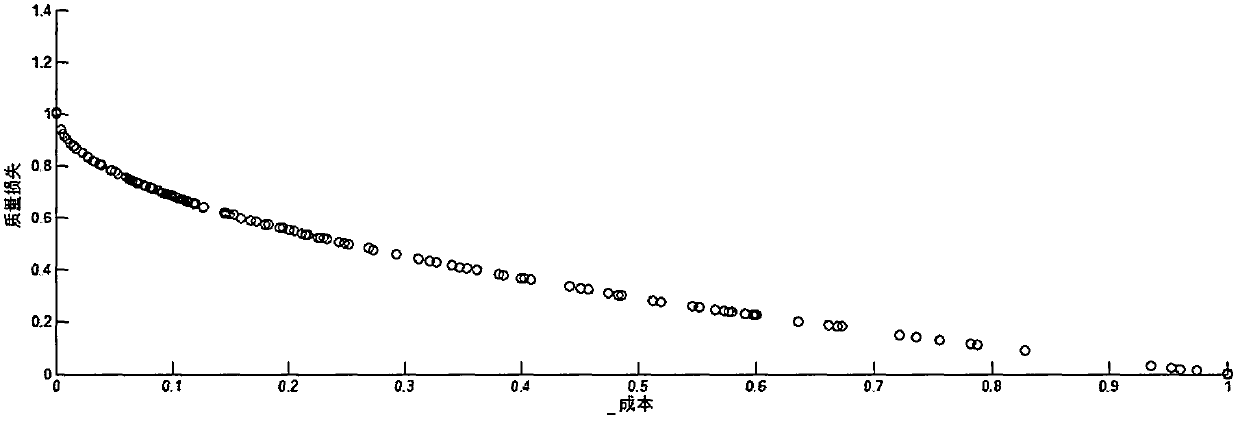

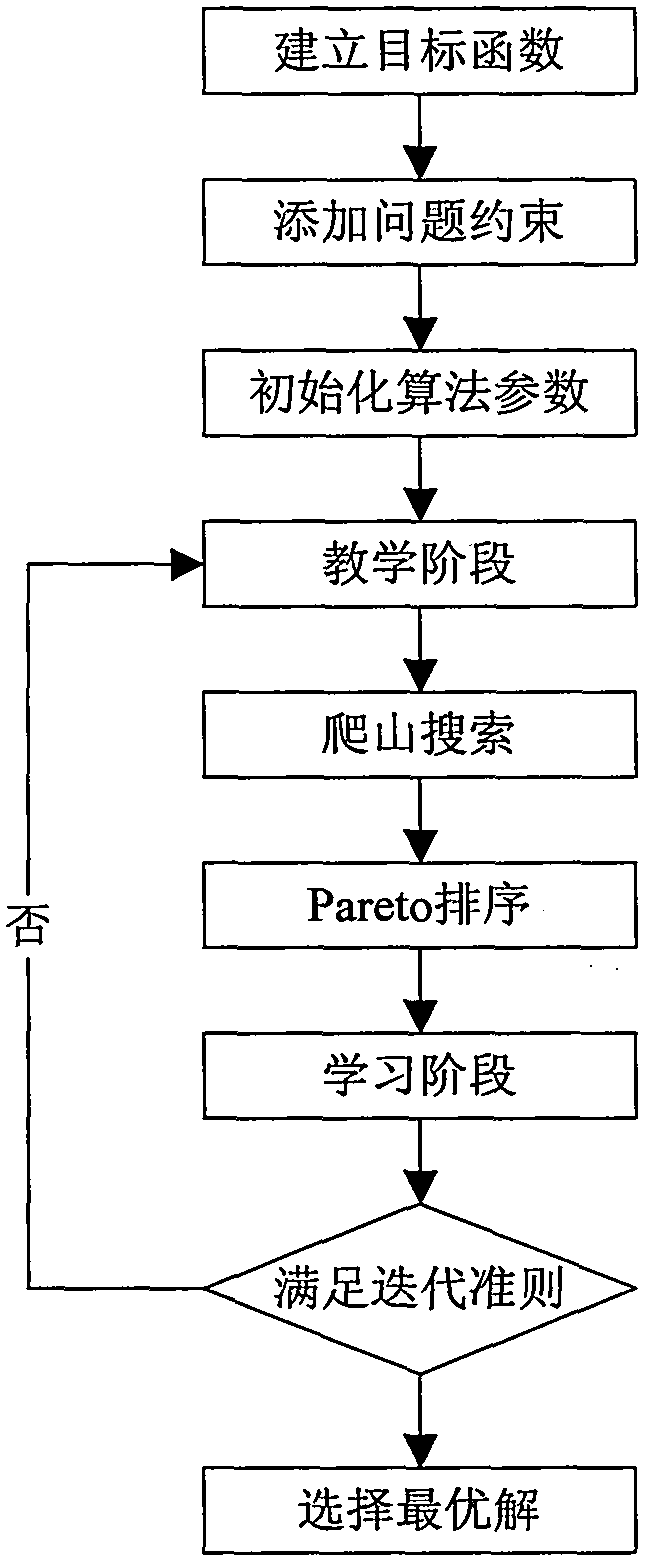

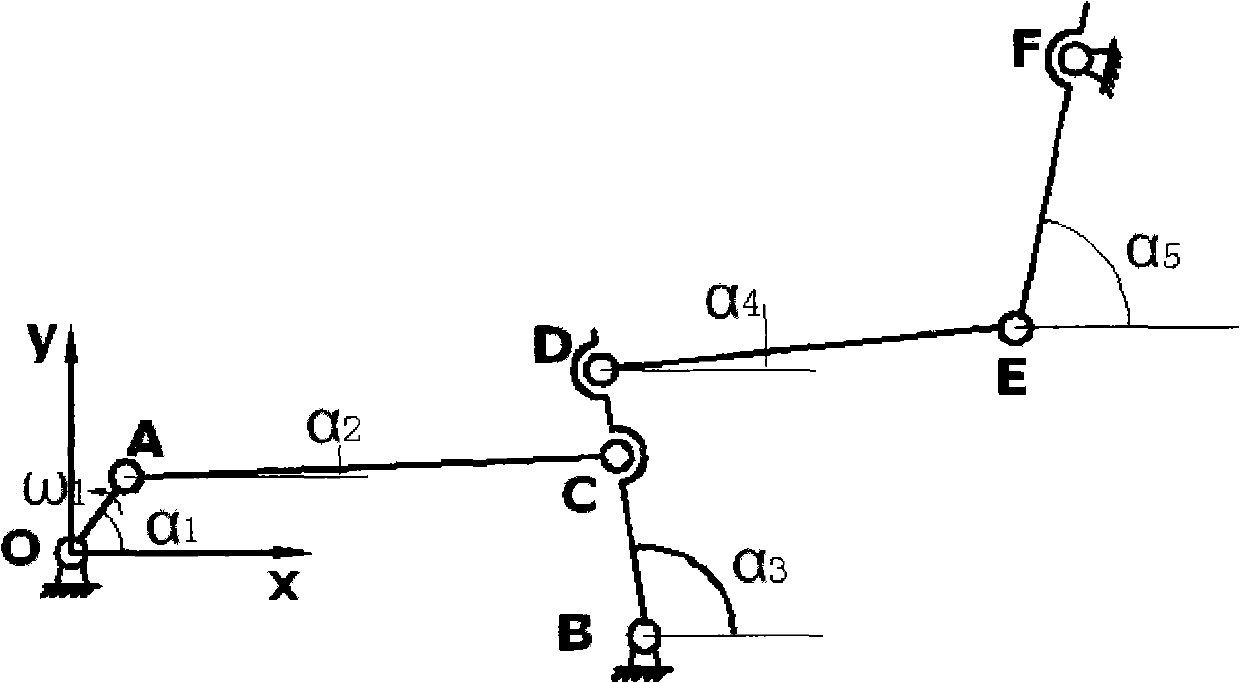

The invention relates to an assembly tolerance optimization method based on quality loss and cost minimization. The method mainly comprises the following steps: establishing a mathematical model of quality loss and processing cost; adding actual processing capability constraints; performing parameter initialization on a multi-objective teaching and learning algorithm; performing iteration in a teaching phase on an initial solution of the algorithm; adopting a hill-climbing search strategy to further develop the solution; performing Pareto ranking on a population; further studying the solution, and further increasing the accuracy of the solution; and completing the iterative process and finding the optimal solution. The assembly tolerance optimization method based on the quality loss and cost minimization provided by the invention is based on the computer technology, and combines the swarm intelligent optimization algorithm in the field of artificial intelligence, which further improves the calculation efficiency and calculation accuracy of assembly tolerance design, and aims to satisfy the design accuracy under precision manufacturing, improve the production efficiency, and improve the parts quality, so as to further reduce the production cost.

Owner:SHANGHAI UNIV

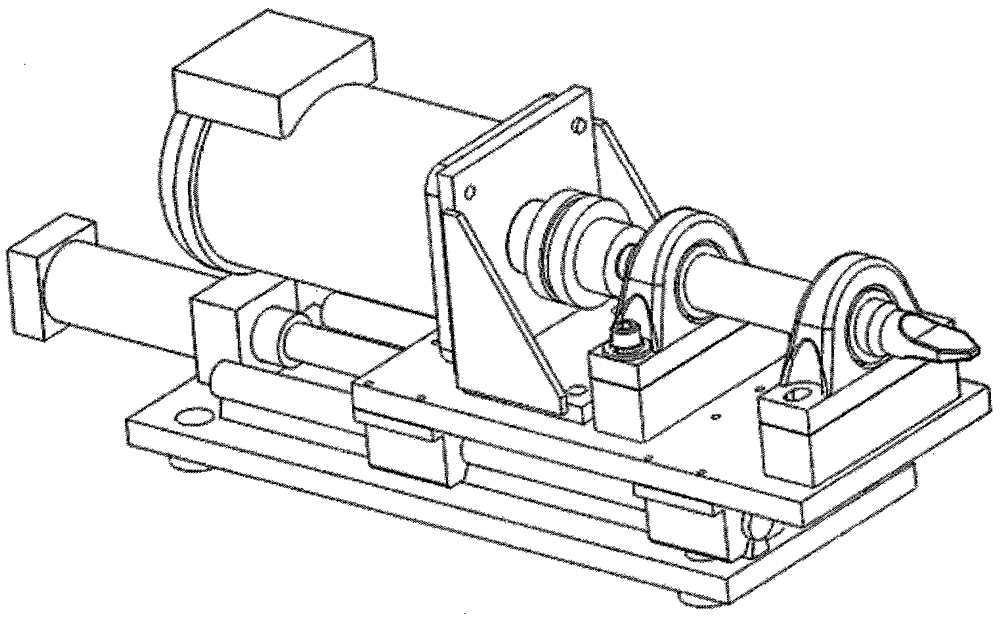

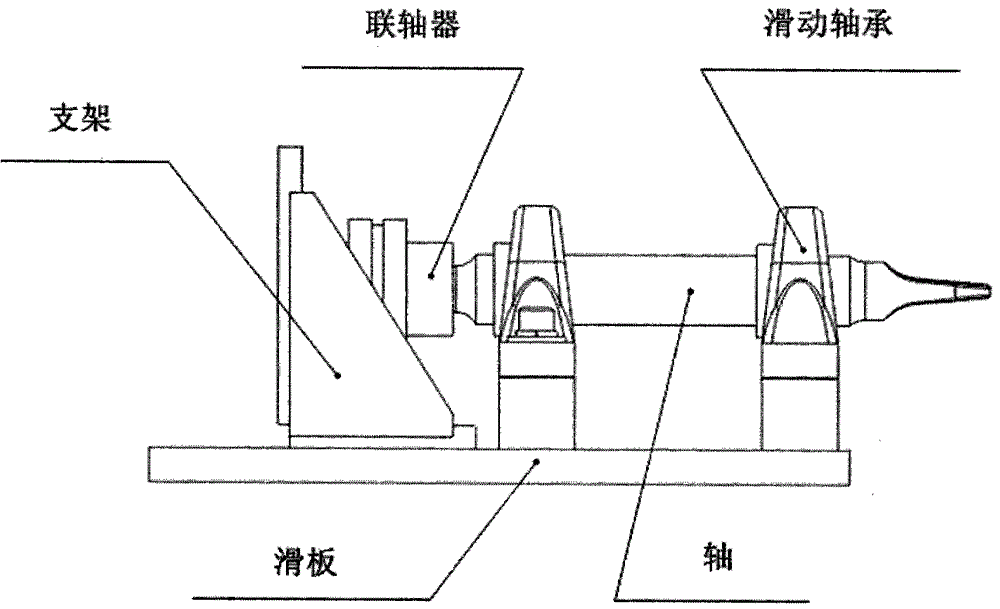

Tolerance optimization method of feed mechanism

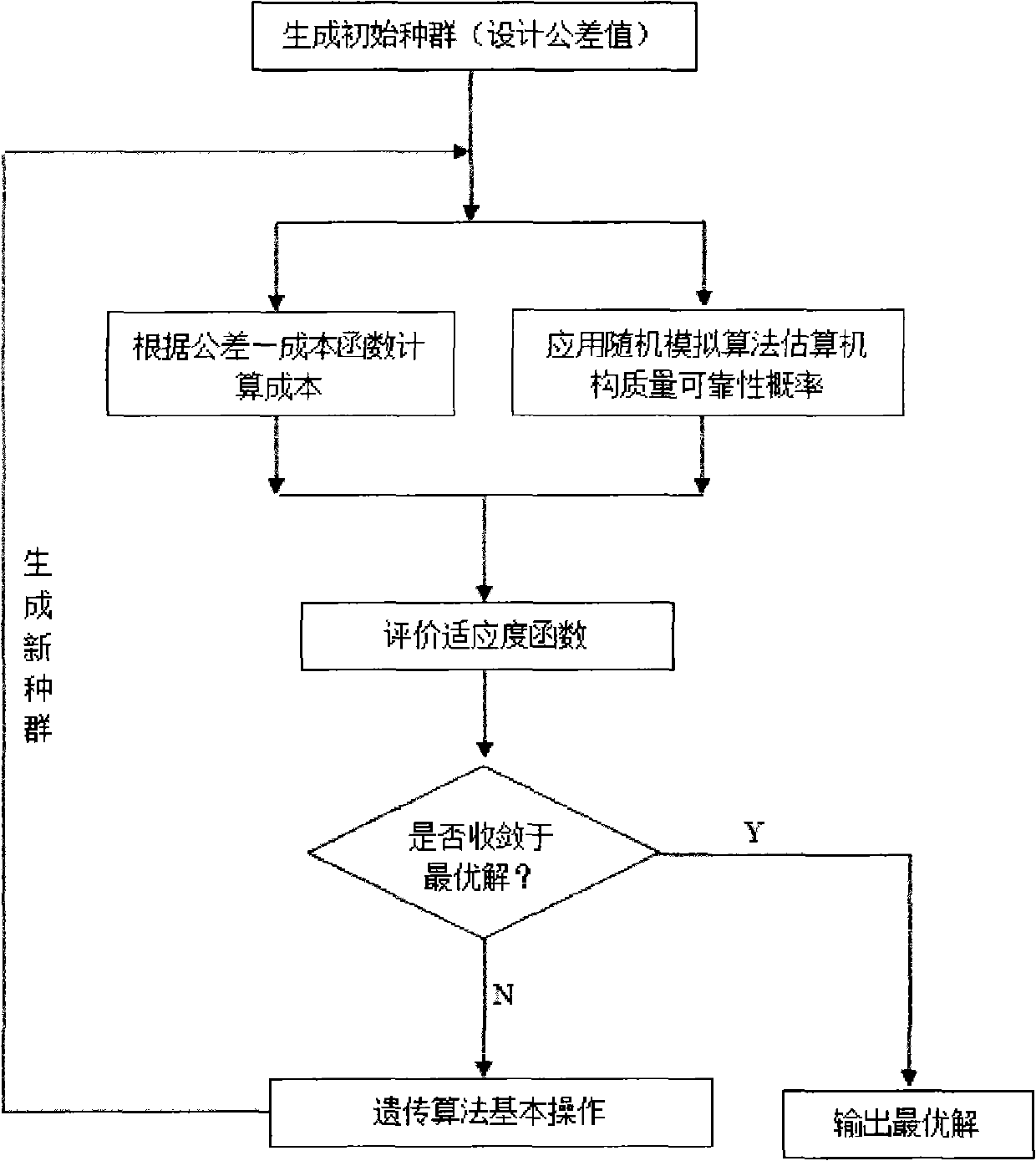

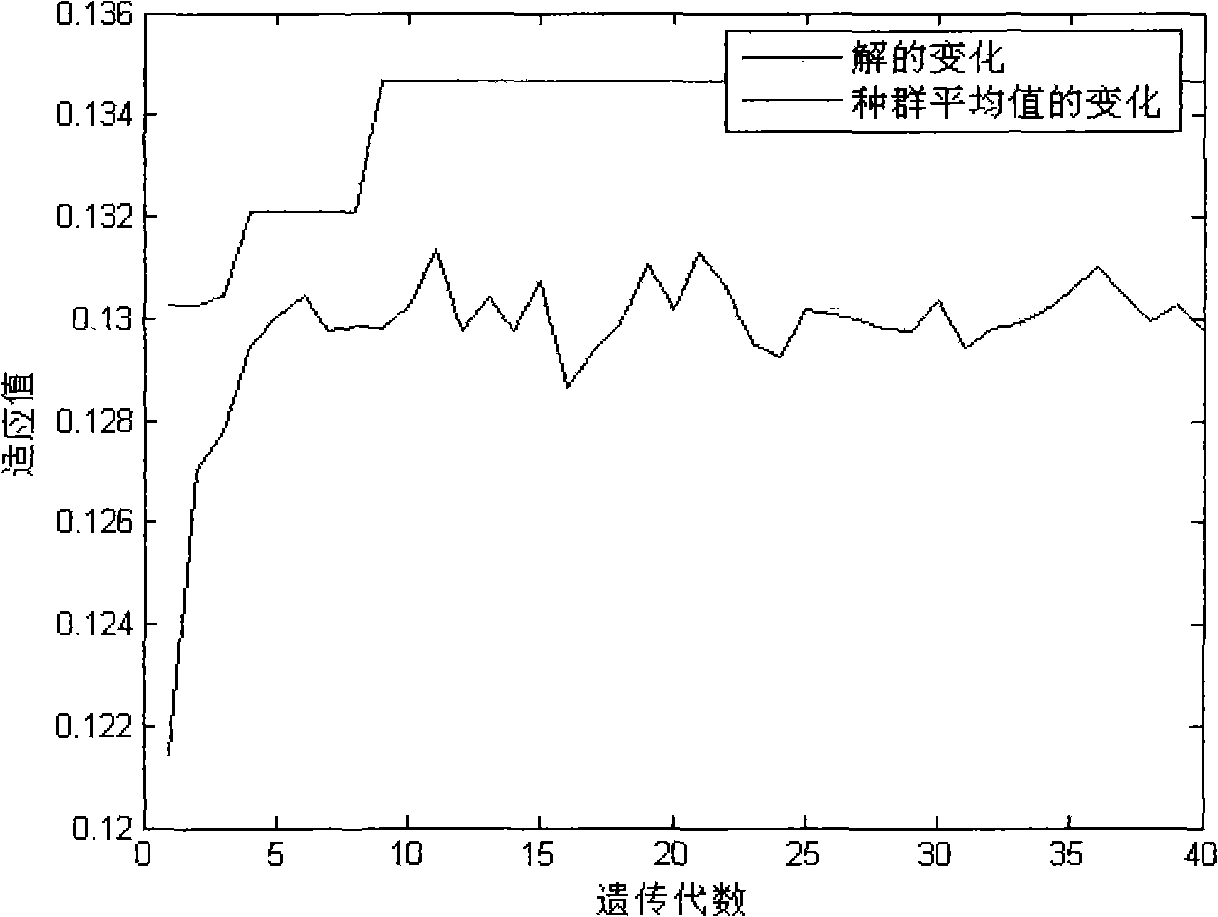

InactiveCN102662356AImprove robustnessReduce processing costsTotal factory controlProgramme total factory controlCost evaluationWeight coefficient

The invention discloses a tolerance optimization method of a feed mechanism. The method comprises the following steps: A, establishing a feed mechanism tolerance-processing cost function model: C(t)=a0e<-a1t>, wherein the C(t) expresses processing cost of a corresponding tolerance t and a0 and a1 are weighting coefficients of different processing cost evaluation functions; B, employing a random simulation algorithm to calculate a correlated statistic characteristic of a feed mechanism quality characteristic according to design parameters of all components of the feed mechanism and initial tolerance data; and C, employing a genetic algorithm to output an optimized tolerance of the design parameters according to the correlated statistic characteristic of the feed mechanism quality characteristic. According to the invention, correlated knowledge of tolerance robustness is employed and a quality-cost balance relation is utilized as a quality maxim for a tolerance robustness optimization design; therefore, it can be ensured that the quality of the feed mechanism has good robustness and processing cost of the mechanism can be effectively reduced, thereby reaching an optimum balance between the product quality and the cost and thus further improving product market competitiveness.

