Patents

Literature

53results about How to "Fully oiled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

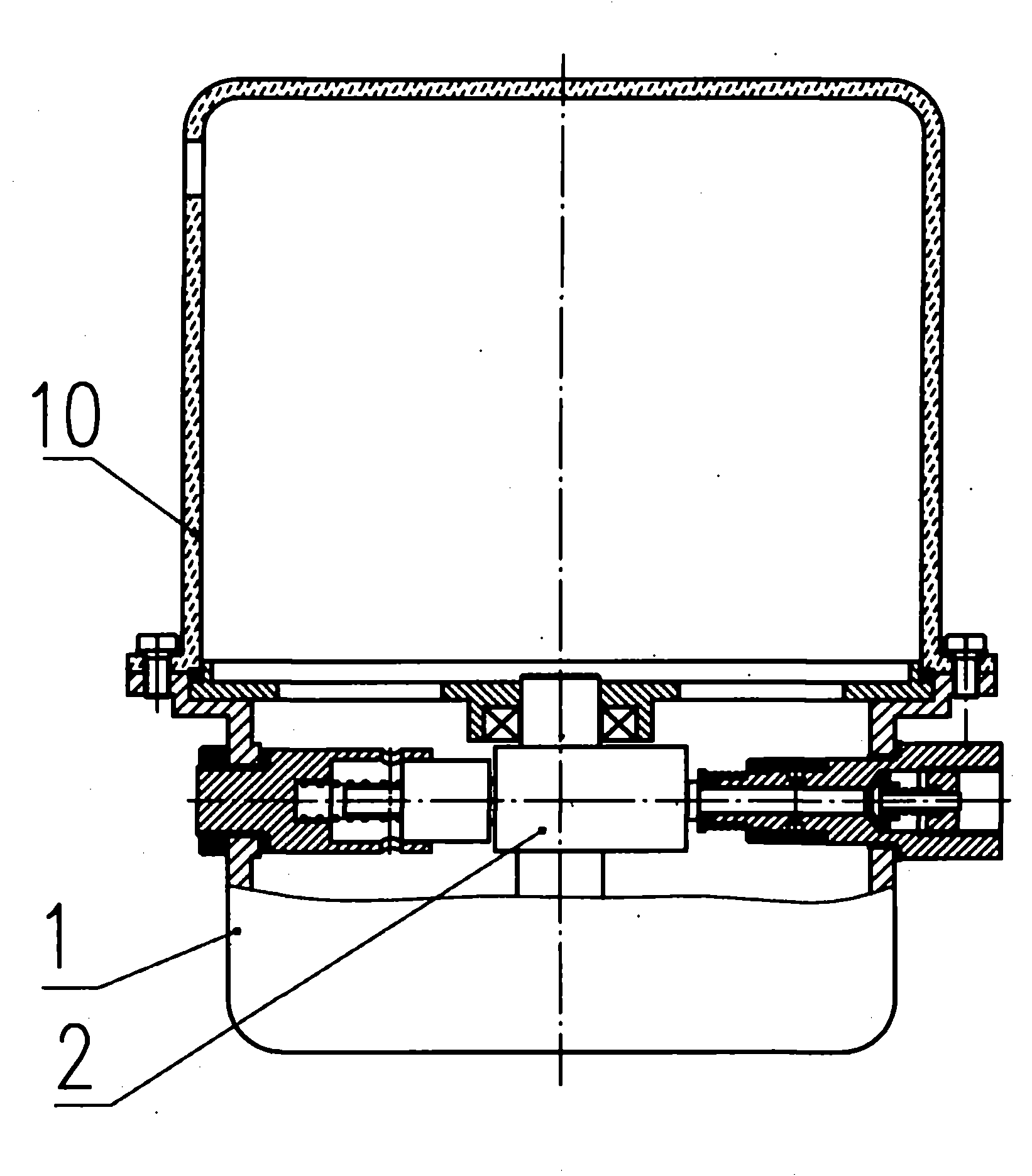

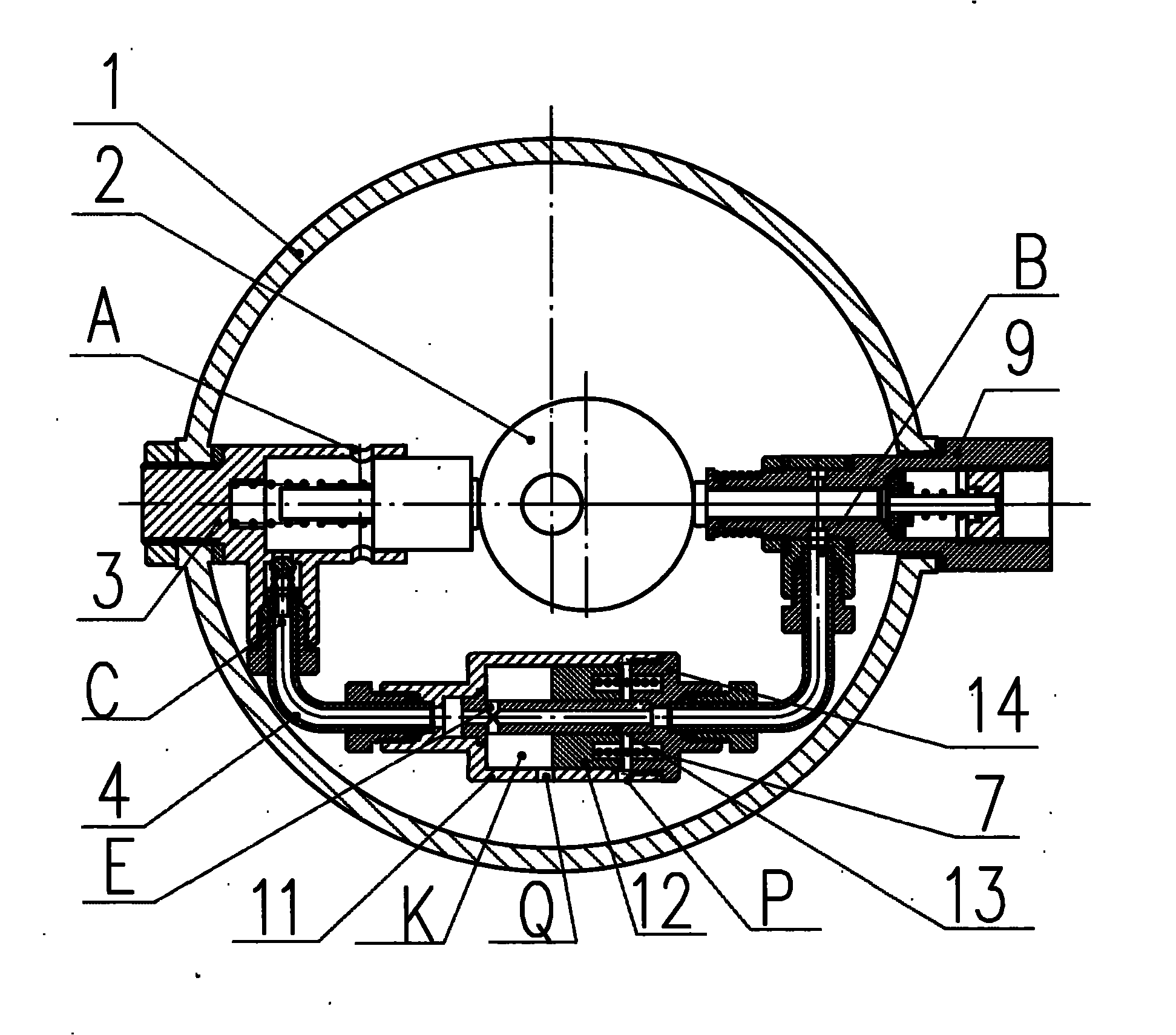

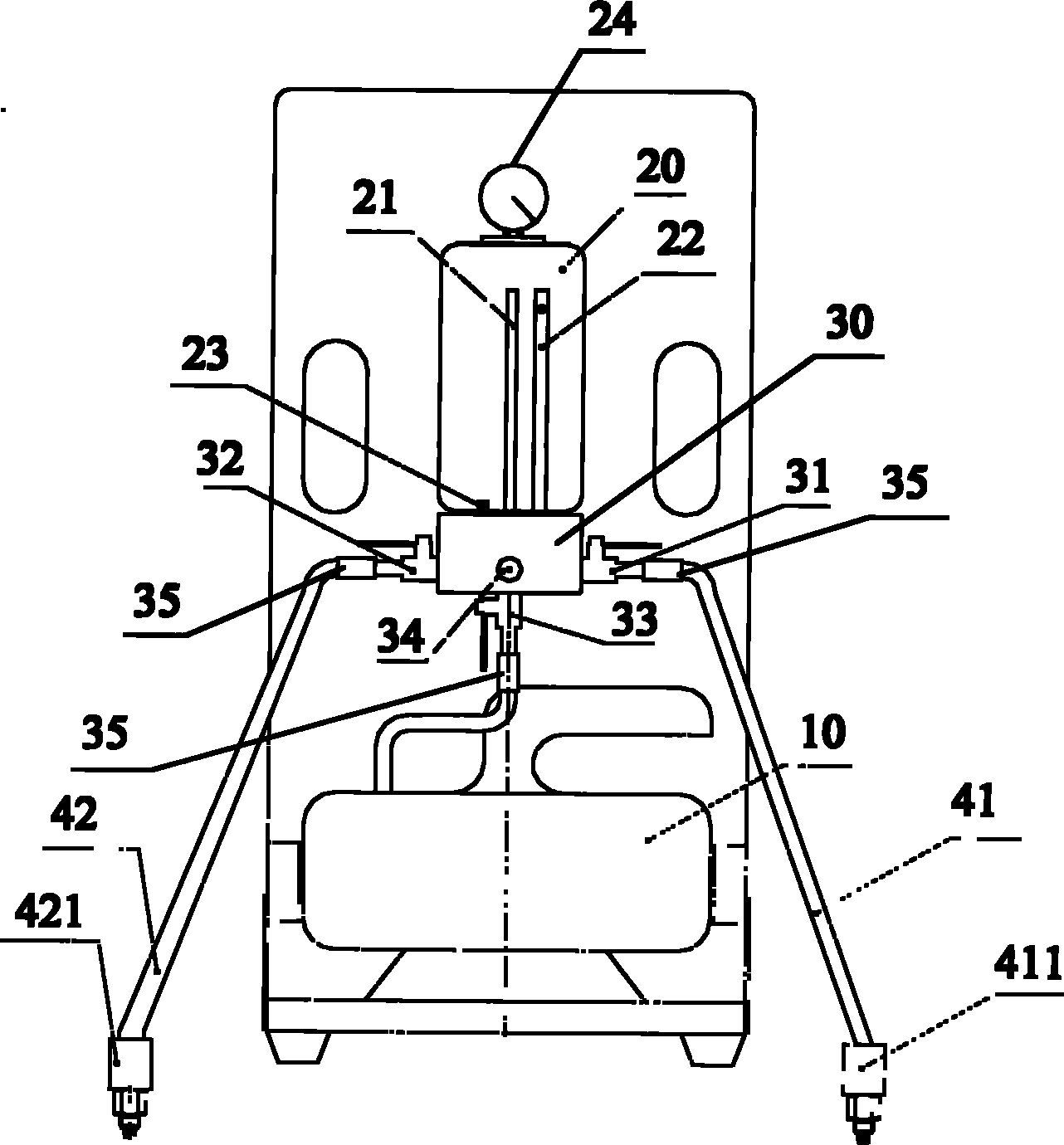

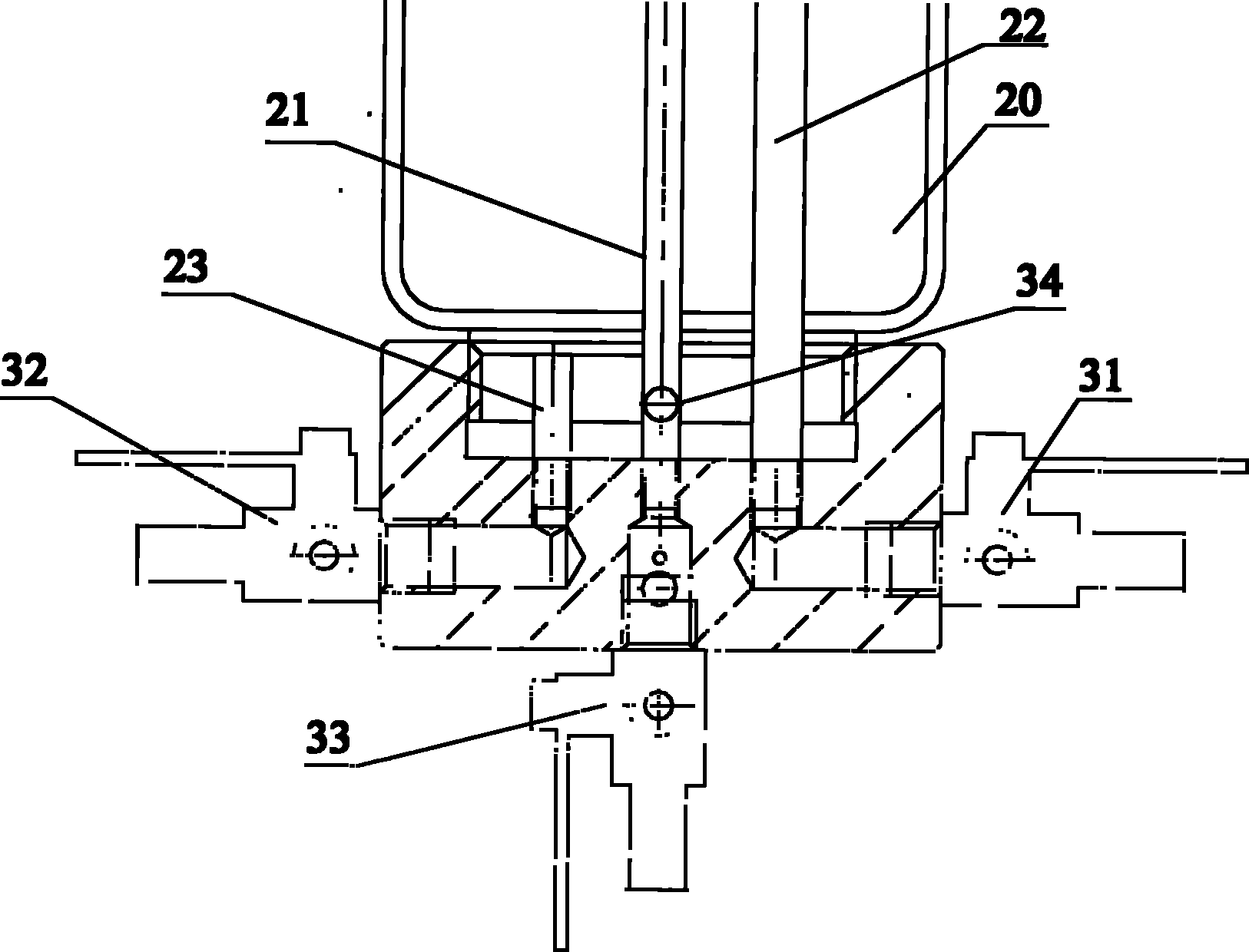

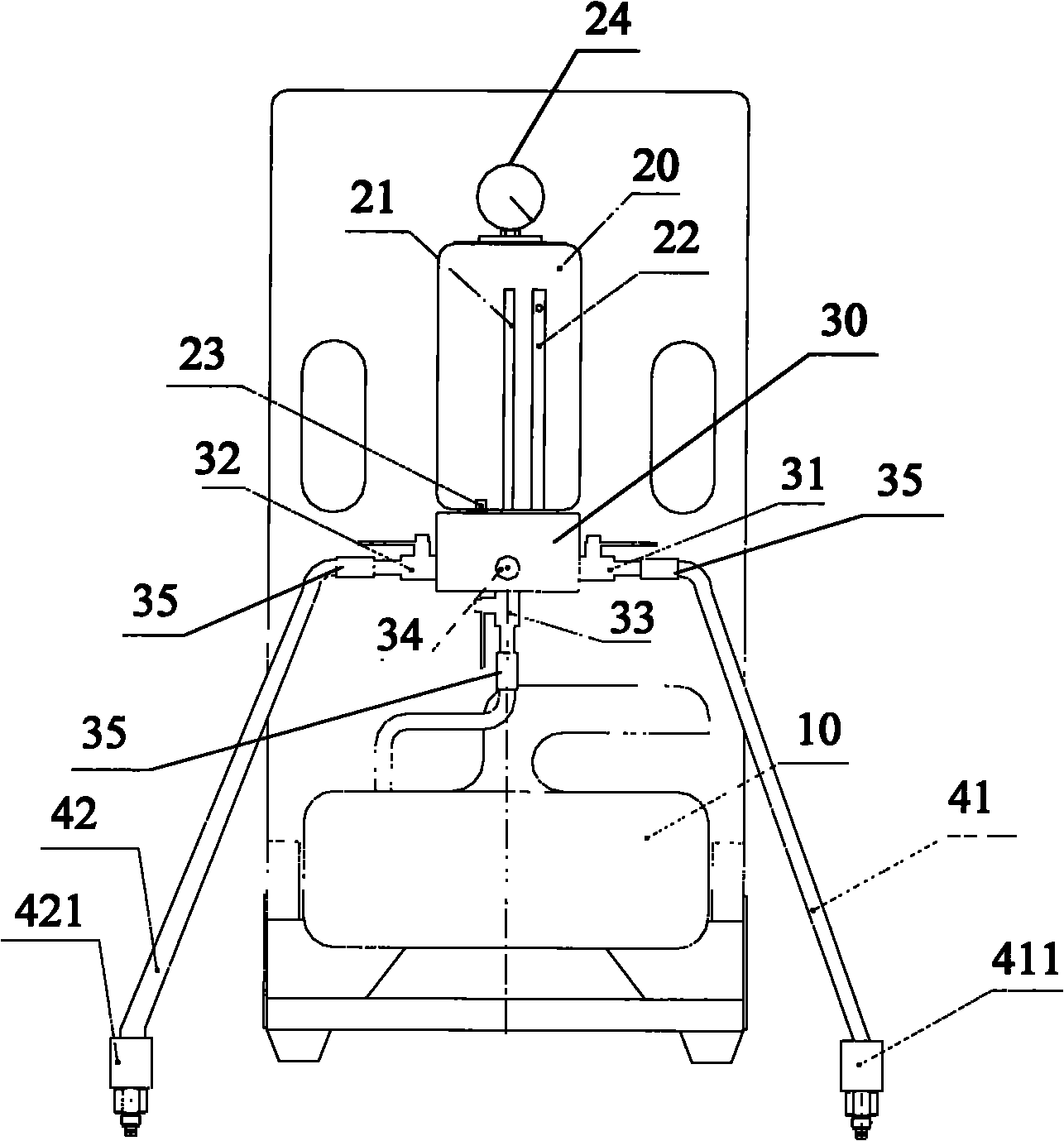

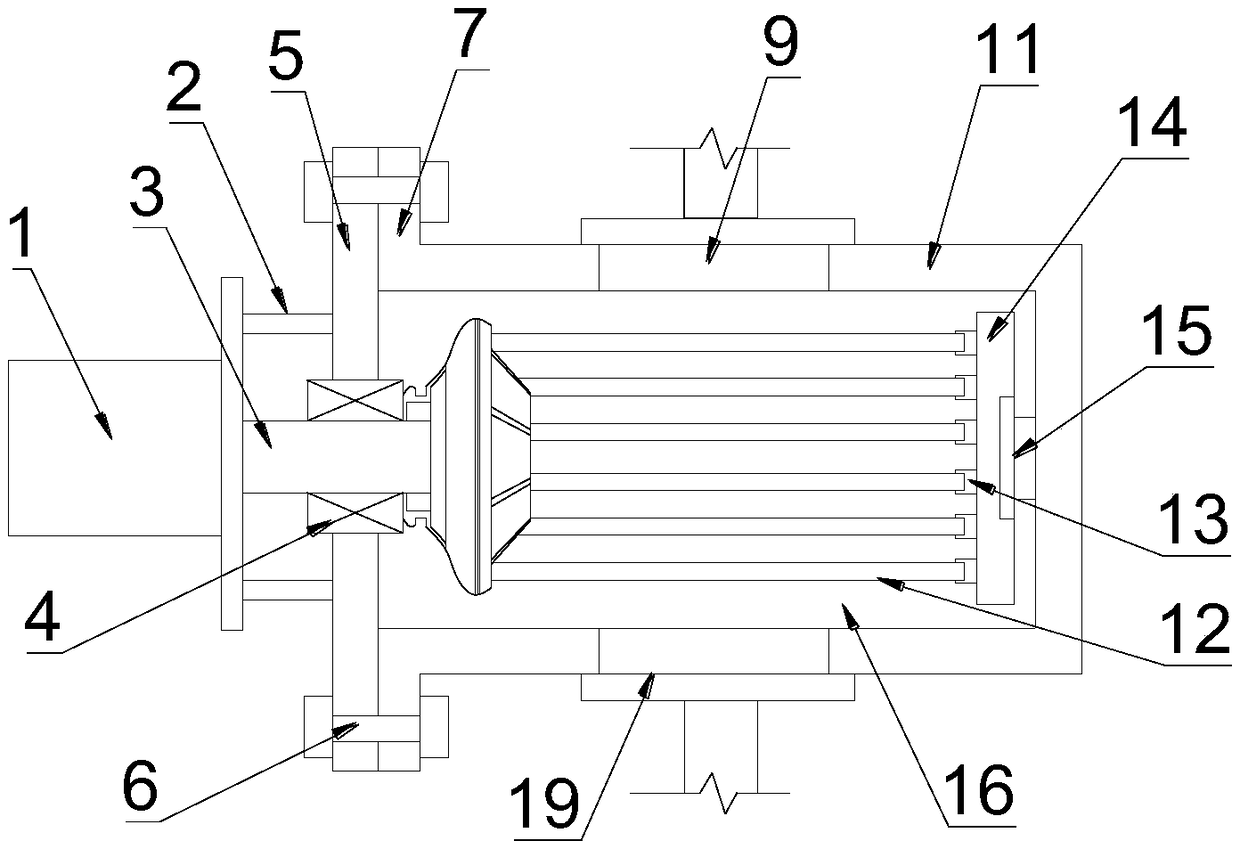

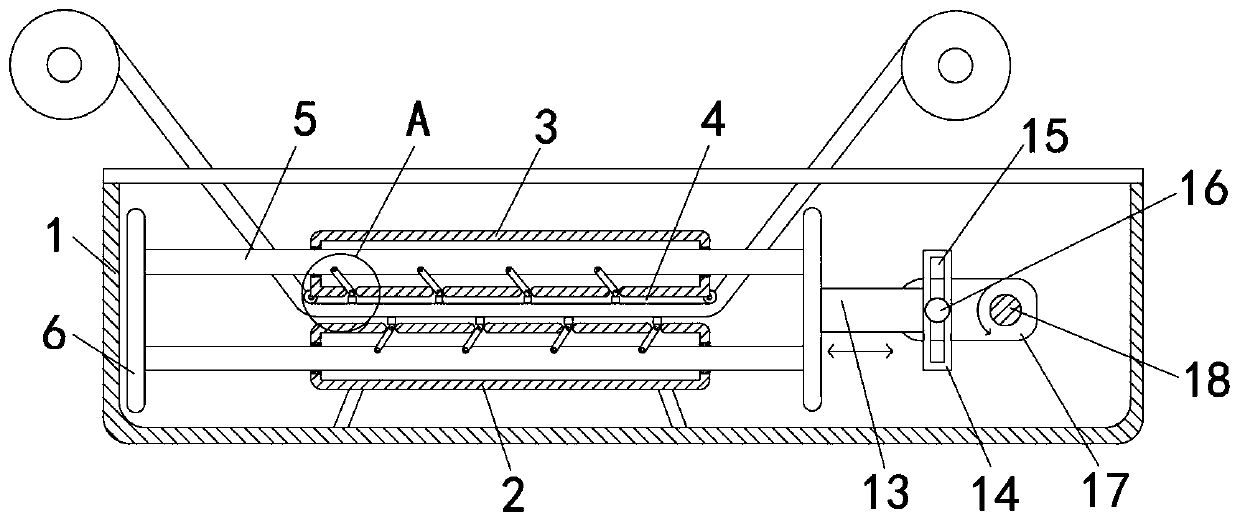

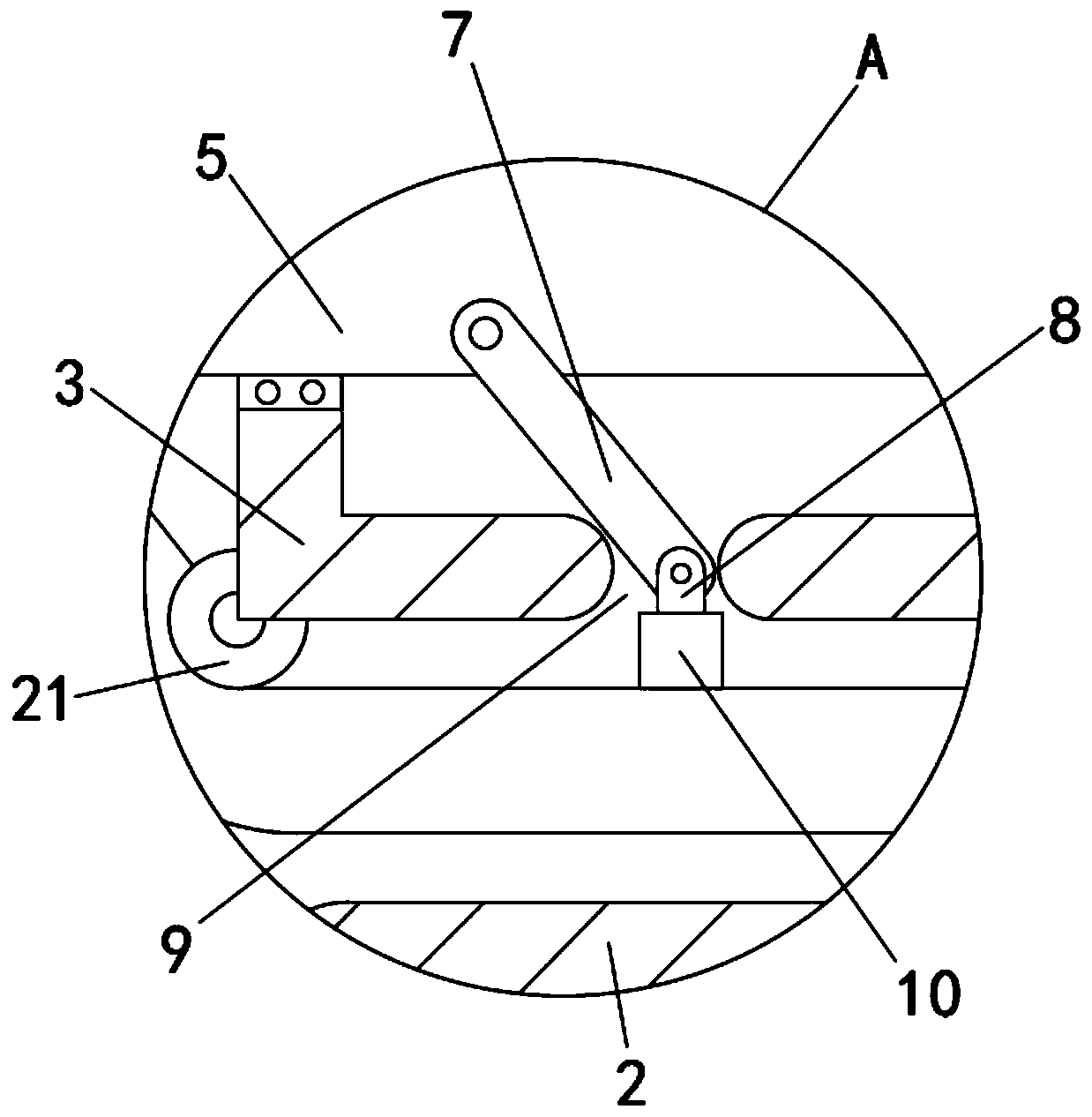

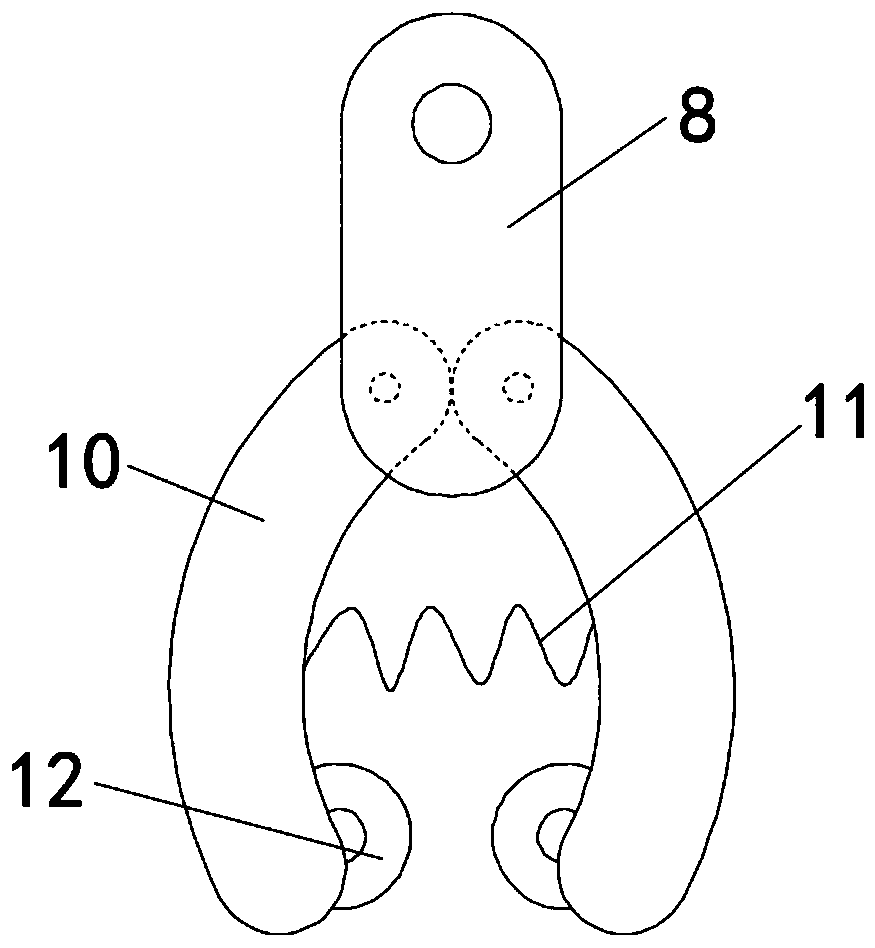

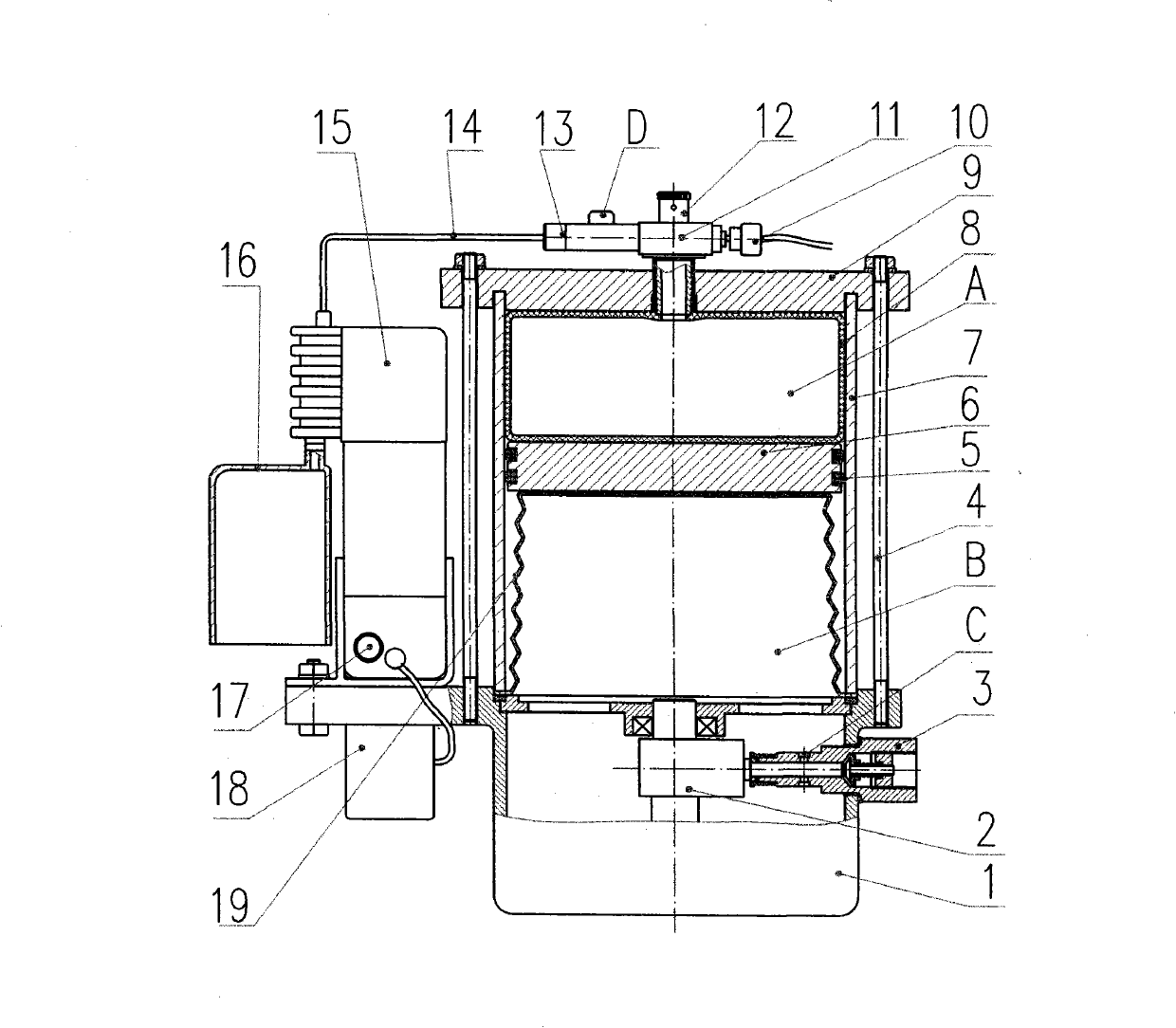

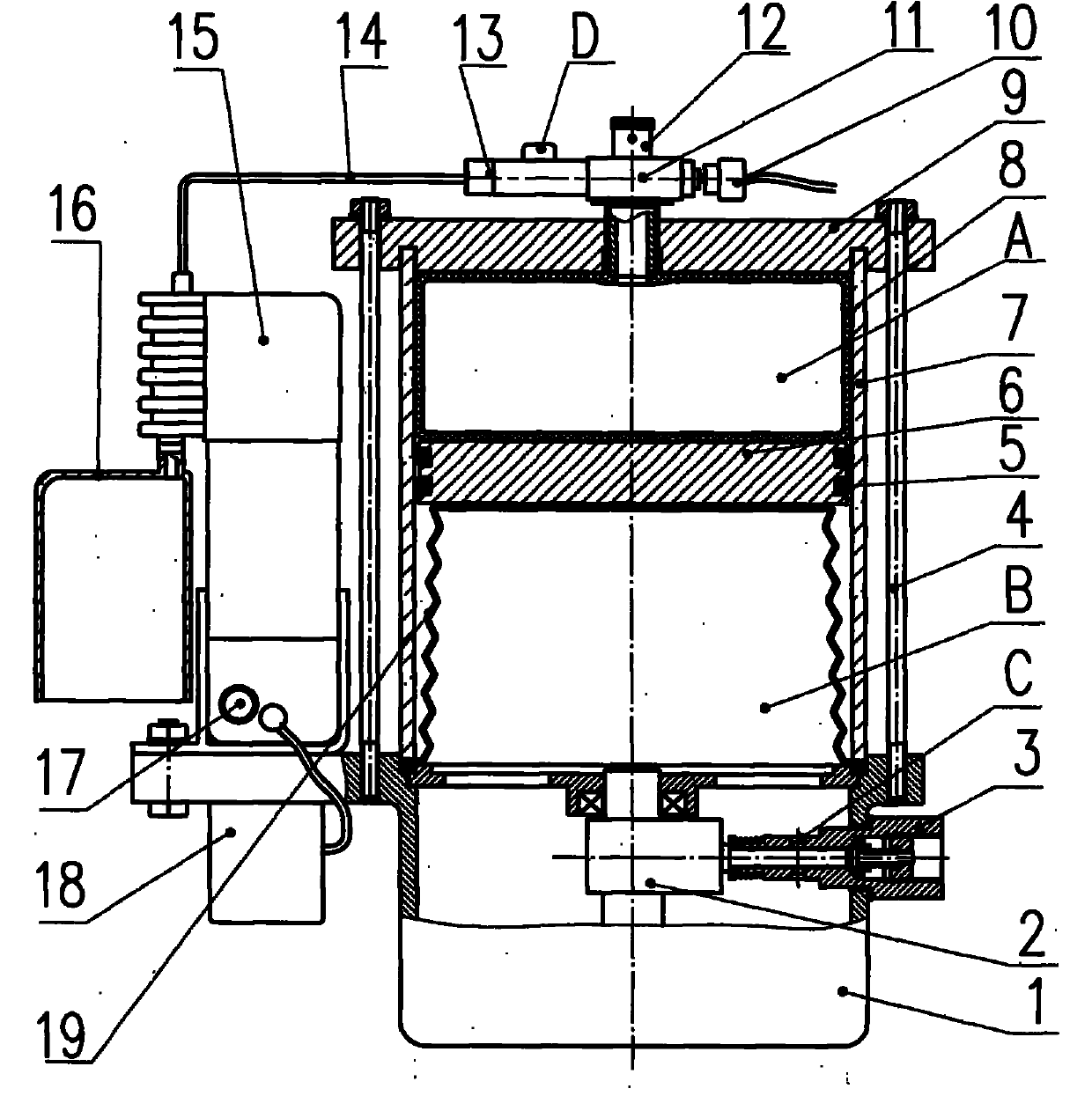

Thick grease secondary lubricating pump device

A thick grease secondary lubricating pump device comprises a lubricating pump shell, a power assembly, a high-pressure plunger pump and an oil tank, wherein the power assembly and the high-pressure plunger pump driven by the power assembly are arranged on the lubricating pump shell; the oil tank is fixedly connected with the lubricating pump shell which is also provided with a low-pressure plunger pump driven by the power assembly; an oil suction port A of the low-pressure plunger pump is communicated with the oil tank, and an oil discharge port C of the low-pressure plunger pump is connectedwith an oil suction port B of the high-pressure plunger pump in a sealing way by a pipeline which is further connected with an energy storage device and an overflow valve; and an oil inlet and an oiloutlet of the energy storage device are respectively communicated with the oil discharge port C of the low-pressure plunger pump and the oil suction port B of the high-pressure plunger pump. By adopting the structure, the lower-pressure plunger pump with the section of a first-stage oil inlet being larger is added, enough grease is pressed into an oil inlet of the high-pressure plunger pump, and the mode that mainly depends on the oil suction of the oil inlet of high-pressure plunger pump is changed to the mode mainly depending on pressing the oil, so that the oil charging at the oil inlet ofthe high-pressure plunger pump is sufficient, the capacity of the pump for delivering the grease is enhanced, and the pump is capable of delivering the grease with high thickness even under low temperature and low pressure.

Owner:AUTOL TECH

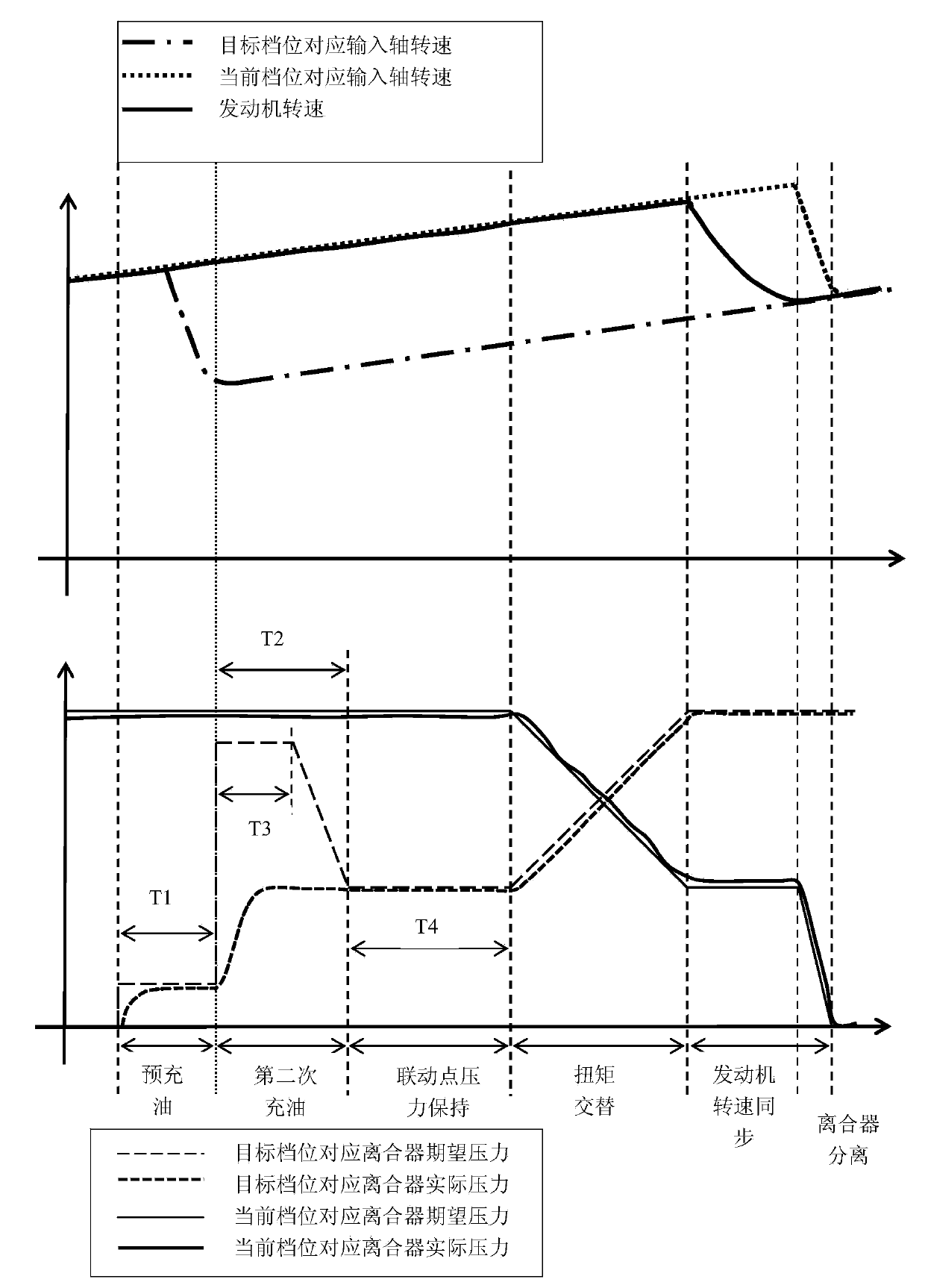

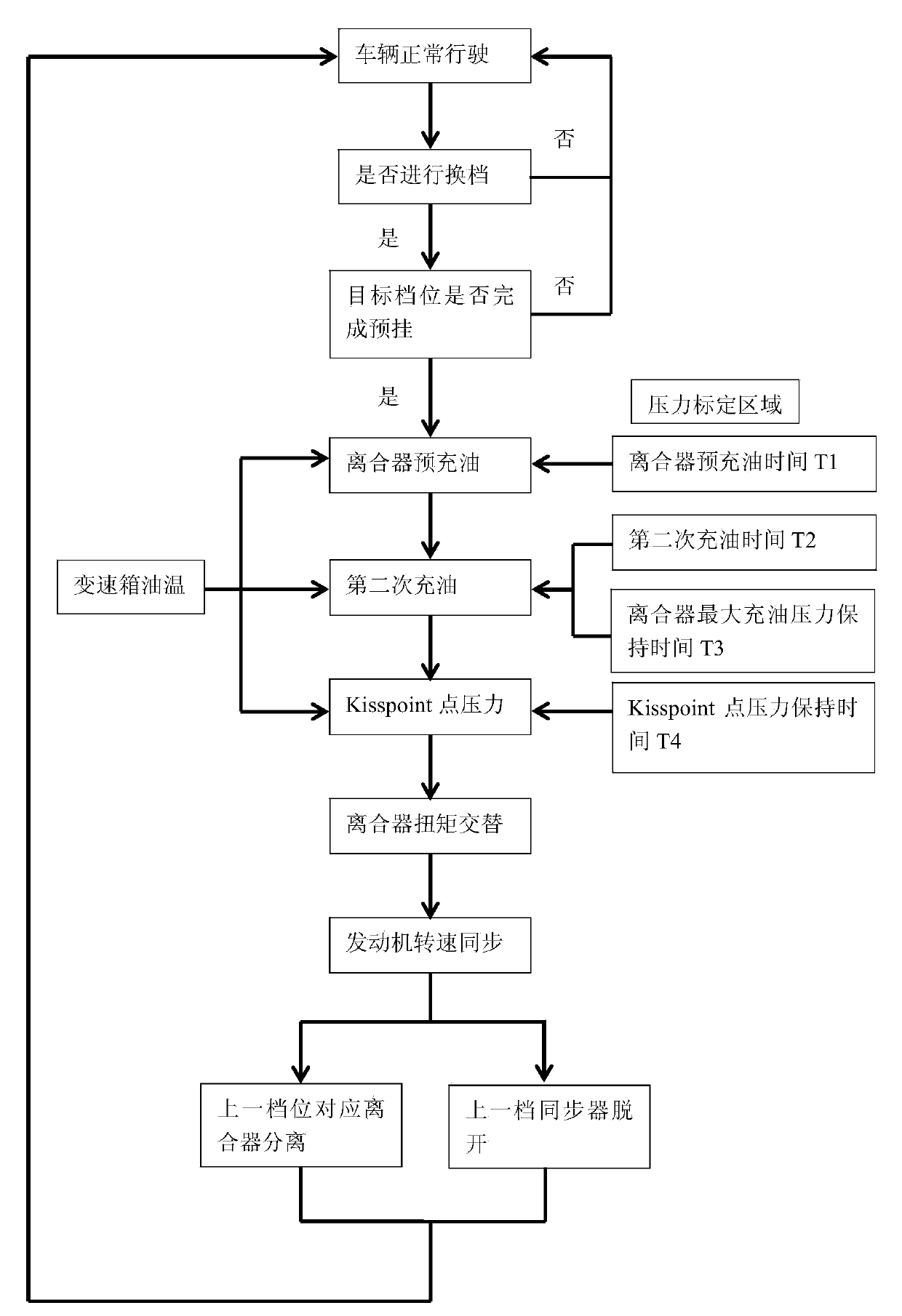

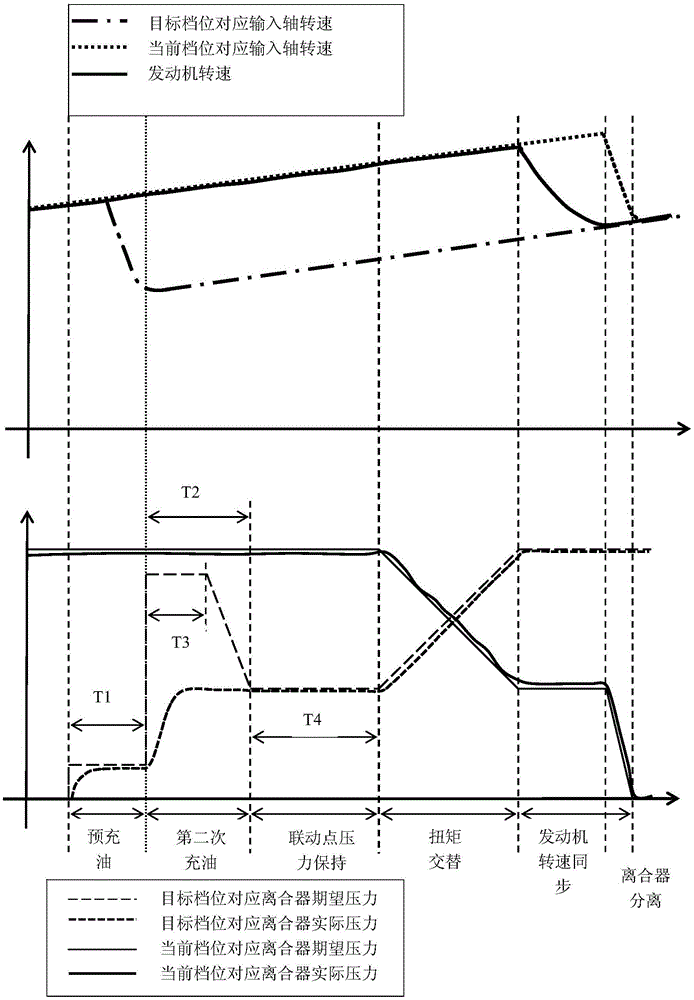

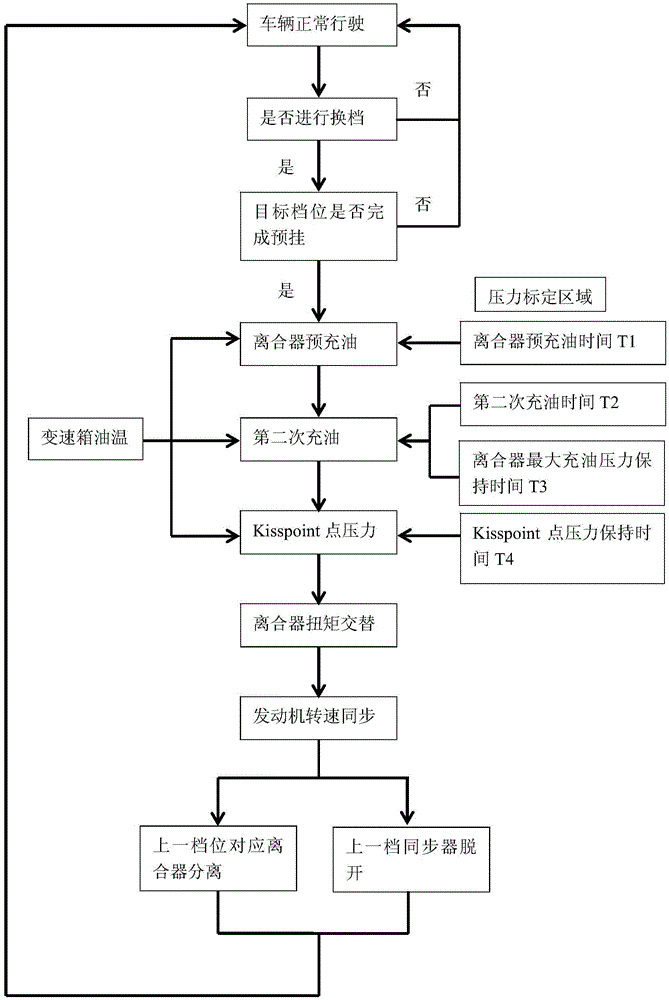

Method for controlling oil filling of clutches of automatic double-clutch gearbox

ActiveCN103438124APlay a preventive effectImprove shiftFluid actuated clutchesOil temperatureFault rate

The invention provides a method for controlling oil filling of clutches of an automatic double-clutch gearbox. The method comprises the step of filling oil in advance, wherein the clutches are filled with the oil in advance after pre-shifting of a target gear is finished, and the preset time is maintained; the step of filling the oil for the second time, wherein the clutches of the target gear are filled with the oil for the second time until linkage point pressure is reached; the step of maintaining the linkage point pressure, wherein the linkage point pressure of the clutches of the target gear is maintained until torque is alternated. In the step of filling the oil in advance, the current oil temperature of the gearbox is measured, and filling the oil in advance is carried out according to the current oil temperature of the gearbox. The temperature change of the oil in the gearbox is utilized for controlling the clutch oil filling process, and therefore timeliness and smoothness of clutch motions in the shifting process can be improved, and the fault rate of the automatic wet type double-clutch gearbox can be lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

