Tensile clamping and quick assembling and disassembling multipurpose clamp

A multi-purpose and fast technology, applied in the field of saw blades and hook fixtures, mechanical engineering blades, can solve the problems of low tensile strength, inconvenient water lubrication, and difficult separation, etc., to achieve convenient cleaning, lubrication and sealing, and quick installation , the effect of reducing work resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

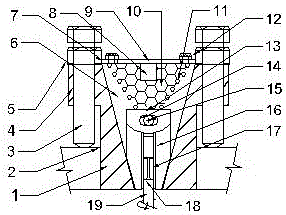

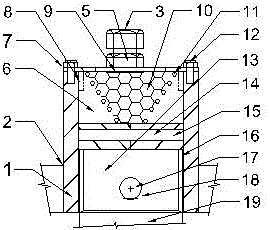

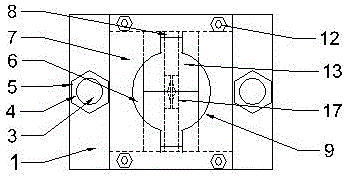

[0035] The present invention is further described in conjunction with accompanying drawing:

[0036] Tensile clamping quick disassembly multi-purpose fixture is composed of five parts including upper jacket (1), water storage bin (6), wedge-shaped clamp (13), blade (19) and lower jacket (20).

[0037] The upper jacket (1) is provided with ejector rod bolts (3), ejector rod threaded holes (4), and self-locking nuts (5). The upper jacket (1) is assembled with the square hole (2) of the upper tooling body jacket, and the upper jacket ( 1) There are two wedge-shaped surfaces connected with the wedge-shaped clamp (13), and the tension-resistant clamping function is realized through the close fit and interaction of the wedge-shaped surfaces. The rod threaded hole (4) is connected, and the ejector rod bolt (3) is tightened on the side of the upper tooling body overcoat square hole (2) to achieve the effect of tensioning the blade (19).

[0038] The water storage bin (6) is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com