Patents

Literature

251results about How to "Realize the clamping function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical clamping equipment with magnetorheological fluid damping effect

InactiveCN107081621AReduce contact areaReduce frictionVibration dampersPositioning apparatusMechanical engineeringMagnetorheological fluid

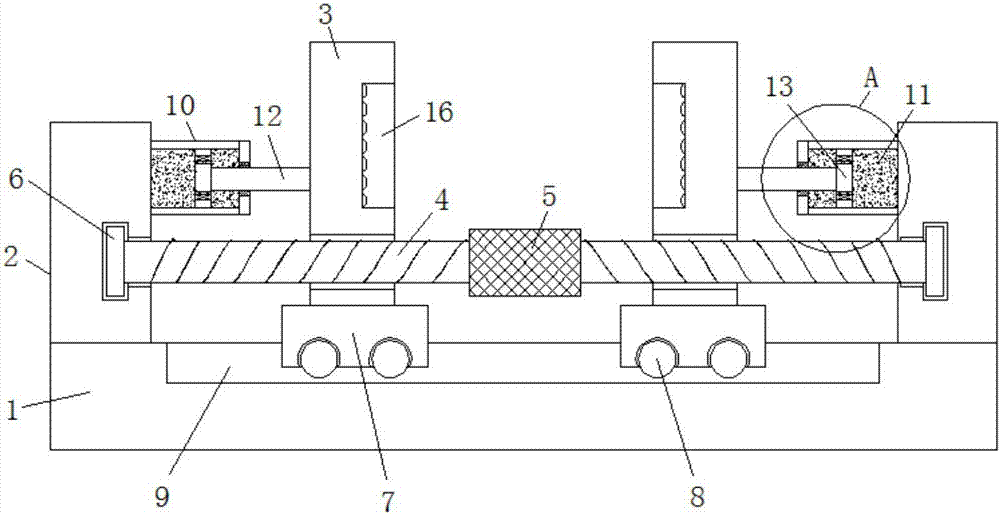

The invention discloses a mechanical clamping device with magneto-rheological fluid shock absorption, which includes a base, the upper end of the base is fixedly connected with baffle plates symmetrically on both sides, and a circular card slot is provided on one side of the outer wall of the baffle plate , and a circular block is arranged in the circular card slot, a lead screw is connected between the two circular blocks, and the middle outer wall of the lead screw is sleeved with a rotating block, and the outer walls of both ends of the lead screw are A clamping plate is socketed, and the clamping plate is threadedly connected with the lead screw. The bottom of the clamping plate is provided with a slider, and the upper end of the base is provided with a chute corresponding to the slider. The inner wall of the baffle is a A sleeve is fixedly connected to the side, and the inner cavity of the sleeve is filled with magnetorheological fluid. The inner wall of the sleeve is provided with a piston block, and one end of the piston block is connected with a support rod. The invention is simple in structure, easy to operate, has better stability, and keeps the clamping force constant within a certain range at the same time, avoiding damage to the workpiece.

Owner:LIANYUNGANG NORMAL COLLEGE

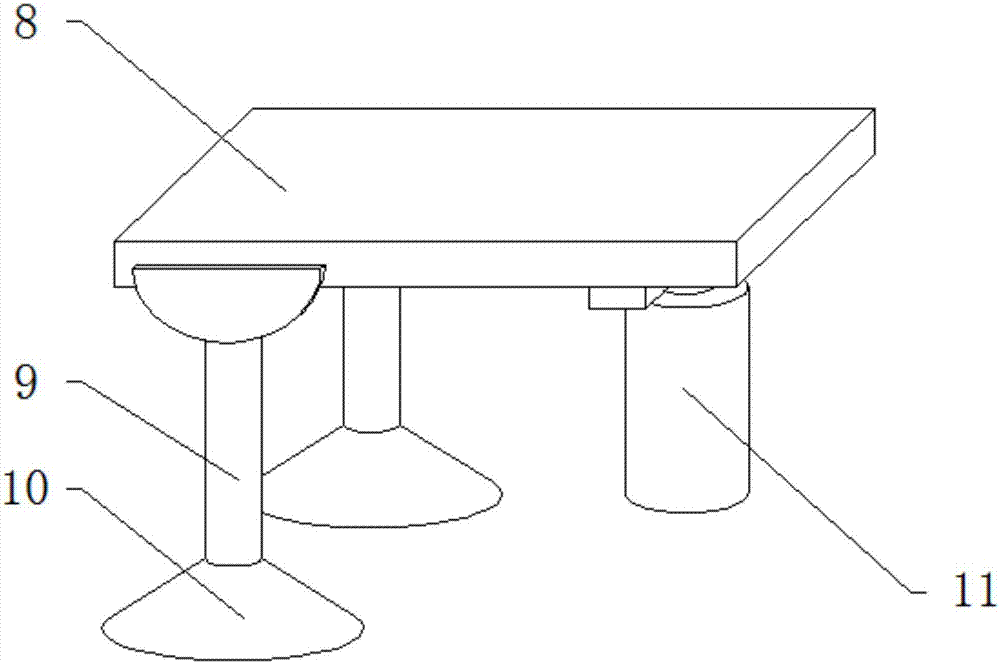

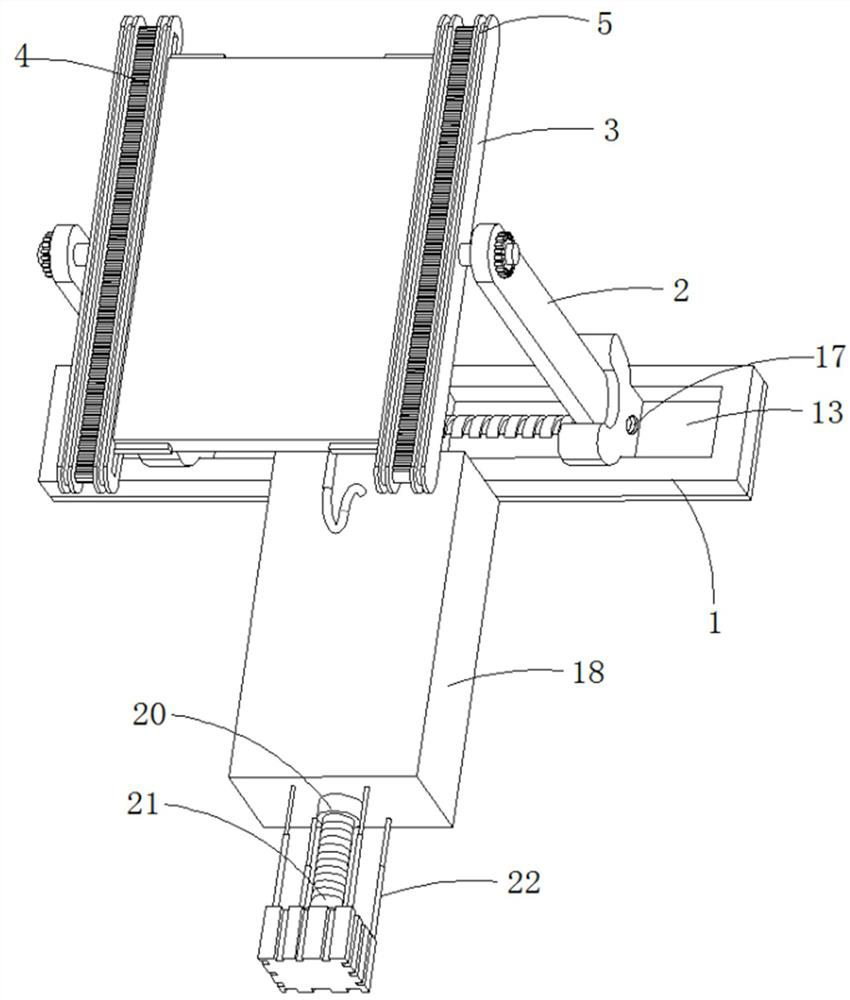

Fixing device for machining

InactiveCN107877428AAdjustable distanceRealize the clamping functionWork holdersPositioning apparatusArchitectural engineeringMachining

The invention provides a fixing device for machining, comprising a base plate, an arc-shaped splint, a two-way screw, a moving seat, an electric telescopic rod, a mounting plate, a support rod, a suction cup and an electric telescopic cylinder. There is an electric telescopic rod, the electric telescopic rod is fixed on the inner end of the moving seat, the moving seat is installed on the two-way screw rod, the two-way screw rod is installed inside the base plate, and the lower end of the moving seat passes through the base plate and the two-way screw rod. The screw rods are connected, the design realizes the clamping function, and the distance between the electric telescopic rods can be adjusted at the same time. For the suction cup, an electric telescopic cylinder is installed on the right side of the support rod, and the design can adjust the angle to meet different processing requirements.

Owner:新昌县羽林街道元洋机械厂

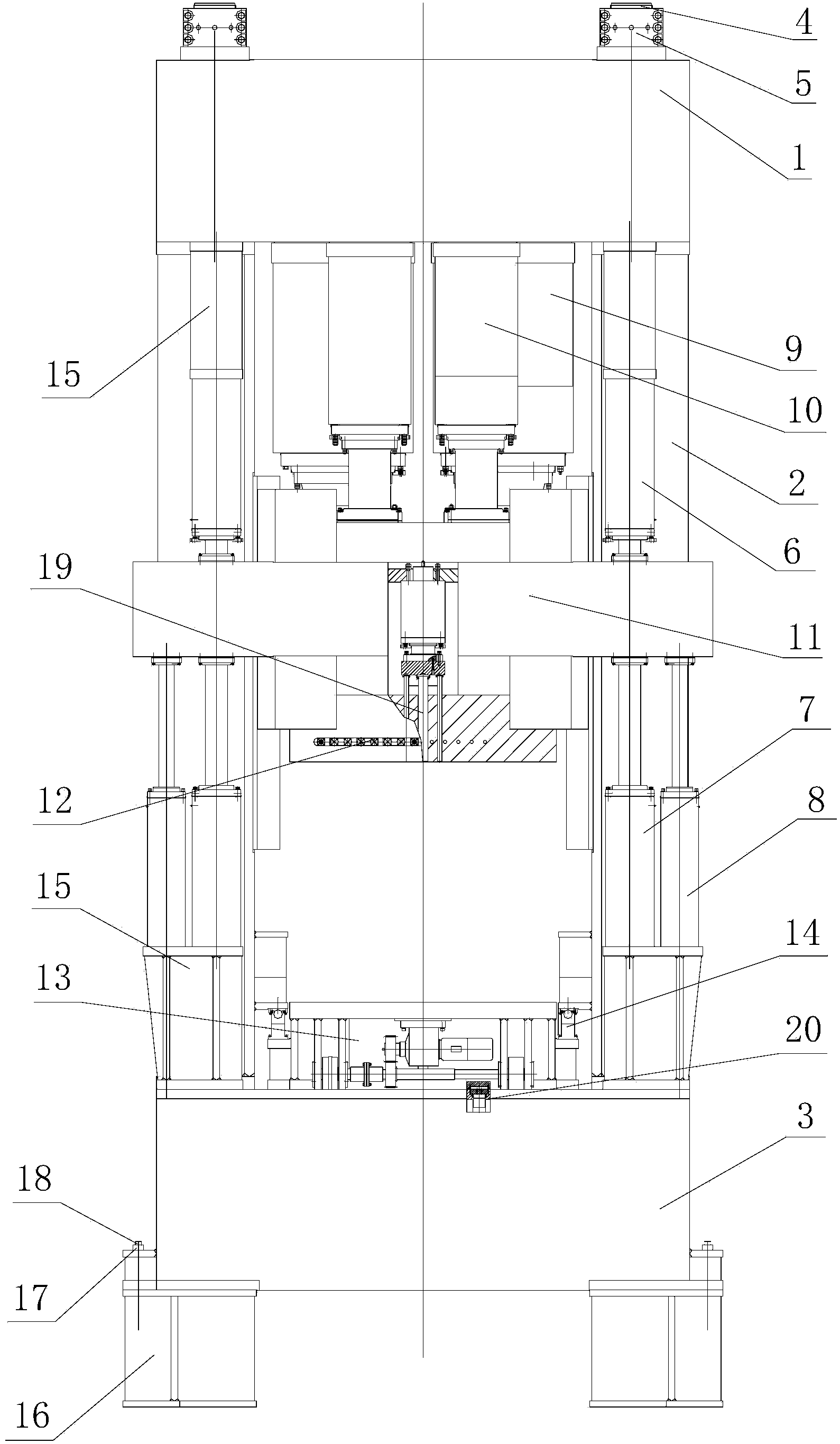

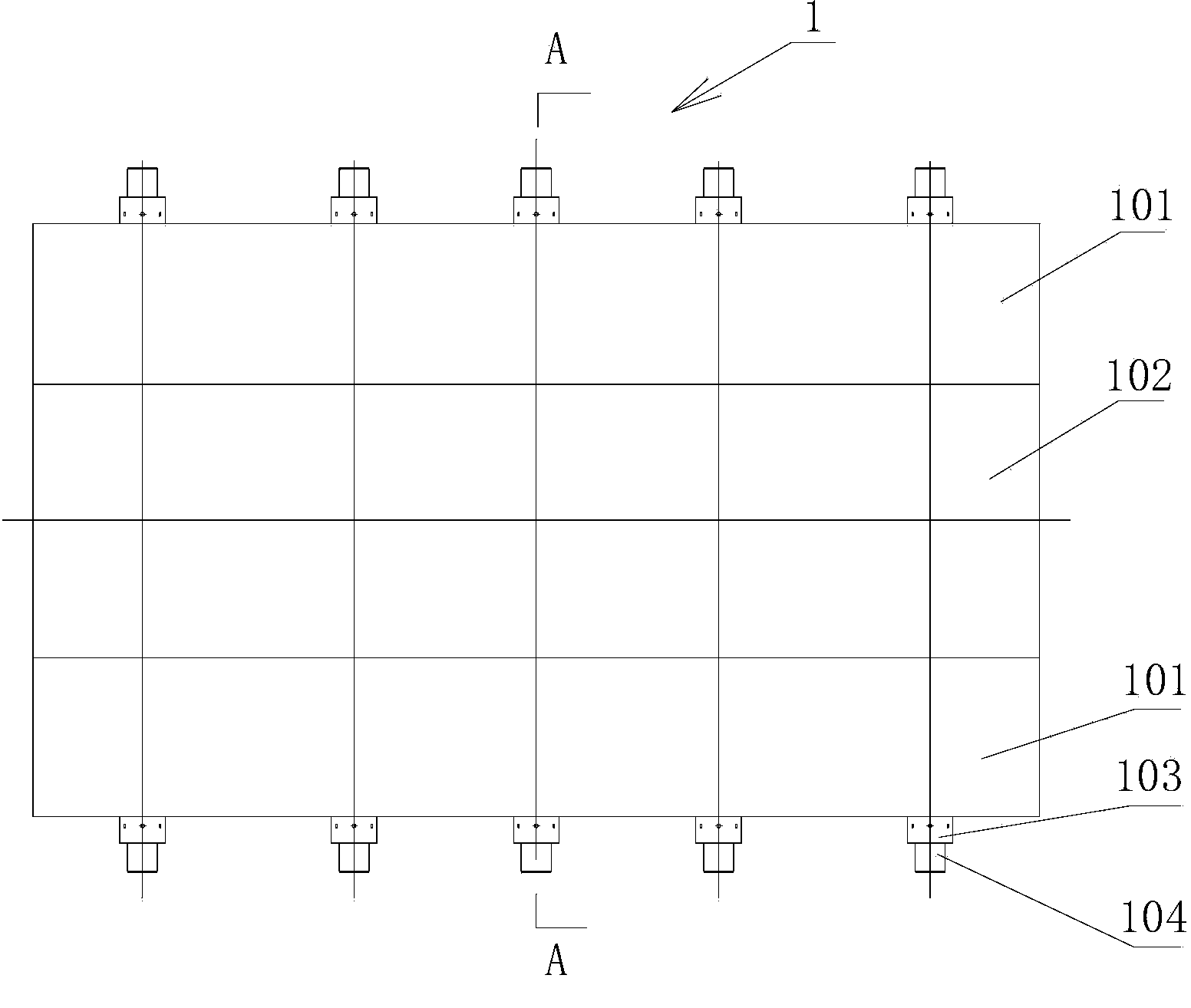

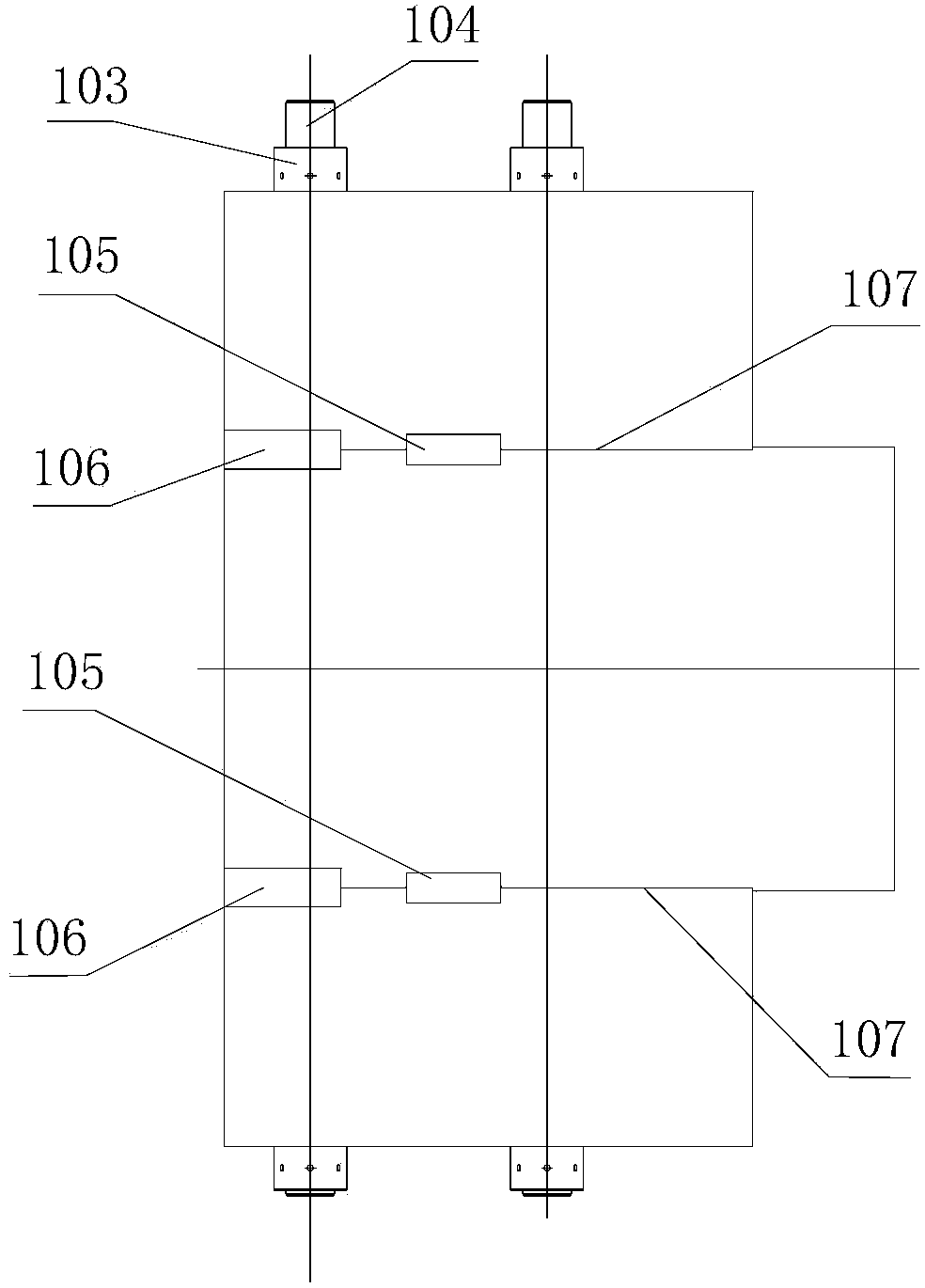

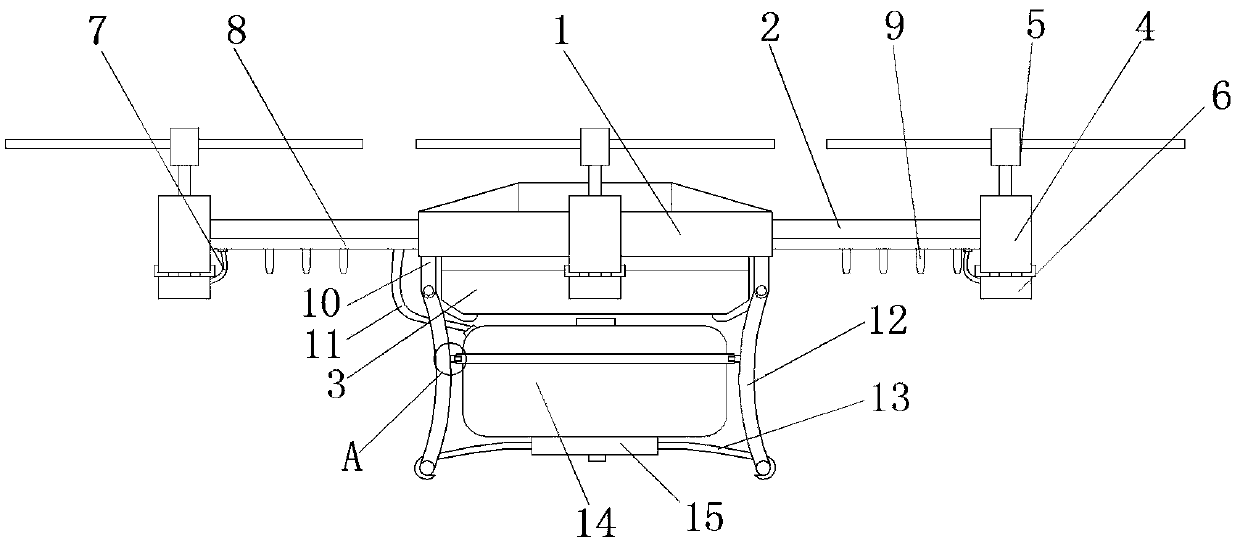

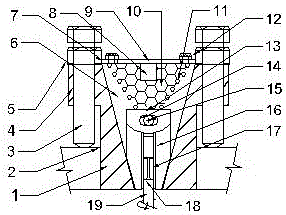

Heavy-duty isothermal forging hydraulic press

ActiveCN103447434AReduce manufacturing costHigh leveling accuracyForging/hammering/pressing machinesForging press detailsAviationLeveling effect