Owner:NINGBO TENGGONG PRECISION MFG

Assembly tolerance optimum design method based on cost objective optimization

InactiveCN103810324AConstraints metRealize the designSpecial data processing applicationsEconomic benefitsRepresentative function

The invention relates to an assembly tolerance optimum design method based on cost objective optimization. According to the method, the minimum machining cost of an assembly body is determined as an optimization target, and an objective function of assembly tolerance optimum is established; the function is obtained through the following steps that a part representative function of a mechanical assembly body is set; a total machining cost representative function of the mechanical assembly body is determined; a machining cost function of each part in the assembly body is determined; a machining cost function of assembly features is determined; a total machining cost-tolerance function of the assembly body is obtained; the objective function of assembly tolerance optimum is obtained. According to the assembly tolerance optimum design method, the optimum tolerance is obtained with the minimum machining cost as the target and with the machining capacity, the machining cost or the machining economic accuracy as constraint conditions respectively, so requirements of products for assembly functions can be met, the constraint conditions of machining can be met, and good economic benefits can be obtained.

Owner:XIJING UNIV

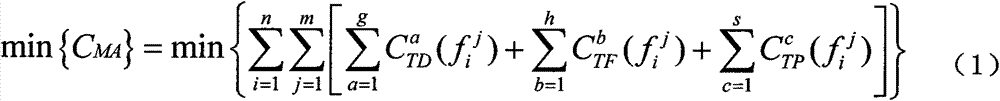

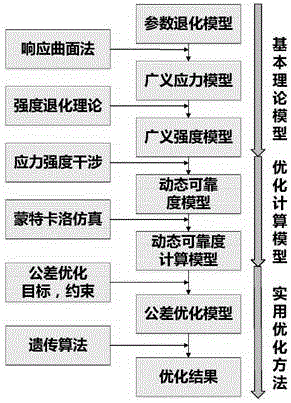

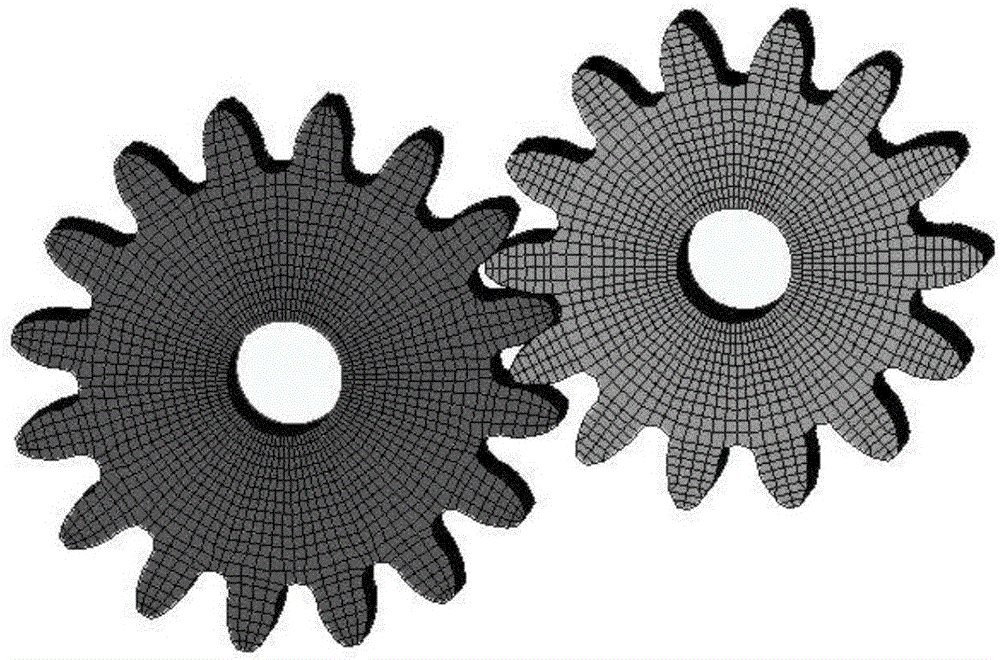

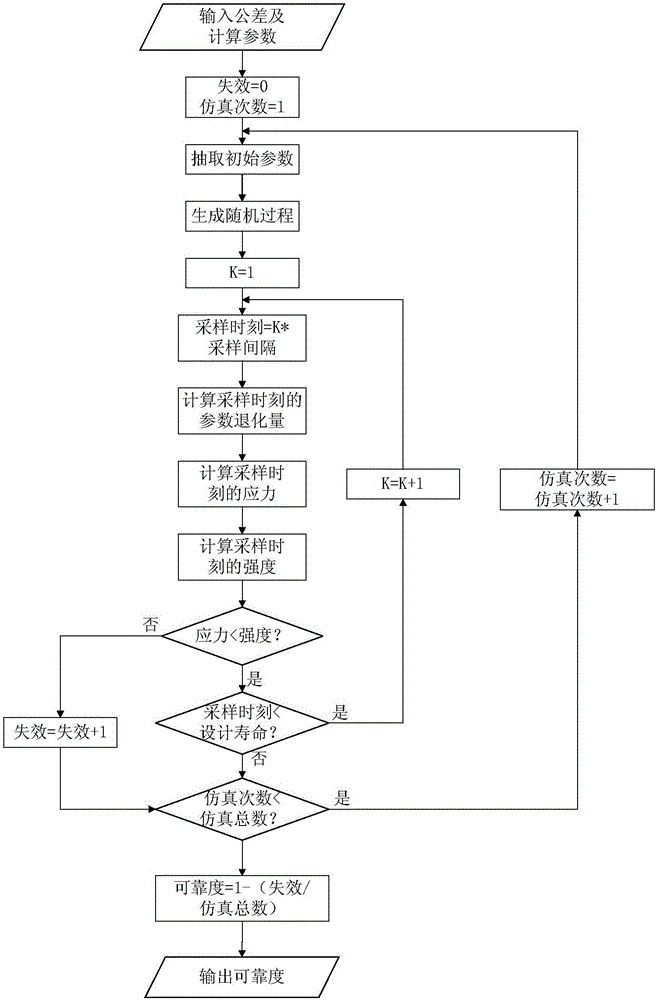

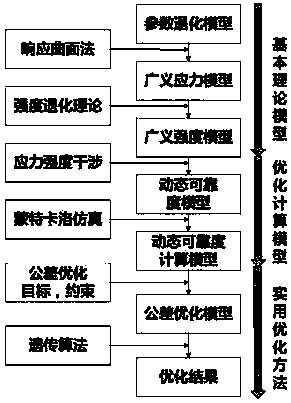

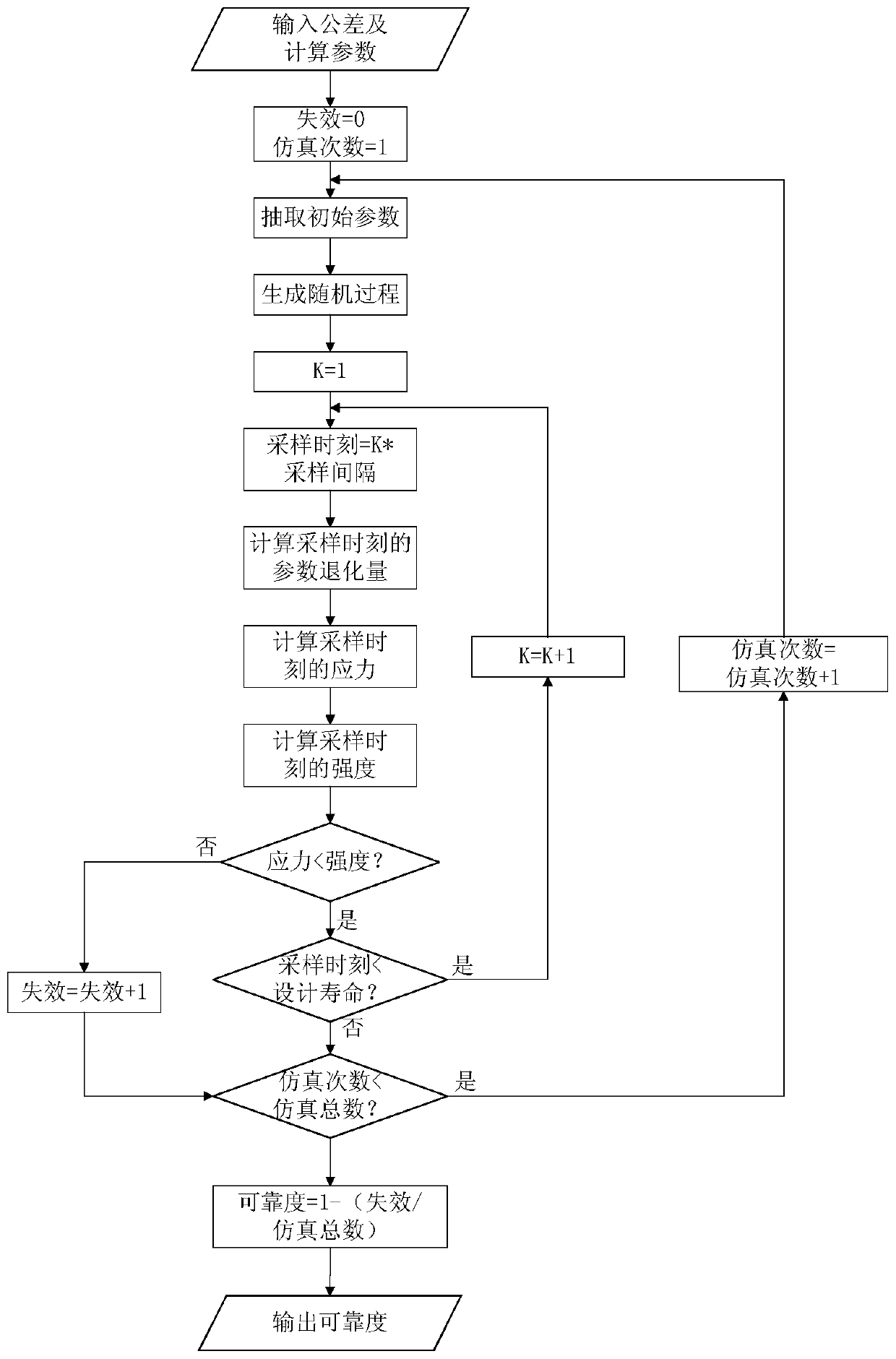

Dynamic reliability-based gear system tolerance optimization calculation method

ActiveCN106599448AEvaluate work abilityComputational reliabilityGeometric CADDesign optimisation/simulationGear systemDistribution characteristic

The present invention provides a dynamic reliability-based gear system tolerance optimization calculation method. The method comprises a first step of modeling for gear system tolerance degradation, analyzing a design requirement of the gear system and processing routing, and determining a processing characteristic, a distribution characteristic and a cost characteristic of each sensitive tolerance parameter and a time-based degradation rule; a second step of determining a general stress model of the gear system; a third step of determining a strength degradation model of the gear system; a fourth step of calculating dynamic reliability; a fifth step of building a tolerance optimization model; and a sixth step of determining an optimal tolerance. Dynamic reliability is introduced to the field of gear system tolerance optimization, so that the traditional optimization model with total mass loss as the target is changed, and the working capability of the gear system can be evaluated more scientifically and objectively.

