Dishwasher

a dishwashing machine and filter technology, applied in the field of dishwashing machines, can solve the problems of cumbersome user, filter clogging, filter clogging during dishwashing,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

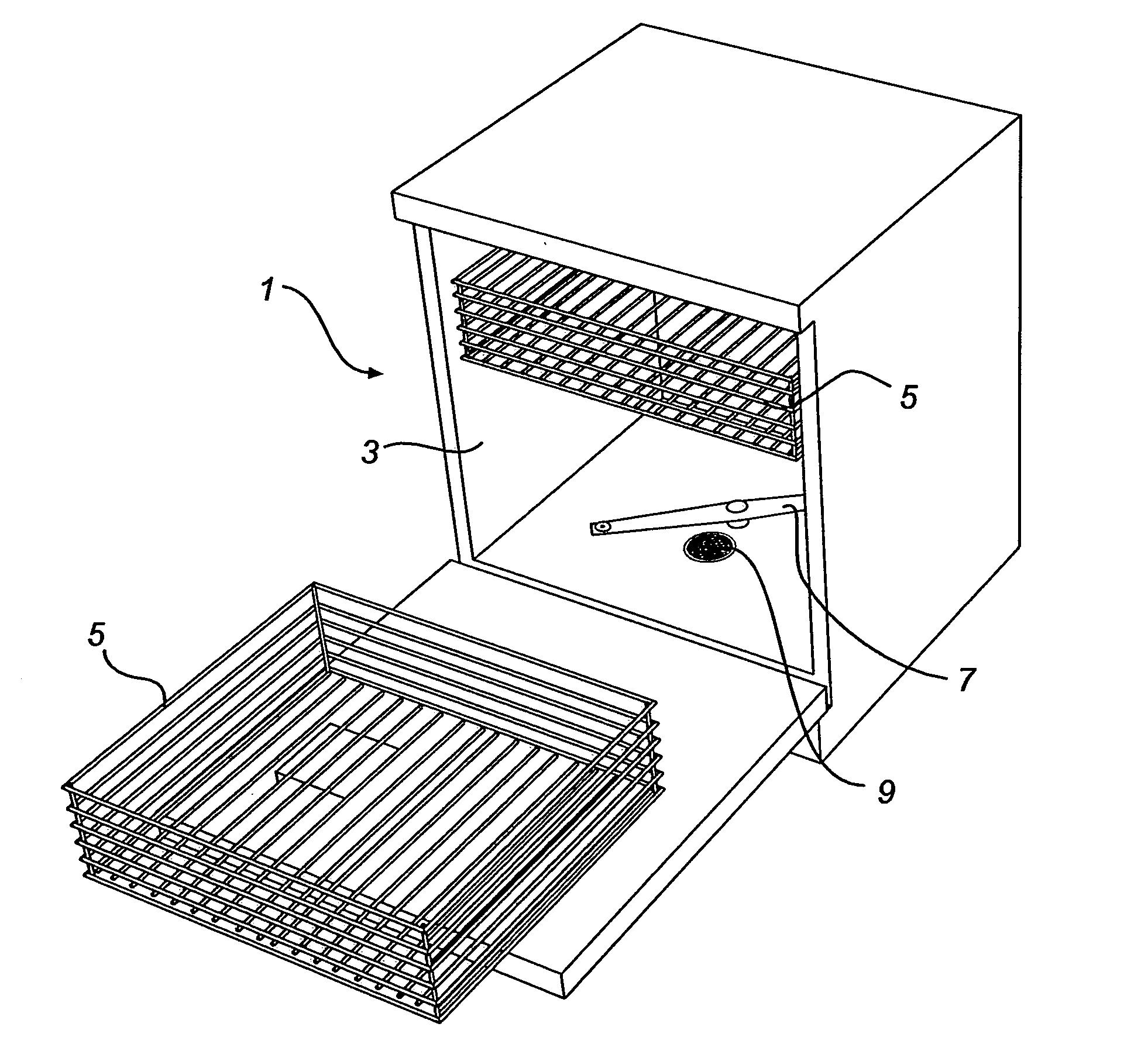

