Scraper with water lubricating performance

A lubricant and blade technology, applied in the field of cleaning devices, can solve the problems of high pumping power and filtration capacity, and the low-pressure injection pipe 20 is easy to be blocked and polluted, and achieve the effect of reducing the risk of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

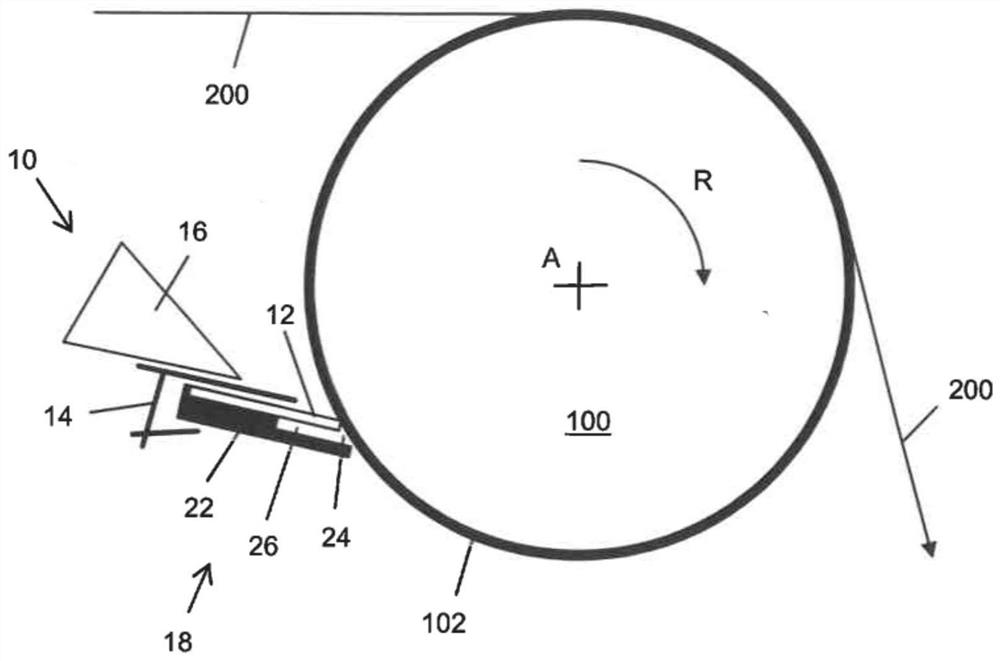

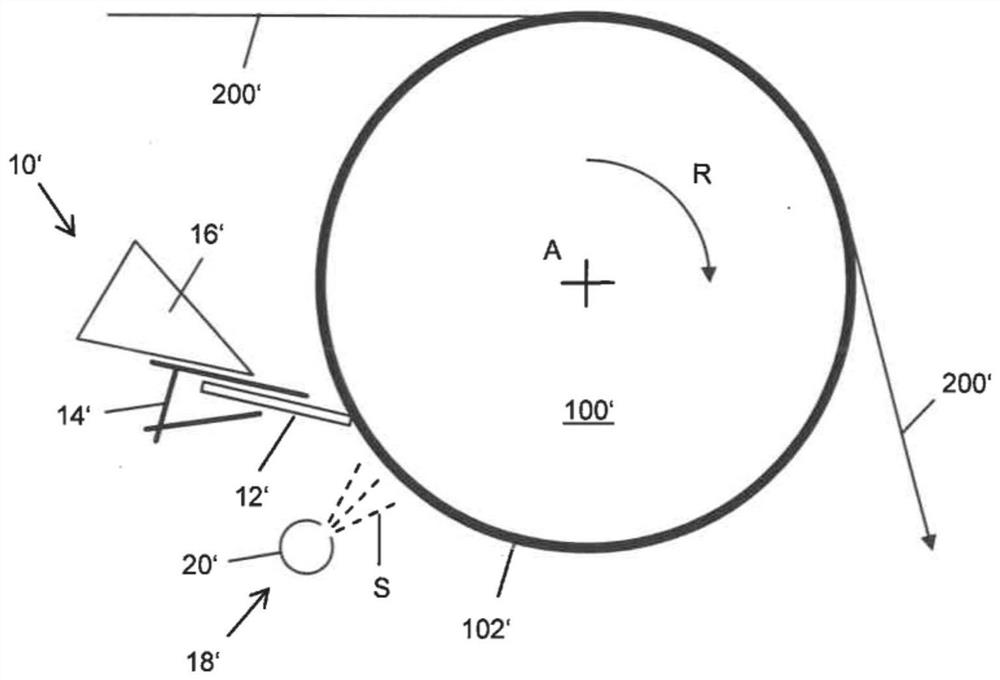

[0025] figure 1In a schematic diagram that is not drawn to the correct scale, a cleaning device 10 according to the invention is shown, together with a roller 100 rotating in the direction of rotation R around the axis of rotation A, the surface 102 of which needs to be cleaned by the cleaning device 10, figure 1 Also shown is the clothing 200 guided on the peripheral section of the roller 100 . The cleaning device 10 ′, the roll 100 and the clothing 200 , for example a forming wire, are components of a machine for producing a fibrous web, in particular a paper, cardboard or tissue web.

[0026] For good comparability, the illustration of the cleaning device 10 according to the invention largely corresponds to the ones known from the prior art. figure 2 The illustration of the cleaning device 10' is consistent. Therefore, only the differences between the two embodiments are discussed below and reference is made to the preceding description for the remainder. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com