Patents

Literature

63results about How to "Fully evenly distributed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fe/pressed active carbon catalyst and preparation method thereof

InactiveCN101480614ASolve the catalytic activityAddressing Catalytic SelectivityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsActivated carbonMinor metals

The invention discloses a catalytic conversion agent of tar in gas for a biomass boiler, which consists of the following ingredients by weight percent: 0.1% to 0.3% of Na2CO3, 0.1% to 0.3% of K2CO3, 0.1% to 1% of Fe3O4, 0.5% to 0.8% of NaCl, 0.5% to 0.8% of KCl, 0.3% to 0.5% of KOH, 0.3% to 0.5% of NaOH, 0.1 to 1% of Ni(NO3)2 6H2O, 0.1 to 1% of KNO3, 0.1 to 0.5% of Ce(NO3)3 6H2O, 20% to 46% of dry attapulgite powder and 46% to 75% of dry dolomite powder, wherein the dry dolomite powder is the dry powder with the grain size not less than 325 meshes, the water content less than 1% and the CaCO3 / MgCO3 ratio ranging from 1 to 1.5, and the dry attapulgite powder has the grain size not less than 325 meshes, the water content is less than 1%, the content of MgO is not less than 23% and the content of SiO2 is not more than 56%. By using the catalyst, tar in biomass gasified gas can be converted into combustible small molecules, so as to reduce the hazard caused by tar remarkably.

Owner:BEIJING UNIV OF CHEM TECH

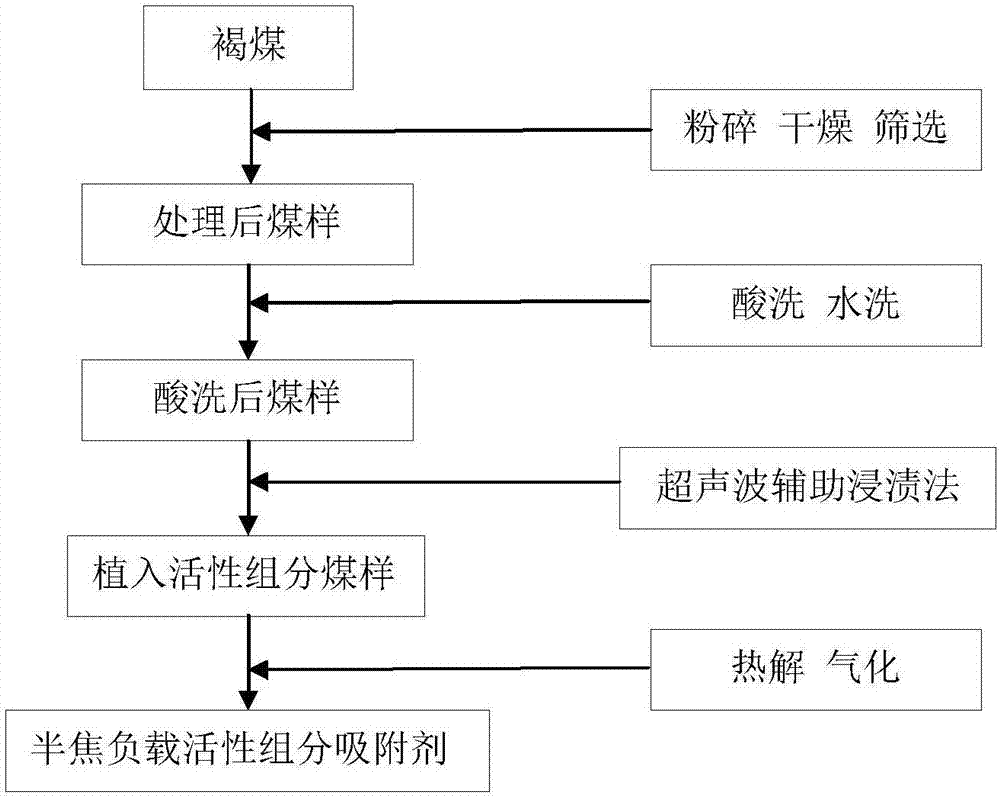

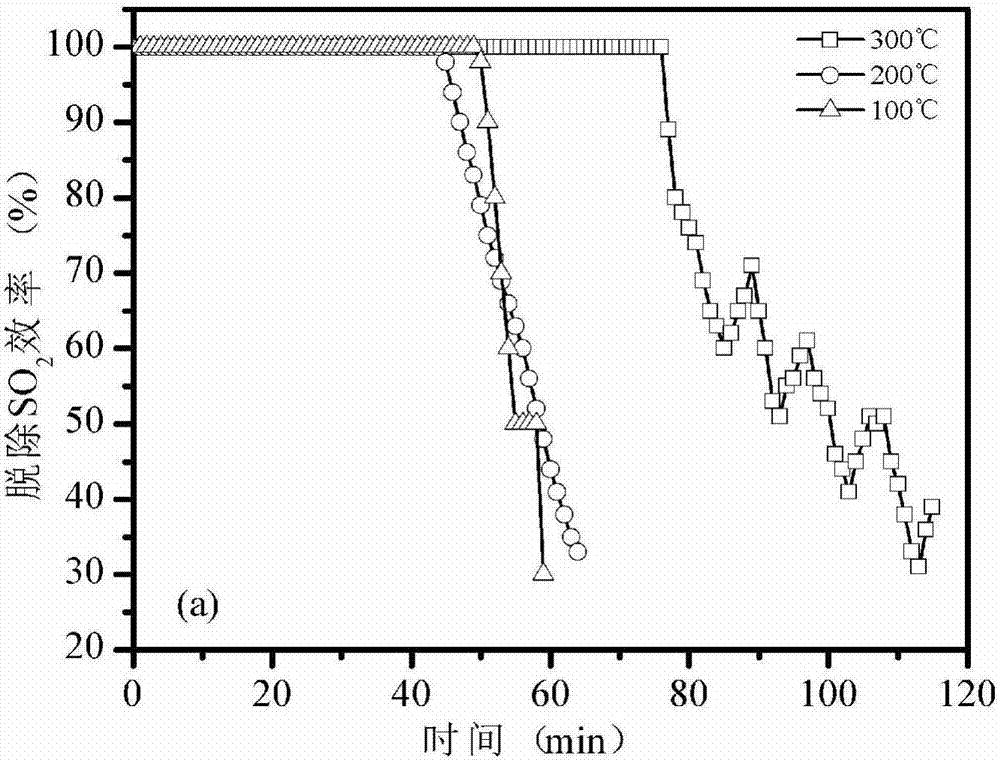

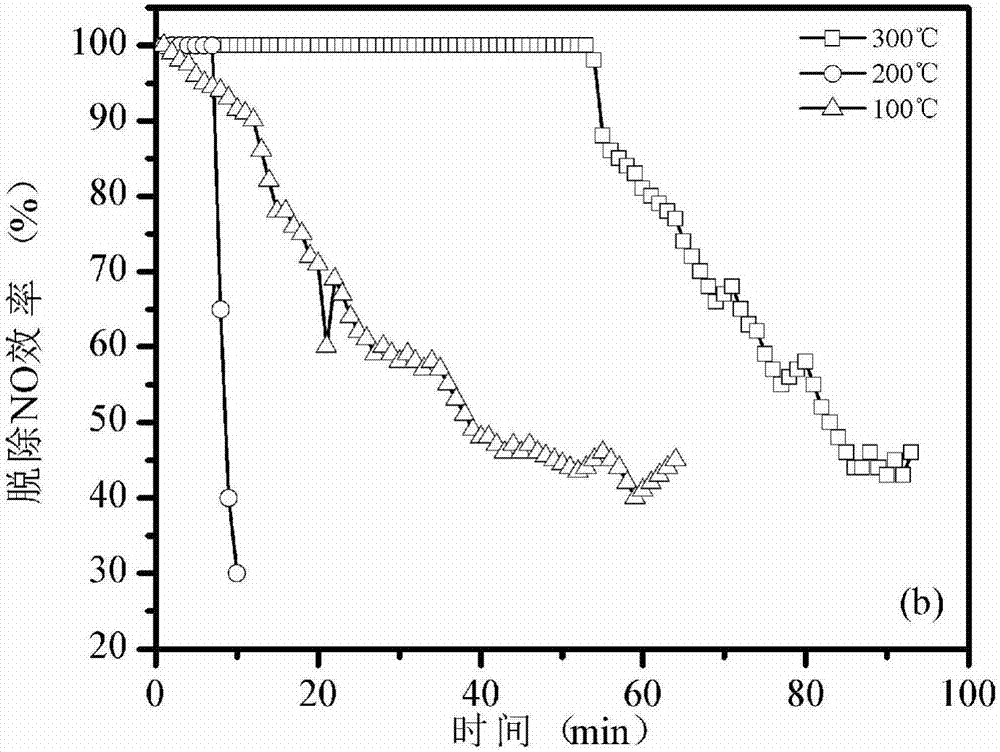

Method for preparing semicoke supported multi-element nano metal oxide desulfurization and denitrification adsorbing agent

InactiveCN107138132AWide variety of sourcesReduce manufacturing costGas treatmentOther chemical processesWater vaporMetal salts

The invention provides a method for preparing a semicoke supported multi-element nano metal oxide desulfurization and denitrification adsorbing agent. The method is characterized in that brown coal is used as the raw material, and pyrolysis and steam gasification are performed on the brown coal under N2 atmosphere by performing ultrasonic-assisted impregnation on metal salts serving as active component precursors to prepare a semicoke supporter and redistribute active components so as to directly obtain semicoke supported multi-element nano metal oxide. The method has the advantages that the low-metamorphic-grade brown coal relatively rich in reserves and the cheap metal nitrate are used as the raw materials prepare the desulfurization agent, and the method is wide in raw material source and low in production cost; compared with impregnation supporting using the semicoke supporter, the method simplifies the operation flow of early coke-making, reduces energy consumption, avoids supporting capacity reduction caused by pore structure changes caused by the fact that pore passages are blocked by tar and the like, is beneficial to the sufficient and even distribution of the active components on the surface of the supporter, increases the desulfurization precision of the desulfurization agent and increases the effective desulfurization time of the desulfurization agent.

Owner:UNIV OF SCI & TECH LIAONING

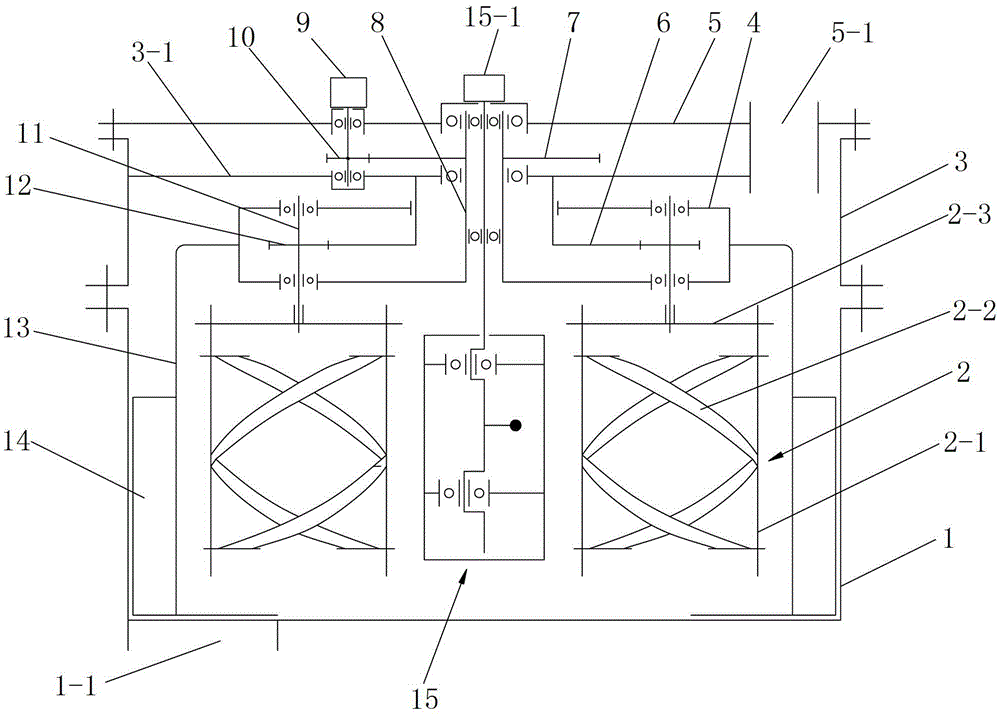

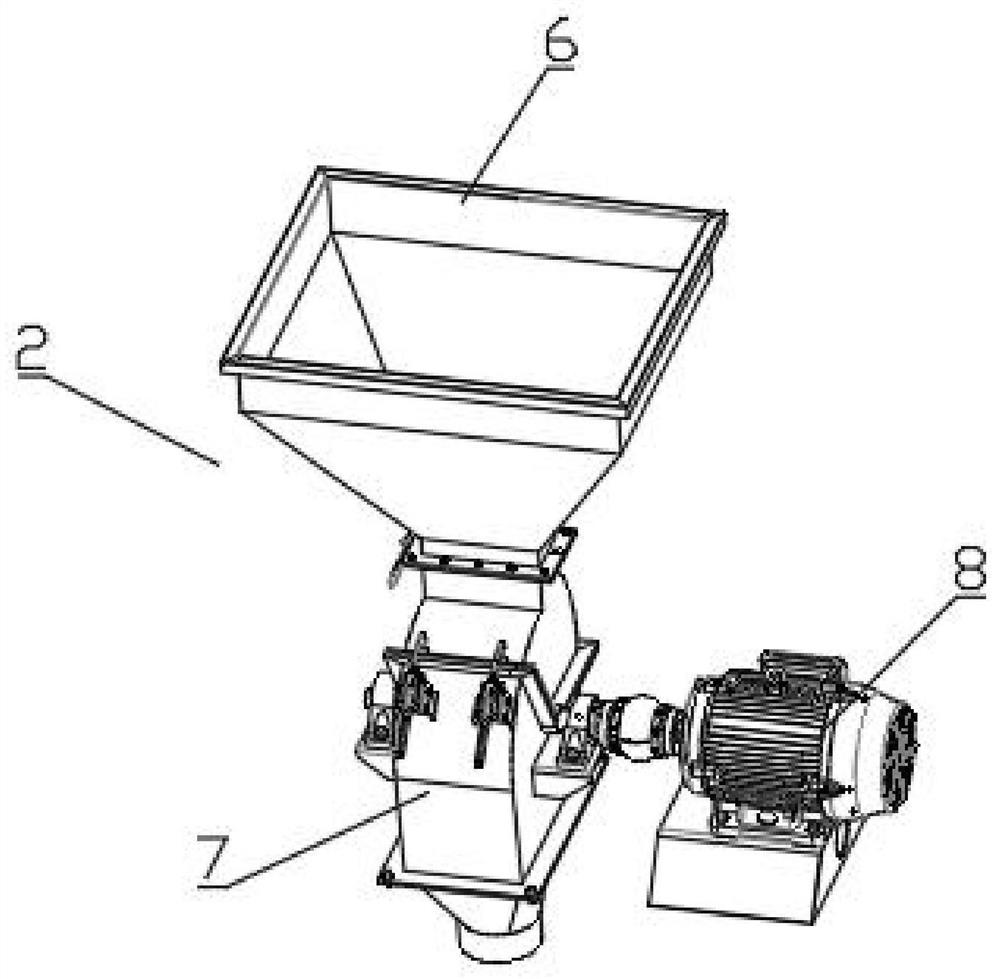

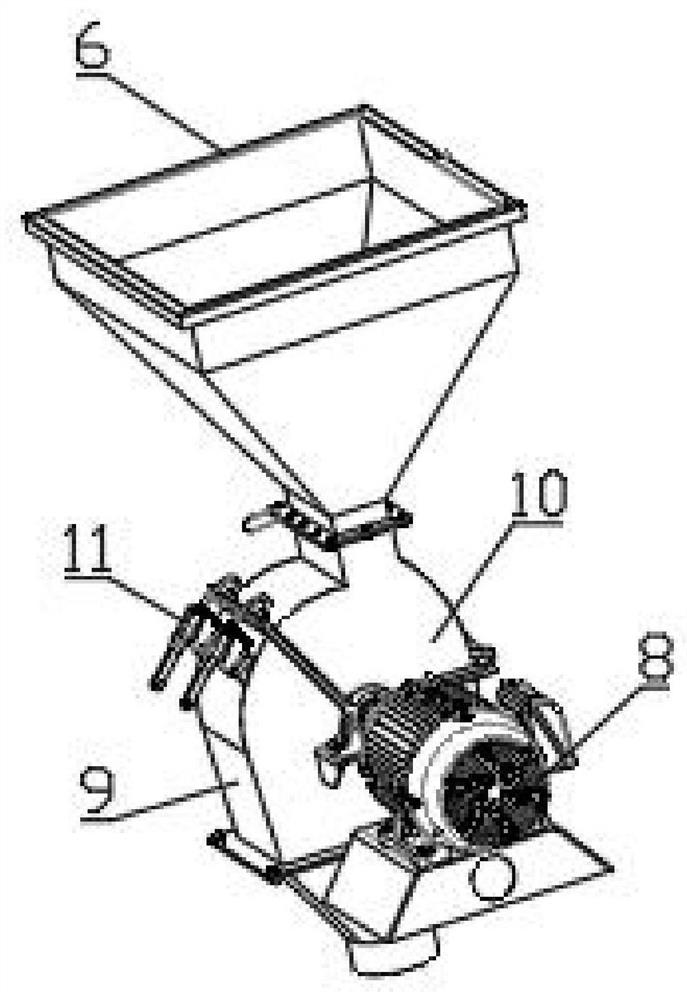

Planetary concrete mixer

InactiveCN102975287ASimple structureNovel and reasonable designCement mixing apparatusGear wheelEpicyclic gearing

The invention discloses a planetary concrete mixer, which comprises a lower barrel body and a plurality of helical ribbon mixing devices, wherein a middle barrel body is connected to the upper part of the lower barrel body; a planetary gear mechanism is arranged in the middle barrel body; a cover plate is arranged at the upper end of the middle barrel body; a mixing drive device is arranged on the cover plate; a mixing input shaft is rotationally connected in the middle of the cover plate; the planetary gear mechanism comprises planetary racks, sun wheels and a plurality of planetary wheels; the planetary racks are connected to the lower end of the mixing input shaft; the sun wheels are sleeved on the mixing input shaft; the upper ends of the sun wheels are connected with the middle barrel body; planetary wheel shafts are arranged on the planetary racks; the planetary wheels are mounted on the planetary wheel shafts; each helical ribbon mixing device comprises two mixing arms; mixing helical ribbons are connected on the inner side surfaces of the two mixing arms; the upper parts of the two mixing arms are connected through a connecting plate; the lower ends of the planetary wheel shafts are connected with the connecting plates; and a vibration mechanism is arranged in the lower barrel body. According to the planetary concrete mixer, the microcosmic uniformity of concrete can be effectively improved.

Owner:CHANGAN UNIV

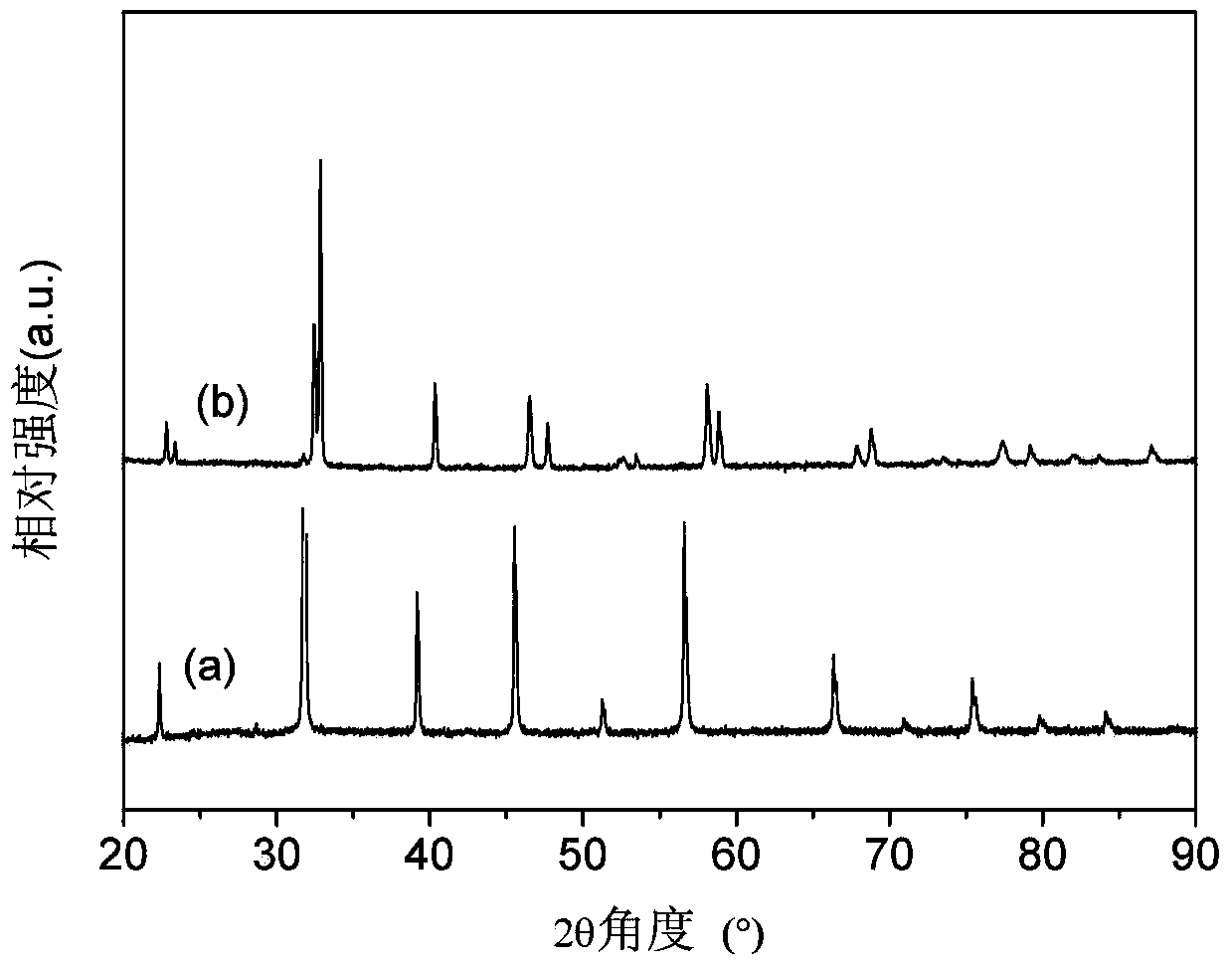

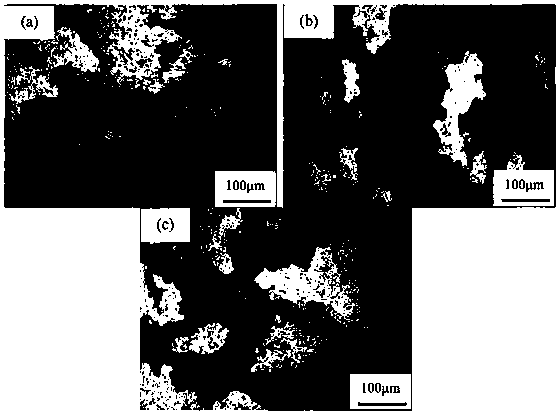

Electrocatalyst with mixed precious metal and perovskite oxides

The invention relates to an electrocatalyst with mixed precious metal and perovskite oxides. The electrocatalyst with mixed precious metal and perovskite oxides is characterized in that precious metal and perovskite oxides are mixed mechanically at different ratios so as to prepare an electrode, thereby obtaining the electrocatalyst with high ORR (oxygen reduction reaction) and OER (oxygen evolution reaction); the single precious metal is an excellent oxygen reduction catalyst, but the catalytic oxygen evolution reaction is relatively poor; the perovskite oxides have relatively high catalytic activity to the oxygen evolution reaction, and have very flow catalytic activity to the ORR. Aiming at the situation, the catalyst obtained by the invention has high ORR and OER activity at the same time only by a simple mixing method, and can act as a double-effect oxygen electrode for the fields of integrated recyclable fuel batteries, chargeable metal-air batteries, water electrolysis and the like.