Owner:BEIHANG UNIV

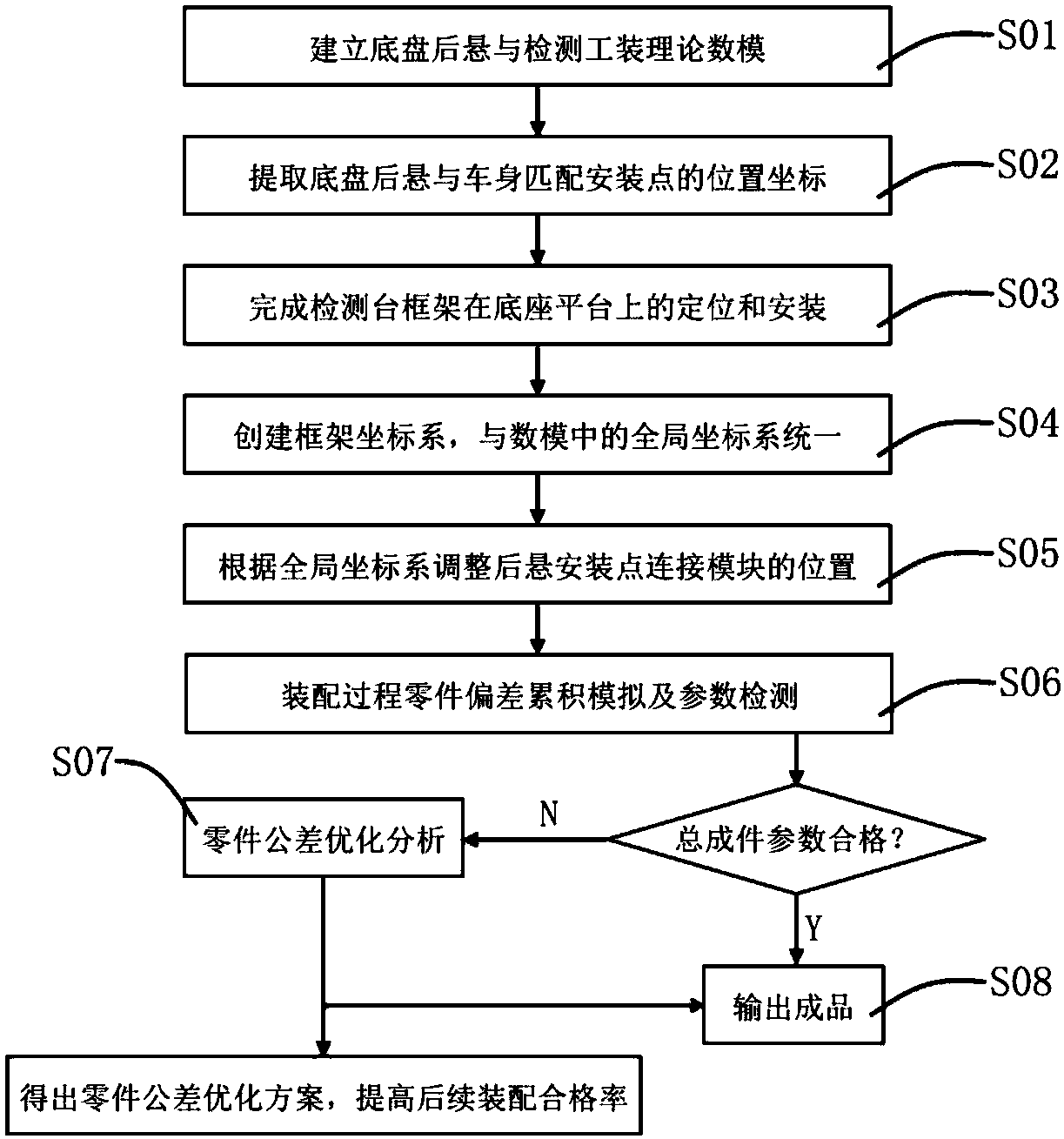

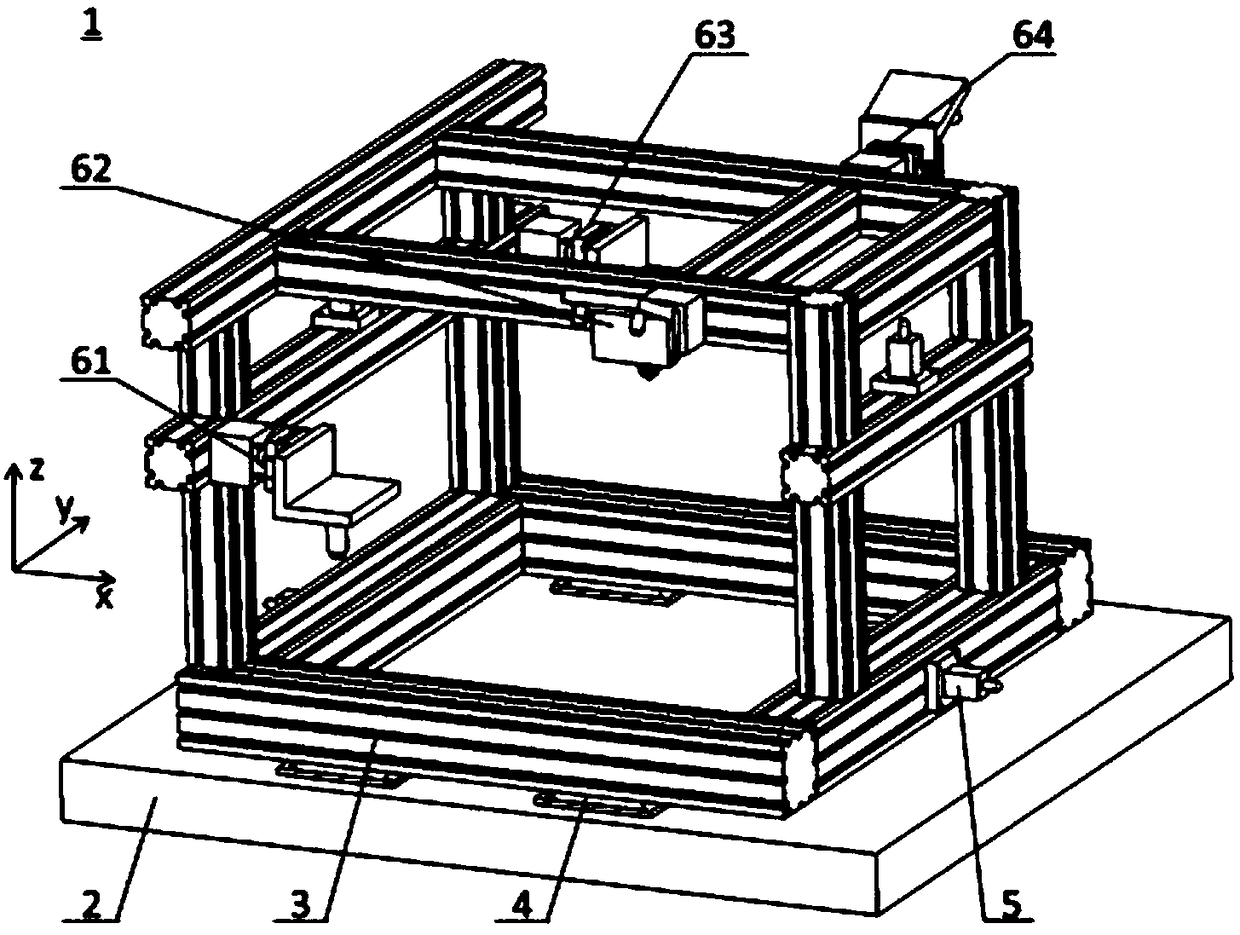

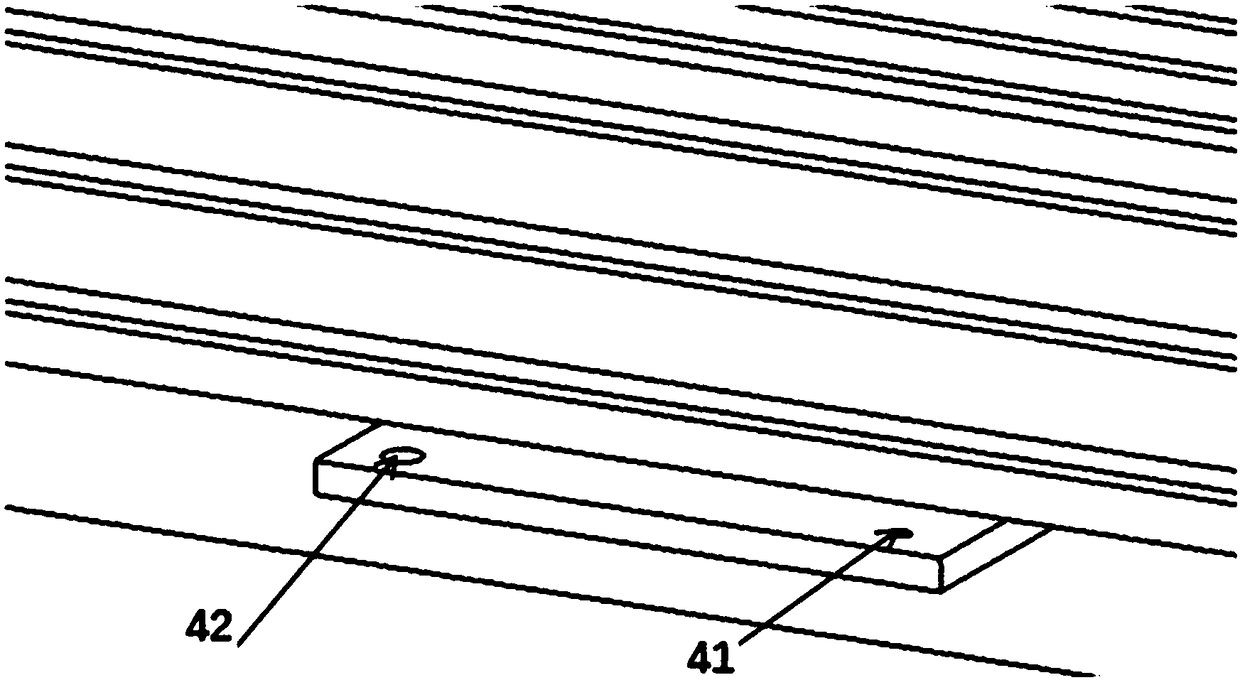

Automobile chassis rear-overhang part assembly simulated detection tool and detection analysis method

PendingCN108132033AHigh precisionImprove driving performanceUsing optical meansMechanical measuring arrangementsGeneral assemblyAnalysis method

The invention relates to an automobile chassis rear-overhang part assembly simulated detection tool and detection analysis method. According to the detection tool, the tool is assembled on a detectionplatform and detection equipment is used to measure the tolerance of the tool after assembly, the tool is used to detect parameters including function, size and manufacturing deviation of automobilechassis rear-overhang parts and function and size of a general assembly, whether a chassis rear-overhang unit is qualified is detected, a deviation accumulated phenomenon in the chassis rear-overhangassembling process is simulated, influence of a manufacturing deviation accumulation effect of parts in the assembling process on the function and size of the assembled general rear-overhang assemblyis analyzed and compared to obtain contribution of the manufacturing deviation of each part to the final assembling error, and thus, guidance is provided for tolerance optimization of the parts, the rear-overhang assembling precision is improved, and the driving performance of the whole automobile is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Tolerance optimization method for die forging

ActiveCN103143661AReduce investmentFulfil requirementsMetal-working apparatusNumerical controlAviation

The invention belongs to the field of aviation machinery, and particularly relates to a tolerance optimization method for a die forging. The tolerance optimization method comprises the following steps of: determining the type of tolerance of a die forging of a part to be optimized according to a drawing of the part, dividing into interior tolerance and exterior tolerance, and then obtaining tolerance data. According to the tolerance optimization method, dimensional tolerance optimization is performed on the die forging of a certain series of a certain airplane, and the requirements of numerical control machining and the technical requirements of part design and manufacturing can be met by rationally adjusting the tolerance of the part and the die forging, so that the machining accuracy, the production efficiency and the yield of products are improved, the machining technical difficulty is reduced, and the method has wide applicability and is convenient to implement. For example, the yield is 80 percent, the production efficiency is 3 pieces per day and the machining accuracy out-of-tolerance use is less than 20 percent before optimization, but the yield reaches over 95 percent, the production efficiency is 5 pieces per day and the machining accuracy out-of-tolerance use can be controlled within 5 percent after optimization; and the equipment and personnel investment is reduced.

Owner:SHAANXI AIRCRAFT CORPORATION

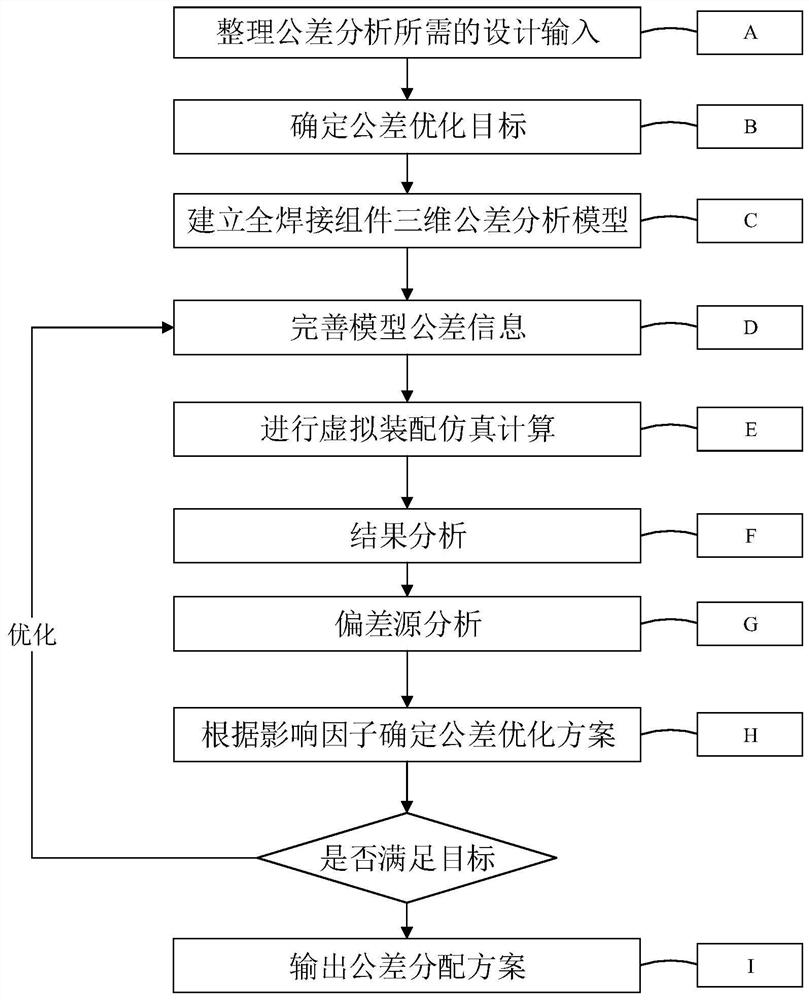

Tolerance optimization method for all-welded assembly

ActiveCN113204851AEffective predictionAchieve Tolerance OptimizationGeometric CADDesign optimisation/simulationStructural engineeringDesign information

Owner:NUCLEAR POWER INSTITUTE OF CHINA

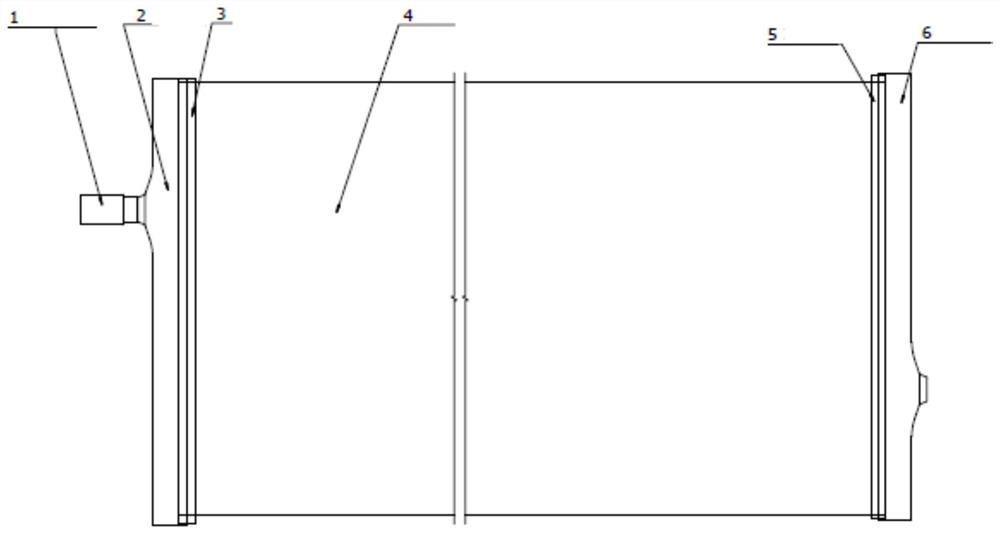

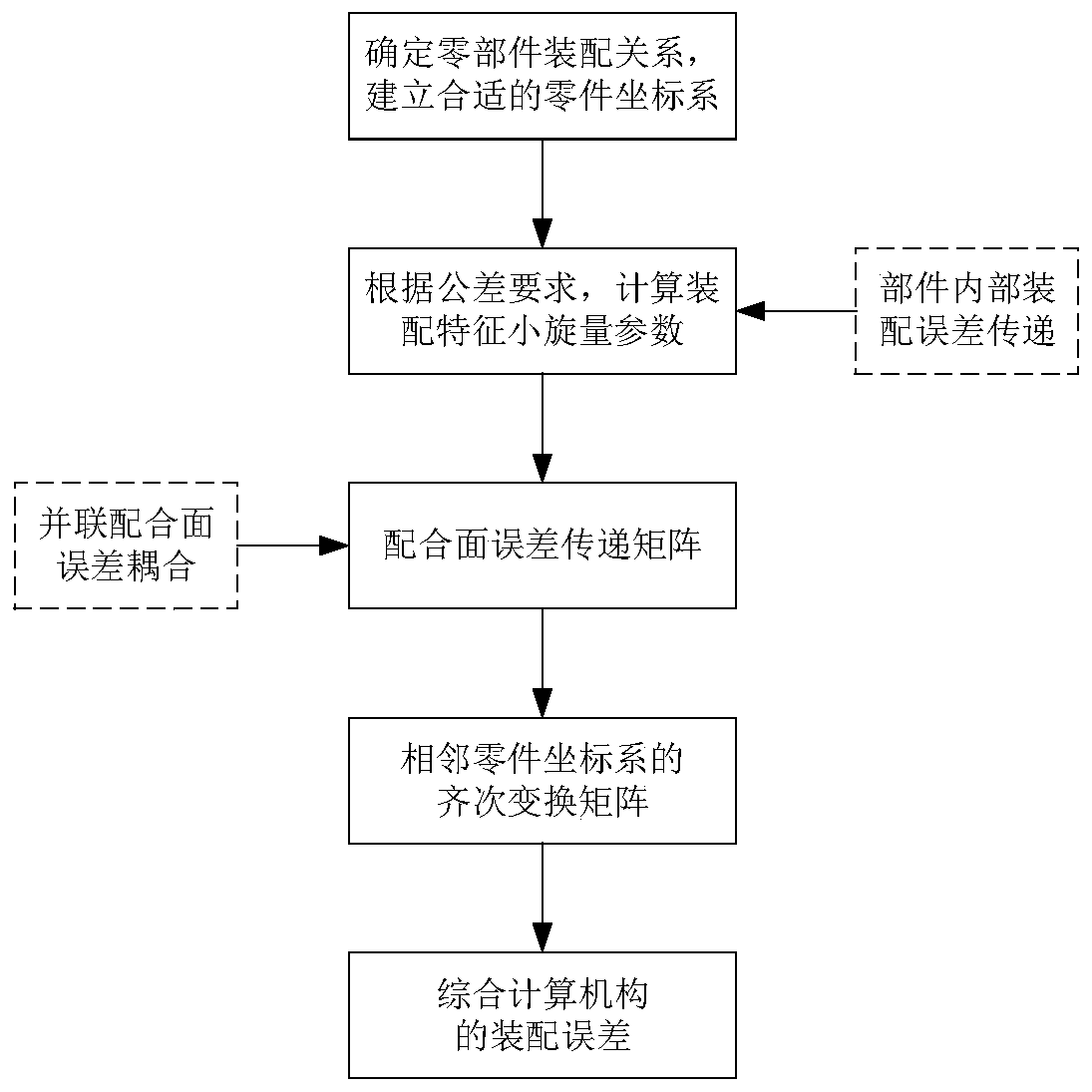

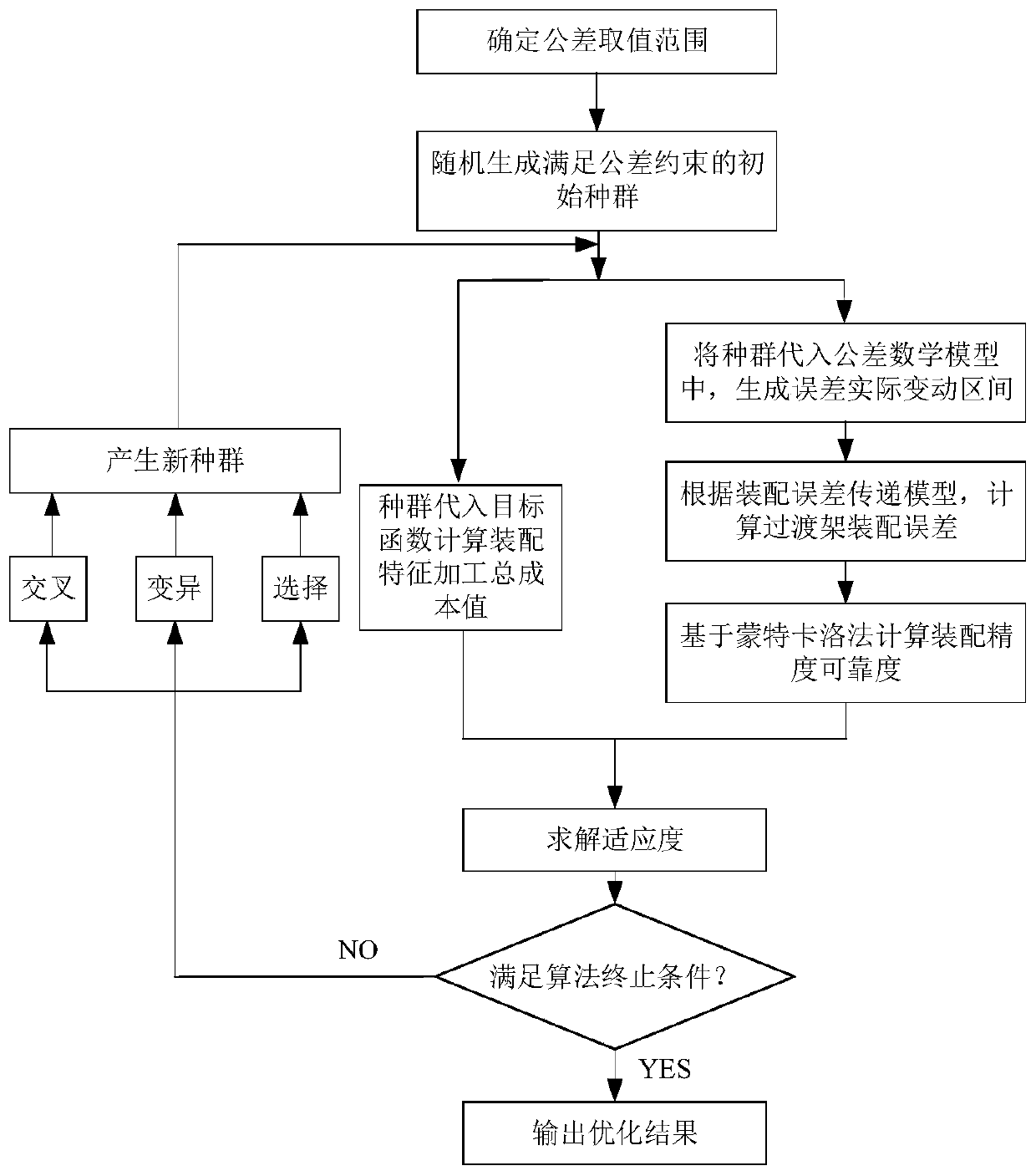

Assembly error analysis and tolerance optimization method for parallel lifting mechanism

ActiveCN110457783AAnalysis results are intuitive and preciseSpecial data processing applicationsManufacturing computing systemsKey sizeTransfer model

The invention discloses an assembly error analysis and tolerance optimization method for a parallel lifting mechanism. The assembly error analysis and tolerance optimization method is characterized byestablishing a part assembly characteristic tolerance model and an assembly error transfer model based on the three-dimensional tolerance model; and establishing a part assembly characteristic tolerance optimization model by taking the minimum machining cost as a target and taking the assembly precision reliability, the parallel matching surface assemblability and the machining capacity as constraint conditions according to the known assembly precision requirement of a certain key size in a mechanism, constructing a fitness function, and solving the part assembly characteristic tolerance optimization model by adopting a genetic algorithm. Based on three-dimensional tolerance model analysis, a tolerance coupling relationship which cannot be expressed by a two-dimensional dimension chain can be introduced into an assembly error transfer model of the mechanism, so that an analysis result of an assembly error is more intuitive and accurate.

