Glass lifter three-dimensional flexible assembly tolerance prediction method based on finite element

A glass lifter and flexible assembly technology, applied in instrumentation, design optimization/simulation, electrical digital data processing, etc., can solve the problem of insufficient rigidity of the inner panel of the car door, and achieve the effect of improving the design level of ride comfort and the ride comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

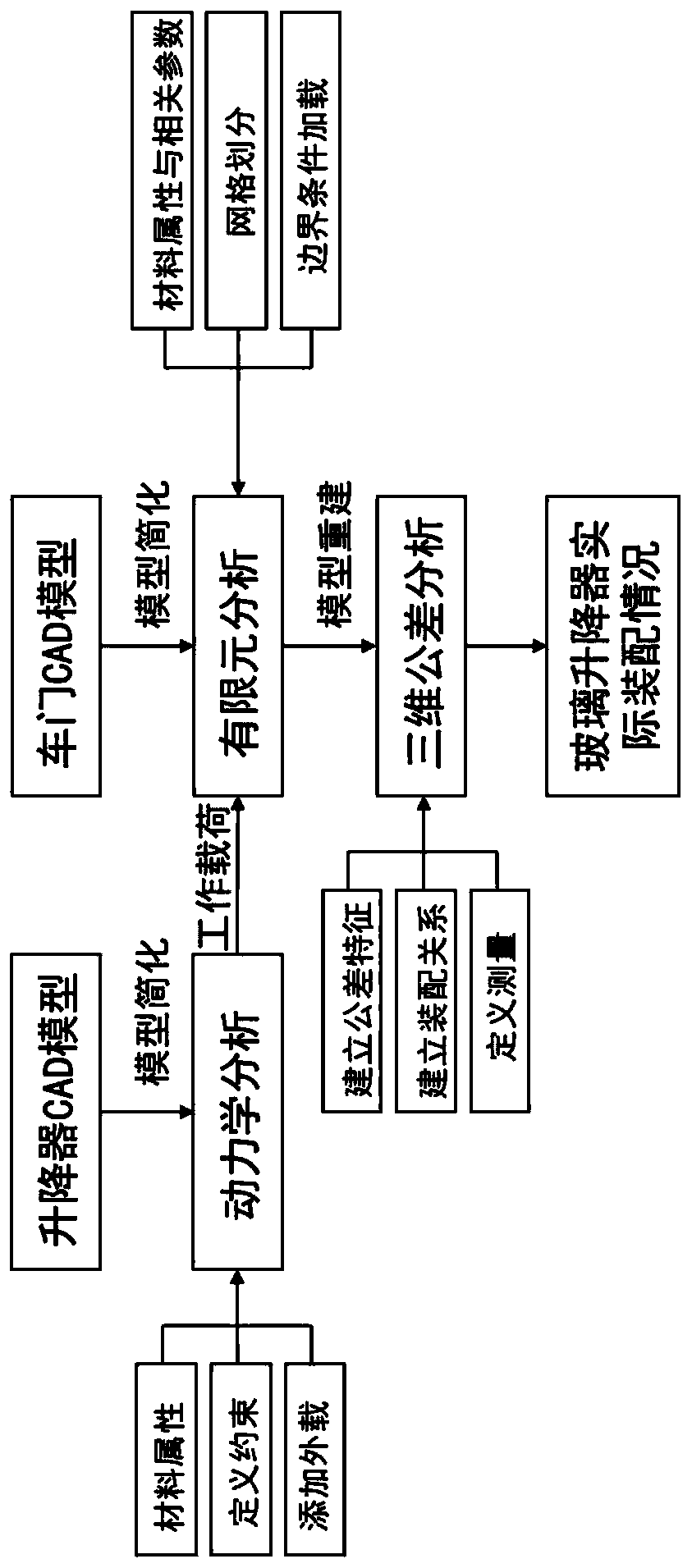

[0072] A finite element-based three-dimensional flexible assembly tolerance prediction method for a glass lifter, comprising the steps of:

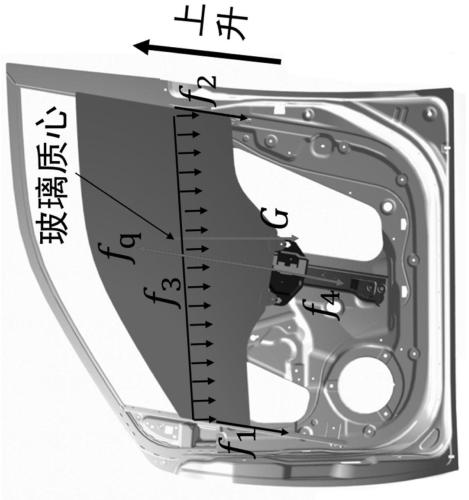

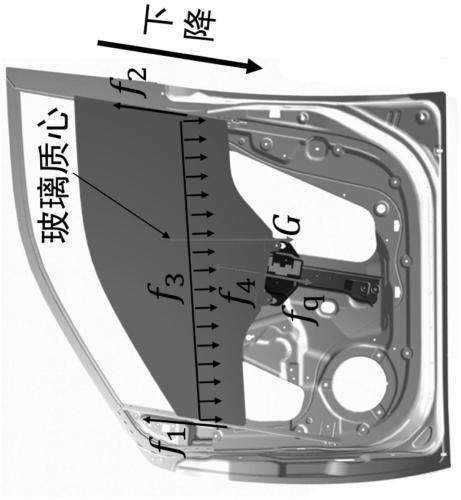

[0073] S1: Establish a dynamic simulation analysis model of the glass lifter to obtain the wire rope load for the glass to rise steadily;

[0074] S2: Establish a finite element analysis model of the door inner panel to obtain the deformation of the installation plane of the door inner panel lifter;

[0075] S3: Establish a three-dimensional assembly tolerance analysis model of the glass regulator considering the flexible deformation of the inner door panel, and obtain the assembly state of the glass and the sealing strip;

[0076] S4: Based on the principal component analysis and experimental design method, the ratio of the reduction of the out-of-tolerance rate to the tightened tolerance is the income ratio of the tightened tolerance, which is used as an evaluation index to realize the optimal design of the window lift system tolerance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com