Automobile chassis rear-overhang part assembly simulated detection tool and detection analysis method

A technology of automobile chassis and detection tooling, which is applied in the direction of measuring devices, optical devices, mechanical devices, etc., to achieve the effect of improving driving performance and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

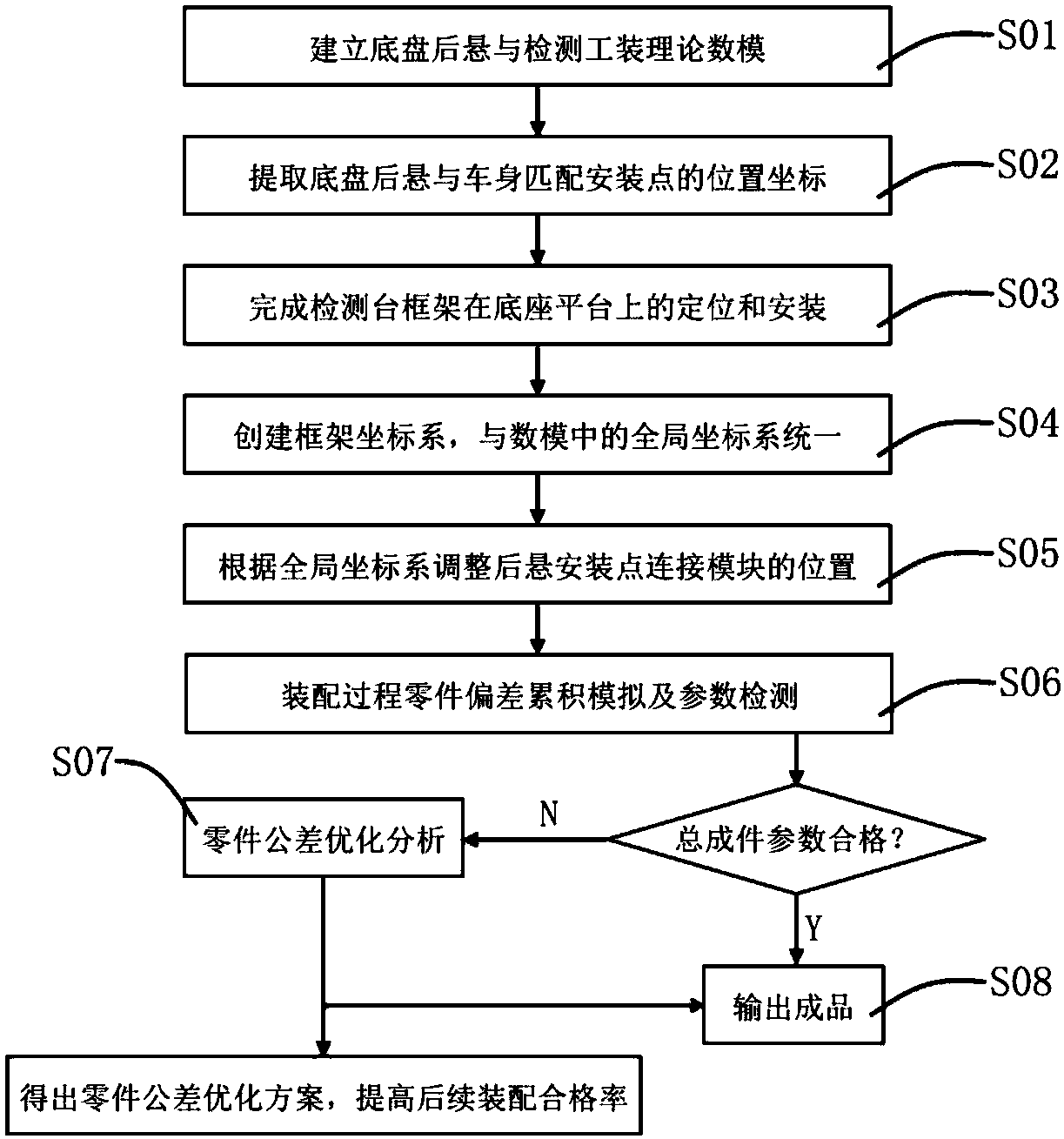

[0034] like figure 1 Shown, a kind of automobile chassis rear suspension part assembly simulation detection analysis method of the present invention comprises steps:

