Punching die capable of realizing self-lubrication

A punching die and self-lubricating technology, applied in the field of punching die, can solve the problems of damage to the die edge, affecting the service life of the die, and deterioration of the working environment of the die, so as to prolong the service life of the die, reduce the defect rate of products, and solve the problem of self-lubrication. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

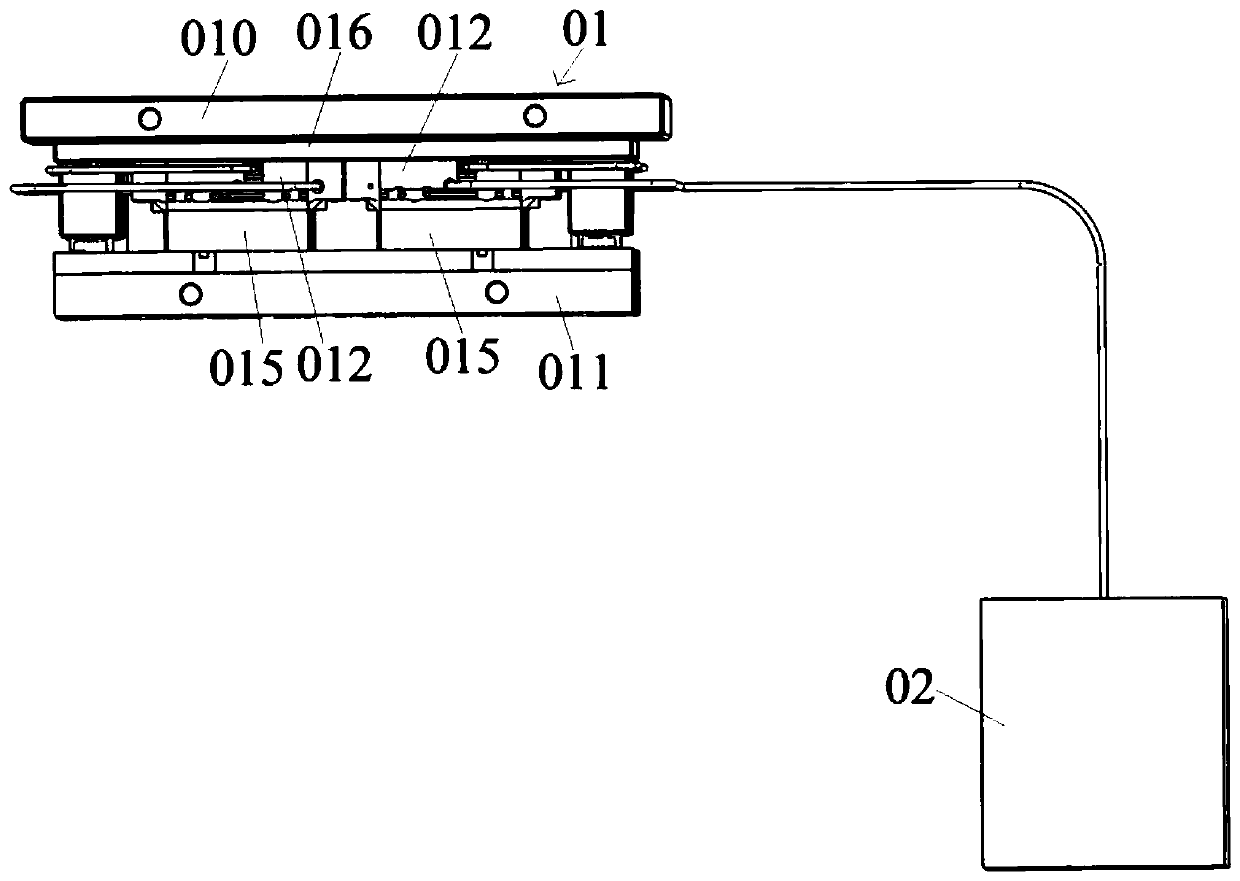

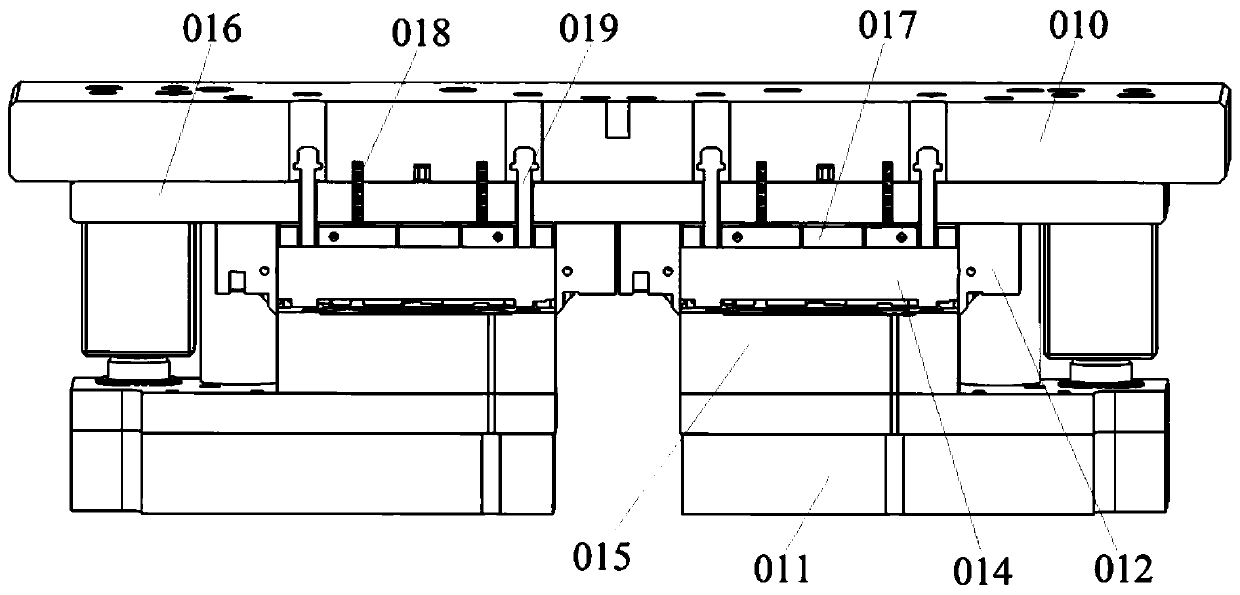

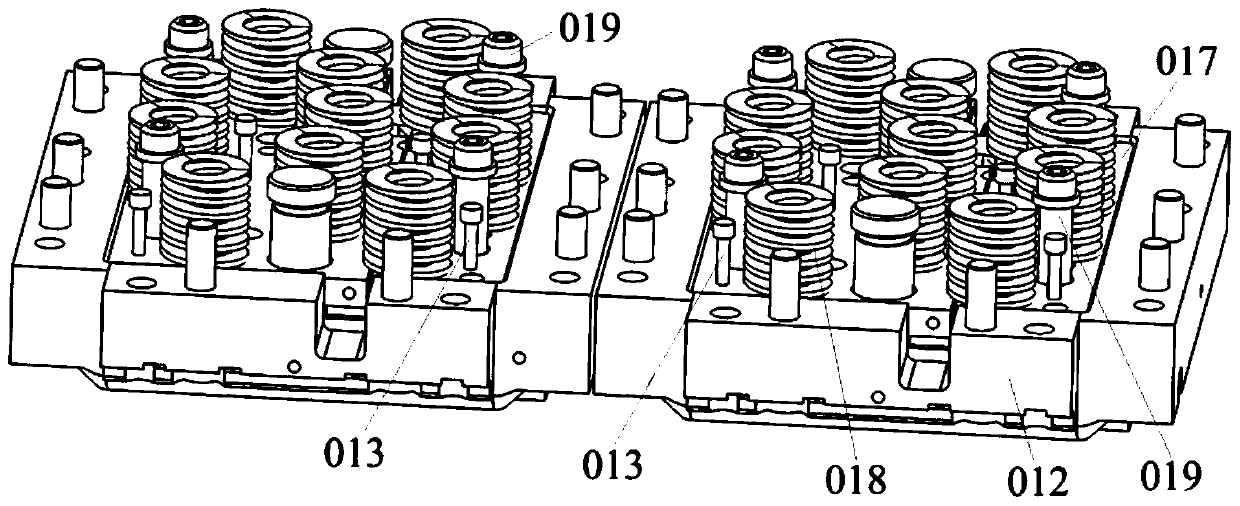

[0031] Please combine Figure 1 to Figure 4 As shown: a self-lubricating punching die provided in this embodiment includes a punching die body 01 and an external automatic oiler 02 . The punching die body 01 includes an upper die base 010, a lower die base 011, a cutter 012, a punch 013, a stripping plate 014 and a lower module 015, and the cutter 012 and the punch 013 are connected with the upper die base 010 Fixed connection (in the present embodiment, by setting upper clamping plate 016, upper clamping plate 016 is fixed on the bottom of upper die base 010, then the tops of cutter 012 and punch 013 are all fixedly connected with upper clamping plate 016); Cutter 012 has the cutting hole 0121 (please combine Figure 7 and Figure 8As shown, what needs to be explained here is that the shape of the cut hole 0121 can be a regular shape or a special shape, which is specifically matched and designed according to the outer edge shape of the product that needs to be punched); the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com