Owner:辽宁沐与康中氢燃料电池有限公司

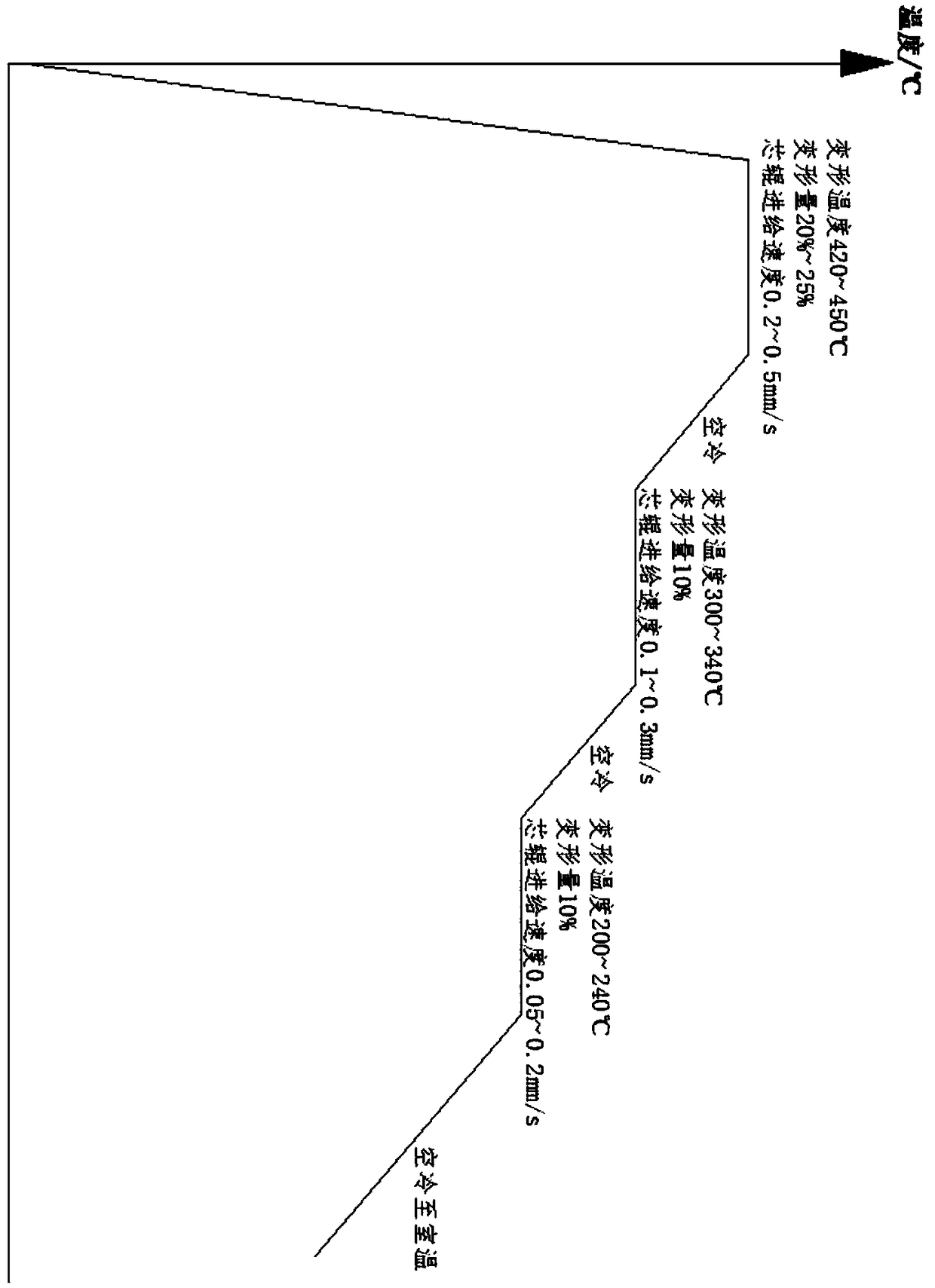

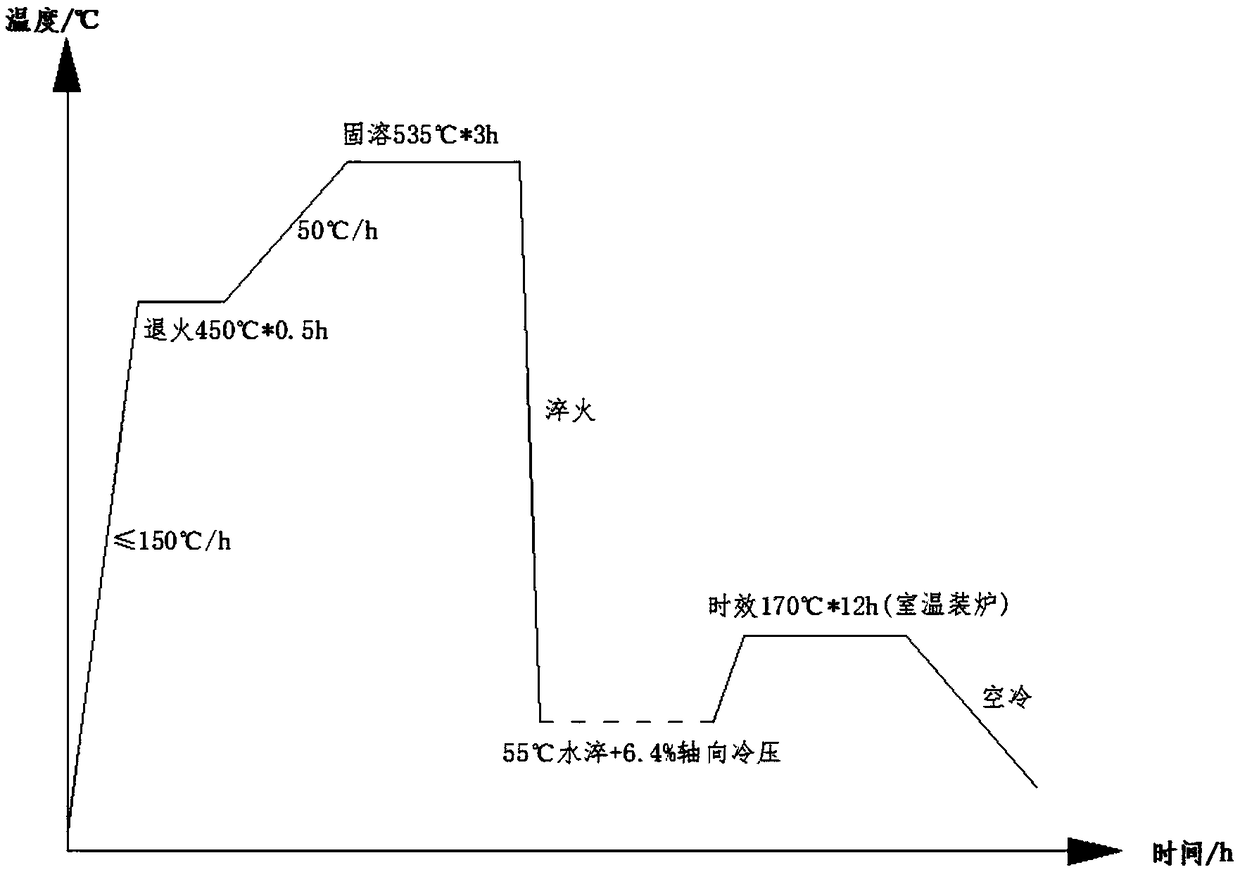

Manufacturing technology of high-strength heat-resistant aluminum alloy forge piece

ActiveCN108890218AImprove mechanical propertiesImprove heat resistanceMetal rollingManufacturing technologyAlloy

The invention discloses a manufacturing technology of a high-strength heat-resistant aluminum alloy forge piece. The manufacturing technology comprises the following steps of material preparation, heating, multi-axial forging, machining, heating, trestle broaching, heating, ring rolling, machining, annealing, solid solution hardening, cold pressing deformation, ageing and the like, wherein the ring rolling technology is divided into three temperature sections for rolling, in the first temperature section, the deformation temperature is 420-450 DEG C, the feeding speed of a core roller is 0.2-0.5 mm / s, and the deformation quantity is 20-25%; in the second temperature section, the deformation temperature is 300-340 DEG C, the feeding speed of the core roller is 0.1-0.3 mm / s, and the deformation quantity is 10%; in the third temperature section, the deformation temperature is 200-240 DEG C, the feeding speed of the core roller is 0.05-0.2 mm / s, and the deformation quantity is 10%.

Owner:JIANGSU UNIV OF TECH

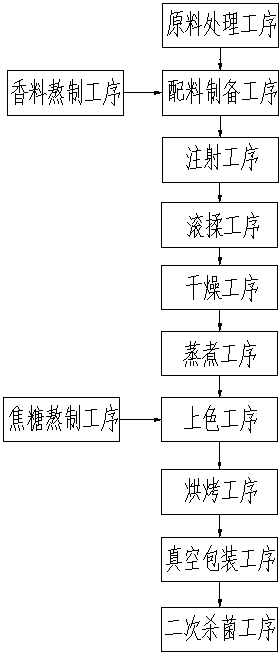

Preparation method of upper part of leg of pork

ActiveCN103989193ASalty and sweetLarge color fluctuationsFood preparationAdditive ingredientSalinity

The invention relates to a preparation method of the upper part of a leg of pork, belonging to a preparation method of a meat product. The method of the upper part of the leg of pork sequentially comprises the steps of processing raw materials, stewing spice, preparing ingredients, injecting, kneading in a rolling way, drying, cooking, making caramel, coloring, baking, carrying out vacuum package and carrying out secondary sterilization. The upper part of the leg of pork prepared by the method is more delicious in flavor and more attractive and stable in color; the traditional Chinese style sauce halogen upper part of the leg of pork adopts the traditional marinating technology, and the thick gravy is prepared and the cooking, the salinity and the color modulation are mastered by human experience, so that the upper parts of the legs of pork which are made by different people in different batches have larger difference; the upper part of the leg of pork is prepared by combining the western style technology and the Chinese style technology, so that all indexes such as flavor, salinity and the like of the product are stable, the processing technology of the product is standard, and the defects that the traditional Chinese style sauce halogen product can not realize quantization and standardization can be avoided; furthermore, according to the method, all the auxiliary material is utilized once, so that the defects that the soup stock of the traditional Chinese style sauce halogen product is repeatedly used, the residue of the soup stock is stored and the like can be avoided, and the cost of the product formula can be lowered.

Owner:ZHEJIANG QINGLIAN FOOD

Preparation method of high crystallization thermoplastics type polybutylene terephthalate slice

ActiveCN101824143AFully evenly distributedEvenly distributedPolytetramethylene terephthalateThermoplastic

The invention relates to a preparation method of a high crystallization thermoplastics type polybutylene terephthalate slice, comprising the following steps of firstly, preparing 1 percent of tetrabutyl titanate catalyst solution and 1 percent of nanometer titania solution, and mixing the tetrabutyl titanate catalyst solution and the nanometer titania solution by two metering pumps and a static mixer to be used as a composite catalyst; secondly, mixing talcum powder and 1, 4 butanediol, and preparing 1 percent of talcum powder solution by stirring the talcum powder and the 1, 4 butanediol; thirdly, mixing cobalt acetate and the 1, 4 butanediol and preparing 1 percent of cobalt acetate solution by stirring the cobalt acetate and the 1, 4 butanediol; and fourthly, adding purified terephthalic acid and the 1, 4 butanediol into a slurry preparation groove to stir, sending the mixture into an esterfication reactor, adding the talcum powder solution, the cobalt acetate solution and the composite catalyst solution into the esterfication reactor to react to obtain ester, inputting the ester into a prepolycondensation reactor, inputting a product into a finishing reactor, and obtaining a crystallization slice by cutting a product casting band after final polycondensation into particles. The prepared polybutylene terephthalate slice can rapidly carry out high crystallization in the processes of backend processing injection, extrusion, blow molding and coating.

Owner:JIANGSU HESHILI NEW MATERIAL

Method for preparing human vaginal microecological preparation-probiotics condom

ActiveCN104382685AFully evenly distributedRestore balanceMale contraceptivesBacteria material medical ingredientsBiotechnologyGYNECOLOGIC DISORDERS

The invention discloses a method for preparing a human vaginal microecological preparation-probiotics condom. The method is characterized in that probiotics are added to the front end of a condom or a stock solution by adopting the ecology theory of bacteria inhibition through probiotics, so that probiotics are fully and evenly distributed into female vaginas when men and women make love, thus the functions of restoring vaginal flora balance and self-cleaning are achieved; gynecological diseases such as bacterial vaginitis (BV), colpitis mycotica and trichomonas vaginitis are effectively treated and prevented. The method has the advantages that the method that the probiotics enter the vagina to adjust vaginal flora balance is simple and convenient, has both treating and protecting functions, is used for supporting the healthy energy, and is good in treatment effect, free of recurrence after curing, high in efficiency, economical, safe and wide in application range.

Owner:NANCHANG UNIV

High crack-proof, impervious composite material for concrete and producing method thereof

ActiveCN101172808ASimple production methodLow costSolid waste managementMaterials scienceReducing agent

The invention relates to high anti-cracking and high anti-penetrating composite material for concrete and the preparation method thereof, and contains the following components according to the weight ratio: expansion agent of 80 to 99 percent, synthetic fibre of 0.5 to 4.0 percent, water retention agent of 0 to 4.0 percent and water reducing agent of 0 to 12 percent. The preparation method comprises the steps as follows: mixing the components till the coefficient of dispersion of the distributed synthetic fibre is less than 0.03. The invention having the advantages of simple preparation method and low cost greatly simplifies the production art of the concrete and brings higher anti-cracking and anti-penetrating abilities of the concrete.

Owner:南京派尼尔科技实业有限公司

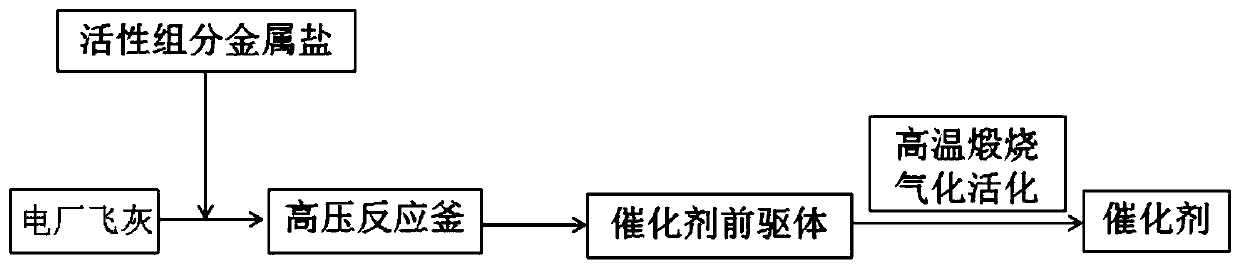

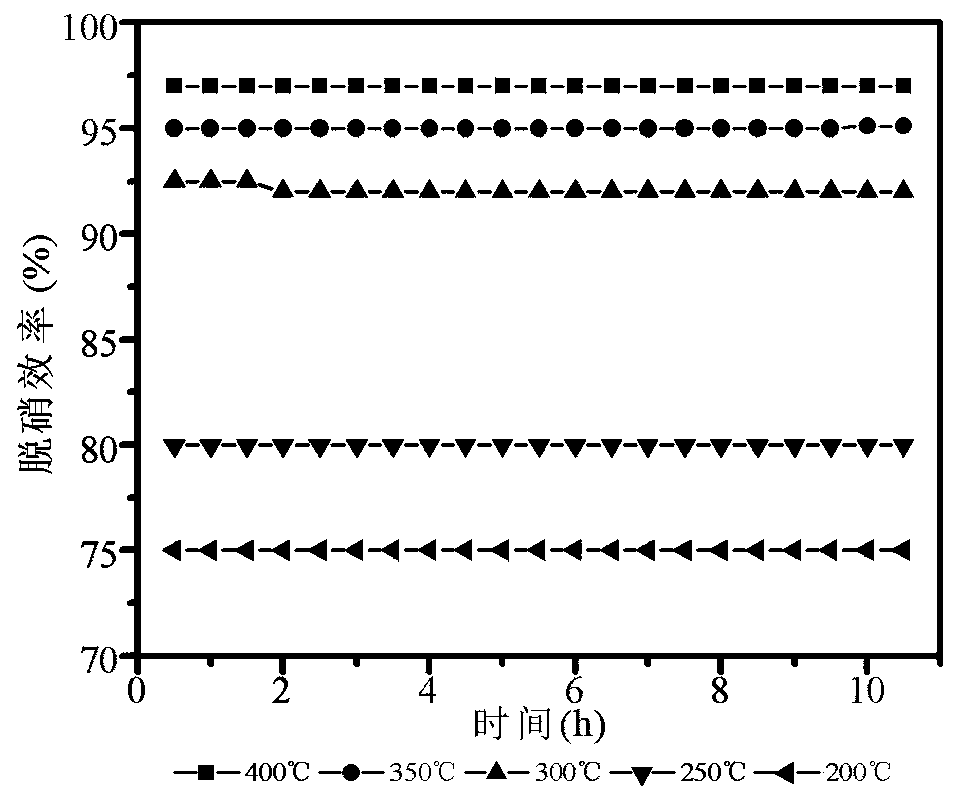

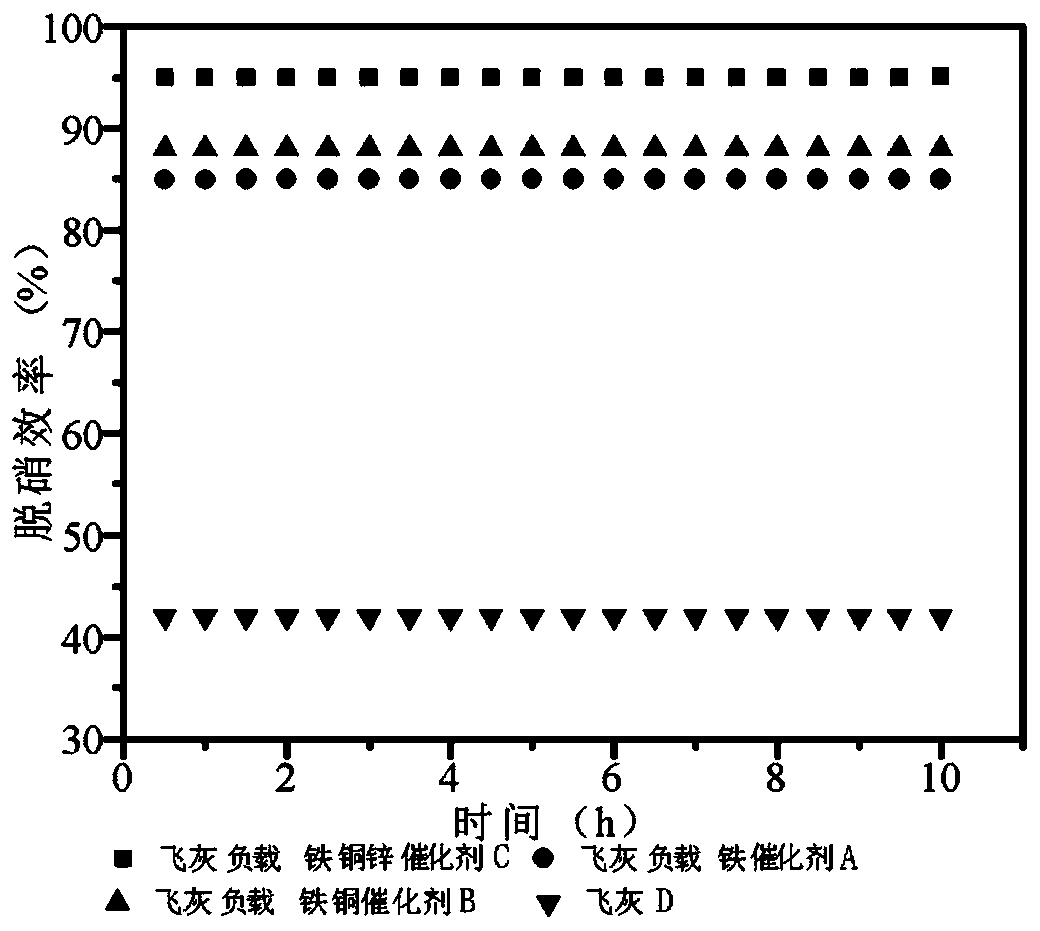

Low-cost flue gas denitration catalyst and preparation and use methods thereof

InactiveCN109794248ALow costNo secondary pollutionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioSteam activation

The invention relates to a low-cost flue gas denitration catalyst, which is a fly ash supported metal ion catalyst prepared from metal salt and fly ash. The mass ratio of metal to fly ash in the catalyst is 1:20-1:10. The processes of the thermal decomposition of the fly ash of a power plant and the precursor of an active component and the uniform distribution of the active component is integrated. The surface of the fly ash of the power plant is smooth and compact, the pores of the fly ash are developed by using a high-pressure reaction kettle, the pore structure is richer, meanwhile, the steam activation is adopted, so that the active components are more fully and uniformly distributed on the surface of the fly ash of a carrier; the active component of the catalyst, iron-zinc-copper metal oxide, exists in the nanometer-scale particle size, so that the denitration efficiency of the catalyst is improved and the effective denitration time is prolonged; the catalyst has higher denitration efficiency, high denitration precision and strong capability of removing NOX in flue gas; the catalyst carrier fly ash raw material is cheap and easy to obtain, has no secondary pollution and reduces the cost; the equipment process is simple and the investment cost is low.