Owner:WUHAN UNIV OF TECH

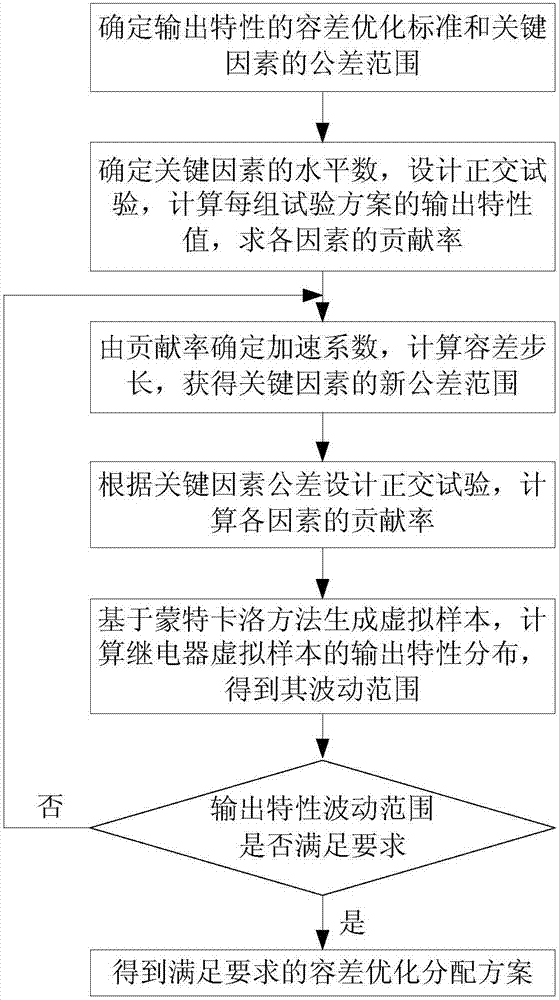

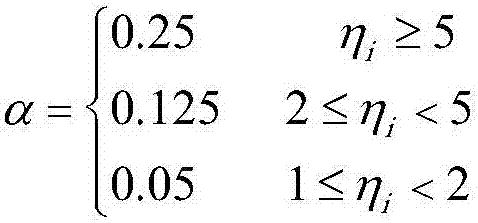

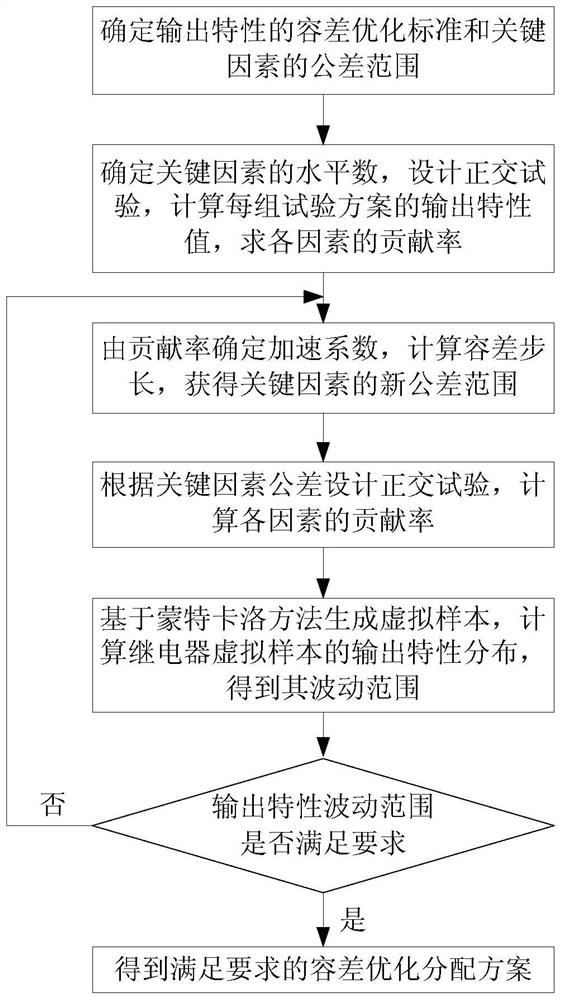

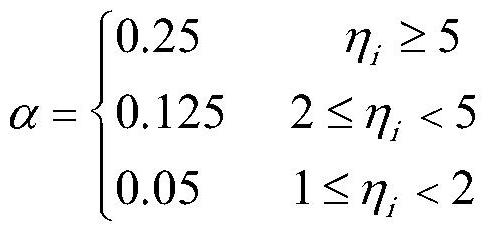

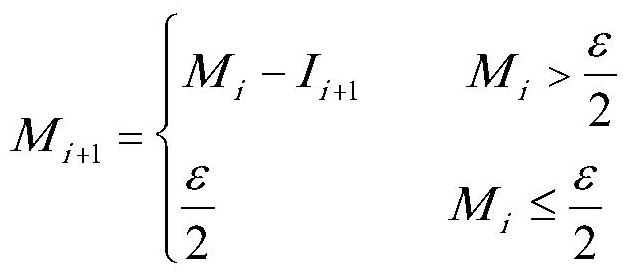

Electromagnetic relay step tolerance optimization method based on varying contribution rates

ActiveCN107016141AHigh tolerance optimization speedAutomatic adjustment factor tolerance rangeCAD circuit designSpecial data processing applicationsLower limitKey factors

The invention discloses an electromagnetic relay step tolerance optimization method based on varying contribution rates. The method comprises the steps of S1, determining a tolerance optimization standard; according to the relations between key elements and output characteristics and an actual processing capacity, determining a tolerance range of the key elements; S2, determining a number of levels of the key elements; design an orthogonal test, and calculating an output result of each group of orthogonal test; solving the contribution rates of all the key elements; S3, according to a certain tolerance step length, subtracting the contribution rates with the tolerance to obtain a new tolerance range of the key elements; calculating the concentration rates of all the key elements again; S4, in the new tolerance range determined in the step S3, solving an output characteristic fluctuation range of the corresponding new tolerance range; S5, repeating work in the step S3 and S4 till the output characteristic fluctuation range meets the tolerance optimization standard, or the new tolerance range reaches a processing precision lower limit, wherein the new tolerance range is a final result of step tolerance optimization.

Owner:HARBIN INST OF TECH

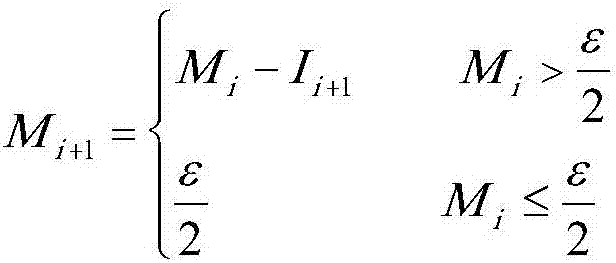

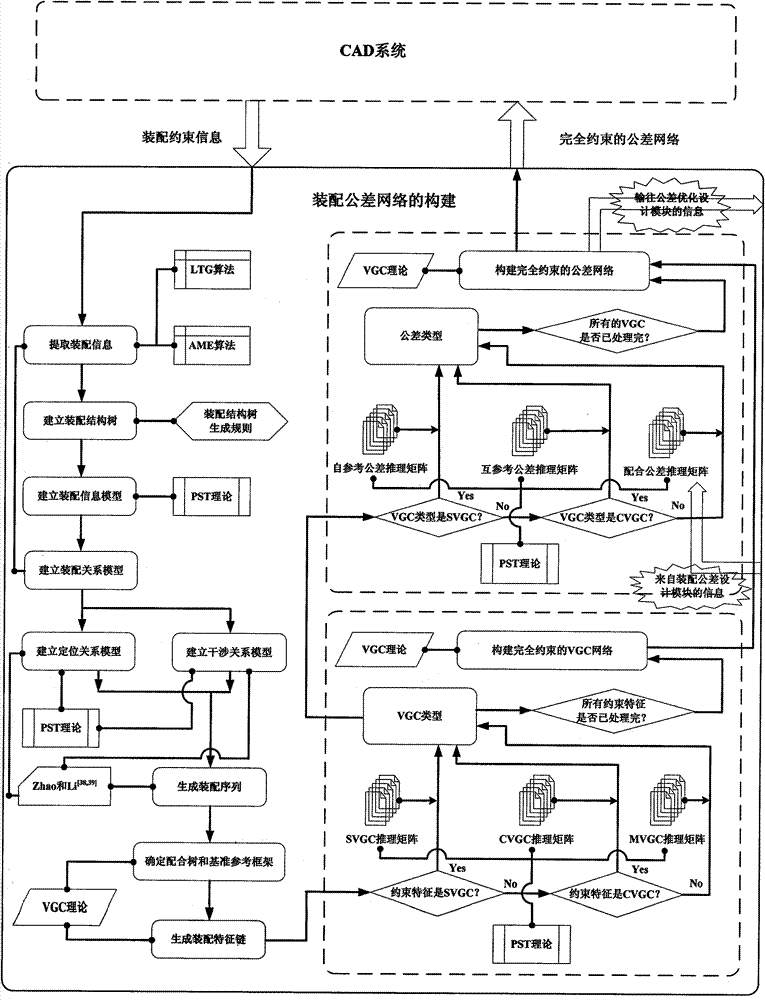

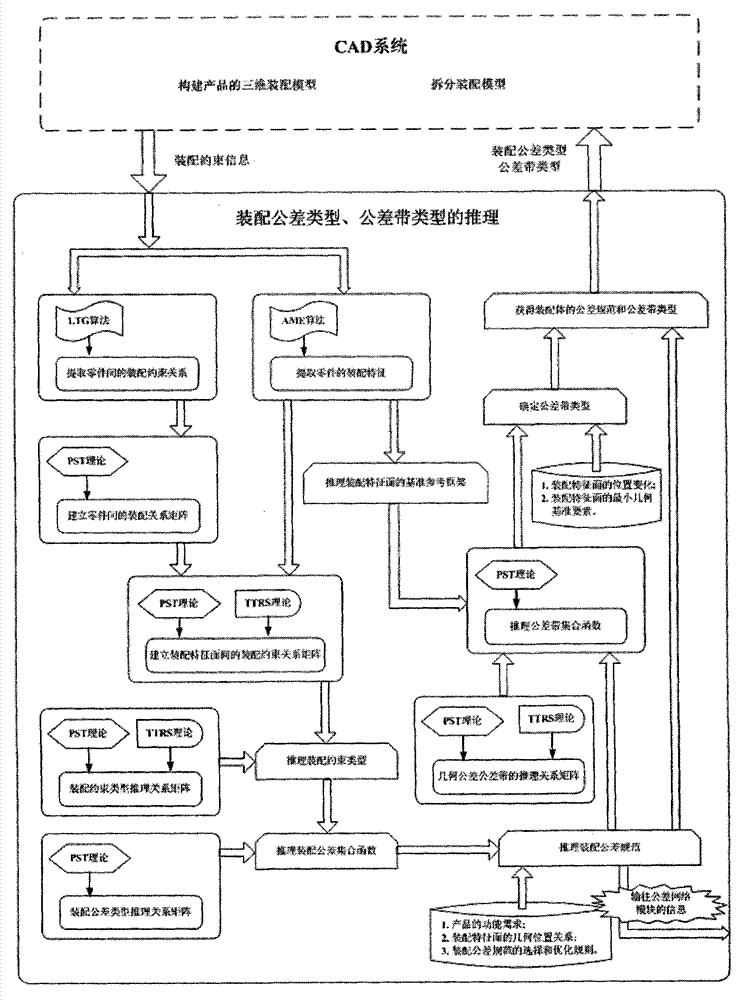

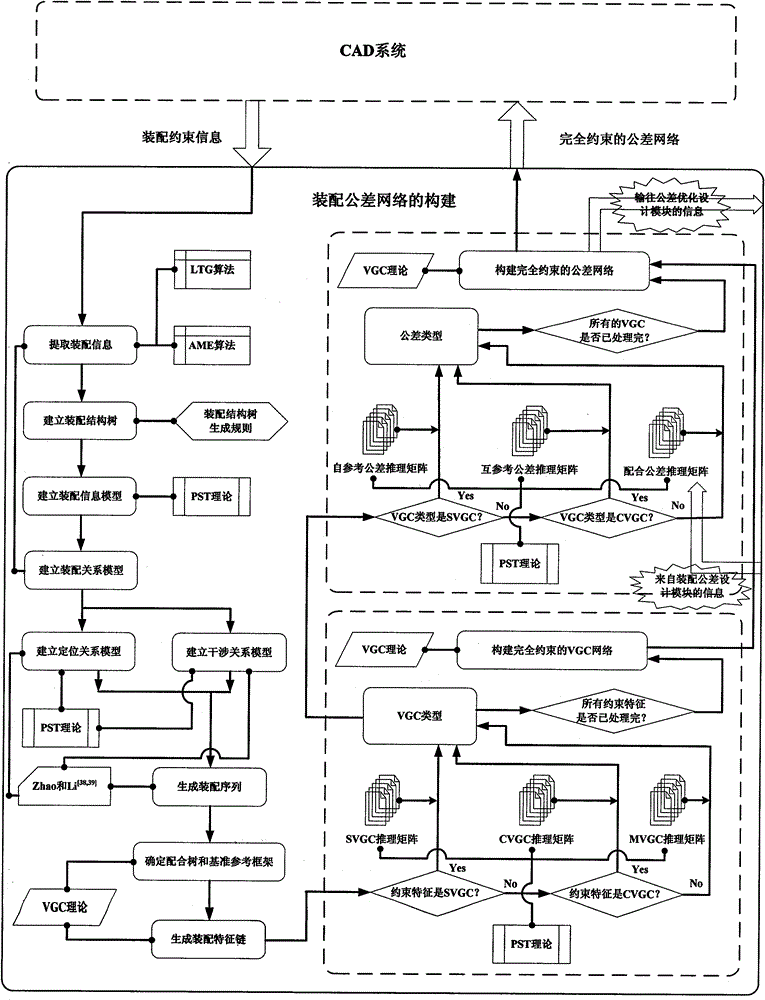

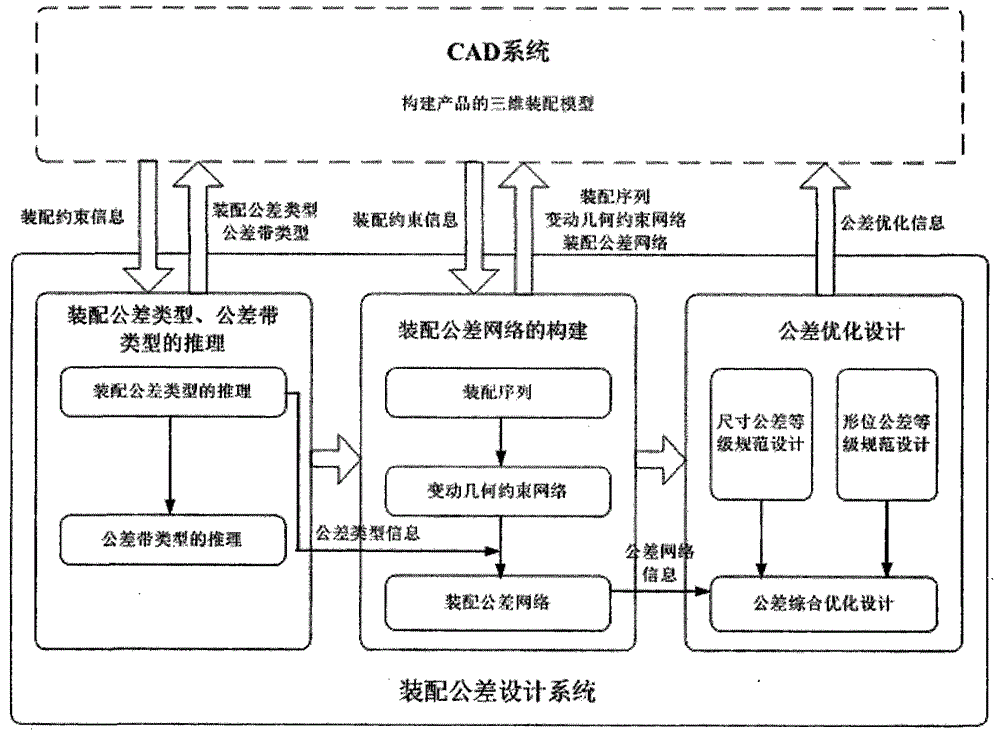

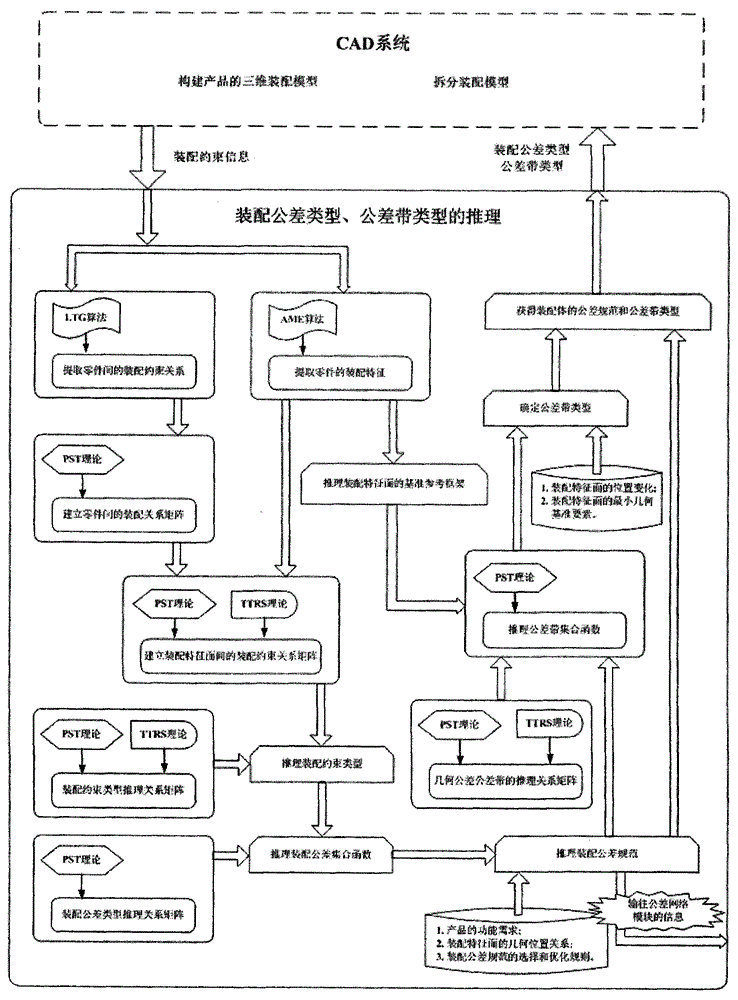

Fitting tolerance network establishing method

The invention relates to a fitting tolerance network establishing method. The fitting tolerance network establishing method includes extracting fitting information of products from a three-dimensional model of the CAD (computer-aided design) system, generating fitting sequences of the product, and establishing a VGC (viscosity gravity constant) network on the basis of the VGC theory; reasoning to generate three fitting tolerance types via the corresponding relation of the VGC and the tolerance types and tolerance type information input from the step a, adding the fitting tolerance types to the VGC network and establishing a fitting tolerance network; displaying fitting sequence generated in the step b, the VGC network and the fitting tolerance network on the CAD system, and outputting the tolerance network information for tolerance optimization and design. The fitting tolerance design system is established on the CAD system platform, and comprehensive design of fitting dimensional tolerance and geometric tolerance is realized by means of information acquired from a product entity model.

