High-abrasion-resistance and impact-resistance niobium and titanium microalloying high-carbon alloy steel and production method thereof

A high-carbon alloy steel and micro-alloying technology, applied in the field of high-carbon alloy steel, can solve the problems of improper chemical composition design, unstable product quality, and narrow production process window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

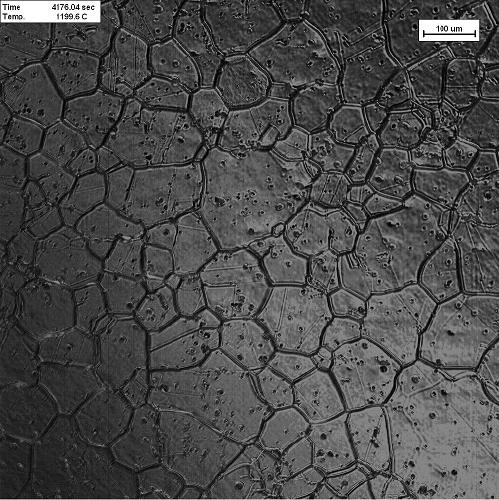

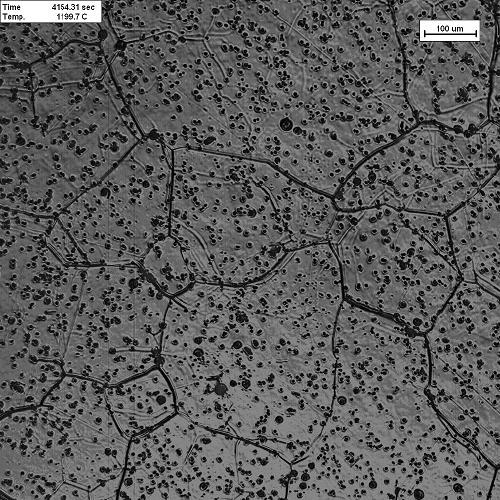

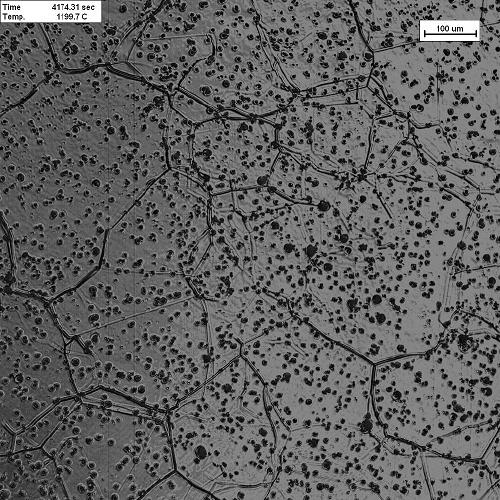

Image

Examples

Embodiment 1

[0079] C: 0.78%, Si: 0.29%, Mn: 0.93%, P: 0.012%, S: 0.008%, Ni: 0.08%, Cr: 0.86%, Al: 0.034%, Nb: 0.042%, Ti: 0.037%, [H]: 0.0001%, [O]: 0.0013%, [N]: 0.003%, and the rest Fe.

[0080] According to the mass percentage of the above components,

[0081] 1) Pre-desulfurization of molten iron: Desulphurization by spraying granular magnesium;

[0082] 2) Converter smelting: Smelting is carried out in a top-bottom double-blown converter with a capacity of more than 90 tons, using molten iron and scrap steel as raw materials for primary smelting, double slag operation to achieve pre-removal of P, and adding 350kg of special refining slag, 450kg of lime, metal Manganese, silicomanganese, high-carbon ferrochrome and other alloys are pre-deoxidized and the composition is initially adjusted, and slag is used to prevent slag from returning to steel;

[0083] 2) Refining: Deep deoxidation and alloying of steel in LF furnaces of more than 90 tons. According to the LF slag condition and t...

Embodiment 2

[0117] C: 0.82%, Si: 0.27%, Mn: 0.92%, P: 0.009%, S: 0.007%, Ni: 0.06%, Cr: 0.76%, Al: 0.035%, Nb: 0.047%, Ti: 0.042 %, [H]: 0.0001%, [O]: 0.0011%, [N]: 0.002, and the rest Fe.

[0118] According to the mass percentage of the above components,

[0119] 1) Pre-desulfurization of molten iron: Desulphurization by spraying granular magnesium;

[0120] 2) Converter smelting: Smelting is carried out in a top-bottom double-blown converter with a capacity of more than 90 tons, using molten iron and scrap steel as raw materials for primary smelting, double slag operation to achieve pre-removal of P, and adding 350kg of special refining slag, 450kg of lime, metal Manganese, silicomanganese, high-carbon ferrochrome and other alloys are pre-deoxidized and the composition is initially adjusted, and slag is used to prevent slag from returning to steel;

[0121] 2) Refining: Deep deoxidation and alloying of steel in LF furnaces of more than 90 tons. According to the LF slag condition and t...

Embodiment 3

[0155]C: 0.68%, Si: 0.35%, Mn: 0.82%, P: 0.013%, S: 0.010%, Ni: 0.06%, Cr: 0.77%, Al: 0.025%, Nb: 0.029%, Ti: 0.023%, [H]: 0.0001%, [O]: 0.001%, [N]: 0.004%, and the rest Fe.

[0156] According to the mass percentage of the above components,

[0157] 1) Pre-desulfurization of molten iron: Desulphurization by spraying granular magnesium;

[0158] 2) Converter smelting: Smelting is carried out in a top-bottom double-blown converter with a capacity of more than 90 tons, using molten iron and scrap steel as raw materials for primary smelting, double slag operation to achieve pre-removal of P, and adding 350kg of special refining slag, 450kg of lime, metal Manganese, silicomanganese, high-carbon ferrochrome and other alloys are pre-deoxidized and the composition is initially adjusted, and slag is used to prevent slag from returning to steel;

[0159] 2) Refining: Deep deoxidation and alloying of steel in LF furnaces of more than 90 tons. According to the LF slag condition and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com