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

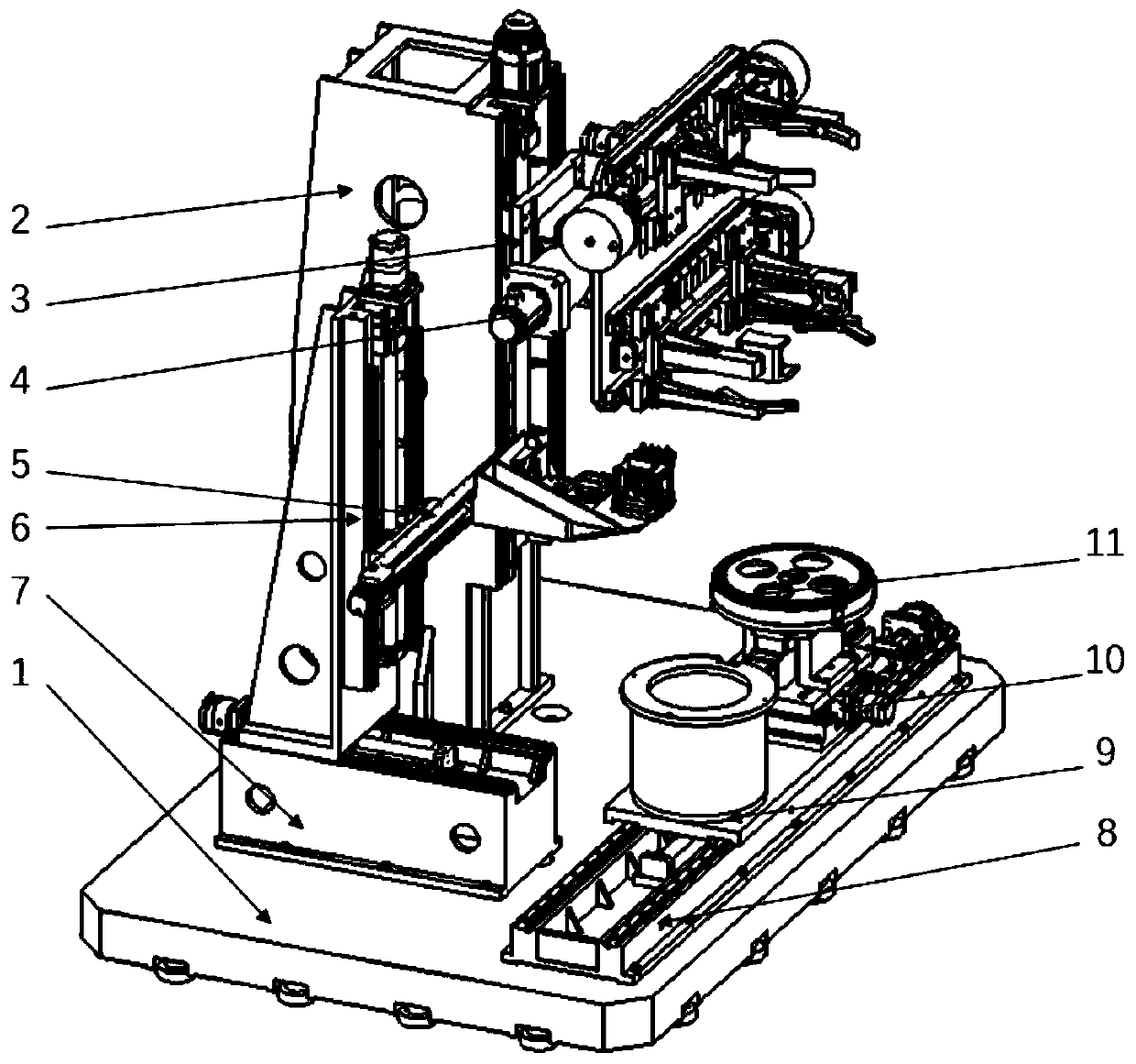

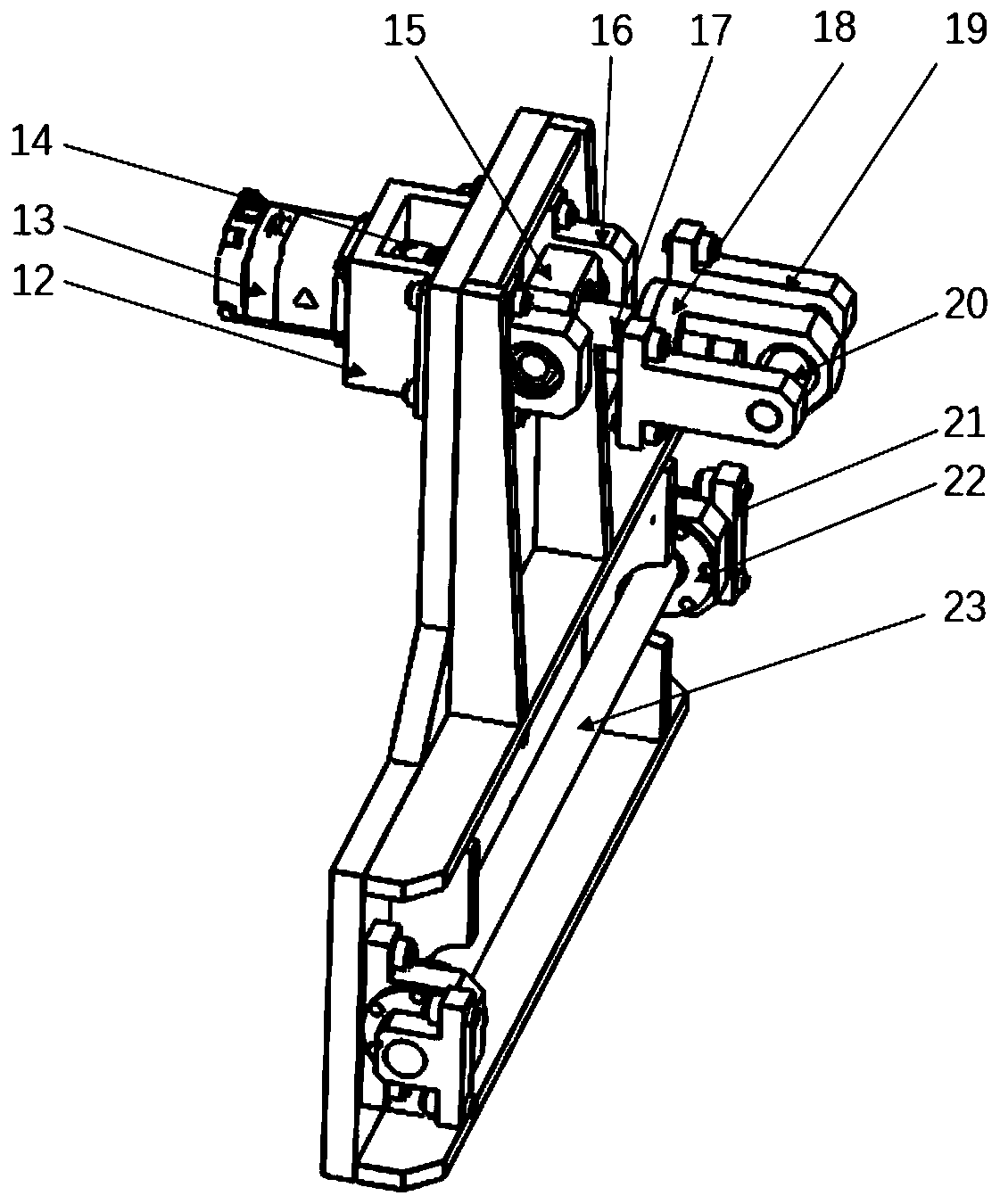

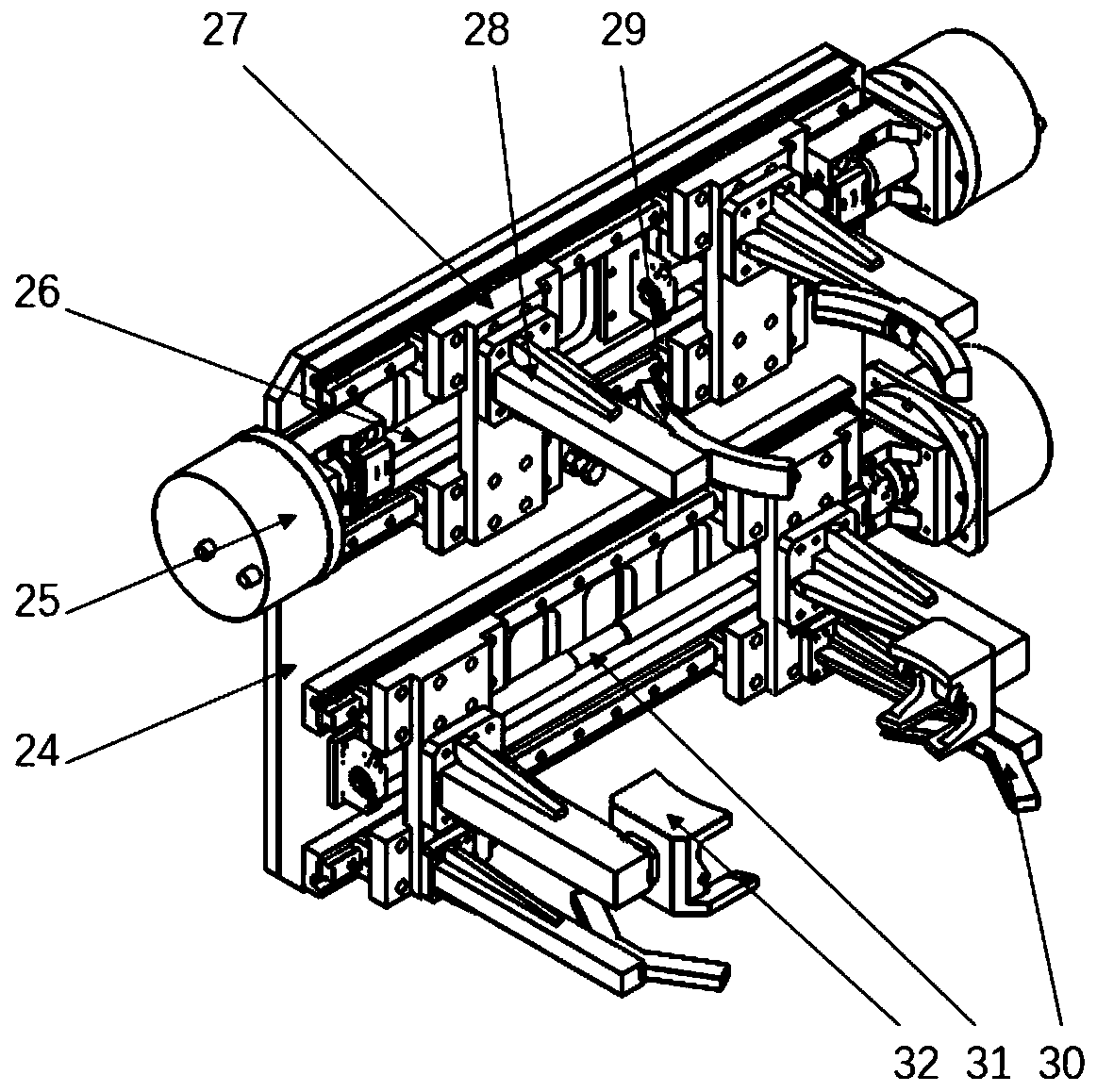

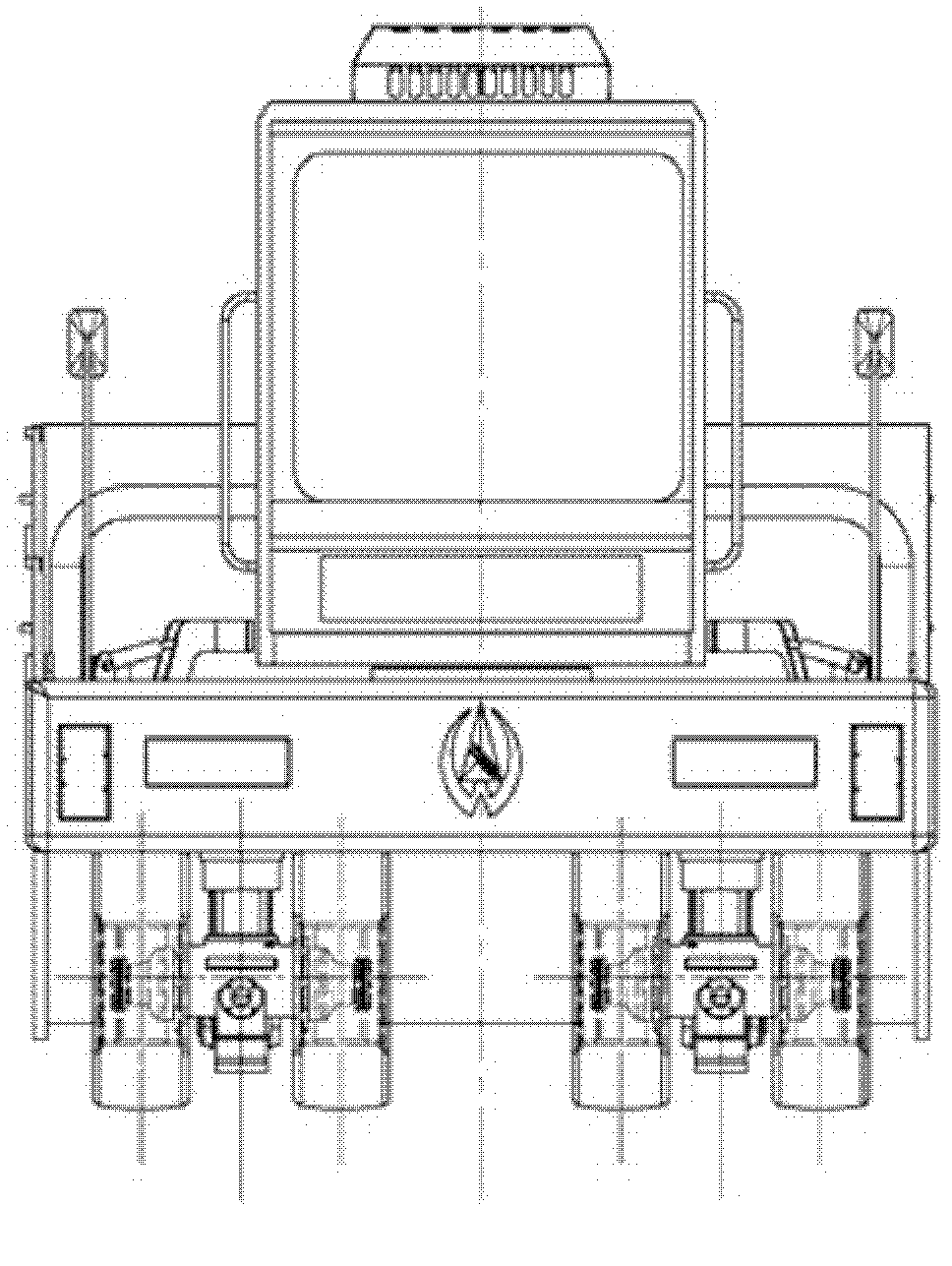

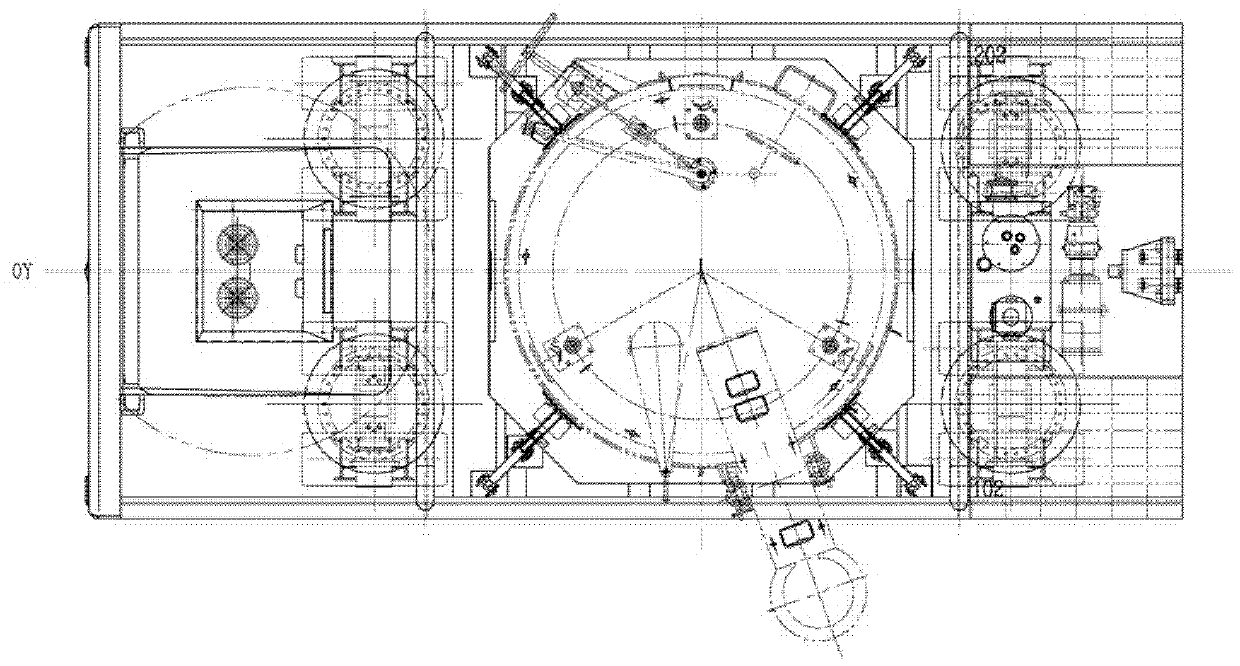

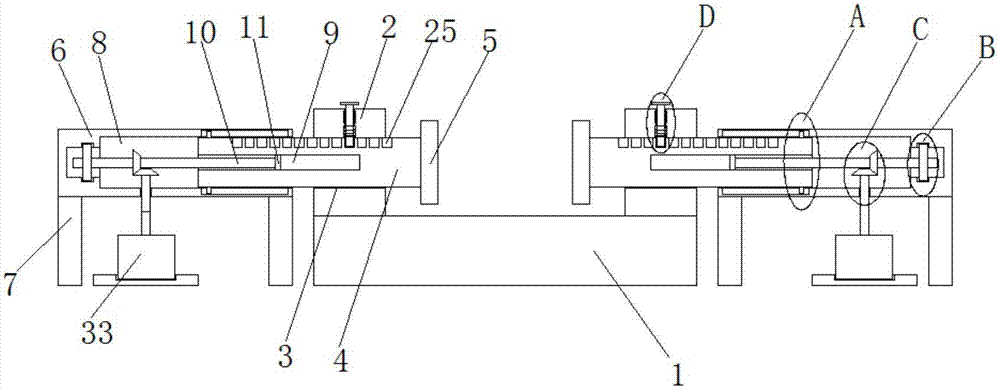

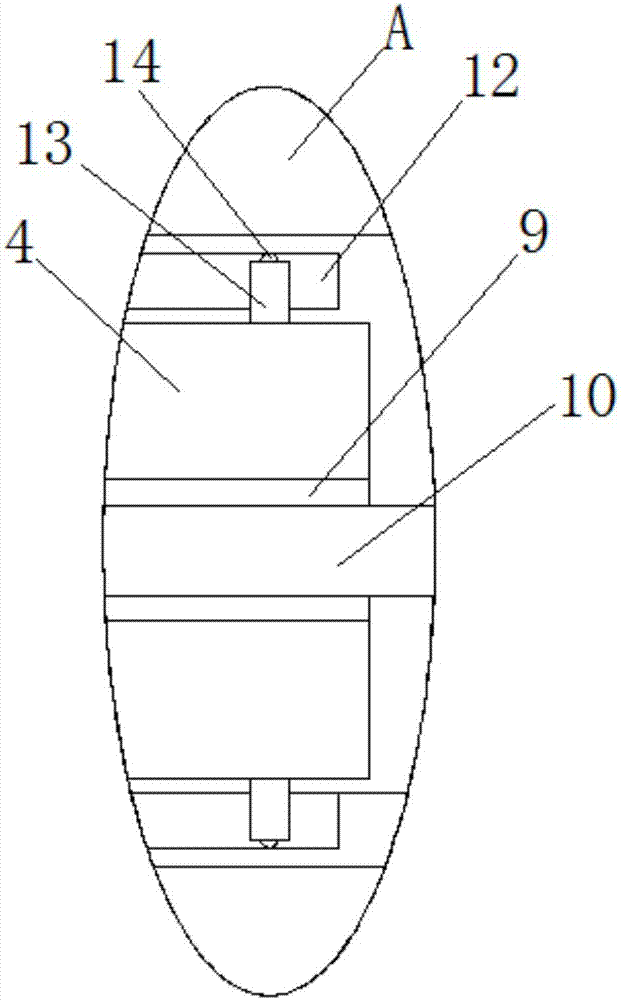

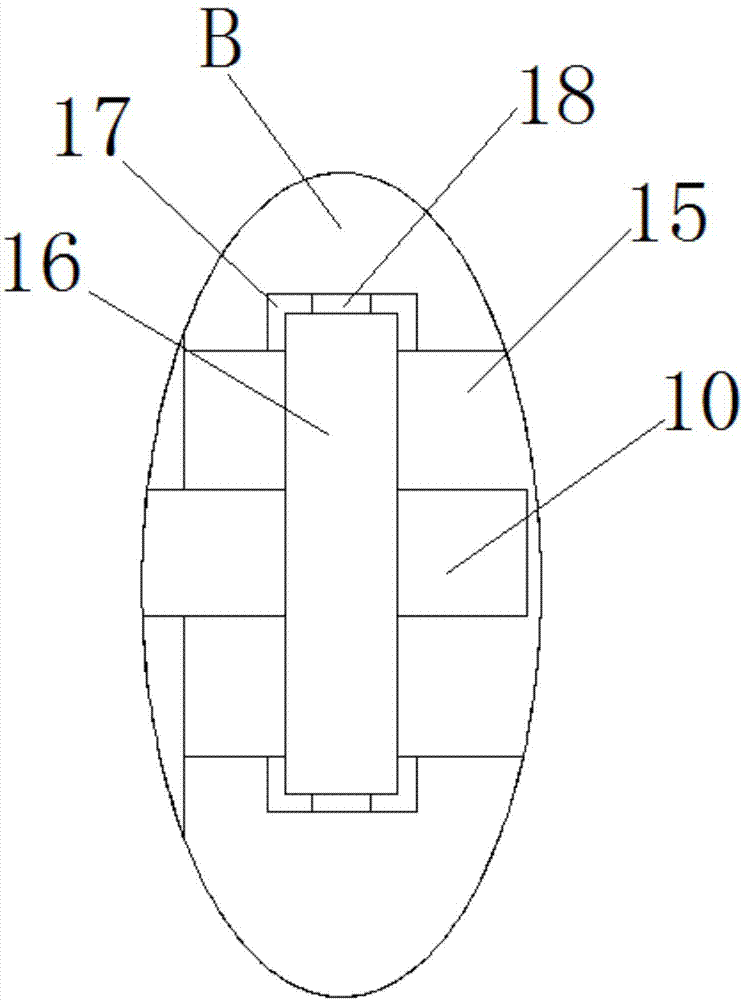

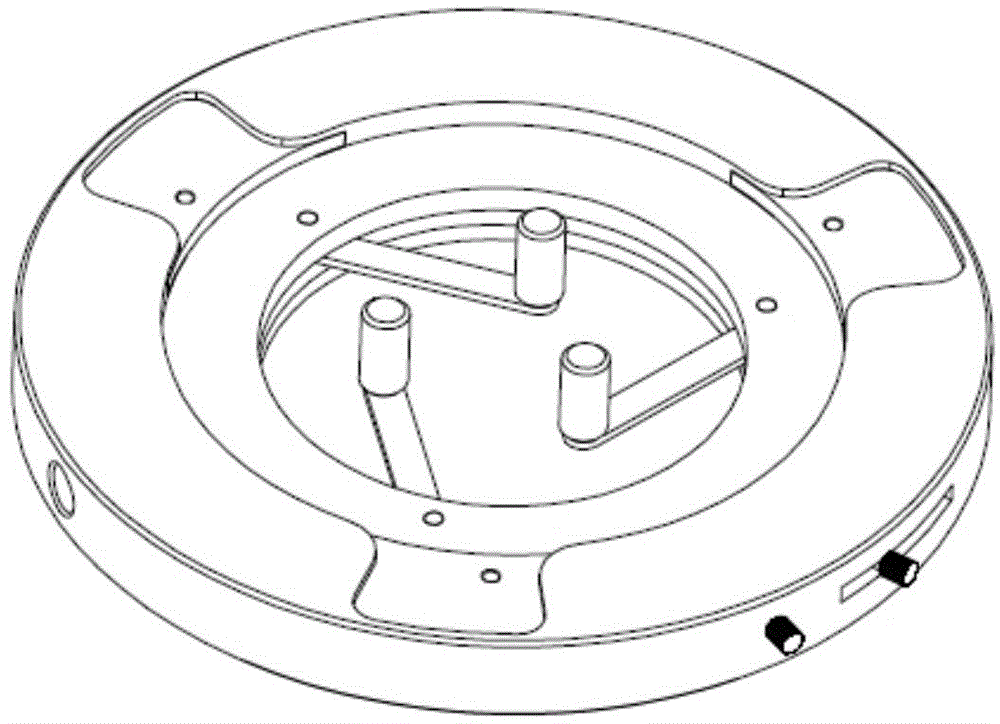

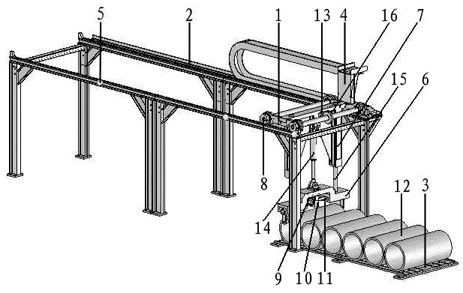

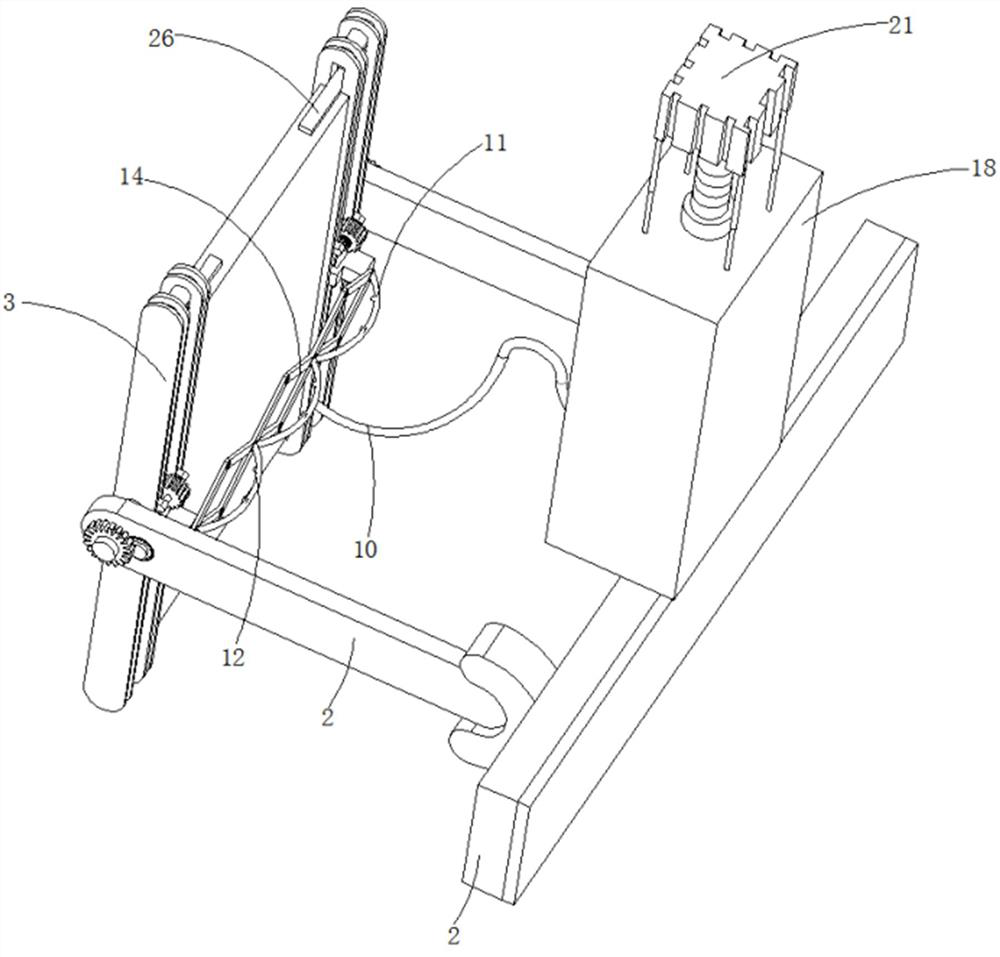

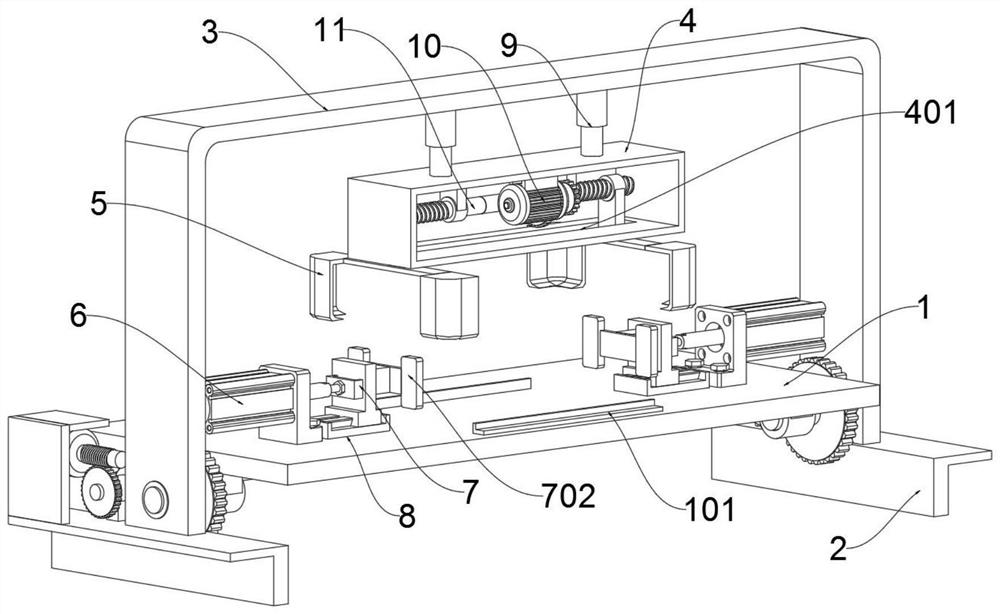

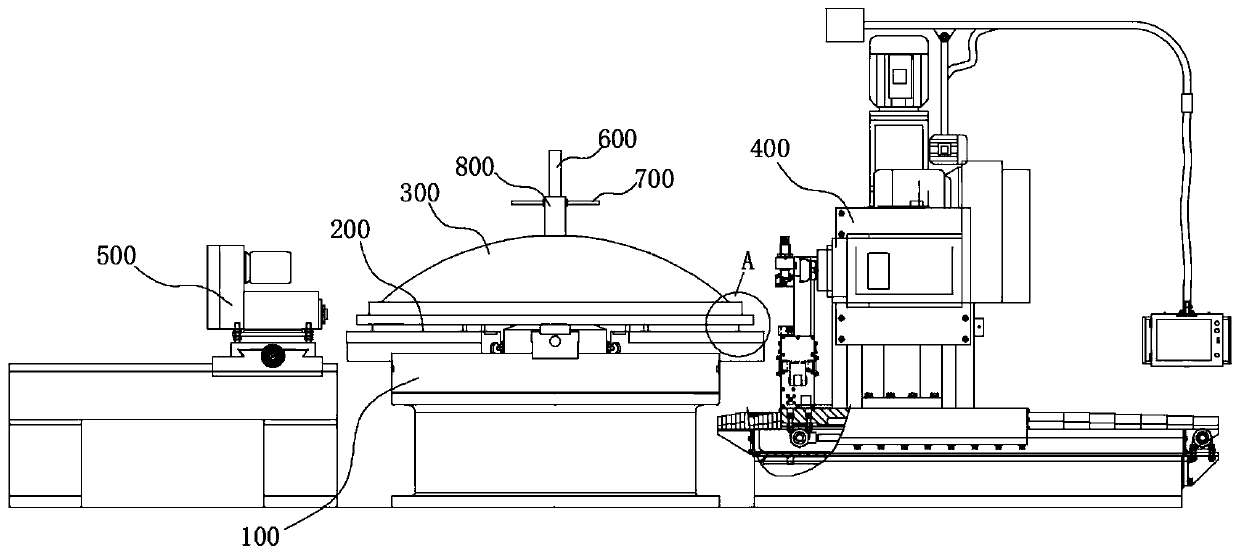

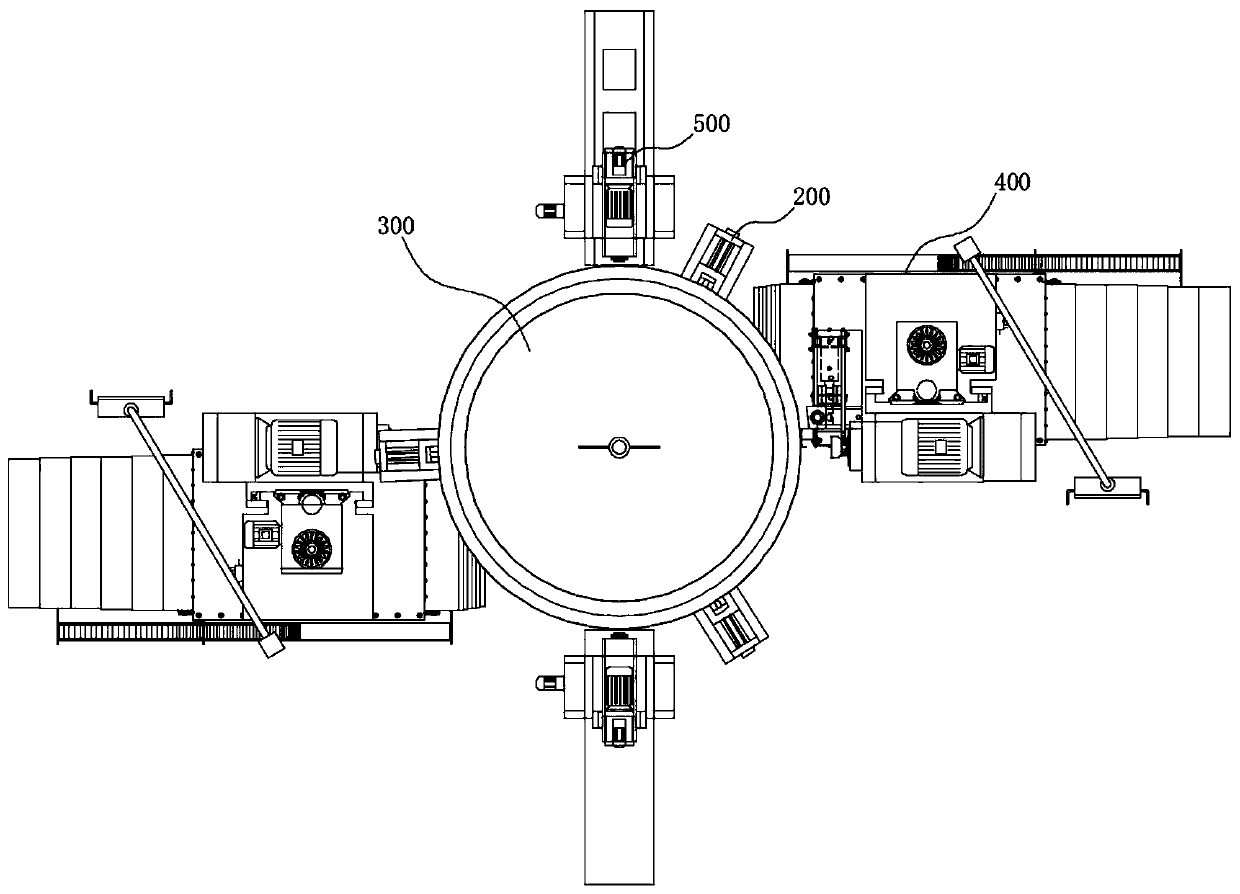

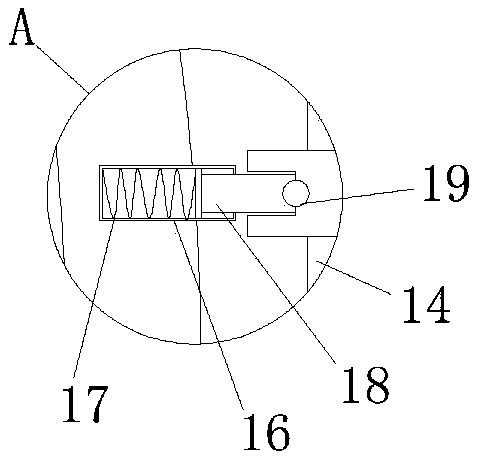

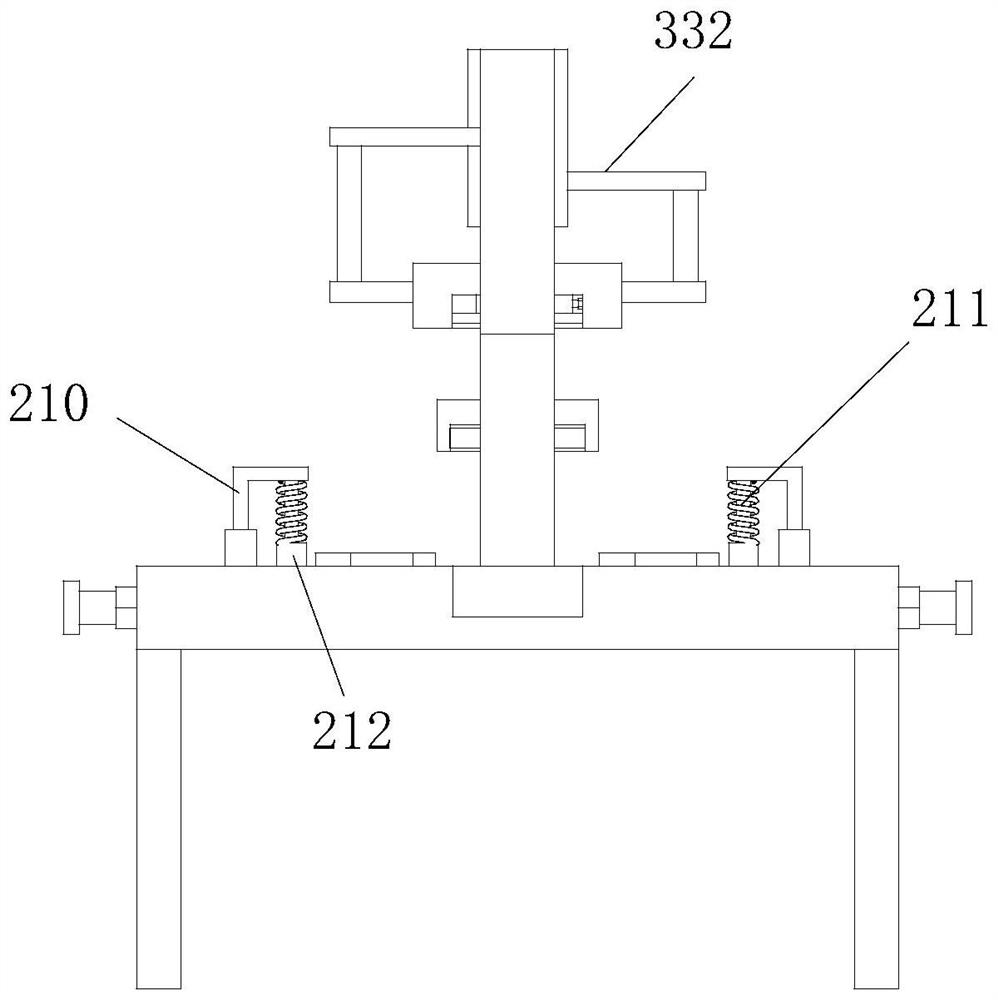

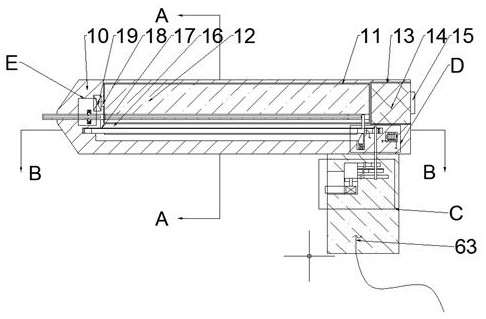

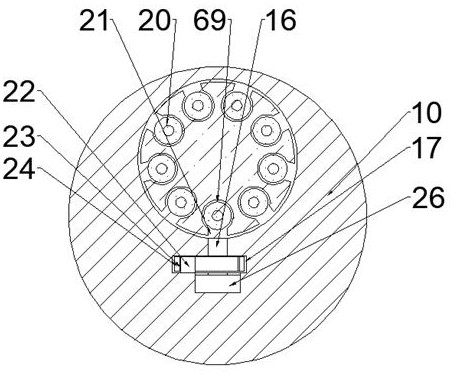

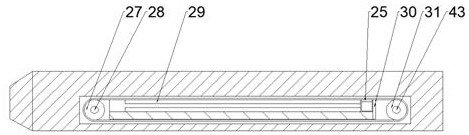

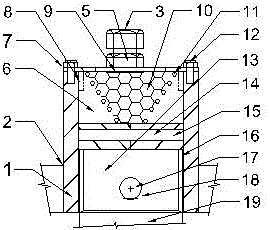

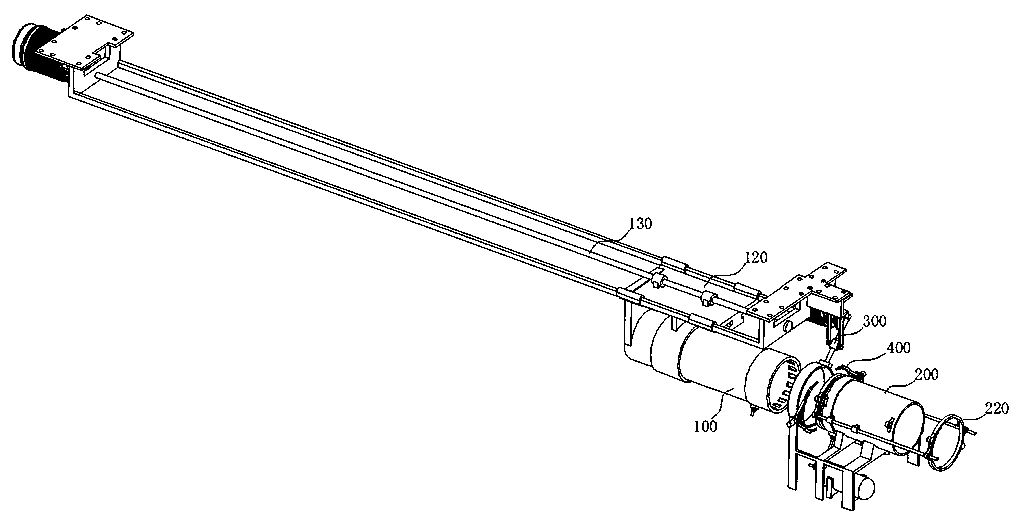

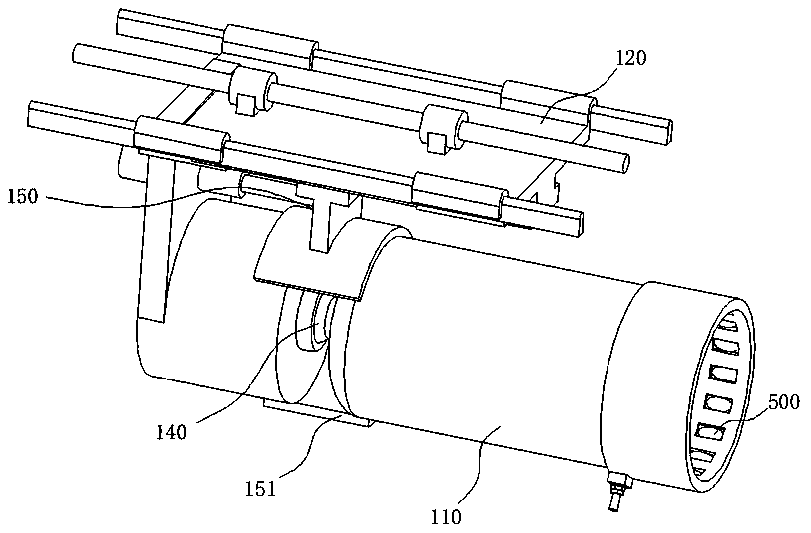

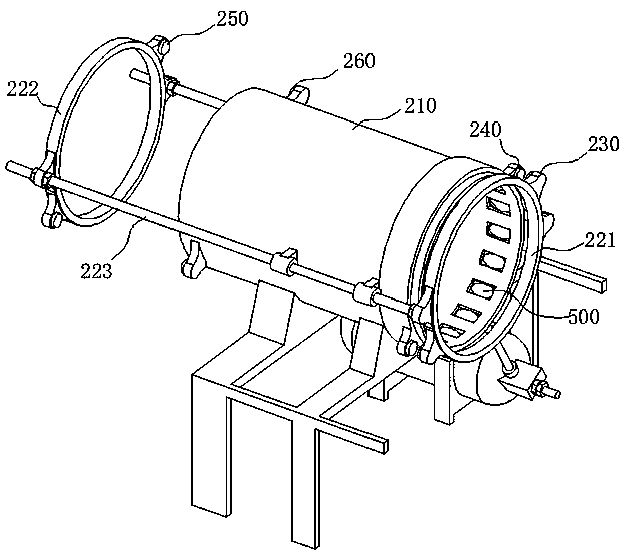

Reconfigurable man-machine coordination assembling system for aero-engine

ActiveCN110238649AReduce the difficulty of operationOperation Difficulty GuaranteedAssembly machinesWork holdersAviationProduction rate

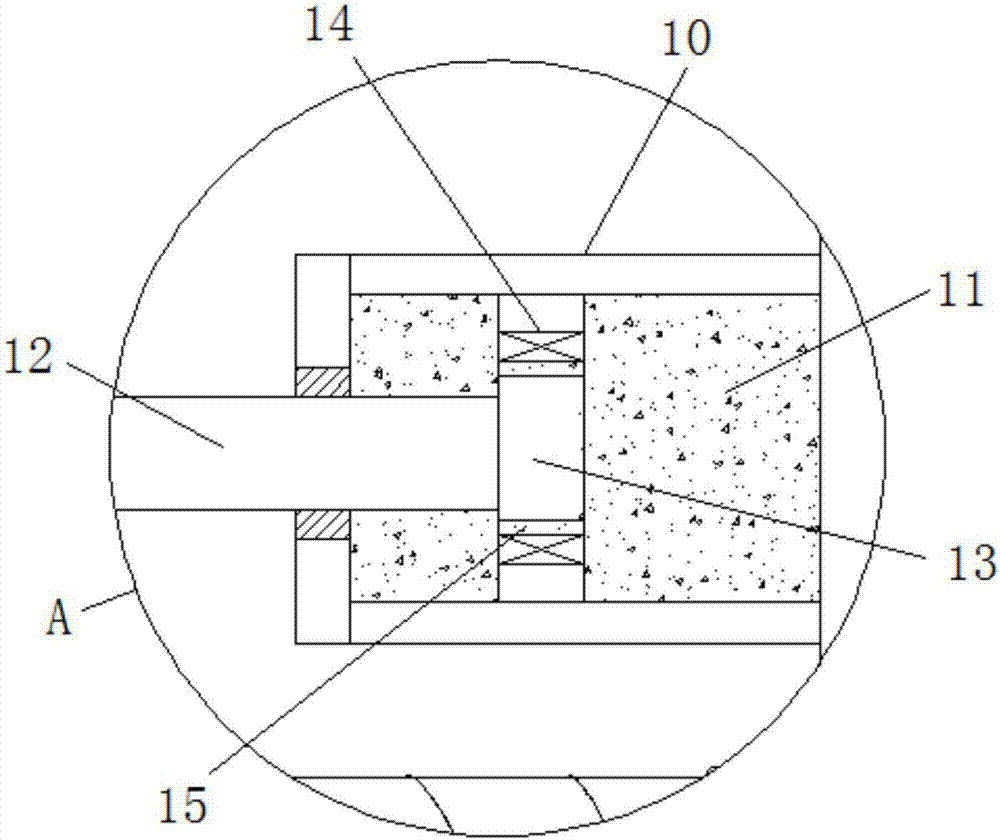

The invention discloses a reconfigurable man-machine coordination assembling system for an aero-engine. The system comprises a base, a lifting mechanism, a turnover mechanism, an angular fine-adjustment mechanism, a clamping mechanism, a feeding and assembling mechanism and a detecting mechanism, wherein the lifting mechanism drives the turnover mechanism to move up and down vertically; a feeding station and an assembling station are disposed on the feeding and assembling mechanism; the feeding station and the assembling station move horizontally in an X direction together; the assembling station can move horizontally in a Y direction and rotate around a C axis; to-be-assembled parts are put on the feeding station and the assembling station separately; the turnover mechanism drives the clamping mechanism to rotate around a B axis; the angular fine-adjustment mechanism is mounted between the clamping mechanism and the turnover mechanism so as to achieve fine-adjustment of the rotating amount of the clamping mechanism around an A axis; and the detecting mechanism finishes measurement of the plane gaps among the parts and the angle deflection amount, and deviation amount adjustment is finished through the feeding and assembling mechanism, the turnover mechanism and the angular fine-adjustment mechanism. By means of the reconfigurable man-machine coordination assembling system for the aero-engine, the on-site operation difficulty can be effectively lowered for workers, and the production rate is improved while the safety is ensured.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