Owner:UNIV OF SCI & TECH LIAONING

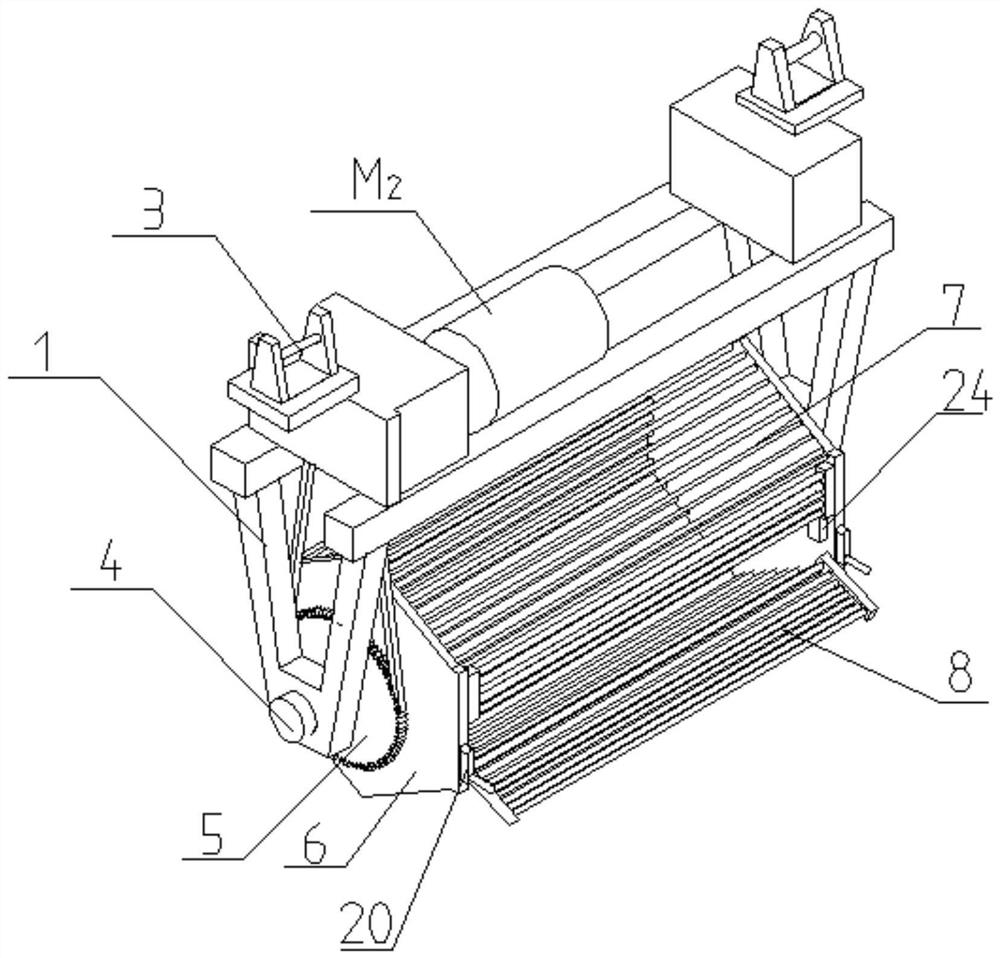

Screen surface distributing device of vibrating screen

ActiveCN103480571AFully evenly distributedReduce accumulationSievingScreeningEngineeringCotton material

Owner:BAOSHAN IRON & STEEL CO LTD

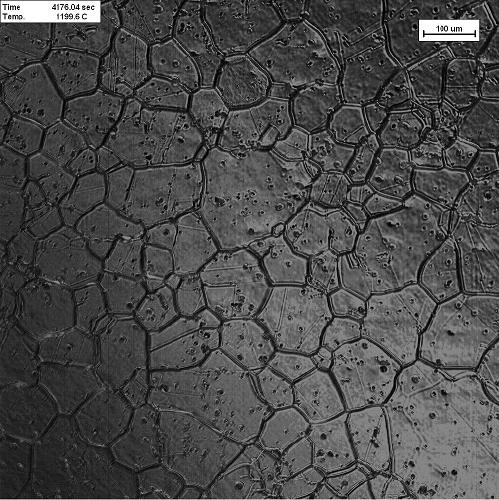

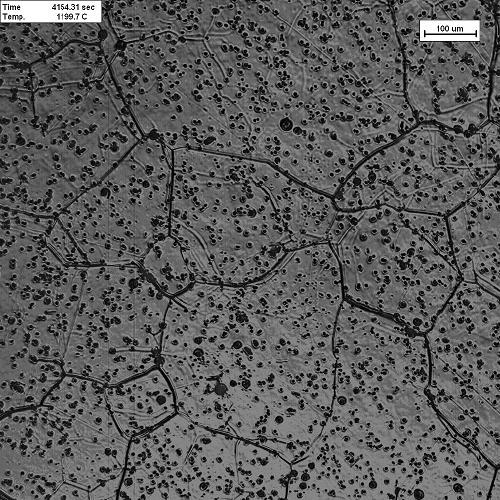

High-abrasion-resistance and impact-resistance niobium and titanium microalloying high-carbon alloy steel and production method thereof

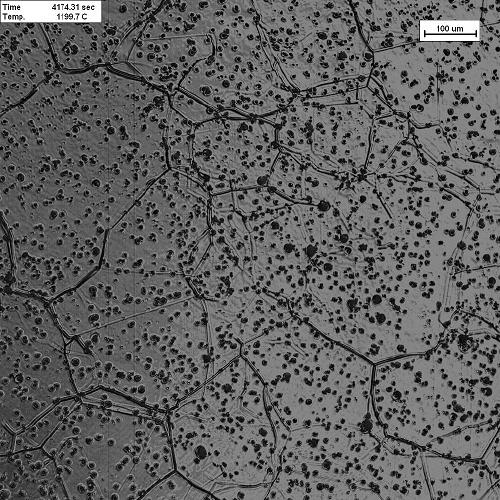

InactiveCN108998727ABroaden the rolling production process windowImprove wear resistanceProcess efficiency improvementAustenite grainNiobium

The invention discloses high-abrasion-resistance and impact-resistance niobium and titanium microalloying high-carbon alloy steel. The high-abrasion-resistance and impact-resistance niobium and titanium microalloying high-carbon alloy steel comprises chemical components including, by mass percent, 0.65%-0.85% of C, 0.20%-0.45% of Si, 0.80%-1.00% of Mn, 0.015% or less of P, 0.015% or less of S, 0.05%-0.10% of Ni, 0.75%-0.95% of Cr, 0.010%-0.045% of Al, 0.020%-0.050% of Nb, 0.010%-0.050% of Ti, 0.0002% or less of [H], 0.002% or less of [O], 0.006% or less of [N] and the balance Fe. Through a formula, according to the high-abrasion-resistance and impact-resistance niobium and titanium microalloying high-carbon alloy steel and a production method thereof, based on original components, moderatemicroalloy elements of Nb and Ti are added to control austenite grain sizes, the elements of Nb and Ti carry out microalloying, by optimizing the chemical components of the steel, rolling productionprocess windows of steel balls are expanded, the abrasion resistance and the tenacity of the steel alloy are improved, and the breaking in advance of the steel balls is avoided.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