Owner:XIJING UNIV

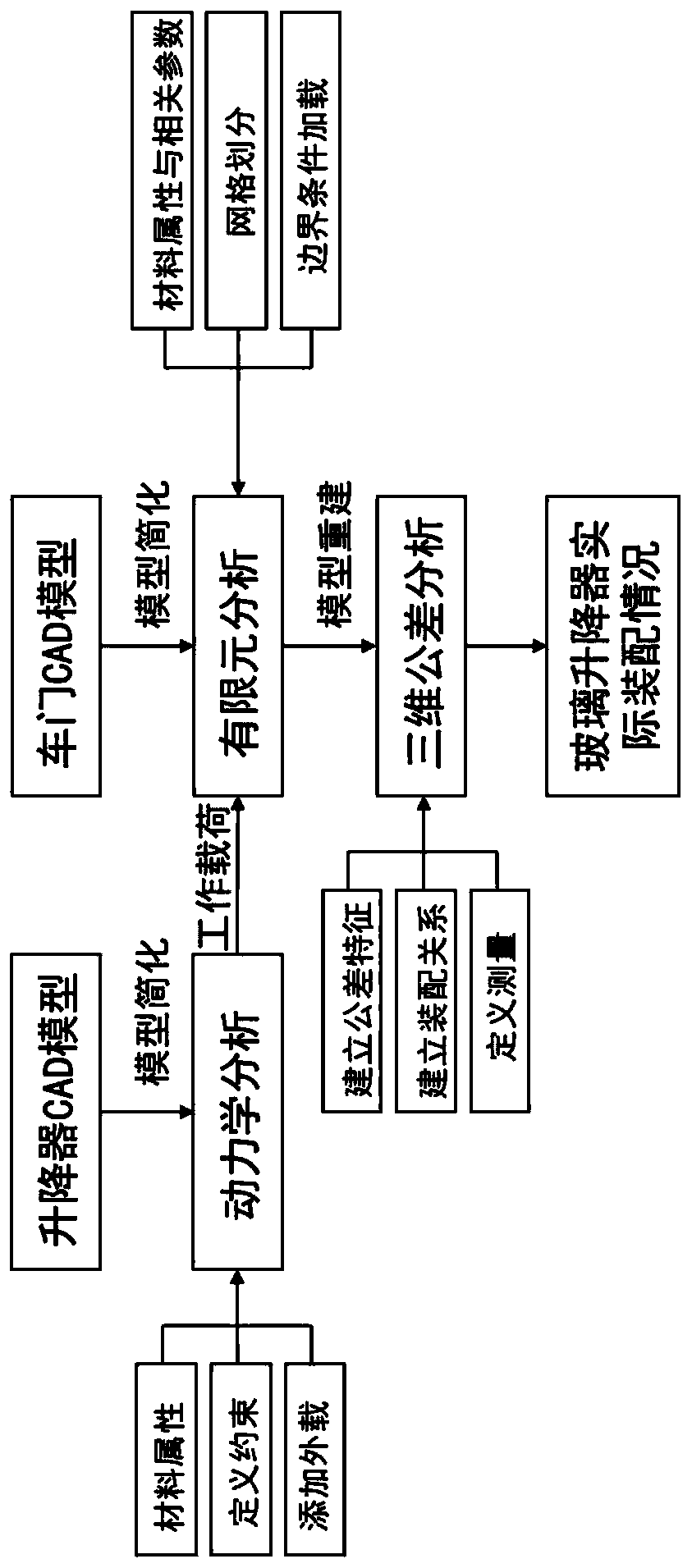

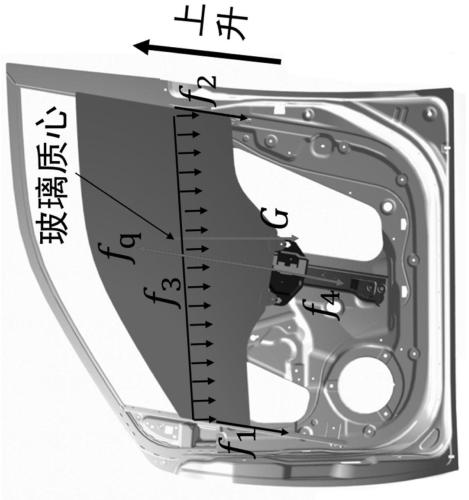

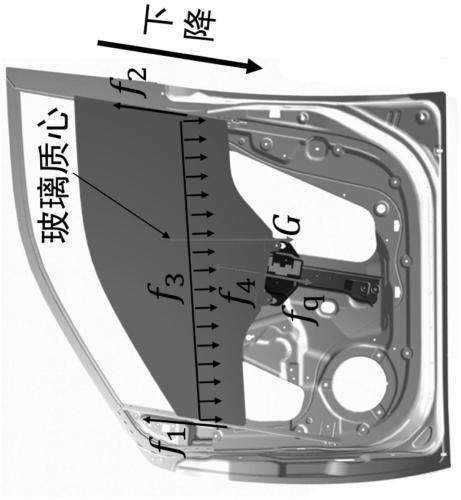

Glass lifter three-dimensional flexible assembly tolerance prediction method based on finite element

PendingCN111209705AImprove ride comfort design levelImprove lifting smoothnessDesign optimisation/simulationPredictive methodsClassical mechanics

The invention relates to a glass lifter three-dimensional flexible assembly tolerance prediction method based on a finite element, and the method comprises the steps: 1, building a glass lifter dynamic simulation analysis model, and obtaining a lifting load; 2, based on the extracted lifting load, calculating the rigidity expression of the vehicle door inner plate under the action of the load, andobtaining the deformation of the upper and lower mounting surfaces of the glass lifter; 3, reconstructing lifter mounting surface characteristics according to an obtained deformation result, and establishing a three-dimensional flexible assembly tolerance model of the glass lifter; and 4, defining the ratio of the out-of-tolerance rate reduction amplitude to the tolerance reduction as the yield ratio of the tolerance reduction, and taking the yield ratio as an evaluation index to realize the tolerance optimization design of the vehicle window lifting system. According to the method, the finite element and three-dimensional tolerance design combined method is adopted, the influence of lifting loads on the assembly relation is considered, the influence of sealing resistance and the rigidityof the vehicle door inner plate on the assembly state of the lifter is revealed, the assembly relation of the glass and the sealing strip is guaranteed by optimizing tolerance design, and the liftingsmoothness is improved.