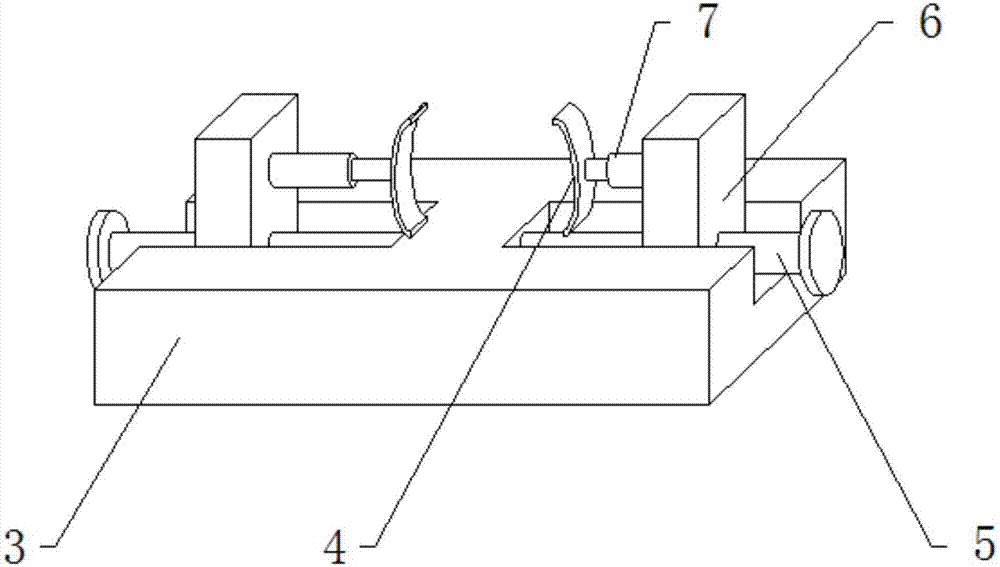

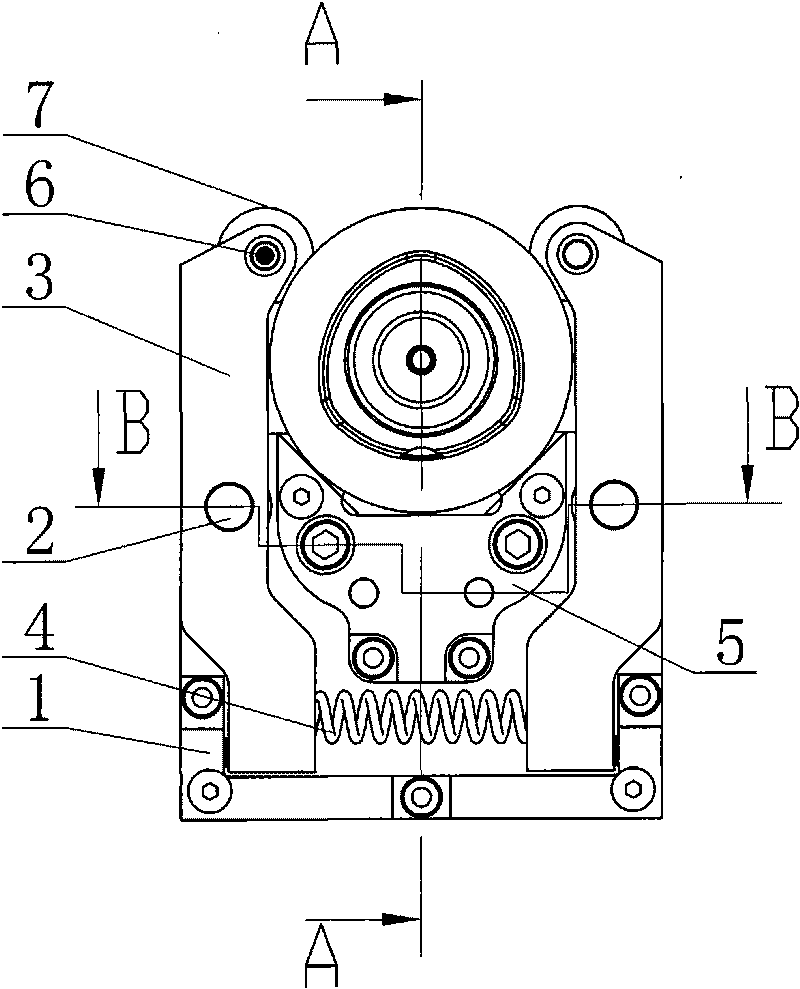

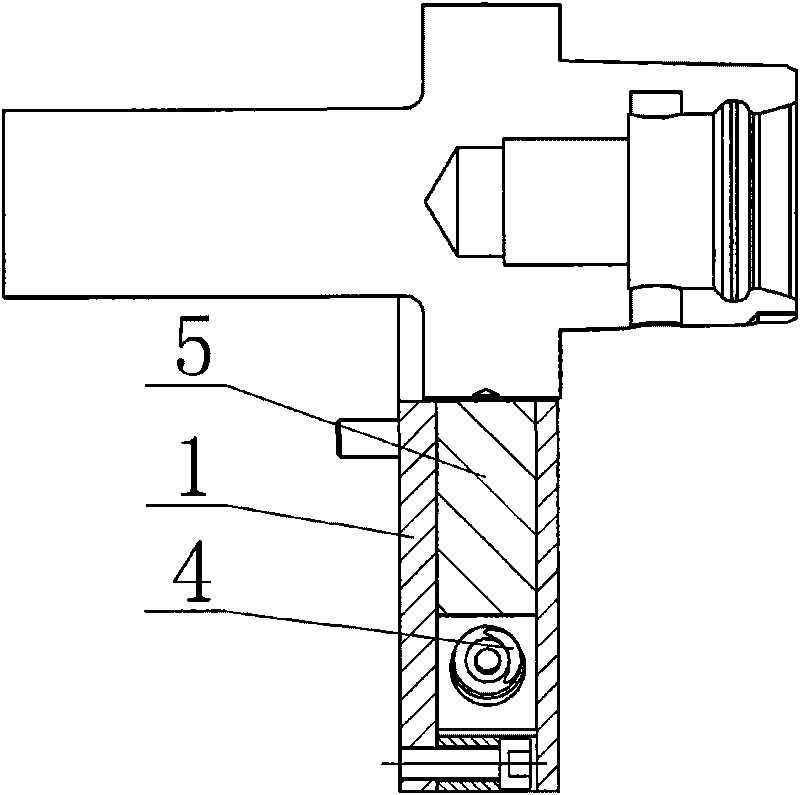

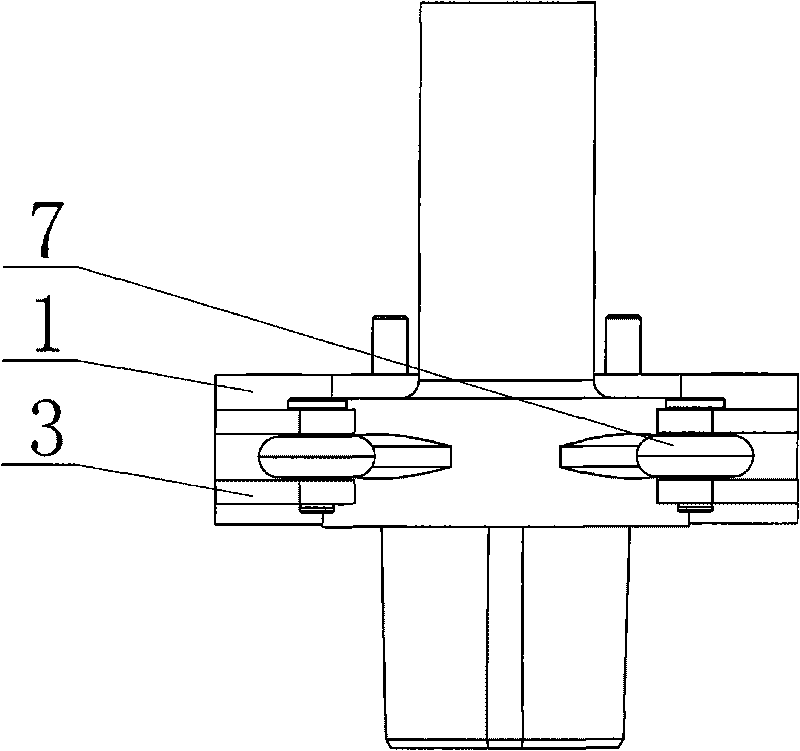

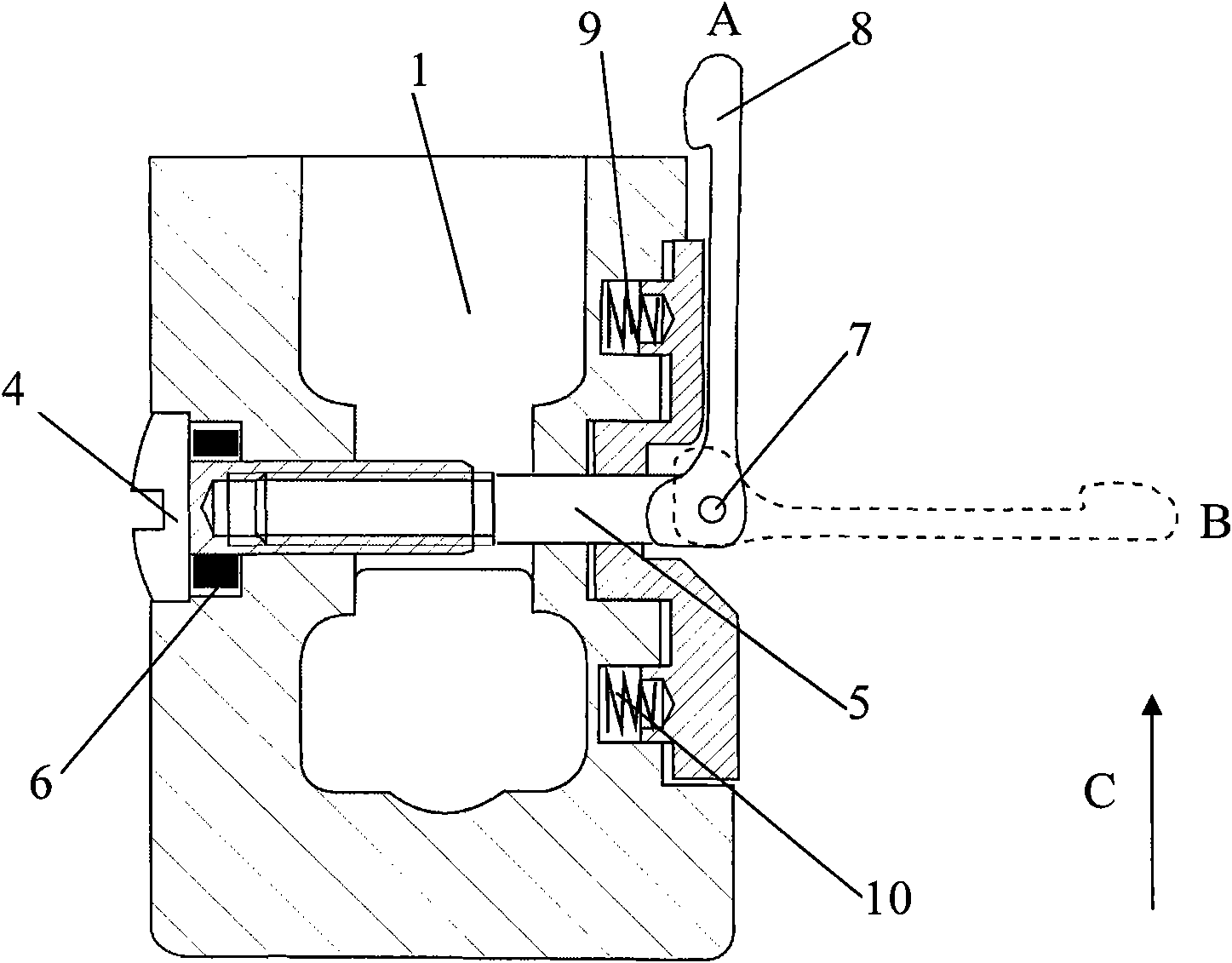

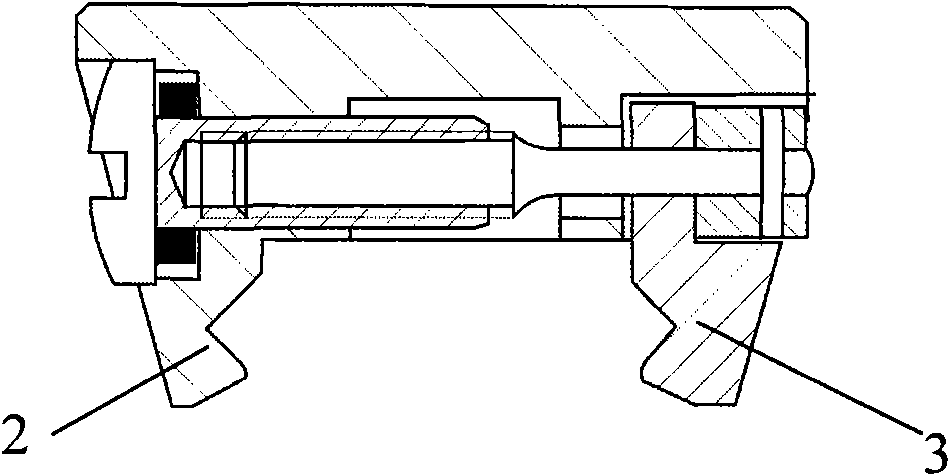

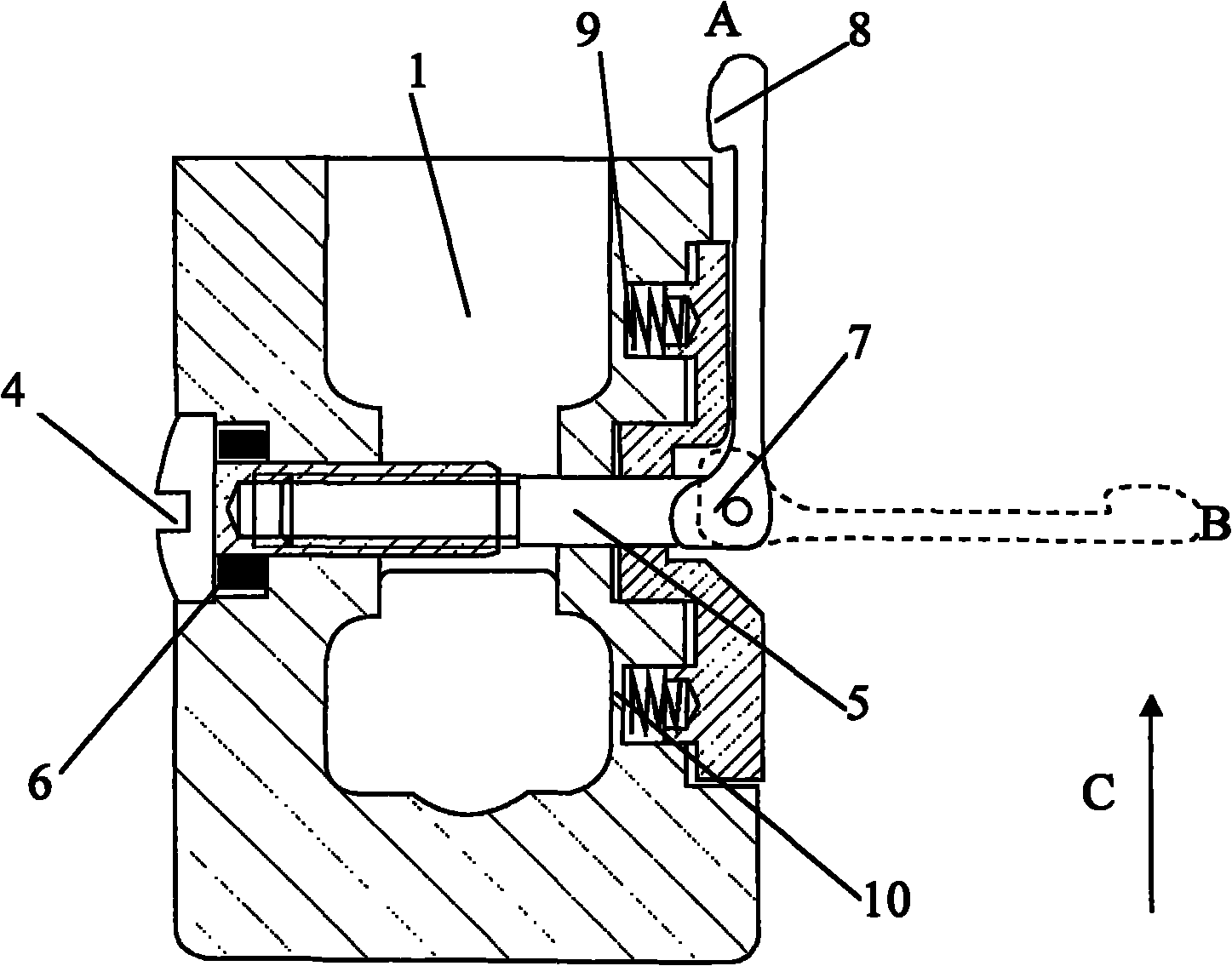

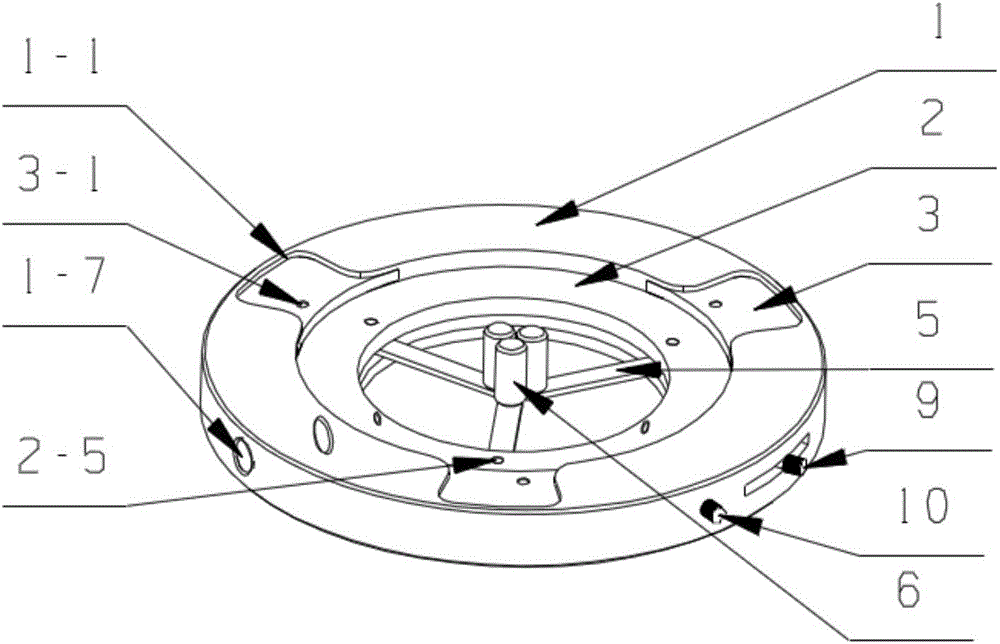

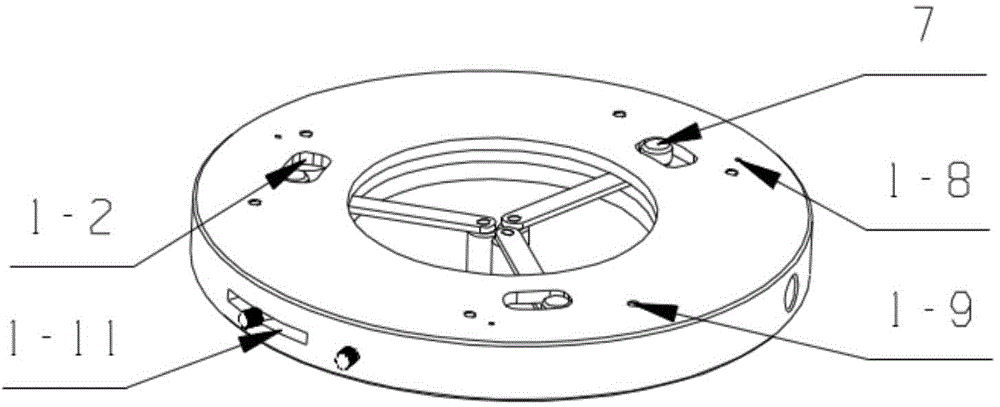

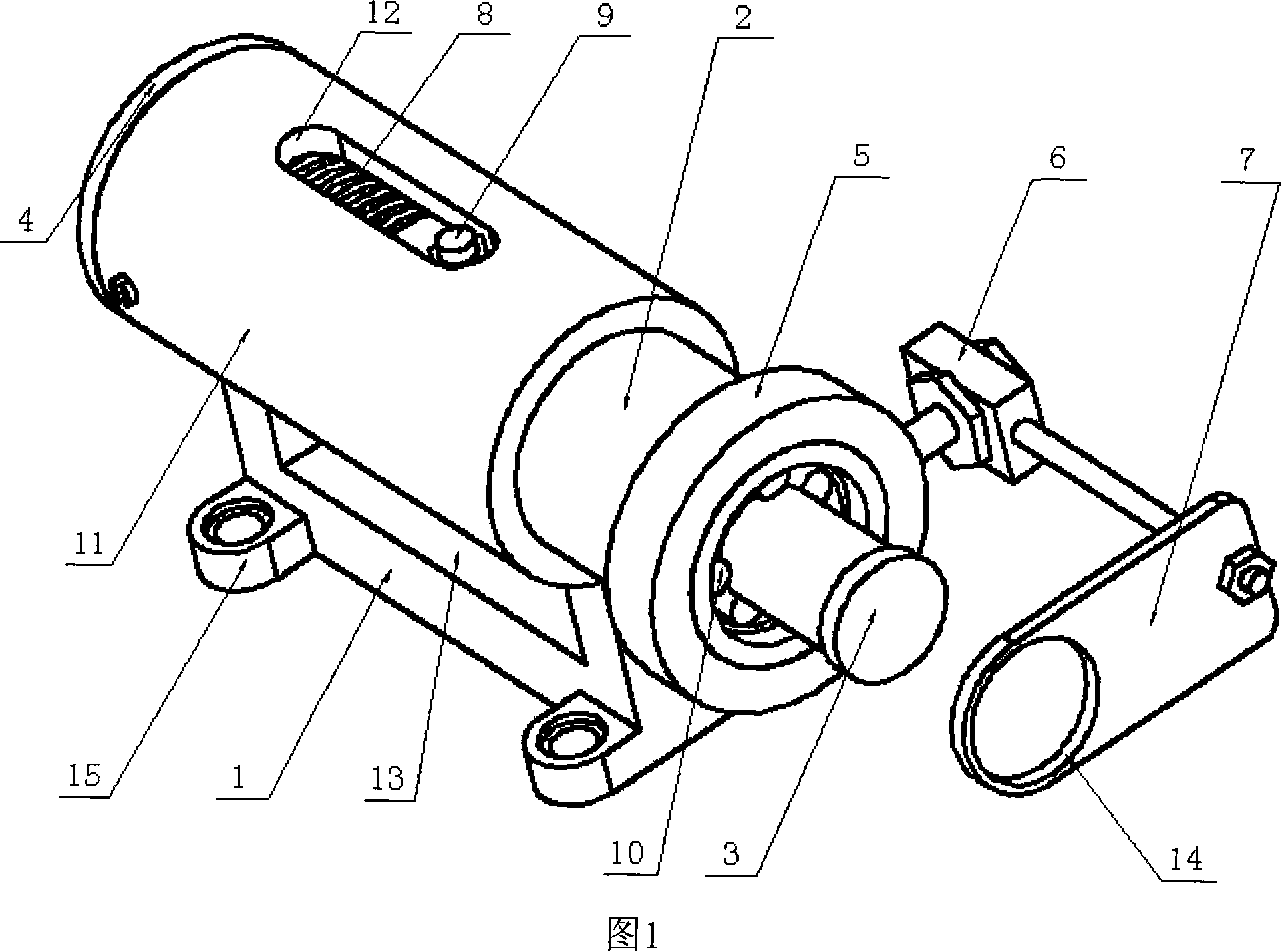

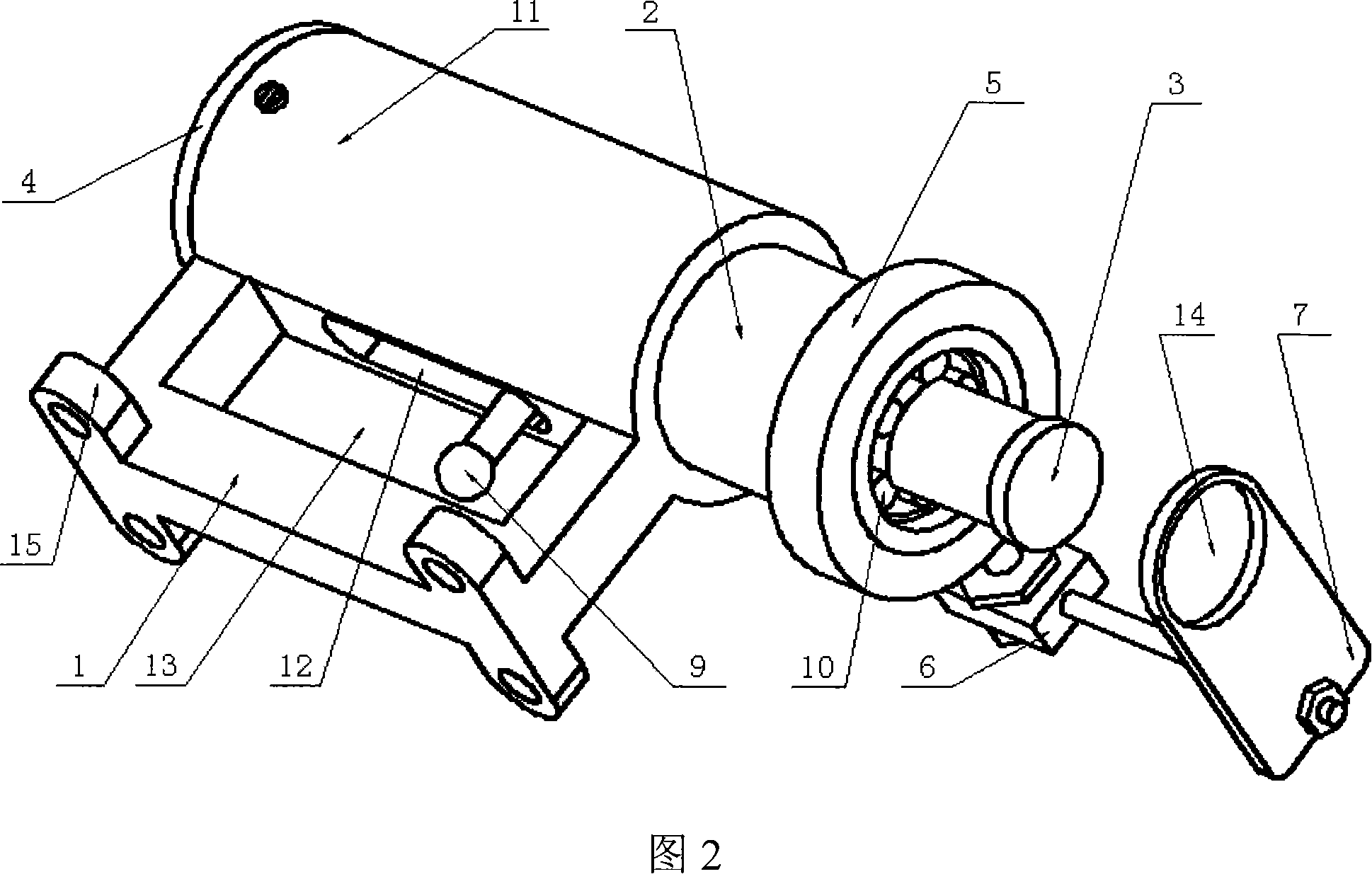

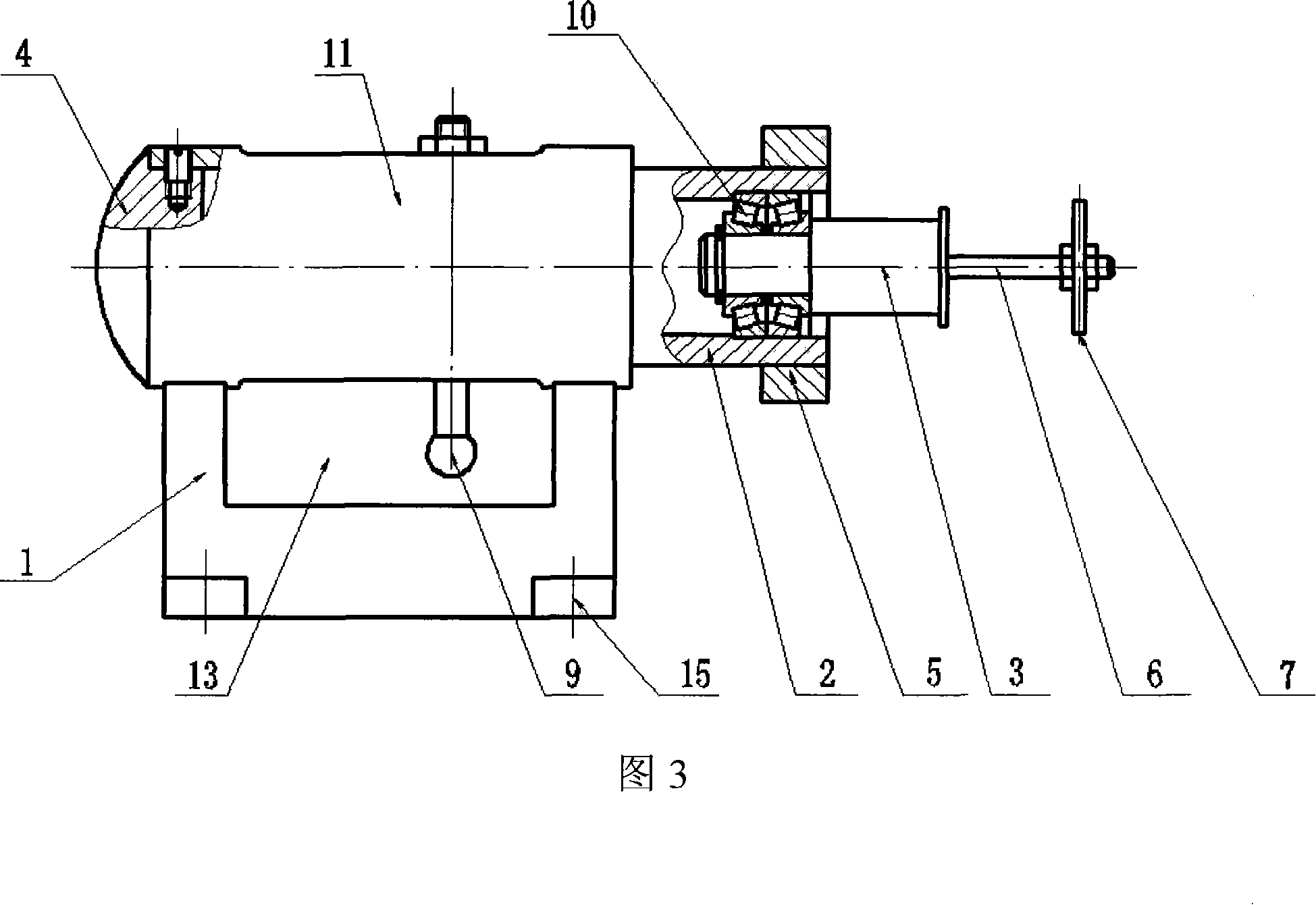

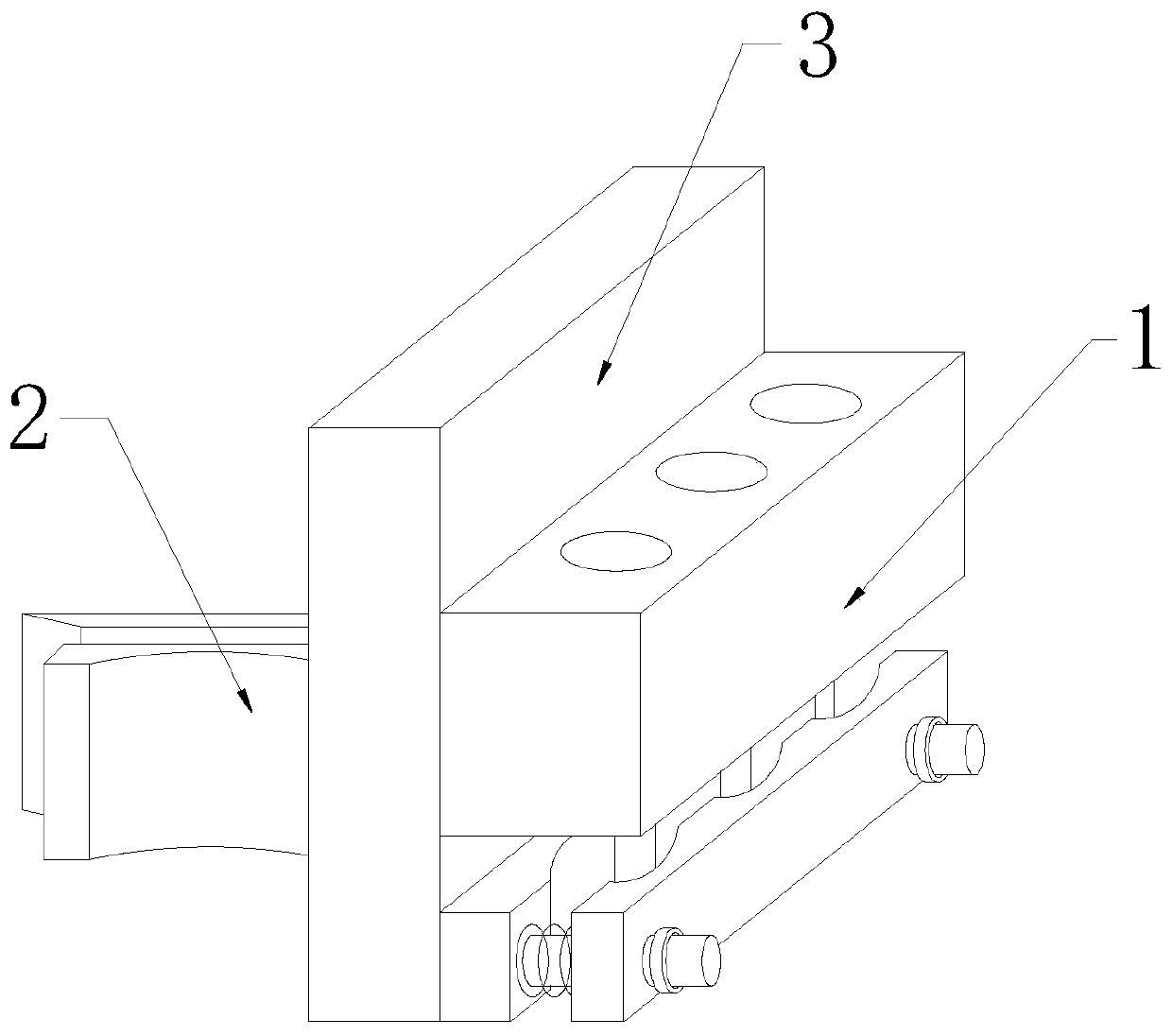

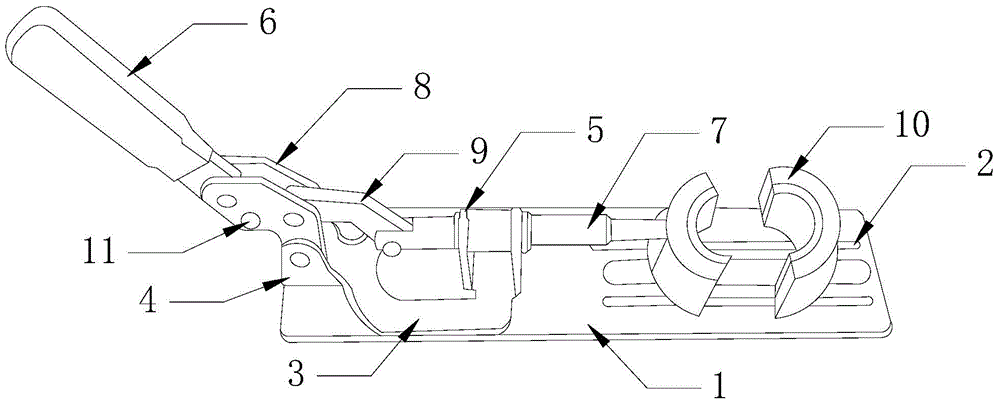

Triangular pyramid cutter clamping paw and method for clamping cutter

InactiveCN101745832AMeet needsExquisite structurePositioning apparatusMetal-working holdersMechanical engineeringPyramid

The invention relates to a triangular pyramid cutter clamping paw and a method for clamping a cutter. The invention aims to solve the problem that a newly released CAPTO tool system is not shaped and is being researched by a plurality of manufacturers at present. The triangular pyramid cutter clamping paw comprises a fixed mount (1); two sides of the fixed mount are connected with a pair of paws (3) through a shaft (2); a spring (4) is connected between the pair of paws; a positioning block (5) is arranged between the pair of paws; a pin shaft (6) arranged at the points of the paws is connected with a roller (7). The invention relates to a device and a method for clamping the cutter.

