Preparation method of graphene-doped two-dimensional nitrogen and phosphorus

A graphene, nitrogen and phosphorus technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as high surface free energy of two-dimensional nanomaterials, loss of electrical properties of graphene, structural defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

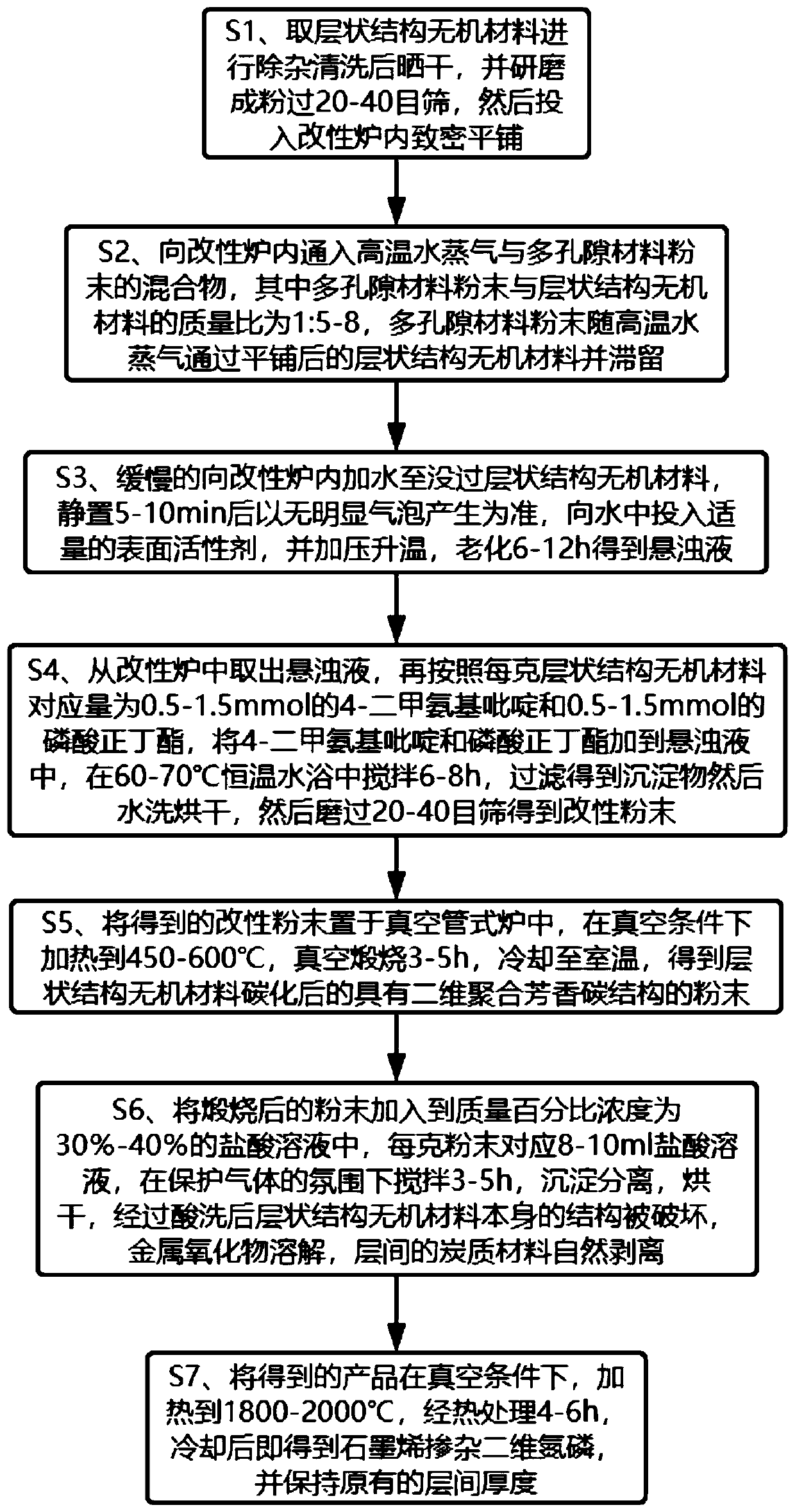

[0046] A preparation method for graphene-doped two-dimensional nitrogen and phosphorus, comprising the following steps:

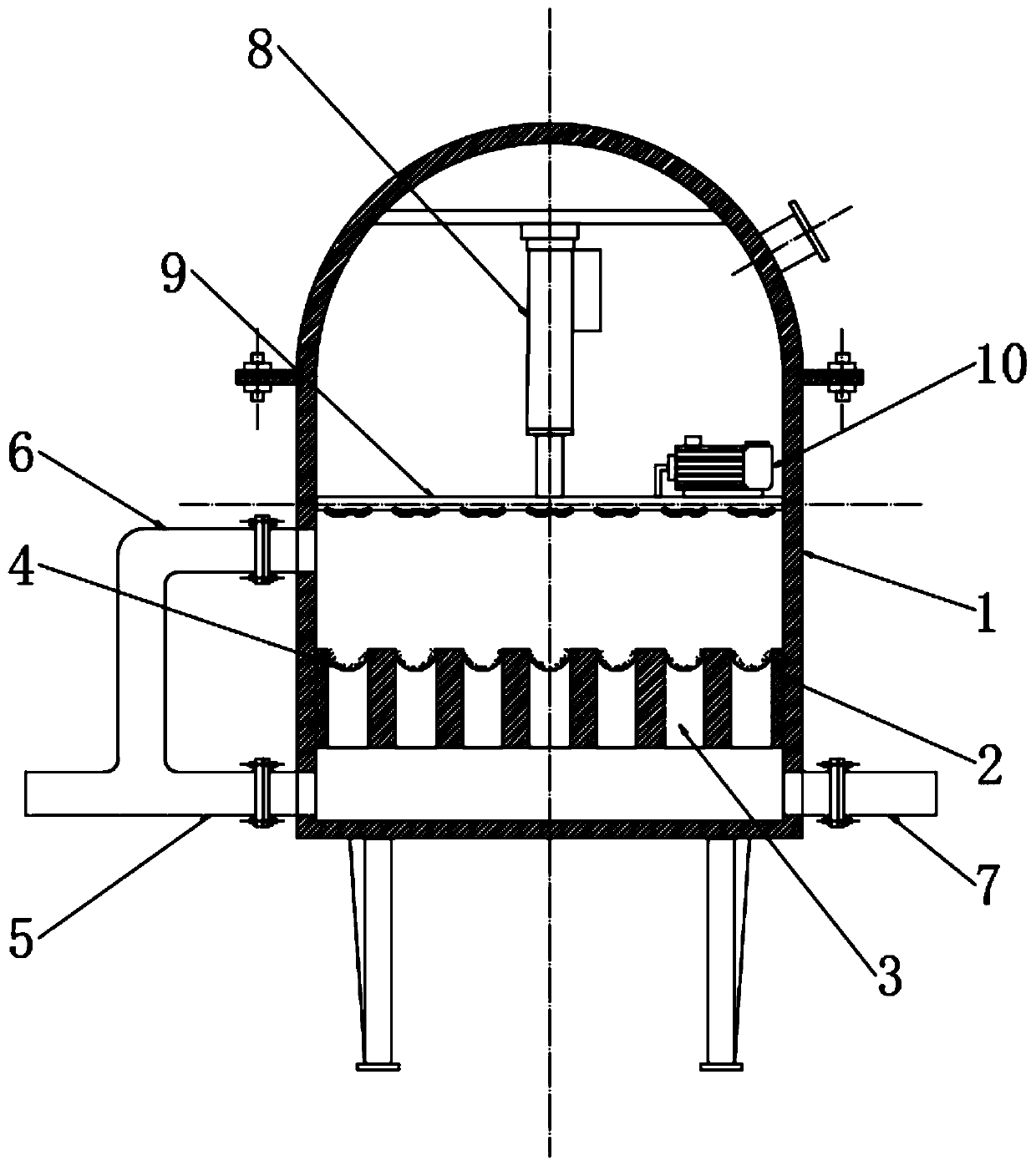

[0047] S1. Take the inorganic material with layered structure, remove impurities, clean it, dry it in the sun, grind it into powder and pass it through a 20-40 mesh sieve, and then put it into the modification furnace 1 and spread it densely;