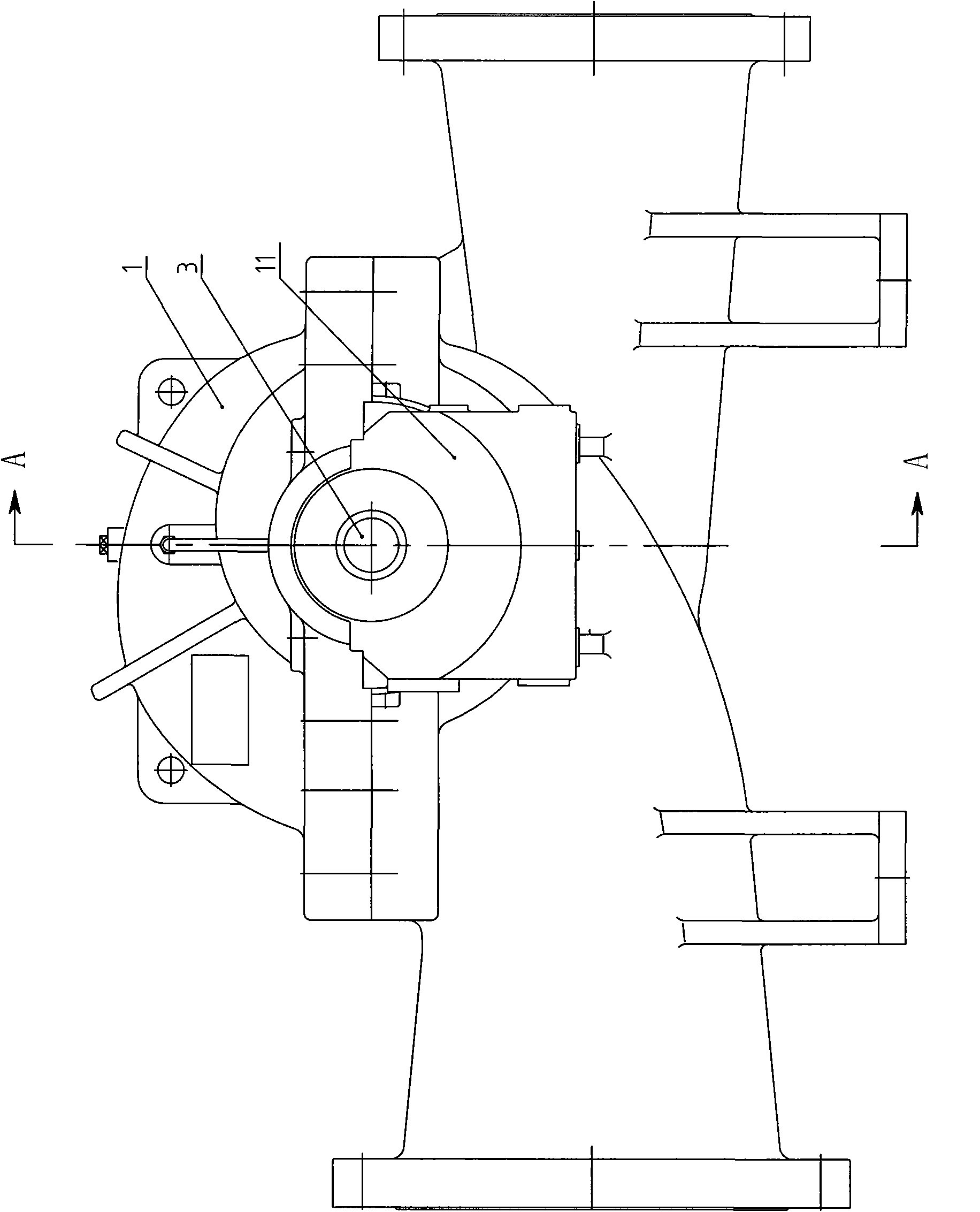

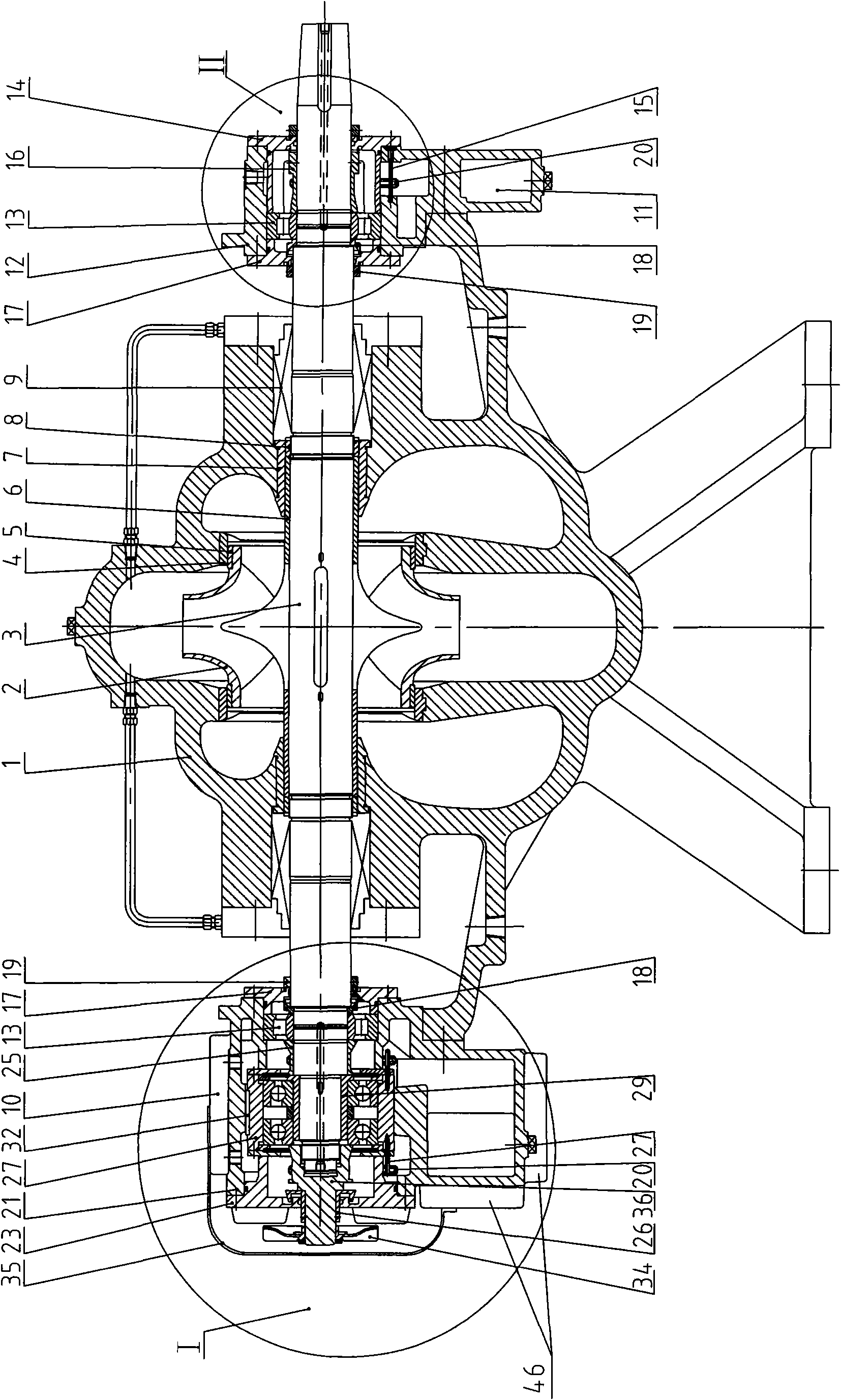

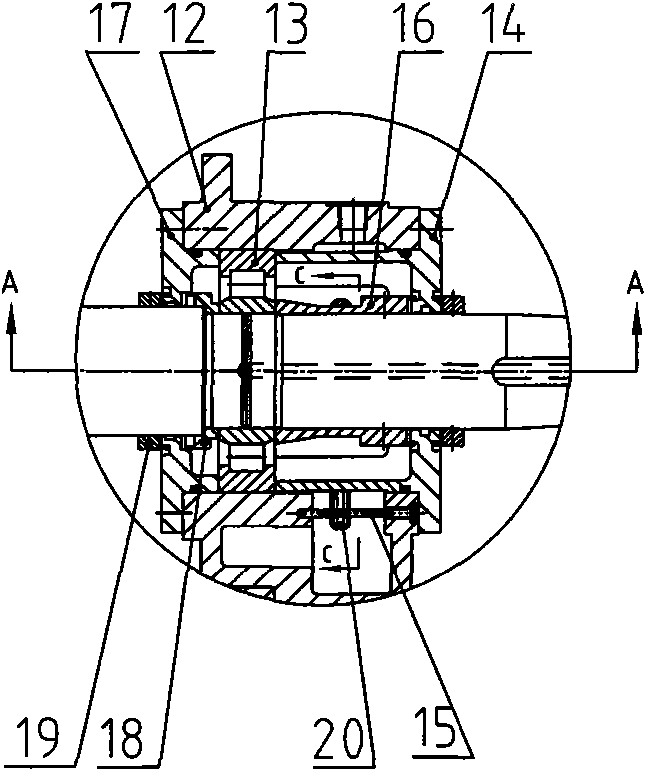

Pipeline delivery pump

ActiveCN101994701AEasy to disassembleShorten maintenance timePump componentsRadial flow pumpsImpellerDesalination

The invention relates to a pipeline delivery pump, which is suitable for the pipeline delivery of crude oil and natural gas and the sea water transportation in long distance in the field of desalination of sea water. The pump comprises a pump body, an impeller, a shaft, a left bearing device and a right bearing device; the impeller is arranged on the shaft in the pump body; two ends of the shaft extending out of the pump body are respectively provided with the left and right bearing devices which are connected with the pump body; the shaft end of the right bearing is connected with the outputshaft of a motor; two ends of the shaft are respectively provided with an axial hole; a shaft platform is arranged on the shafts of the first bearings of the left and right beating devices; and a circular groove is arranged in the middle of the shaft platform; and any part of the circumference of the circle groove is provided with a radial hole communicated with the axial hole. In the invention, the problems of difficult disassemble of the pipeline delivery pump bearing and unbalanced axial force are solved, and the bearing is extremely convenient and rapid to disassemble and maintain, a great amount of time is saved, and the work efficiency is greatly improved; and in addition, the impact of the axial force to the bearing is reduced and the service life of the bearing is improved by improving the structure of the bearing device.

Owner:辽宁恒星泵业有限公司

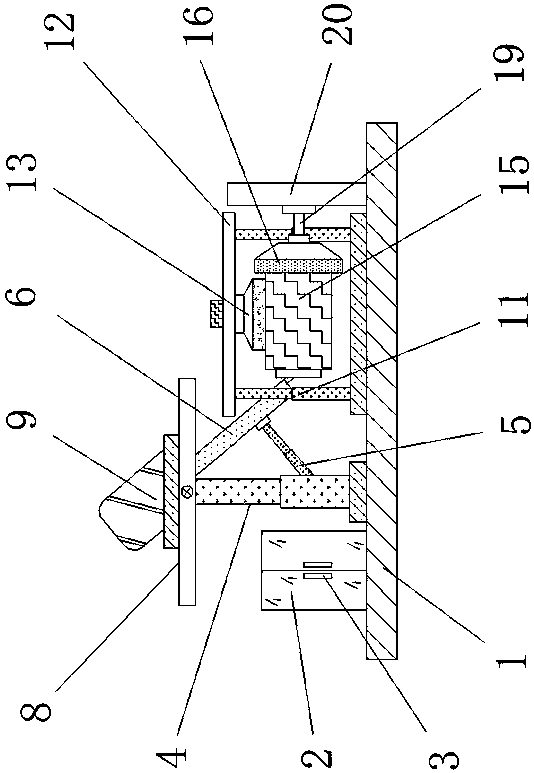

Speed oil filling device for pulse generator of wireless inclinometer and using method thereof

ActiveCN102080534AReduce residual air bubblesNo looseningSurveyLubrication check valvesVacuum pumpAtmosphere

The invention relates to a speed oil filling device for a pulse generator of a wireless inclinometer and a using method thereof, wherein the oil-filled device comprises a vacuum pump, an oil tank, an oil inlet pipeline and an oil outlet pipeline; the oil tank is internally provided with a suction pipe, an oil filling pipe and an oil charging pipe, wherein the suction pipe is connected with the vacuum pipe, and the communication is controlled by a third valve; the oil filling pipe is connected with the oil inlet pipeline, and the communication is controlled by a first valve; and the oil charging pipe is connected with the oil outlet pipeline, and the communication is controlled by a second valve; the lower end of the suction pipe is provided with a fourth valve for controlling the communication between the oil tank and the atmosphere; the ports of the oil inlet pipeline and the oil outlet pipeline are respectively provided with fast insertion type oil filling plugs; and each valve is in seal connection with the corresponding pipeline via a quick screwing type fast plug. The speed oil filling device provided by the invention has excellent sealing performance; a single-hole oil filling method or a double-hole oil filling method is provided; the air remained in an oil bag of the pulse generator is reduced as possible; and the oil is fast and conveniently filled in the pulse generator.