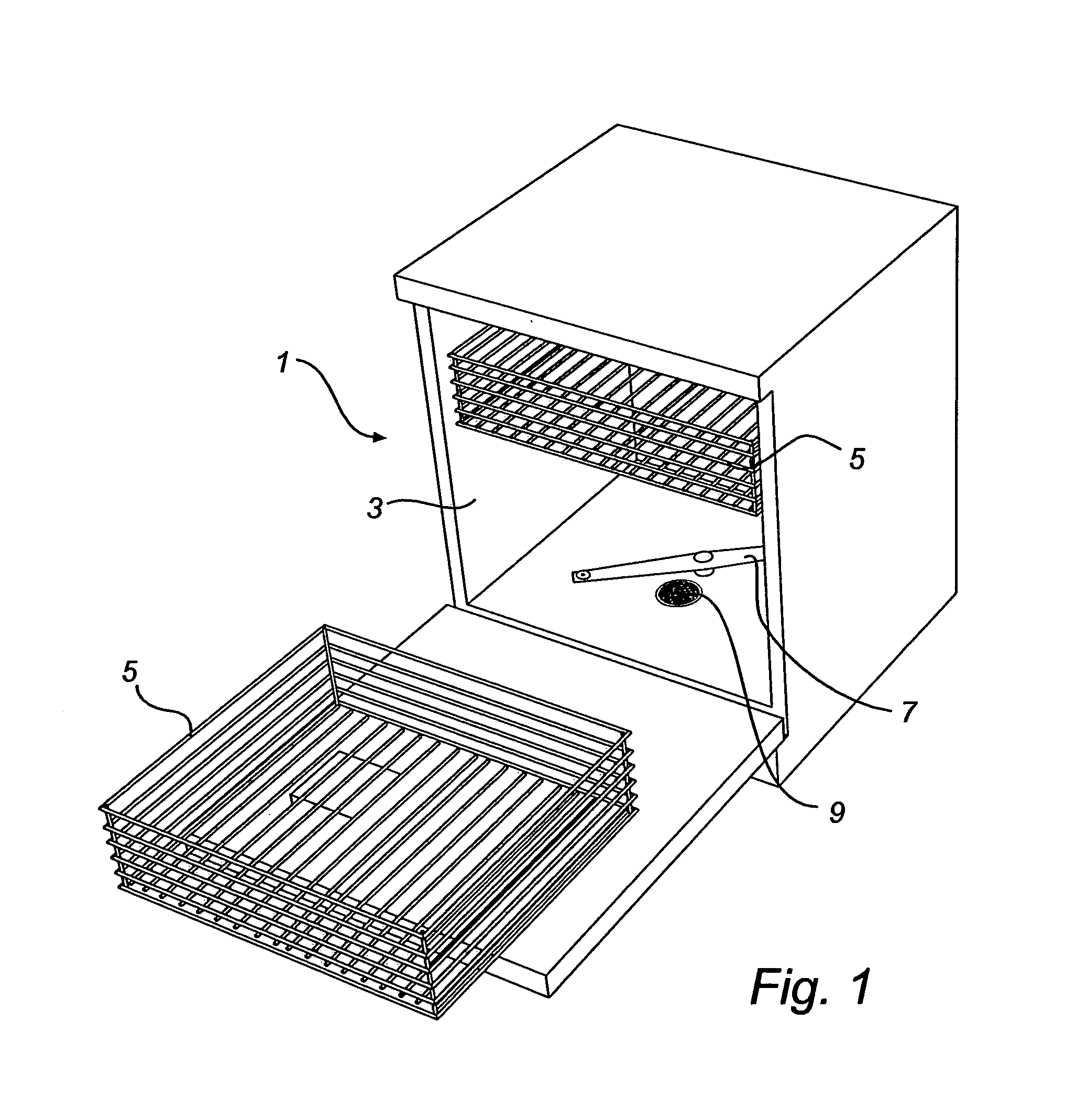

FIG. 1 is a schematic perspective view of an embodiment of a dishwasher 1 according to the invention. The dishwasher 1 includes a washing chamber 3, baskets 5 to hold soiled items to be washed, a spray arm 7 and a glass trap 9 arranged above a sump 17.