Owner:HARBIN MEASURING & CUTTING TOOL GROUP CO LTD

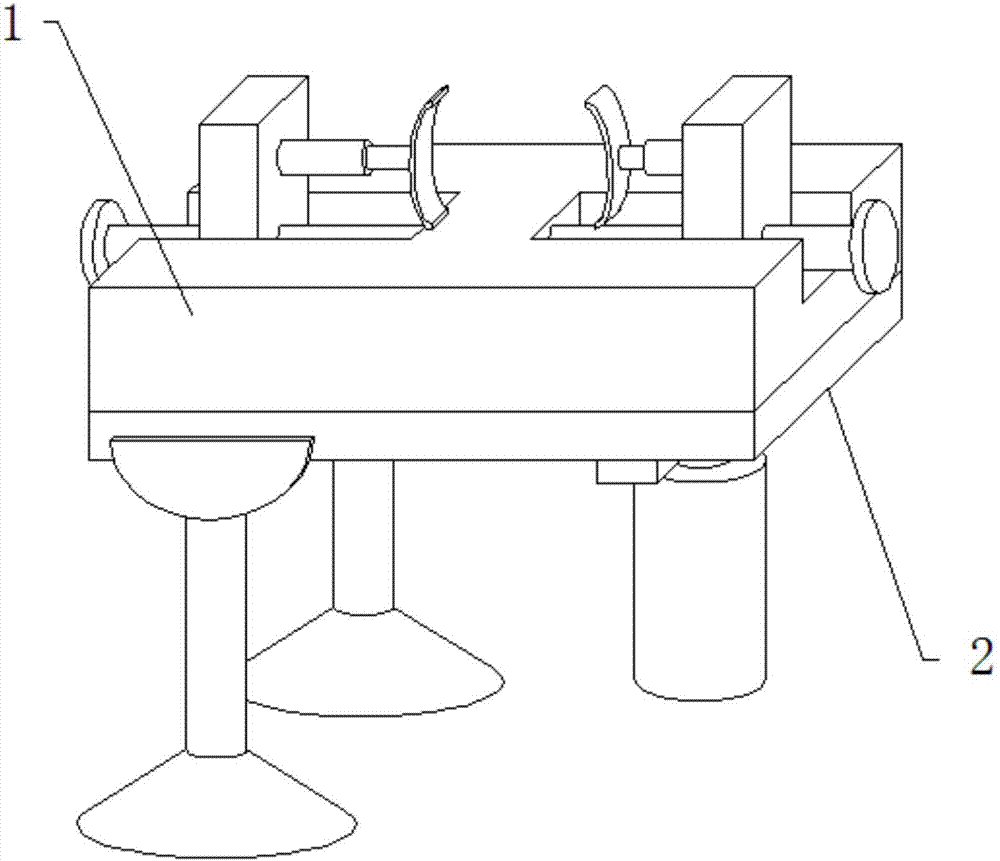

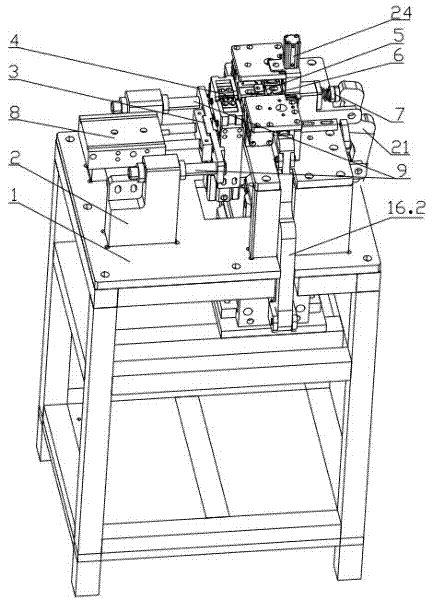

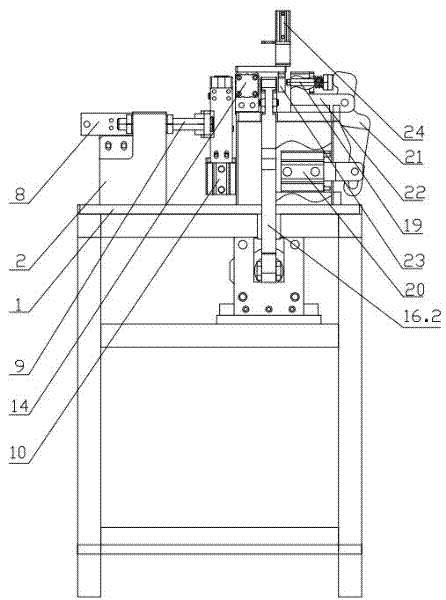

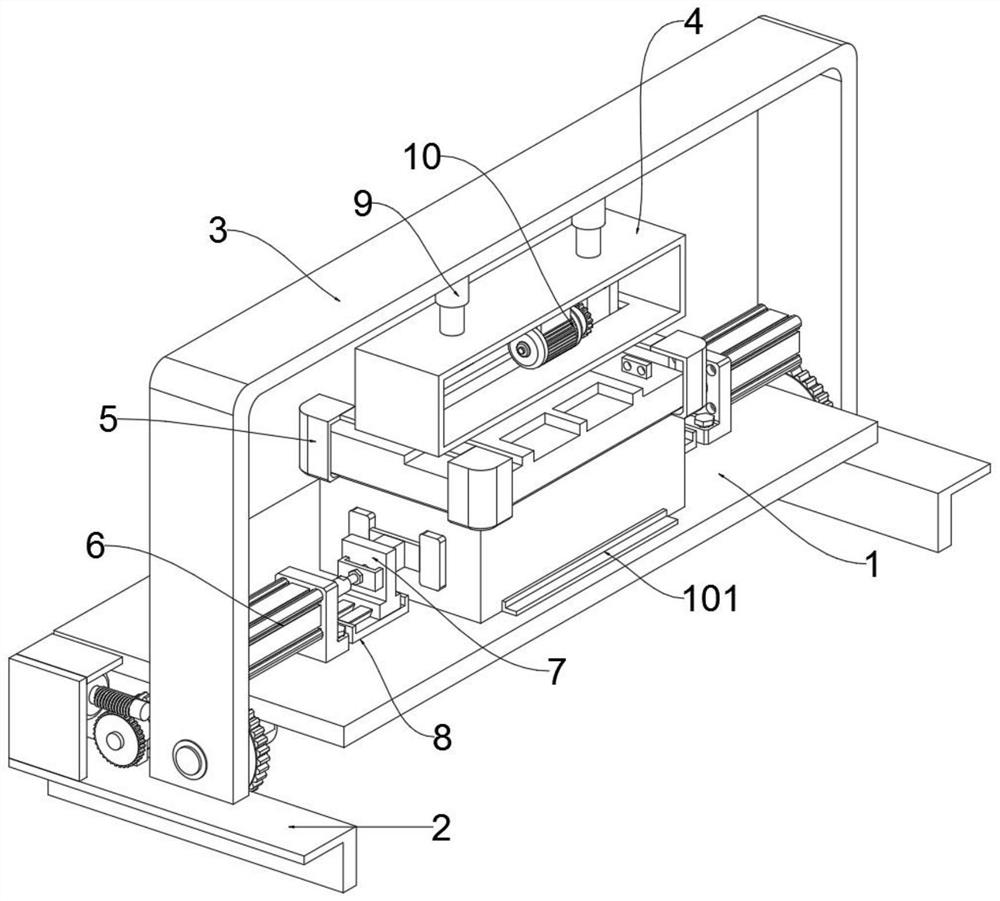

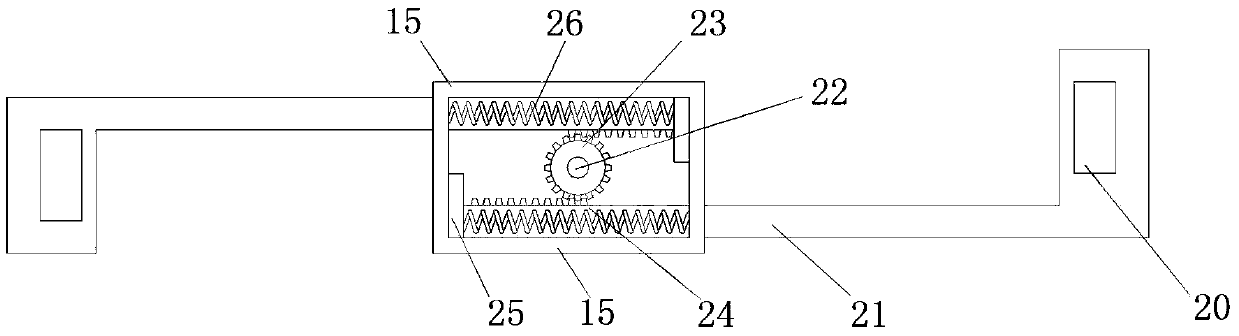

Integrated machine for peeling and embossing steel wire rope

The invention discloses an integrated machine for peeling and embossing a steel wire rope. The integrated machine comprises a frame (1), a base (2) fixed on the frame, a first driving device fixed on the base (2), a connecting seat (3) connected with the first driving device, a first clamping device (4) fixed on the connecting seat (3), a first clamping driving device connected with the first clamping device (4), a cutter assembly (5) fixed on the frame (1), a cutter driving device connected with the cutter assembly (5), a second clamping device (6) fixed on the frame (1), a second clamping driving device abutted against the second clamping device (6), an embossing device (7) fixed on the frame (1) and an embossing driving device abutted against the embossing device (7). The integrated machine disclosed by the invention simultaneously has the functions of peeling and embossing the steel wire rope, and is simplified in the process flow and reduced in occupied area.

Owner:NINGBO AUTO CABLE CONTROLS

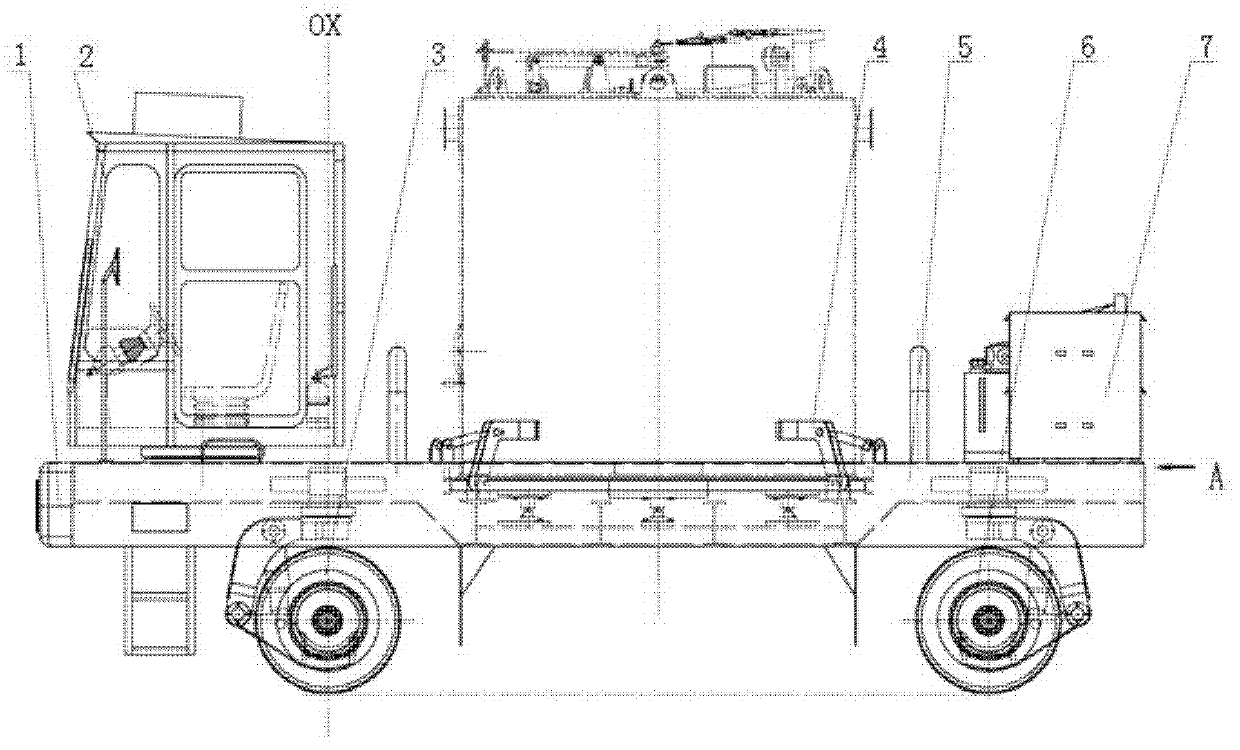

Two-man ladle transportation vehicle

ActiveCN102381229AEasy to operateEnvironmentally friendlyLoading/unloading vehicle arrangmentVehicular energy storageIn vehicleAutomotive engineering

The invention discloses a two-man ladle transportation vehicle, which relates to the technical field of a transportation vehicle and comprises a weighing system and a tilting prevention device, wherein the weighing system comprises a weighing sensor, an installing module, a weighing controller and a weight information display screen, the weighing sensor is arranged at the lower end of a two-man ladle platform of the two-man ladle transportation vehicle through the installing module, the weighing controller is respectively connected with the weighing sensor and the weight information display screen, and the tilting prevention device is arranged at the periphery of the two-man ladle platform. The invention provides a new transfer tool for the steel ladle transportation in a factory, and thetwo-man ladle transportation vehicle is improved, so the two-man ladle transportation vehicle has the weighing and tilting prevention function, a power storage battery device is used as motive power,the static hydraulic transmission is adopted, a lifting function and a multi-mode steering function are realized, the two-man ladle transportation vehicle belongs to a tire type transportation devicerealizing wireless communication of central control instructions and vehicle-mounted information, the two-man ladle transportation vehicle is environmental-friendly and does not cause pollution, and the conveyance work of magnesium chloride high-temperature melt is completed under the condition of ensuring the safety.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

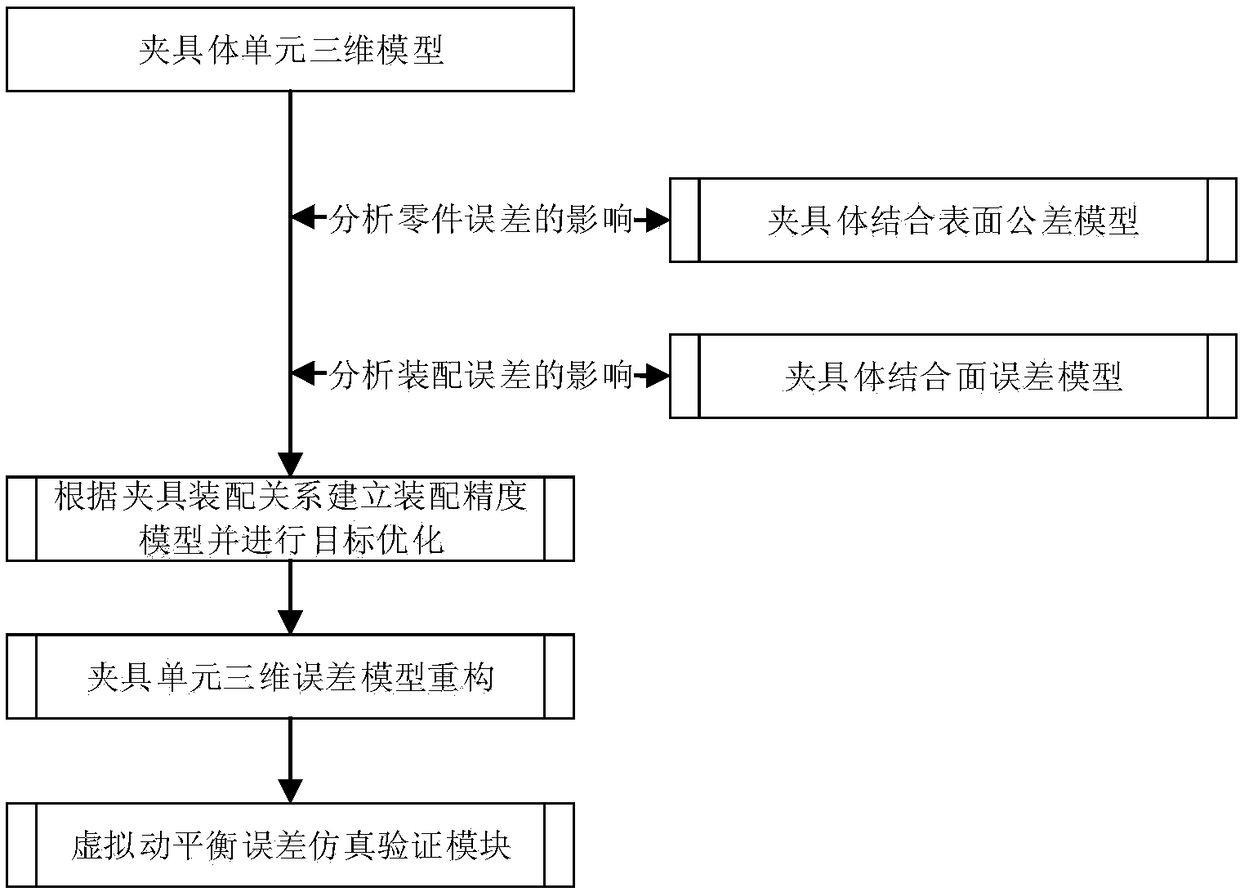

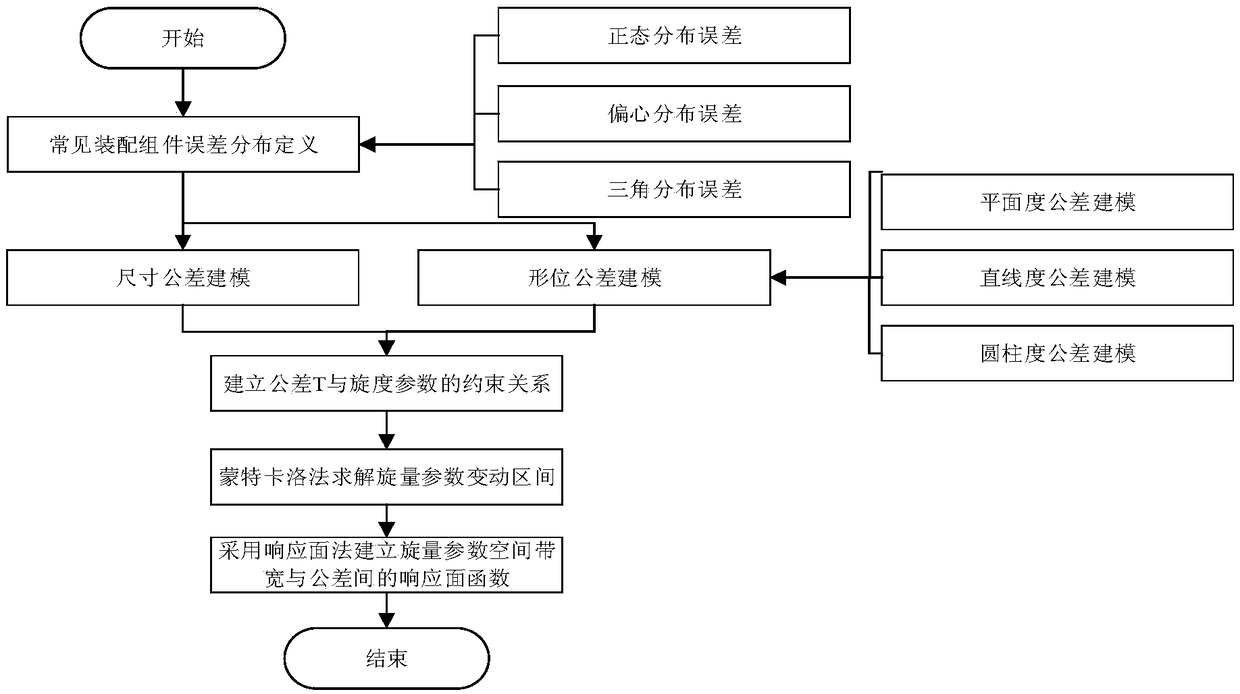

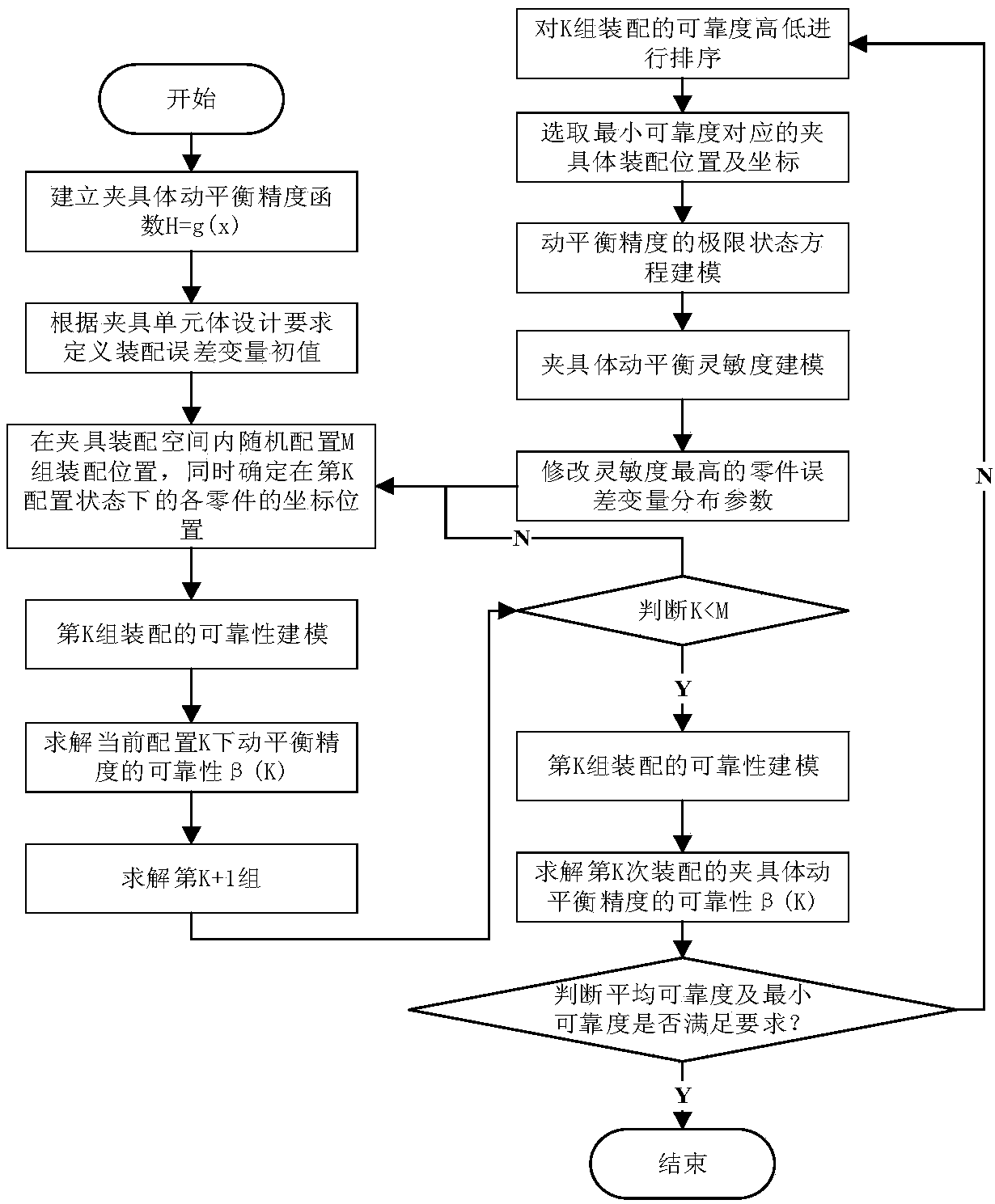

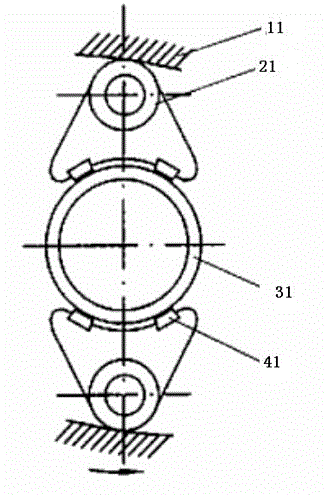

Joint surface error and joint surface tolerance optimization method for machine tool fixture component

InactiveCN108268010ARealize the clamping functionCancel or reduce the passive trim processProgramme controlComputer controlGeometric errorDynamic balance

The invention relates to a joint surface error and joint surface tolerance optimization method for a machine tool fixture component. According to the prior art, the quality characteristics of a machine tool fixture component cannot truly reflect the quality distribution condition of the machine tool fixture component, which can influence calculation accuracy and trimming precision and make automation hard to realize, and therefore, the invention provides the method to solve the problems in the prior art. The method of the invention includes the following steps that: 1, surface tolerance is represented by a homogeneous matrix; 2, joint surface error is represented by a homogeneous matrix; 3, a geometric error transfer model of assembly is constructed; 4, the surface tolerance and joint surface error are optimized according to the nature of error terms; 5, sensitivity is analyzed; 6, a part surface error or surface tolerance parameter optimization method is established with the processing cost of the fixture component adopted as an objective and assembly precision reliability and tolerance selection principles adopted as constraints; and 7, the distribution rule and parameter of theimbalance of a fixture component assembly body are obtained through a simulation experiment after the optimization result of the spinor parameter of the assembly body is obtained, and therefore, the dynamic balance optimization design of the assembly body is realized.