Owner:SHANGHAI GASOLINEEUM & CHEM EQUIP +1

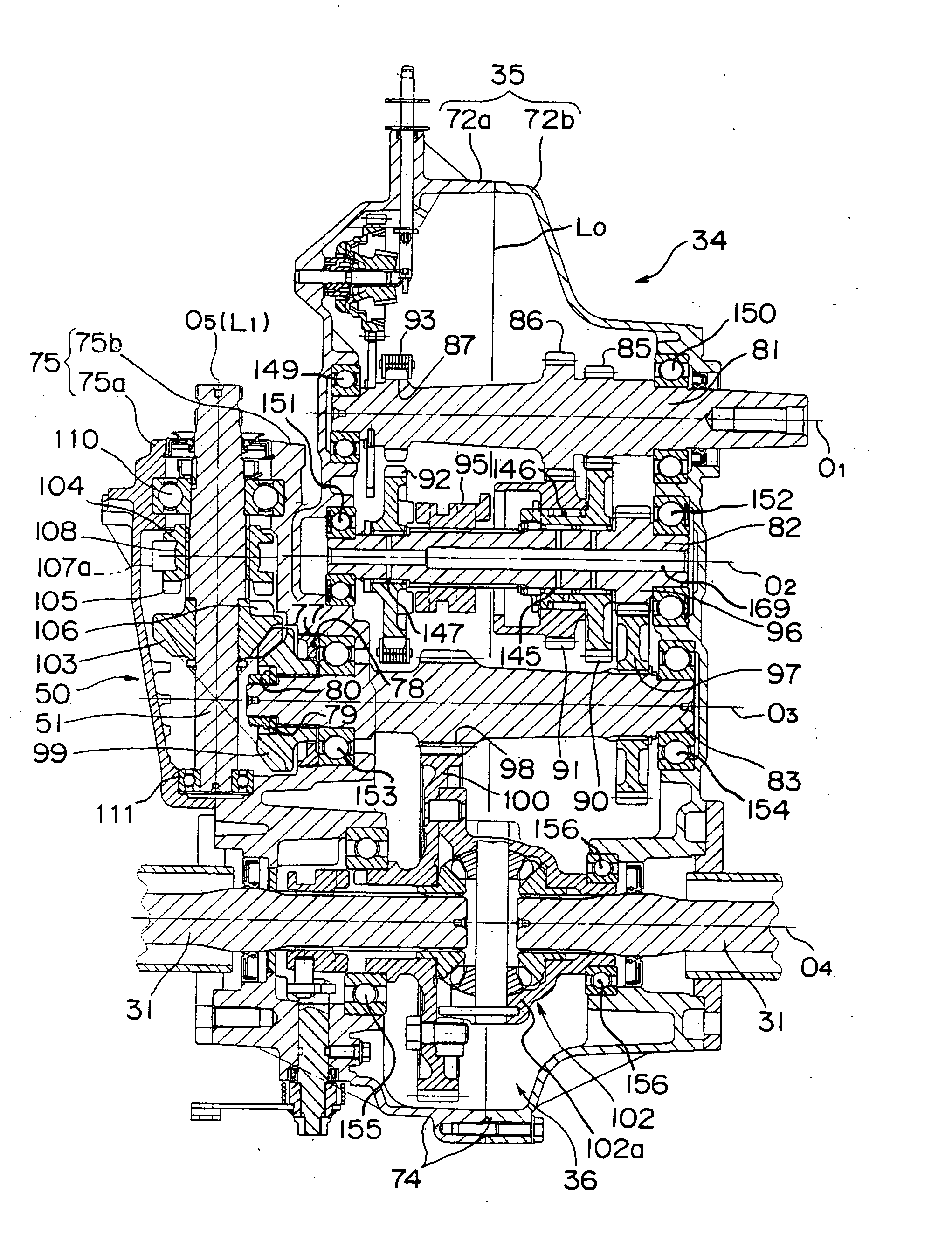

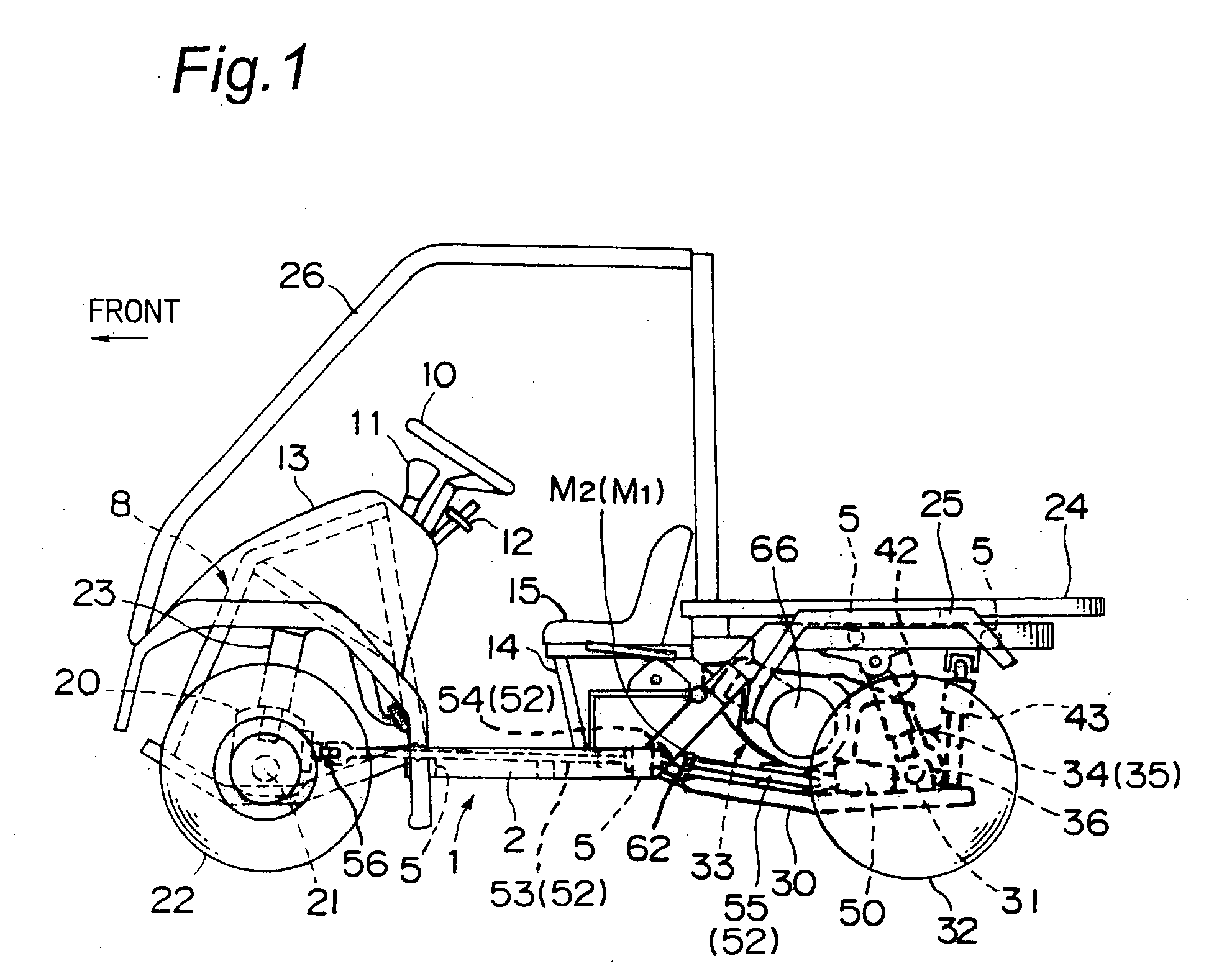

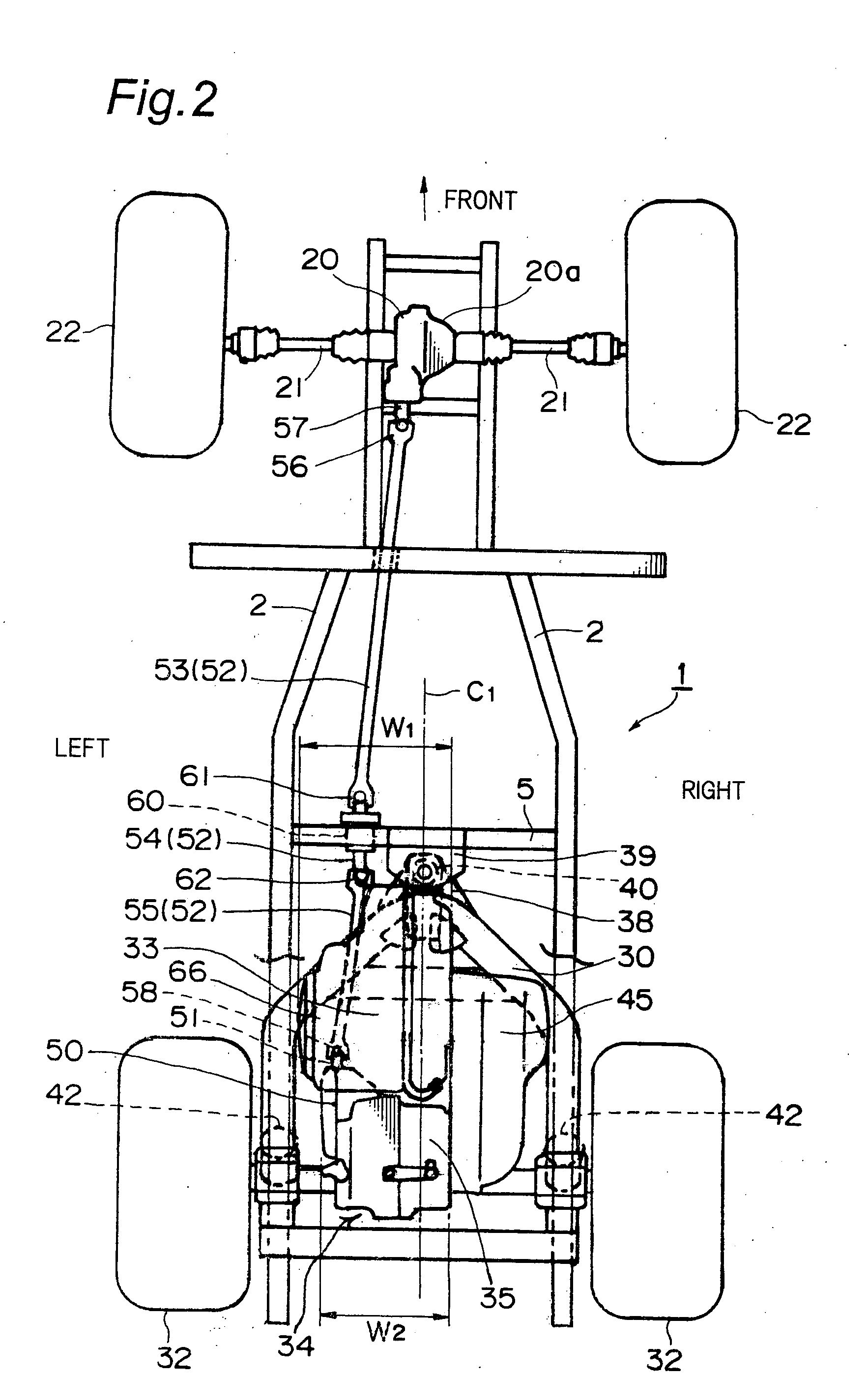

Oil supplying structure of transmission for vehicle

InactiveUS20060054409A1Improve oil separation effectImprove performanceGearboxesGear lubrication/coolingDrive shaftGear wheel

Disclosed is a structure which is able to supply oil to engagement parts of transmission gears mutually rotatably mounted on a transmission shaft inside a transmission case for a vehicle, even when the vehicle tilts during its run. The transmission shaft in the transmission case, has an oil passage which penetrates through its length axially and communicates with the engagement parts of the transmission gears fluidically, where the transmission shaft extends in a direction of width of the vehicle. Both ends of the oil passage of the transmission shaft fluidically communicate with oil intake passages which extend upwards and open inside the transmission case so as to capture the oil inside the transmission case.

Owner:KAWASAKI HEAVY IND LTD

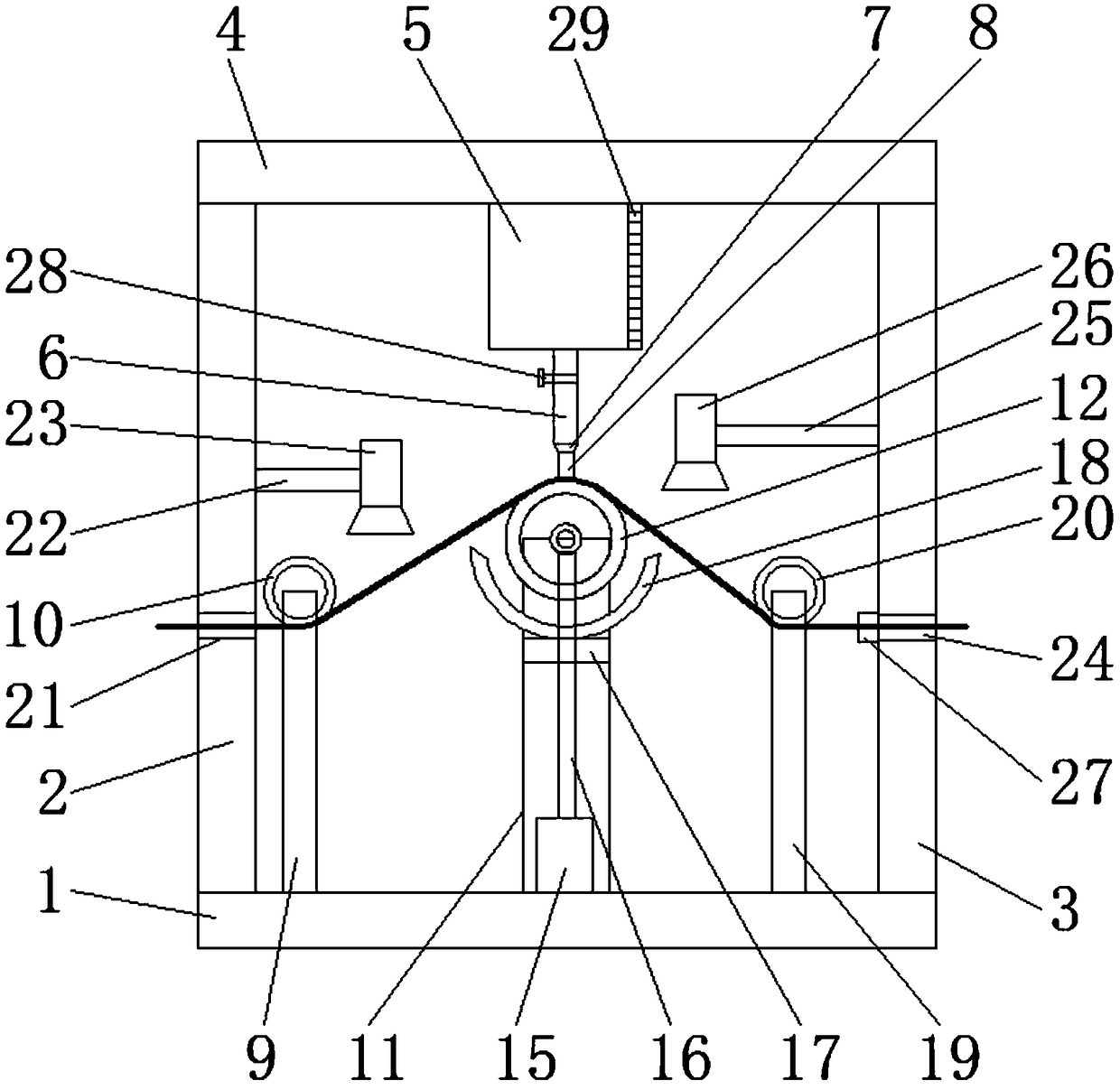

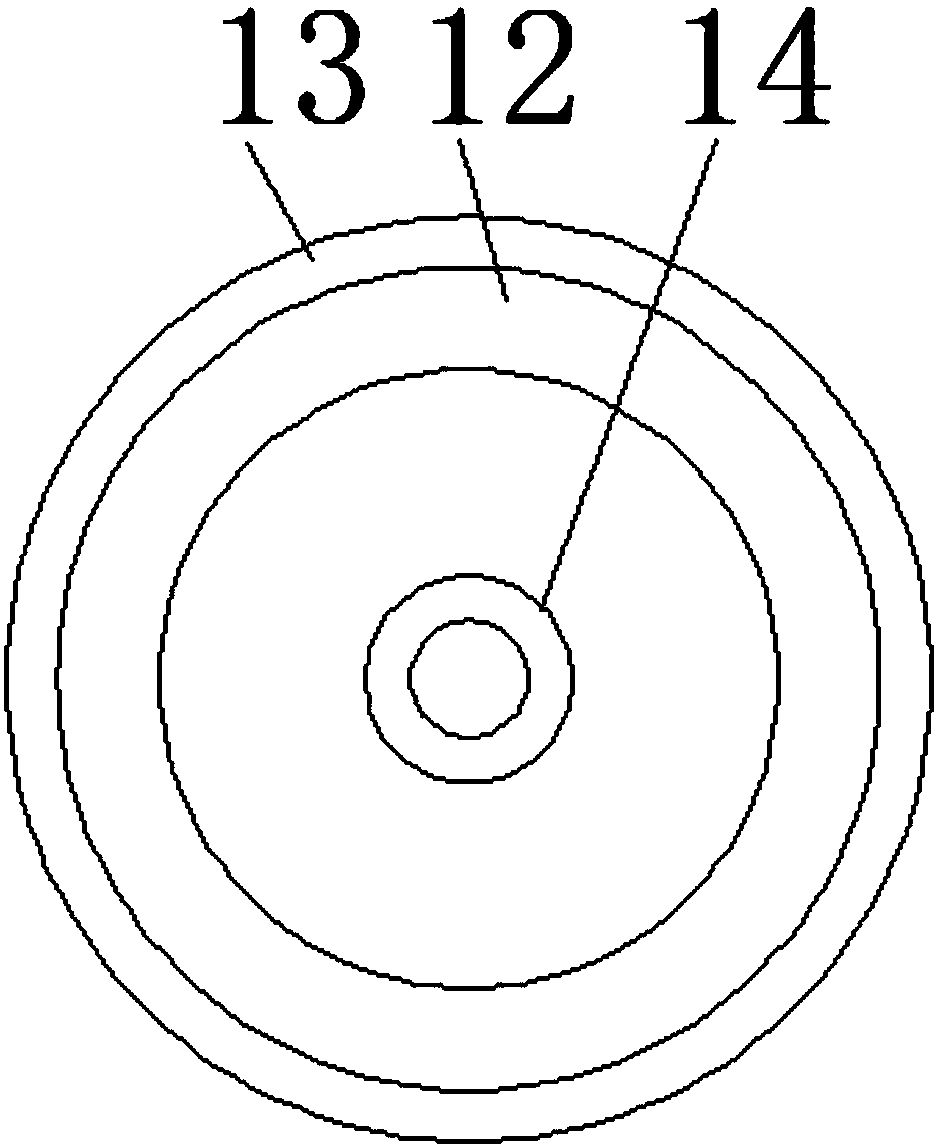

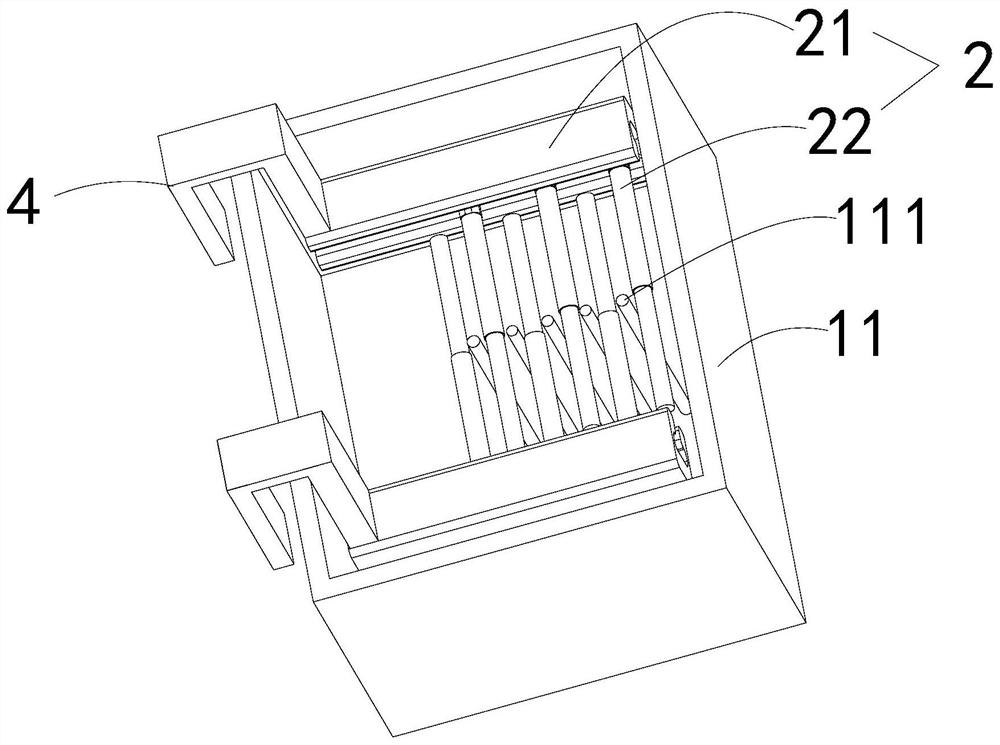

Textile yarn oiling device

InactiveCN108532007APrevent oil drippingAvoid wastingArtificial filament washing/dryingFilament/thread formingTextile yarnFuel tank

The invention discloses a textile yarn oiling device. The textile yarn oiling device comprises a base, a left supporting plate and a right supporting plate are arranged on the tops of the two sides ofthe base respectively, one top plate is arranged on the tops of the left supporting plate and right supporting plate, an oil storage tank is arranged at the bottom of the top plate, a connecting pipeis arranged at the bottom of the oil storage tank, an oil discharging nozzle is arranged at the bottom of the connecting pipe, a sponge is arranged at the bottom of the oil discharging nozzle, and asecond supporting rod is arranged on the top of the base; an oil rubbing roller is arranged on the top of the second supporting rod, a roller is arranged at the center of the oil rubbing roller, a motor is arranged at the bottom of an inner cavity of the second supporting rod, a connecting shaft is connected with the roller and arranged at an output end of the motor, a fixing plate is arranged onthe upper portion of the second supporting rod, and an oil saving groove is formed in the top of the fixing plate; a first connecting rod is arranged on one side of a left supporting plate, a dust suction machine is arranged at one end of the first connecting rod, a second connecting rod is arranged on one side of a right supporting plate, and a dryer is arranged at one end of the second connecting rod. According to the textile yarn oiling device, waste of oil materials can be effectively reduced, and textile yarn after oiling can be quickly dried.

Owner:XIANGSHUI ZHONGXING TEXTILE CO LTD

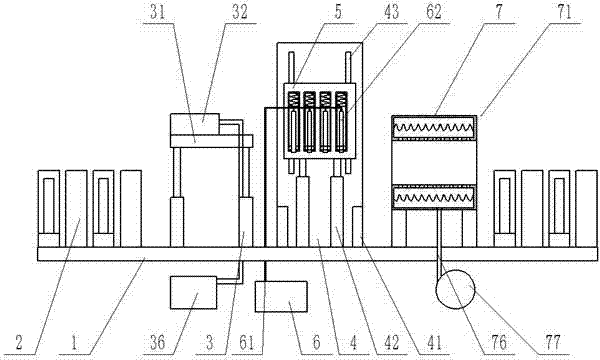

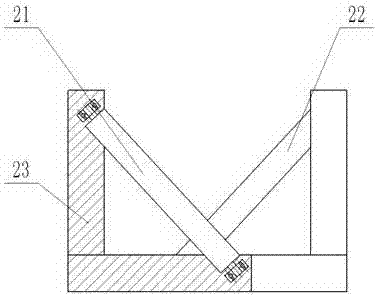

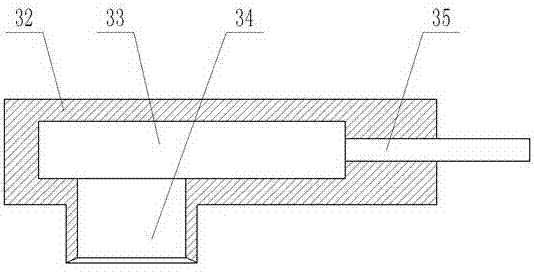

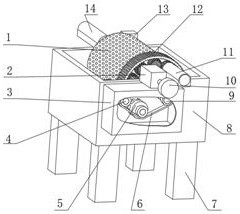

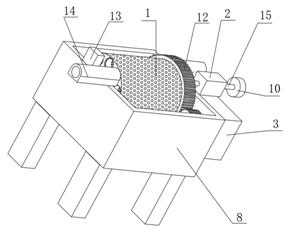

Oil coating equipment used for production and manufacturing of motor rotor

InactiveCN107231070AEnsure stabilityFully oiledPretreated surfacesManufacturing stator/rotor bodiesEngineeringMechanical engineering

The invention discloses oil coating equipment used for production and manufacturing of a motor rotor. The oil coating equipment comprises a working table, a dust removing apparatus and an oil coating apparatus drying apparatus; two supporting roller groups are symmetrically arranged on the working table; the supporting roller groups comprise four first supporting rollers and four second supporting rollers which are arranged in an inclined manner; the first supporting rollers and the second supporting rollers are all mounted on the table surface of the working table through L-shaped brackets; the L-shaped brackets are fixedly connected with the working table through bolts; and the first supporting rollers and the second supporting rollers are rotationally connected with the L-shaped brackets. Along with left and right movement and rotation of the motor rotor, it is ensured that an oil coating needle can be attached to the surface of the motor rotor through a compression spring, so that the oil coating needle can coat oil on the motor rotor in an all-around and uniform manner; and an induced draft fan works to introduce external air from a hot air inlet pipe, and then the air enters a heating cavity to take the heat in the heating cavity out of a hot air outlet, so that the drying effect can be reinforced.

Owner:黄志洁

Automobile brake pad steel backing oil immersion device

InactiveCN108838024AReduce wasteAvoid the effects of oil immersionLiquid surface applicatorsCoatingsDrive shaftFuel tank

The invention discloses an automobile brake pad steel backing oil immersion device. The automobile brake pad steel backing oil immersion device comprises a sealing cover, a rotating drum, an oil immersion cylinder, oil immersion rods, a rotating disk, an oil storage tank, an oil pump and a separating sleeve; the oil immersion cylinder is fixed to the top of the oil storage tank through a bracket;one end of the oil immersion cylinder is connected with the sealing cover; a mechanical seal is arranged in the middle of the sealing cover; a driving shaft is erected in the mechanical seal; the inner end of the driving shaft is connected with the rotating drum; and the multiple oil immersion rods are welded to the outer side of the rotating drum circumferentially. Connected automobile brake padsteel backings are separated through the separating sleeve, the situation that oil immersion of the automobile brake pad steel backings is affected due to the fact that the adjacent automobile brake pad steel backings are closely attached is avoided, the automobile brake pad steel backings can be subjected to oil immersion in batch, the oil immersion effect is good, oil immersion is complete, excess oil can be removed, the quality of oil immersion is improved, waste of oil is reduced, and the cost of oil immersion is lowered.