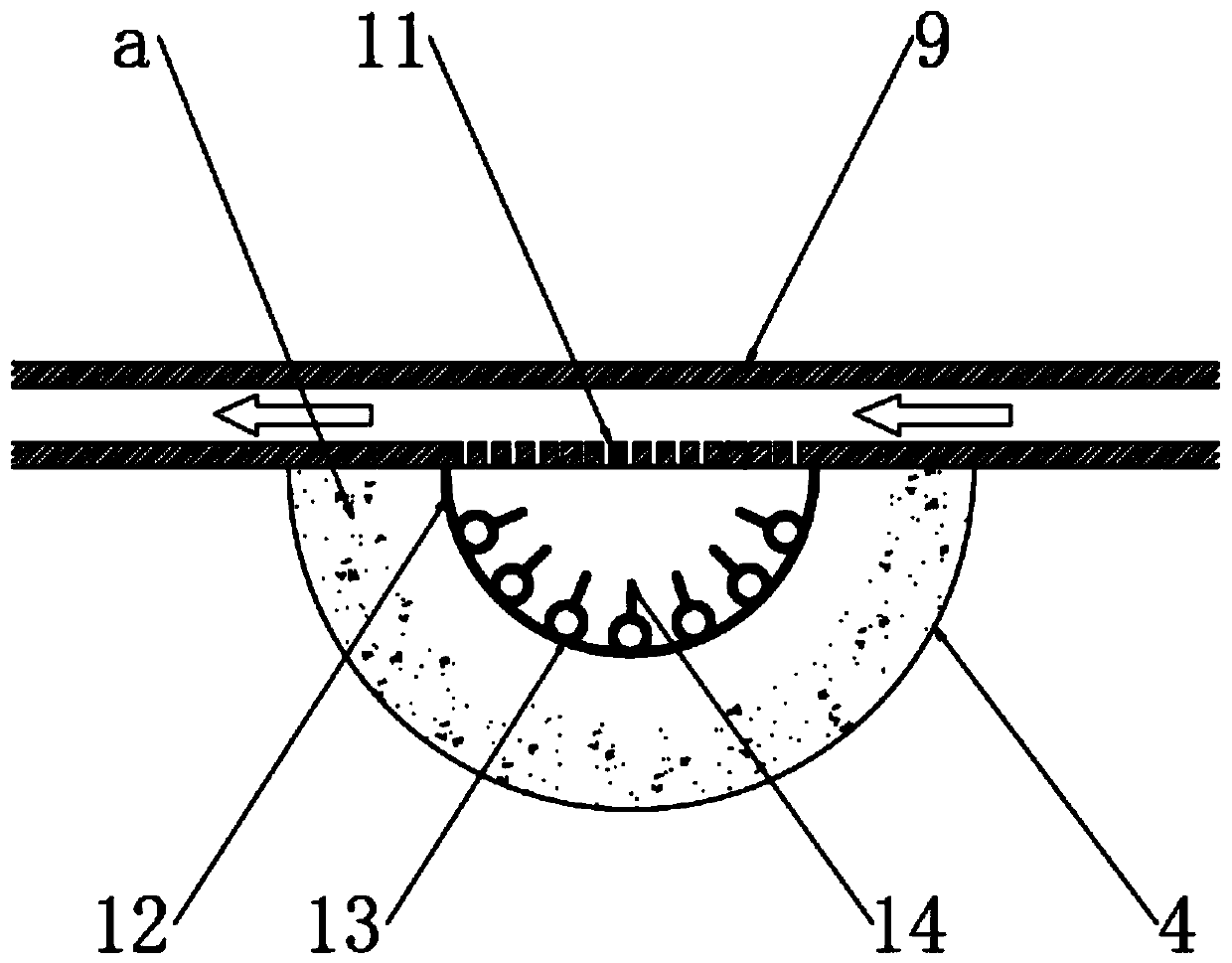

[0048] S2. Introduce a mixture of high-temperature water vapor and activated carbon material into the reforming furnace 1, wherein the mass ratio of activated carbon material to layered structure inorganic material is 1:5, and the activated carbon material passes through the layered structure after being tiled with high-temperature water vapor Inorganic material and retention;

[0049] S3. Slowly add water to the modification furnace 1 until the layered structure inorganic material is submerged. After standing for 5 minutes, as long as there is no obvious bubble generation, put an appropriate amount of surfactant int...

Embodiment 2

[0063] A preparation method for graphene-doped two-dimensional nitrogen and phosphorus, comprising the following steps:

[0064] S1. Take the inorganic material with layered structure, remove impurities, clean it, dry it in the sun, grind it into powder and pass it through a 20-40 mesh sieve, and then put it into the modification furnace 1 and spread it densely;

[0065] S2. Introduce a mixture of high-temperature water vapor and activated carbon material into the reforming furnace 1, wherein the mass ratio of activated carbon material to layered structure inorganic material is 1:6, and the activated carbon material passes through the layered structure after being tiled with high-temperature water vapor Inorganic material and retention;

[0066]S3. Slowly add water to the modification furnace 1 until the layered structure inorganic material is submerged. After standing for 8 minutes, subject to the absence of obvious bubbles, put an appropriate amount of surfactant into the wa...

Embodiment 3

[0073] A preparation method for graphene-doped two-dimensional nitrogen and phosphorus, comprising the following steps:

[0074] S1. Take the inorganic material with layered structure, remove impurities, clean it, dry it in the sun, grind it into powder and pass it through a 20-40 mesh sieve, and then put it into the modification furnace 1 and spread it densely;

[0075] S2. Introduce a mixture of high-temperature water vapor and activated carbon material into the reforming furnace 1, wherein the mass ratio of activated carbon material to layered structure inorganic material is 1:8, and the activated carbon material passes through the layered structure after being tiled with high-temperature water vapor Inorganic material and retention;

[0076] S3. Slowly add water to the modification furnace 1 until the layered structure inorganic material is submerged. After standing for 10 minutes, as long as there is no obvious bubble generation, put an appropriate amount of surfactant in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com