Owner:TONGJI UNIV

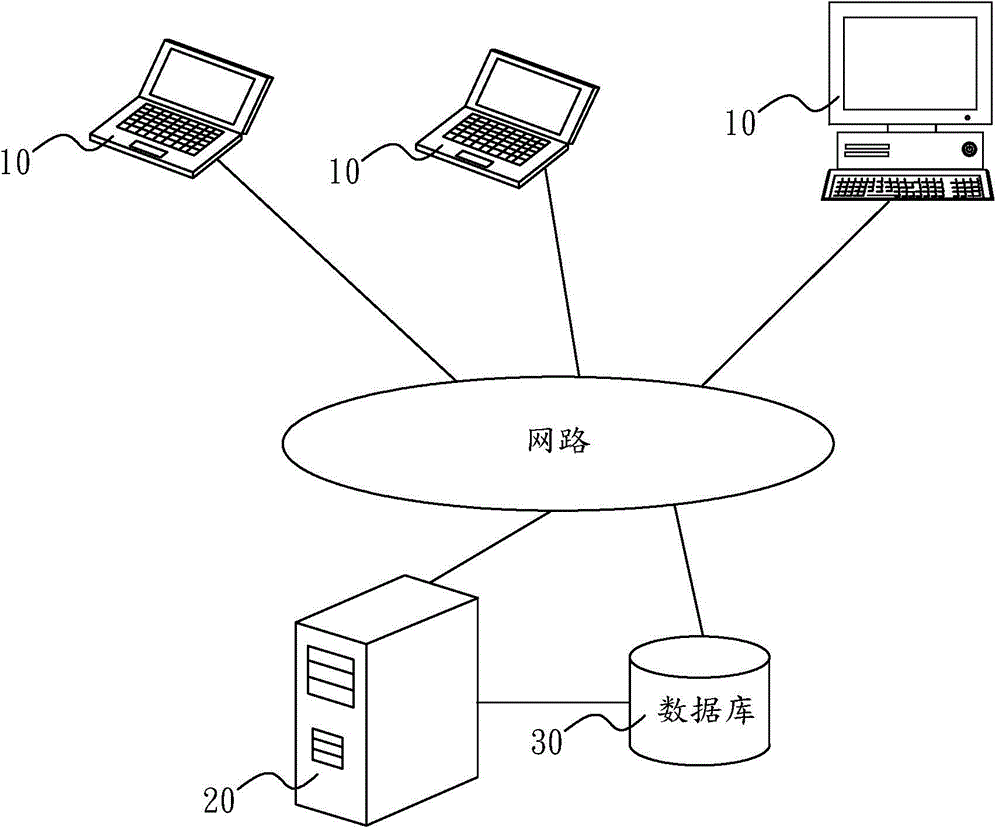

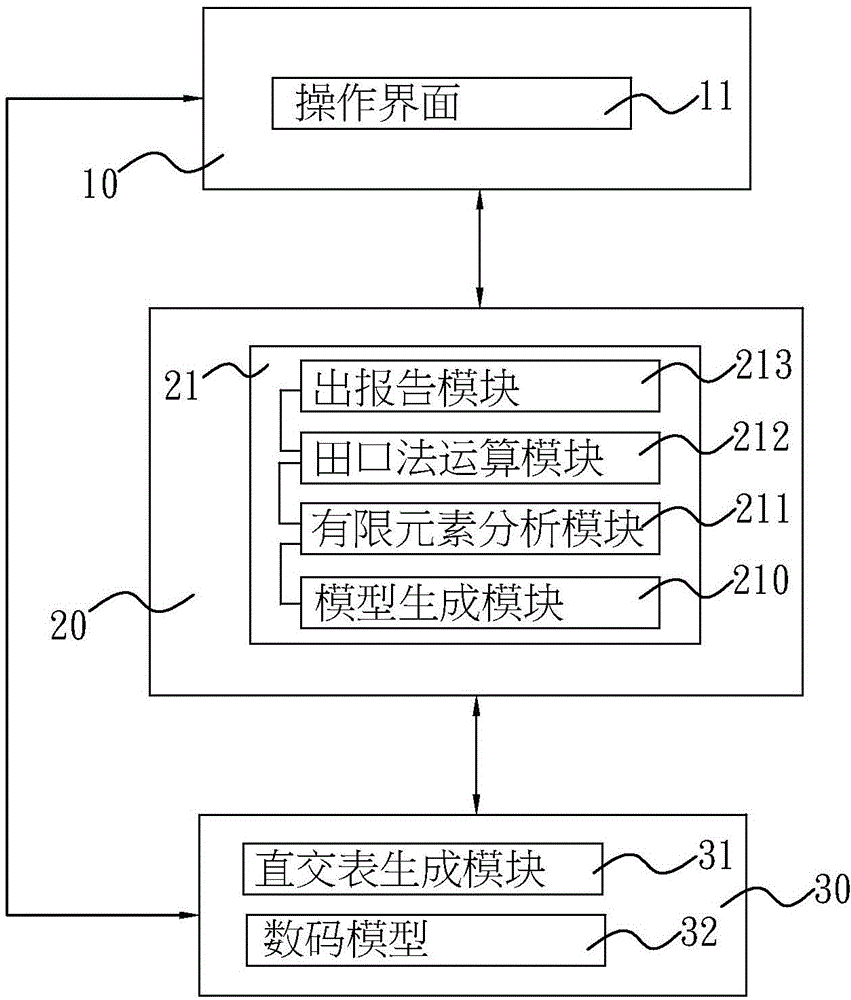

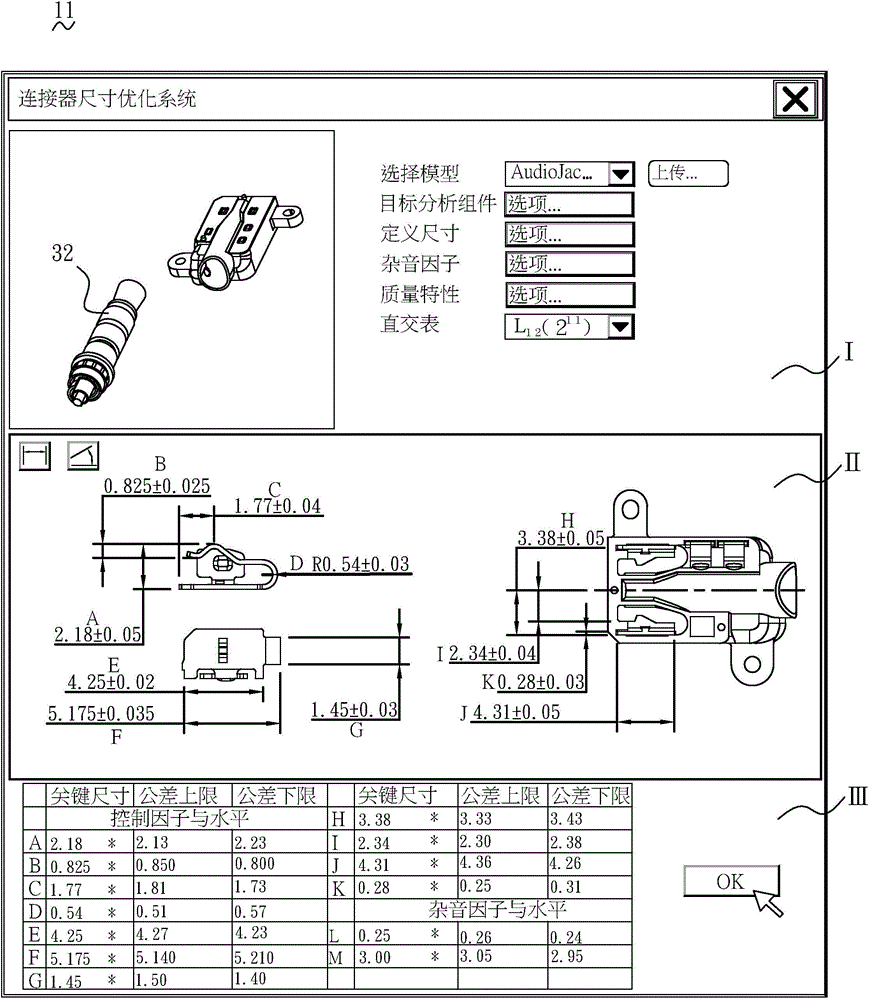

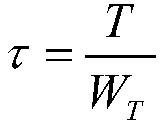

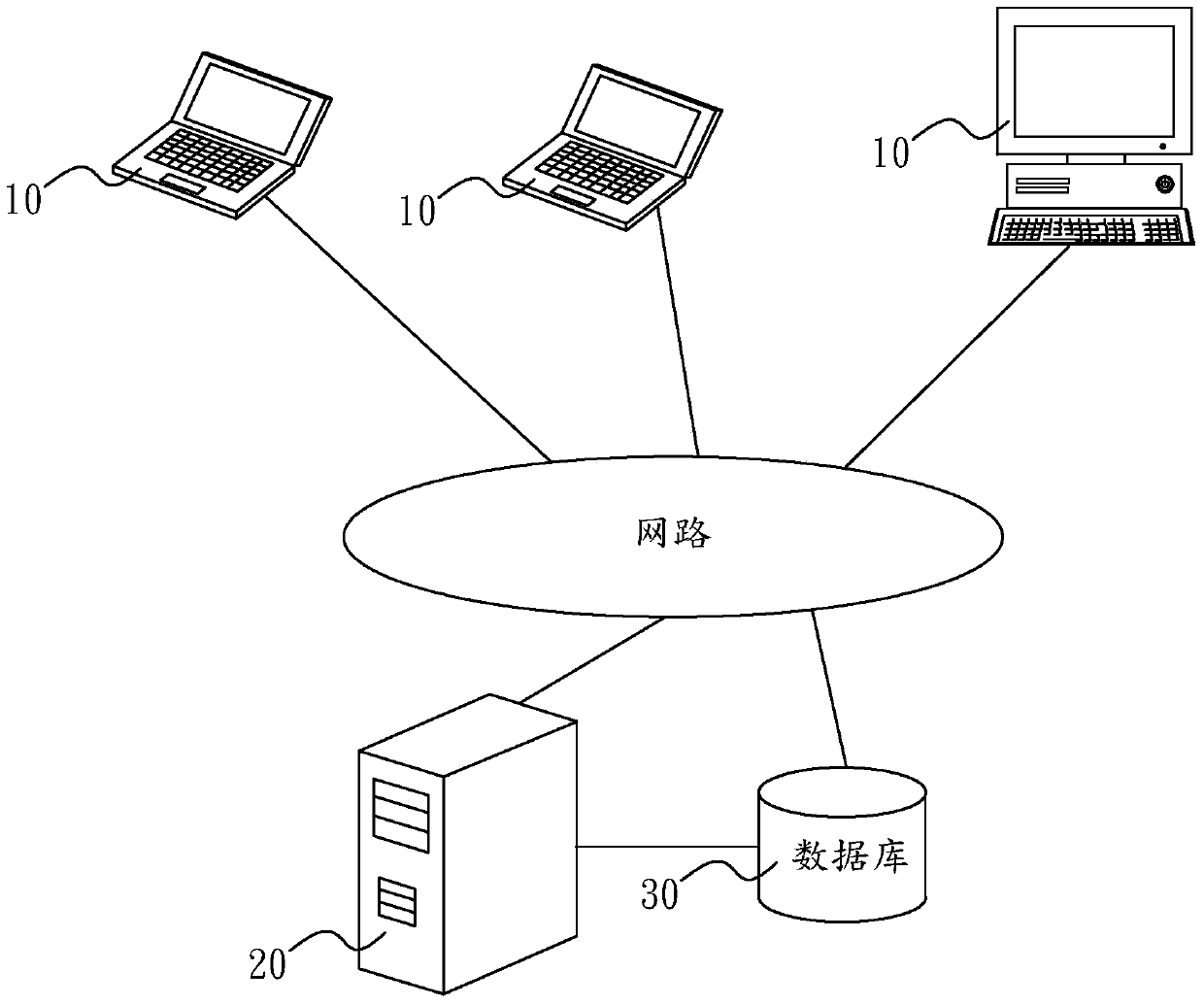

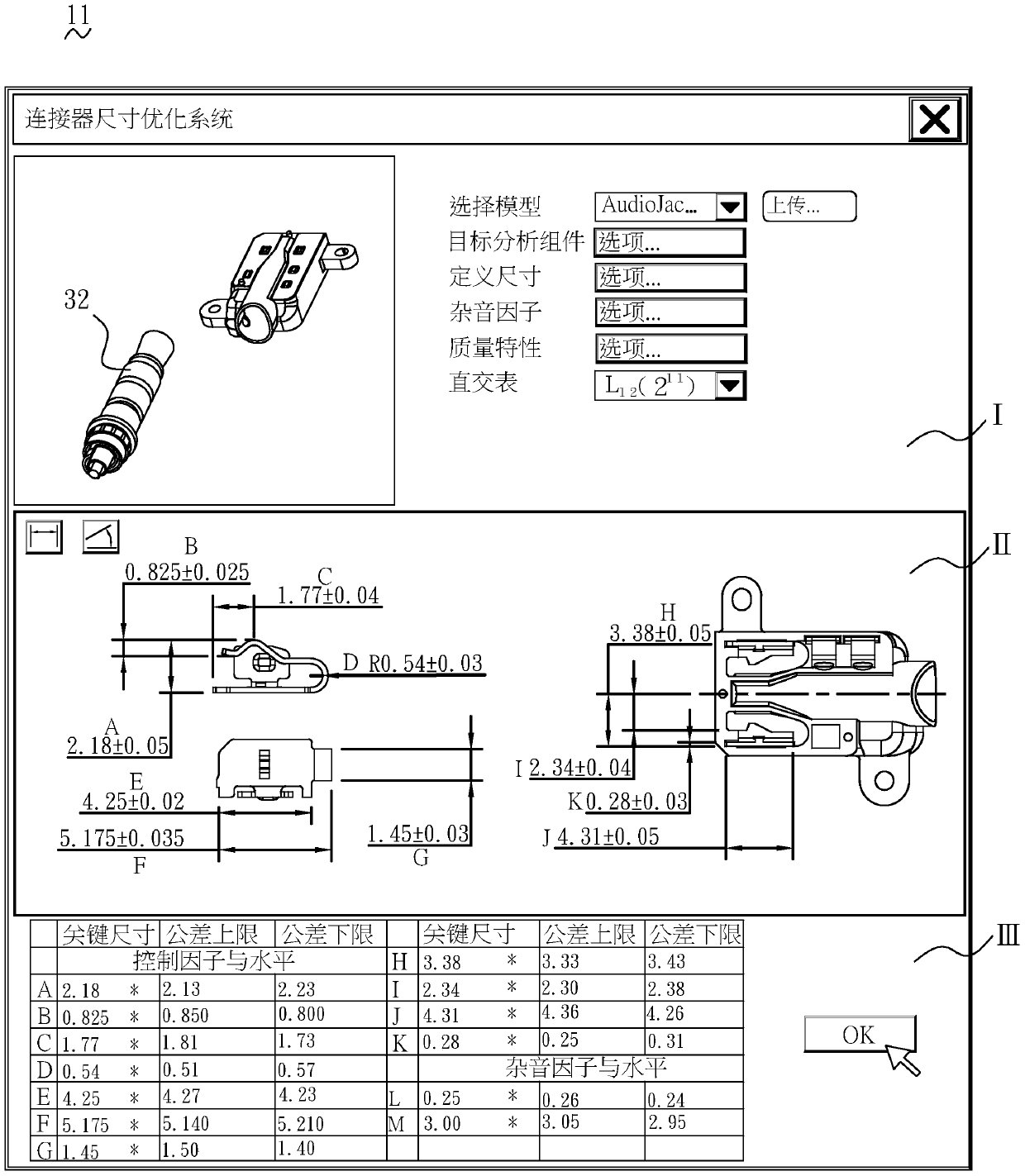

Connector dimension optimization system and connector dimension optimization system

InactiveCN105095538ASmall sizeImprove toleranceSpecial data processing applicationsTarget analysisUser input

The invention discloses a connector dimension optimization system and a connector dimension optimization method, which are used for manufacturing a connector dimension and tolerance optimization analysis report. The connector dimension optimization system comprises an operation interface, an engineering module, an orthogonal table generating module and a digital model, wherein the operation interface is used for inputting analysis conditions and calling the engineering module and the orthogonal table generating module to execute the analysis conditions; and the analysis conditions include an input target analysis assembly, quality features, a terminal thickness tolerance, a connection dimension tolerance, an orthogonal table format, a key dimension and a tolerance. The connector dimension optimization system and the connector dimension optimization method have the advantages that a Taguchi analysis report can be automatically output after a user inputs the analysis conditions, so that the basis for optimizing the connector dimension and tolerance is obtained; and the goals of reducing the production cost and reducing the development time are achieved.

Owner:DONGGUAN FUQIANG ELECTRONICS +1

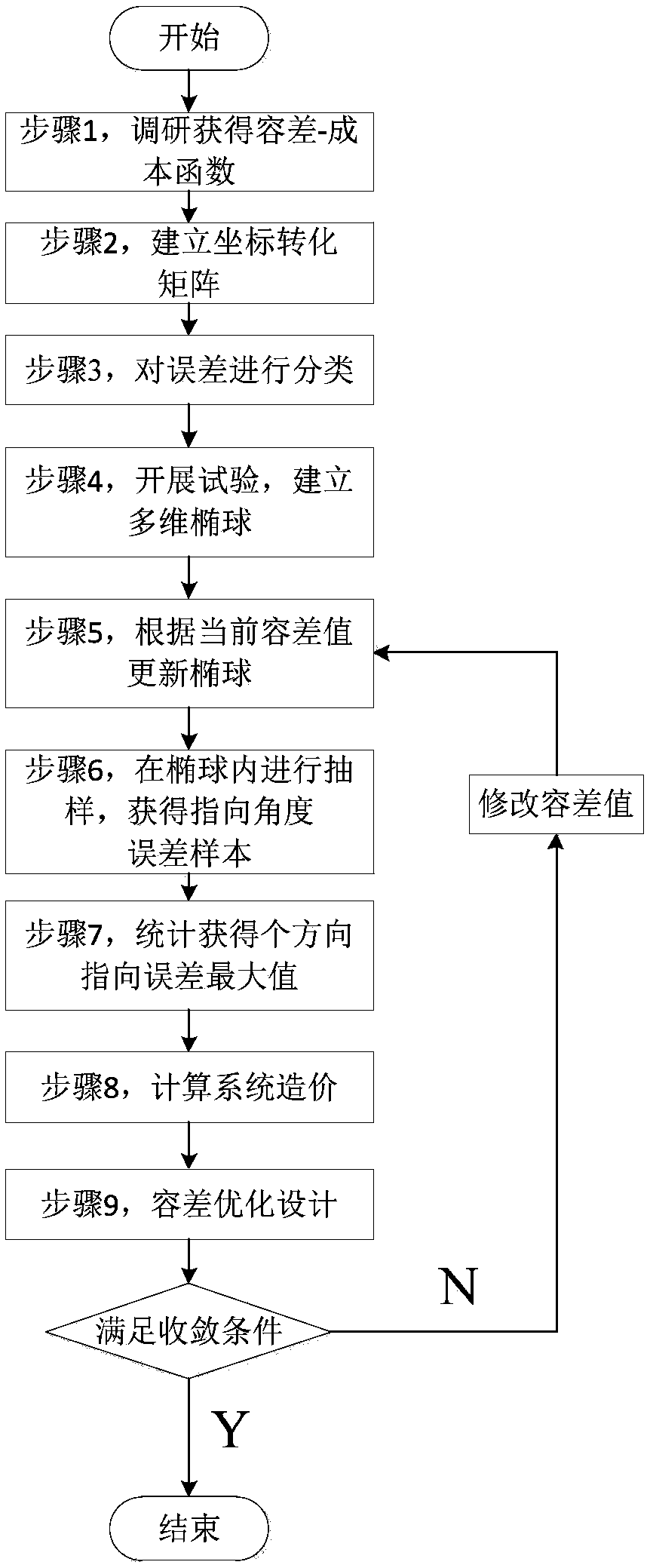

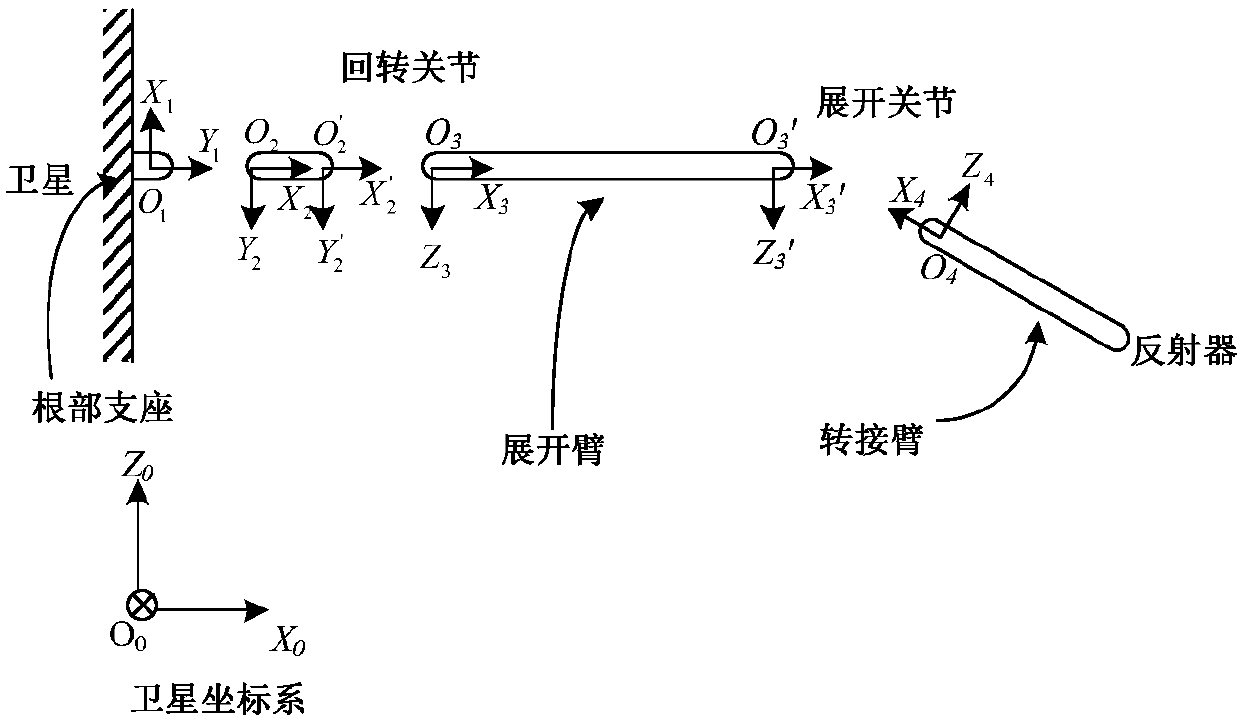

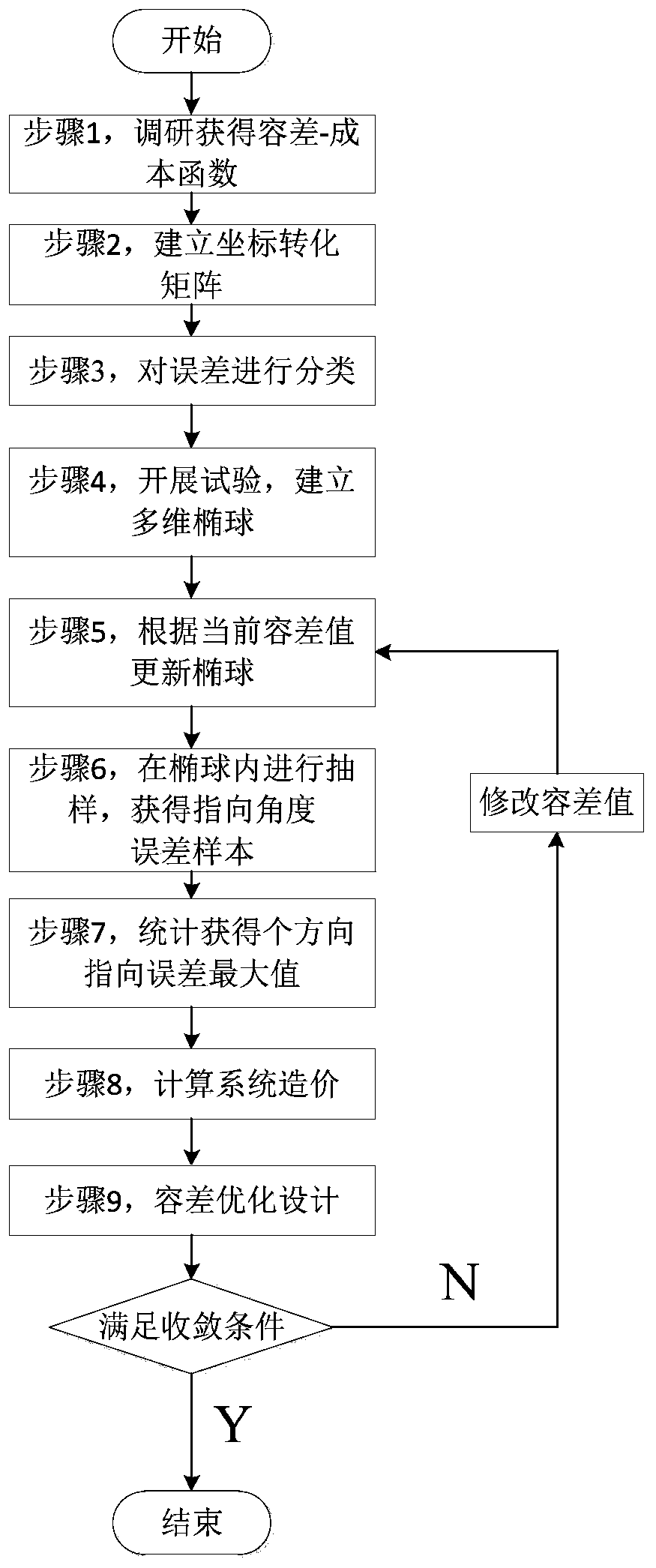

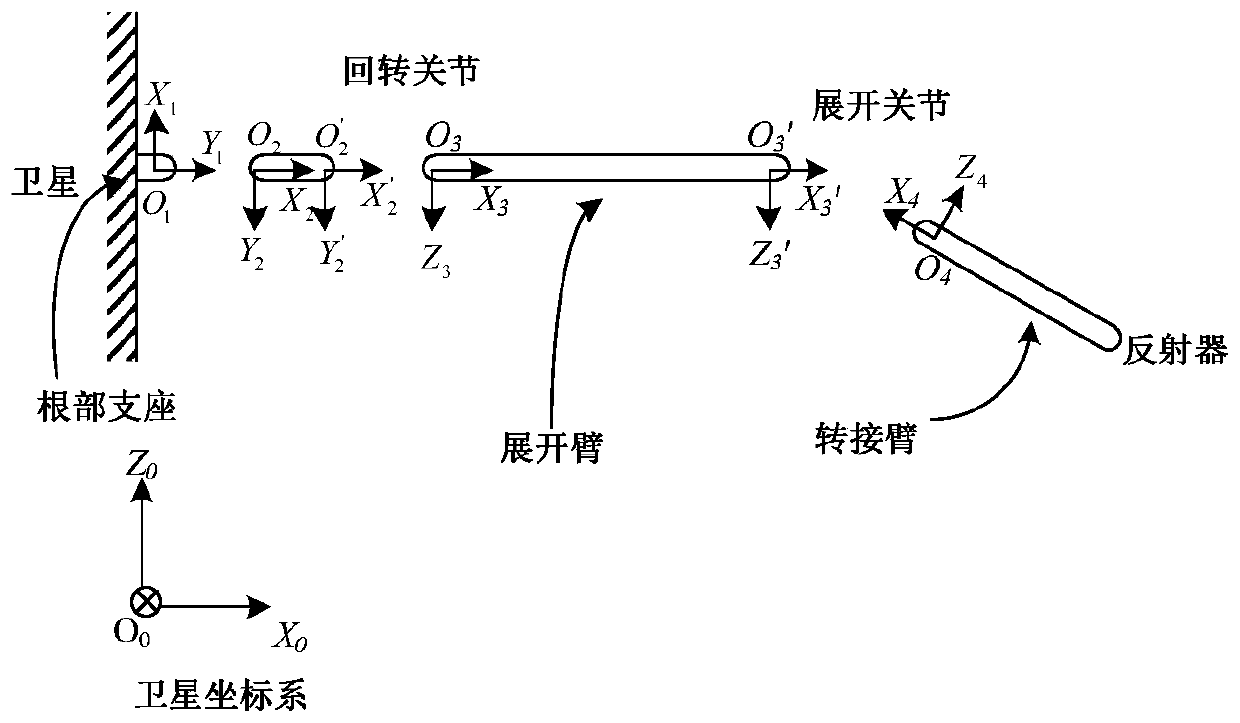

Ellipsoidal model-based expandable antenna unfolding arm tolerance design method

ActiveCN107863599ACorrelation representationFit the actual engineeringPivotable antennasDesign optimisation/simulationMathematical modelEngineering

The invention relates to a related ellipsoidal model-based expandable antenna unfolding arm joint tolerance design method. According to the method, a coordinate conversion matrix from a reflector on the end part of an unfolding arm to a satellite coordinate system is established firstly; and meanwhile, a tolerance-cost relation is obtained through research analysis. Specific to the overall structural form of the unfolding arm, various errors in the multi-stage unfolding arms are classified based on correlation; meanwhile, specific to each type of errors with internal correlation, an ellipsoidal mathematical model which represents the correlation is obtained through tests; next, Monte Carlo random sampling is performed in the ellipsoidal sphere, and a final angle error of the reflector is obtained based on the coordinate conversion matrix; and finally, by taking the total cost minimization as the object, by taking tolerance as a design variable, and by taking pointed error for satisfying design requirement as the constraint, tolerance optimization design is performed. A simulation structure shows that effective unfolding arm joint tolerance design can be realized by the method, andmeanwhile, design difficulty of the conventional method caused by no consideration of the correlation is avoided.