Owner:YANCHENG LICHENG AUTO PARTS CO LTD

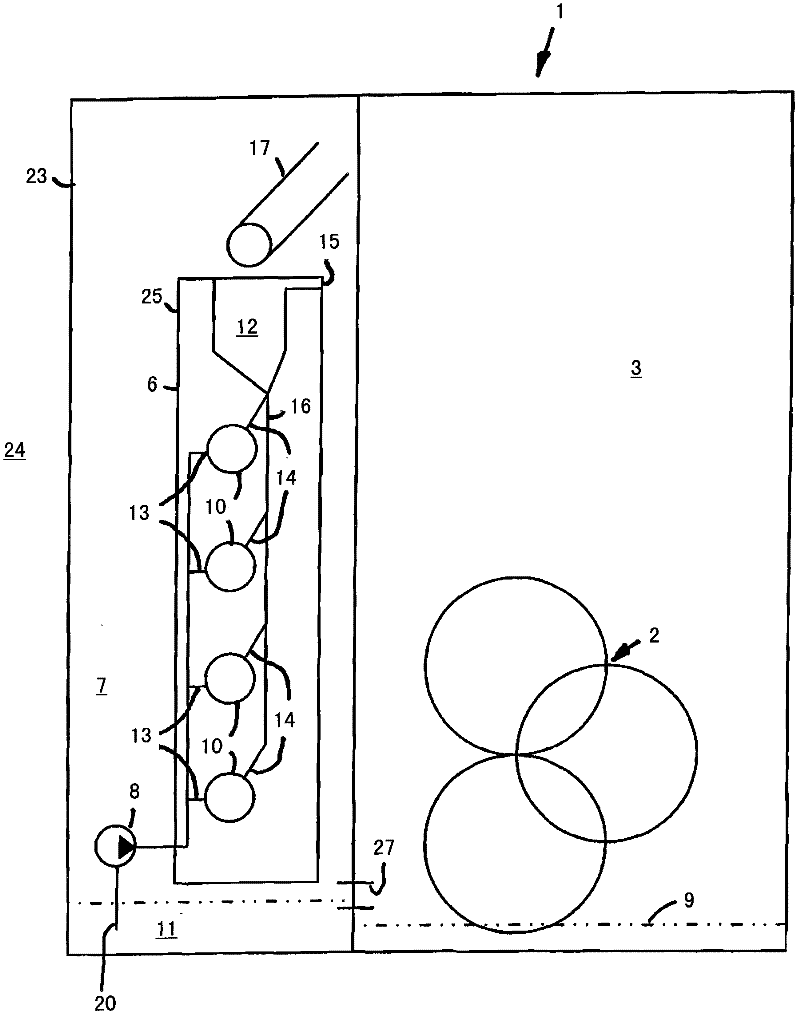

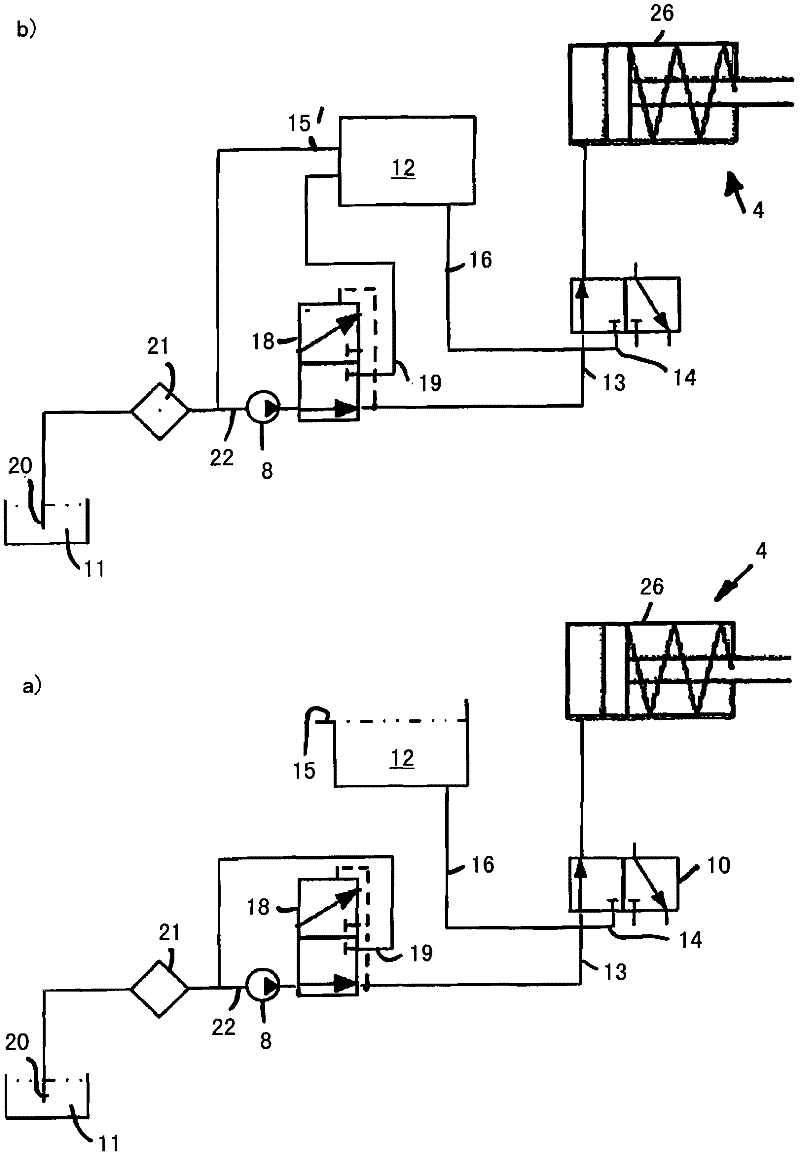

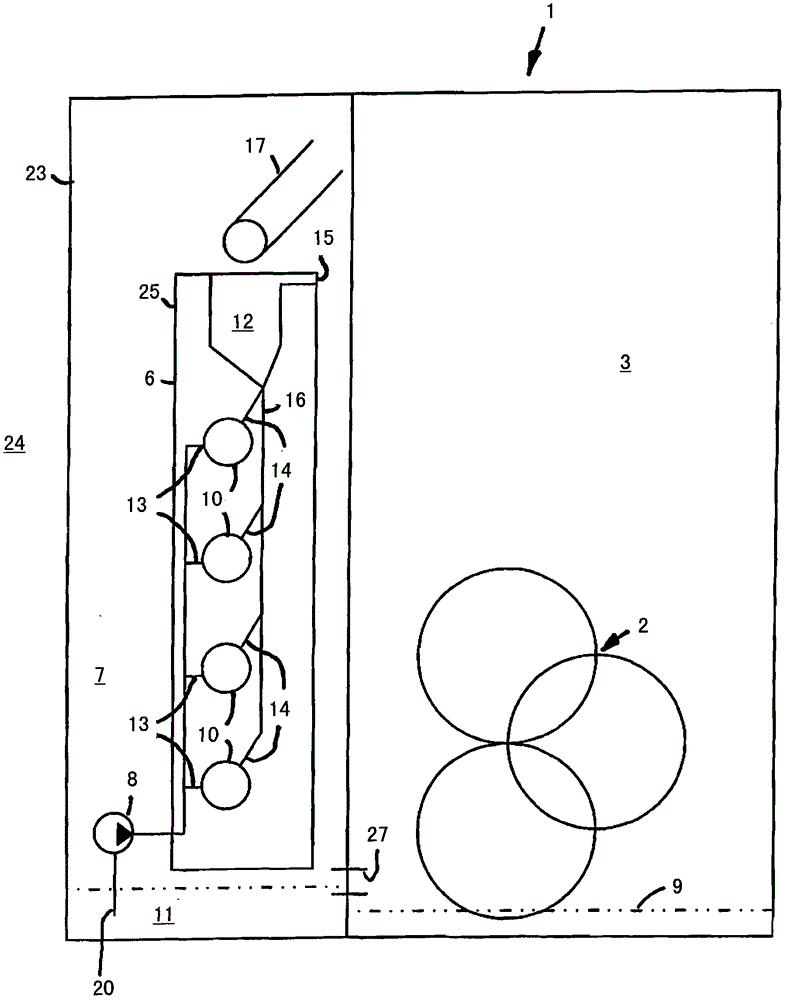

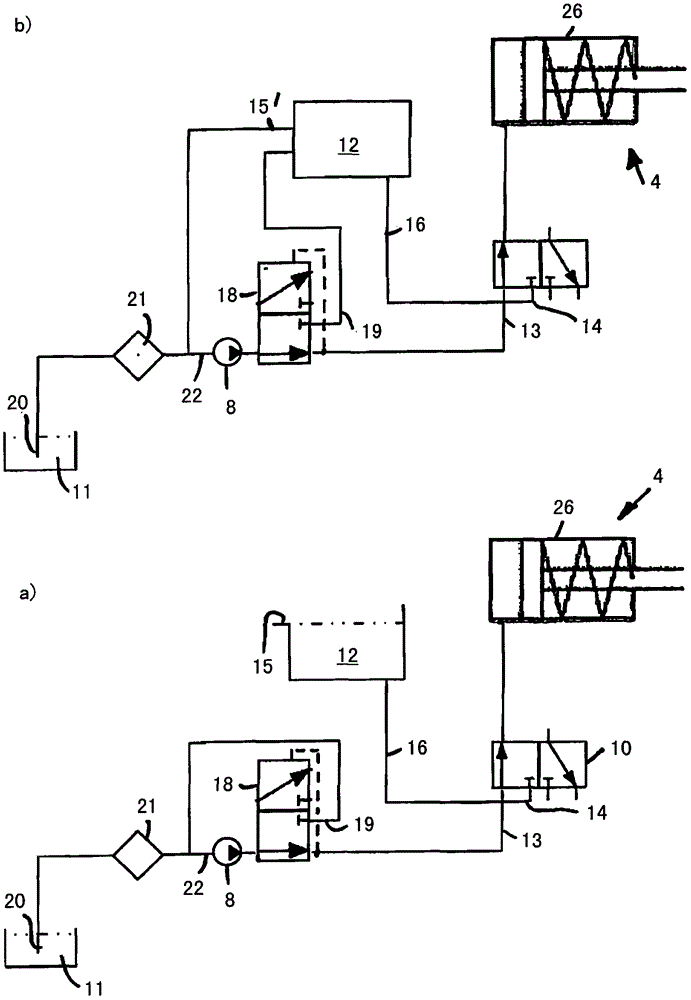

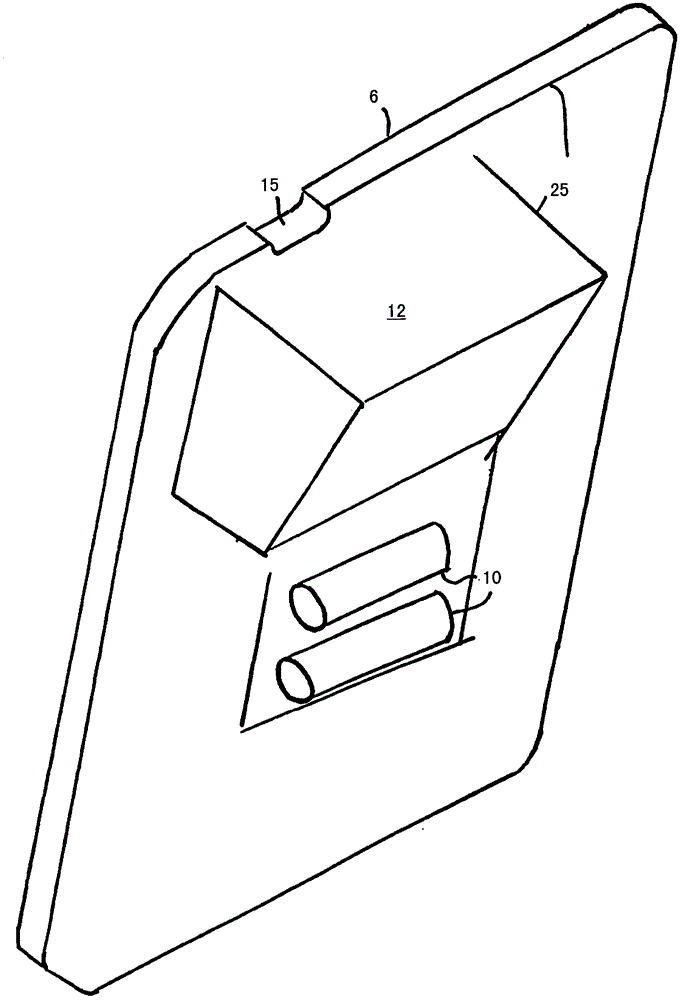

Transmission with electromechanical units and oil loop

InactiveCN102537296AAvoid no loadCompensation for oil leakage lossGear lubrication/coolingGearing controlClutchEngineering

The present invention relates to a transmission, particularly an automatic vehicular shift transmission which comprises the following components: a transmission unit (2); a clutch unit (4); an electromechanical unit (6); wherein the transmission (1) is internally provided with an oil loop which comprises an oil pump (8). The oil pump takes oil (9) out through a first oil reservoir (11), and furthermore the oil (9) which is taken out can be supplied to various unit. The electromechanical unit (6) comprises at least one clutch valve (10). The clutch valve is equipped for controlling the clutch unit (4). At least one clutch valve (10) comprises a pressure opening (13) which is used for at least indirectly connecting the clutch valve (10) with the oil pump (8) and an exhaust opening that is at least indirectly connecting the clutch valve with a second oil reservoir. The second oil reservoir is formed separately from the first oil reservoir. The second oil reservoir is provided with an overflow opening which is equipped above all clutch valves of the electromechanical unit.

Owner:GETRAG FORD TRANSMISSIONS GMBH

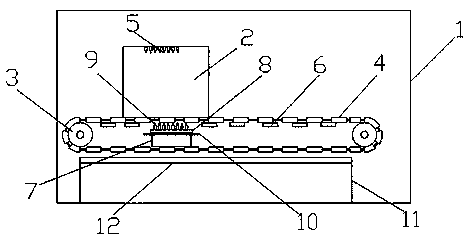

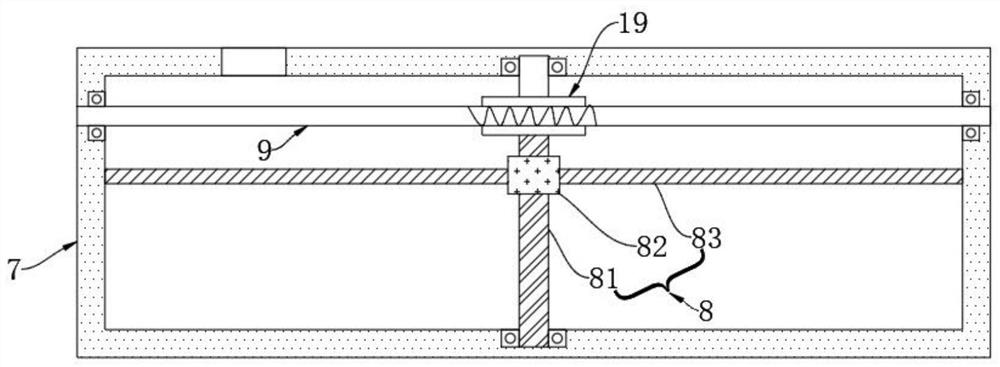

Oil immersing device

The invention discloses an oil immersing device which comprises an installing case. A conveying mechanism and an oil immersing box are arranged in the installing case, and the conveying mechanism comprises two driving rollers which are symmetrically arranged. A crawler belt is connected between the two driving rollers, and an oil injection device is also arranged between the two driving rollers. The oil immersing box is positioned above the crawler belt corresponding to the oil injection device, and an oil injection nozzle b is arranged at the top end of the oil immersing box. A plurality of vibrating motors are arranged between the two driving rollers, and the vibrating motors are attached to the lower part of the crawler belt. The oil injection device comprises a gear motor, an installing disk is arranged above the gear motor, and a plurality of oil injection nozzles a are arranged on the installing disk. The oil injection nozzles a rotate back and forth to inject oil by the positive-negative rotating of the gear motor, so that parts can be immersed in oil more thoroughly. The oil immersing device has a reasonable design and is suitable for promotion and use.

Owner:江阴和港机械有限公司

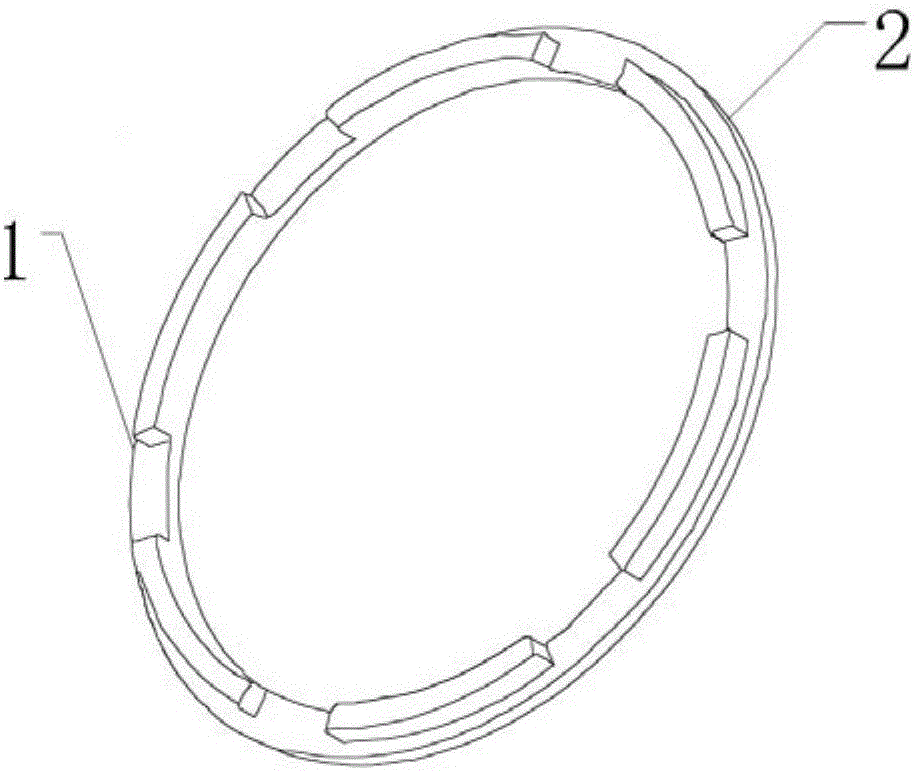

Bearing outer distance ring and gear box

InactiveCN106195224AGood conditionTimely oil intakeBearing componentsGearing detailsMechanical engineeringEngineering

Owner:BEIJING NANKOU RAILWAY TRANSIT MACHINERY

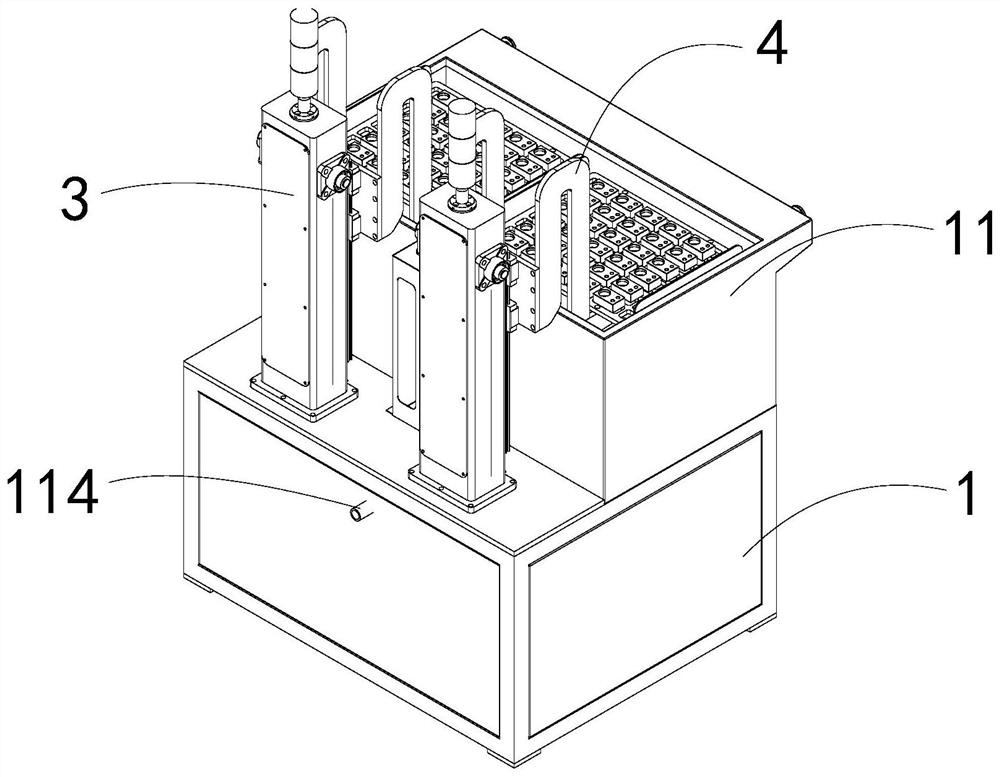

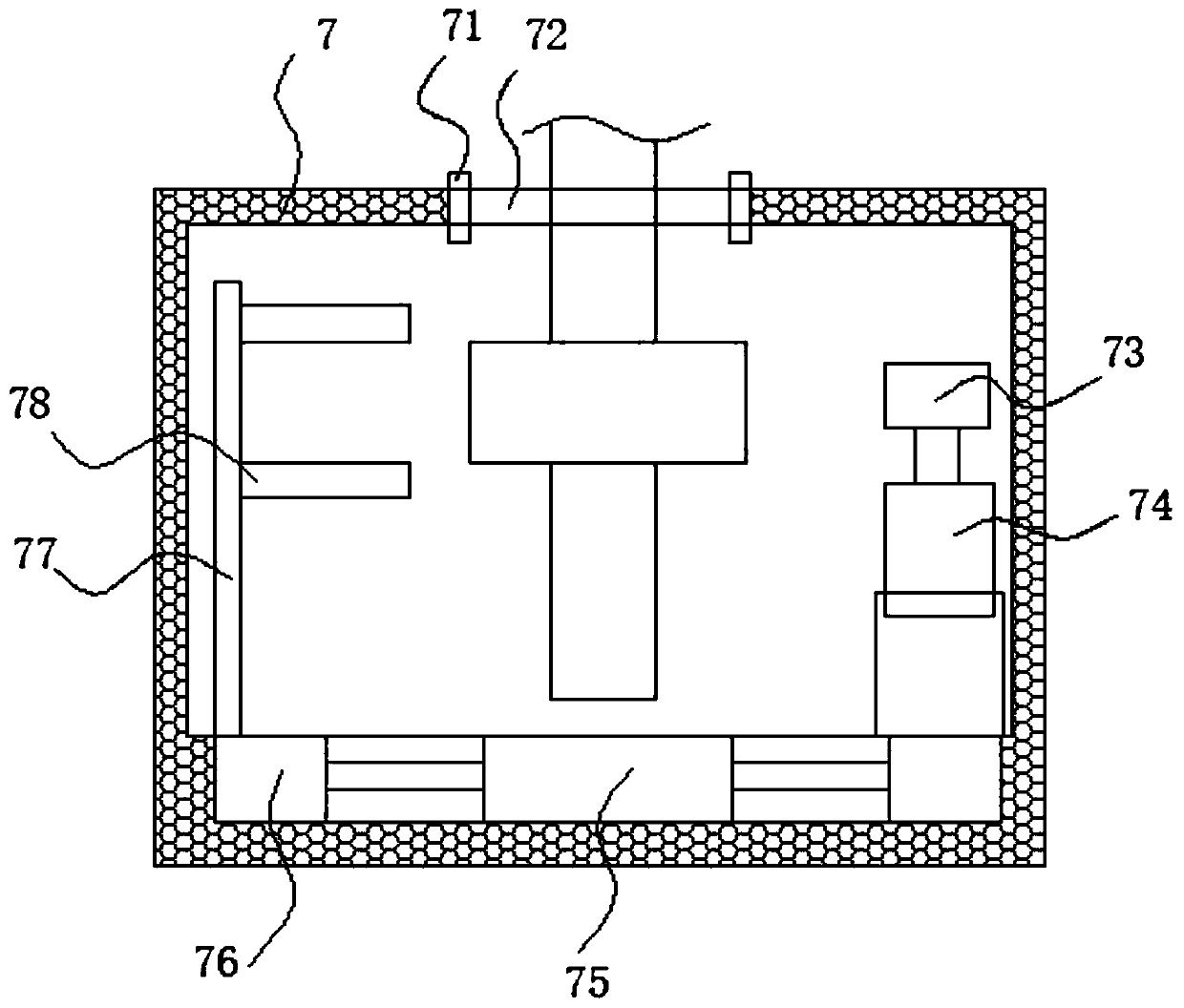

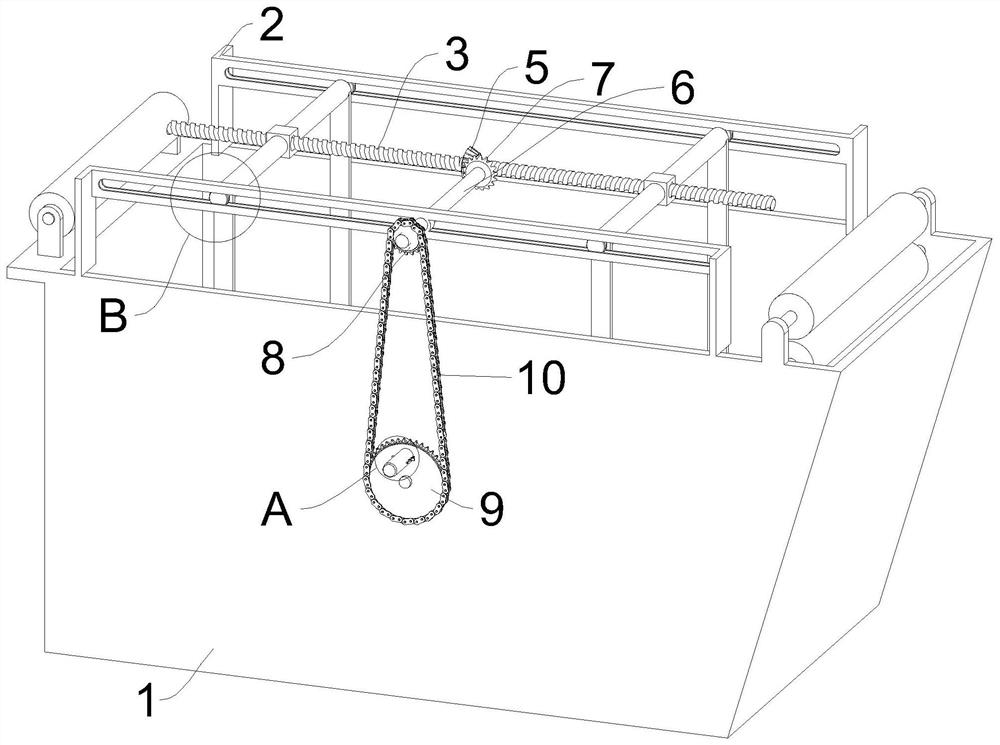

Oil soaking machine

ActiveCN112974127AFully oiledAvoid soaking oil for too longLiquid surface applicatorsCoatingsEngineeringMechanics

The invention provides an oil soaking machine which comprises a machine frame, a material placing disc, an up-down mechanism, a connecting frame, a driving device and a timing assembly. An oil tank is arranged above the machine frame, the upper end of the oil tank is open, the material placing disc is arranged in the oil tank and used for containing product for soaking oil, the up-down mechanism is connected to the machine frame and located on one side of the oil tank, the upper end of the up-down mechanism is connected with the material placing disc, and the up-down mechanism is used for driving the material placing disc to move up and down in the oil tank; and the connecting frame is connected with the material placing disc and the up-down mechanism and is in an n-shaped bent shape, the driving device is arranged on the machine frame, located below the oil tank, connected with the up-and-down mechanism and used for providing power for the up-down mechanism, and the timing assembly is arranged in the machine frame, connected with the driving device and used for controlling the driving device in a timing mode. According to the oil soaking machine, the driving device is arranged to drive the up-down mechanism, the machine p disc is driven to move up and down in the oil tank, products on the material placing disc are immersed below the liquid level of oil to be soaked in oil at regular time, oil soaking is sufficient, the oil soaking time is effectively prevented from being too long, and the oil soaking efficiency is high.