Owner:XIAN TECHNOLOGICAL UNIV

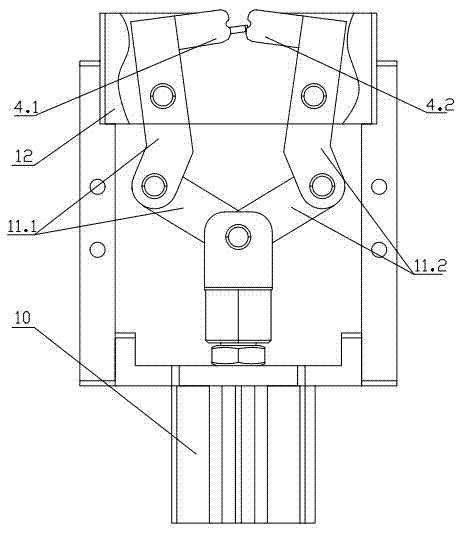

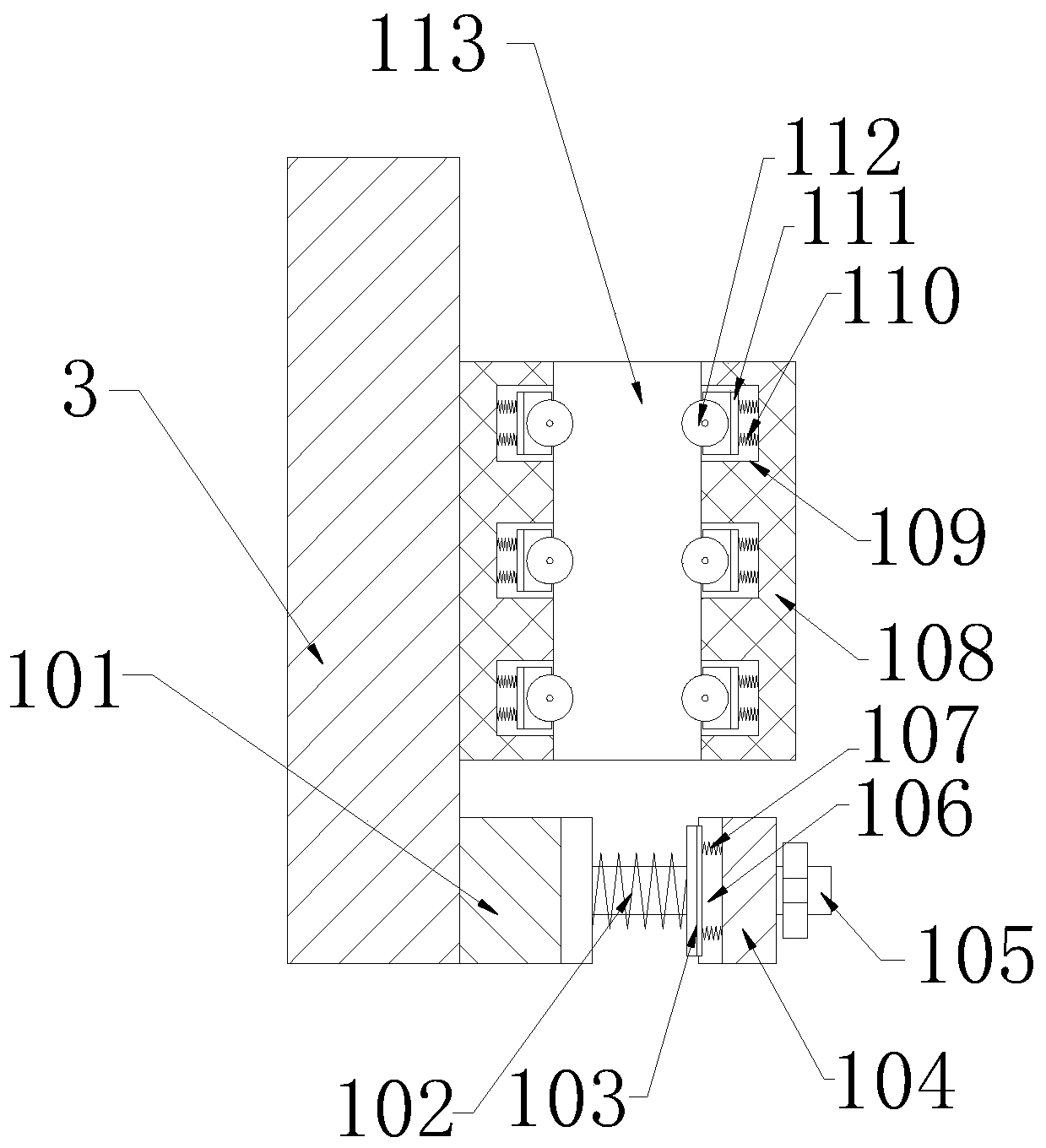

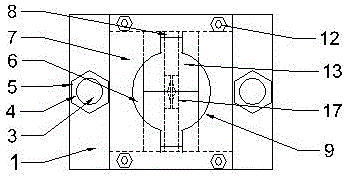

Clamping mechanism adaptable to multiple pipe diameters

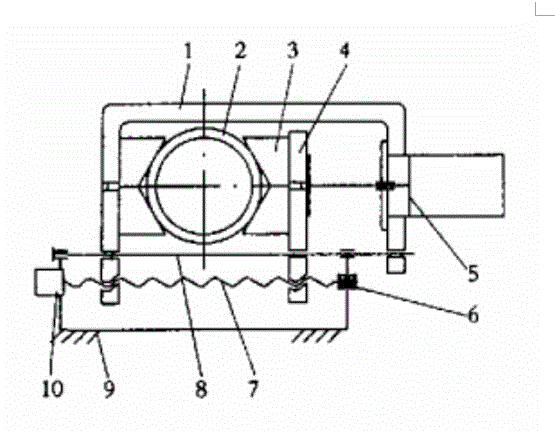

InactiveCN105751099ASolve problems requiring different clamping mechanismsRealize the clamping functionWork holdersMetal working apparatusHydraulic motorHydraulic cylinder

The invention discloses a clamping mechanism adaptable to multiple pipe diameters. The clamping mechanism is characterized by comprising a rack (9) playing a supporting role, a lead screw (7) playing a transmission role is mounted on the rack (9), a hydraulic motor (10) is mounted at one end of the lead screw (7), the other end is connected with a limit device (6), a supporting frame (1) and a V-shaped block base (4) are assembled on the lead screw (7) in a meshed manner, a V-shaped block (3) for clamping a pipe fitting (2) is mounted on each of the supporting frame (1) and the V-shaped block base (4) oppositely, a supporting shaft (8) which plays guiding and supporting roles and is fixed on the rack (9) is also mounted on the supporting frame (1) and the V-shaped block base (4), and a hydraulic cylinder (5) playing a pressing role is mounted on the outer side of one end, far away from the V-shaped block (3), of the supporting frame (1).

Owner:CHENGDU WENDA MAOYUAN TECH

Welding rod conveying device used for welding machinery

InactiveCN108705229AUniform and continuous weldingAvoid burns and electric shock accidentsWelding/cutting auxillary devicesAuxillary welding devicesScaldingEngineering

The invention relates to the technical field of welding rod conveying, in particular to a welding rod conveying device used for welding machinery. The welding rod conveying device includes a bottom plate and a GM12-N20 motor; the front end of the bottom plate is fixedly connected with the GM12-N20 motor, the tail end of a spindle of the GM12-N20 motor is fixedly connected with a vertically-arranged reciprocating screw rod, a sliding block is arranged at the rear end of the reciprocating screw rod, and the rear end of the sliding block is in sliding connection with the front end surface of thebottom plate; and the front end surface of the bottom plate is fixedly connected with a storing box, and the left end of the inner side of the storing box is fixedly connected with a horizontally-arranged first spring. According to the welding rod conveying device, the exhausted welding rod is replaced automatically through the arranged GM12-N20 motor, the reciprocating screw rod and the sliding block, the uniform and continuous welding is ensured, the time to manually replace the welding rod is saved, the scalding and electric shock accidents can be prevented during the replacement of the welding rod, the safety and high efficiency of the welding work are ensured, the design concept is novel, the design is scientific, the huge economic benefits and wide market prospects are achieved, andthe welding rod conveying device is worthy of being used and popularized.

Owner:繁昌县通民机械制造有限公司

Quick clamping device

InactiveCN102052882ARealize the clamping functionRealize self-locking and anti-off functionSighting devicesSelf lockingCam

The invention relates to a nonlinear curve eccentric cam type quick clamping device. When a handle of a nonlinear curve eccentric cam is closed, the eccentric cam reaches a highest point to realize a clamping function; the curve surface of the cam is a nonlinear curve surface, and a self-locking and anti-falling function is realized; when a spanner is pulled, the eccentric cam reaches a lowest point, and under the action of a tension spring, a fixed slip groove and a movable slip groove are loosened. In the invention, the clamping force is regulated through regulating the connecting threads of a pull rod sleeve and a pull rod shaft, thus the eccentric cam can be used for realizing the functions of quickly assembling and disassembling, quickly clamping, self-locking and preventing loosening. The eccentric cam has the advantages of compact structure, small size, light weight, convenience for operation, and the like and solves the problems of slower mounting, complicated operation and low efficiency of the traditional clamping device.

Owner:XIAN HUANIC OPTOELECTRONICS CORP

Clamping mechanism applied to mould machining

The invention discloses a clamping mechanism applied to mould machining. The clamping mechanism comprises a clamping base. Two first fixing blocks are welded to the top end of the clamping base and arranged away from each other. Fixing through holes are formed in the first fixing blocks. Clamping rods are slidably mounted in the fixing through holes, and the two ends of the clamping rods both extend out of the fixing through holes. Rubber blocks are fixedly mounted on the sides, close to each other, of the two clamping rods correspondingly. Second fixing blocks are arranged on the two sides of the clamping base correspondingly. Two supporting feet are welded to the bottom end of each second fixing block. Clamping rod grooves are formed in the sides, close to the first fixing blocks, of the second fixing blocks and slidably connected with the ends, located outside the fixing through holes, of the clamping rods. Screw holes are formed in the sides, away from the rubber blocks, of the clamping rods. The clamping mechanism is simple in structure, convenient to use, capable of clamping a mould rapidly, high in automation degree and capable of saving time and improving the working efficiency.

Owner:RUGAO CITY XIANGQIANG MACHINERY EQUIP CO LTD

Optical element clamping and angle adjusting mechanism

An optical element clamping and angle adjusting mechanism comprises an outer base, an inner top plate, a magnetic plate, one magnet, connection rods, vertical rods, a limiting column, another magnet, a fixed rod and a movable rod. The top plate and a bottom plate rotate relative to each other by adjusting the fixed rod and the movable rod. Under the action of the magnetic plate and the magnets, the top plate keeps in contact with the bottom plate. The three vertical rods are driven to separate through the three connection rods, optical elements of different sizes can be placed, then the rods are reset under the magnetism action of the magnets, the optical elements are clamped among the vertical rods, and accordingly the function of clamping the optical elements of different diameters and sizes is achieved. Due to screw holes in the magnets and a thread screwing mechanism, the vertical rods can move in kidney-shaped limiting through holes in the rear side of the bottom plate, and three-angle adjusting in a plane is achieved. By means of the optical element clamping and angle adjusting mechanism, clamping is achieved through the magnets, a flexible hinge or a spring adjusting mechanism in the prior art is omitted, the structure is simple, and the whole structure is stable, reliable and compact.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Thin-wall pipe automatic material returning and clamping device

InactiveCN101121232ASimple structureEasy to operateThread cutting feeding devicesMetal-working feeding devicesOne shotBiomedical engineering

The present invention is an automatic material returning and clamping device for tubing of thin wall belonging to the technical field of machine manufacturing. The present invention mainly comprises a supporting plate (1), an internal sliding sleeve (2), a lifting head (3), a clamping spring (8), a material return slip (7) and a connecting screw (9). The supporting plate is equipped with an external sleeve and the clamping spring and internal sliding sleeve are equipped in the external sleeve and can slide in the external sleeve; the upper and lower surfaces of the external sleeve are equipped with a key through hole; the connecting screw is penetrated through the key through hole and connected with a sliding block; the connecting screw can move right and left in the key through hole; the internal sliding sleeve is a hollow cylinder with one open end; the lifting end of the lifting head (3) is processed into a mold corresponding to the tubing finished product. The present invention can realize automatic clamping; by processing the lifting head and knife end face into molds, one-shot molding of thin-wall tubing end face and side can be realized.

Owner:BEIJING UNIV OF TECH

Wire-bunching device for electronic communication cable

InactiveCN109787162ARealize guided movement functionGood orientationElectrical apparatusElectronic communicationEngineering

The invention provides a wire-bunching device for an electronic communication cable. The device comprises a support platform, a return spring, a wire-bunching block and a wire-bunching port, the support platform is welded at the lower side of the right end surface of an installing plate, a screw rod is welded on the right side surface of the support platform, the return spring is arranged on an external annular side surface of the screw rod in a sleeved manner, the left end of the return spring is connected with the right end surface of the support platform in a welding manner, the right portion of the screw rod is provided with a clamping plate in a sleeved manner, the left side surface of the clamping plate is provided with an arc slot, a first resetting spring is welded on the internalsurface of the arc slot, a pressure plate is welded at the left end of the first resetting spring, the wire-bunching block is arranged at the central portion of the right side surface, the wire-bunching port is arranged at the central portion of the wire-bunching block, the right portion of the inner annular side surface of the wire-bunching port is provided with a groove, a second resetting spring is welded on the right side surface in the groove, a support is welded at the left end of the second resetting spring, and a guide wheel is arranged in the support. Compared with the prior art, thebeneficial effects of the device are that functions of guiding and clamping during installation of the communication cable are realized, and the clamping stability is good.

Owner:郑州拓华仪器有限公司

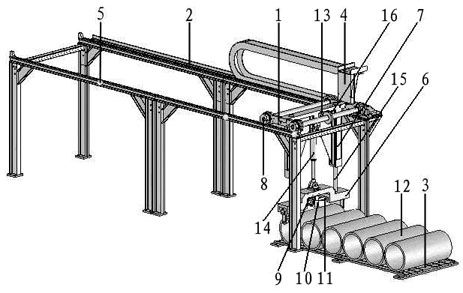

Multistation automatic upper sleeve system

ActiveCN101885013ARealize the clamping functionRealize lifting functionIndustrial engineeringElectrical and Electronics engineering

The invention belongs to the field of metallurgical equipment, in particular to a multistation automatic upper sleeve system, an outlet of which is provided with a full continuous cold mill train of two coiling machines. The multistation automatic upper sleeve system at least comprises a body, a rail body and a sleeve storage bracket, wherein the rail body and the sleeve storage bracket are fixed on a foundation by foundation bolts, the body comprises a clamping mechanism, a lifting mechanism and a cross travelling trolley, the cross travelling trolley of the body is connected with the rail body through a roller wheel in a rolling way; the clamping mechanism and the lifting mechanism are respectively connected with the cross travelling trolley, the clamping mechanism is used for clamping a sleeve of the sleeve storage bracket; the lifting mechanism is used for upwards moving the sleeve clamped by the clamping mechanism, then the cross travelling trolley on the rail body completes the conveying of the sleeve along the rail body, and when the multistation automatic upper sleeve system does not work, the cross travelling trolley stops at the end part of the rail body. The multistation automatic upper sleeve system meets the working condition of an upper sleeve on a station and upper sleeves on two stations and more than two stations.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