Owner:XIDIAN UNIV

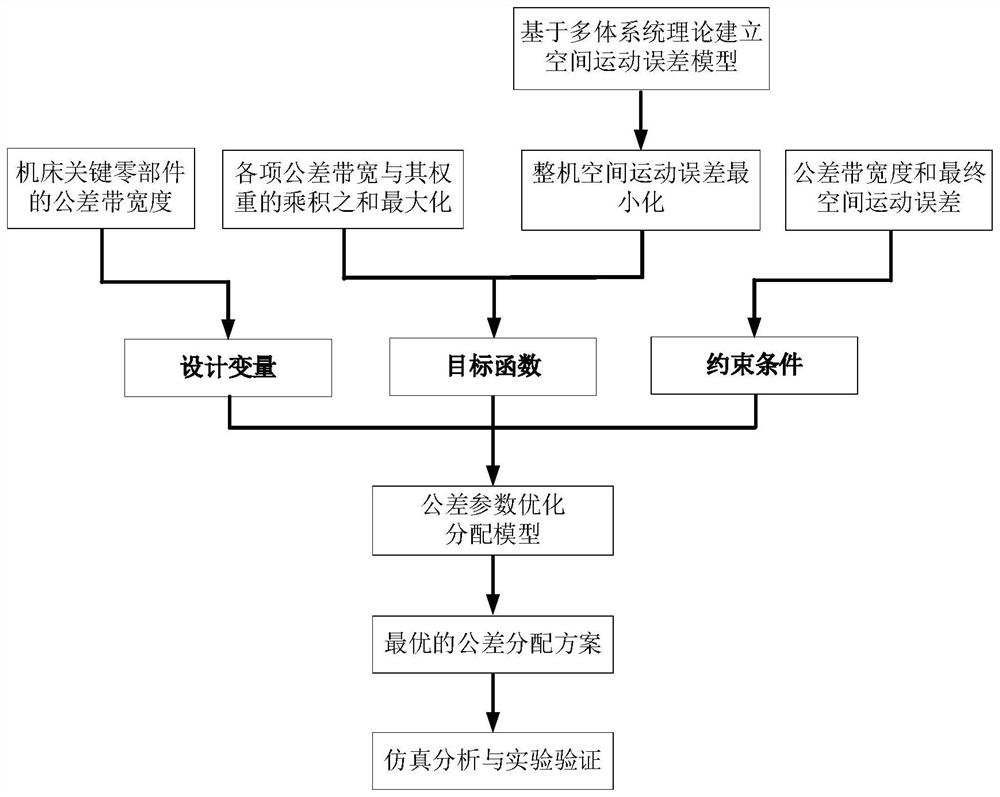

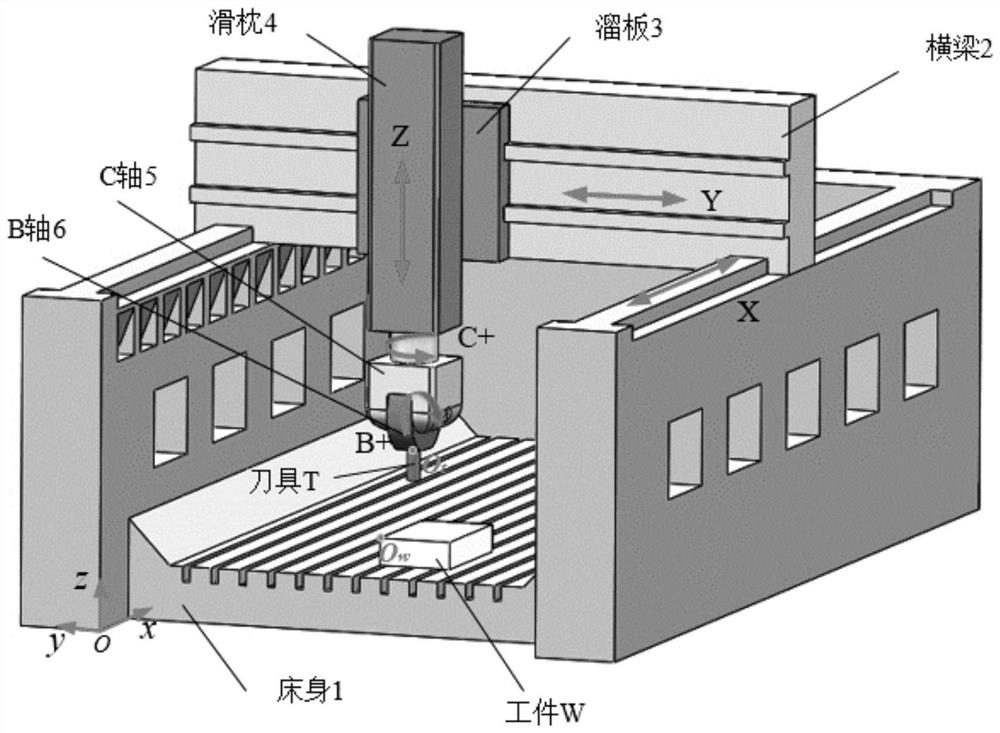

Tolerance optimization design method of key part of multi-axis numerical control machine tool

The invention discloses a tolerance optimization design method of key parts of a multi-axis numerical control machine tool, and belongs to the technical field of machine tool precision optimization design. The invention particularly relates to a multi-axis numerical control machine tool space error modeling method based on a multi-body system theory and an optimization design method of tolerance parameters of key parts of a multi-axis numerical control machine tool. According to the method, a multi-axis numerical control machine tool space error model and a multi-target optimization distribution model of tolerance parameters of key parts of a multi-axis numerical control machine tool are established; and in an initial design stage of a machine tool, tolerance parameters of key parts of the multi-axis numerical control machine tool are optimally distributed, so that most of the tolerance parameters can be relaxed to different degrees, the whole machine manufacturing cost of the numerical control machine tool is indirectly reduced, and the machine tool with the optimally distributed tolerance parameters can obtain higher machining precision.

Owner:ANHUI SCI & TECH UNIV

A method and system for optimizing tolerance of K&C characteristics of automobile suspension

ActiveCN107247830BShorten development timeLow costGeometric CADSpecial data processing applicationsKinetic modelRolling chassis

The invention provides an automobile suspension K&C characteristic tolerance optimization method. The method includes: building a chassis kinetic model according to each coordinate in a hard spot table, and building a first correlation between suspension hard spot tolerance and suspension K&C characteristic tolerance; analyzing the tolerance of the coordinates of key hard spots, and building a second correlation between the suspension hard spot tolerance and part tolerance; according to the first correlation and the second correlation, acquiring the third correlation between the suspension K&C characteristic tolerance and the part tolerance, and acquiring the influence quantity representing the influence of each part tolerance on the suspension K&C characteristic tolerance; when the accumulated tolerance of the suspension K&C characteristic tolerance exceeds a preset tolerance range threshold, prompting that design alteration needs to be performed on part structures or tolerance with high influence quantity so as to allow the final accumulated tolerance to be located within the preset tolerance range threshold. The invention further provides a corresponding system. By the automobile suspension K&C characteristic tolerance optimization method, development time can be shortened evidently, and cost can be saved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Tolerance optimization distribution method

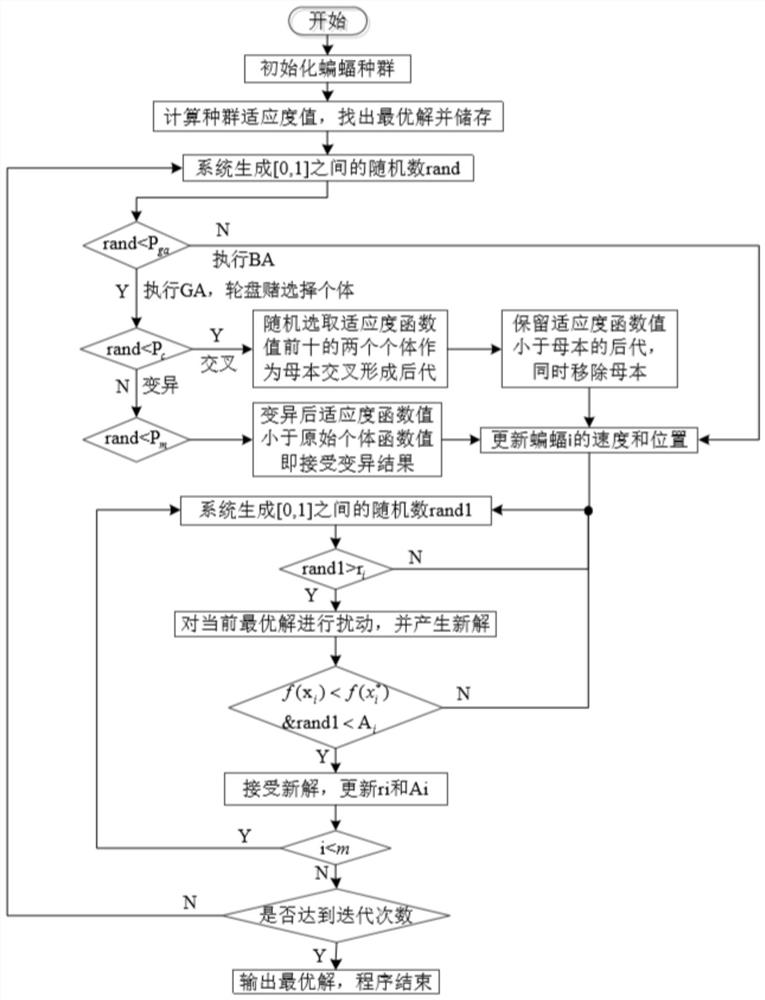

PendingCN112749517AUnderstand the purposeLearn about featuresGeometric CADArtificial lifeMutation operatorAlgorithm

The invention discloses a tolerance optimization distribution method, which comprises the following steps of: (1) constructing a fitness function which takes the total processing cost, total mass loss and total sensitivity cost as objective functions and takes processing capacity and assembly tolerance constraint as constraint conditions, and determining a weight factor between the objective functions by adopting an analytic hierarchy process; (2) importing assembly information into the fitness function; and (3) solving the fitness function by adopting an improved bat algorithm and outputting a result, wherein the improved bat algorithm is obtained by introducing a crossover operator and a mutation operator of a genetic algorithm into the bat algorithm.

Owner:ZHEJIANG UNIV

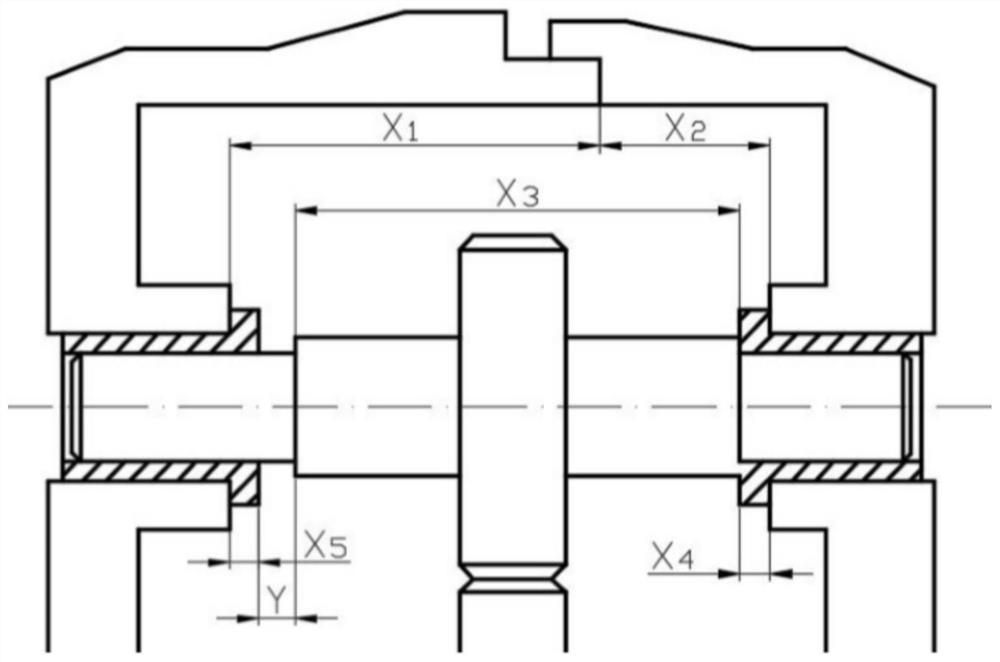

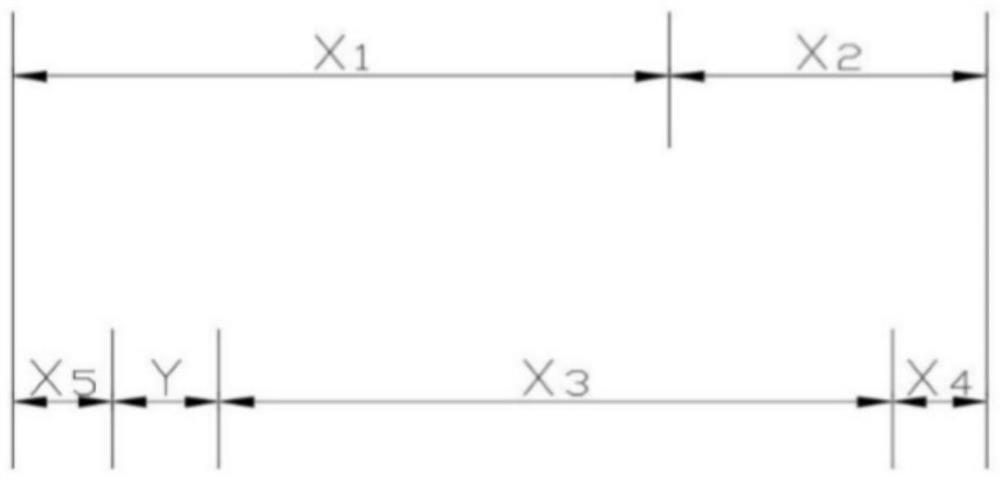

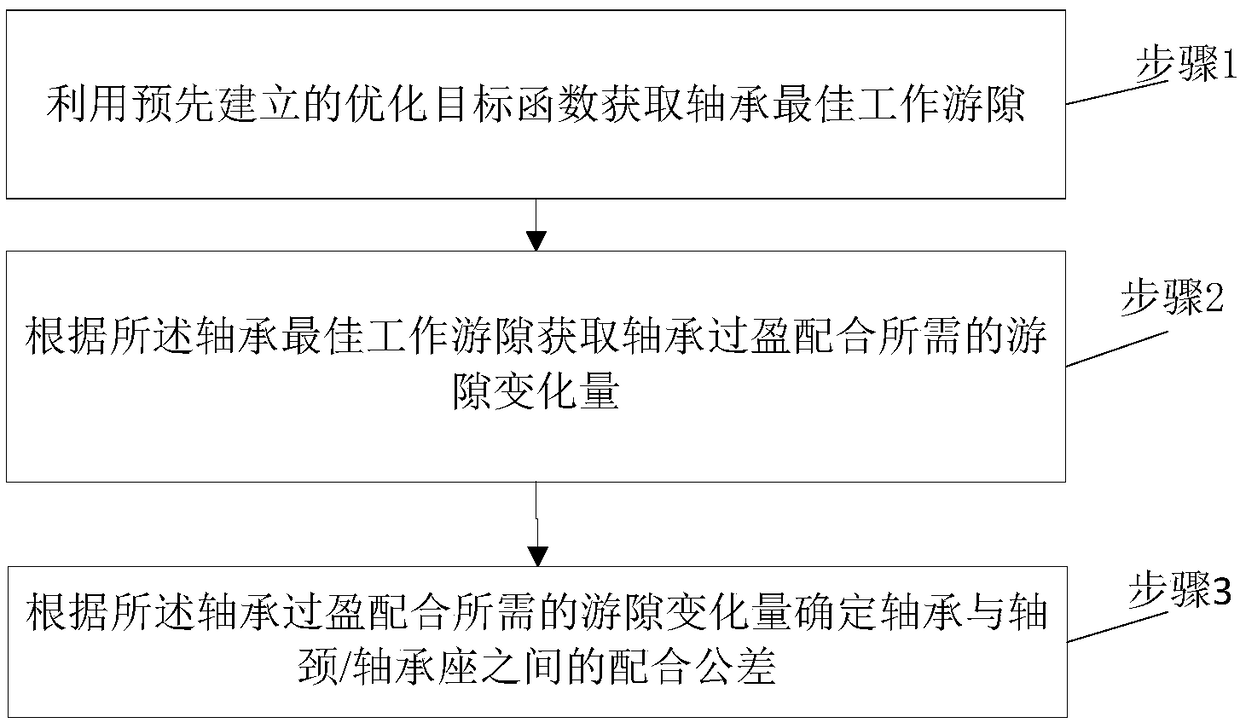

A bearing fitting tolerance optimization design method and device

PendingCN108984968ABest working clearanceMaximum service lifeGeometric CADSpecial data processing applicationsInterference fitFixed service

The invention relates to a bearing fitting tolerance optimization design method and device. The method comprises the following steps: obtaining the optimal working clearance of a bearing by using an optimized objective function established in advance; obtaining the clearance change amount required by the bearing interference fit according to the optimal working clearance of the bearing; and determining the fit tolerance between the bearing and the journal / bearing housing according to the clearance change amount required by the bearing interference fit. The technical scheme provided by the invention realizes the best working clearance of the bearing by optimizing the fitting tolerance between the bearing and the journal / bearing housing, thereby realizing the maximum minimum fixed service life of the bearing supported by the shaft system, and providing the design basis for the fine design of the shaft system and the transmission case.