Owner:深圳市鑫瑞华通信设备技术有限公司

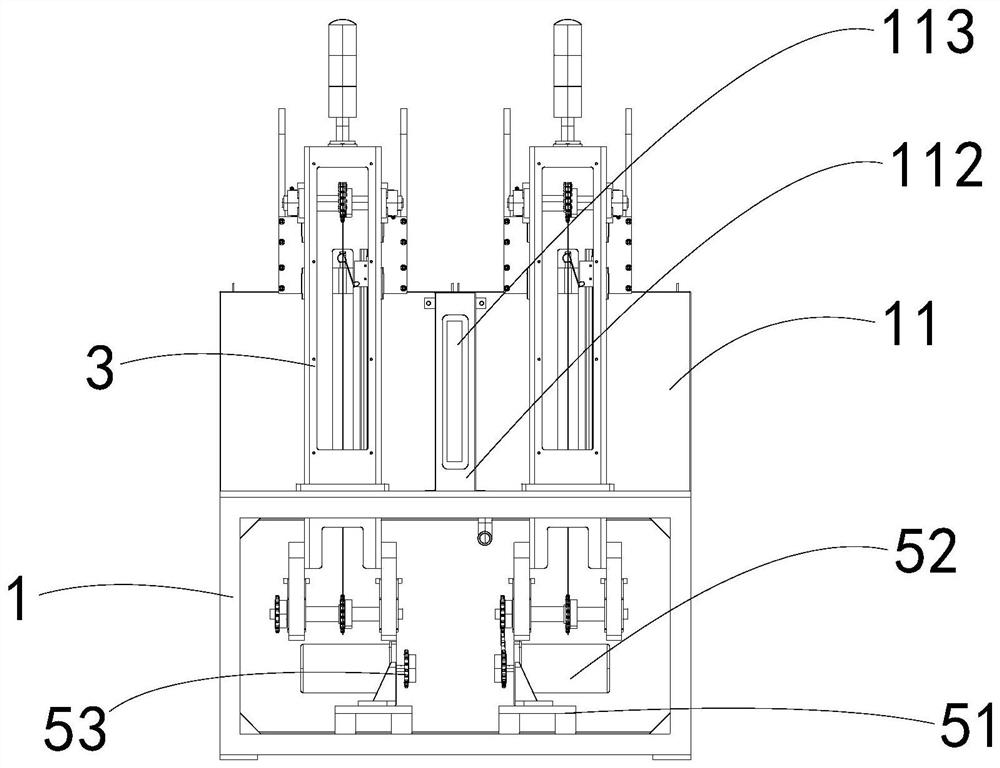

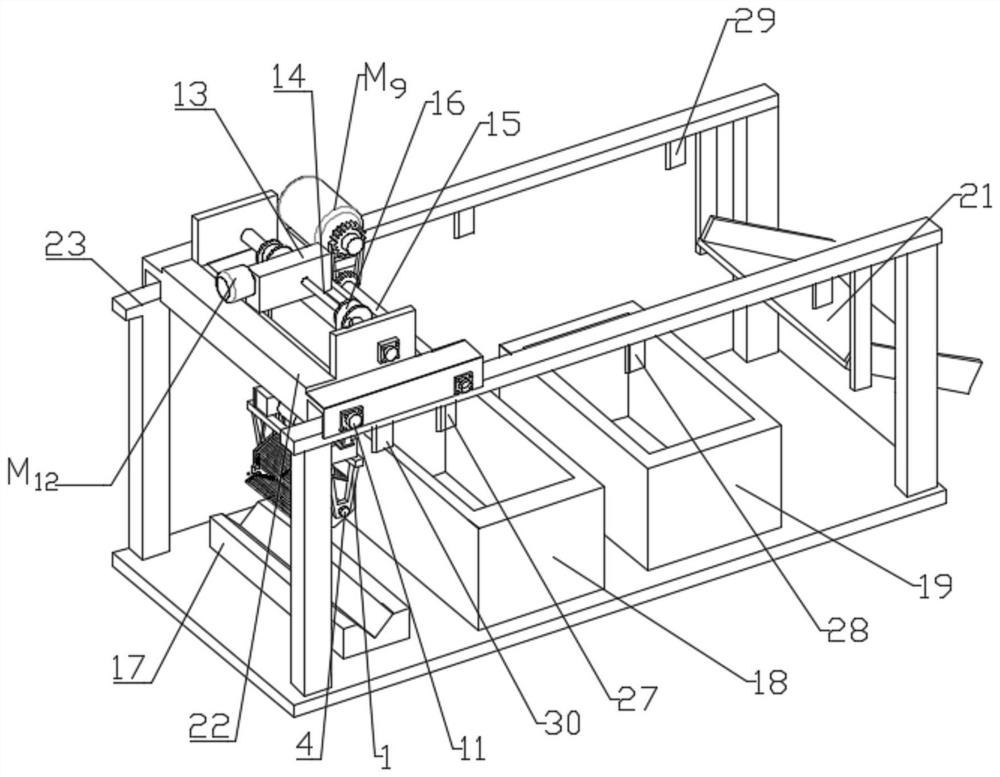

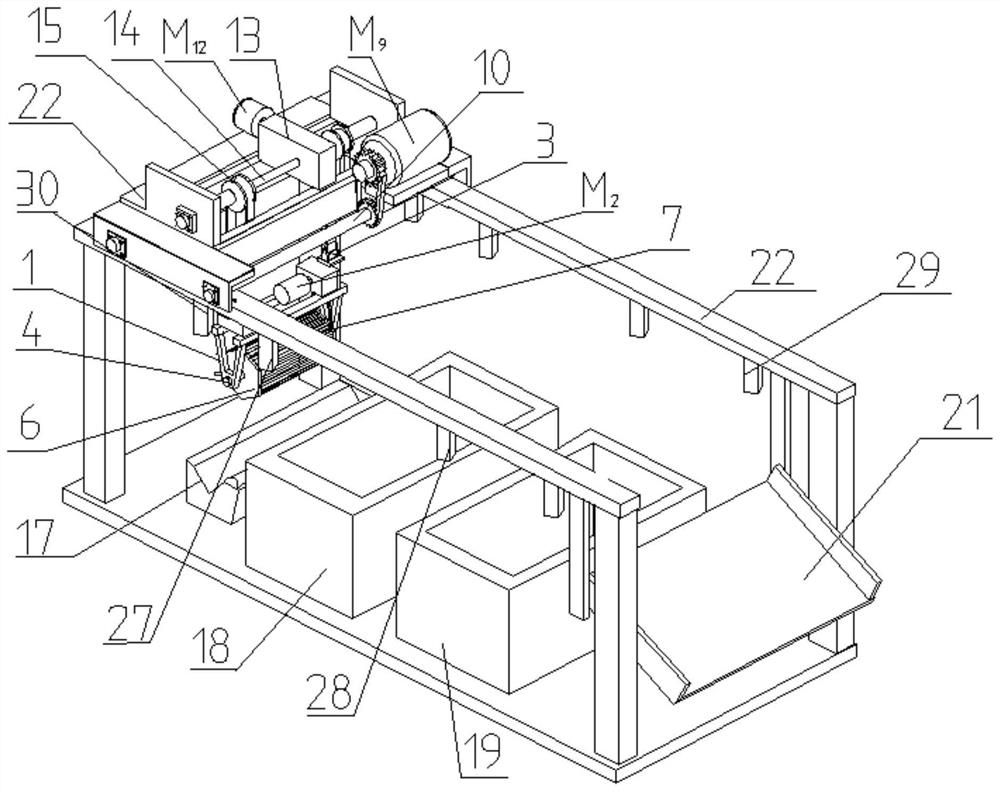

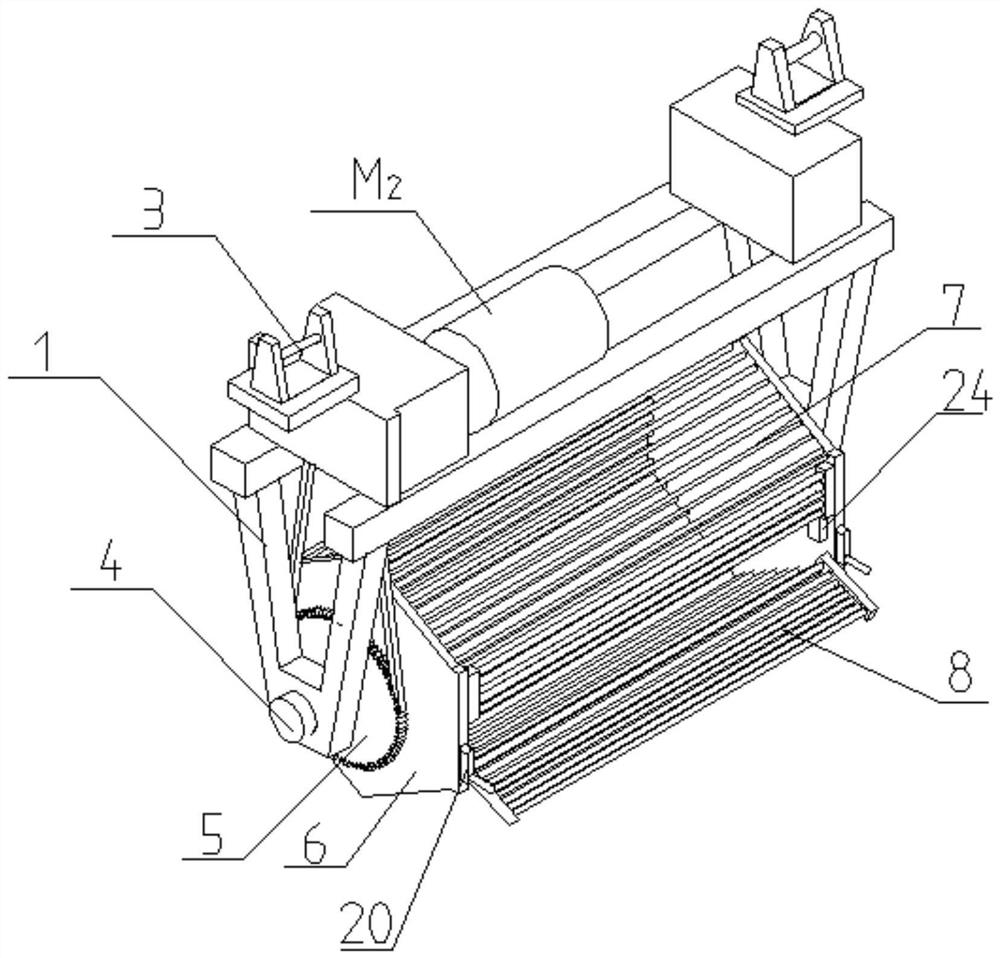

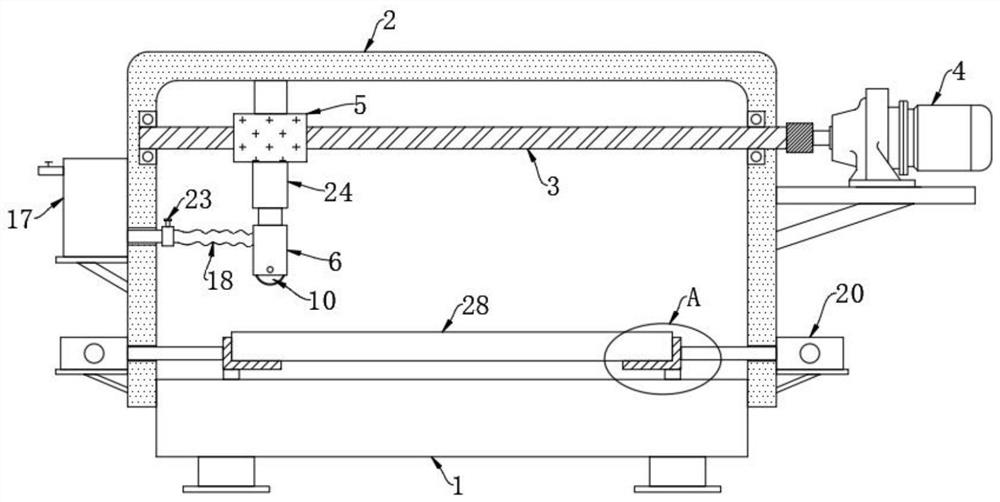

Automatic oil immersion device and oil immersion method for pipe fittings

ActiveCN111804524AReduce labor intensityFully evenly distributedHollow article cleaningPretreated surfacesPipe fittingRotation - action

The invention discloses an automatic oil immersion device and oil immersion method for pipe fittings. The automatic oil immersion device comprises a lifting part, a sliding part, a roller part, an oildipping pool and a rack. The sliding part is assembled on the rack and drives the lifting part to move back and forth, and the oil dipping pool is located at the rear end of the rack. The lifting part is matched with the roller part and drives the roller part to move up and down. The roller part comprises a charging bin, a connecting piece and a power piece. The charging bin and the power piece are both arranged on the connecting piece. The power piece drives the charging bin to rotate. The charging bin is of a cage structure. By the adoption of the automatic oil immersion device, the operation steps of oil immersion and oil control work are simplified, the labor intensity of workers is reduced, the efficiency of smearing anti-rust liquid is improved, and the anti-rust liquid covering thepipe fittings is sufficiently and uniformly distributed; and the automatic oil immersion device and the oil immersion method have the beneficial effects that the operation is easy, the oil immersionefficiency is high, and oil immersion is comprehensive.

Owner:HEBEI JIANZHI CASTING GROUP

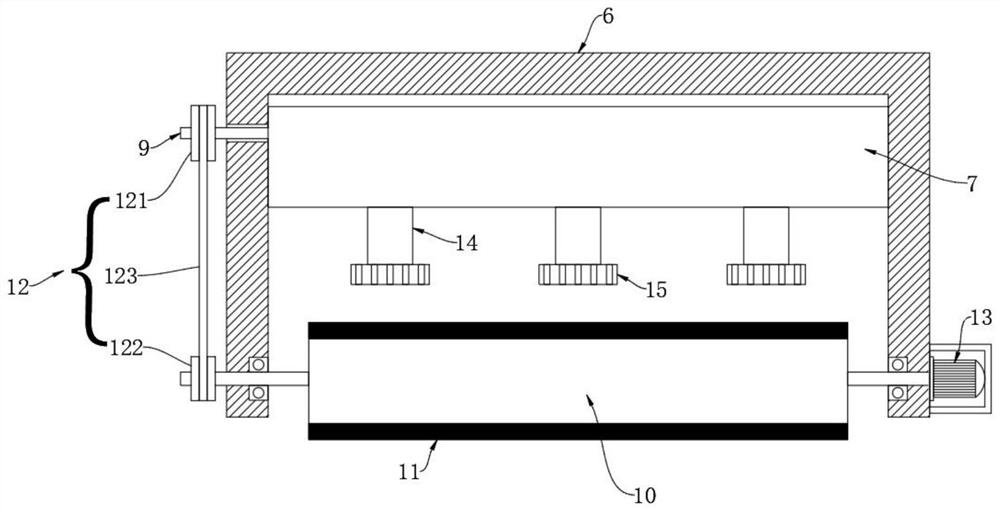

Efficient oil brushing device for wood plates

InactiveCN112718368AFully oiledSave human effortLiquid surface applicatorsCoatingsBrush deviceWorkbench

The invention belongs to the field of plate processing and particularly relates to an efficient oil brushing device for wood plates. The efficient oil brushing device comprises a workbench; a support is fixedly connected to the workbench; a lead screw is rotatably connected to the support; a servo motor is in transmission connection with the lead screw; a threaded block is in threaded connection with the lead screw; the threaded block is in sliding connection with the support; the threaded block is connected with a frame; a liquid discharging box is fixedly connected to the frame; a pushing mechanism is arranged in the liquid discharging box; and a worm matched with the pushing mechanism is rotationally connected into the liquid discharging box. According to the efficient oil brushing device for the wood plates, through the arrangement of the lead screw and the threaded block, the servo motor can be matched to drive the roller to axially move, all positions of a wood plate are fully brushed with oil through a bristle layer, manpower is greatly saved, and in addition, the liquid discharging box is enabled to spray oil liquid to the bristle layer at intervals through the arrangement of the pushing mechanism, so that the trouble of manually dipping the oil liquid is avoided.

Owner:李炀炀

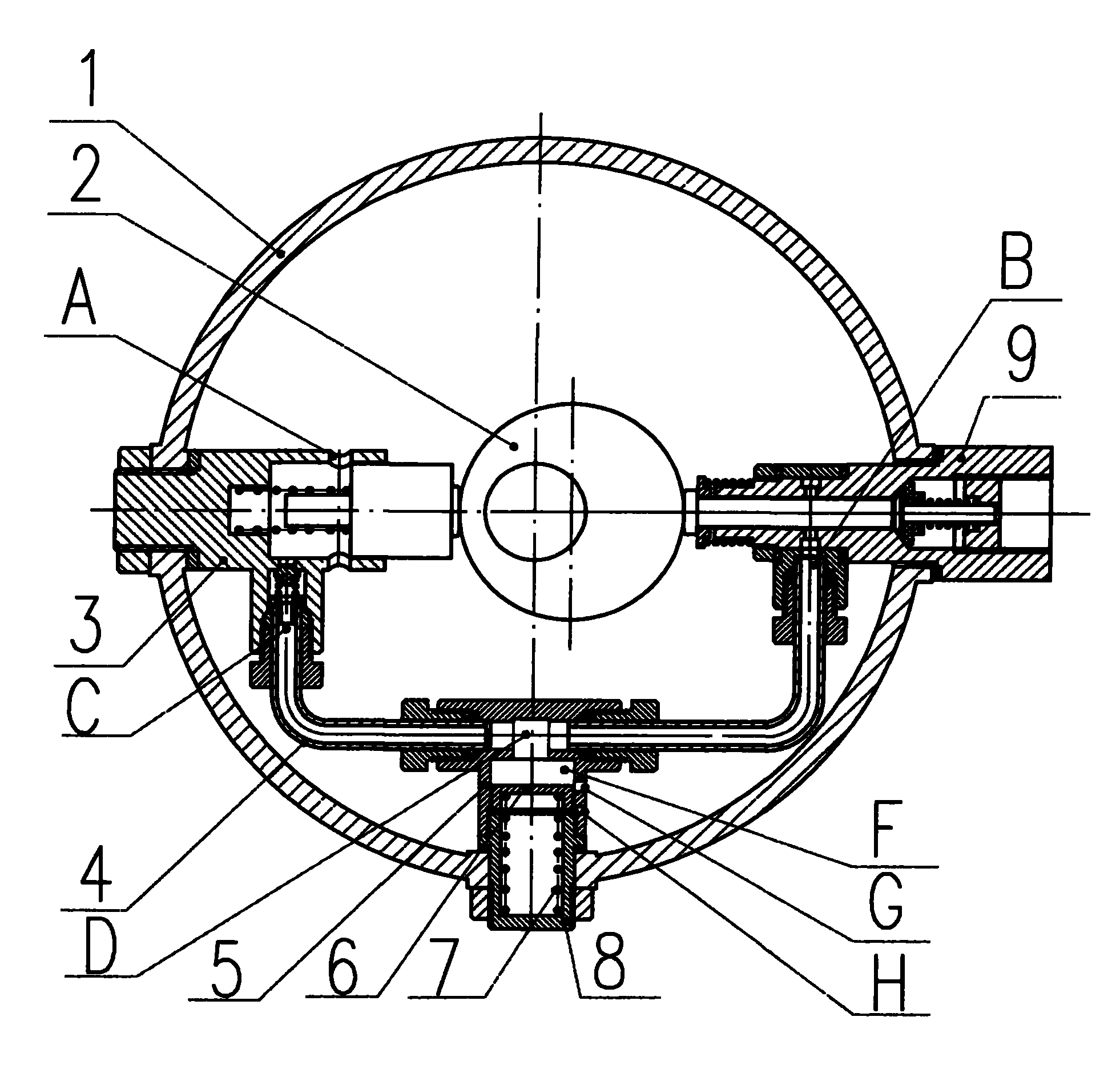

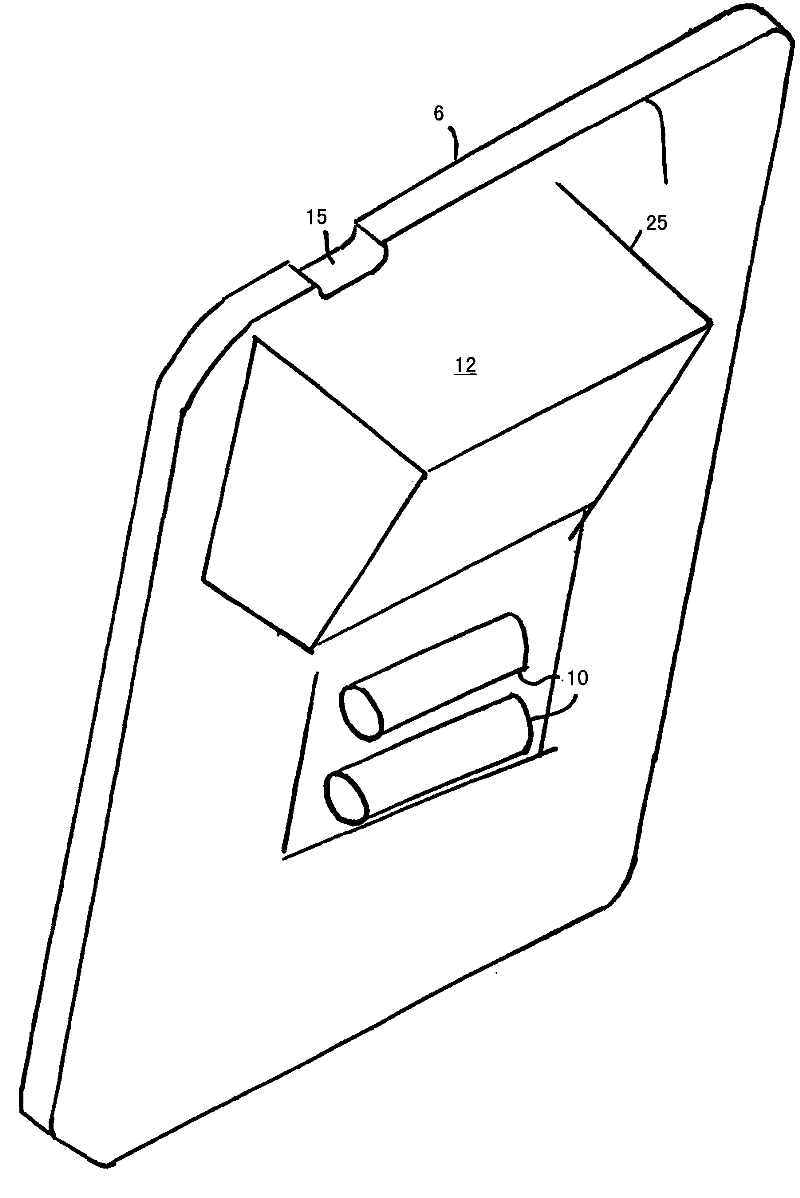

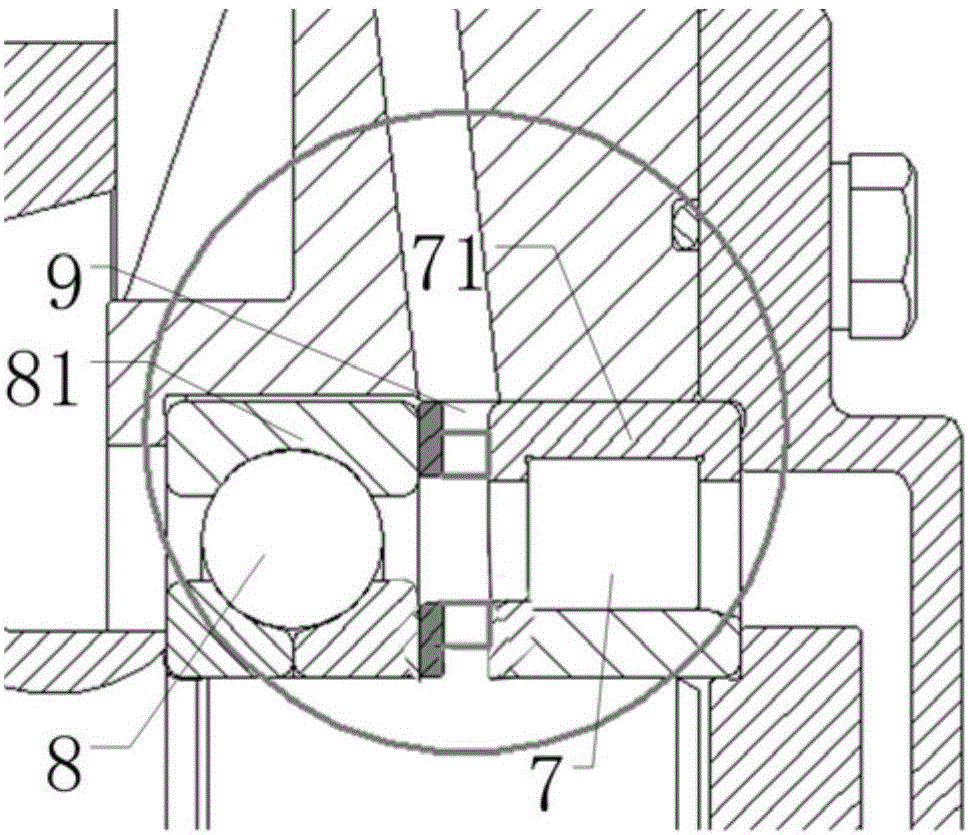

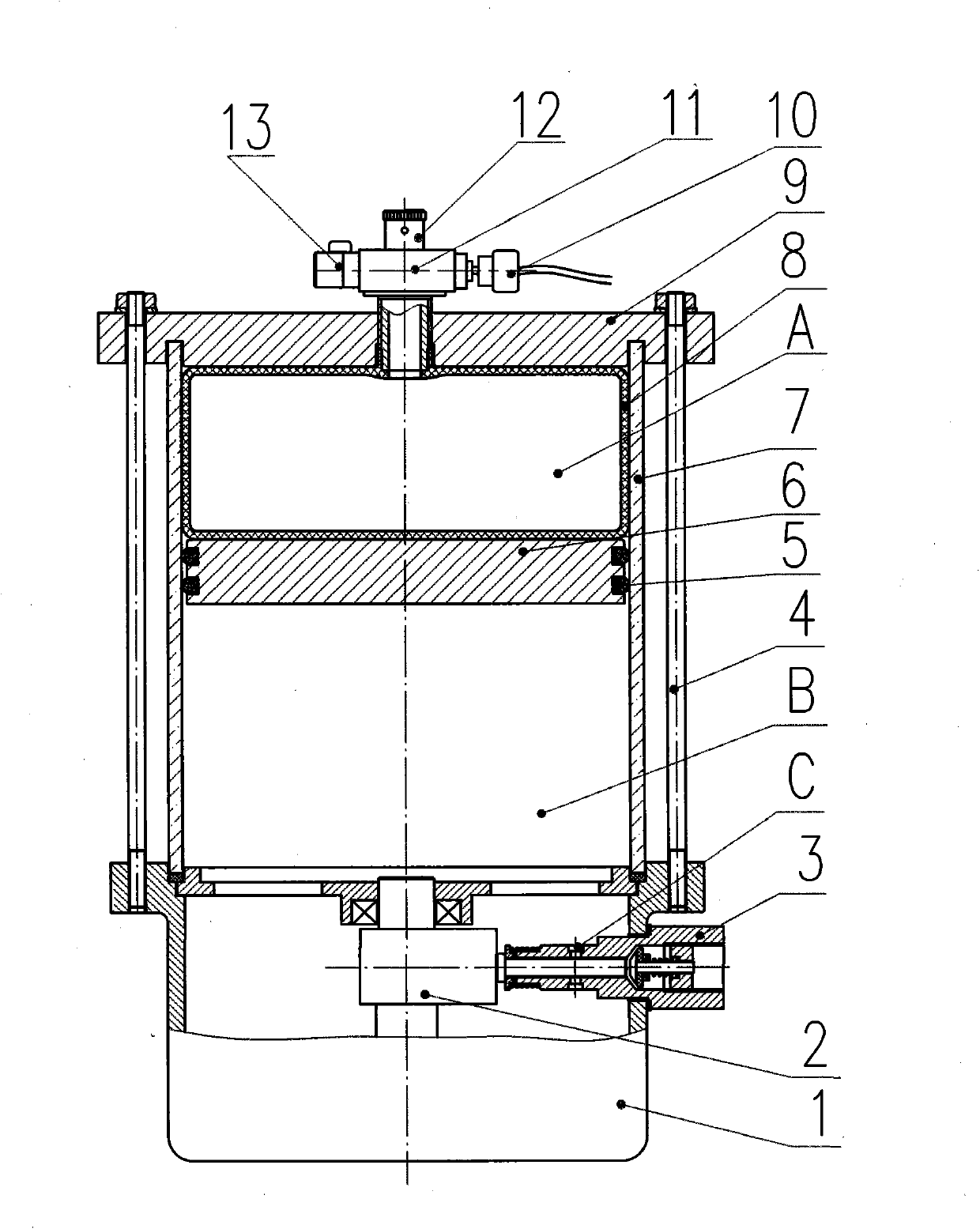

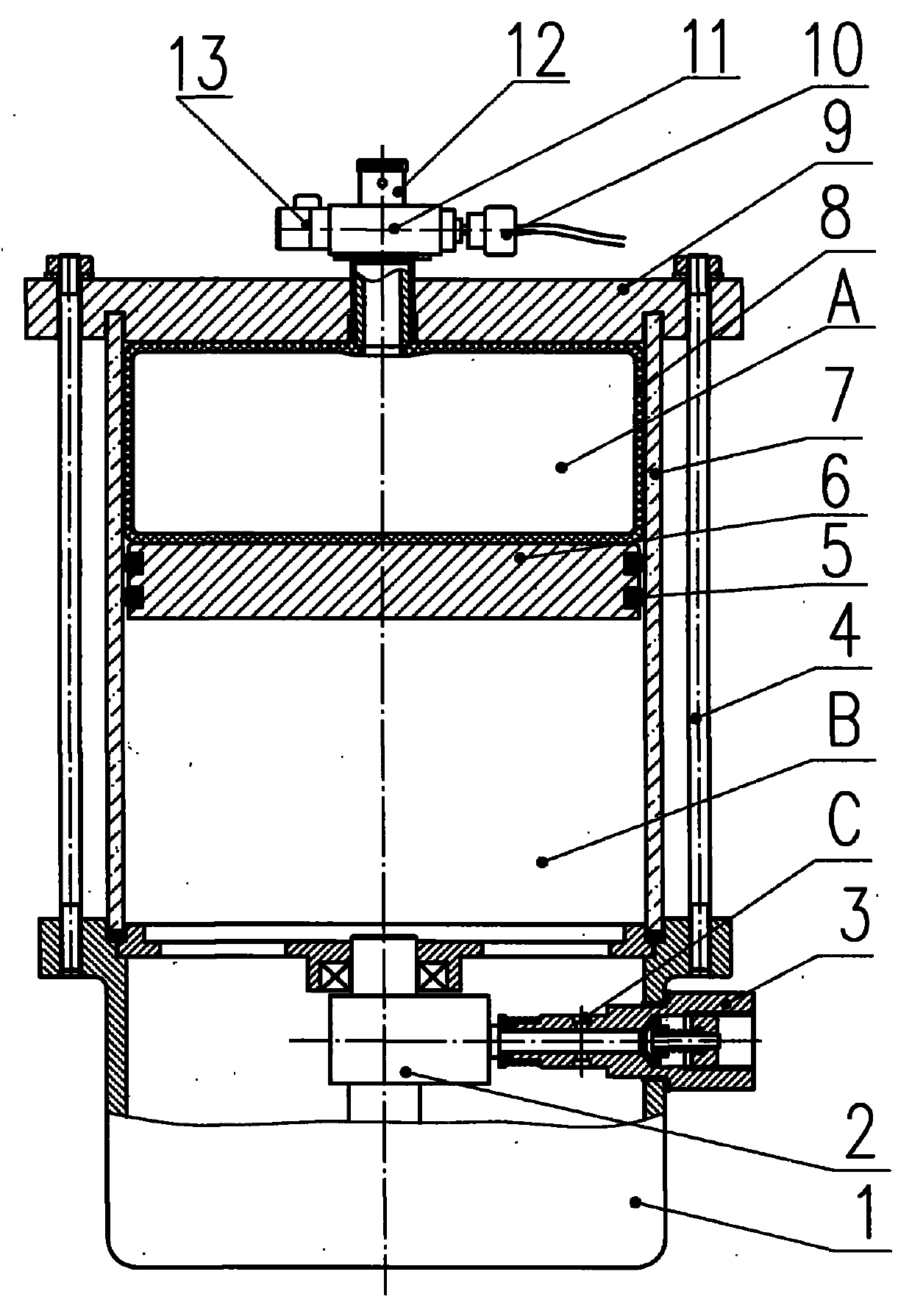

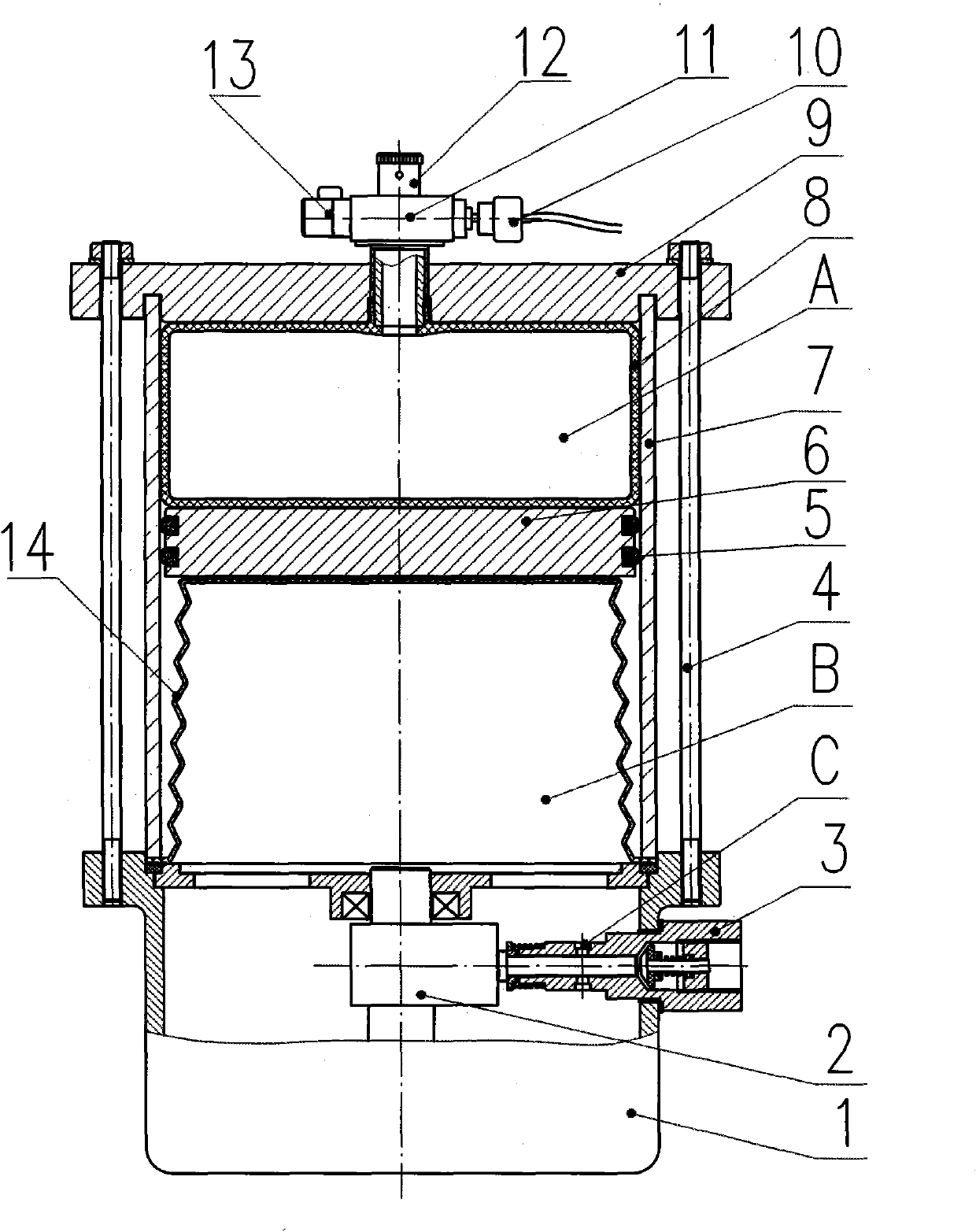

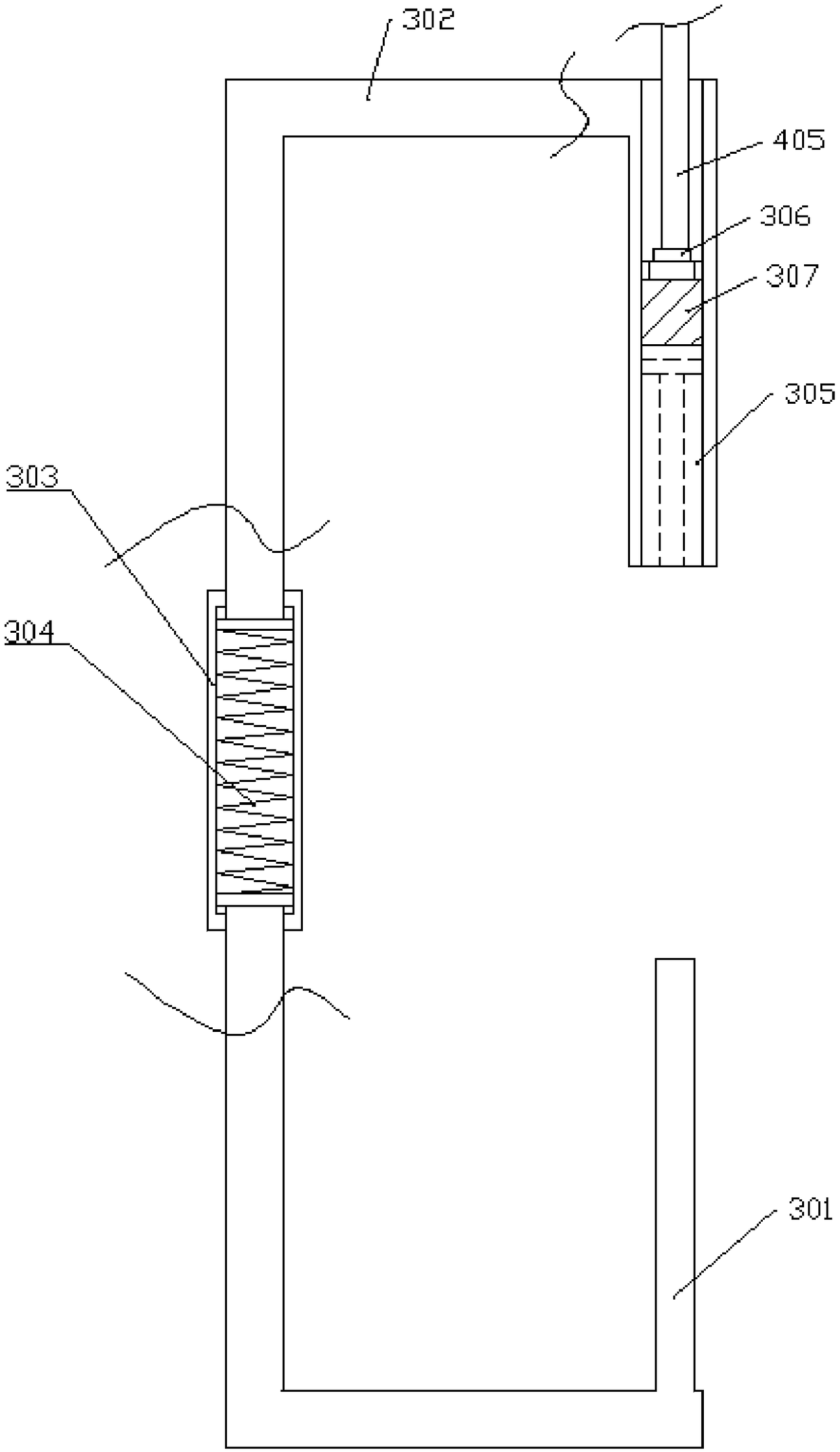

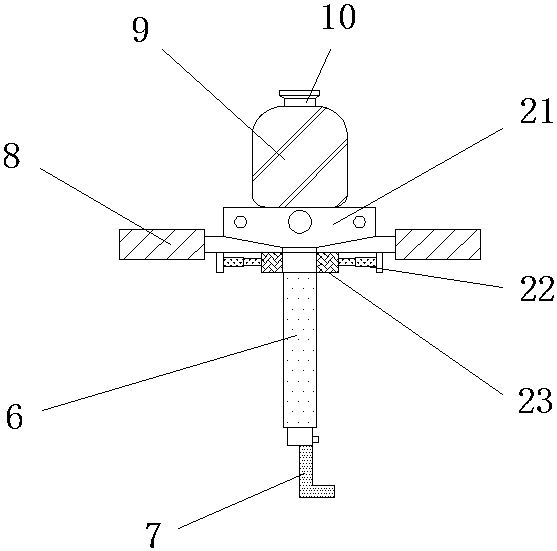

Lubricating device with automatic inflating and deflating structure and air chamber pressure oil tank

InactiveCN102168794AFully oiledHigh pumping capacity for greaseLubricating pumpsLubrication elementsOil canOil and grease

The invention discloses a lubricating device with an automatic inflating and deflating structure and an air chamber pressure oil tank. An oil tank upper cavity A is communicated with a two-position and three-way valve which is also provided with an interface which is communicated with the atmosphere. By adopting the structure, an oil inlet mode can be changed; and oil can be fully fed into an oil inlet of a lubricating pump and the capability of pumping grease is greatly improved. The lubricating device with the automatic inflating and deflating structure and the air chamber pressure oil tank comprises a lubricating pump casing, a power assembly, a lubricating pump, a cylindrical oil tank, a piston, a sealing ring and an automatic controller, wherein the power assembly and the lubricating pump driven by the power assembly are arranged on the lubricating pump casing; the cylindrical oil tank is fixedly connected with the lubricating pump casing; the cylindrical oil tank is separated into the oil tank upper cavity A and an oil tank lower cavity B, which are mutually sealed, by the piston through the sealing ring; an oil inlet port C of the lubricating pump is communicated with the oil tank lower cavity B for storing the grease; the automatic controller is connected with an electric air pump and the power assembly through a line; the electric air pump is also arranged outside the cylindrical oil tank; the oil tank upper cavity A is a sealing air chamber and is connected with the two-position and three-way valve extending out of the upper part of the oil tank upper cavity A; and an exhaust port of the electric air pump passes through an interface of the two-position and three-way valve.