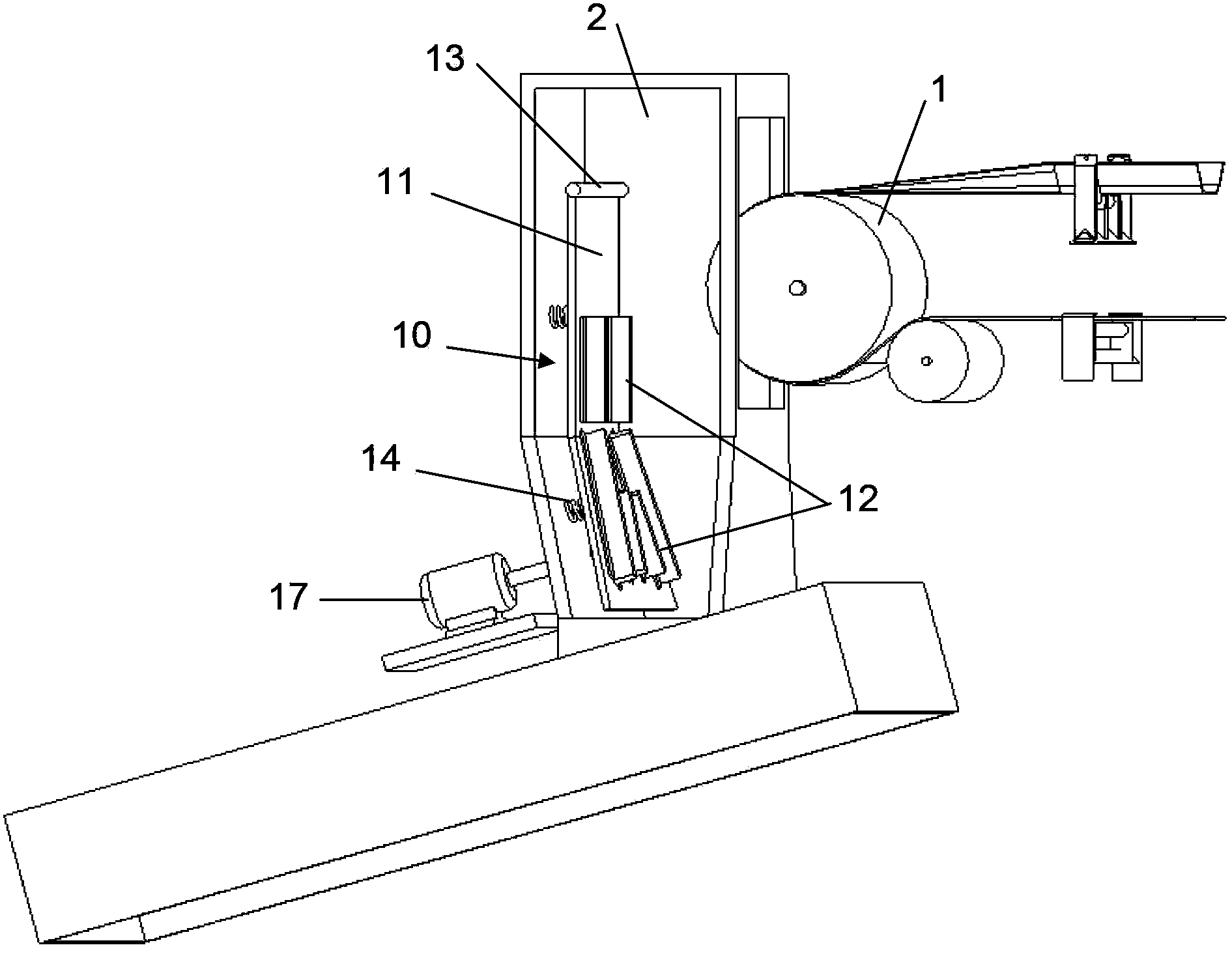

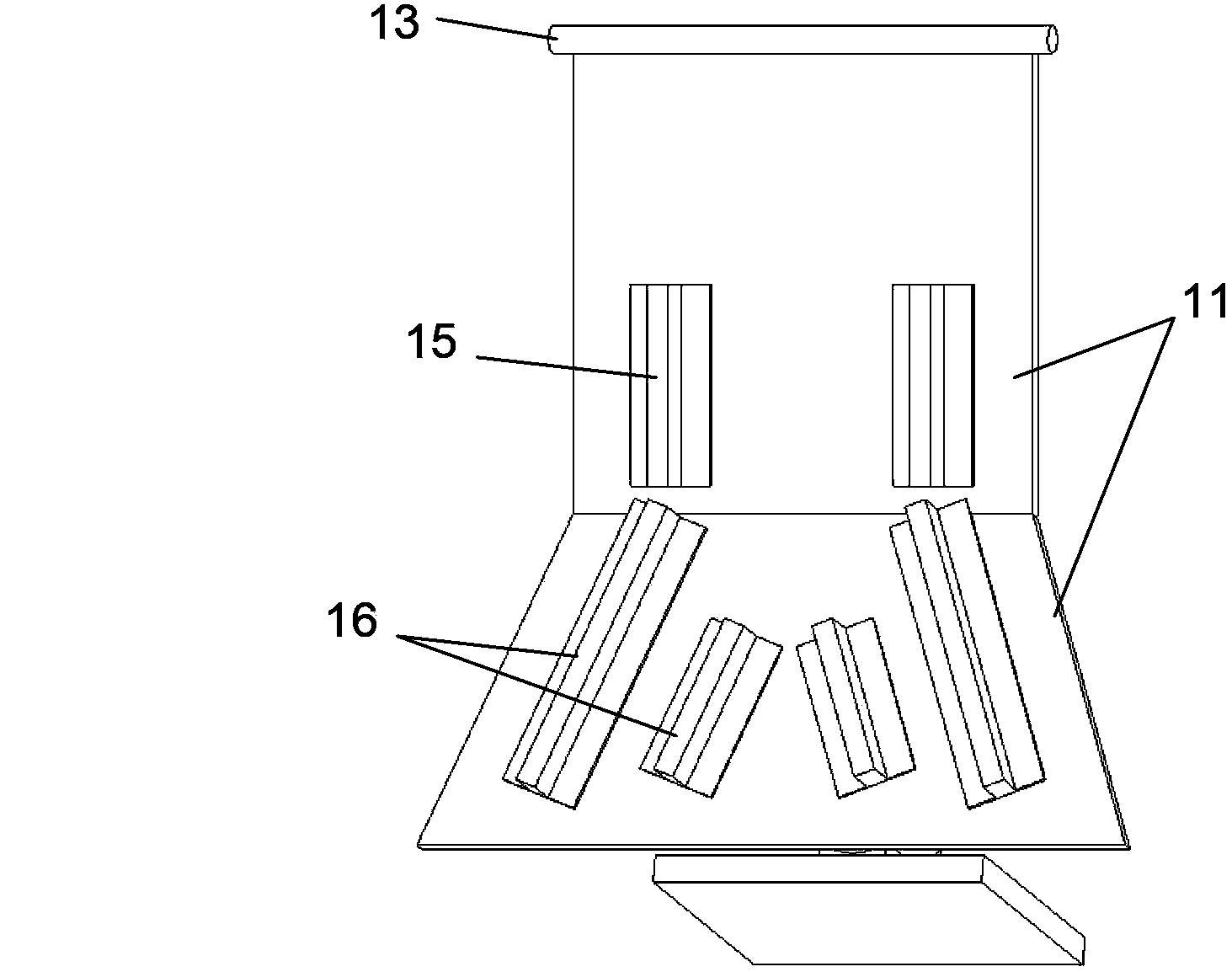

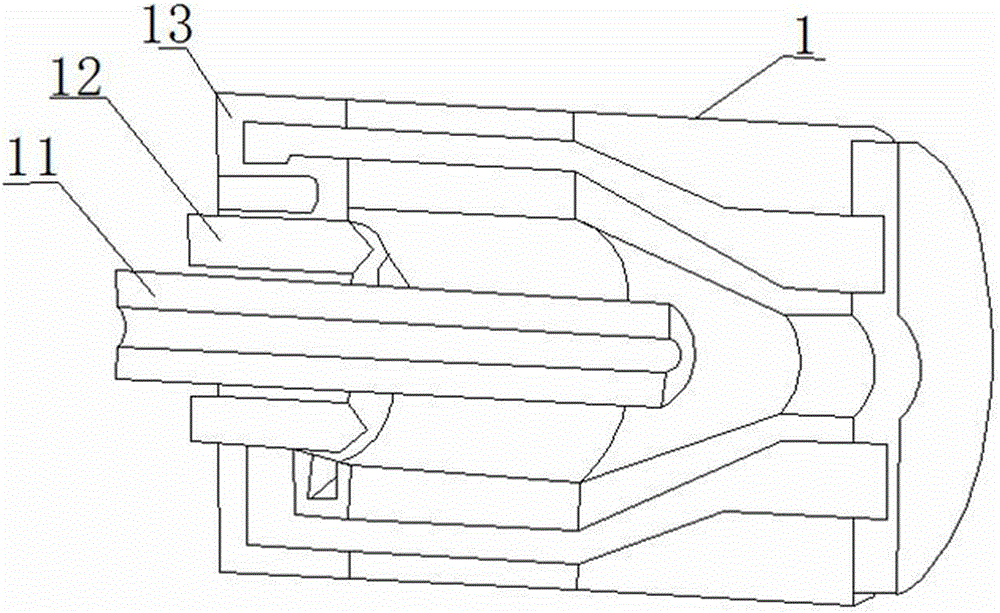

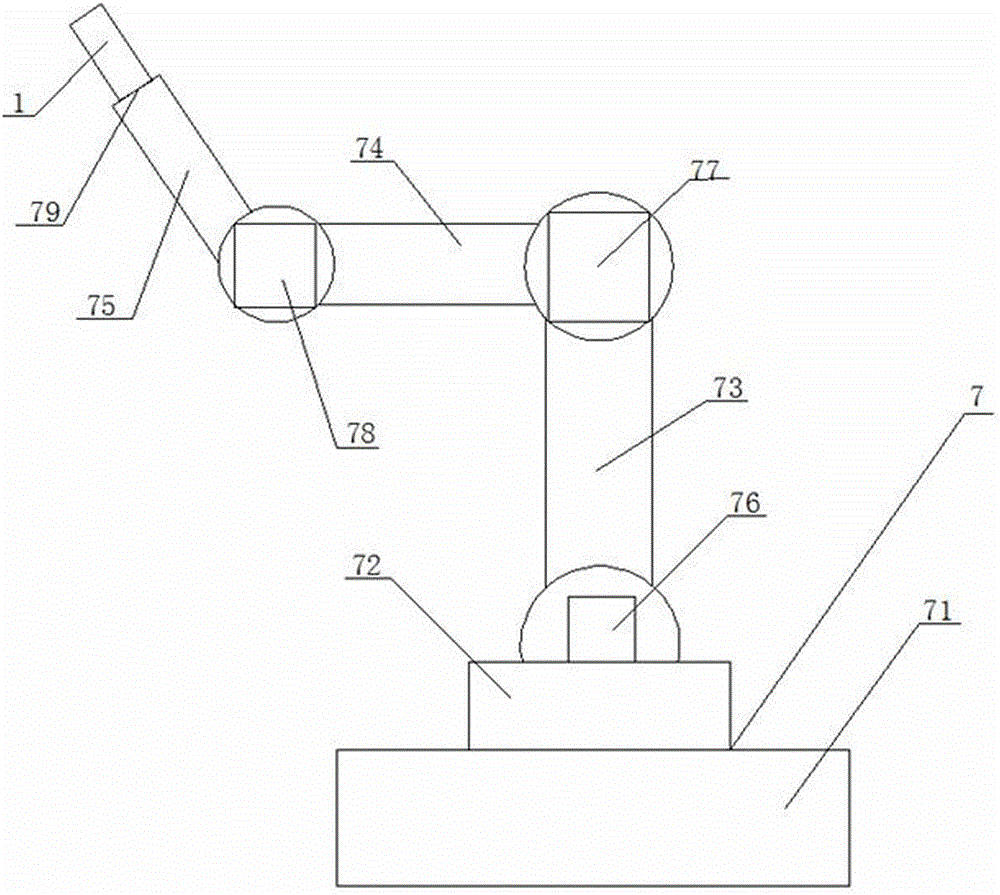

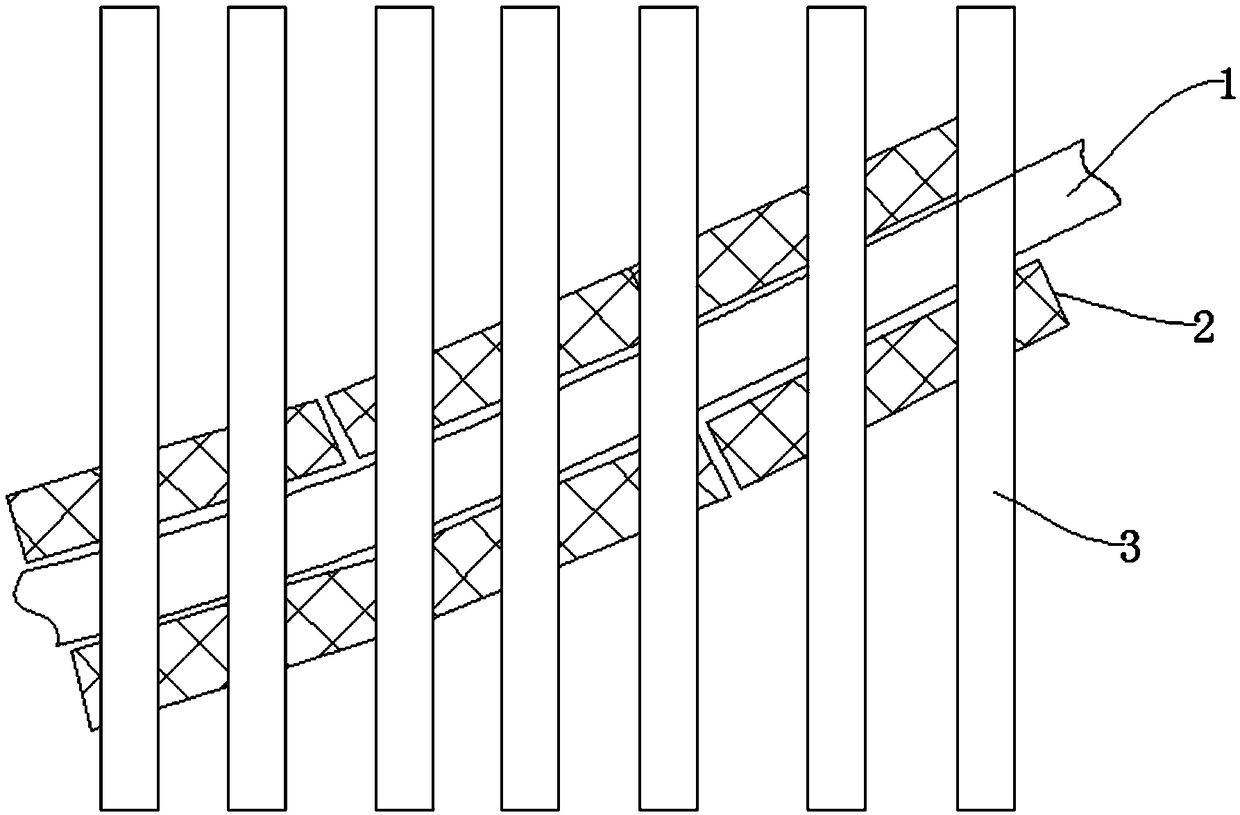

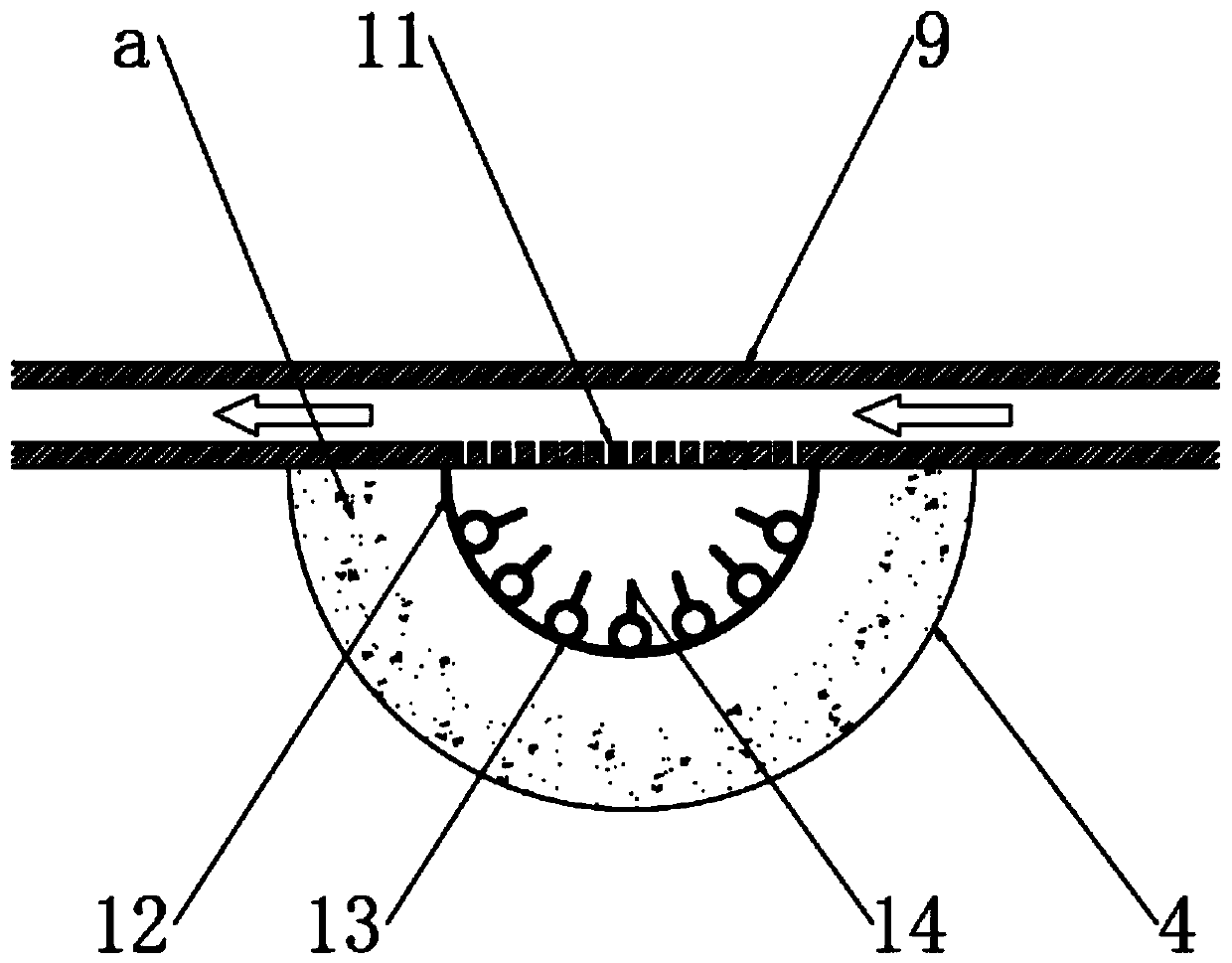

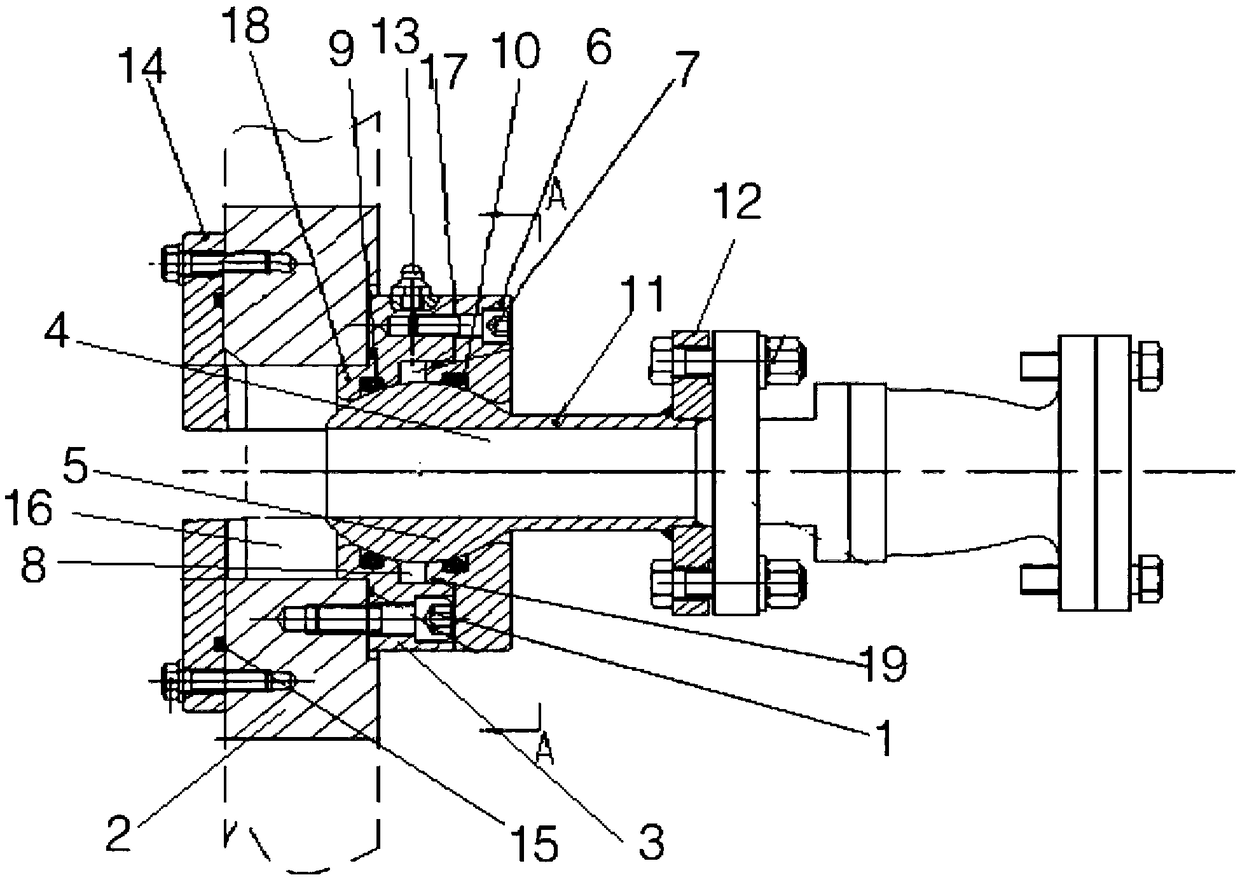

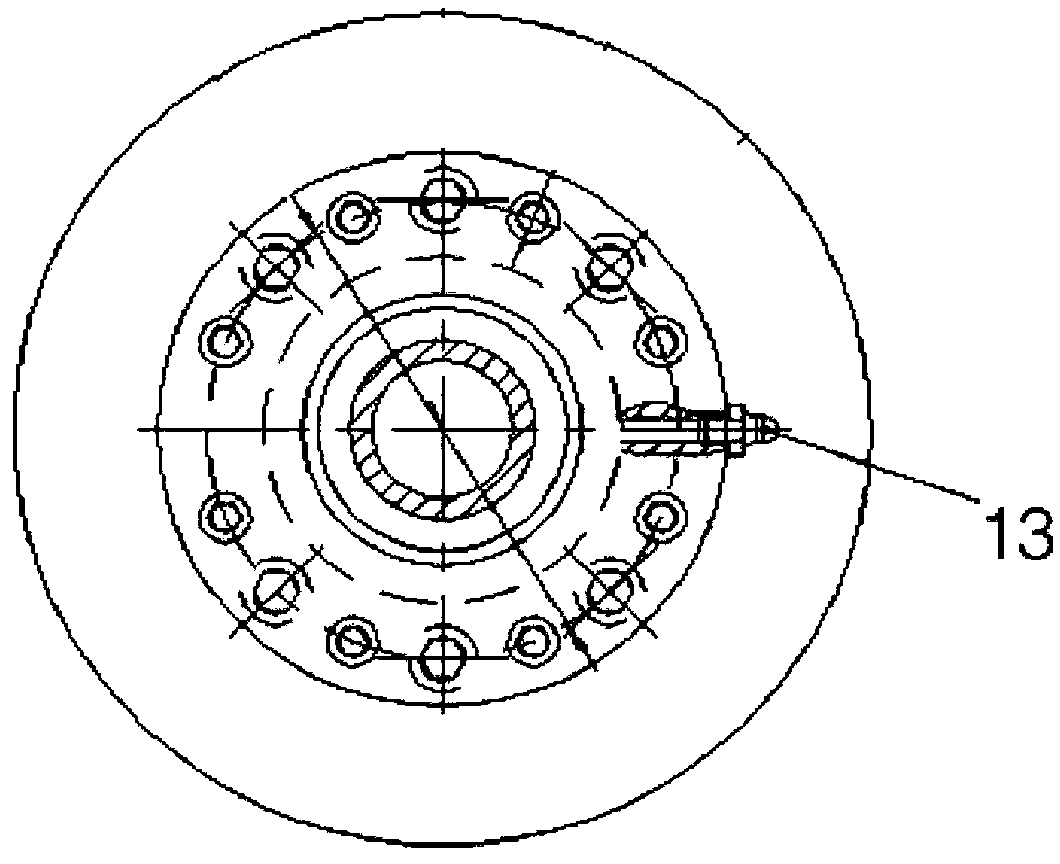

Steel rail surface treatment system using laminar plasma

InactiveCN106637039AImprove wear resistanceExtended service lifeMolten spray coatingPlasma generatorEngineering

The invention discloses a steel rail surface treatment system using laminar plasma, and relates to the technical field of steel rail remanufacturing treatment. The system comprises a non-transfer arc laminar plasma beam spraying gun, a high-frequency rectifying power supply, a control cabinet, a wire and powder feeding device, a circulating water cooling device, a gas supply device, an industrial robot and a steel rail mounting platform; the non-transfer arc laminar plasma generator is used as a heat source, and performs a relatively parallel constant-speed motion along the longitudinal axis of a steel rail; the wire and powder feeding device axially feeds powder along the center of the non-transfer arc laminar plasma generator; and the surface of the steel rail mounted on the steel rail mounting platform is treated. The system adopts a laminar arc plasma beam remanufacturing system equipment to perform the heat surface reinforcement treatment for rail junctions, steel rails, wheels and other rail vehicle parts; and treated materials are more obvious in surface hardness reinforcement effect, and greatly improve the wear resistance.

