Preparation method of high crystallization thermoplastics type polybutylene terephthalate slice

A polybutylene terephthalate and thermoplastic technology, which is applied in the field of polybutylene terephthalate chips and their preparation, can solve direct production cost and capacity constraints, prolonged production cycle, crystallinity problems such as lowering, to achieve the effect of stable and reliable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

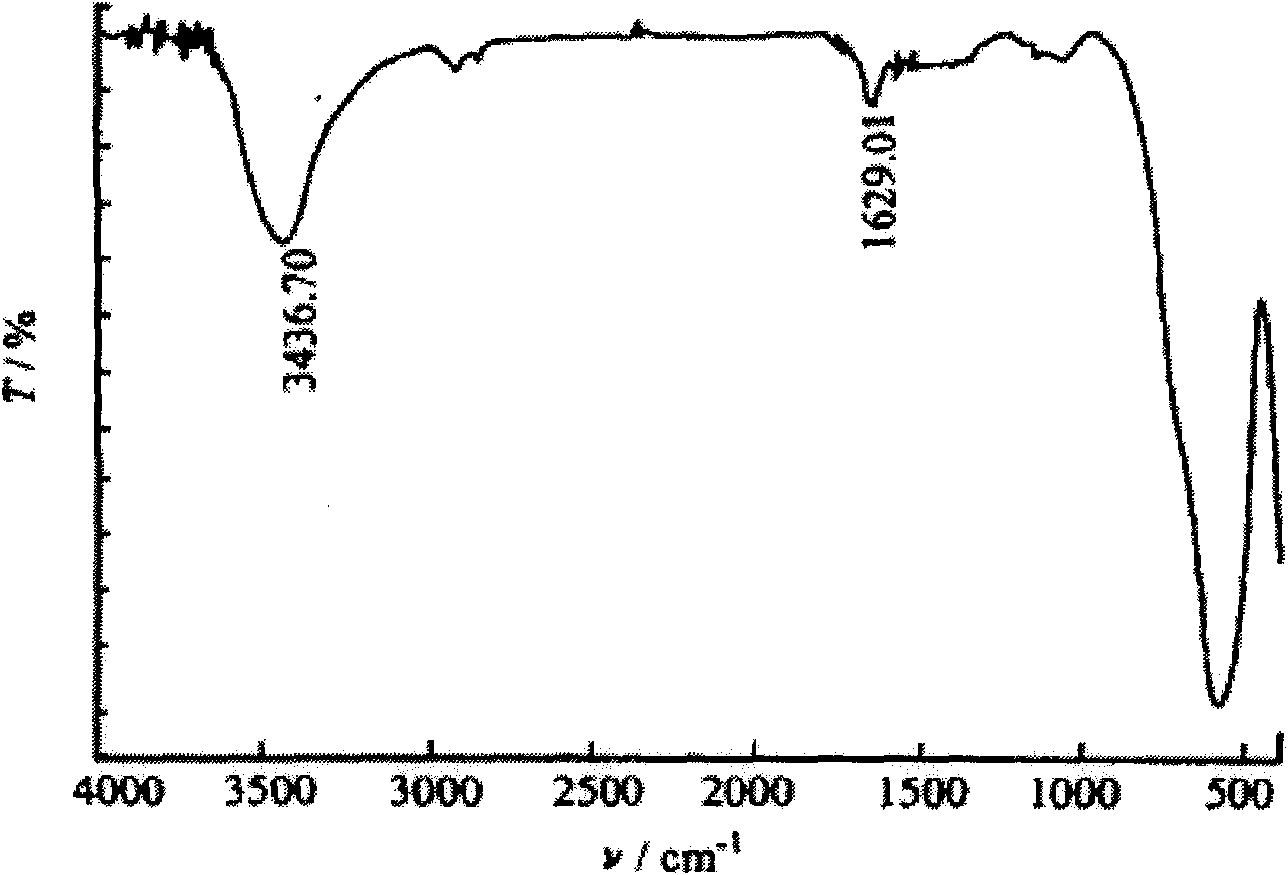

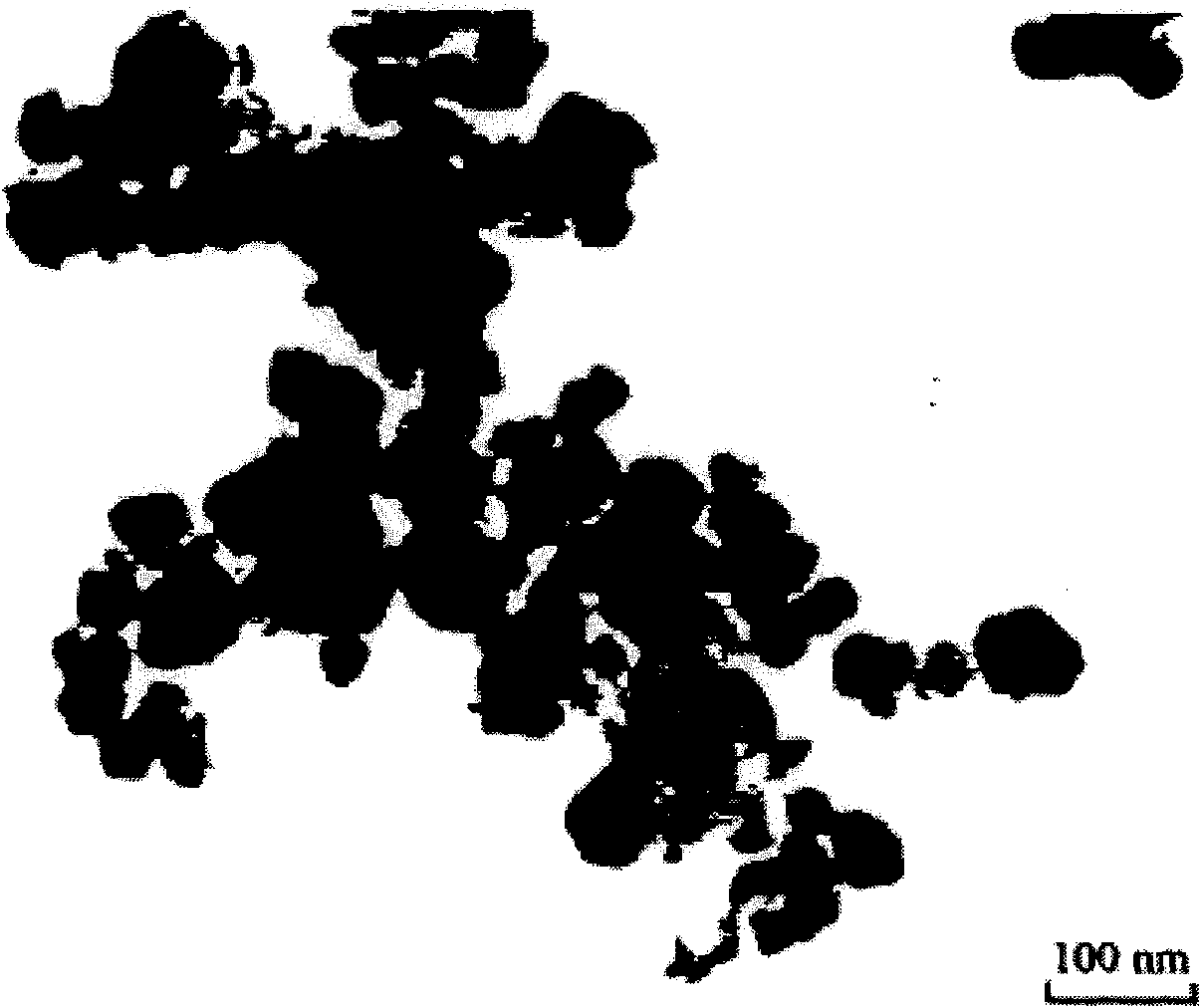