Owner:赵大平

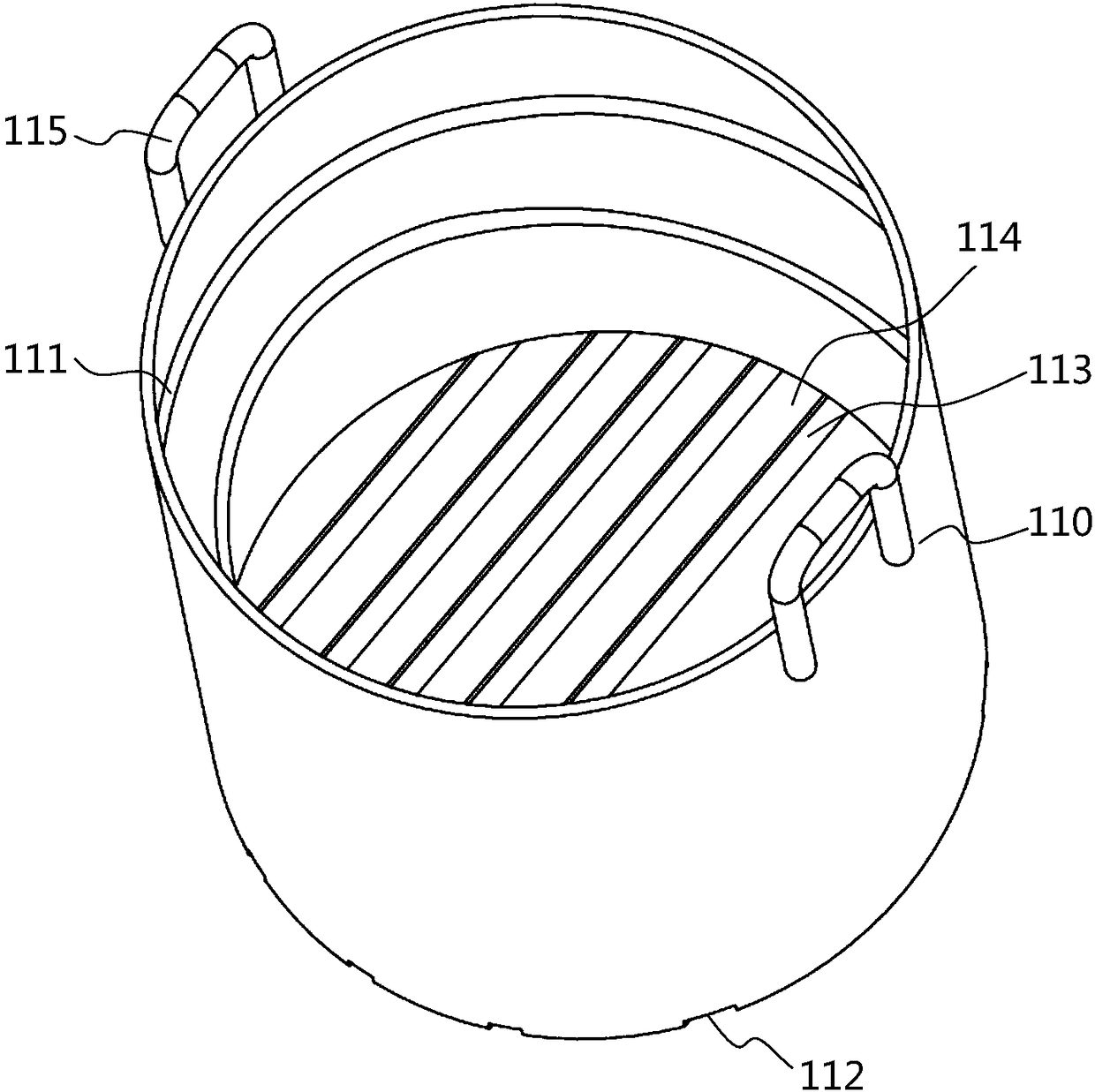

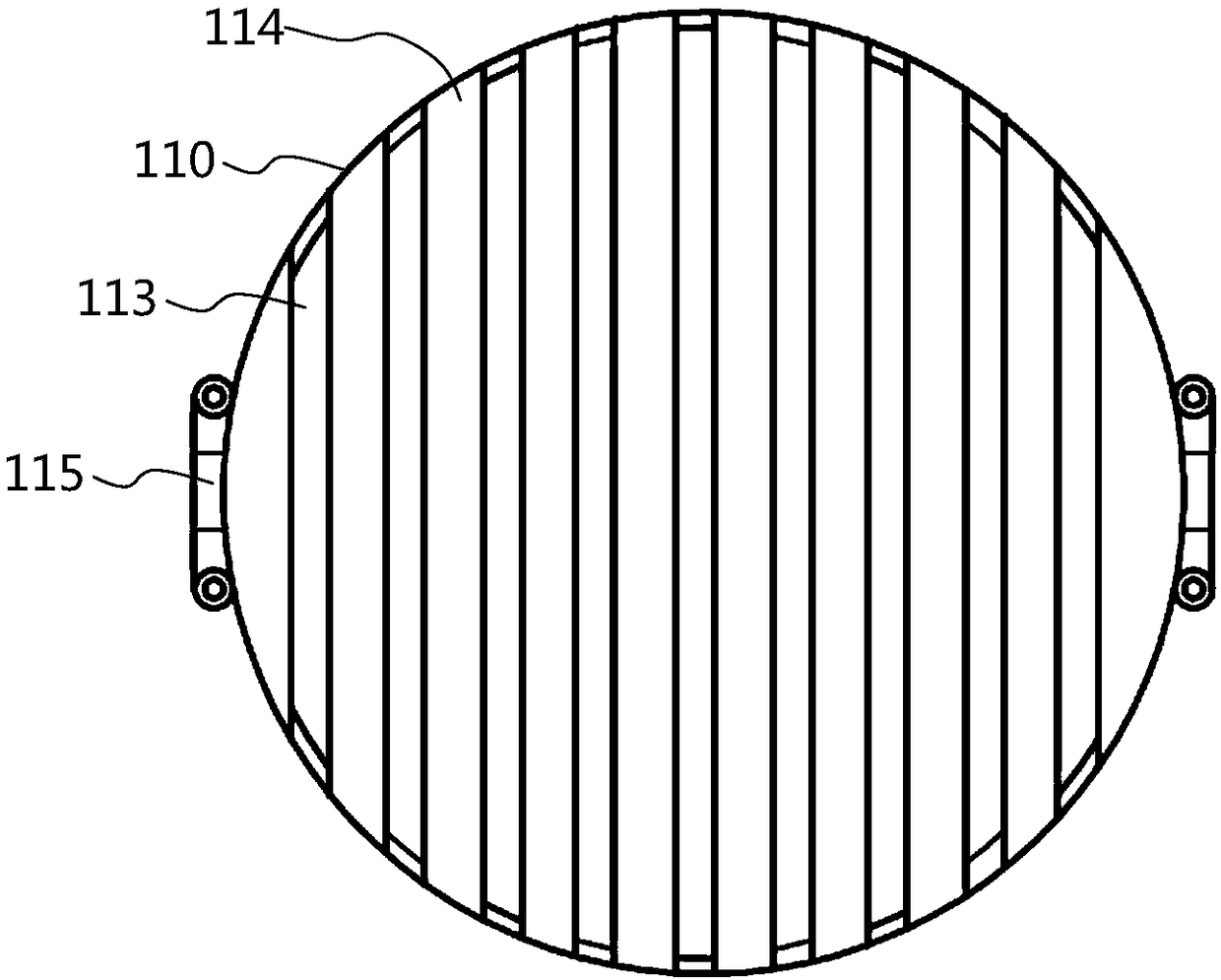

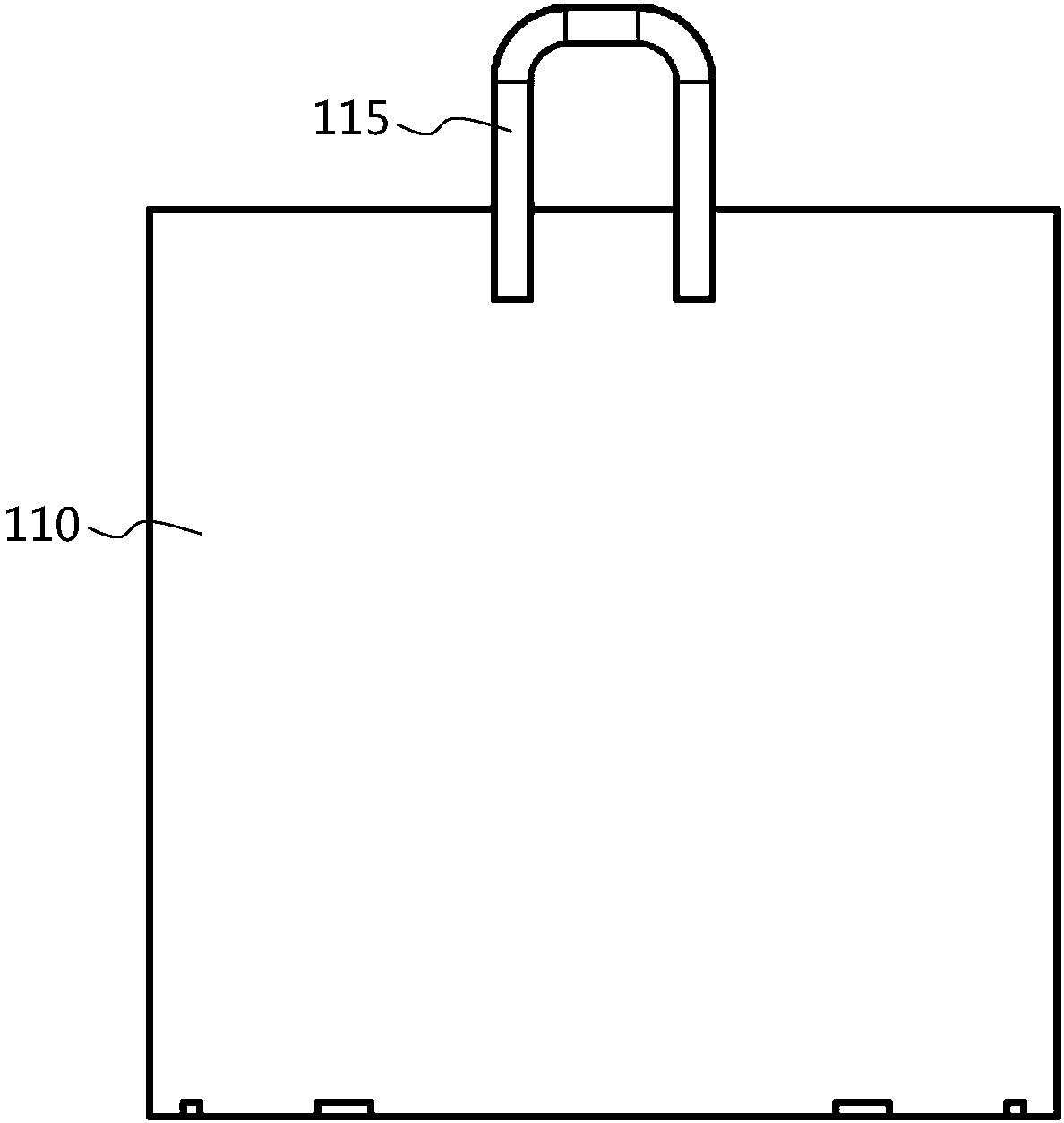

Steel ball immersion oil storage bucket and application method

PendingCN108543667AReduce rustGood oil resistanceLiquid surface applicatorsCoatingsCorrosionOil immersion

The invention discloses a steel ball immersion oil storage bucket and an application method and belongs to the technical field of production of steel balls. The steel ball immersion oil storage bucketcomprises a bucket body; the section of the bucket body is circular or elliptic; the inner sidewall of the bucket body is provided with at least one spiral groove; the bottom of the bucket body is opened and is provided with a mounting groove; the mounting groove is provided with a plurality of isolating bars; a plurality of oil charging clearances are formed among the isolating bars; the surfacetension of oil is increased due to the spiral groove and is larger than the adhesive force, so rising of the oil is quickened; a produced steel ball is subjected to oil immersion treatment so that the surface of the steel ball is coated with an oil layer, and thus corrosion of the steel ball is effectively reduced and the steel ball meets the quality requirements of customers.

Owner:MAANSHAN YIFENG INDAL GROUP

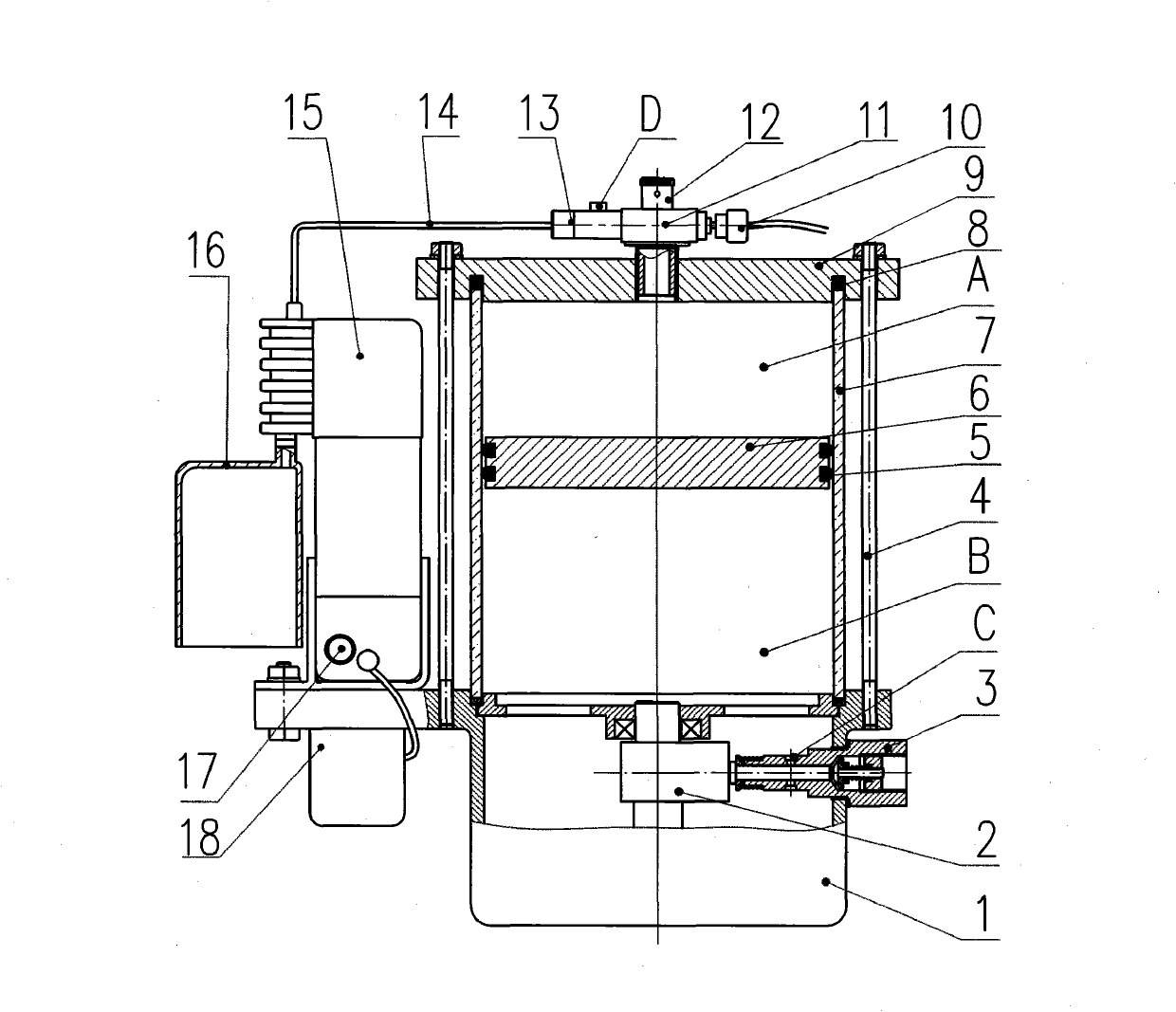

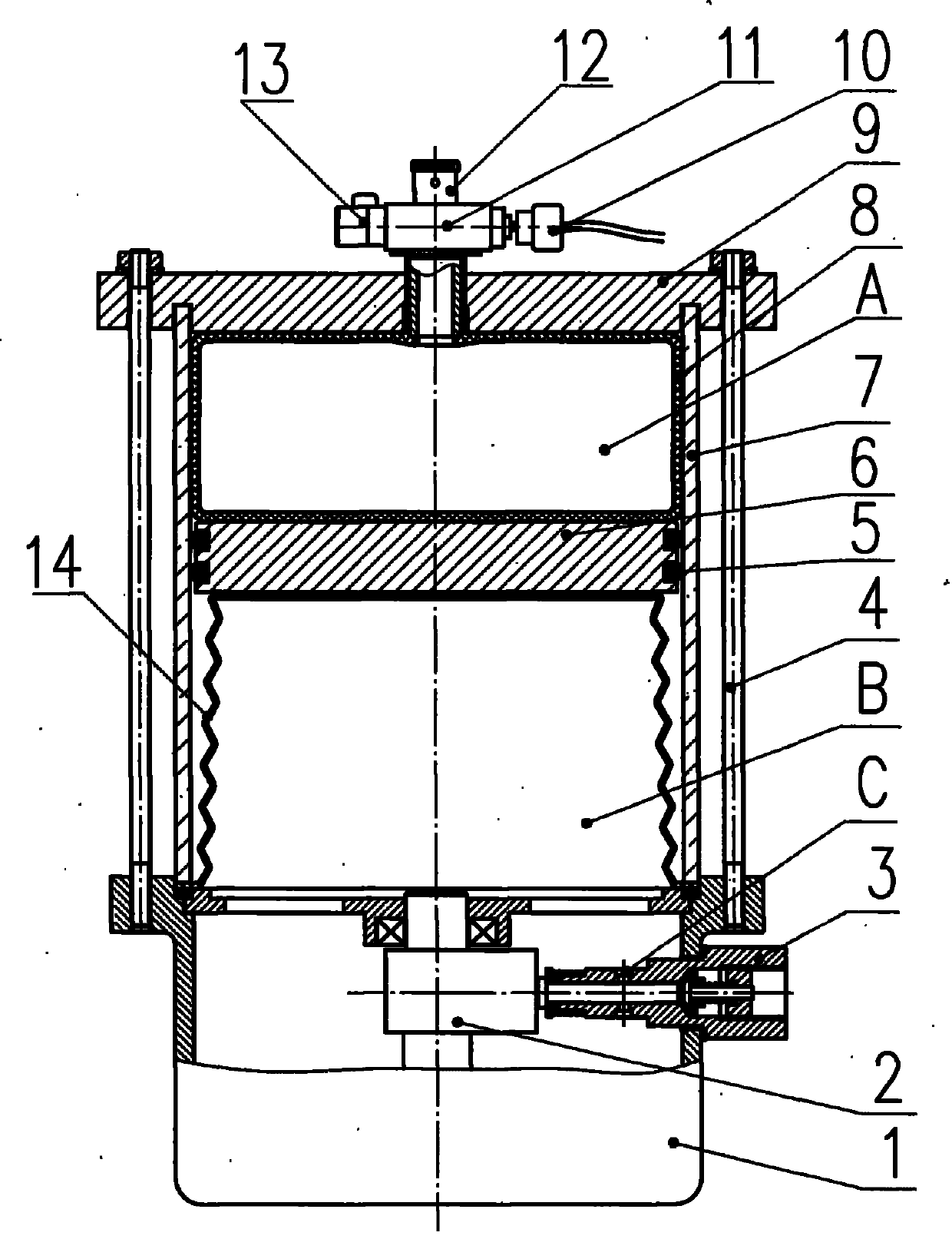

Lubricating device with pneumatic tire pressure oil tank

InactiveCN102168791AFully oiledHigh pumping capacity for greaseLubricating pumpsLubrication elementsOil and greaseFuel tank

The invention relates to a lubricating device with a pneumatic tire pressure oil tank, which comprises a lubricating pump shell, a power assembly, a lubricating pump, a cylindrical oil tank, a piston and a sealing ring, wherein the power assembly and the lubricating pump driven by the power assembly are arranged on the lubricating pump shell; the cylindrical oil tank is fixedly connected with the lubricating pump shell; the piston divides the cylindrical oil tank into an oil tank upper cavity A and an oil tank lower cavity B which are sealed mutually by the sealing ring; and an oil inlet C of the lubricating pump is communicated with the oil tank lower cavity B for storing oil. The lubricating device is characterized in that: a sealing pneumatic tire is arranged in the oil tank upper cavity A and is connected with an inflating valve extending out of the upper part of the oil tank upper cavity A. Due to the adoption of the structure, an oil inlet mode of oil suction from the oil inlet of the lubricating pump can be changed into an oil inlet mode of powerful oil press-in to ensure that the oil enters from the oil inlet of the lubricating pump fully, so the oil pumping capacity of the lubricating device is higher than that of the conventional product, high-viscosity oil still can be pumped at a certain low temperature and under low air pressure, and the application range is expanded simultaneously.