Owner:四川金虹等离子技术有限公司

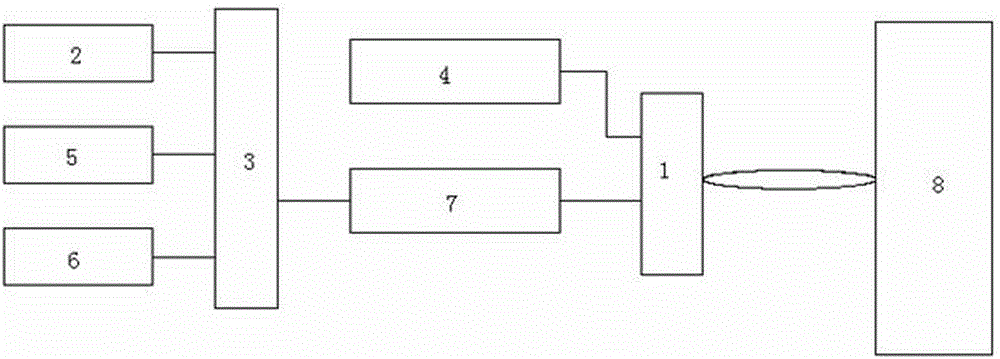

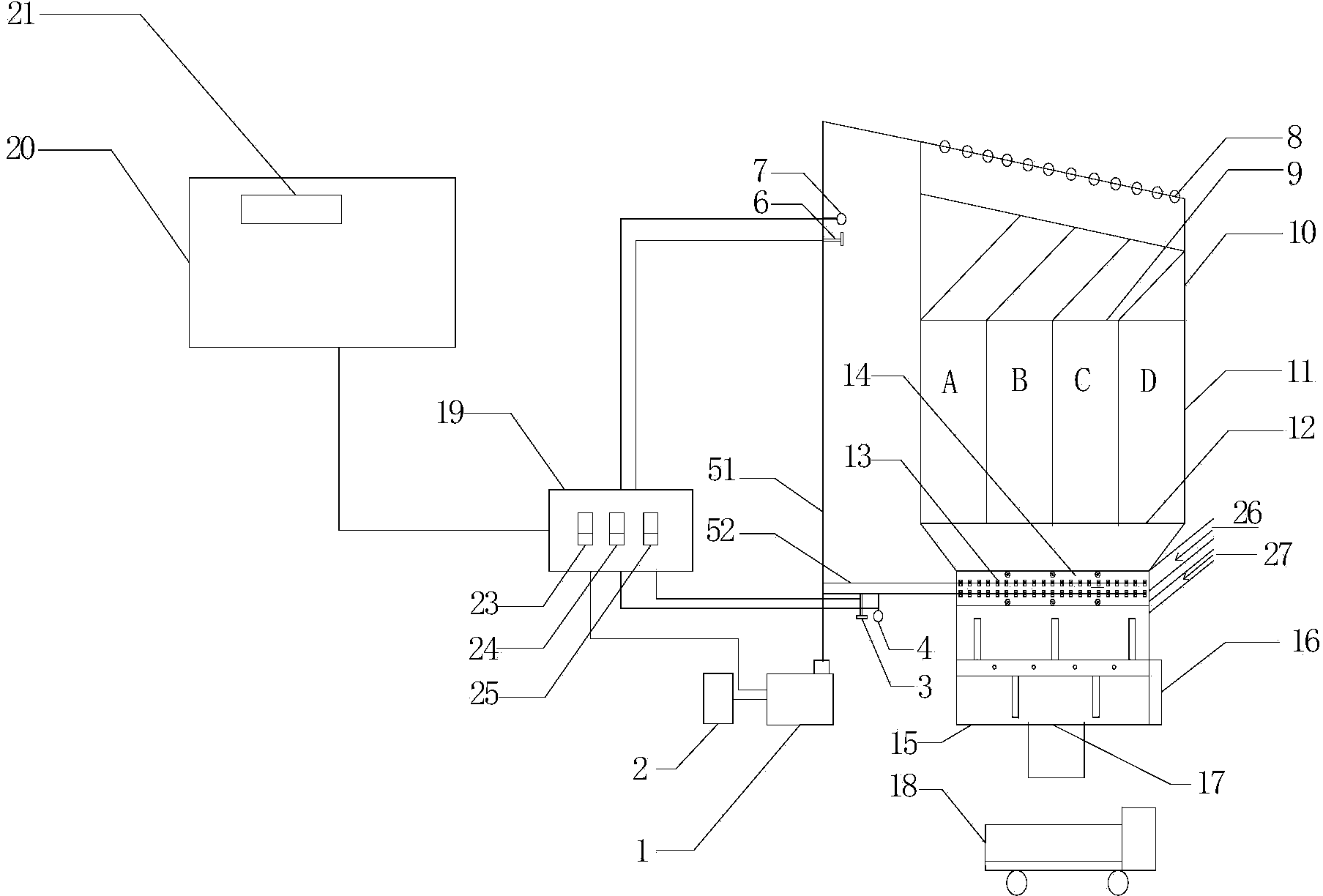

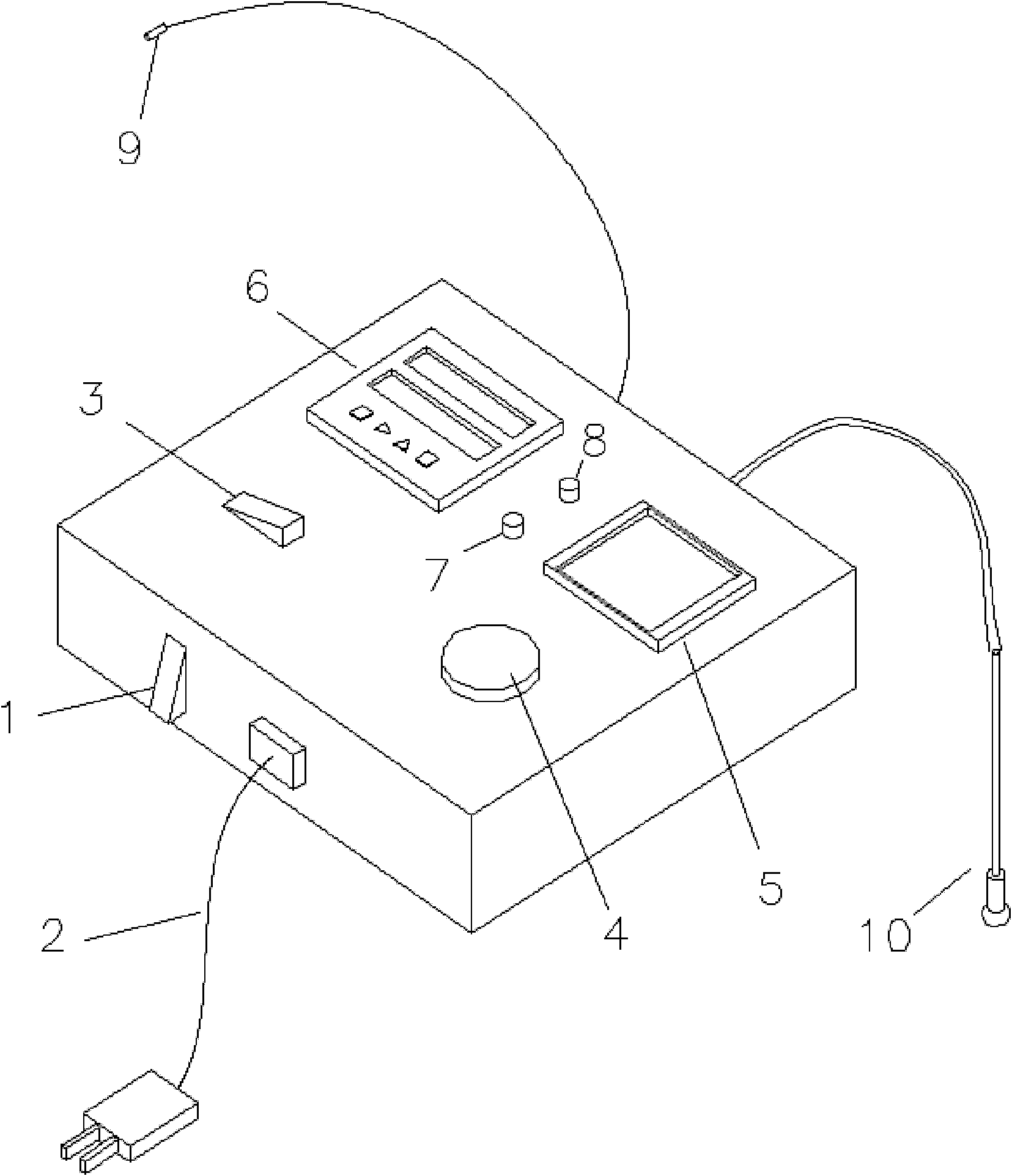

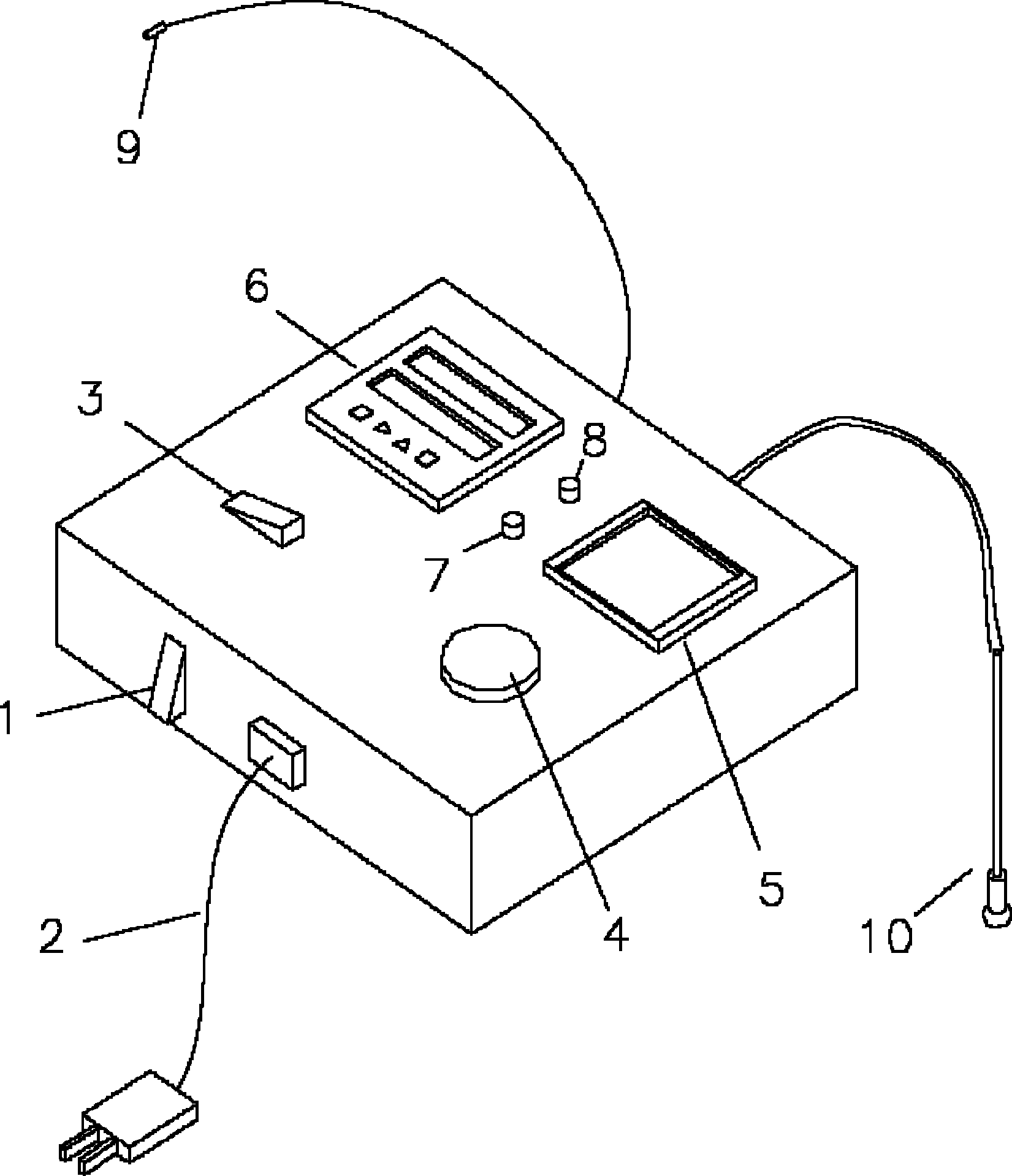

Surface modification atomizing device for stone materials butted to pitch mixing floor and control method thereof

ActiveCN104074119AImprove performance indicatorsFully evenly distributedRoads maintainenceElectronic switchEngineering

The invention discloses a surface modification atomizing device for stone materials butted to a pitch mixing floor and a control method thereof. The device comprises a control unit, a raw material bucket, a conveying pump, a first electronic switch, a second electronic switch, a first atomization spraying head device and a second atomization spraying head device, wherein the conveying pump is communicated with the first atomization spraying head device and the second atomization spraying head device through a first pipeline and a second pipeline; a first electric valve and a second electric valve are respectively arranged on the first pipeline and the second pipeline; the first atomization spraying head device is arranged at the upper part of a screening cabin; the second atomization spraying head device is arranged on a mixing cylinder; the conveying pump and the first electric valve are connected with a power supply through the first electronic switch; the conveying pump and the second electric valve are connected with the power supply through the second electronic switch; the first electronic switch and the second electronic switch are respectively connected with the control unit. For the device, the surface modification is carried out twice for the stone materials, great specific surface area can be reached, and surface modification agents of the stone materials can be fully and uniformly distributed onto the surfaces of the stone materials.

Owner:GUANGDONG GT TECH ROAD MATERIAL TECH CO LTD

Production process of concrete tubular pile

ActiveCN111958821AFast heating stateRealize heat treatmentCement mixing apparatusElectric machineStructural engineering

The invention discloses a production process of a concrete tubular pile. The production process mainly comprises the following processing steps: charging; liquid injection and heating; and stirring. Processing equipment used in a processing course of the production process of the concrete tubular pipe comprises a stirring cylinder. A water tank is fixed to the outer bottom of the stirring cylinder, a partition plate is fixed to the inner wall of the water tank, a motor is fixed to the upper end of the partition plate, and an auger rotating shaft is fixed to an output shaft of the motor. The production process has the advantages that by arranging a magnetic block in a scraper blade, when the stirring rod drives electromagnets to rotate, the magnetic block subjected to an magnetic forces ofthe electromagnets drives the scraper blade to slide along the inner wall of the stirring cylinder, so that raw materials are not attached to the inner wall of the stirring cylinder for a long time, and therefore, the raw materials are mixed and stirred uniformly; meanwhile, two electromagnets which are high and low are arranged, so that the scraper blade moves circularly in a reciprocating mannereffectively in the rotating process of the electromagnets, the inner wall of the stirring cylinder is scraped and cleaned effectively all the time, and the mixing and stirring process is more thorough .

Owner:台州伟兴科技有限公司

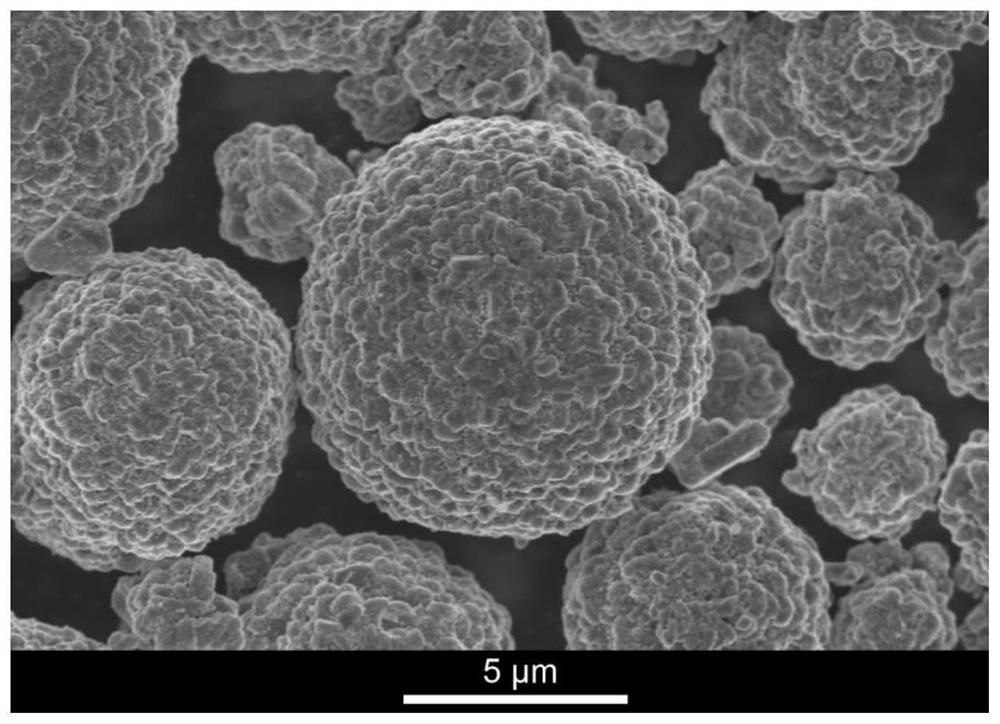

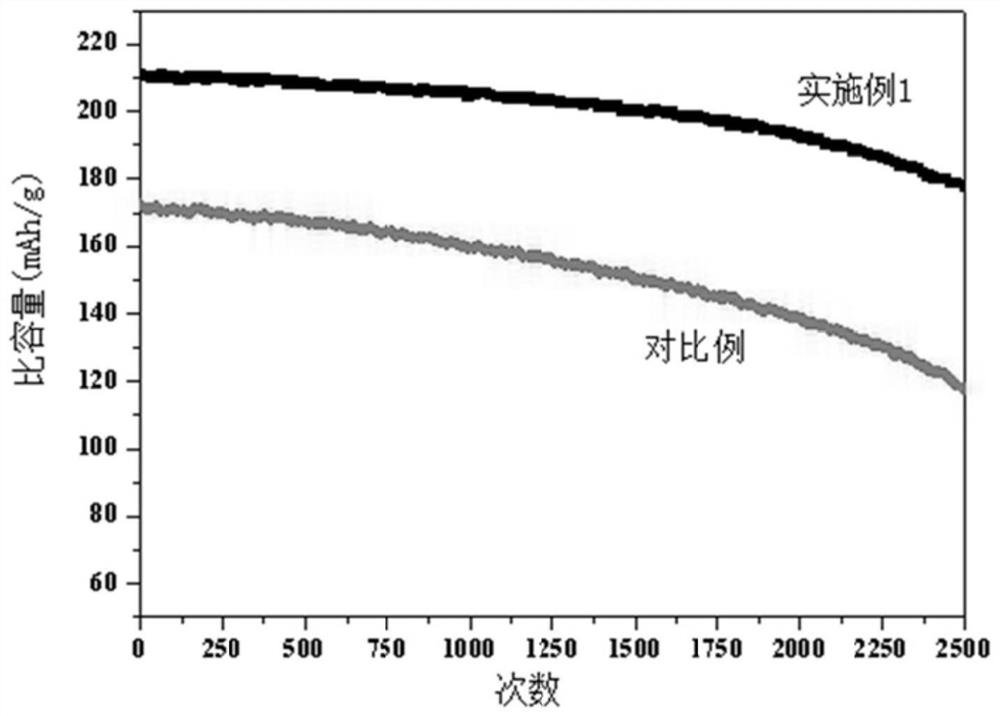

Method for preparing lithium nickel cobalt manganese oxide by reverse positioning of power battery and application

ActiveCN112661201AReduce consumptionFully evenly distributedCell electrodesWaste accumulators reclaimingAl powderPower battery

The invention belongs to the technical field of lithium battery recovery, and provides a method for preparing lithium nickel cobalt manganese oxide by reverse positioning of a power battery and application, which comprises the following steps: mixing and grinding a positive plate and a slag former, drying and cooling the mixture, adding aluminum powder, uniformly mixing the components, carrying out self-propagating reaction on the uniformly mixed material, cooling the reaction product, and collecting the lower coarse nickel cobalt manganese alloy; grinding the crude nickel-cobalt-manganese alloy, adding alkali liquor, soaking the alloy again, filtering the liquid and washing and drying the filter residues to obtain porous nickel-cobalt-manganese alloy powder; then adding a lithium salt solution into the porous nickel-cobalt-manganese alloy powder, stirring the solution, dropwise adding the alkali liquor, and ageing and filtering the liquid and collecting the filter residues; cleaning and drying the filter residues to obtain precursor mixed powder, sintering and cooling the precursor mixed powder, and drying the powder to obtain the lithium nickel cobalt manganate. According to the invention, short-distance butt joint of waste and raw materials is achieved, the technological process is short, consumption of used raw materials and auxiliary materials is small, energy consumption is low, the treatment cost is low, pollutant emission is small, and the whole process is environmentally friendly.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

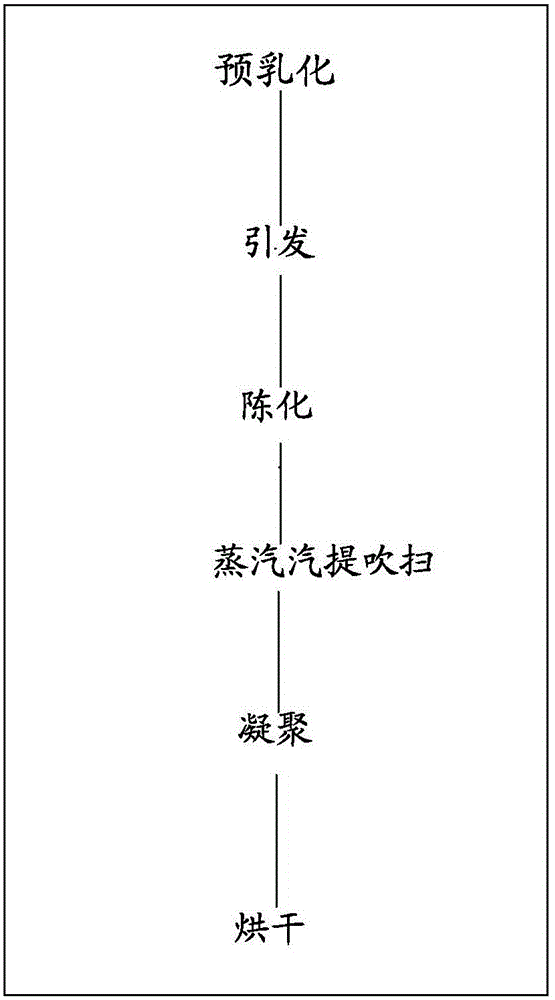

Preparation method of low-compression permanent-deformation carboxylic acrylate rubber

The invention relates to a preparation method of low-compression permanent-deformation carboxylic acrylate rubber. The preparation method includes: using an acrylate monomer and a maleic carboxylic cross-linked monomer as monomer mixed materials, performing pre-emulsification in nitrogen with regulator D, mixing peroxide and sodium hydrogen sulfite to allow initiating, adding initiator and the regulator D by several times during the initiating period, and subjecting obtained polymer to ageing, steam stripping and purging, gelling and drying to obtain a product, the low-compression permanent-deformation carboxylic acrylate rubber. The product is up to 38-42 in Mooney viscosity, 3-4 in intrinsic viscosity and less than 20% in compression set, and processing and extrusion safety of the product is greatly improved.

Owner:CHANGZHOU HAIBA RUBBER CO LTD

Tunnel crack reinforcing method

ActiveCN109322676APrevent local collapseReduce stressNon-macromolecular adhesive additivesUnderground chambersPolymerMaterials science

The invention discloses a tunnel crack reinforcing method. The tunnel crack reinforcing method comprises the following steps that S1, the surface of soil around a crack is cleared to form a to-be-reinforced face, a reinforcement mesh is hung on the to-be-reinforced face, and polymer mortar is poured; S2, crack sealing glue is poured into the crack; and S3, a plurality of steel plates are anchoredin the direction of the crack path at intervals. According to the tunnel crack reinforcing method, the reinforcement mesh is arranged on the to-be-reinforced face, the reinforcement mesh and the tunnel soil form an integral structure, the stress at the tunnel crack can be effectively lowered, and the situation that the crack is further expanded and consequently partial collapse of the soil is caused is prevented; meanwhile, the crack sealing glue is poured into the crack, the steel plates are laid on the surface of the crack, thus the crack is filled, the surface of the crack is also blocked through chemical anchoring bolts and the steel plates glued by sticky steel glue, the situation that external water permeates into tunnel concrete through the crack is reduced, meanwhile, the reinforcing effect of the steel plates at the crack is also utilized, thus the bearing capability of the tunnel concrete is improved, and the service life of the tunnel concrete is prolonged.

