Automatic swing-type material twisting-off mechanism

A swing type, material technology, applied in the direction of plant fiber, mechanical treatment, textile and paper making of other plant raw materials, can solve the problems of low production efficiency, high labor intensity, time-consuming and laborious operation, etc., and achieve the effect of stable and convenient coordination with movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

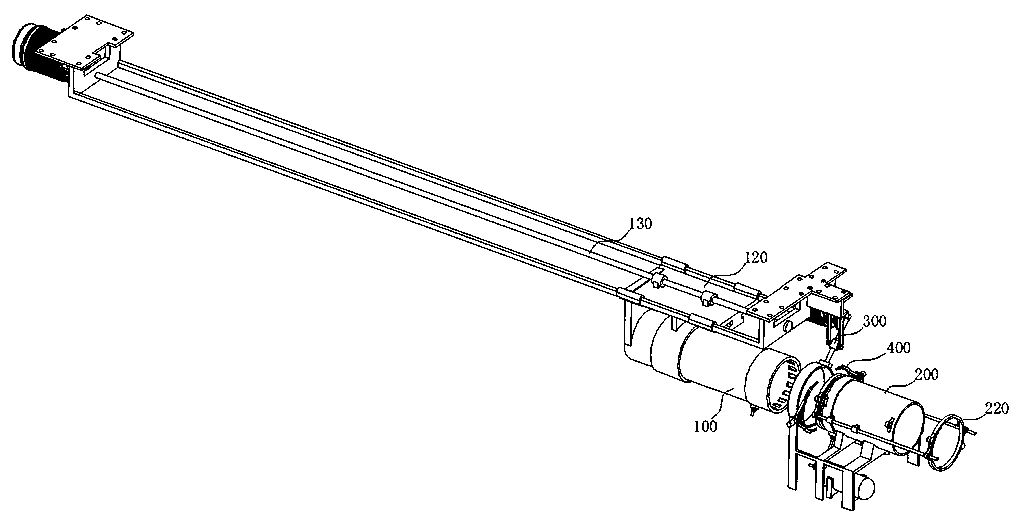

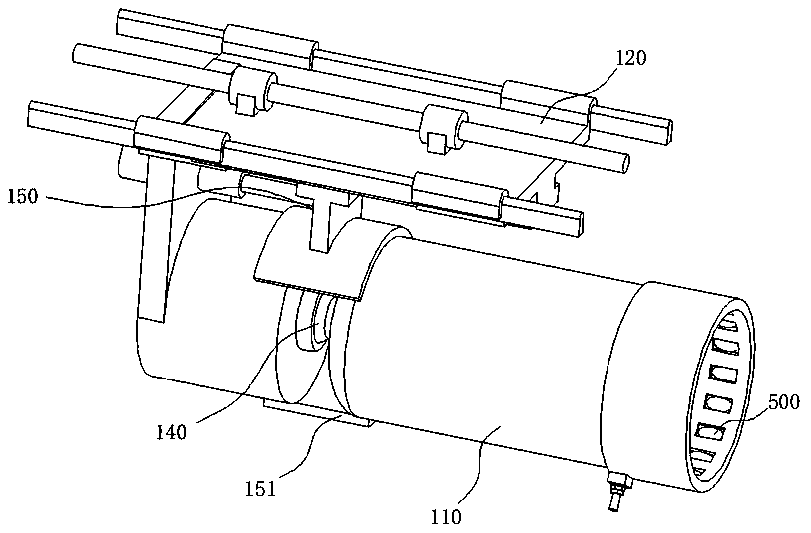

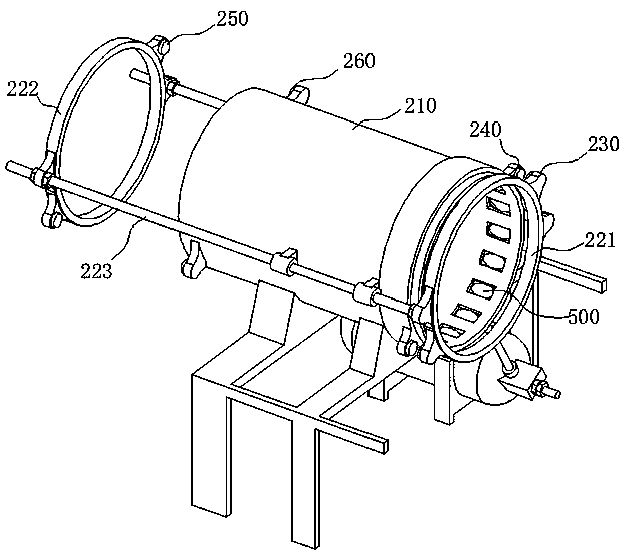

[0053] refer to Figure 1-5 , in the embodiment of the present invention, an automatic swing-type material twisting mechanism is proposed, including the A clamping mechanism 100 for clamping the A material section, the B clamping mechanism 200 for clamping the B material section, and the adjustment Mechanism 300, the A and B material sections are two material rod sections adjacent to the material, the adjustment mechanism 300 is connected with the A clamping mechanism 100 and / or the B clamping mechanism 200, and the adjustment mechanism 300 is used to adjust the A and B clamping The adjacent ends of the mechanism move relative to each other in the A direction, and the plane where the A direction is located forms an included angle with the length direction of the material.

[0054] Through the setting of the A clamping mechanism 100 and the B clamping mechanism 200, the function of clamping the two material rod sections adjacent to the material is realized, and then through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com