Owner:赵大平

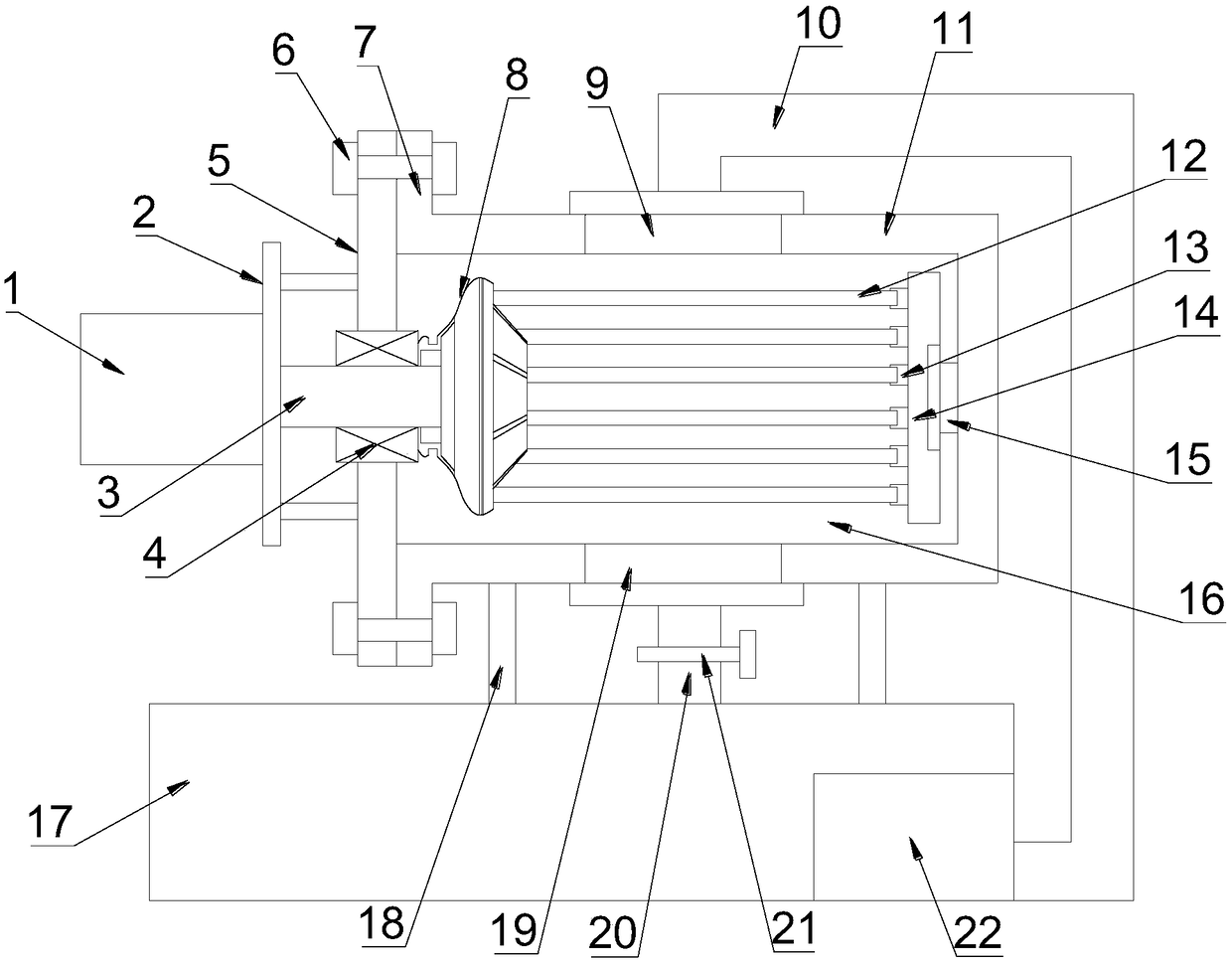

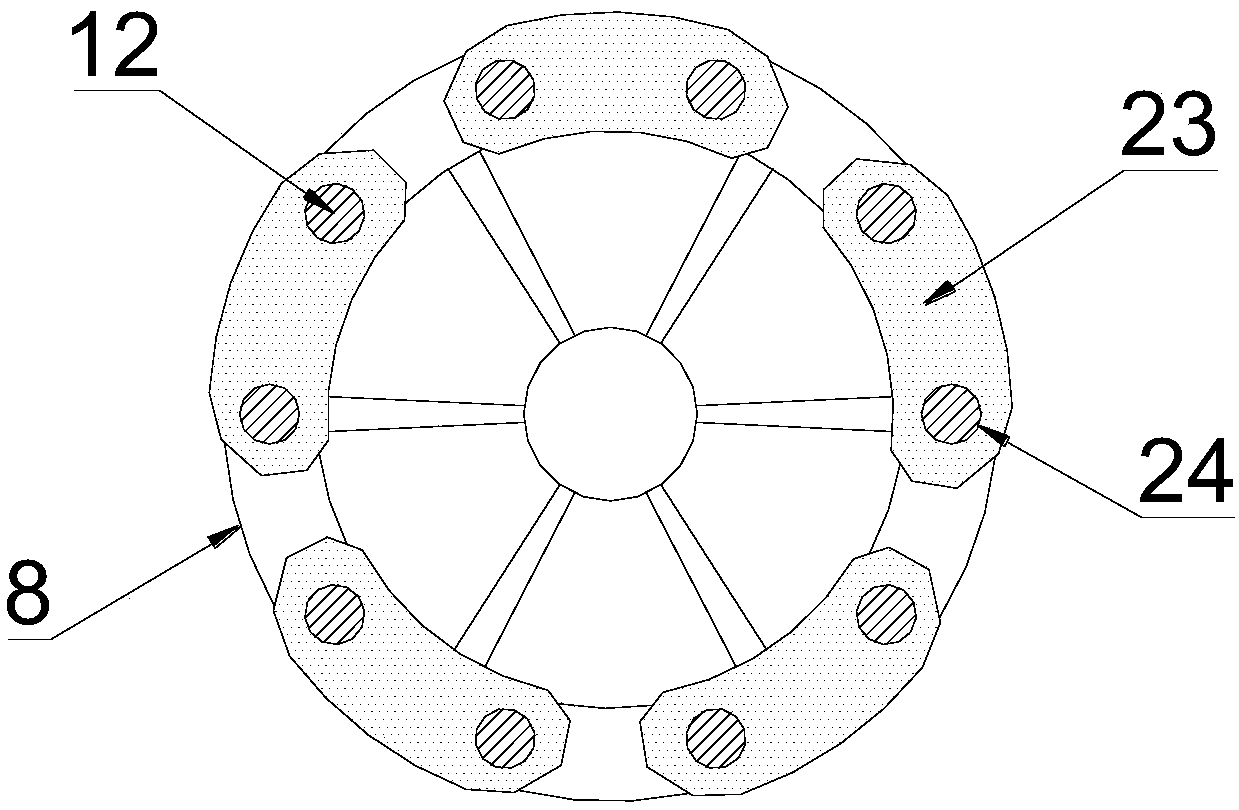

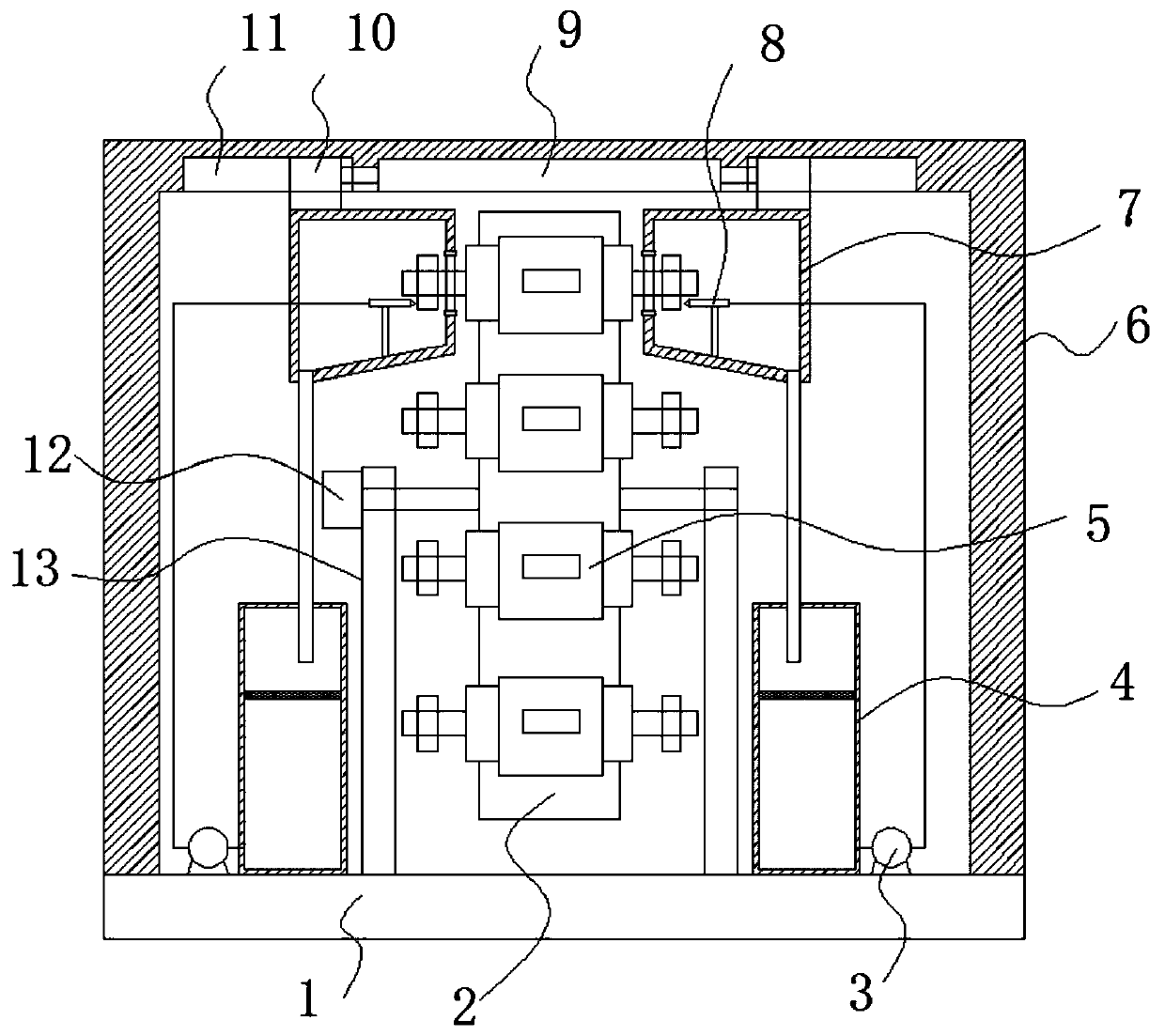

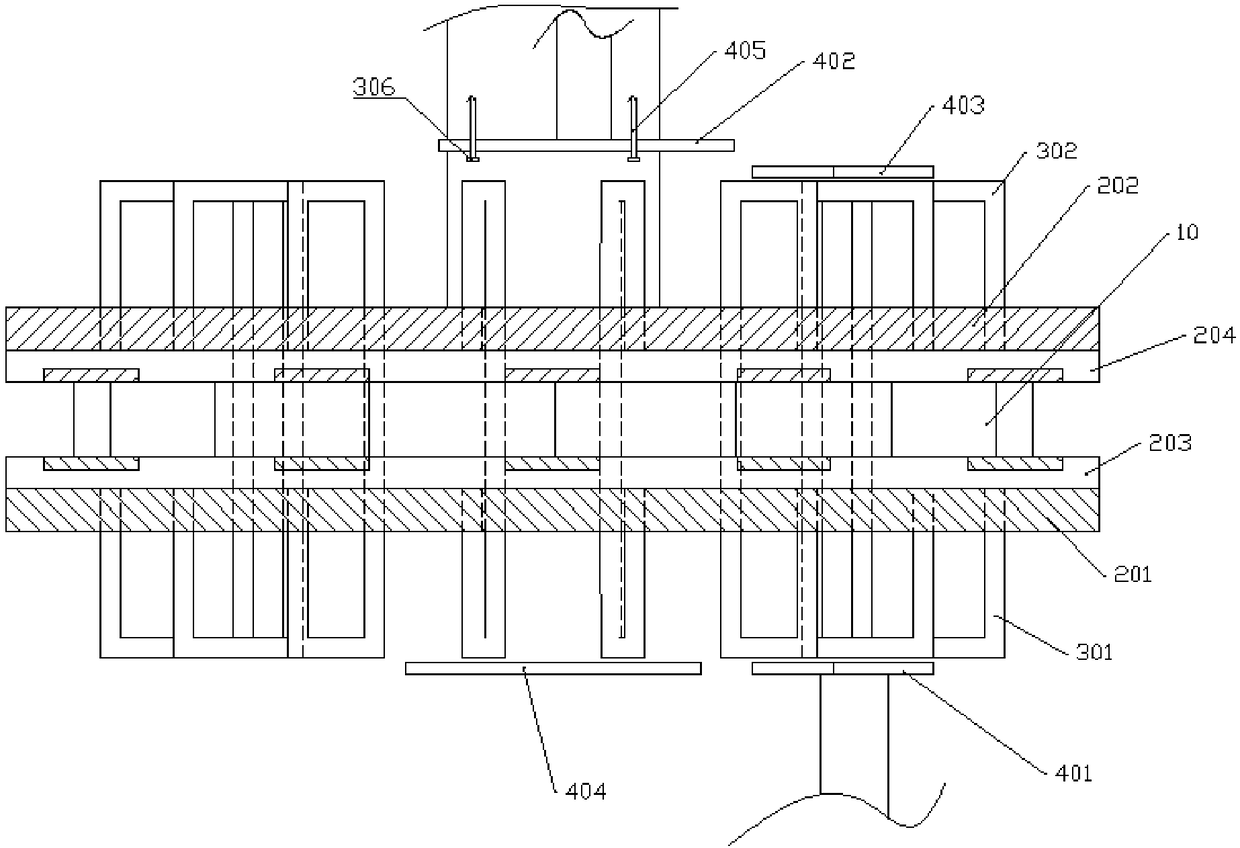

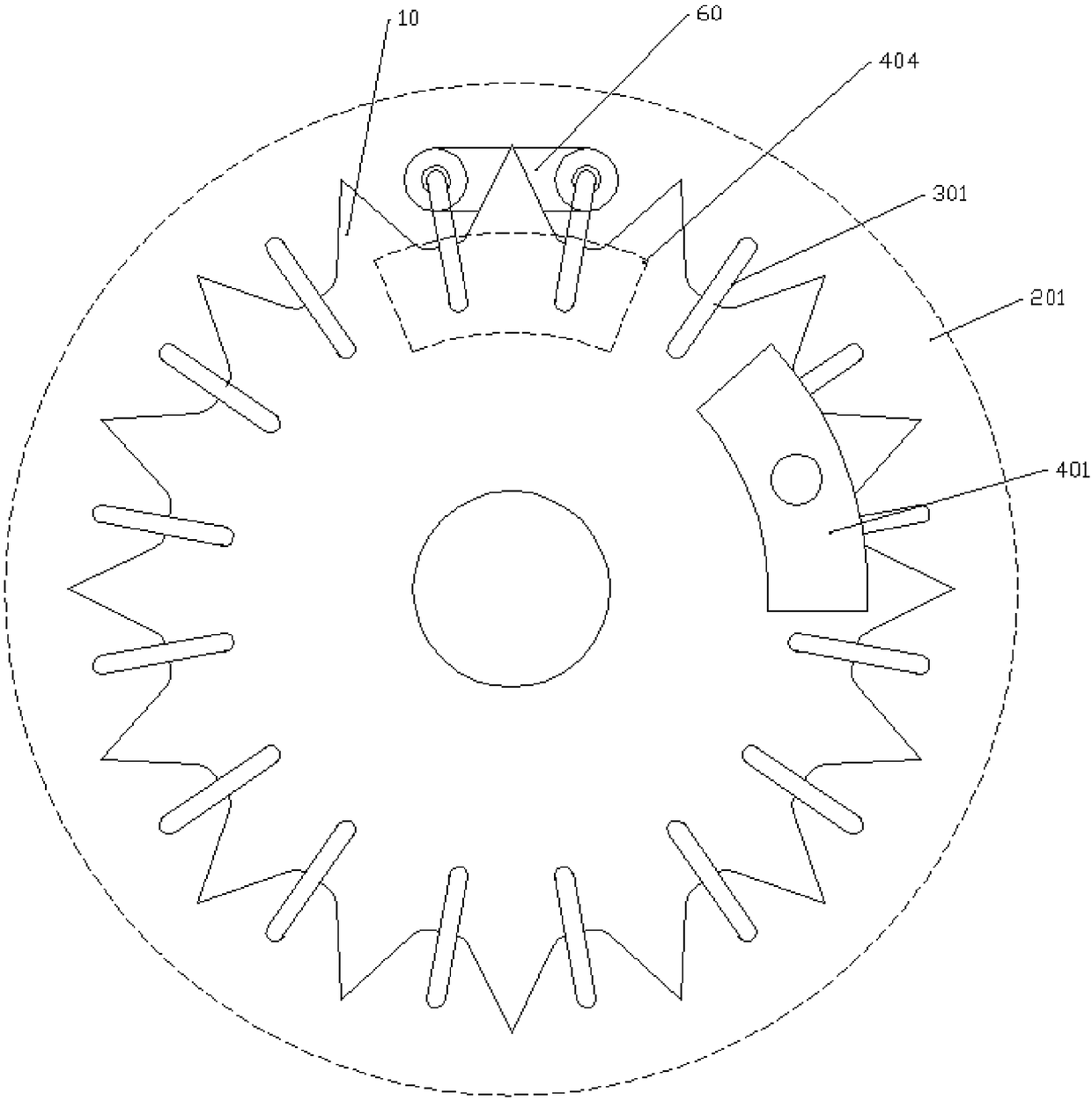

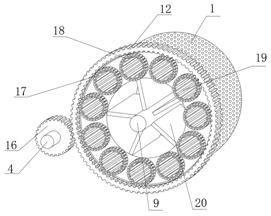

Full automatic oil injection equipment for motor

ActiveCN110535297ASolve the problem of low oil injection efficiencyUninterrupted oil injectionManufacturing dynamo-electric machinesLubrication elementsLocking mechanismInjection equipment

The invention belongs to the field of motor bearings, and especially provides full automatic oil injection equipment for a motor. The following scheme is put forward. The full automatic oil injectionequipment comprises a base. A support frame is arranged at the middle position of the top end of the base. A motor 2 is installed on the side wall of the support frame. The output shaft of the motor 2is connected with a rotating disc rotatably connected inside the support frame. A plurality of annular-array-arranged fixing grooves are arranged on the outer side wall of the rotating disc, and a locking mechanism is arranged on the fixing grooves. The top end of the base is provided with a fixing frame located outside the rotating disc. A horizontal double-head cylinder 1 is arranged on the topinner wall of the fixing frame. The two output shafts of the double-head cylinder 1 are connected with a slide block 1. Working boxes located on the two sides of the rotating disc are arranged on thebottom end of the slide block 1. A communication hole is arranged in the side wall of the working boxes close to the rotating disc. The device can quickly realize oil injection of the bearing of themotor rotor and has good oil injection effect and high working efficiency.

Owner:中擎电机有限公司

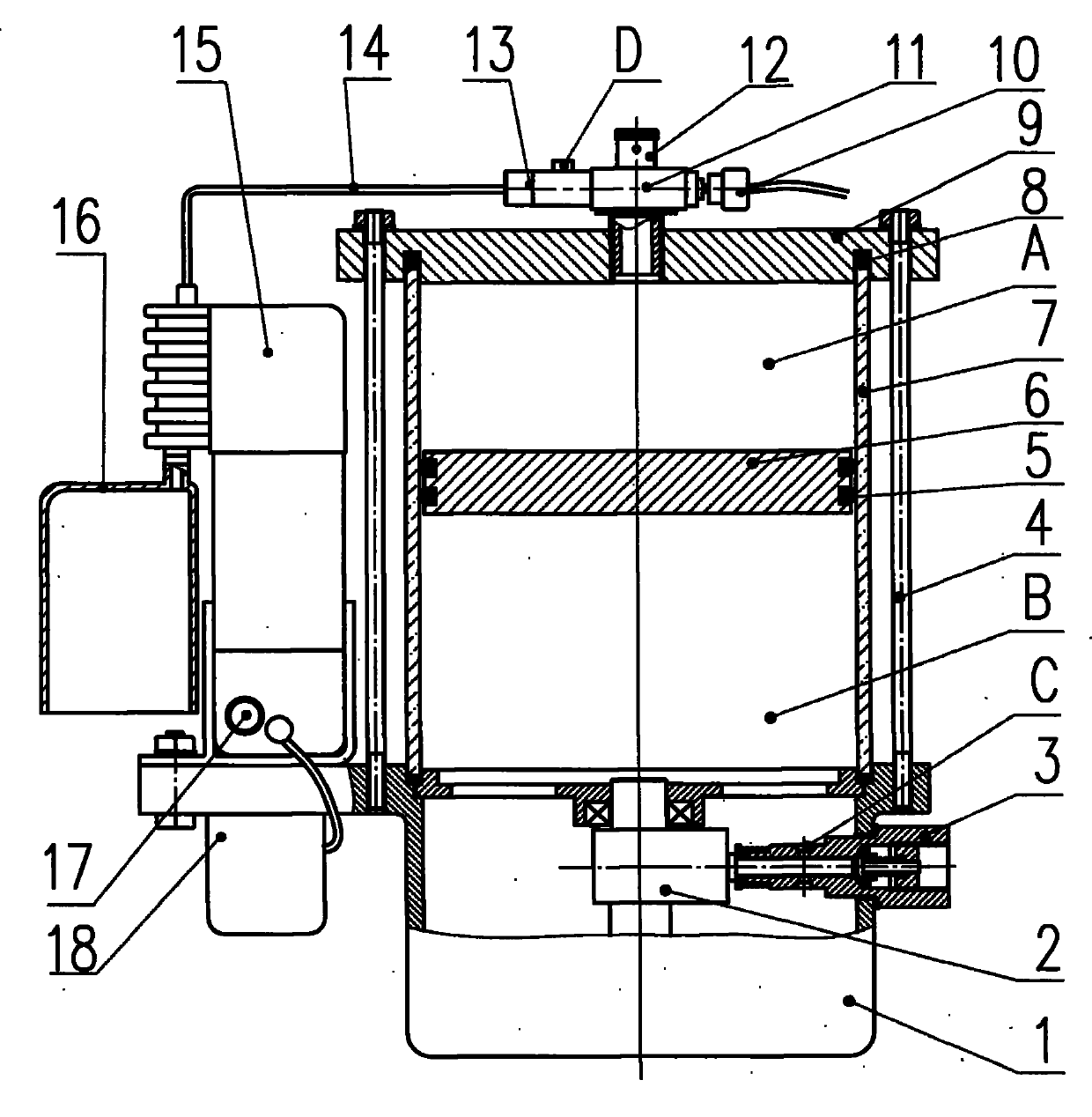

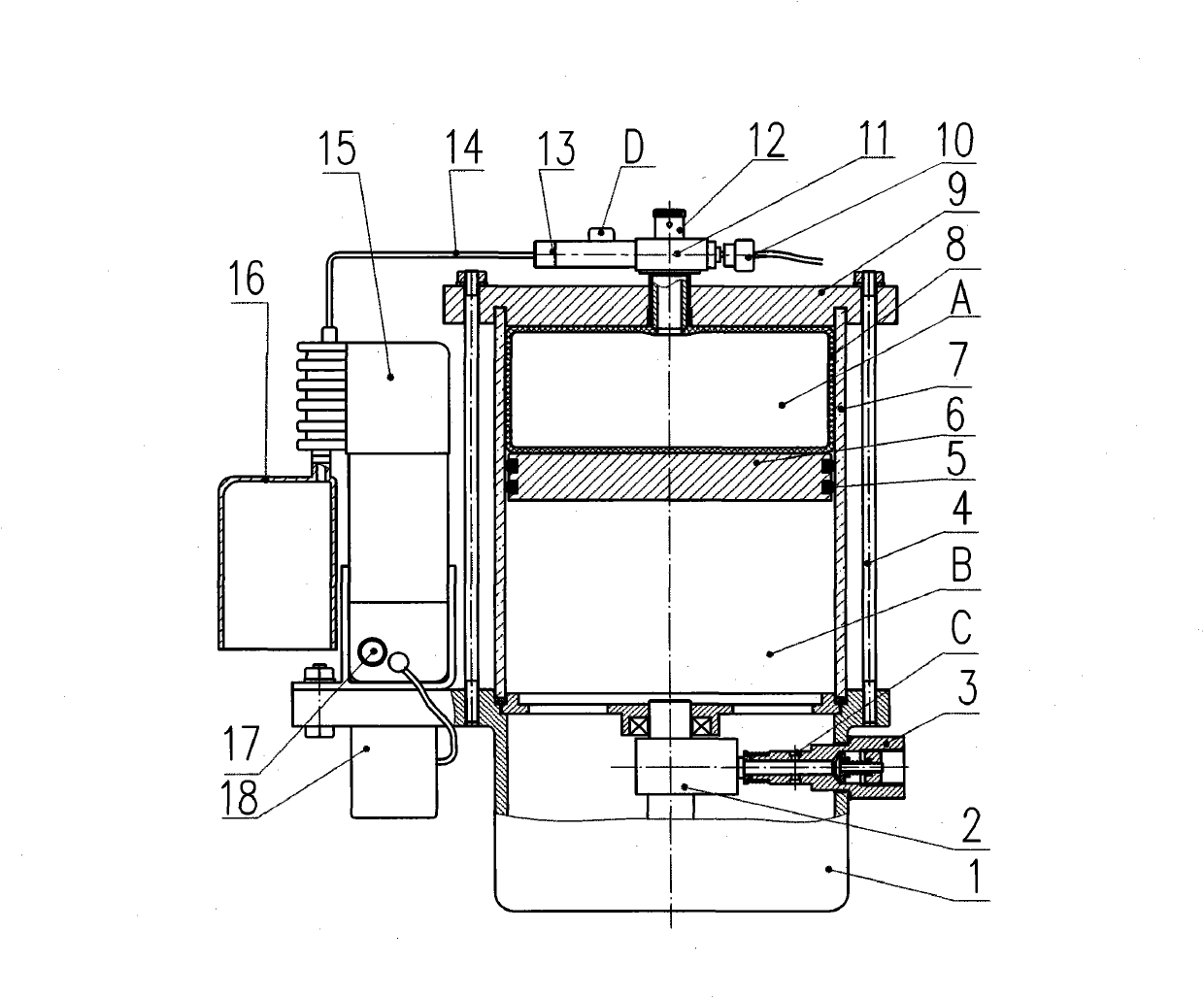

Lubricating device with pneumatic tire pressure oil tank and oil tank lining

InactiveCN102168790AFully oiledHigh pumping capacity for greaseLubrication check valvesOil and greaseViscosity

The invention relates to a lubricating device with a pneumatic tire pressure oil tank and an oil tank lining, which comprises a lubricating pump shell, a power assembly, a lubricating pump, a cylindrical oil tank, a piston and a seal ring, wherein the power assembly and the lubricating pump driven by the power assembly are arranged on the lubricating pump shell; the cylindrical oil tank is fixedly connected with the lubricating pump shell; the piston divides the cylindrical oil tank into an oil tank upper cavity A and an oil tank lower cavity B which are sealed mutually by the sealing ring; a retractable lining for storing oil is arranged in the oil tank lower cavity B; the periphery of an opening at the lower end of the lining is in fixed sealing connection with the periphery of an opening at the lower end of the oil tank lower cavity B, and the opening at the lower end of the lining is communicated with an oil inlet C of the lubricating pump; and a sealing pneumatic tire is arranged in the oil tank upper cavity A and is connected with an inflating valve extending out of the upper part of the oil tank upper cavity A. Due to the adoption of the structure, an oil inlet mode of the oil inlet of the lubricating pump can be changed to ensure that the oil enters from the oil inlet of the lubricating pump fully, so the oil pumping capacity of the lubricating device is improved, high-viscosity oil still can be pumped at a certain low temperature and under low air pressure, and the application range is expanded simultaneously.

Owner:赵大平

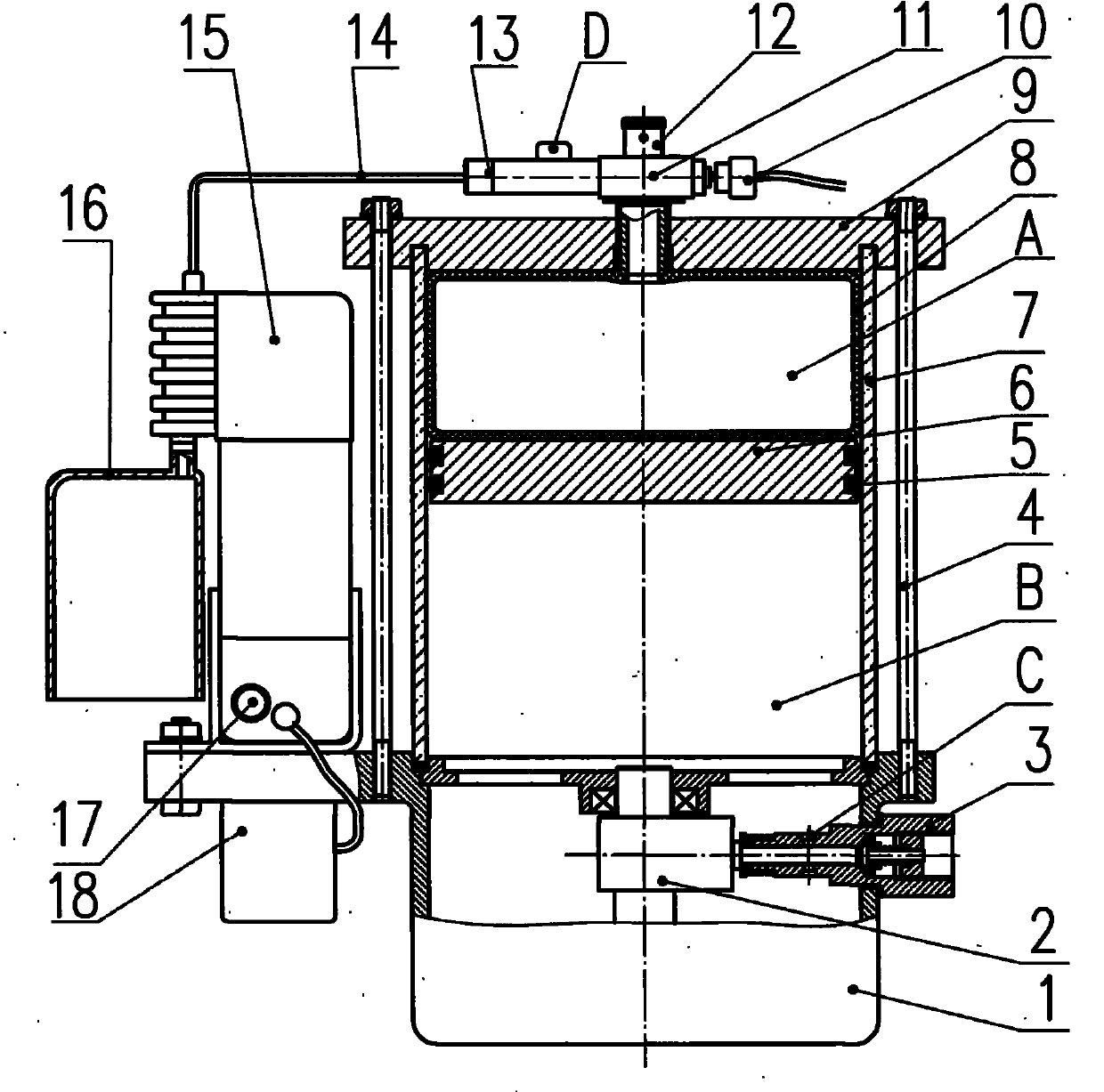

Lubricating device with automatic air inflation discharging structure and air tyre pressure oil tank

InactiveCN102168798AFully oiledHigh pumping capacity for greaseLubricating pumpsLubrication elementsOil and greaseAir pump

The invention relates to a lubricating device with an automatic air inflation discharging structure and an air tyre pressure oil tank. The lubricating device comprises a lubricating pump shell, a power assembly, a lubricating pump, a cylindrical oil tank, a piston, an automatic controller; the power assembly and the lubricating pump which is driven by the power assembly are installed on the lubricating pump shell; the cylindrical oil tank and the lubricating pump shell are fixedly connected; the cylindrical oil tank is divided into an oil tank upper cavity A and an oil tank lower cavity B which are mutually sealed through the seal ring by the piston; an oil inlet C of the lubricating pump is communicated with the oil tank lower cavity B which is used for storing grease; the automatic controller is connected with a motor-driven air pump and the power assembly through circuits; the outer part of the cylindrical oil tank is provided with the motor-driven air pump; the oil tank upper cavity A is internally provided with a seal air tyre which is connected with a two-position three-way valve extending out of the upper part of the oil tank upper cavity A; an air exhaust port of the motor-driven air pump is connected with the oil tank upper cavity A through an interface of the two-position three-way valve; and the two-position three-way valve is also provided with the interface which is communicated with atmosphere. By adopting the structure, the oil-intake mode of the oil inlet of the lubricating pump can be changed, and the pumping grease capability is improved.

Owner:赵大平

Compressed spring type oil immersion equipment for textile threads

ActiveCN110485087AFully contactedImprove permeabilityLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsWire rodHorizontal transmission

The invention belongs to the field of textiles, and particularly relates to compressed spring type oil immersion equipment for textile threads. The equipment comprises an oil immersion cylinder, the lower bottom face in the oil immersion cylinder is fixedly connected with a lower transmission box through a supporting column, and the upper end of the lower transmission box is fixedly connected withan upper transmission box through a connecting rod. The upper transmission box and the lower transmission box are horizontally arranged, a threading layer is formed between the upper transmission boxand the lower transmission box, horizontal transmission plates are arranged in the upper transmission box and the lower transmission box, and the two ends of the transmission plate at the upper end penetrate through the side wall of the upper transmission box and are in sliding connection with the side wall of the upper transmission box. Springs are arranged, and the springs gradually stretch andextrude flax threads in the process that two arc-shaped pressing plates press the flax threads downwards so that the flax threads deform and absorb more oil, and the oil immersion efficiency of the flax threads is greatly improved; when the arc-shaped pressing plates are retracted, the springs can also play a reset role, so that the two arc-shaped pressing plates move to the middle, and the two arc-shaped pressing plates can retract into transmission holes conveniently.