[0035] S01. Establish the model of the rear suspension of the automobile chassis and the detection tooling in the drawing software environment;

[0036] S02. In the drawing software environment, extract the theoretical position data of each installation point on the rear suspension of the chassis;

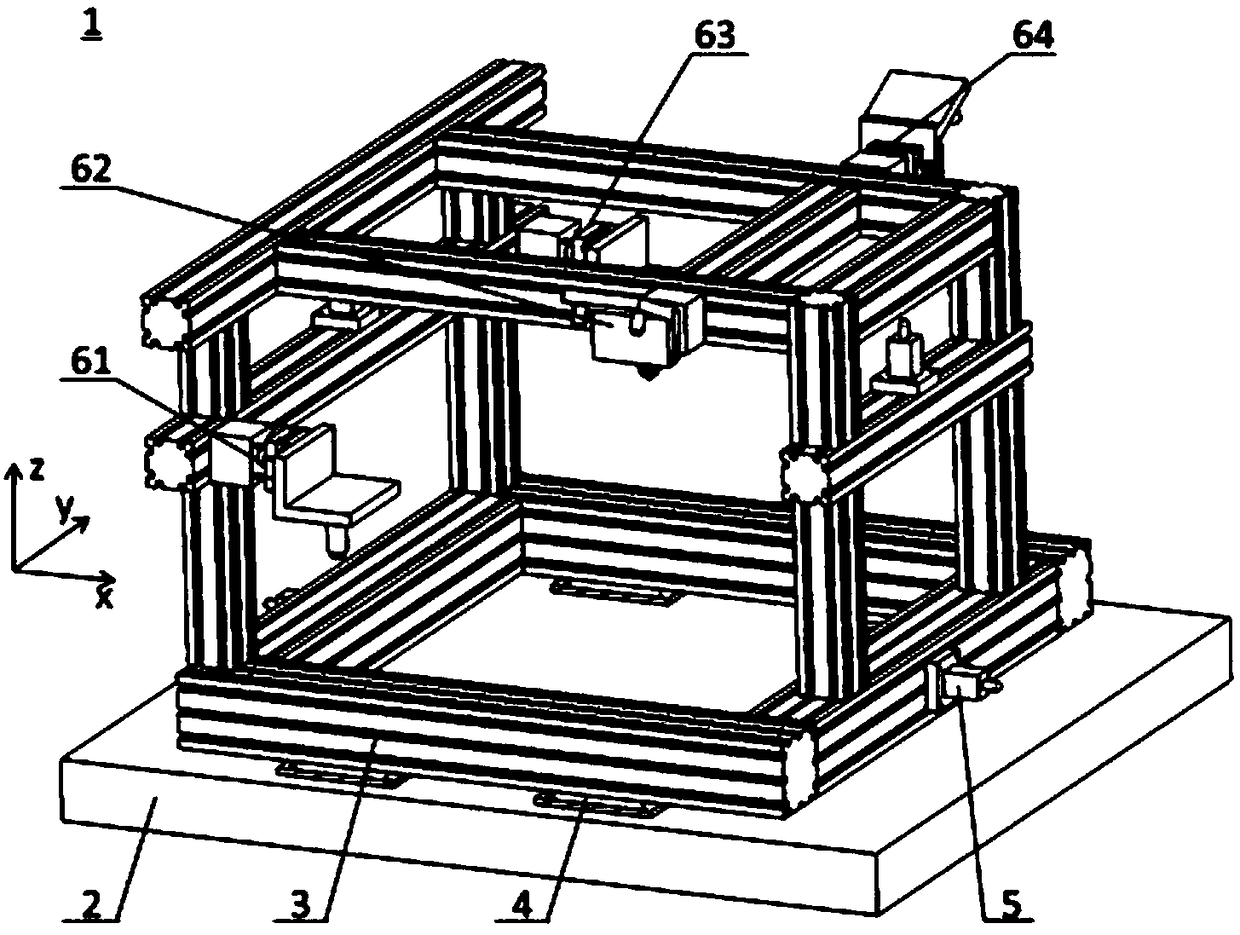

[0037] S03. Place the test bench frame on the base platform, and position and fix the frame on the platform through the frame connecting plate, positioning pins and bolts;

[0038] S04. Create a frame coordinate system with the help of auxiliary measuring equipment, high-precision conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com