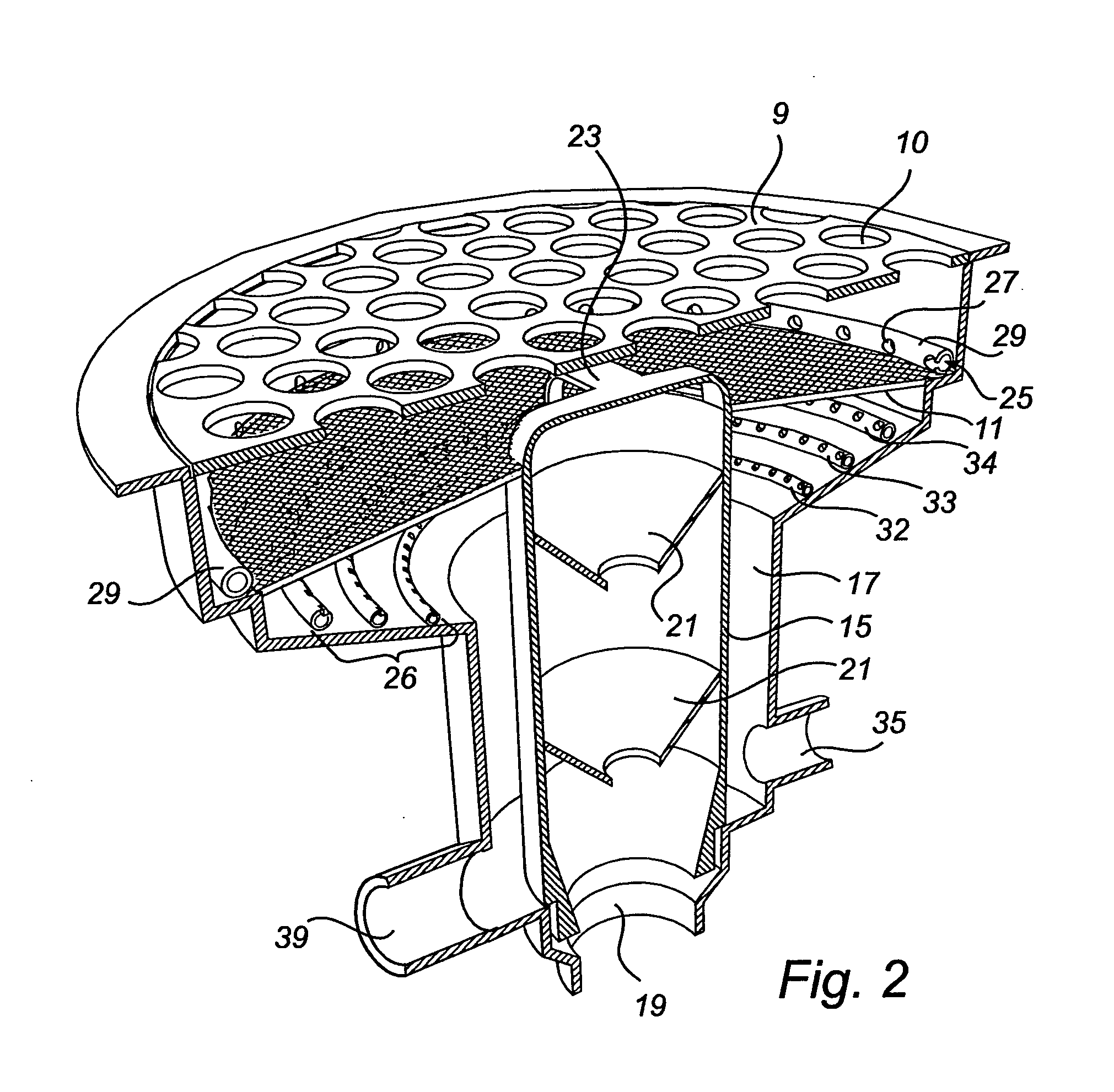

FIG. 2 is a sectional perspective view of a part of a dishwasher 1 according to an embodiment of the invention, showing a glass trap 9, a filter 11, a soil trap 15 and a sump 17. The glass trap 9 is a very coarse filter, in this example a plane surface covered with regularly distributed circular holes 10. Underneath the glass trap 9 there is arranged a fine-mesh filter 11. The filter 11 has the shape of a truncated cone with its centre part raised relatively its periphery part. In the centre of the filter 11, the soil trap 15 is located. The filter comprises a filter surface having a filter edge and the inlet of the soil trap is arranged abutting against the filter edge.

The soil trap 15 is a liquid-tight cylinder with its upper end at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com