Owner:江苏思园织造印染有限公司

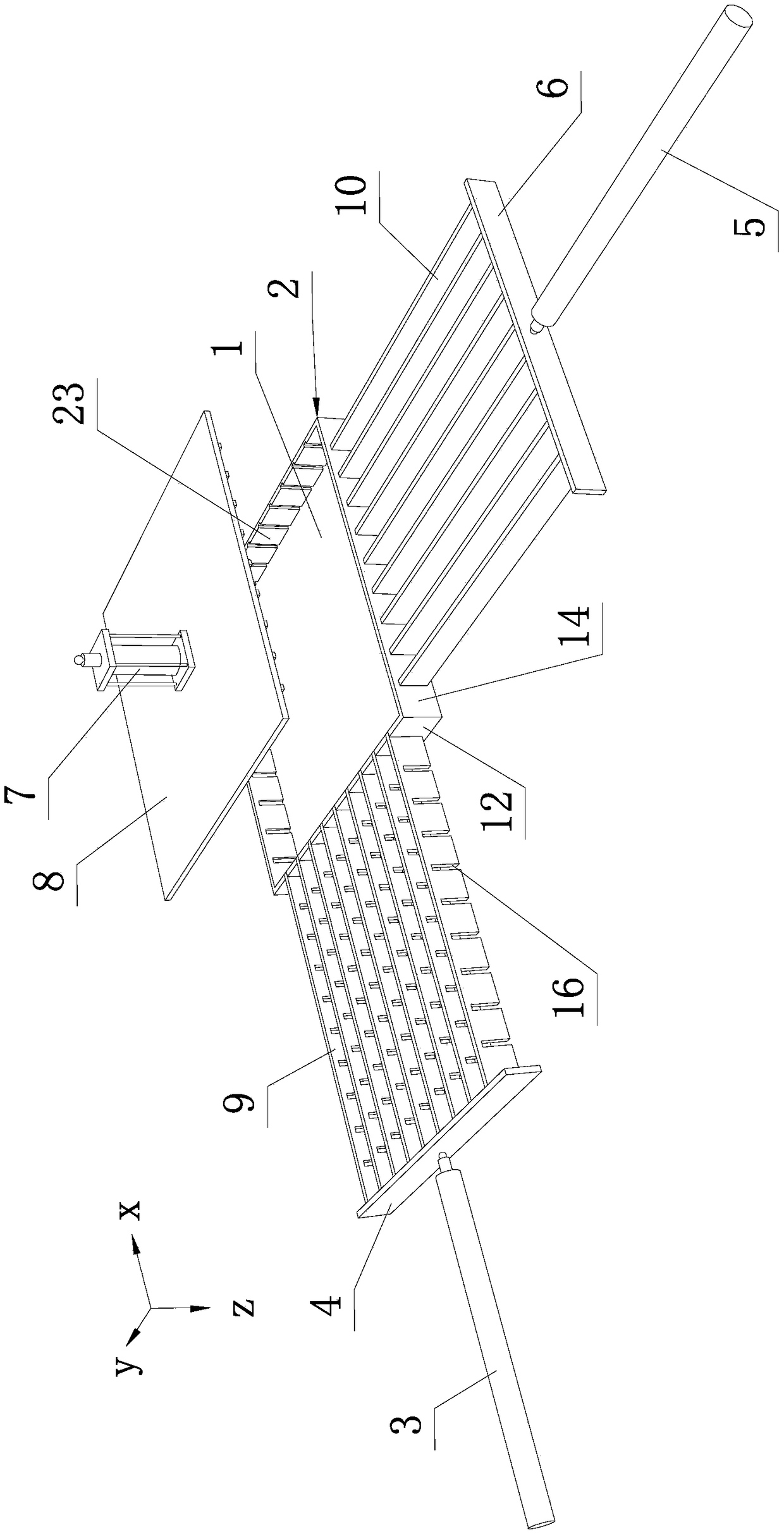

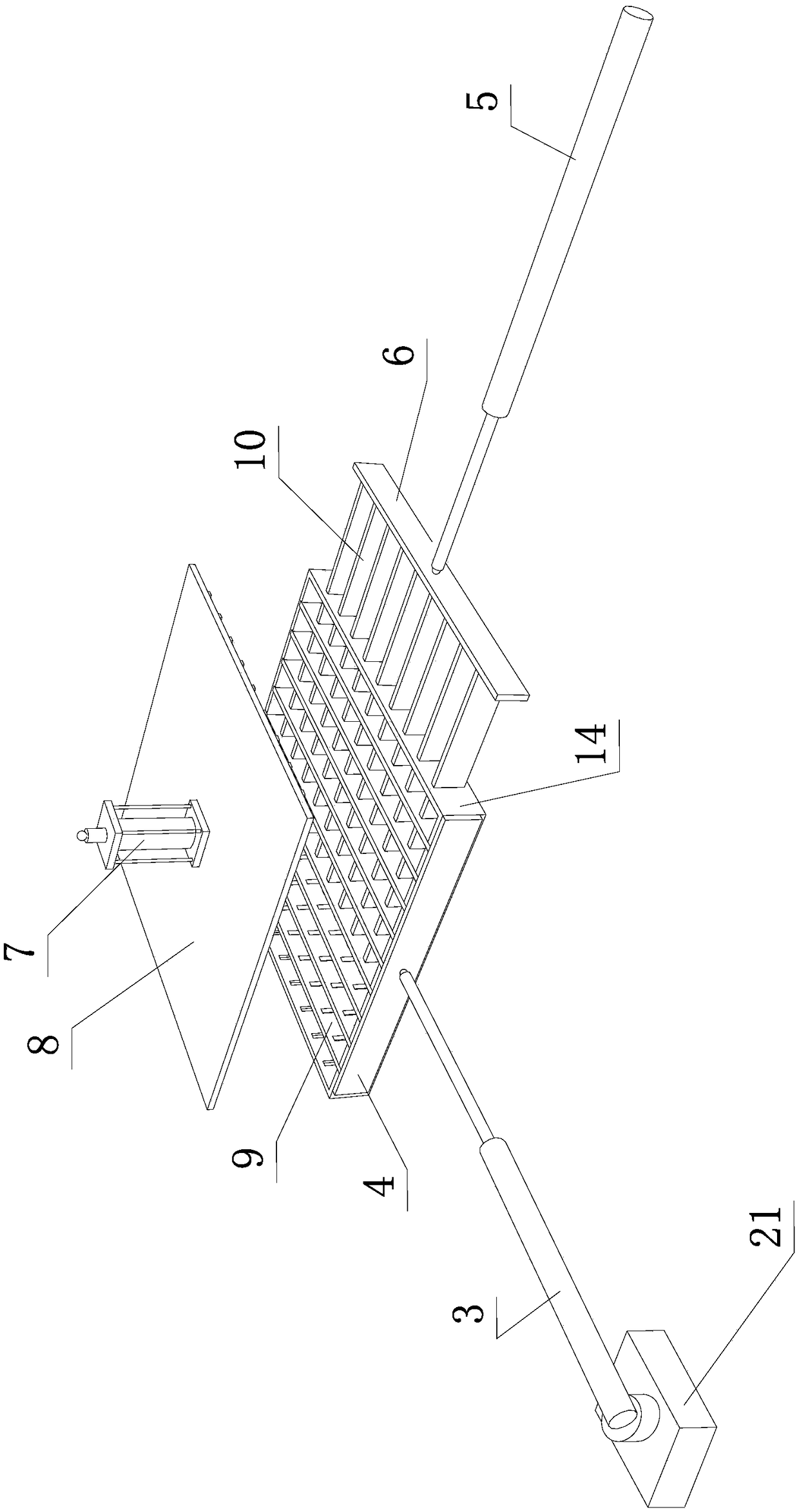

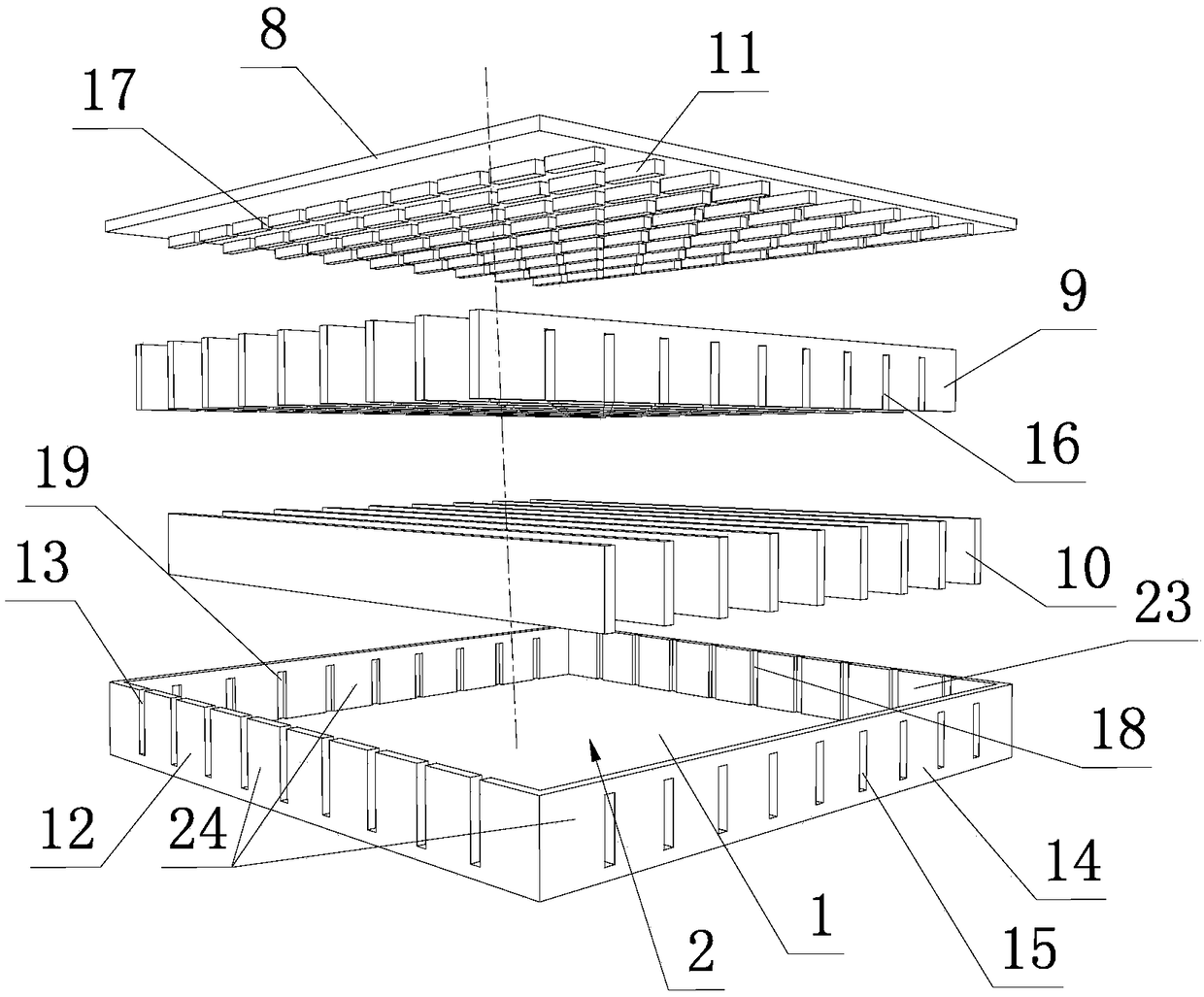

Device for recycling surplus materials of fine aggregate concrete and processing method thereof

PendingCN108818896AReduce labor intensityReduced bond resistanceMouldsStructural engineeringConstruction aggregate

The invention discloses a device for recycling surplus materials of fine aggregate concrete and a processing method. The device comprises a hopper, an x-direction driving cylinder, a y-direction driving cylinder, a z-direction driving cylinder and a pressing plate. A row of tooth-shaped inserting strips are fixed to the x-direction driving cylinder, a row of straight inserting strips are fixed tothe y-direction driving cylinder, and a row of pressing strips are fixed to the z-direction driving cylinder. A row of upper inserting grooves are formed in a first mounting side wall of the hopper ina penetrating mode. A row of strip-shaped inserting holes are formed in a second mounting side wall of the hopper in a penetrating mode. A row of lower inserting grooves are formed in the tooth-shaped inserting strips. When all the tooth-shaped inserting strips, the straight inserting strips and the pressing strips are fully extended into a cavity, the straight inserting strips are inserted intothe corresponding lower inserting grooves, the tooth-shaped inserting strips are clamped into the corresponding lower inserting grooves, and the pressing strips are placed on the corresponding straight inserting strips. The key of the method is that the concrete in the cavity is integrally poured, and the concrete is separated by the straight inserting strips, the tooth-shaped inserting strips andthe pressing strips. According to the device for recycling the surplus materials of fine aggregate concrete and the processing method, a grouting pipe nozzle is not required to be moved in the pouring process, and the separation of grids and concrete cushion blocks after pouring can be automatically realized.

Owner:浙江省二建建设集团有限公司

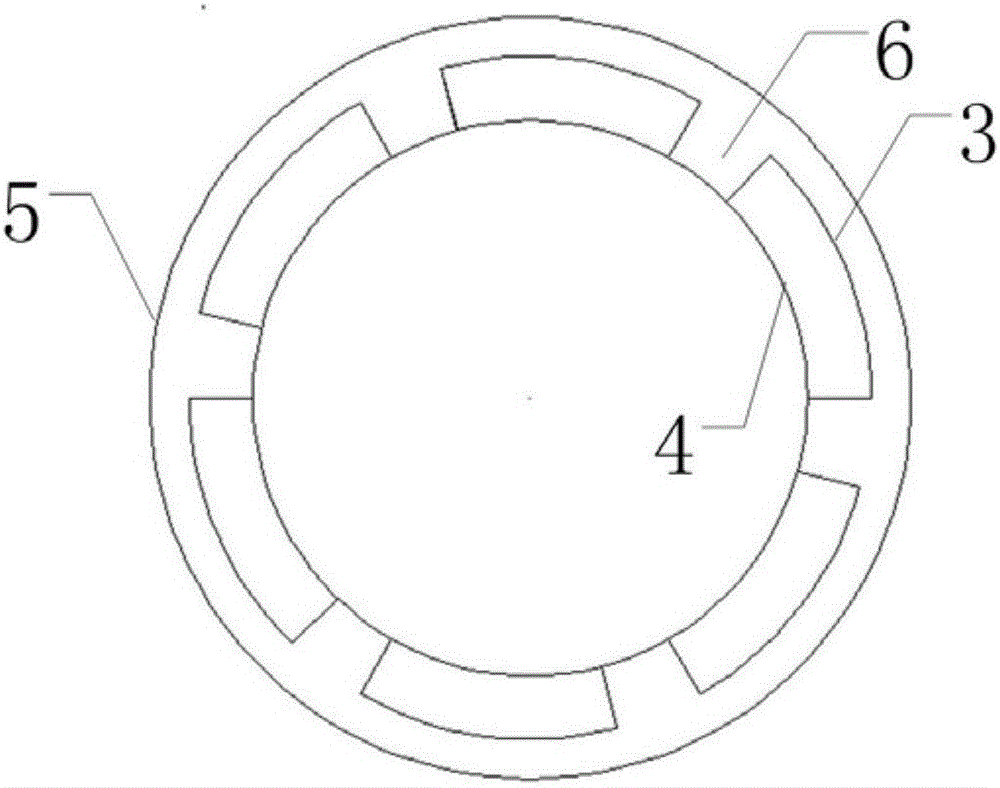

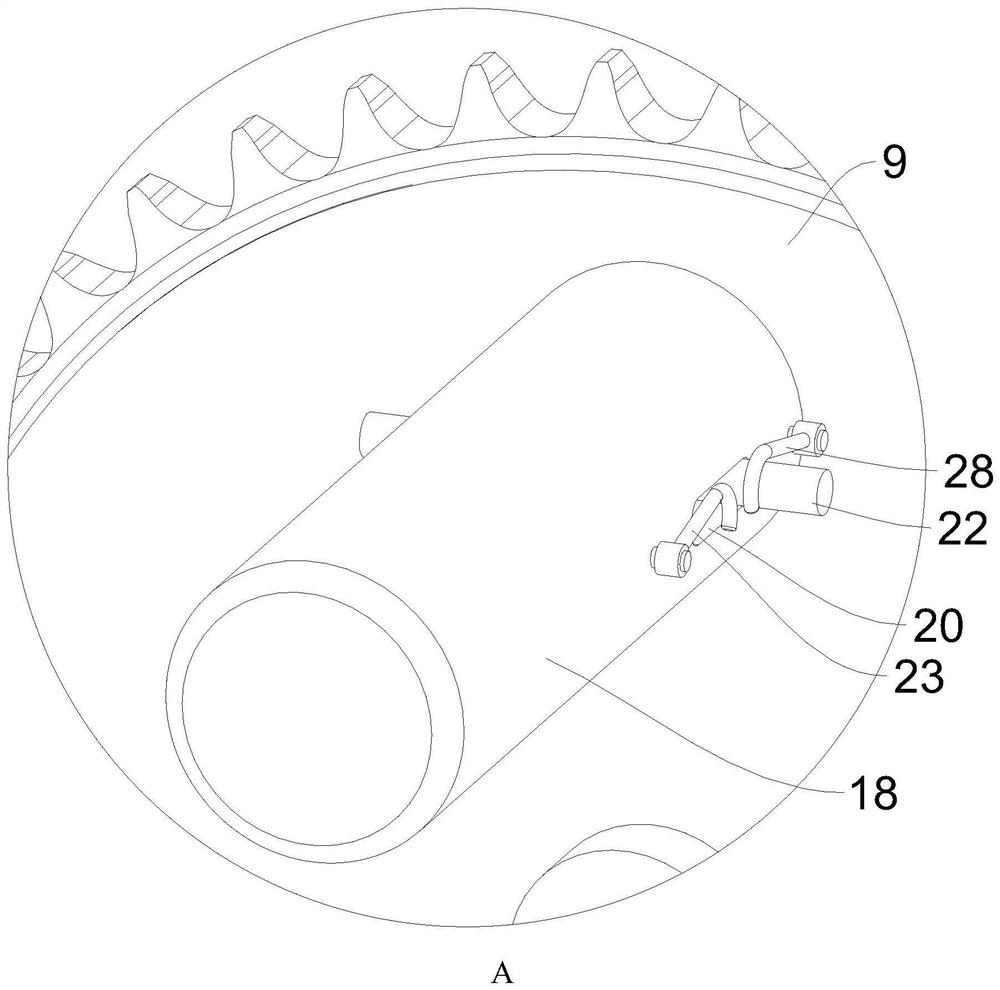

Oil collecting recycling system

The invention relates to the field of lubricating, and particularly discloses an oil collecting recycling system. The oil collecting recycling system comprises a mounting mechanism and an oil applyingmechanism; the mounting mechanism comprises an elastic first mounting block and an elastic second mounting block; both the first mounting block and the second mounting block are annular; the first mounting block is coaxially welded at one end of a chain wheel; the second mounting block is coaxially welded at the other end of the chain wheel; a first limiting groove is formed in the first mountingblock; a second limiting groove is formed in the second mounting block; the first limiting groove and the second limiting groove are opposite to the chain teeth of the chain wheel; the oil applying mechanism comprises pushing rods and oil applying rods; first through holes for the pushing rods to slide are formed in the first mounting block; second through holes for the oil applying rods to slideare formed in the second mounting block; an accommodating cavity is formed in one end of the oil applying rod; a pushing block and oil absorbing sponge are mounted in the accommodating cavity. According to the scheme, connecting parts between a chain pin and an inner chain plate as well as an outer chain plate can be coated with lubricating oil.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Lubricating device with automatic inflating and deflating pressure oil tank and oil tank inner lining

InactiveCN102168797AFully oiledHigh pumping capacity for greaseLubricating pumpsLubrication elementsOil and greaseMotor drive

The invention relates to a lubricating device with an automatic inflating and deflating pressure oil tank and an oil tank inner lining. The device comprises a lubricating pump shell, a power assembly, a lubricating pump, a cylindrical oil tank, a piston, an automatic controller and the like; the power assembly and the lubricating pump are installed on the lubricating pump shell; the cylindrical oil tank and the lubricating pump shell are connected; the cylindrical oil tank is divided into an oil tank upper cavity A and an oil tank lower cavity B which are mutually sealed through the seal ring by the piston; the oil tank lower cavity B is internally provided with an elastic inner lining; the lower end of the inner lining is fixedly connected with the lower end of the oil tank lower cavity B in a seal mode; an opening at the lower end of the inner lining is communicated with an oil inlet C of the lubricating pump; the automatic controller is connected with a motor-driven air pump and the power assembly; the outer part of the cylindrical oil tank is provided with a motor-driven air pump; the oil tank upper cavity A is internally provided with a seal air tyre which is connected with a two-position three-way valve extending out of the upper part of the oil tank upper cavity A; an air exhaust port of the motor-driven air pump is connected with the oil tank upper cavity A through an interface of the two-position three-way valve; and the two-position three-way valve is also provided with the interface which is communicated with atmosphere. By adopting the structure, the oil-intake mode of the oil inlet of the lubricating pump can be changed, and the pumping grease capability is improved.

Owner:赵大平

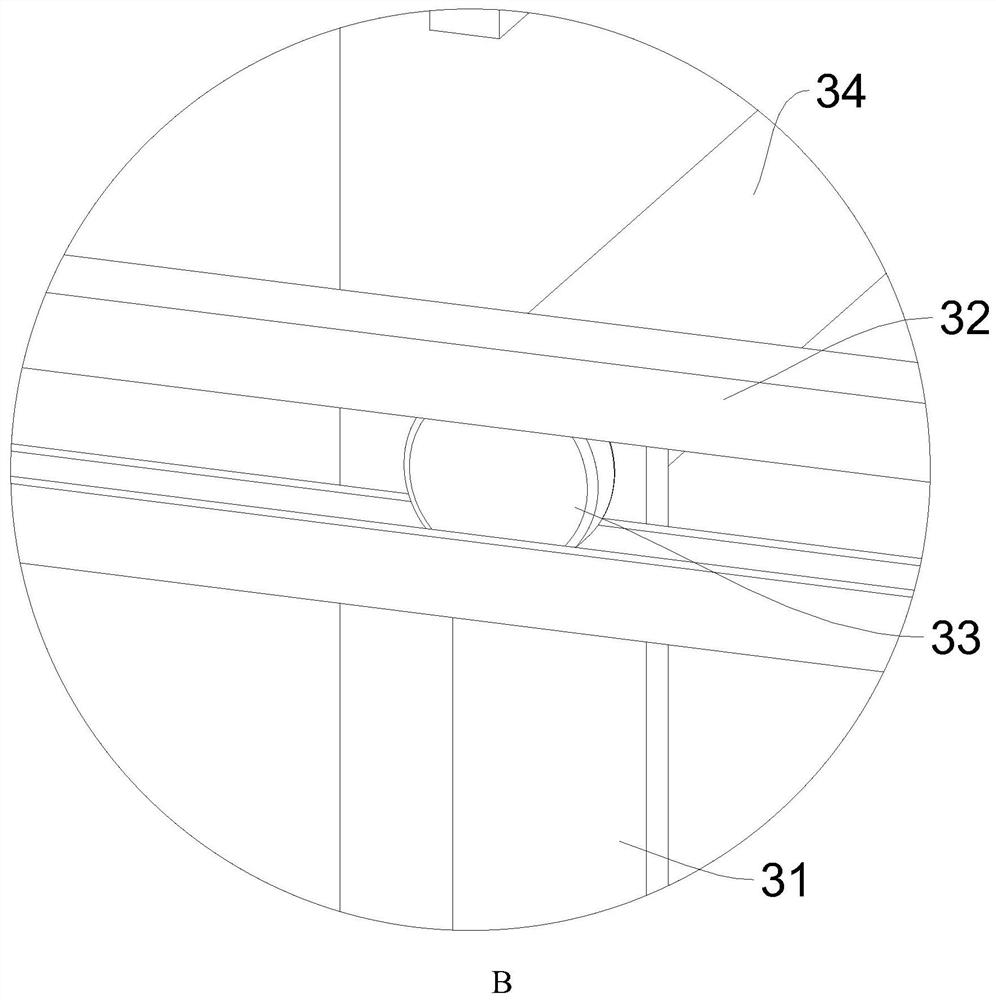

Preimpregnation equipment on production line of self-adhesive waterproof coiled materials with base fabrics

ActiveCN112917743AGuaranteed production efficiencyFully oiledCoatingsManufacturing engineeringBevel gear

The invention relates to the field of waterproof coiled material production, and discloses preimpregnation equipment on a production line of self-adhesive waterproof coiled materials with base fabrics. The preimpregnation equipment comprises an oil immersion pool, a support frame arranged on the oil immersion pool and a reciprocating screw rod rotationally arranged on the support frame, and matched connecting pieces are symmetrically arranged at the two sides of the reciprocating screw rod; the top ends of the connecting pieces are movably connected with the support frame, oil immersion rollers are rotationally arranged at the bottom ends of the connecting pieces, a first bevel gear is arranged in the middle of the reciprocating lead screw, a driving rod is rotationally arranged on the support frame in the direction perpendicular to the central axis of the oil immersion pool, and a second bevel gear meshed with the first bevel gear is arranged at the end, close to the reciprocating lead screw, of the driving rod; and a first driving gear is arranged at the end, away from the reciprocating lead screw, of the driving rod. According to the preimpregnation equipment, by adjusting the distance between the two oil immersion rollers, the purpose of adjusting the dipping time of the base fabrics is achieved, and the waterproof coiled materials with different thickness requirements can be fully immersed in oil in the oil immersion pool.

Owner:湖北卓宝科技有限公司

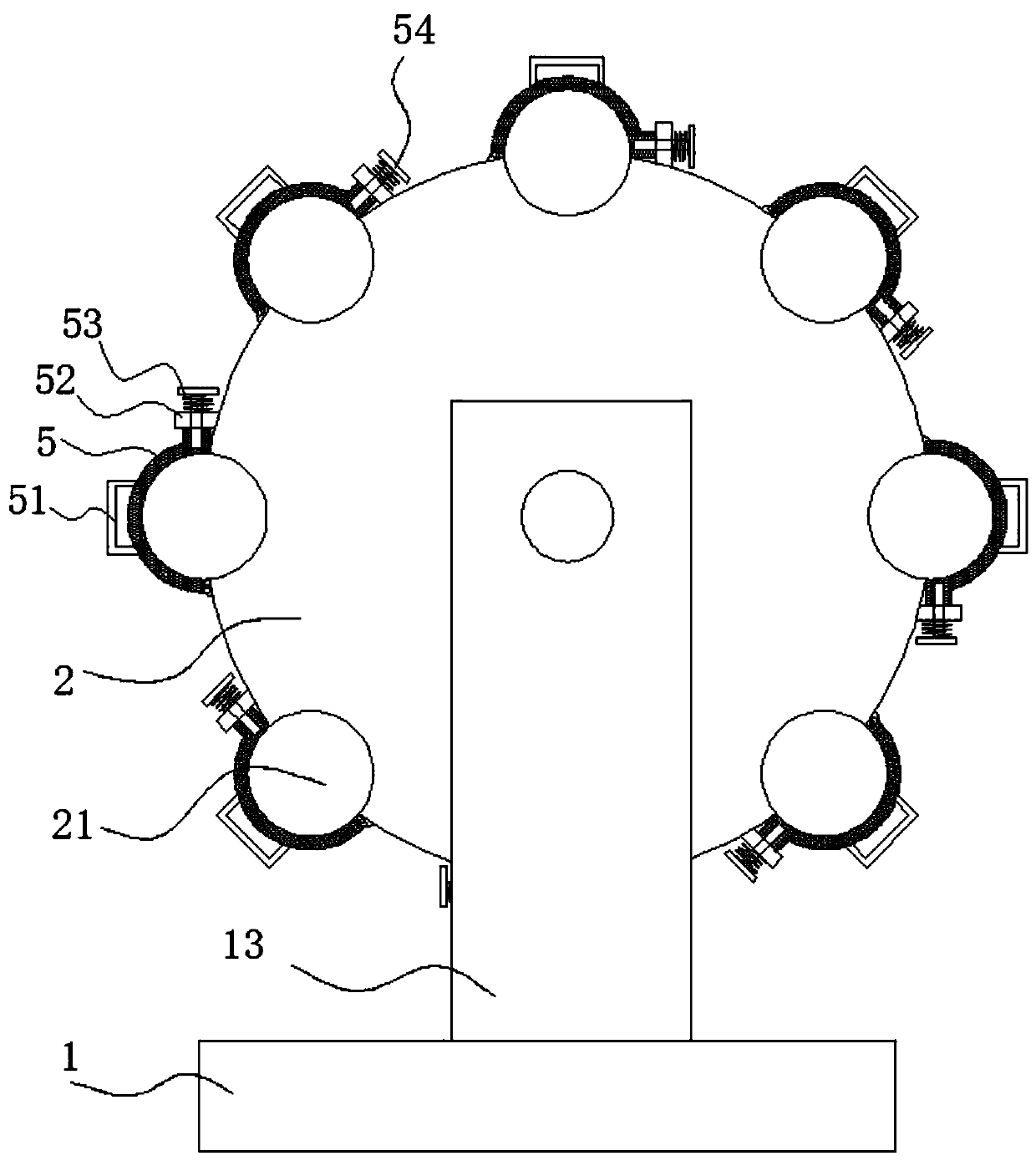

Rotary shaft rapid oil immersion device for machining

ActiveCN111842007AAvoid damageAvoid bouncingLiquid surface applicatorsCoatingsRotational axisMechanics

The invention discloses a rotary shaft rapid oil immersion device for machining. The rotary shaft rapid oil immersion device for machining comprises an oil immersion shell and four supporting legs, the inner walls of the two ends of the oil immersion shell are rotationally connected with the same rotating shaft, fixing plates distributed at equal intervals are installed on the circumferential outer wall of the rotating shaft, the outer walls of the ends, away from the rotating shaft, of the fixing plates are provided with the same mesh ring, circular grooves distributed at equal intervals areformed in the outer wall of one end of the mesh ring, circular pipes are rotationally connected to the inner walls of the circular grooves, and triangular sharp blocks distributed at equal intervals are installed on the circumferential inner walls of the circular pipes. According to the rotary shaft rapid oil immersion device for machining, through the arrangement of a fixing block, an extrusion spring and a rubber protection block, a pushed-in rotary shaft can be buffered and blocked, so that the situation that the rotary shaft impacts the device to cause damage is avoided, through the arrangement of an extrusion rod and a buffer spring on a first guide shell, the rotary shaft rebounded by the extrusion spring can be blocked, the rotary shaft is prevented from rebounding into the first guide shell, and the rotary shaft can flow into the circular pipes to be subjected to subsequent oil immersion treatment.

Owner:卓能电气(天津)有限公司

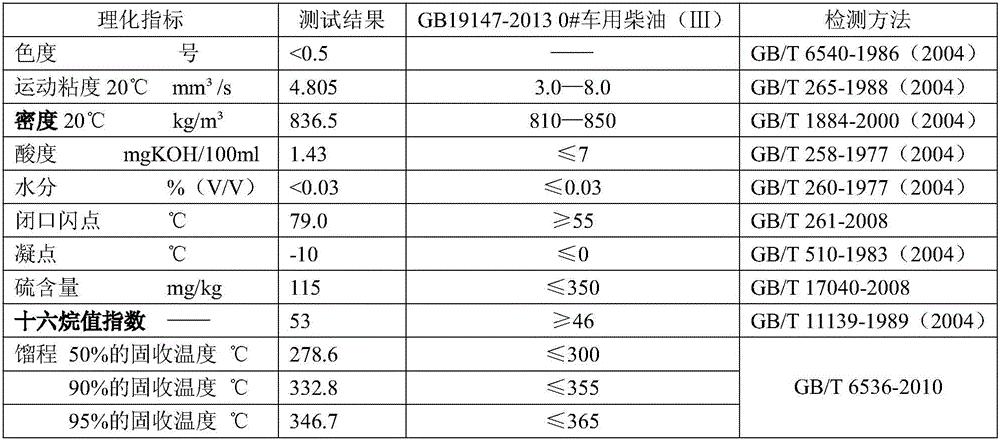

Method for preparing recycle oil and pickling neutralizer thereof in preparation process

ActiveCN106085488ALower requirementWide applicabilityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentAcetic acidAlcohol

The invention discloses a method for preparing recycle oil. The method comprises the following steps: adding illegal cooking oil, used oil and plastics of any component into a distillation tank, wherein the components can be totally illegal cooking oil or totally used oil or totally plastics, and also can be any combination of the three; sequentially heating, condensing, pickling, performing primary filtering, performing alkaline wash, performing secondary filtering, and blending oil to obtain refined oil product reaching the ordinary level. The invention also discloses a formula for preparing a pickling neutralizer in the pickling process by utilizing glacial acetic acid, phosphoric acid, oxalic acid, absolute ethyl alcohol and concentrated sulfuric acid. The invention aims to provide a method for preparing recycle oil and a pickling neutralizer thereof in the preparation process, the illegal cooking oil, used oil and plastics of different components can be effectively mixed to obtain the recycle oil, the applicability is wide, and requirements on raw materials are low. Moreover, oil is scrubbed in the production process, and the finished oil meets the oil grade requirement and can be used for requirements of normal vehicle and industrial oil.

Owner:侯平福

Oil feeding device for mechanical automation

PendingCN108397670ASimple structureReduce manufacturing costConduits/junctionsFuel tankPetroleum engineering

The invention discloses an oil feeding device for mechanical automation. The oil feeding device comprises a bottom plate, an oil feeding machine and a transferring block, wherein a temporary storage box is arranged on the upper surface of the bottom plate, and box doors are arranged on the temporary storage box; a first supporting rod is arranged on the right side of the temporary storage box, theright end of a first telescopic rod is provided with a first lower oil pipe, and a connecting plate is arranged above a second lower oil pipe; a second supporting rod is arranged on the right side ofan oil tank, a top plate is arranged at the top end of the second supporting rod, and the oil feeding machine is located on the inner side of the second supporting rod; a second telescopic rod is arranged in a fixing ring, a second connecting rod is arranged at the right end of the fixing ring, and the transferring block is located below the oil tank. The oil feeding device for mechanical automation has the advantages of being simple in structure, low in manufacture cost, and easy to produce; and through rotation of the oil feeding machine and rotation of a machine, so that the machine can becomprehensively oiled, and the machine can also be subjected to dust removal in the oil feeding process.

Owner:盐城士联凯精密机电制造有限公司

Clutch Oil Filling Control Method for Dual Clutch Automatic Transmission

ActiveCN103438124BPlay a preventive effectImprove timelinessFluid actuated clutchesAutomatic transmissionOil temperature

The invention provides a method for controlling oil filling of clutches of an automatic double-clutch gearbox. The method comprises the step of filling oil in advance, wherein the clutches are filled with the oil in advance after pre-shifting of a target gear is finished, and the preset time is maintained; the step of filling the oil for the second time, wherein the clutches of the target gear are filled with the oil for the second time until linkage point pressure is reached; the step of maintaining the linkage point pressure, wherein the linkage point pressure of the clutches of the target gear is maintained until torque is alternated. In the step of filling the oil in advance, the current oil temperature of the gearbox is measured, and filling the oil in advance is carried out according to the current oil temperature of the gearbox. The temperature change of the oil in the gearbox is utilized for controlling the clutch oil filling process, and therefore timeliness and smoothness of clutch motions in the shifting process can be improved, and the fault rate of the automatic wet type double-clutch gearbox can be lowered.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Transmission with electromechanical unit and oil circuit

InactiveCN102537296BAvoid no loadCompensation for oil leakage lossGear lubrication/coolingGearing controlClutchEngineering

The invention relates to a transmission (1), especially an automatic shift transmission for automobiles, comprising: a transmission unit (2); a clutch unit (4); an electromechanical unit (6); The circuit comprises an oil pump (8) which draws oil (9) from a first reservoir (11) and from which oil (9) can be supplied to the various units, the electromechanical unit (6) comprising at least one clutch valve (10 ), the clutch valve is set to control the clutch unit (4), at least one clutch valve (10) includes a pressure port (13) for at least indirectly connecting the clutch valve (10) to the oil pump (8) and for at least indirectly The clutch valve is connected to the drain connection of the second oil reservoir, which is formed separately from the first oil reservoir, and the second oil reservoir has an overflow port, which is arranged on the electromechanical unit above all clutch valves.

Owner:GETRAG FORD TRANSMISSIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com