Owner:CHINA NORTH VEHICLE RES INST

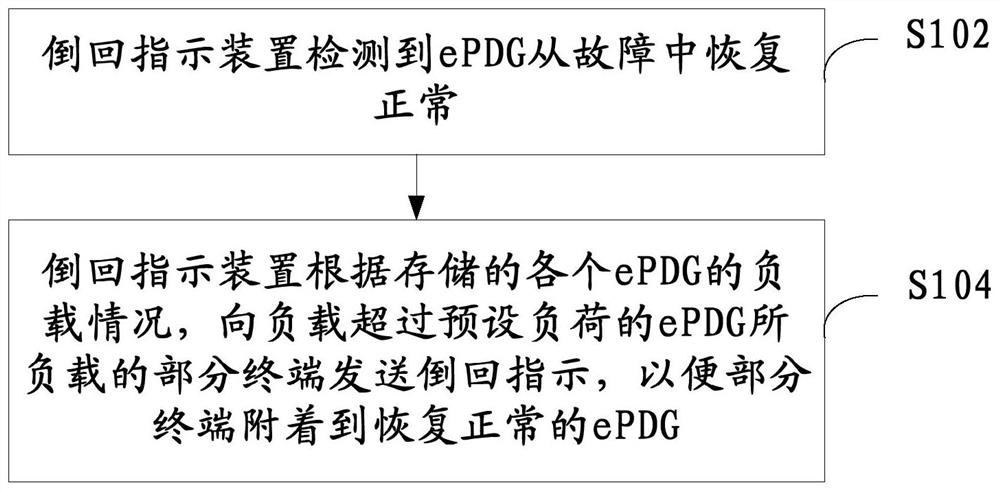

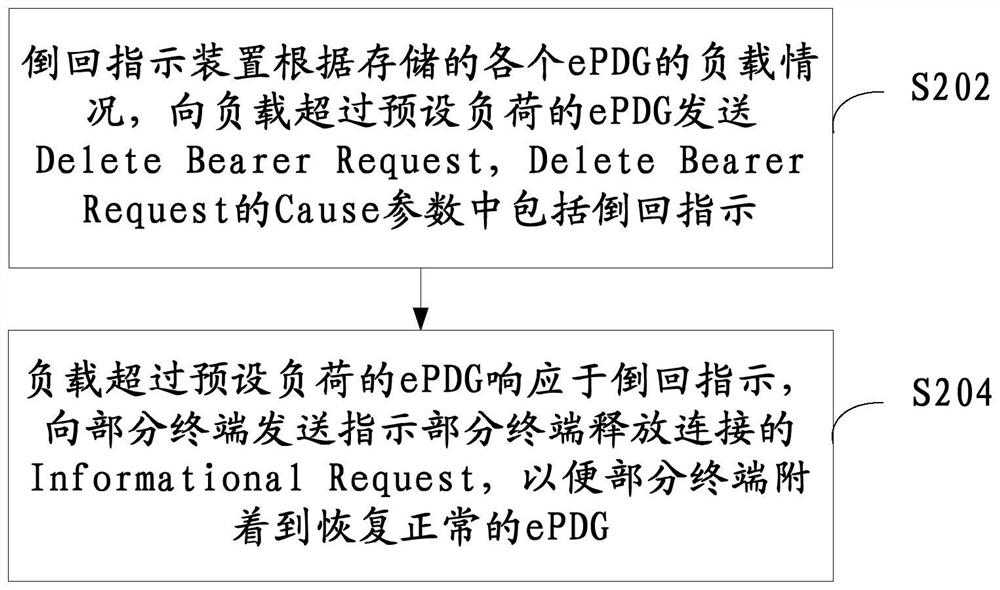

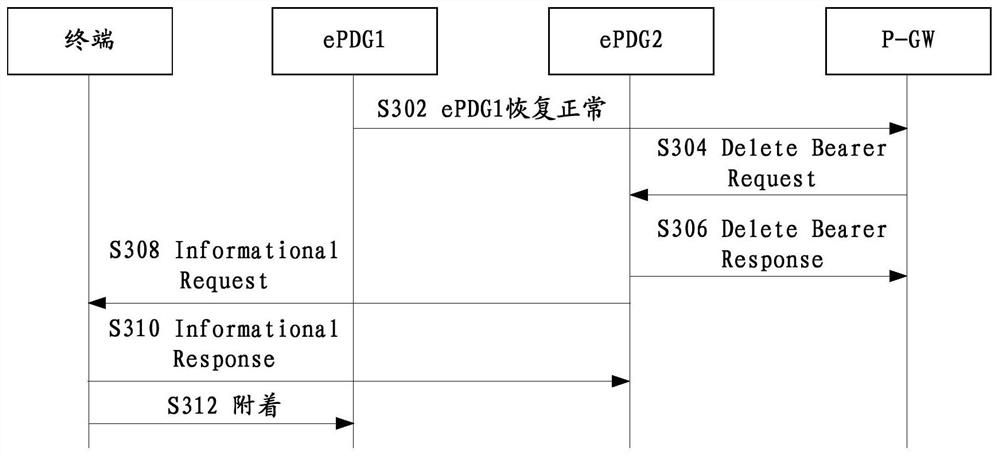

Disaster recovery optimization method and system, and fallback indicating device

The invention discloses a disaster recovery optimization method, a system and a fallback indicating device, and relates to the field of mobile communication. The disaster recovery optimization method includes: the rewinding indicating device detects that the evolved packet data gateway ePDG recovers from a failure; the reversing indicating device sends the load to the part of the ePDG whose load exceeds the preset load according to the stored load conditions of each ePDG The terminal sends a rewind indication, so that some terminals can attach to the recovered ePDG. After detecting that the ePDG returns to normal from a fault, send a revert instruction to some terminals loaded by the ePDG whose load exceeds the preset load, so that some terminals are attached to the recovered ePDG, so that the load of each ePDG after disaster recovery tends to balanced.

Owner:CHINA TELECOM CORP LTD

An Optimal Design Method for Assembly Tolerance Based on Genetic Algorithm

InactiveCN103902759BImprove robustnessStrong application potentialGenetic modelsSpecial data processing applicationsRobustificationAlgorithm

The invention relates to an assembly tolerance optimization designing method based on the genetic algorithm. The method comprises the steps that a target function for assembly tolerance optimization is established with the minimum processing cost of an assembly body as the optimization target; the constraint conditions of assembly tolerance are determined; tolerance type information is added to a VGC network to obtain a tolerance network of the assembly body and the value range of dimensional tolerance of various assembly features and the value range of geometric tolerance of the assembly features are selected and determined; genetic coding is conducted by the adoption of a multi-parameter cascade coding method; a fitness function is determined; an operator function is selected and determined; operating parameters of the genetic algorithm are determined. According to the assembly tolerance optimization designing method based on the genetic algorithm, the genetic algorithm shows great application potential through the global searching capacity, the high robustness and the calculation parallelism.

Owner:XIJING UNIV

Step-by-step tolerance optimization method for electromagnetic relay based on changing contribution rate

ActiveCN107016141BHigh tolerance optimization speedAutomatic adjustment factor tolerance rangeDesign optimisation/simulationCAD circuit designAlgorithmControl theory

The invention discloses an electromagnetic relay step tolerance optimization method based on varying contribution rates. The method comprises the steps of S1, determining a tolerance optimization standard; according to the relations between key elements and output characteristics and an actual processing capacity, determining a tolerance range of the key elements; S2, determining a number of levels of the key elements; design an orthogonal test, and calculating an output result of each group of orthogonal test; solving the contribution rates of all the key elements; S3, according to a certain tolerance step length, subtracting the contribution rates with the tolerance to obtain a new tolerance range of the key elements; calculating the concentration rates of all the key elements again; S4, in the new tolerance range determined in the step S3, solving an output characteristic fluctuation range of the corresponding new tolerance range; S5, repeating work in the step S3 and S4 till the output characteristic fluctuation range meets the tolerance optimization standard, or the new tolerance range reaches a processing precision lower limit, wherein the new tolerance range is a final result of step tolerance optimization.

Owner:HARBIN INST OF TECH

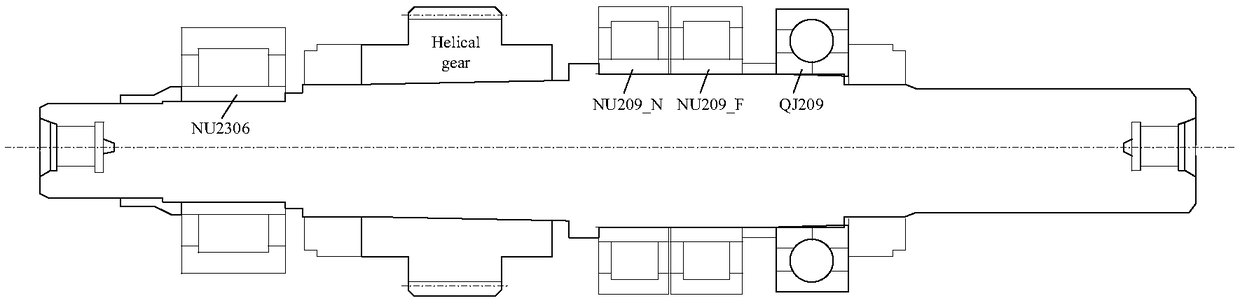

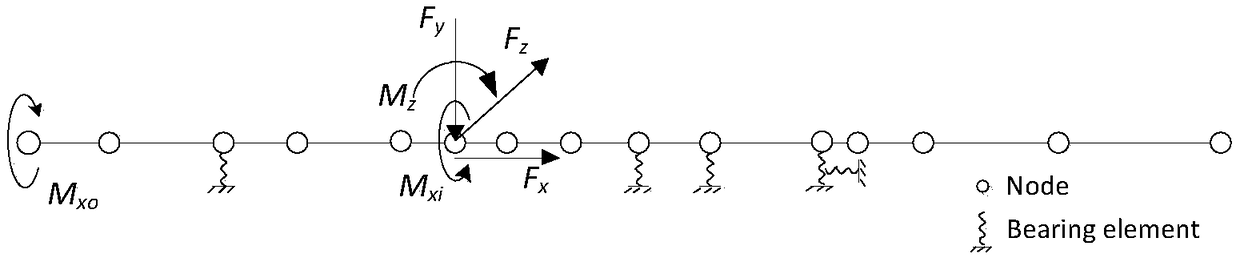

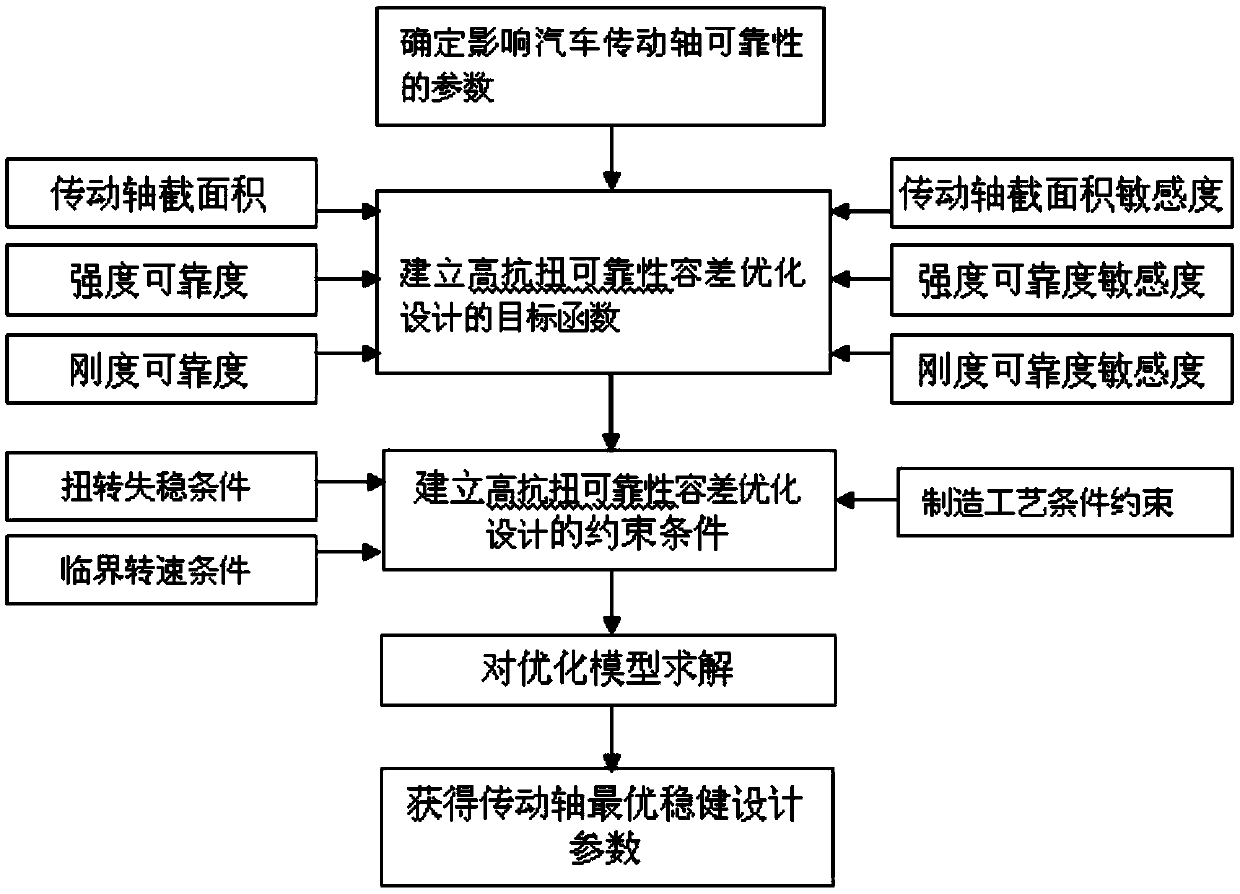

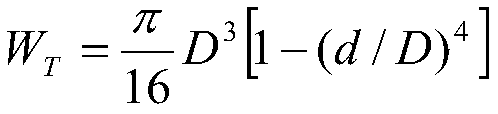

Automobile transmission shaft high-antitorque-reliability tolerance optimization design method

PendingCN108920764AImprove reliabilityRobust Design ParametersGeometric CADSpecial data processing applicationsDrive shaftReliability design

The invention discloses an automobile transmission shaft high-antitorque-reliability tolerance optimization design method. The method includes following steps: according to structure and material characteristic of an automobile transmission shaft, determining parameters having impact on reliability of the automobile transmission shaft; building a multi-target function of automobile transmission shaft high-antitorque-reliability tolerance optimization design; building optimization design multimode constraint conditions; solving an automobile transmission shaft high-antitorque-reliability tolerance optimization design model to acquire optimal design parameters. Antitorque strength reliability, antitorque rigidity reliability and weight of the transmission shaft are taken as a target function, the antitorque reliability and section area sensitivity information are embedded in the target function, and constraint conditions of parameters are taken into comprehensive consideration, so that high reliability of the transmission shaft can still be maintained while design parameter perturbation is ensured, and size and weight of a transmission device are reduced; the problem of key technology in automobile transmission device reliability design is solved.

Owner:WENZHOU UNIVERSITY

Connector size optimization system and method

InactiveCN105095538BSmall sizeImprove toleranceSpecial data processing applicationsTarget analysisUser input

The invention discloses a connector dimension optimization system and a connector dimension optimization method, which are used for manufacturing a connector dimension and tolerance optimization analysis report. The connector dimension optimization system comprises an operation interface, an engineering module, an orthogonal table generating module and a digital model, wherein the operation interface is used for inputting analysis conditions and calling the engineering module and the orthogonal table generating module to execute the analysis conditions; and the analysis conditions include an input target analysis assembly, quality features, a terminal thickness tolerance, a connection dimension tolerance, an orthogonal table format, a key dimension and a tolerance. The connector dimension optimization system and the connector dimension optimization method have the advantages that a Taguchi analysis report can be automatically output after a user inputs the analysis conditions, so that the basis for optimizing the connector dimension and tolerance is obtained; and the goals of reducing the production cost and reducing the development time are achieved.

Owner:DONGGUAN FUQIANG ELECTRONICS +1

Tolerance Design Method of Deployable Antenna Deployment Arm Based on Ellipsoid Model

ActiveCN107863599BCorrelation representationFit the actual engineeringPivotable antennasDesign optimisation/simulationMathematical modelEngineering

The invention relates to a related ellipsoidal model-based expandable antenna unfolding arm joint tolerance design method. According to the method, a coordinate conversion matrix from a reflector on the end part of an unfolding arm to a satellite coordinate system is established firstly; and meanwhile, a tolerance-cost relation is obtained through research analysis. Specific to the overall structural form of the unfolding arm, various errors in the multi-stage unfolding arms are classified based on correlation; meanwhile, specific to each type of errors with internal correlation, an ellipsoidal mathematical model which represents the correlation is obtained through tests; next, Monte Carlo random sampling is performed in the ellipsoidal sphere, and a final angle error of the reflector is obtained based on the coordinate conversion matrix; and finally, by taking the total cost minimization as the object, by taking tolerance as a design variable, and by taking pointed error for satisfying design requirement as the constraint, tolerance optimization design is performed. A simulation structure shows that effective unfolding arm joint tolerance design can be realized by the method, andmeanwhile, design difficulty of the conventional method caused by no consideration of the correlation is avoided.

Owner:XIDIAN UNIV

Tolerance optimization allocation method based on tolerance grade and genetic algorithm

ActiveCN102622495BImprove execution efficiencyImprove efficiencyBiological neural network modelsSpecial data processing applicationsMathematical modelComputer aid

Owner:BEIHANG UNIV

A Construction Method of Assembly Tolerance Network

The invention relates to a fitting tolerance network establishing method. The fitting tolerance network establishing method includes extracting fitting information of products from a three-dimensional model of the CAD (computer-aided design) system, generating fitting sequences of the product, and establishing a VGC (viscosity gravity constant) network on the basis of the VGC theory; reasoning to generate three fitting tolerance types via the corresponding relation of the VGC and the tolerance types and tolerance type information input from the step a, adding the fitting tolerance types to the VGC network and establishing a fitting tolerance network; displaying fitting sequence generated in the step b, the VGC network and the fitting tolerance network on the CAD system, and outputting the tolerance network information for tolerance optimization and design. The fitting tolerance design system is established on the CAD system platform, and comprehensive design of fitting dimensional tolerance and geometric tolerance is realized by means of information acquired from a product entity model.

Owner:XIJING UNIV

A Tolerance Optimization Calculation Method of Gear System Based on Dynamic Reliability

ActiveCN106599448BEvaluate work abilityComputational reliabilityGeometric CADDesign optimisation/simulationGear systemDistribution characteristic

The present invention provides a dynamic reliability-based gear system tolerance optimization calculation method. The method comprises a first step of modeling for gear system tolerance degradation, analyzing a design requirement of the gear system and processing routing, and determining a processing characteristic, a distribution characteristic and a cost characteristic of each sensitive tolerance parameter and a time-based degradation rule; a second step of determining a general stress model of the gear system; a third step of determining a strength degradation model of the gear system; a fourth step of calculating dynamic reliability; a fifth step of building a tolerance optimization model; and a sixth step of determining an optimal tolerance. Dynamic reliability is introduced to the field of gear system tolerance optimization, so that the traditional optimization model with total mass loss as the target is changed, and the working capability of the gear system can be evaluated more scientifically and objectively.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com