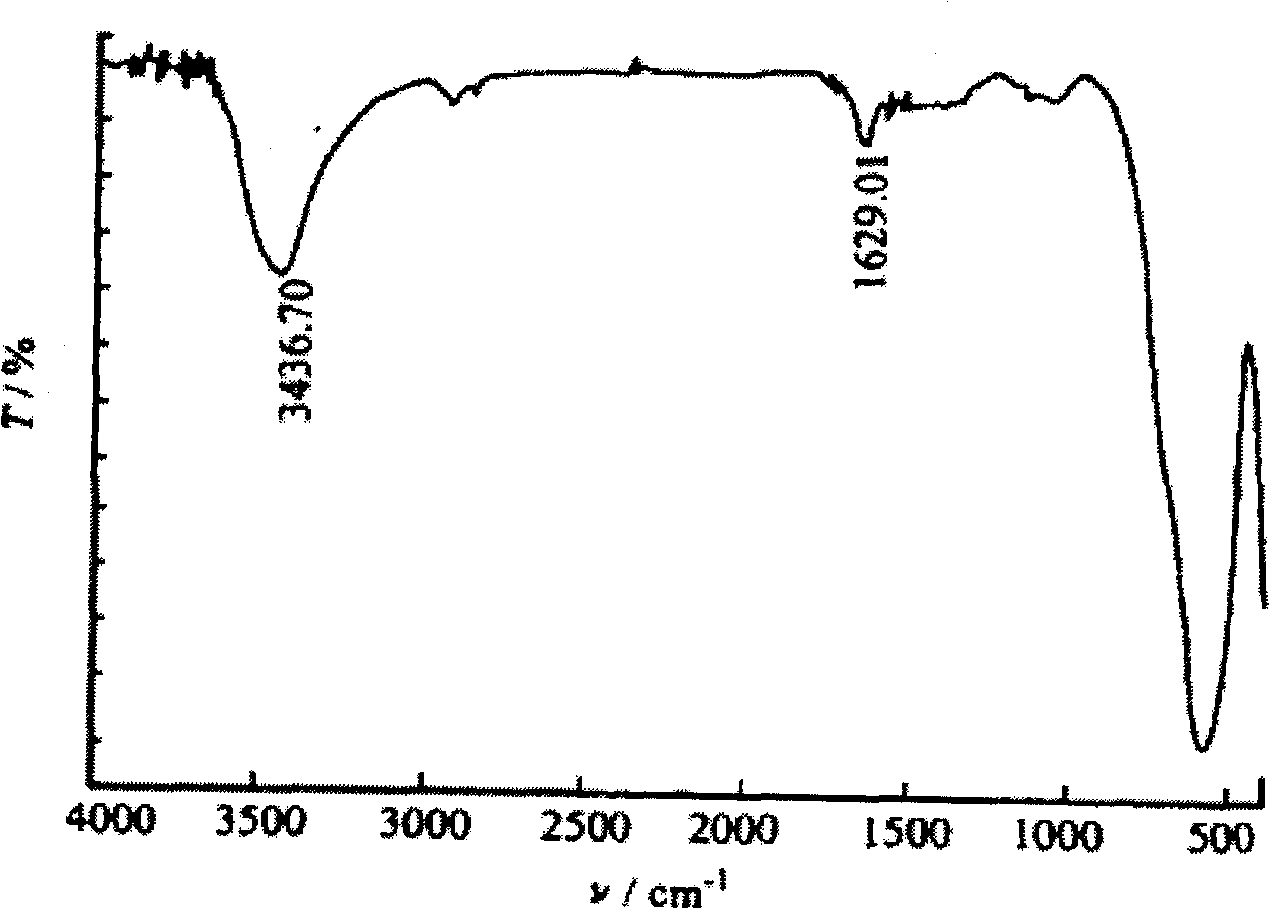

Image

Examples

Embodiment Construction

[0030] The present invention relates to a kind of preparation method of high crystalline thermoplastic polybutylene terephthalate chip, and described method comprises following process:

[0031] Step 1. Mix 10kg tetrabutyl titanate with 990kg1,4-butanediol to prepare a 1% by weight tetrabutyl titanate catalyst solution, mix 10kg nano-titanium dioxide with 990kg1,4-butanediol to prepare 1% by weight of the nano-titanium dioxide catalyst solution, the tetrabutyl titanate catalyst solution and the nano-titanium dioxide catalyst solution are mixed by two metering pumps and a static mixer and injected into the system as a composite catalyst; 10kg talcum powder and 990kg1 , 4 butanediols are mixed, and stirring generates the talcum powder solution of 1% by weight; 1kg cobalt acetate is mixed with 99kg1, 4 butanediols, and the stirring is configured into the cobalt acetate solution of 1% by weight,

[0032] Step 2: Purified terephthalic acid and 1,4 butanediol are added and stirred i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com