Owner:中铁隧道局集团建设有限公司

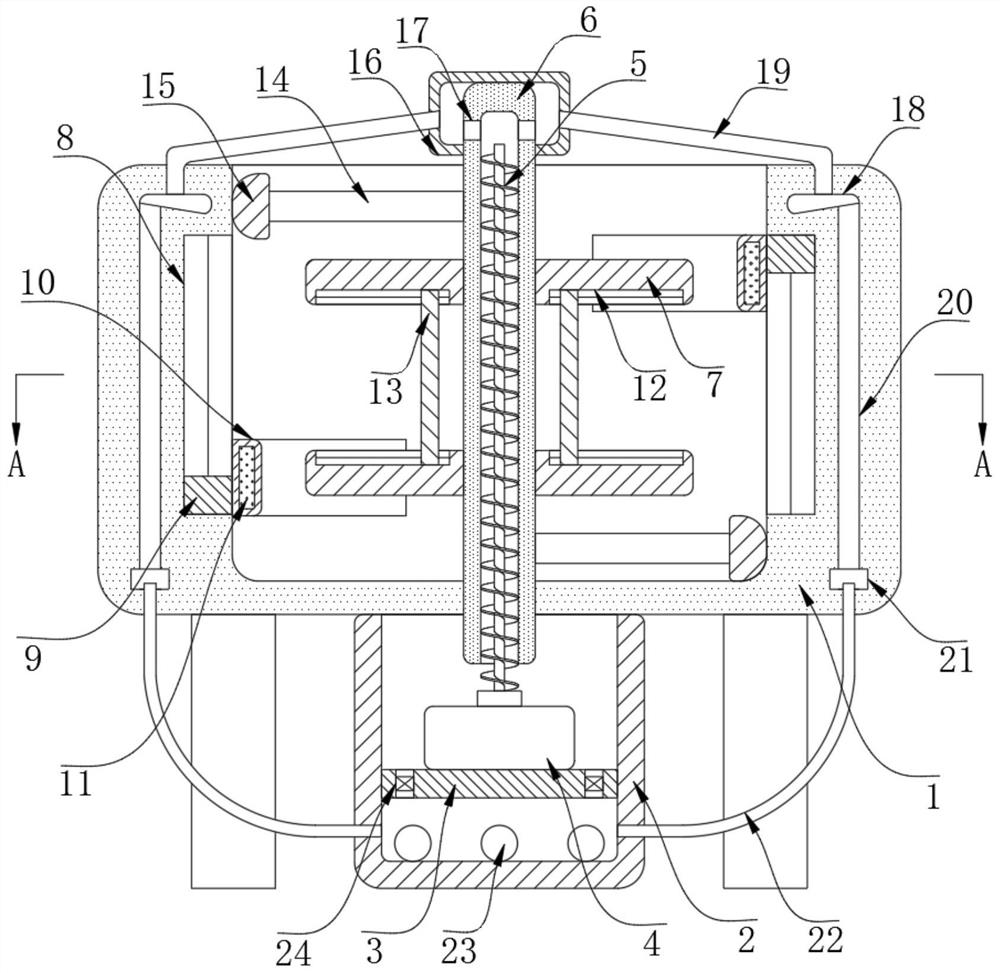

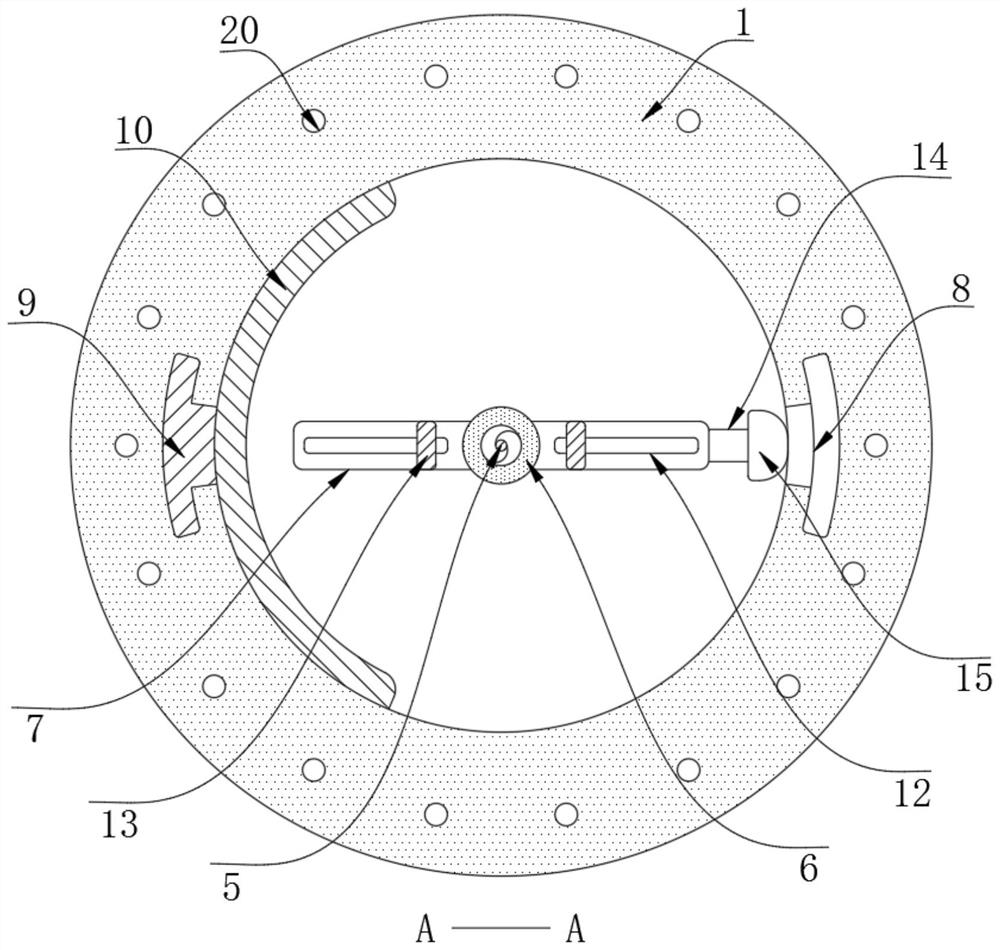

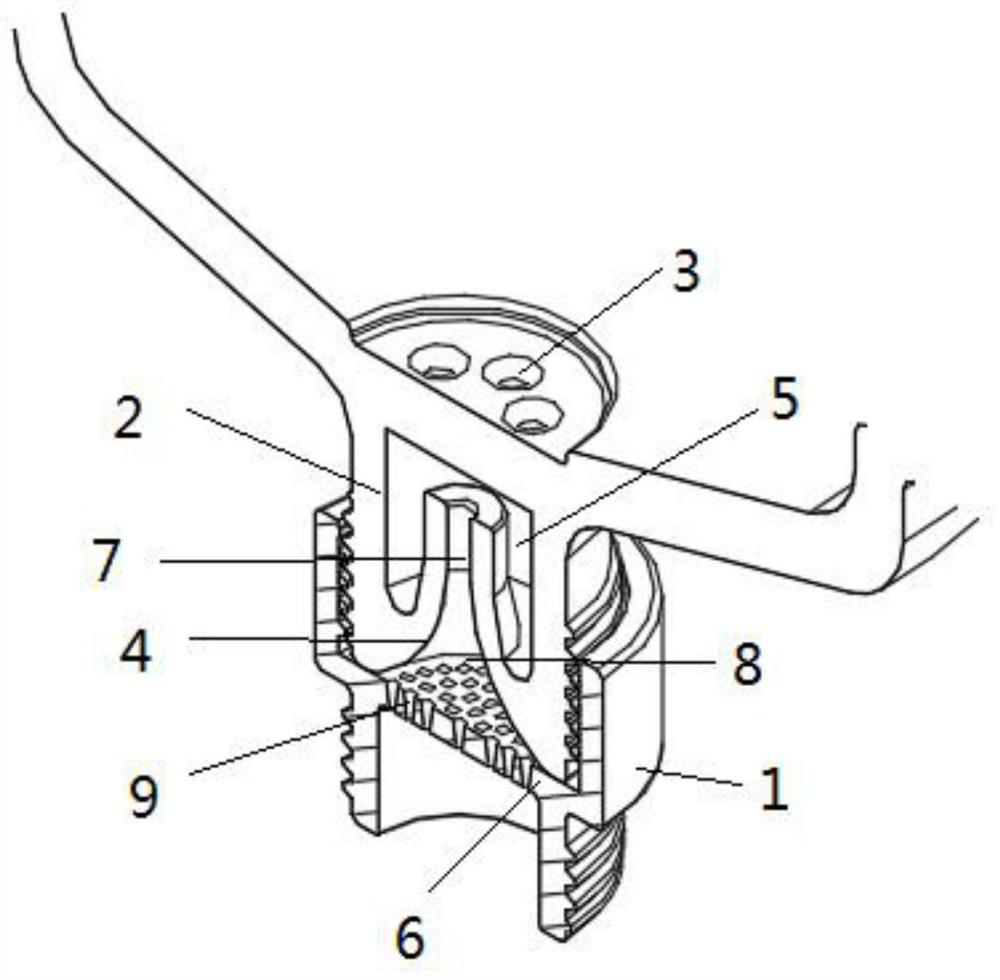

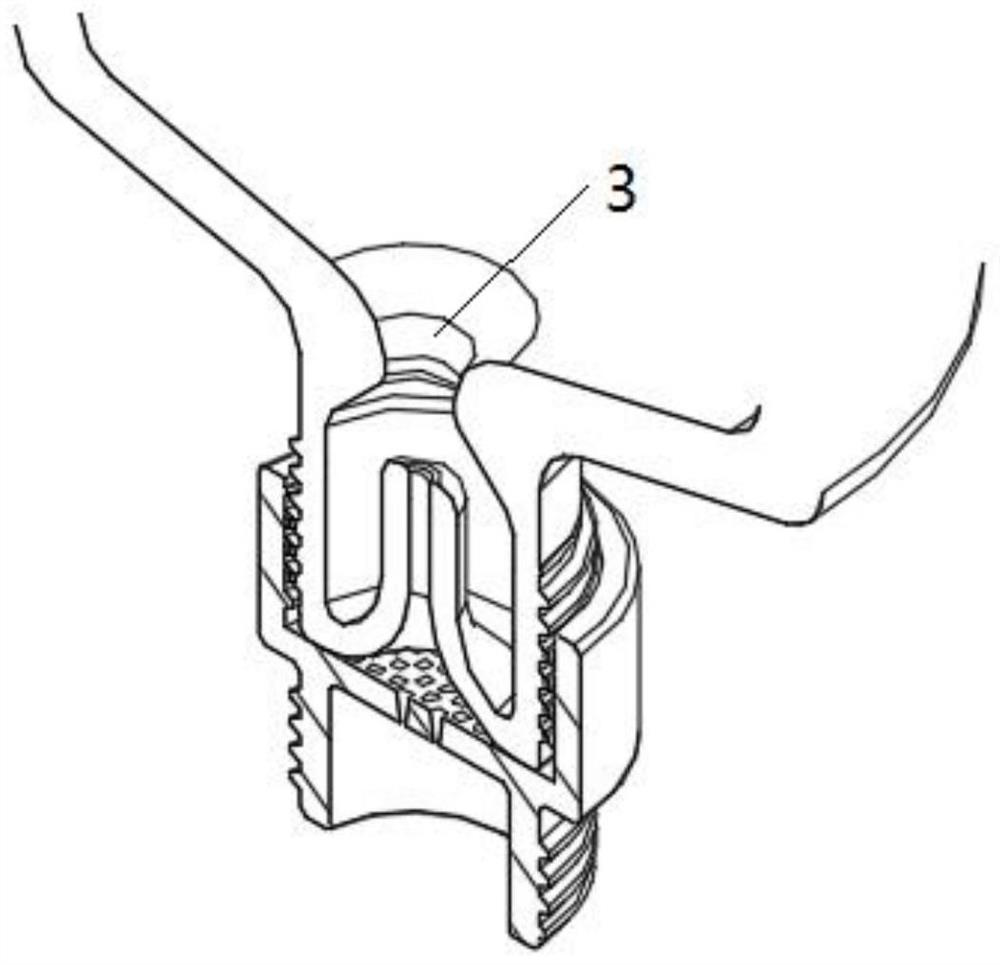

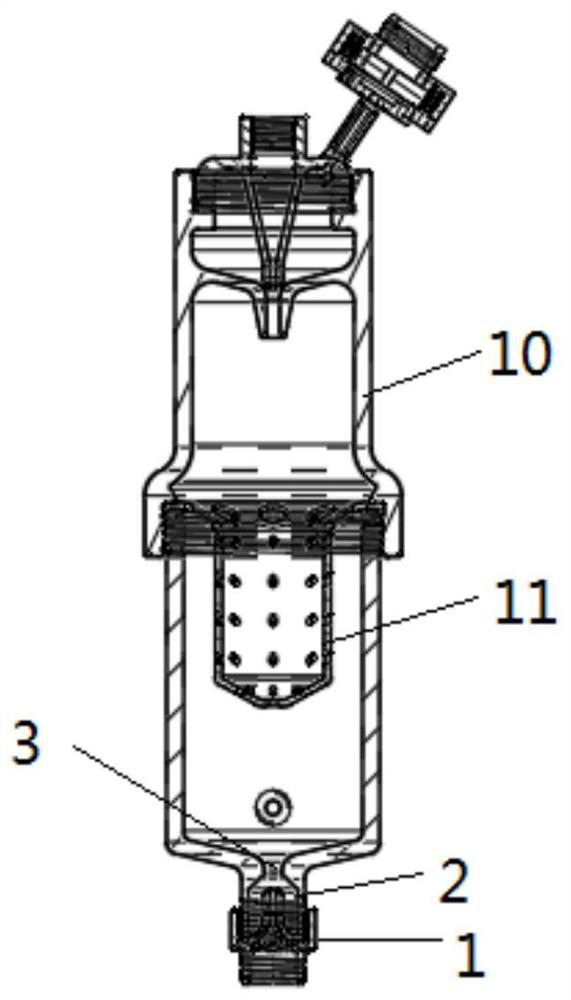

Micro-nano foaming mechanism and micro-nano bubble water device

PendingCN113368718AFully evenly distributedIncrease contentFlow mixersMixing methodsMicro nanoEngineering

The invention relates to the technical field of bubble water preparation devices, in particular to a micro-nano foaming mechanism and a micro-nano bubble water device. The micro-nano bubbling mechanism comprises a bubbler and a vortex structure, the vortex structure is provided with a first inlet and a first outlet, a vortex cavity is formed in the vortex structure, the first inlet is communicated with the vortex cavity, the bubbler comprises a body and a bubbling piece, the body is provided with a second inlet and a second outlet, the first outlet is communicated with the second inlet, a bubbling opening is formed in the bubbling piece, and a gas-liquid mixture entering the body flows into the second outlet through the bubbling opening. When the mixed gas-liquid mixture enters the vortex cavity of the vortex structure from the first inlet to form vortex, due to the vortex effect of the vortex structure, gas in the gas-liquid mixture flowing out of the first outlet is evenly distributed and high in content, and therefore micro-nano bubble water with evenly distributed and high content of micro-nano bubbles is formed after the gas-liquid mixture is rapidly cut through the bubbling opening.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

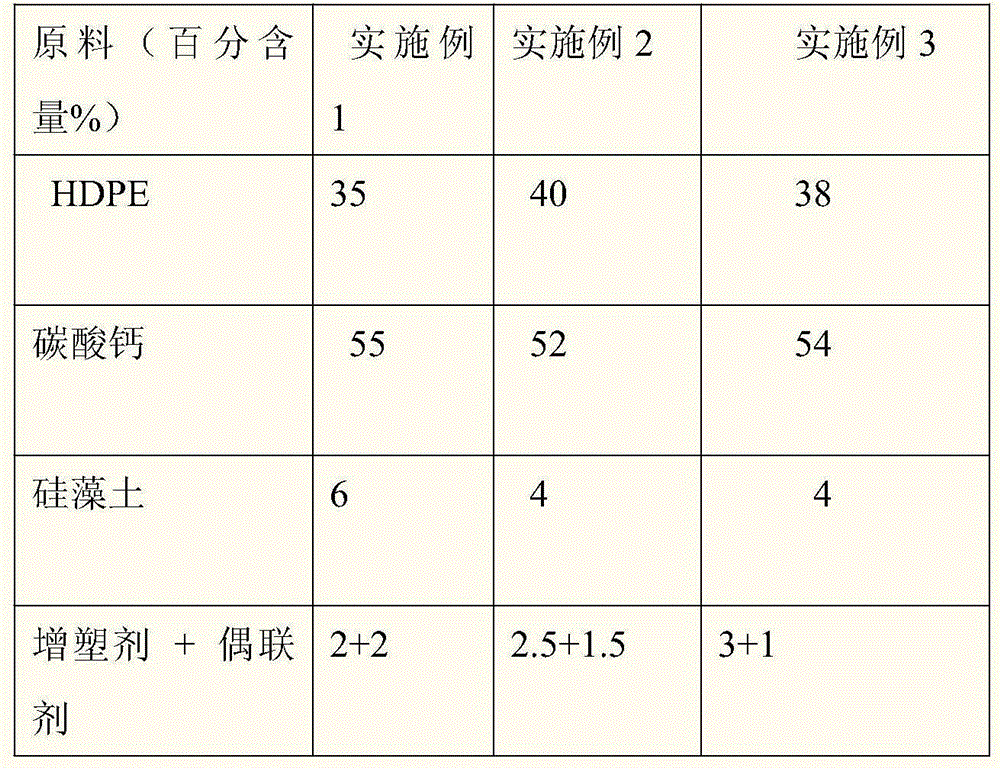

High density polyethylene and diatomite composite material for cushion packaging and preparation method thereof

The invention discloses a high density polyethylene and diatomite composite material for cushion packaging and a preparation method thereof. The composite material is characterized by being composed of the following raw materials in percentage by weight: 30 to 40% of high density polyethylene, 50 to 60% of calcium carbonate, 3 to 6% of diatomite, and 2 to 4% of plasticizer and coupling agent. The components are reasonably compounded to generate a synergetic effect, the content of calcium carbonate and the production cost are reduced; at the same time, the high density polyethylene and diatomite can generate a synergetic effect to overcome the shortages of bad low temperature buffering property and easiness in aging, moreover, the ductility is effectively enhanced, and the provided composite material has the advantages of high impact strength, tensile strength, and tear strength, lightness, softness, and good wear-resistant property. The cushion packaging material prepared from the composite material has the advantages of damp and water resistant property, high toughness, difficulty in breaking, and strong impact resistant performance, is dustless, pollution-free, and environment-friendly, and can be recovered and reutilized.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

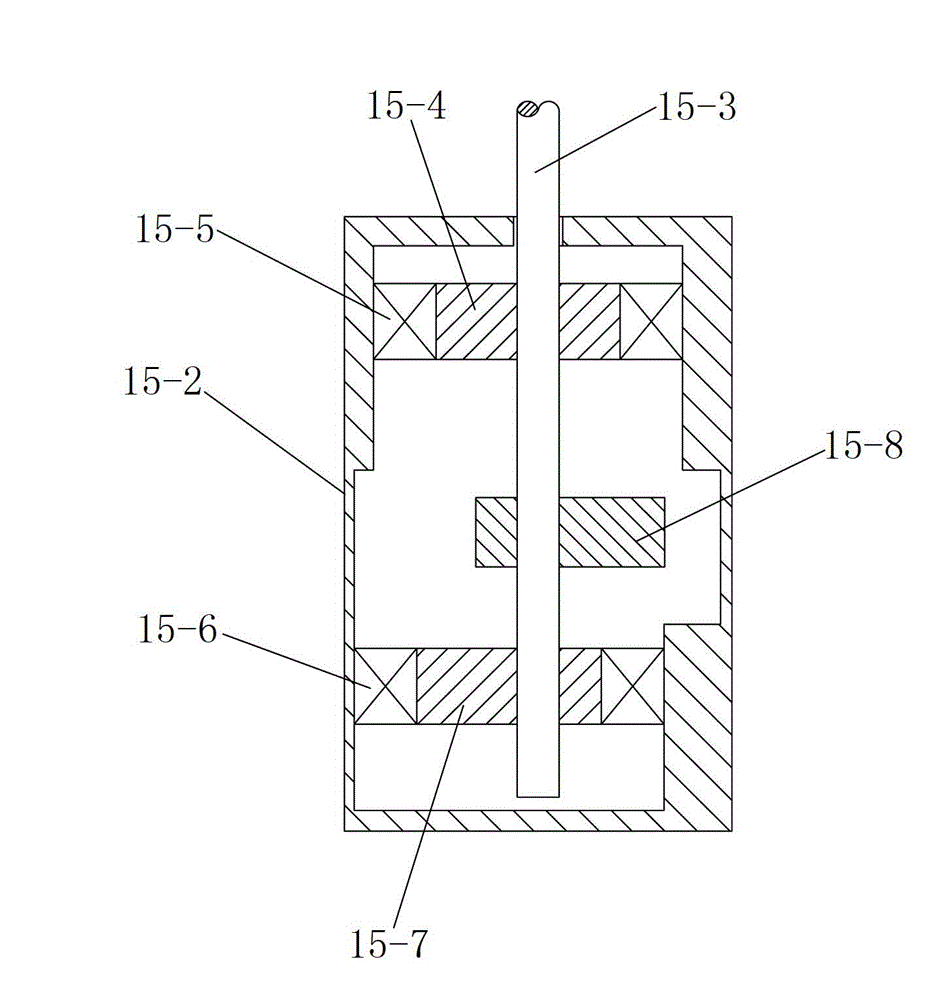

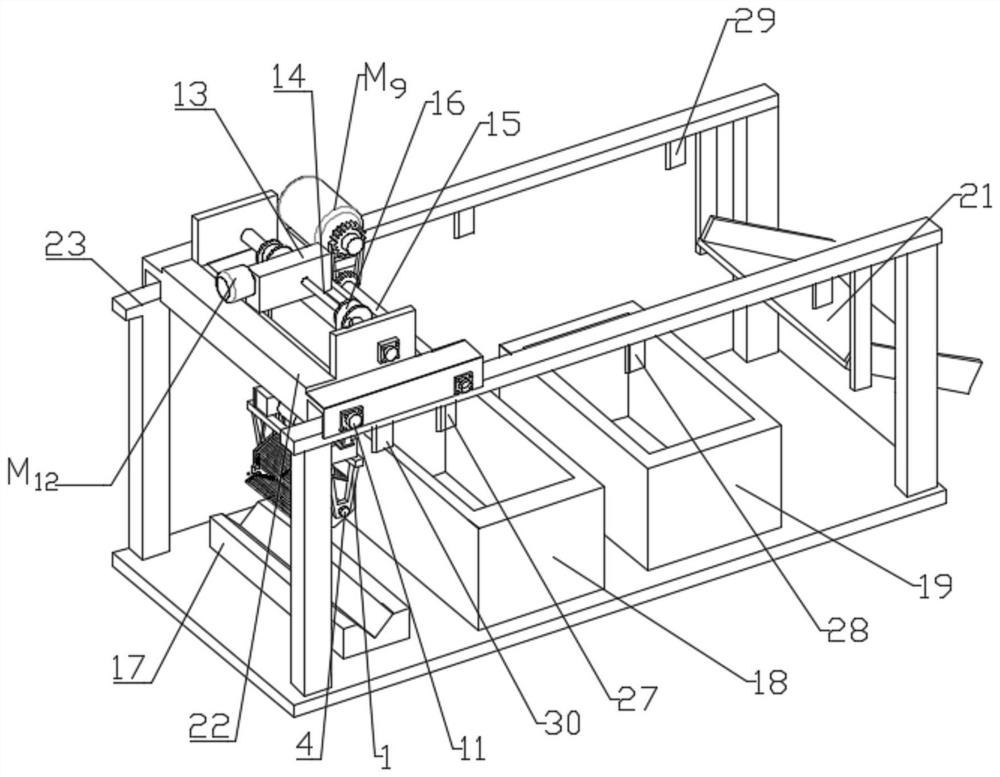

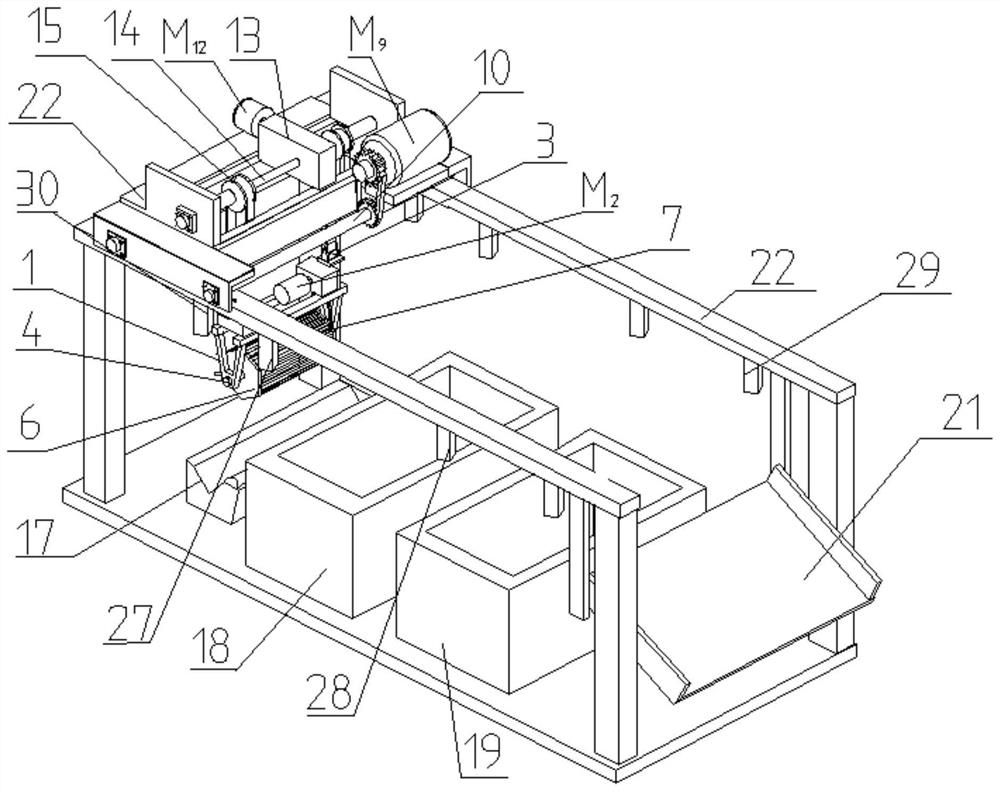

Uniform stirring soil particle suspension device for particle analysis experiment by densimeter method

InactiveCN102590048ASolve the shortage of manual mixingPrevent overflowParticle size analysisSpecific gravity measurementDisplay deviceEngineering

The invention discloses a uniform stirring soil particle suspension device for a particle analysis experiment by a densimeter method. The device comprises a casing, an air pump, a stirring rod, a temperature display, a temperature sensor and a timer, wherein the air pump is arranged in the casing, the temperature display and the timer are disposed on the casing, the stirring rod is connected with the air pump, and the temperature sensor is connected with the temperature display in a circuit mode. The device overcomes defects of manual stirring existing in stirrers in prior experiments. Movement of a suspension is driven by the rising of bubbles which are subjected to electronic control to enable soil particles in the suspension to be fully uniformly distributed, the suspension is effectively prevented from spilling when stirred by the control over bubble amount, and errors in manual measurement are reduced by electronic measurement of time. The measurement of suspension temperature is more accurate, convenient and rapid by addition of the temperature sensor. Compared with prior researches, by means of the device, the operation is simpler and more convenient, the experiment efficiency is increased, and the device is more practical.

