High density polyethylene and diatomite composite material for cushion packaging and preparation method thereof

A high-density polyethylene and composite material technology, applied in the field of polymer materials, can solve the problems of easy aging, low corrugated adhesion, low heat resistance temperature, etc., and achieves the effect of toughness, stable performance, and improved ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] (1) First dry the diatomite at 110-115°C until the moisture reaches 0.6%;

[0020] (2) Place high-density polyethylene in a high-speed mixer, and simultaneously add a plasticizer and a coupling agent in a formula ratio, mix for 6 minutes at a speed of 450-500r / min, and make a mixture A;

[0021] (3) the diatomite after step (1) drying is mixed with the calcium carbonate of formula proportion, makes mixture B;

[0022] (4) Mix compound A and compound B evenly, banbury in a banbury mixer, banbury temperature is 150-155 ℃, time is 12min; 155° C. for 10 minutes; and finally calendering in a four-roll calender (tablet press) at a calendering temperature of 140-145° C. to obtain a sheet after calendering.

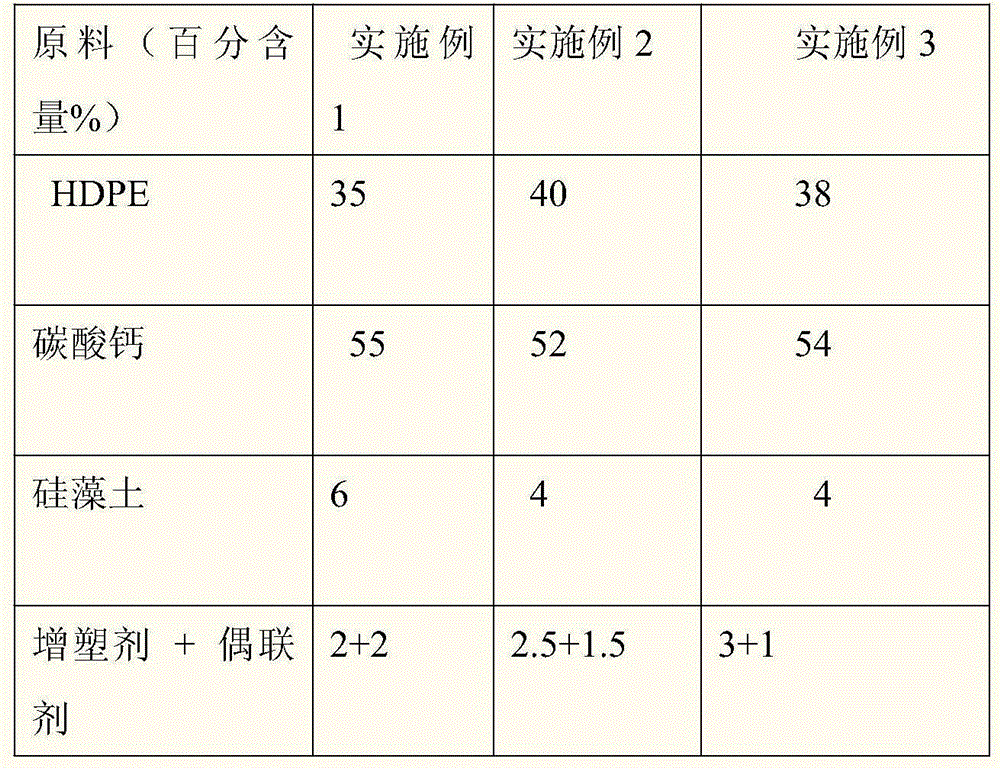

[0023] Concrete raw material ratio is as shown in table 1:

[0024] Table 1

[0025]

[0026] The sample that above-mentioned embodiment 1-3 of the present invention prepares, its mechanical property is as shown in table 2:

[0027] Table 2 Sample performance retrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com