Optical element clamping and angle adjusting mechanism

An optical element and angle adjustment technology, applied in optical elements, optics, instruments, etc., can solve the problems of high cost, complicated processing and assembly, inconvenient operation, etc., and achieve the effect of convenient operation, simple structure and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described, but should not limit protection scope of the present invention with this:

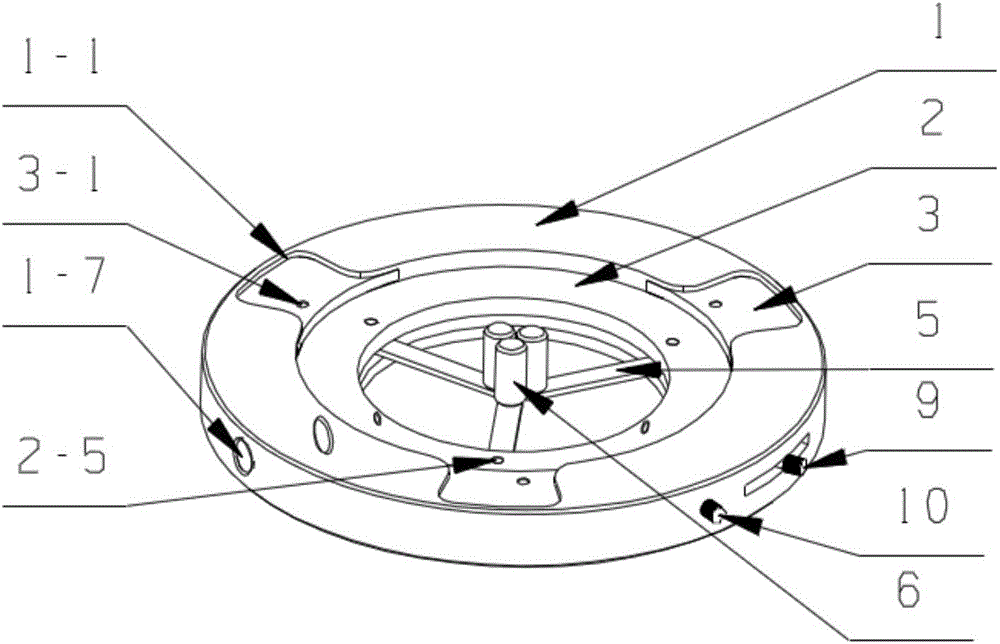

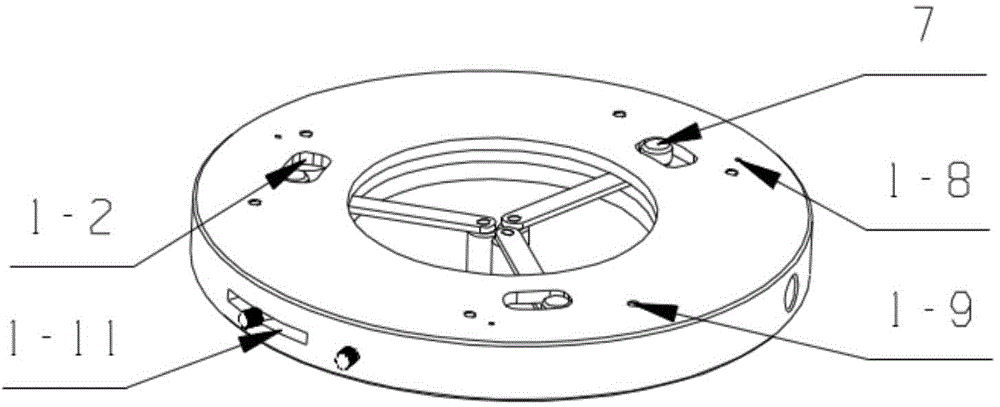

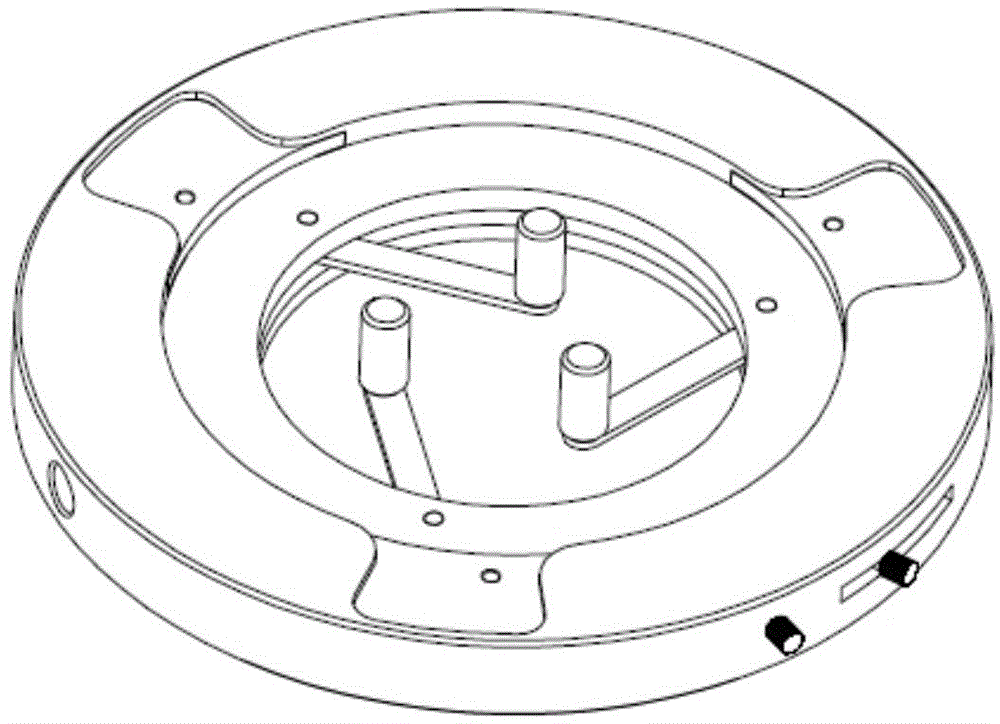

[0043] like Figure 1-5 As shown, a fixture and angle adjustment mechanism for an optical element includes an outer base 1, an inner top plate 2, a magnetic plate 3, a magnetic block 4, a connecting rod 5, a vertical rod 6, a limit post 7, a magnet 8, and a fixed rod 9 and moving rod 10, such as figure 2 and Figure 6 As shown, the outer base 1 is a cylindrical ring structure, and the top surface of the outer base 1 has three U-shaped grooves 1-1 uniformly distributed at 120 degrees in the circumferential direction, and there is a first reference circle in the middle of the outer base 1 Hole 1-3; the first reference circular hole 1-3 is surrounded by a centrally symmetrical annular step 1-4 and communicates with the U-shaped groove 1-1; the U-shaped groove 1- There is a magnetic pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com