Owner:SHANDONG UNIV

Automatic oil immersion device and oil immersion method for pipe fittings

ActiveCN111804524AReduce labor intensityFully evenly distributedHollow article cleaningPretreated surfacesPipe fittingRotation - action

The invention discloses an automatic oil immersion device and oil immersion method for pipe fittings. The automatic oil immersion device comprises a lifting part, a sliding part, a roller part, an oildipping pool and a rack. The sliding part is assembled on the rack and drives the lifting part to move back and forth, and the oil dipping pool is located at the rear end of the rack. The lifting part is matched with the roller part and drives the roller part to move up and down. The roller part comprises a charging bin, a connecting piece and a power piece. The charging bin and the power piece are both arranged on the connecting piece. The power piece drives the charging bin to rotate. The charging bin is of a cage structure. By the adoption of the automatic oil immersion device, the operation steps of oil immersion and oil control work are simplified, the labor intensity of workers is reduced, the efficiency of smearing anti-rust liquid is improved, and the anti-rust liquid covering thepipe fittings is sufficiently and uniformly distributed; and the automatic oil immersion device and the oil immersion method have the beneficial effects that the operation is easy, the oil immersionefficiency is high, and oil immersion is comprehensive.

Owner:HEBEI JIANZHI CASTING GROUP

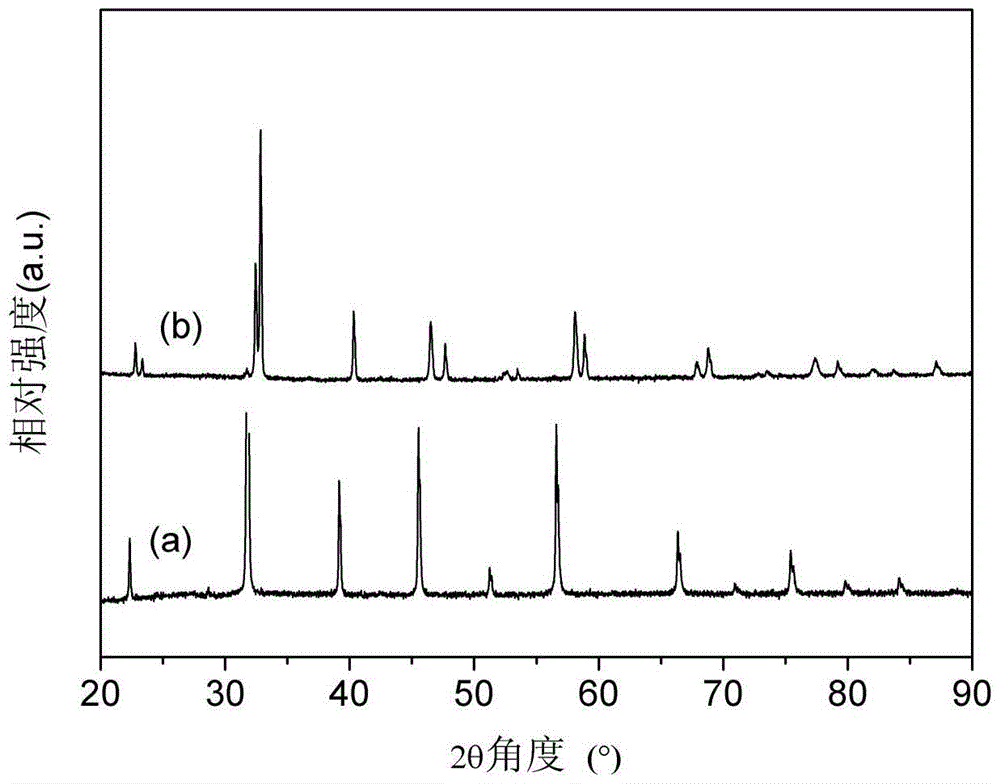

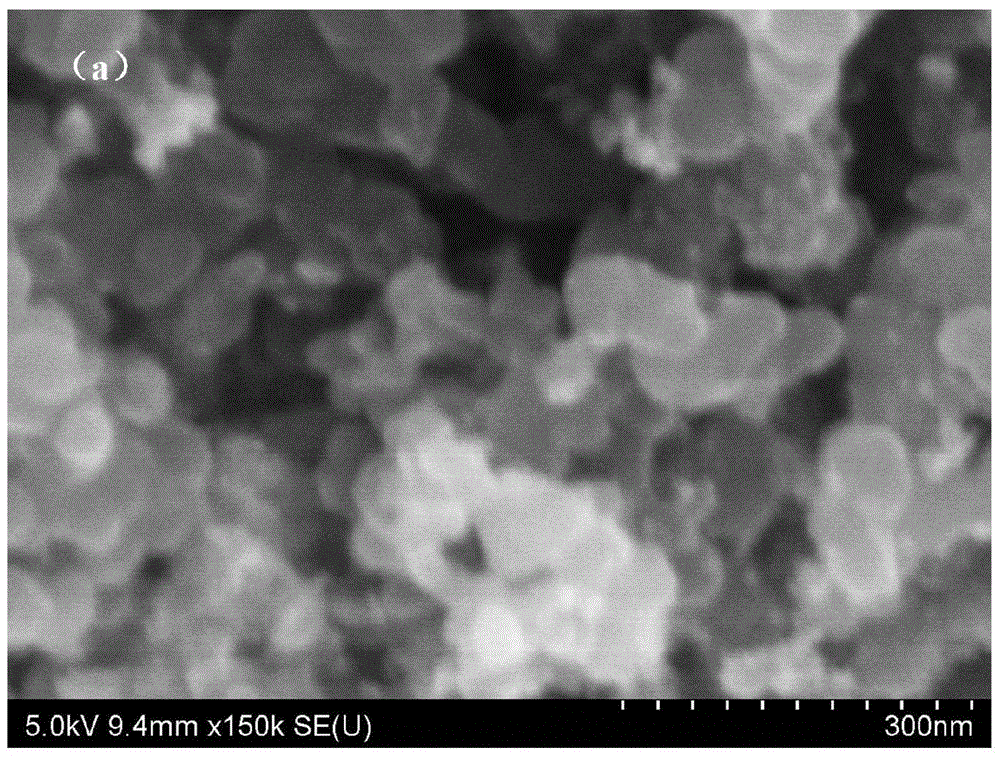

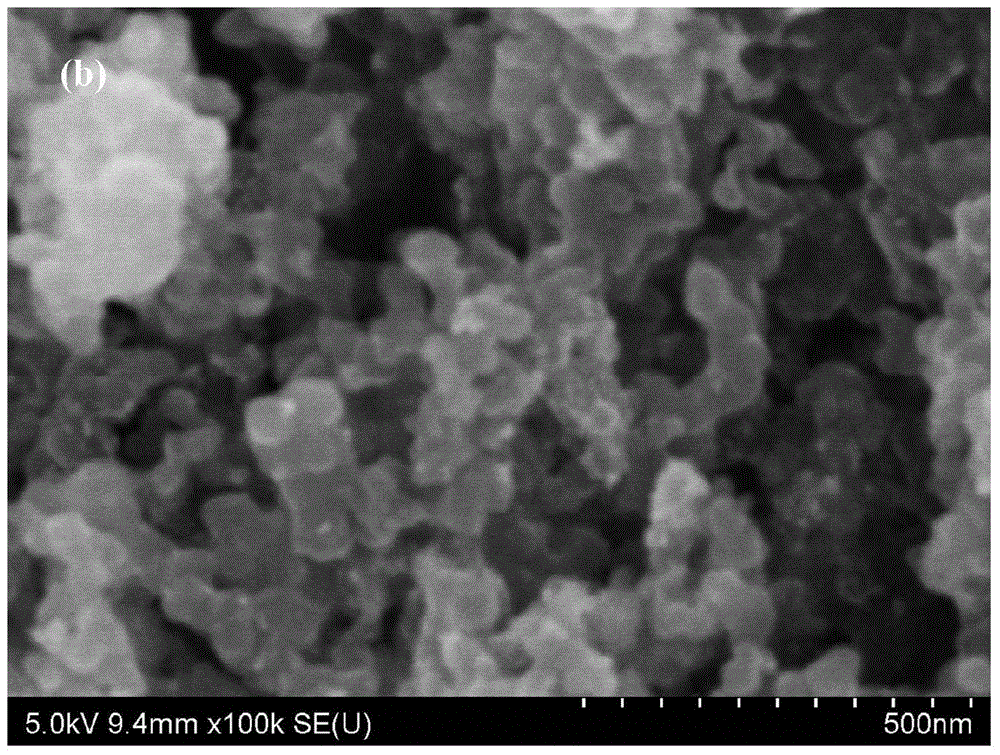

An electrocatalyst mixed with noble metal and perovskite oxide

The invention relates to an electrocatalyst with mixed precious metal and perovskite oxides. The electrocatalyst with mixed precious metal and perovskite oxides is characterized in that precious metal and perovskite oxides are mixed mechanically at different ratios so as to prepare an electrode, thereby obtaining the electrocatalyst with high ORR (oxygen reduction reaction) and OER (oxygen evolution reaction); the single precious metal is an excellent oxygen reduction catalyst, but the catalytic oxygen evolution reaction is relatively poor; the perovskite oxides have relatively high catalytic activity to the oxygen evolution reaction, and have very flow catalytic activity to the ORR. Aiming at the situation, the catalyst obtained by the invention has high ORR and OER activity at the same time only by a simple mixing method, and can act as a double-effect oxygen electrode for the fields of integrated recyclable fuel batteries, chargeable metal-air batteries, water electrolysis and the like.

Owner:辽宁沐与康中氢燃料电池有限公司

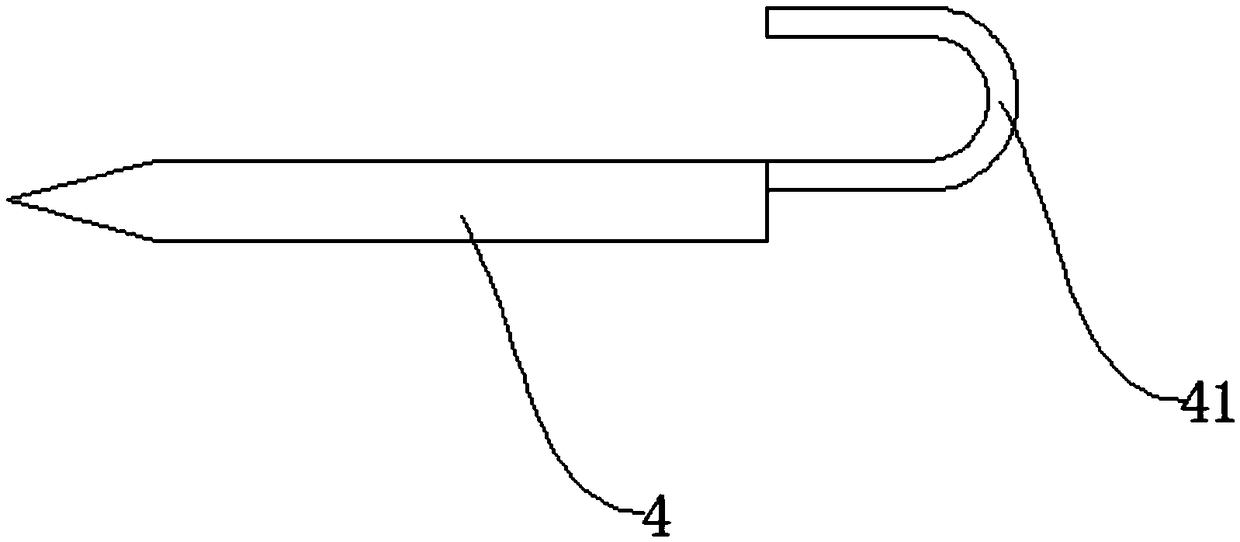

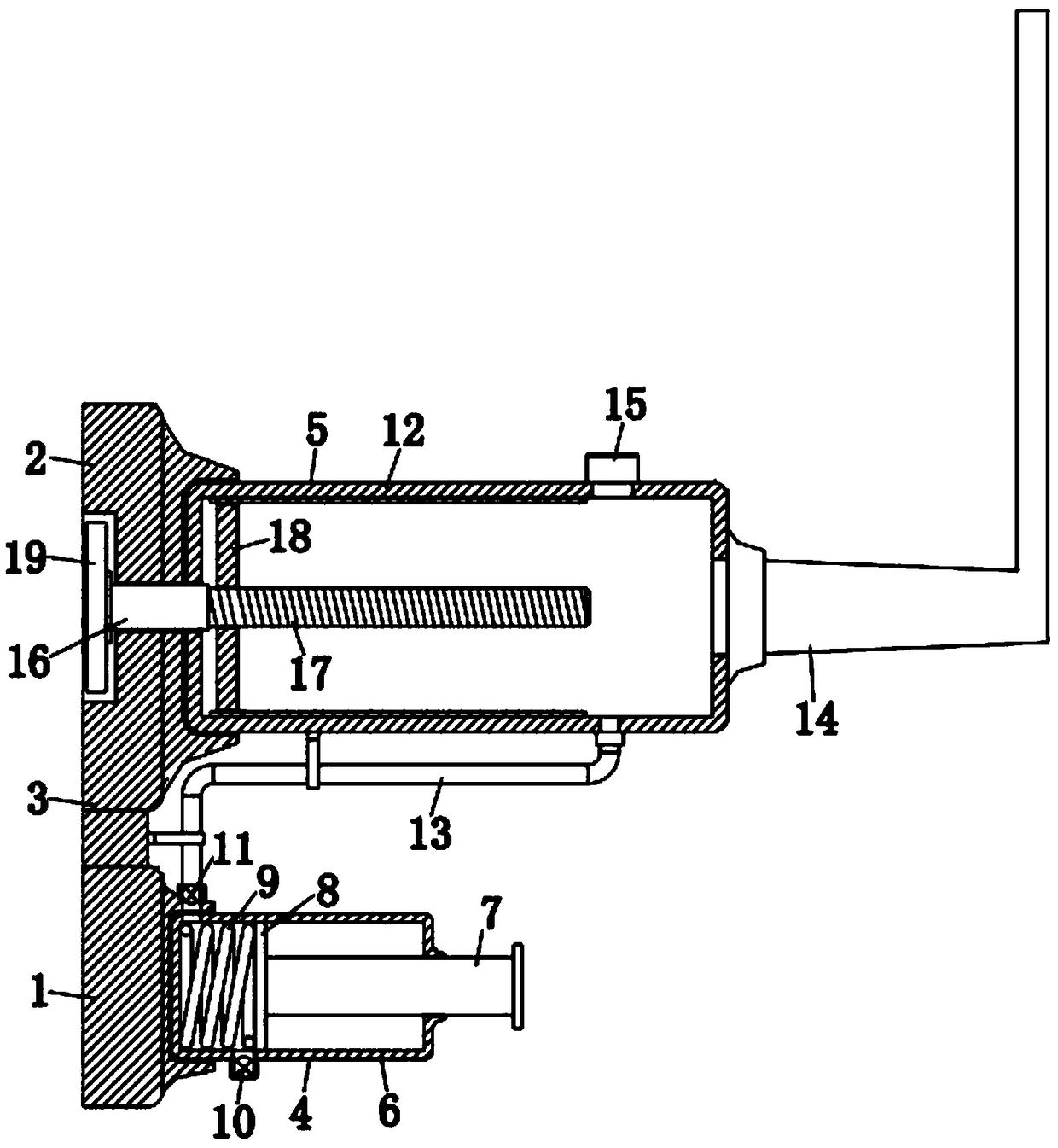

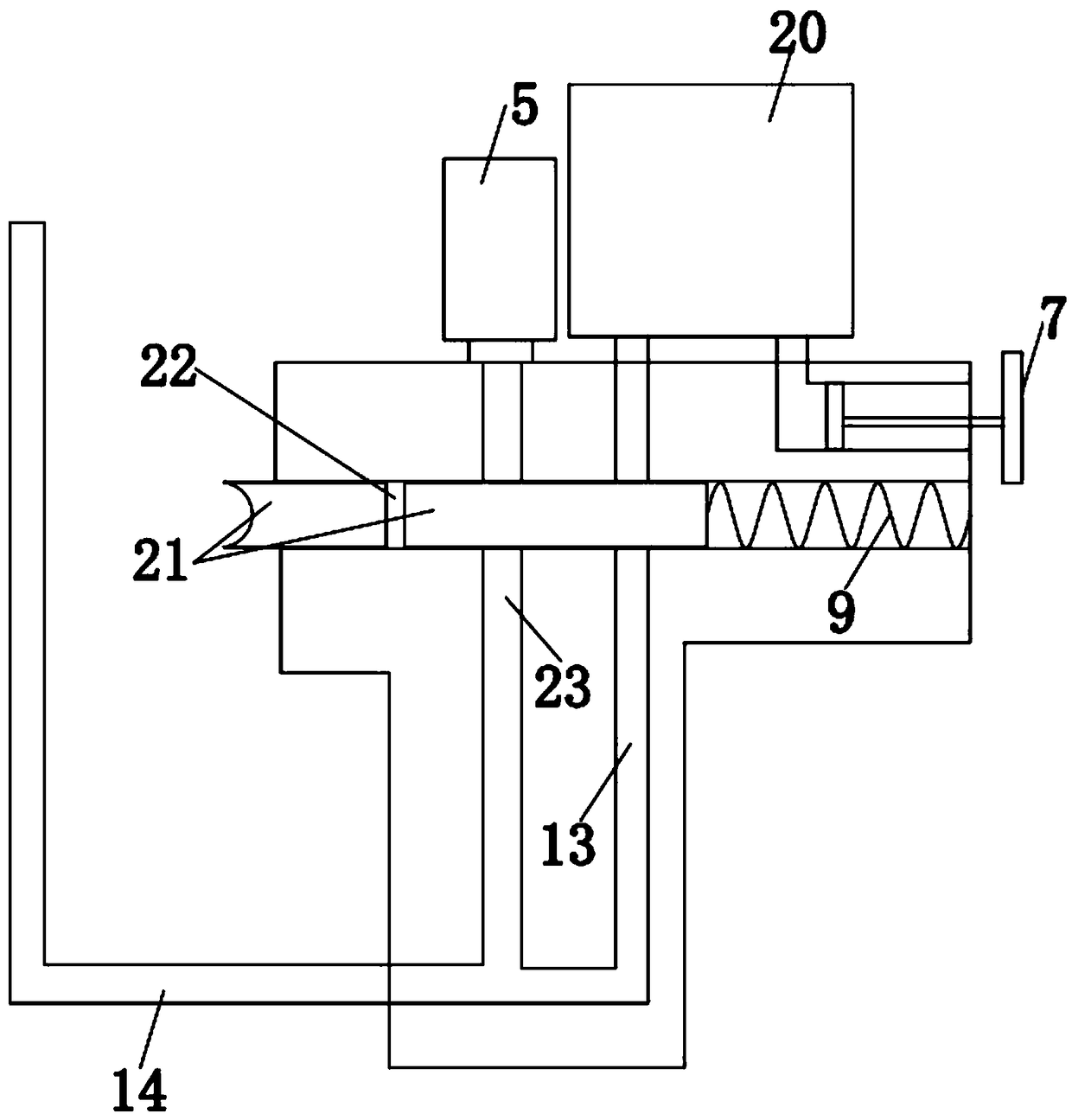

Corn ear pollinator and pollination method thereof

PendingCN108713497AAvoid pollutionAvoid interferenceAgriculturePlant genotype modificationAgricultural engineeringEngineering

The invention discloses a corn ear pollinator and a pollination method thereof, belonging to the technical field of agricultural tools. The corn ear pollinator comprise a sleeve seat, wherein one sidesurface of the sleeve seat is sleeved with an inflation device and a pollen collection device respectively, and the inflation device and the pollen collection device are connected through an air pipe; and a pollen discharging guide pipe is arranged on the pollen collection device and comprises two air venting pipes connected through an air guiding pipe, the two air venting pipes are vertical to each other and form an 'L'-shaped structure, and one air venting pip is connected with the pollen collection device through the air guiding pipe. A use method of the corn ear pollinator is as follows:the corn ear pollinator is adopted, and the air venting pipes far from the pollen collection device in the pollen discharging guide pipe stretch into the bottom of an isolation bag. The invention provides the corn ear pollinator and the pollination method aiming at the problem that an existing pollinator is easily interfered by impurity pollen, the interference of the impurity pollen can be avoided, and the descendant gene purity can be guaranteed.

Owner:INST OF TOBACCO ANHUI ACADEMY OF AGRI SCI

Novel anti-oxidation filling rope and preparation method thereof

InactiveCN110183776AStabilizing Antioxidant PropertiesImprove antioxidant capacityTextile cablesWaxAntioxidant

The invention discloses a novel anti-oxidation filling rope. The filling rope comprises the following components: 20-30 parts of polypropylene, 2-4 parts of oxidized wax, 75-85 parts of calcium carbonate, 0.8-1.5 parts of stearic acid, 0.5-1.5 parts of a 1035 antioxidants, 1-2 parts of industrial white oil, and 1-2.5 parts of a coupling agent. The preparation method comprises the following steps:the raw materials are mixed at a high speed, extrusion is performed to obtain a film, the film is stretched, opening is performed, rolling is performed, and finally twisting is performed to form a required size. According to the cable filling rope and the preparation method of the filling rope provided by the invention, the cable filling rope can avoid the problem of oxidation of a cable metal copper tape shield layer caused by a filling rope in a moisture environment with sufficient water.