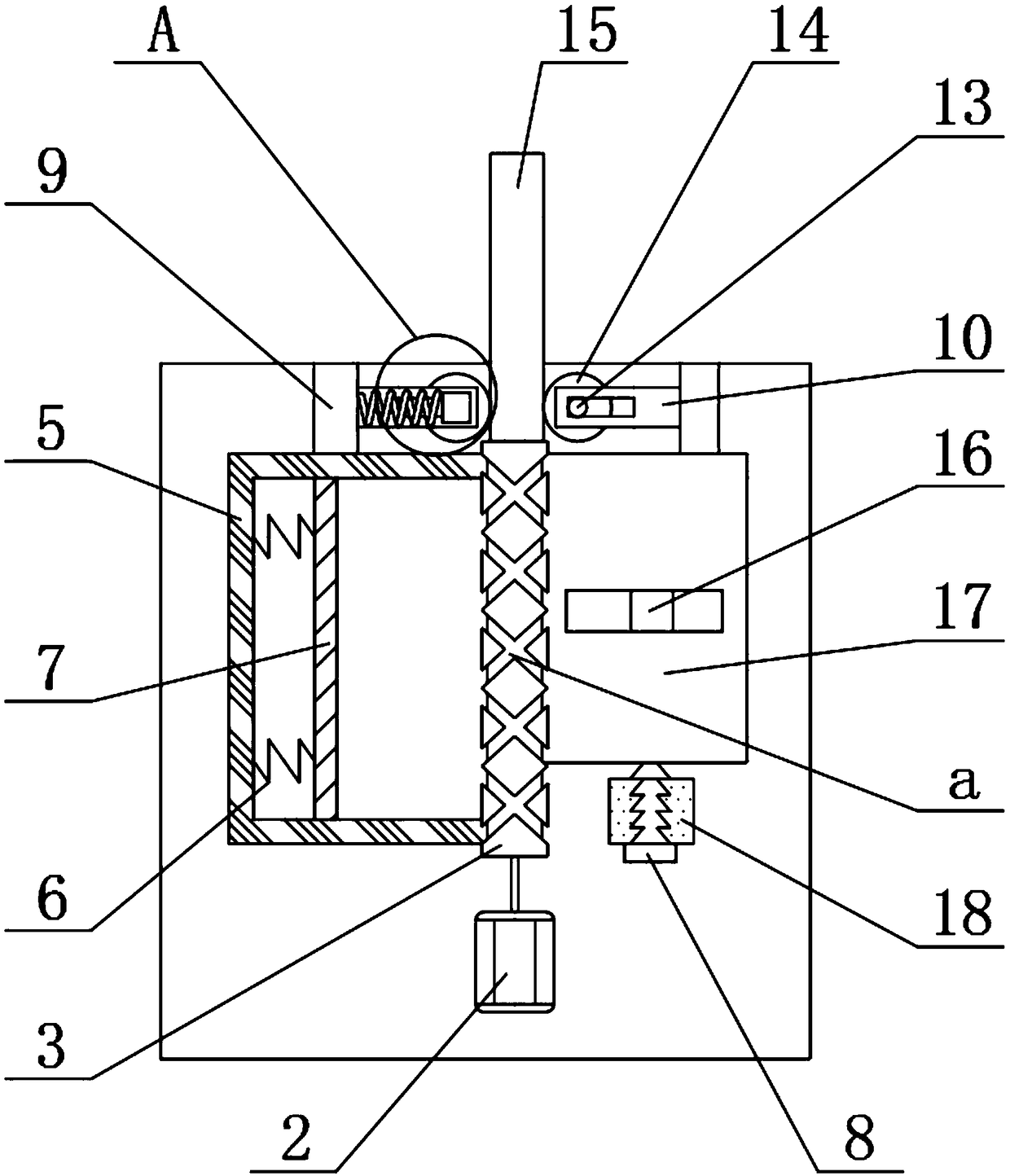

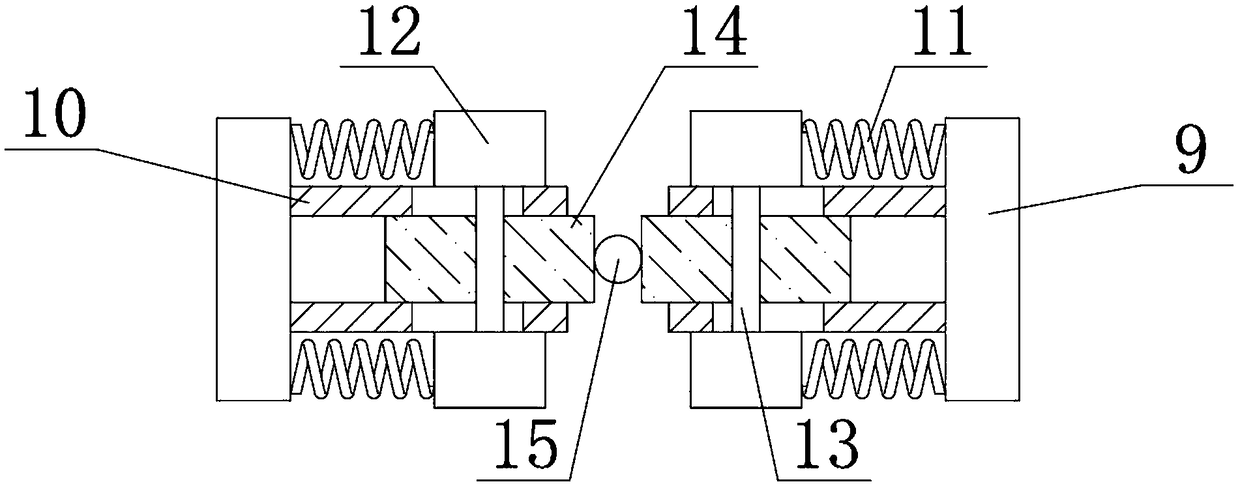

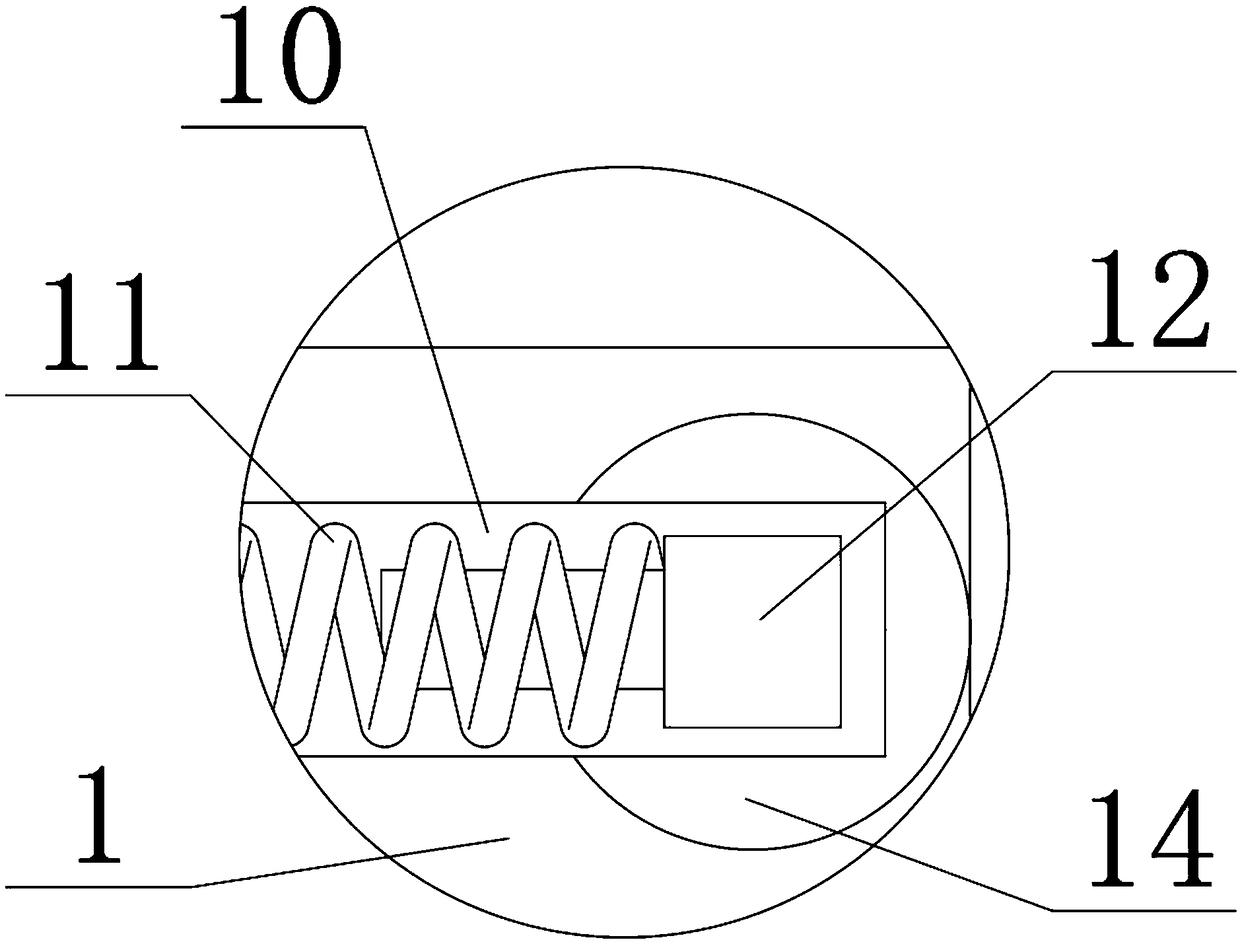

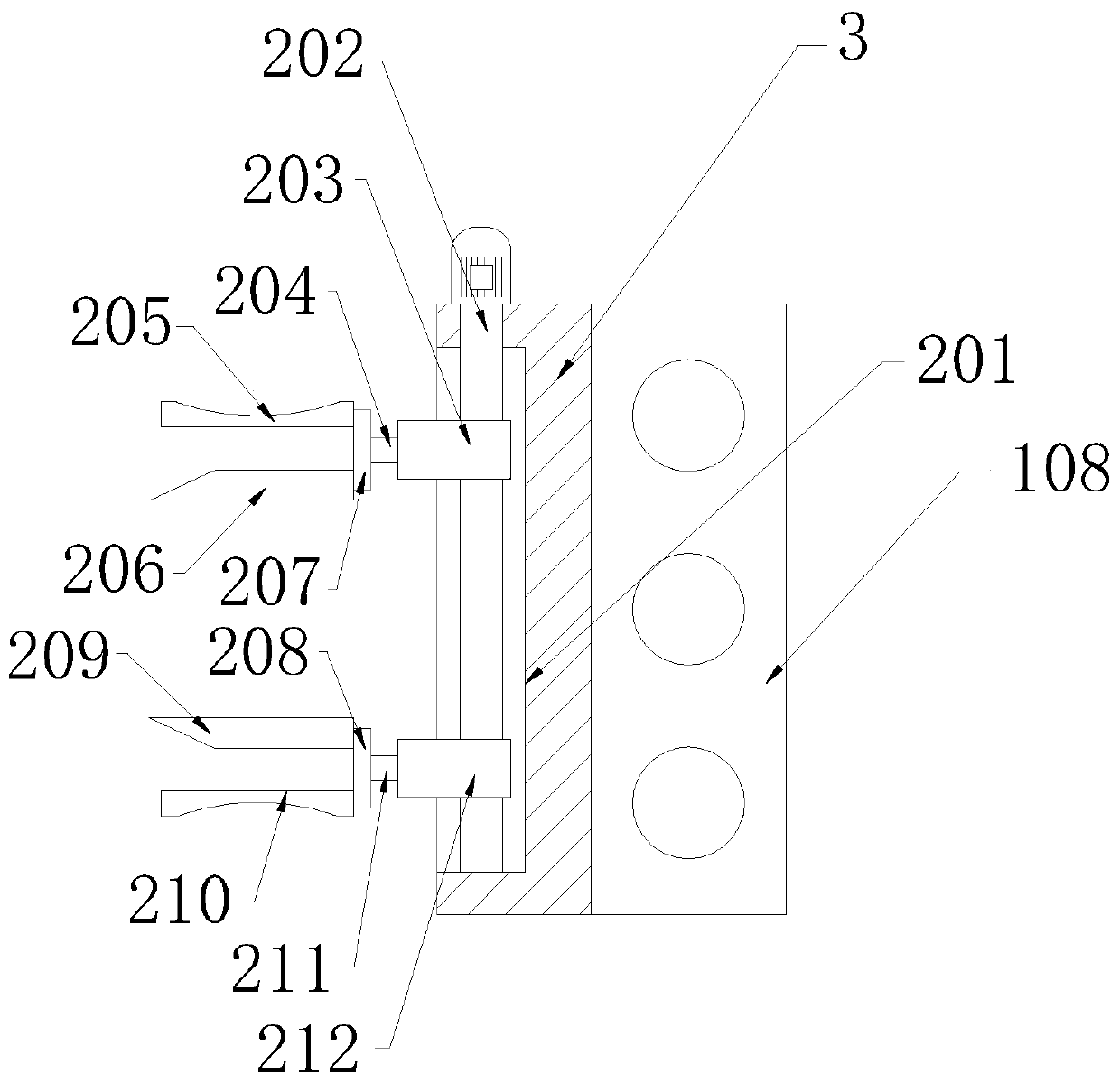

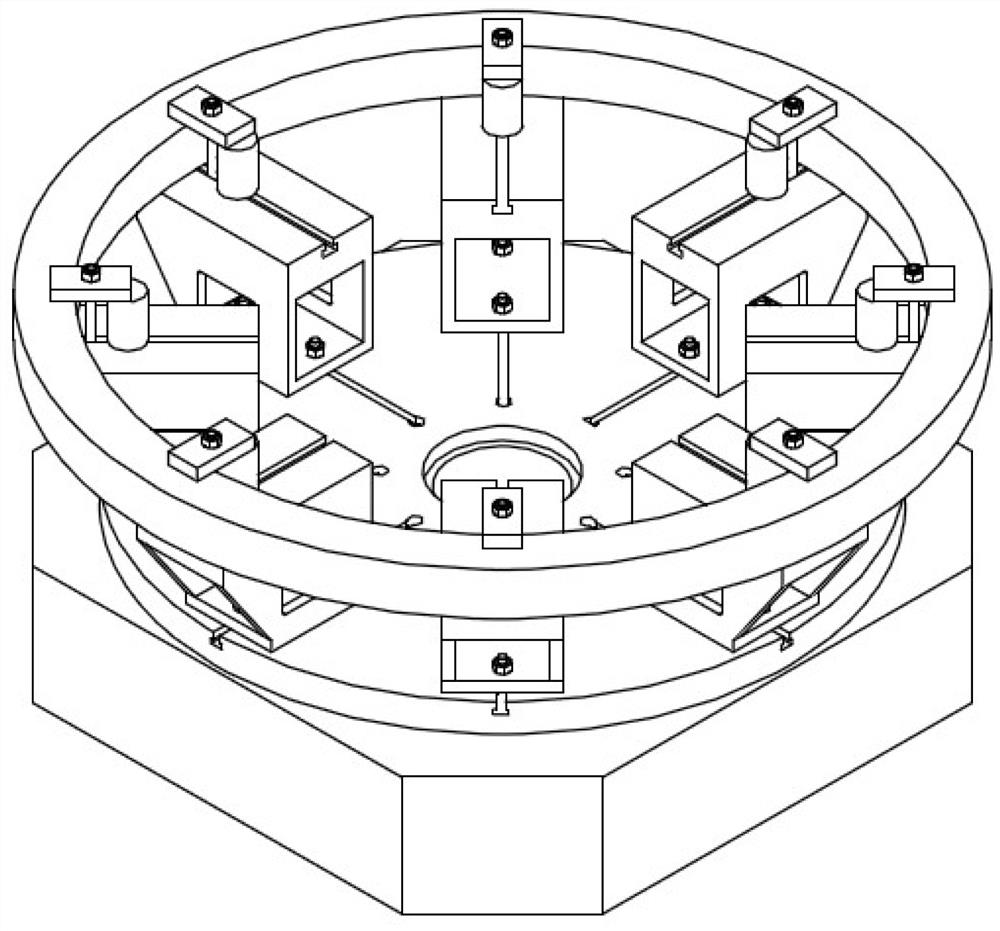

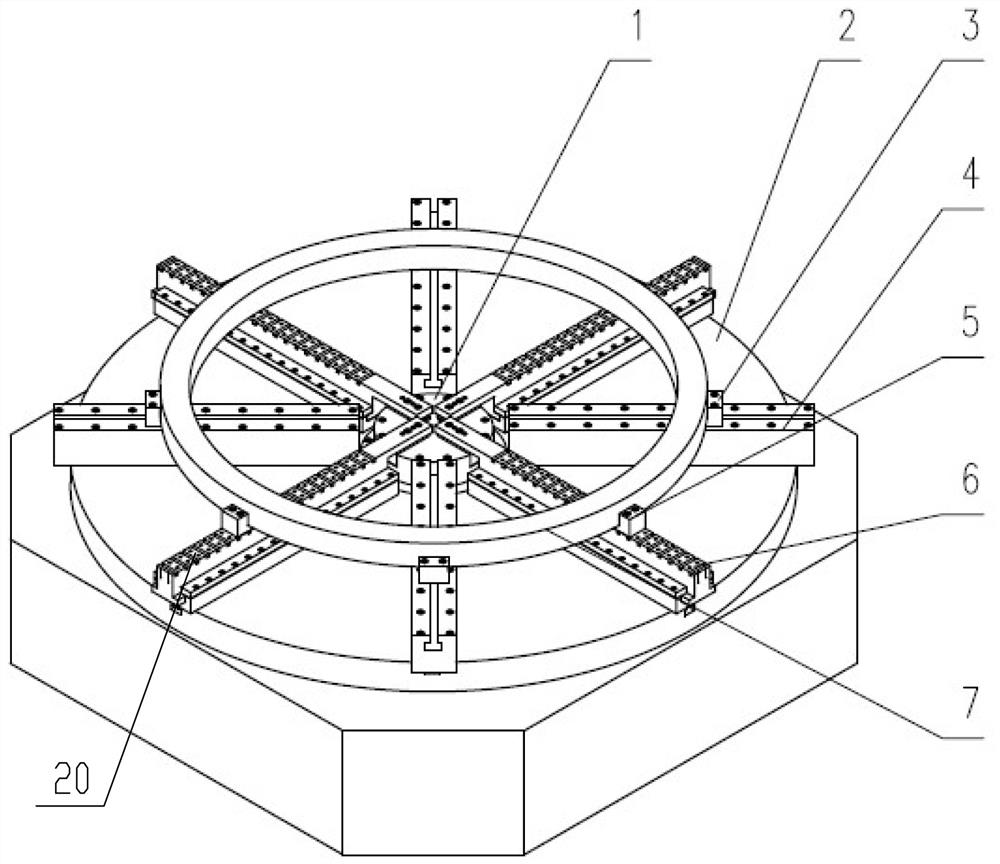

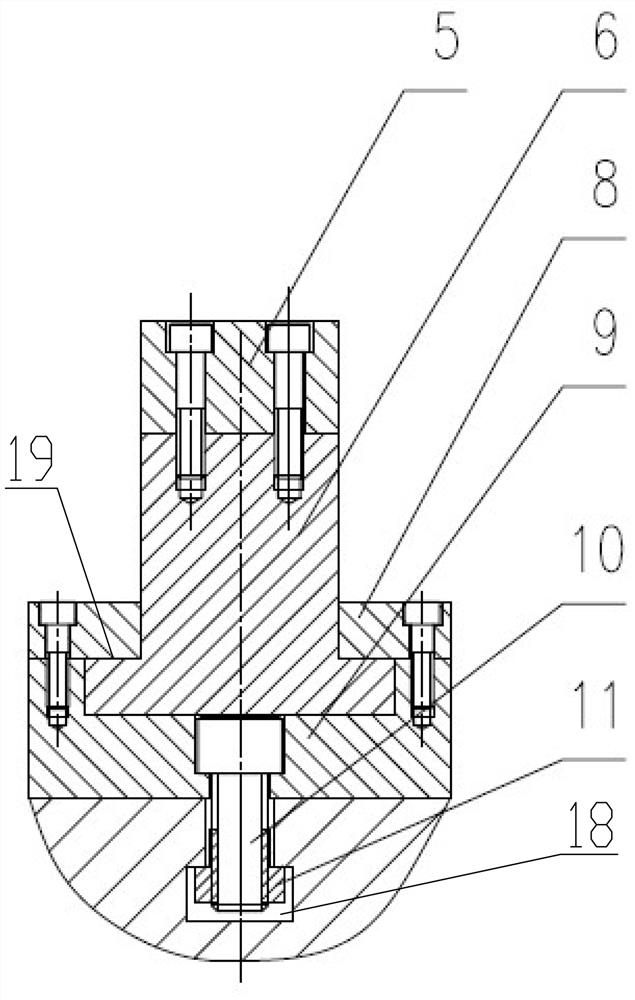

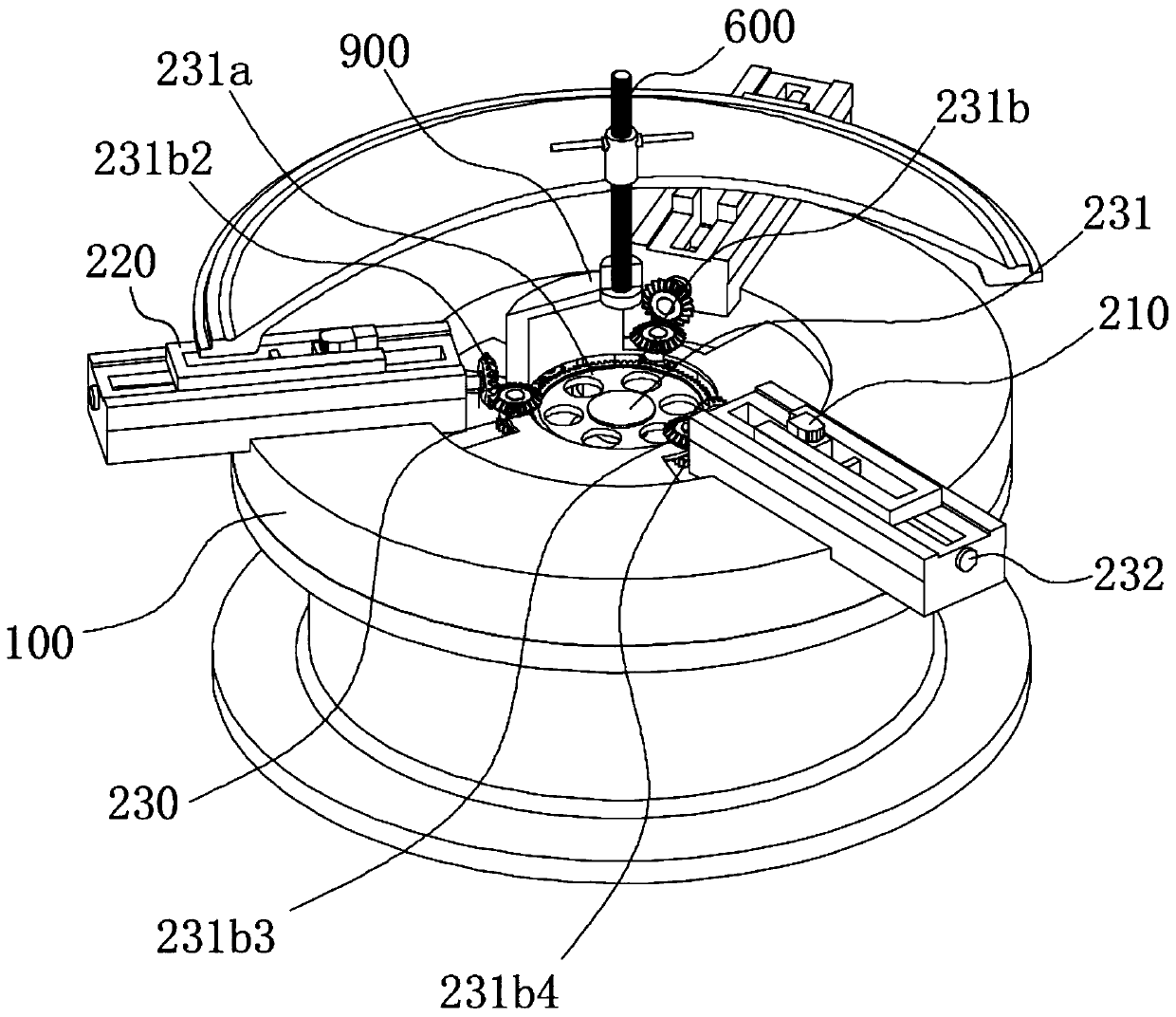

Automatic aligning and clamping device and method for circular parts

ActiveCN112917202ARealize the clamping functionRealize automatic alignmentPositioning apparatusMetal-working holdersStructural engineeringControl theory

Owner:宜昌长机科技有限责任公司

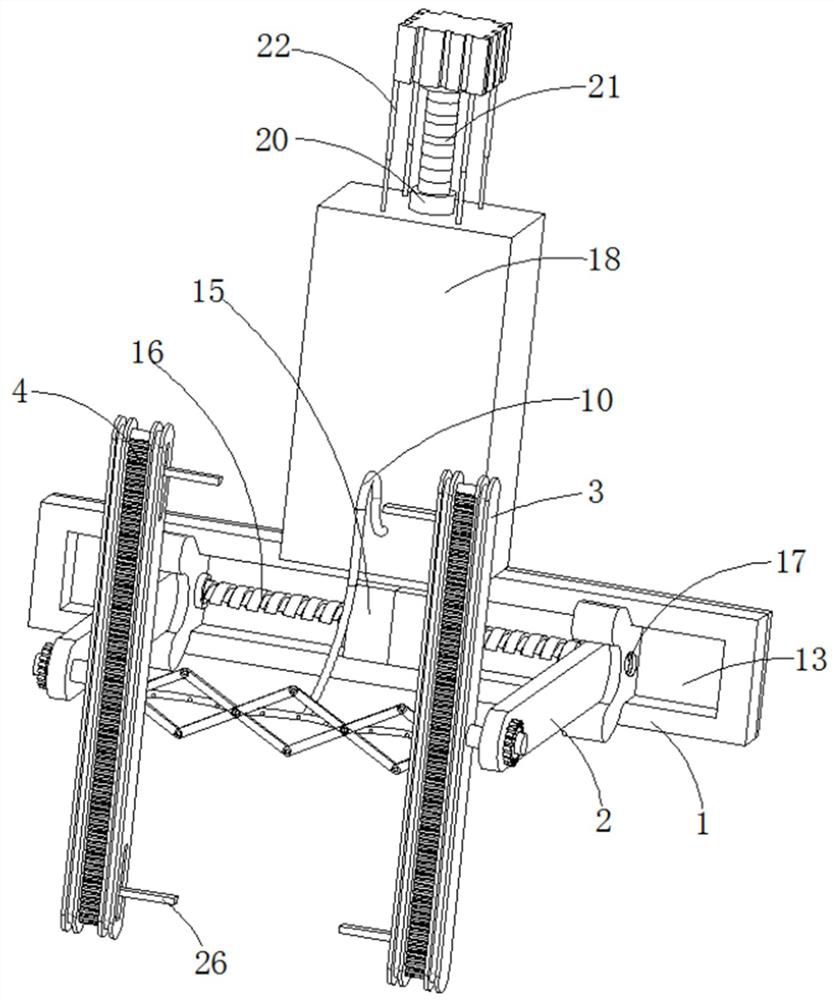

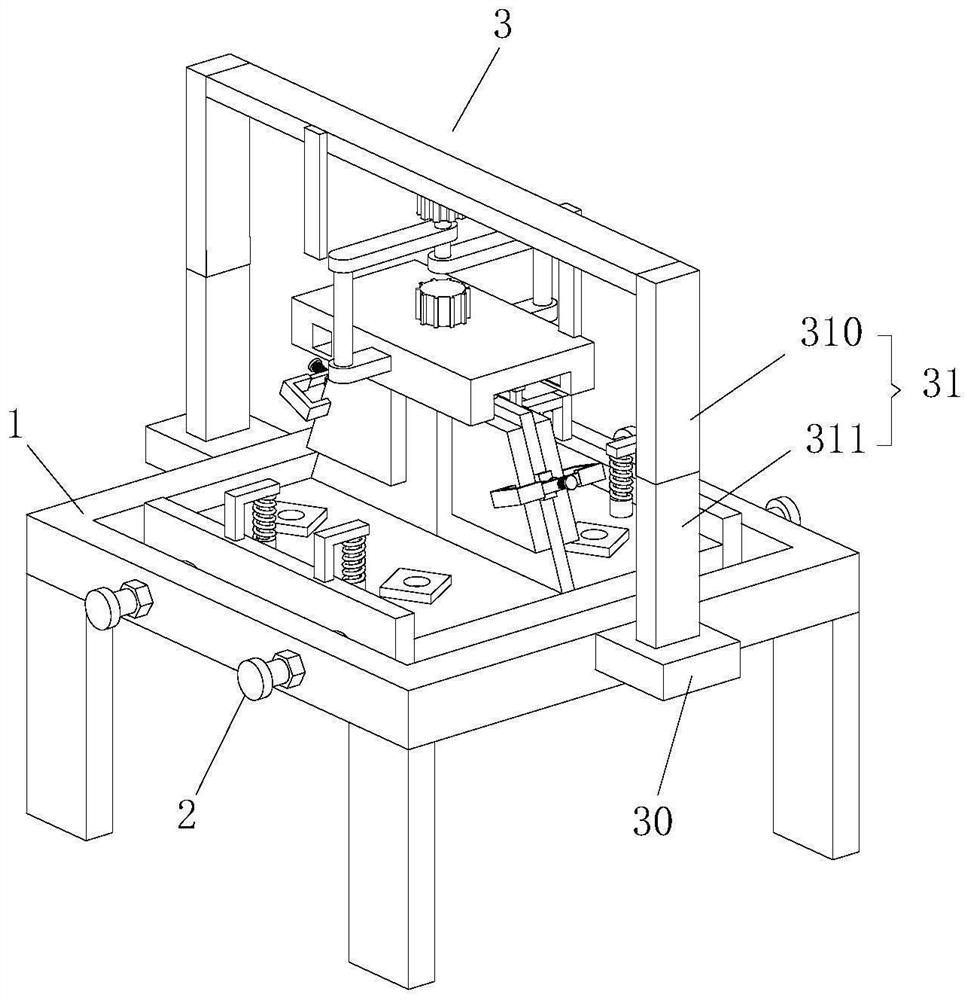

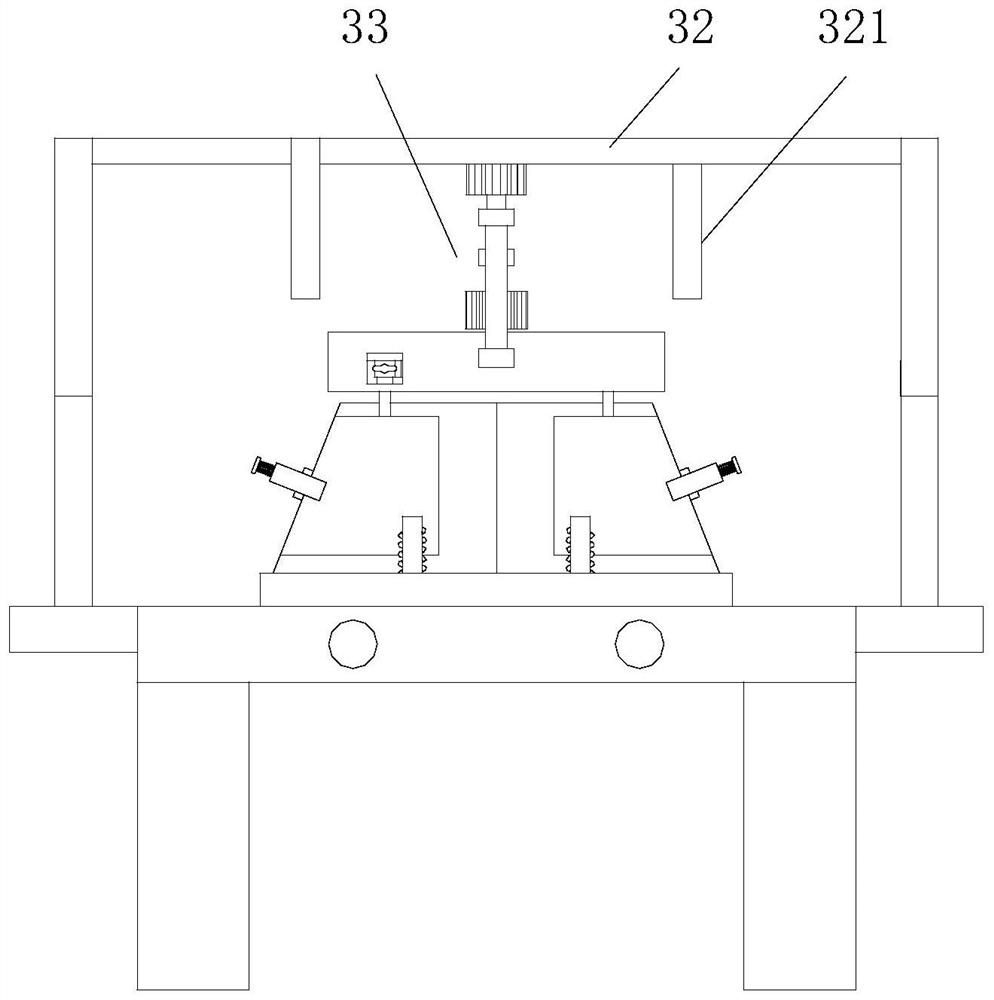

Automatic turnover type plate surface spraying device

ActiveCN111940169AImprove dispersion uniformityImprove automationLiquid spraying apparatusManufacturing engineeringGear wheel

The invention discloses an automatic turnover type plate surface spraying device and a using method thereof, and belongs to the technical field of plate surface spraying devices. The automatic turnover type plate surface spraying device comprises a mounting base, symmetrically-distributed supporting plates are connected to the mounting base, a spraying assembly is arranged at the outer side of themounting base, the spraying end of the spraying assembly is connected with a liquid outlet pipe, and the opposite sides of the supporting plates are rotationally connected with mounting plates through rotating shafts; the ends, penetrating through the supporting plates, of the rotating shafts are connected with intermittent rotating mechanisms fixedly connected to the supporting plates, two toothed plates which are evenly and symmetrically distributed in the length direction of the mounting plate are arranged on each mounting plate, arc transition is formed between the two toothed plates on each mounting plate, sliding grooves parallel to the toothed plates are further formed in the mounting plates, and driving sliding blocks and driven sliding blocks are slidably connected into the sliding grooves; and connecting pieces are connected between the driving sliding blocks and the driven sliding blocks, and the driving sliding blocks are connected with driving gears meshed with the toothed plates. According to the automatic turnover type plate surface spraying device, the automatic turnover function of a plate during spraying is realized.

Owner:濉溪县安乐殡仪服务有限公司

Waste lead-acid storage battery disassembling equipment

InactiveCN111740184AAchieve fixationRealize the clamping functionLead-acid accumulatorsWaste accumulators reclaimingIndustrial engineeringHydraulic pressure

The invention provides waste lead-acid storage battery disassembling equipment. The waste lead-acid storage battery disassembling equipment comprises an overturning table, a base frame, a lifting box,a cutting device, an air cylinder, a clamping block, a sliding base, a hydraulic rod, a first driving device and a synchronizing shaft. The two ends of the overturning table are rotationally connected to the two sides of a supporting frame through bearings. The upper surface of the base frame is connected with the supporting frame through welding. A cylinder body of a hydraulic lever is fixedly connected to the bottom of the supporting frame; the upper surface of the lifting box is fixedly connected to the tail end of a piston rod of the hydraulic lever; the first driving device is fixedly connected to the upper portion of the interior of the lifting box; a double-end lead screw is rotationally connected to a shaft bracket of the lifting box through a bearing; and a driven gear of the double-end lead screw is connected with an output shaft of the first driving device through gear engagement. Compared with an existing method for disassembling the lead-acid battery by utilizing crushingequipment, the provided method has the advantages that the housings and the lead blocks are more convenient to distinguish and classify, the step of manual selection is reduced, the contact time of workers and the lead blocks is shortened, and the probability of heavy metal poisoning is reduced.