Owner:广西纵览线缆集团有限公司

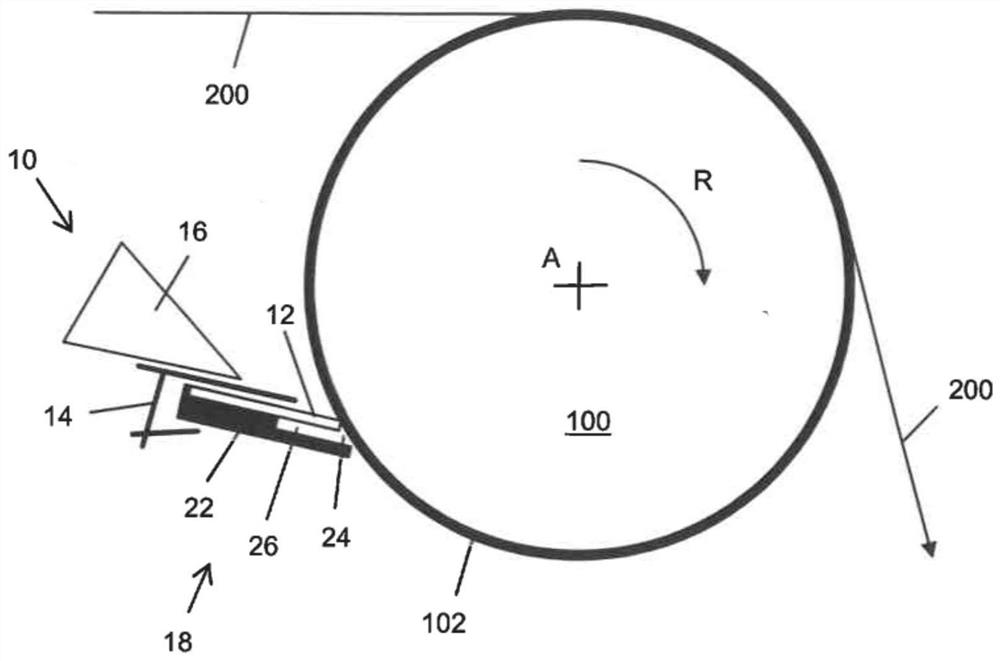

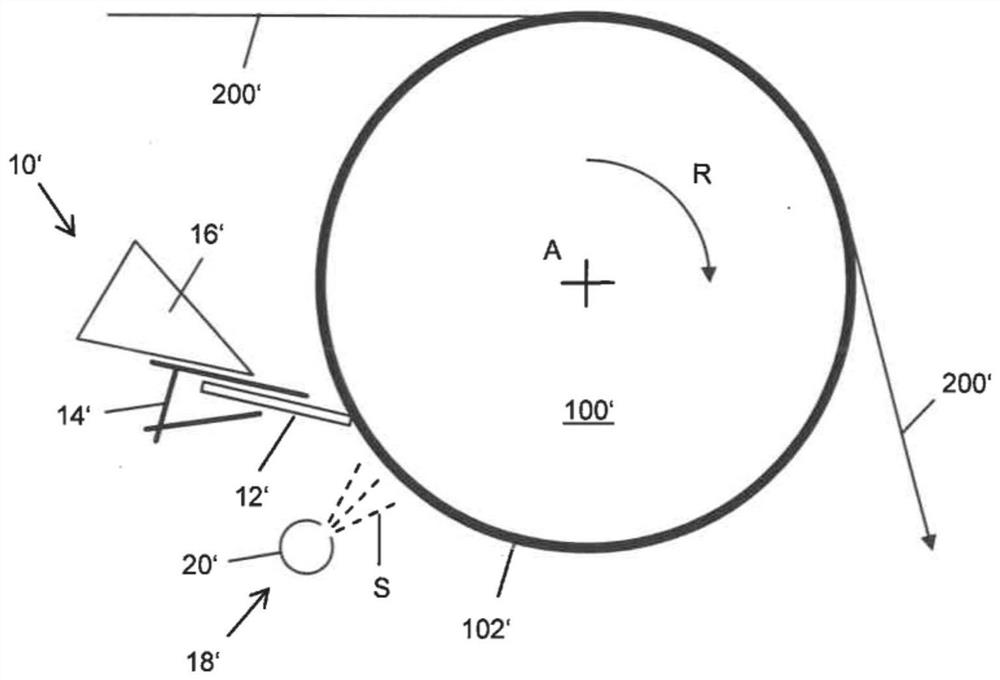

Scraper with water lubricating performance

InactiveCN111637351AReduced risk of cloggingFully lubricatedCleaning using toolsDoctorsEnvironmental geologyStructural engineering

The invention relates to a cleaning device (10), which is used to clean the surface (102) of a roller (100) that rotates in a machine that is used to cleanly produce a fibrous web, in particular, a paper web, a paperboard wed, or a cotton web. The cleaning device comprises a scraper blade (12) that points to the surface (102) of the rotating roller (100) and a lubricant applying device (18). Alonga direction that is opposite to the rotation direction (R) of the rotating roller (100), the lubricant applying device applies a lubricant on the surface (102) of the rotating roller (100) at a peripheral position that is in front of the scraper blade (12). The lubricant applying device (18) comprises an elongated nozzle silt (24); and the nozzle silt basically extends in the whole length of thescraper blade (12) and is arranged as the end, which is directly adjacent to the scraper blade (12), of the surface (102) of the rotating roller (100).

Owner:VOITH PATENT GMBH

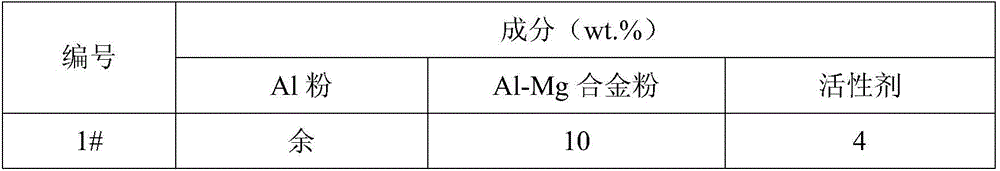

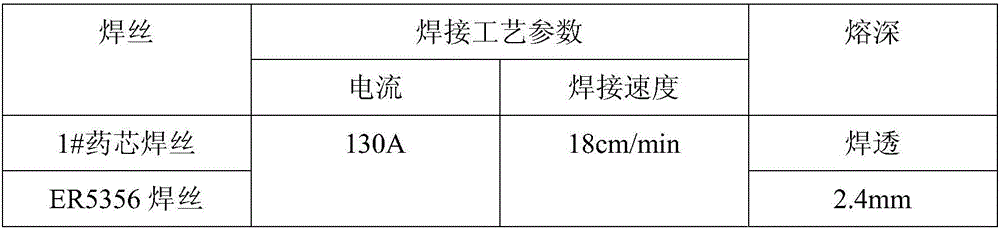

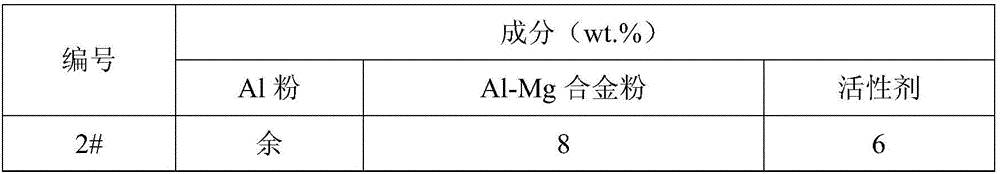

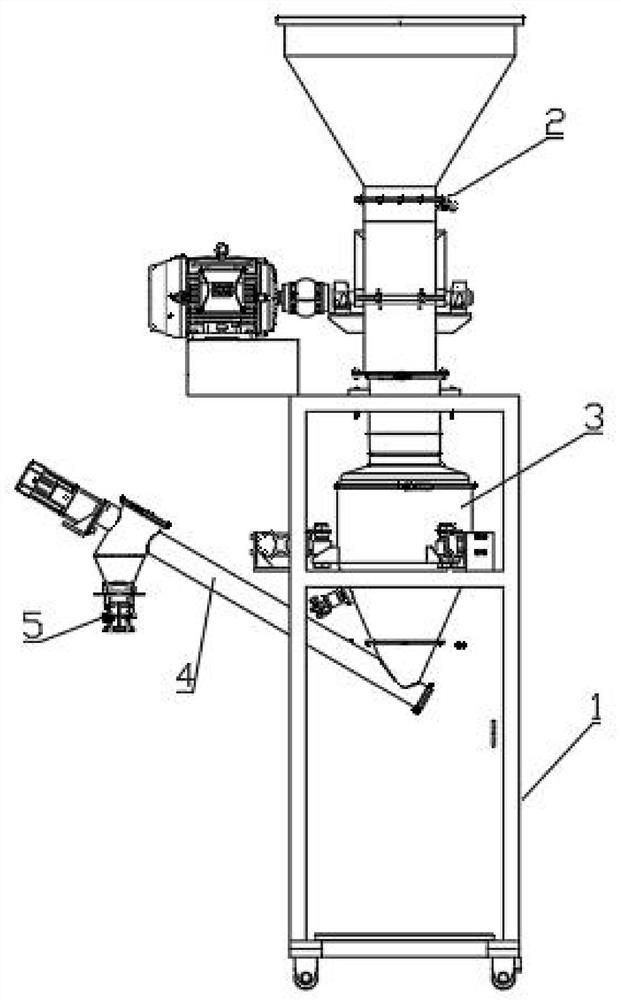

Method for manufacturing aluminum alloy flux-cored wire by utilizing powder sheath extrusion blank-making method

ActiveCN106624472AFully evenly distributedQuality improvementWelding/cutting media/materialsSoldering mediaPorosityFlux-cored arc welding

The invention relates to a method for manufacturing an aluminum alloy flux-cored wire by utilizing a powder sheath extrusion blank-making method. The powder is composed of an activating agent, aluminum powder and aluminum magnesium alloy powder. A sheath is made from aluminum. The method comprises the following steps of: ball-milling and mixing the powder, and then filling into the sheath, heating and vacuumizing; performing thermal compressing, thermal extrusion, rolling and cold drawing, thereby acquiring a flux-cored wire. The flux-cored wire manufactured according to the method is characterized by uniform distribution of the activating agent in the flux-cored wire; the process is simple; the cost is lower; when the flux-cored wire manufactured according to the method provided by the invention is used for welding the aluminum magnesium alloy, the pre-welding cleaning process can be simplified and the weld porosity can be eliminated; the fusion depth is more than 1.6 times of the fusion depth achieved by using a common aluminum alloy welding stick for welding; the joint strength performance is excellent.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Solanum pseudocapsicum inoculation method based on hericium erinaceus cultivation

InactiveCN112314332AWell mixedSimple structureCultivating equipmentsMushroom cultivationBiotechnologyMicrobiology

The invention discloses a solanum pseudocapsicum inoculation method based on hericium erinaceus cultivation. The method comprises the following steps of inoculating coralloid hericium erinaceus flowers onto a mother strain culture medium through tissue separation, carrying out mother strain culture under aseptic conditions, according to the following culture condition, sleeving an opening of a fungus bag on the outer wall of a bottom cylinder, enaling two groups of connecting rods to be close to each other, driving a movable plate to rotate along a lower fixed plate, and enabling two groups ofjackets to clamp and fix the fungus bag on the bottom cylinder; then, starting a feeding motor to drive a feeding screw to rotate, inputtng a mixture in a mixing tank into a discharging pipe along aspiral feeding pipe, then, enabling the mixture to enter the fungus bag along a connecting funnel and the bottom cylinder, then controlling an air cylinder to work, taking down the fungus bag from thebottom cylinder, sterilizing the fungus bag, after sterilizing, inoculating the mother strain under the aseptic condition, and obtaining a coralloid hericium erinaceus mother strain; and culturing the inoculated fungus bag in a dark place, and inoculating the coralloid hericium erinaceus. According to the method, the inoculation efficiency of the coralloid hericium erinaceus is greatly improved.

Owner:安徽亲耳菌业科技股份有限公司

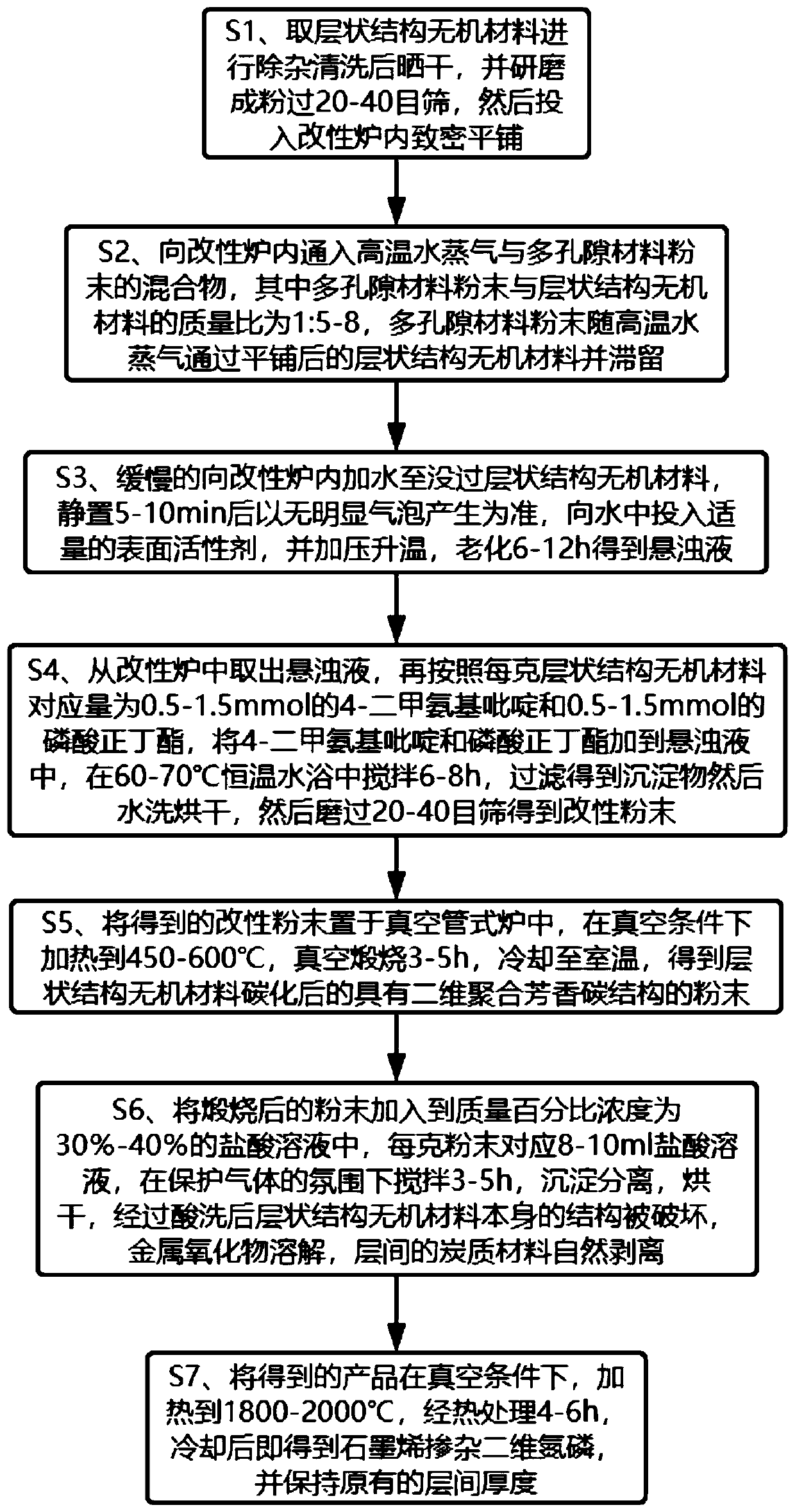

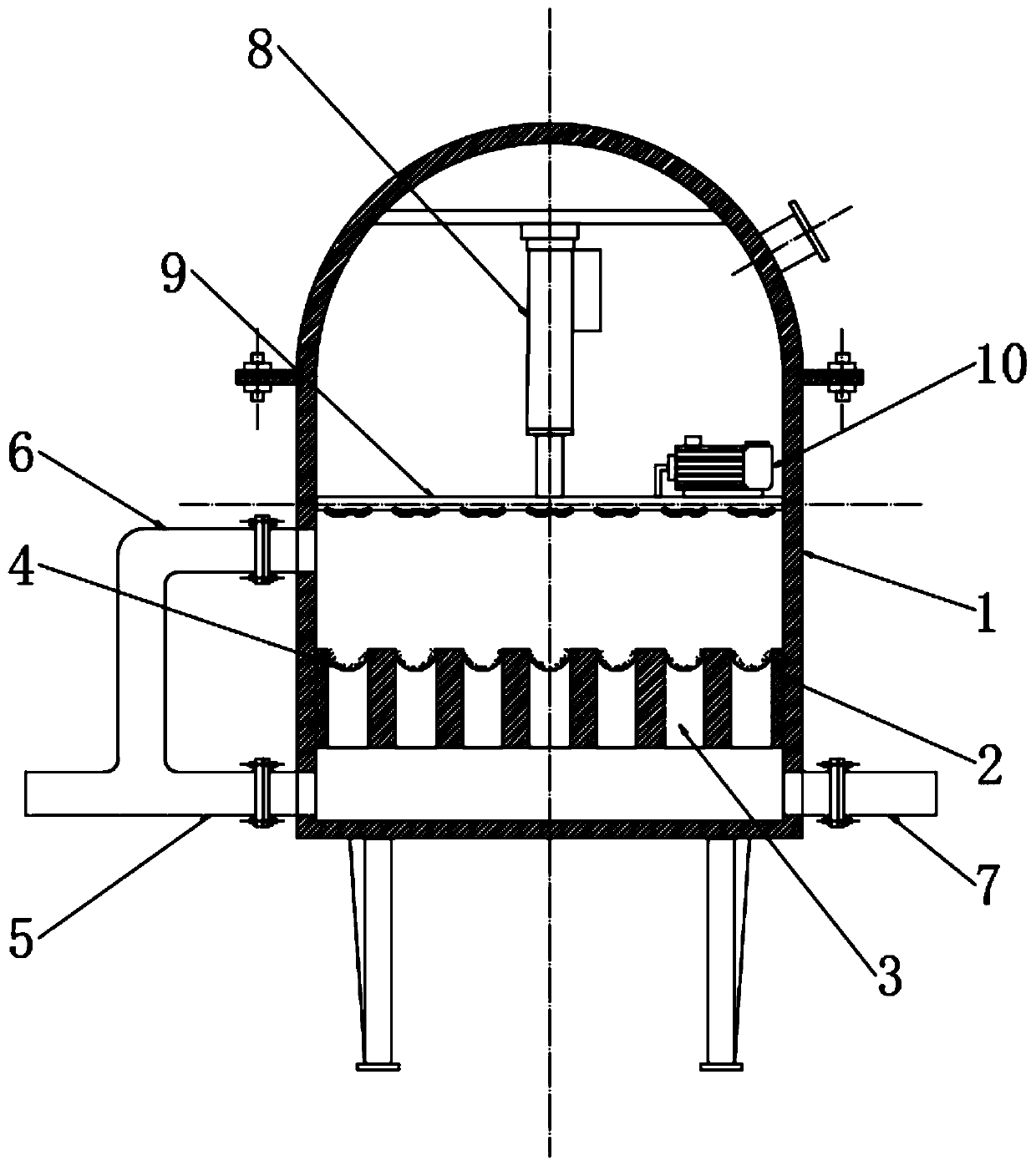

Preparation method of graphene-doped two-dimensional nitrogen and phosphorus

ActiveCN111377439APlay a role in expanding holesStrong ion exchange performanceCarbon compoundsEnergy inputActivated carbonActive agent

The invention discloses a preparation method of graphene-doped two-dimensional nitrogen and phosphorus, which belongs to the technical field of graphene preparation. The modification on an inorganic material based on a layered structure can be realized; while high-temperature steam is adopted for physical modification, pores are filled with activated carbon materials; a surfactant is used to perform surface active treatment, air in micropores in the activated carbon material overflows under the extrusion of water to form tiny bubbles; then, huge energy is released by collapsing and exploding in pores of the inorganic material with the layered structure, which has a pore expanding effect on the layered structure inorganic material, the overall porosity and mesoporous fraction are increased,the ion exchange effect of the layered structure inorganic material can be promoted, subsequent nitrogen-phosphorus atoms can be distributed more sufficiently and uniformly, and the performance of graphene-doped two-dimensional nitrogen and phosphorus is remarkably improved.

Owner:YANAN UNIV

Full cross-section tunnel heading machine hinged type grouting joint

PendingCN108661656AImprove stabilityAvoid easy cloggingUnderground chambersTunnel liningEngineeringFlange

The invention provides a full cross-section tunnel heading machine hinged type grouting joint. The full cross-section tunnel heading machine hinged type grouting joint comprises a spherical hinge front seat fixed to a fixed block through a first connecting assembly and a spherical hinge rear seat installed on the ball head portion of a spherical hinge in a sleeving mode. The spherical hinge rear seat is fixed to the spherical hinge front seat through an adjusting connecting assembly, and a matching cavity rotatably matched with the spherical hinge is formed in the spherical hinge front seat and the spherical hinge rear seat. A first spherical hinge seal is arranged between the spherical hinge front seat and the ball head portion, and a second spherical hinge seal is arranged between the spherical hinge rear seat and the ball head portion. A first flange disc used for being connected with a grouting pipe is arranged at the tail end of the connecting part of the spherical hinge. A lubricating nipple used for injecting grease into the matching cavity is arranged on the spherical hinge front seat. When the grouting joint is used for grouting, grout between segments and soil is not prone to being blocked so that the grout can be fully distributed between the segments and the soil, the stability between the segments is strengthened, the ground is protected from collapsing, work efficiency is improved, and resources and costs are reduced.

Owner:辽宁三三工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com