Owner:刘环

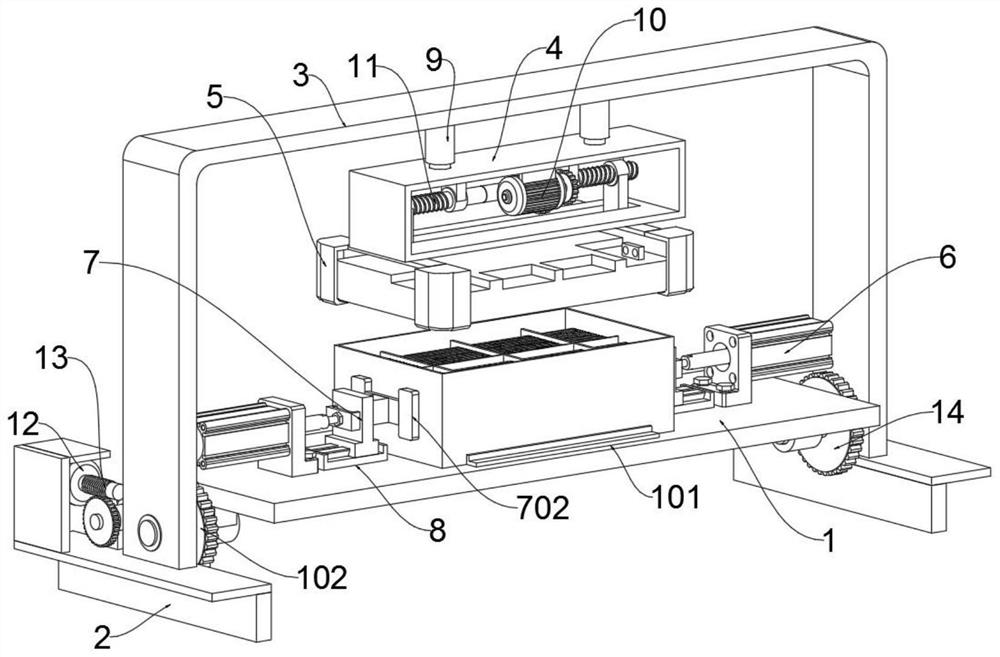

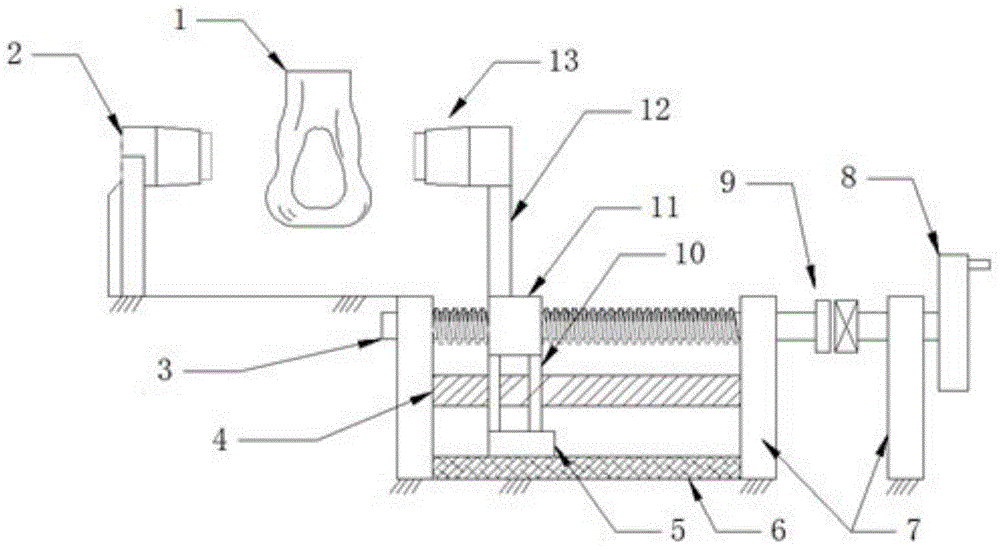

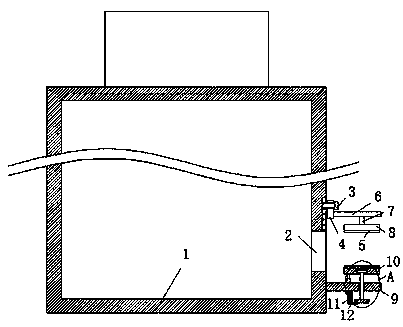

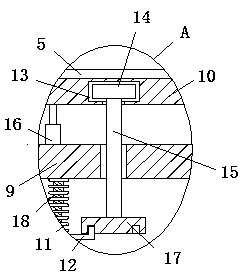

Contact type living body skeleton distance measuring device

InactiveCN103598887AControllable contact pressureConstant compressionDiagnostic recording/measuringSensorsBiological bodyContact pressure

A contact type living body skeleton distance measuring device is characterized by comprising a fixed contact (2) and a test contact (13) which can move on a slide rail. The test contact (13) is driven by a screw rod to move on the slide rail directly or through a connecting device. The screw rod and the slide rail are assembled on a fixed frame (7). One end of the screw rod is axially connected with a drive shaft of a drive device through an electromagnetic clutch (9). The test contact (13) is connected with a distance measuring device body directly or through the connecting device. According to the contact type living body skeleton distance measuring device, the current value of the electromagnetic clutch is monitored and controlled, so that the contact pressure between the test contact and the skin is controllable, the amount of compression of the skin is constant, different measurement person-time results are comparable, and it can be guaranteed that the root bone portion is not subjected to excessive pressure.

Owner:北京华健恒创技术有限公司 +1

Clamp

InactiveCN104440645ARealize the clamping functionEasy to operateClampsEngineeringMechanical engineering

The invention relates to the field of assembling tools, in particular to a clamp. The clamp comprises a plane base. Guide grooves are formed in the plane base. The clamp is characterized in that a pusher is further arranged on the plane base and comprises a fixing plate connected with the plane base, a convex lug is arranged at one end of the fixing plate, a fixing hole is formed in the other end of the fixing plate, the pusher further comprises a push handle and a push shaft, one end of the push handle is connected with an adapter connection sheet, the other end of the adapter connection sheet is connected to the convex lug through a hinge, the middle of the adapter connection sheet is connected with a push rod through a bolt, the other end of the push rod is connected with the push shaft, and the push shaft is embedded into and sleeved with the fixing hole. The clamp further comprises clamping blocks, the at least two clamping blocks can slide on the guide grooves, one of the clamping blocks is connected with the end face of the push shaft, and the other one of the clamping blocks is connected with the plane base through a fastening screw. The clamp has the advantages of being simple in structure, convenient to operate and high in adaptability.

Owner:CHANGZHOU HUAHAO KNITTING

Outer tooth milling machine

ActiveCN110788409AStable processingThere will be no problem of interference with milling gear machiningOther manufacturing equipments/toolsLarge fixed membersEngineeringMachine

The invention relates to an outer tooth milling machine. The outer tooth milling machine comprises a machine frame. A rotary table is installed on the machine frame. A tooth milling device and an exhaust groove machining device are arranged around the rotary table. Clamping devices are arranged on the rotary table and are used for clamping and positioning corresponding workpieces to make the to-be-machined outer ring walls of the workpieces in a machined state. The outer tooth milling machine is reasonable in layout, stable in structure, capable of automatically positioning and clamping workpieces with different sizes and making the outer ring walls of the workpieces with the different sizes in the machined state, and high in applicability, and meets existing using requirements.

Owner:安徽金马热能设备有限公司

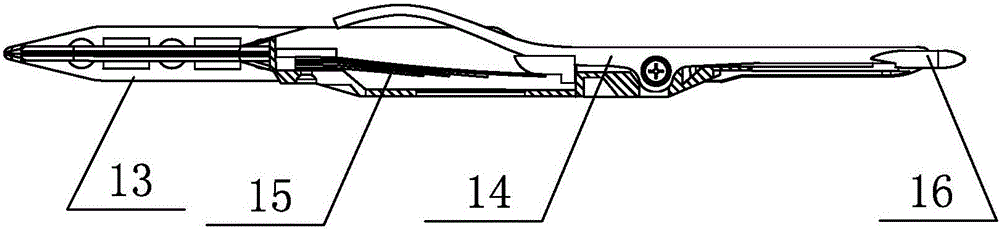

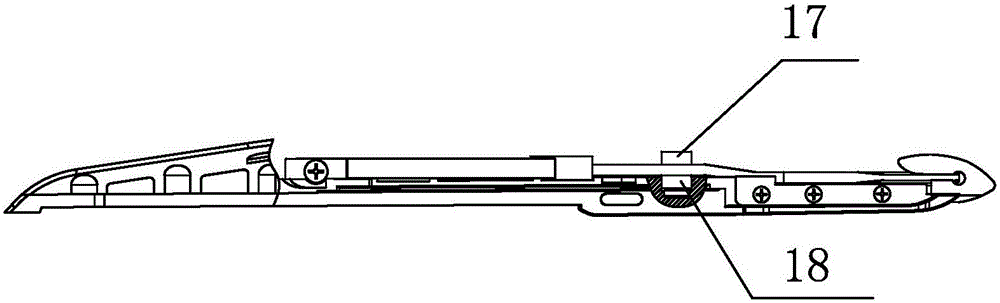

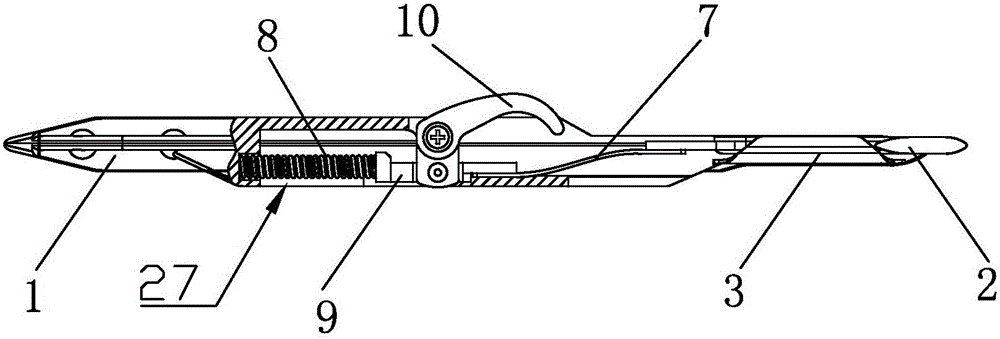

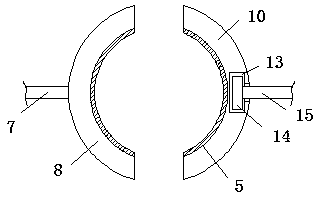

Weaving sword head for flat spun gold textile and sword rod loom

The invention discloses a weaving sword head for a flat spun gold textile and a sword rod loom, and the weaving sword head comprises a sword casing, a hook and a motion actuating mechanism, wherein, the hook is fixed on the sword casing by a screw; the motion actuating mechanism is installed inside the sword casing; a loose thread guiding apparatus is arranged on the hook; the hook is connected to the motion actuating mechanism; the motion actuating mechanism comprises a yarn clamping head, a brace, a linkage spring seat, a folding apparatus and a compression spring; the hook is connected to the yarn clamping head; the yarn clamping head is connected to the brace; the brace is connected to the linkage spring seat; the folding apparatus is arranged at the central section of the linkage spring seat; and the compression spring is arranged at the end of the linkage spring seat. The weaving sword head is used for processing textiles like metal wire or flat spun gold on a sword rod loom. The weaving sword head for the sword rod loom is safe and reliable, has a simple and stable structure, and can get a stable yarn clamping effect.

Owner:SHENGZHOU QIANJIN TEXTILE MACHINERY CO LTD

Unmanned aerial vehicle pesticide spraying device

InactiveCN111202038APrevent from crashingAchieve fixationPower plant typeInsect catchers and killersPeristaltic pumpAgricultural engineering

The invention relates to the technical field of agriculture, in particular to an unmanned aerial vehicle pesticide spraying device, and aims to overcome the disadvantages that liquid pesticide in a pesticide kit is not full, and an unmanned aerial vehicle is easy to crash because of inertia dithering, and the disassembling and assembling of the pesticide kit in the unmanned aerial vehicle are complicated. The unmanned aerial vehicle pesticide spraying device comprises an unmanned aerial vehicle body, wherein an accumulator is fixed to the bottom of the unmanned aerial vehicle body through bolts; wiring frames are welded to the periphery of the unmanned aerial vehicle body; and a dual-shaft motor is fixedly mounted at the tail ends of the wiring frames through bolts. According to the unmanned aerial vehicle pesticide spraying device disclosed by the invention, the output end at the bottom of the dual-shaft motor is used as a power source of a peristaltic pump, the liquid pesticide in the pesticide kit is extracted by the peristaltic pump, and the sprinkling effect is realized through a spray nozzle; a buffer spring mounted in each compression fixing frame is used for pushing a corresponding rubber ball at the tail end of a corresponding supporting rod to slide in a corresponding clamping groove formed in the surface of the pesticide kit, so that the functions of buffering and clamping on the medical kit are realized, the situation of crashing caused by inertia dithering of the liquid pesticide in the medical kit is reduced, the disassembling and assembling of the medical kitare very convenient, and the working performance is improved.

Owner:陕西安格锐信息科技有限公司

Steel structure manufacturing and machining system

ActiveCN113210915AAchieve fixationAdjustable distanceWelding/cutting auxillary devicesAuxillary welding devicesMachineMachining system

The invention relates to a steel structure manufacturing and machining system. The steel structure manufacturing and machining system comprises a workbench, a limiting device and a clamping and aligning device, the workbench is connected with the existing ground, the limiting device is arranged on the workbench, and the clamping and aligning device is arranged above the limiting device. A limiting bolt can push a limiting plate by rotating the limiting bolt, the front end and the rear end of a square base are clamped and limited, so that the square base is fixed, and the square base is prevented from deviating in the welding manufacturing and machining process; and meanwhile, the distance between limiting plates can be adjusted by adjusting the limiting bolt, so that the machine can fix bases of different sizes, and connecting supports of different specifications can be manufactured.

Owner:山东瑞驰钢结构有限公司

Electric welding gun device capable of automatically replacing welding rod and adjusting feeding speed

ActiveCN111843135ARealize automatic replacementRealize the clamping functionElectrode supporting devicesPhysicsWelding

The invention discloses an electric welding gun device capable of automatically replacing a welding rod and adjusting a feeding speed. The device comprises a gun body, wherein a wheel disc cavity is formed in the gun body, a cover body cavity with a rightward opening communicates with the right side of the wheel disc cavity, a cover body is in threaded fit connection with the interior of the coverbody cavity, a rotating block is fixedly connected to the right end face of the cover body, a push plate cavity communicates with the lower end wall of the wheel disc cavity, the lower end wall of the push plate cavity communicates with a delivery cavity, and the lower end wall of the delivery cavity communicates with a reset cavity. According to the device, automatic replacement of the welding rod is achieved through timing rotation of a wheel disc, the working time is saved to a great extent, the working efficiency is improved, meanwhile, a welding rod clamping function is achieved throughextrusion of a tip sliding block, a push plate is driven to move forwards through rotation of a conveying belt to achieve feeding of the welding rod, and the feeding speed is controlled by controllinga rotating speed of the conveying belt, so that working errors are reduced, and the working quality is improved.

Owner:上海中巽科技股份有限公司

Tensile clamping and quick assembling and disassembling multipurpose clamp

ActiveCN106736658AFully and evenly lubricatedWork resistance is smallPositioning apparatusMaintainance and safety accessoriesMechanical engineering technologyEngineering

The invention discloses a tensile clamping and quick assembling and disassembling multipurpose clamp, and relates to the technical field of clamp machinery engineering. The tensile clamping and quick assembling and disassembling multipurpose clamp consists of five parts, namely an upper outer sleeve, water storage bins, wedge-shaped clamps, a blade and a lower outer sleeve, wherein the wedge-shaped clamps and tower-shaped springs which are assembled are arranged in the water storage bins of the upper and lower outer sleeves; spring cover plates are covered, and cover plate screws are tightened; tower-shaped sponge is placed in a water dropping hole; the lower outer sleeve is fixed in a square hole of a lower fixture body outer sleeve through two fixing bolts; two ends of the blade are respectively inserted into openings of the wedge-shaped clamps of the upper and lower outer sleeves; clamp chucks are fastened to blade clamping holes; under the action of the tower-shaped springs, the wedge-shaped clamps are set to clamp the blade, and mandril bolts are tightened, so as to fulfill the aim of tensioning and clamping the blade under the mutual action of the wedge-shaped clamps and the wedge-shaped surfaces in the upper and lower outer sleeves, and realize the tensile clamping function; during removal of the blade, the mandril bolts are screwed to the highest points, the upper outer sleeve and the blade are pressed at the same time, and the wedge-shaped clamps compress the tower-shaped springs to reach cover plate locating strips; the blade is rotated to enable the clamp chucks and the blade clamping holes to be separated, and the blade can be pulled out, thus fulfilling the aim of quick assembling and disassembling.

Owner:温智韬

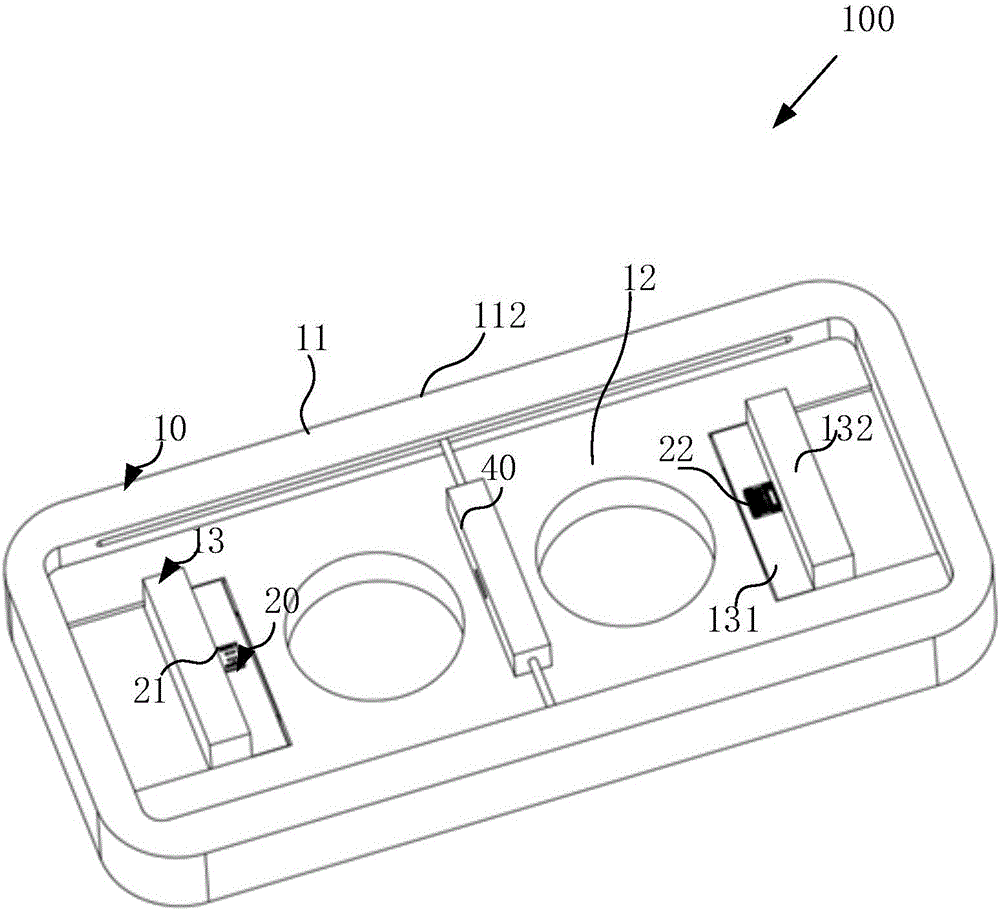

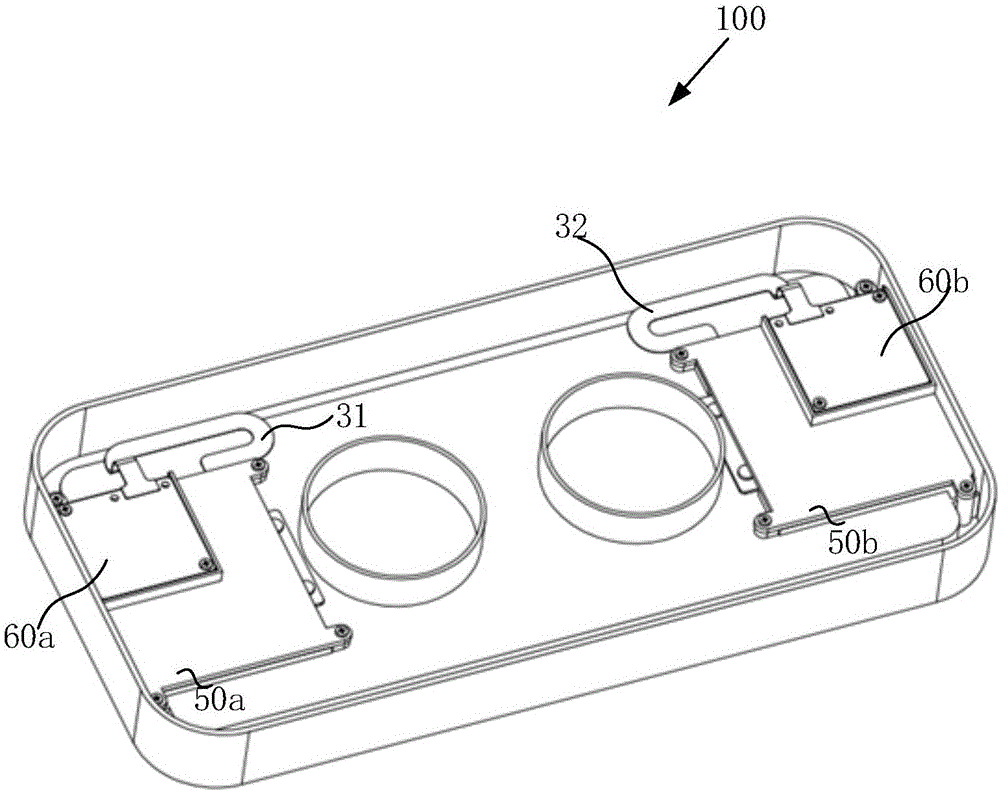

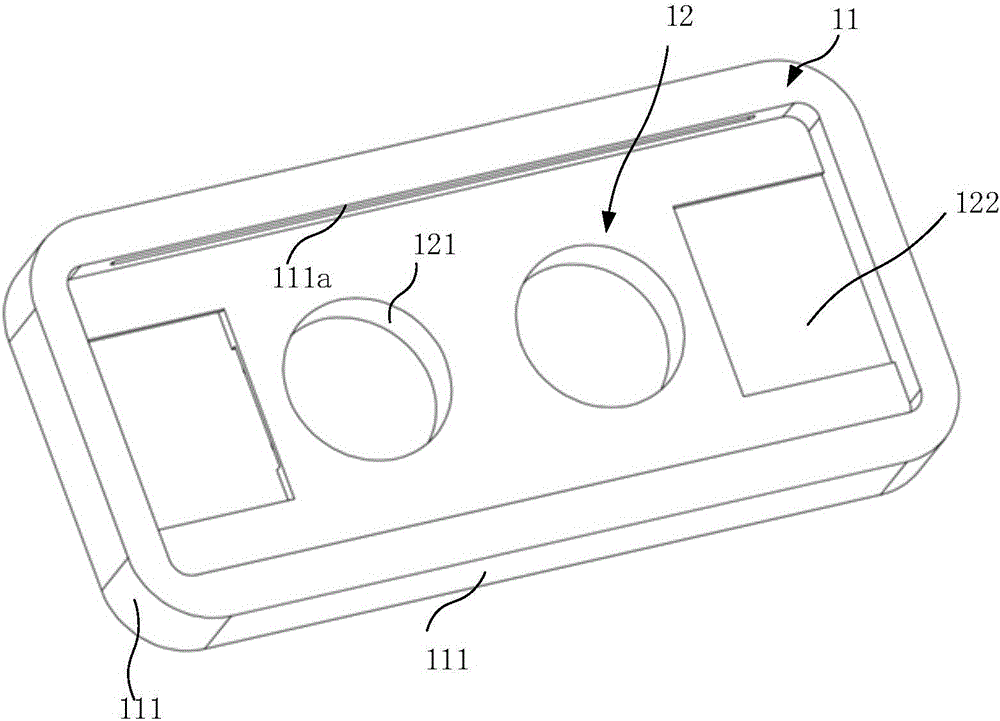

Clamping structure and data interface device including clamping structure

ActiveCN106714485ARealize the clamping functionChange clamping sizeCoupling device connectionsCasings/cabinets/drawers detailsEngineeringData interface

The invention provides a clamping structure and a data interface device including the clamping structure. The clamping structure comprises a shell, a fixing plate and two clamping parts, wherein the shell is wrapped on the exterior of the fixing plate; the clamping structure is characterized in that holes are symmetrically formed in the two ends of the fixing plate; rail slots are respectively formed in two opposite sides of the holes; the clamping parts are equipped with base plates and lug bosses; the lug bosses are arranged on the base plates; bulges which are in sliding fit with the rail slots are respectively arranged on the two sides of the base plates vertical to a central line of the two lug bosses; and the base plates are in matching connection with the fixing plate through elastic elements.

Owner:上海临奇智能科技有限公司

Transformer primary input lead position structure of high-voltage frequency converter

InactiveCN109510441ARealize the clamping functionInhibit sheddingPower conversion systemsTransformerEngineering

The invention discloses a transformer primary input lead position structure of a high-voltage frequency converter. The transformer primary input lead position structure comprises a cabinet body; a wire incoming hole is formed in the outer side wall of the bottom of the cabinet body; the cabinet body is connected with a first supporting column through a fixing mechanism; and the first supporting column is connected with a first clamping block through a supporting rod. According to the transformer primary input lead position structure of the high-voltage frequency converter of the invention, thefirst supporting column, a second supporting column, the supporting rod, the first clamping block, a second clamping block, a threaded rod, a first telescopic rod and a rotating block are matched with one another, so that the threaded rod can be rotated to drive the second clamping block to move toward the first clamping block, and therefore, the first clamping block and the second clamping blockcan clamp a high-voltage cable entering the wire incoming hole; a spring, a second telescopic rod, an L-shaped insertion pin, and a fixing disc are matched with one another, so that the spring pullsthe L-shaped insertion pin to be plugged into an insertion slot in the fixing disc, and therefore, the limiting function of the threaded rod is realized.

Owner:山东迈易特传动有限公司

Automatic swing-type material twisting-off mechanism

ActiveCN110699761ARealize the clamping functionEasy to holdVegetable fibres from other vegetable matterEngineeringMechanical engineering

The invention relates to an automatic swing-type material twisting-off mechanism which comprises a clamping mechanism A for clamping a material section A, a clamping mechanism B for clamping a material section B, and a regulating mechanism; the material section A and the material section B refer to two adjacent rod sections of material; the regulating mechanism is connected with the clamping mechanism A and / or the clamping mechanism B; the regulating mechanism is used for regulating adjacent ends of the clamping mechanism A and the clamping mechanism B to move relatively in a direction A, andthe plane of the direction A and the length direction of the material form an included angle. The automatic swing-type material twisting-off mechanism has reasonable arrangement, stable structure andstable running, realizes automatic twisting-off process of the material with high processing efficiency, and meets current service requirements.

Owner:安庆中巨机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com