Patents

Literature

493results about "Doctors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

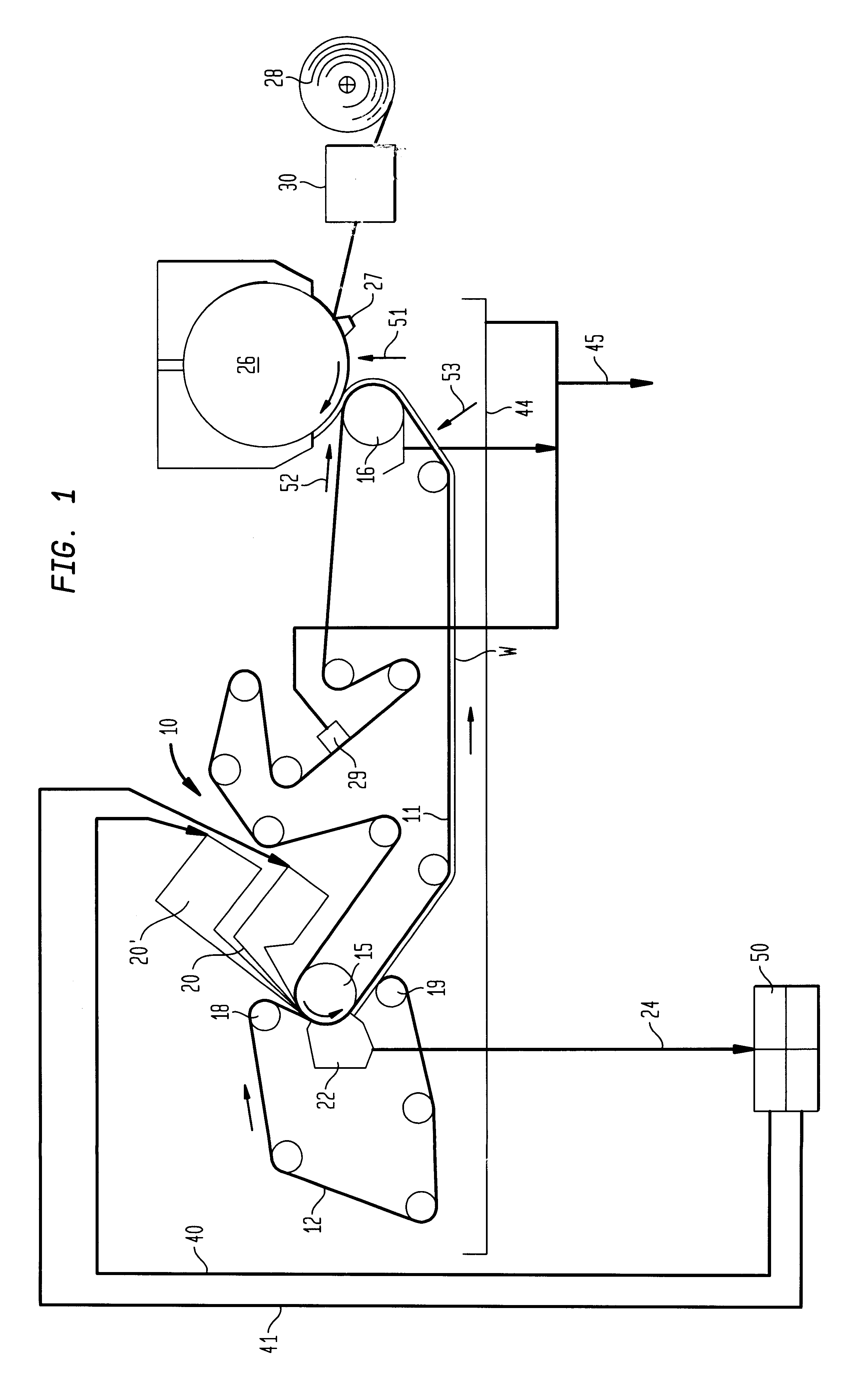

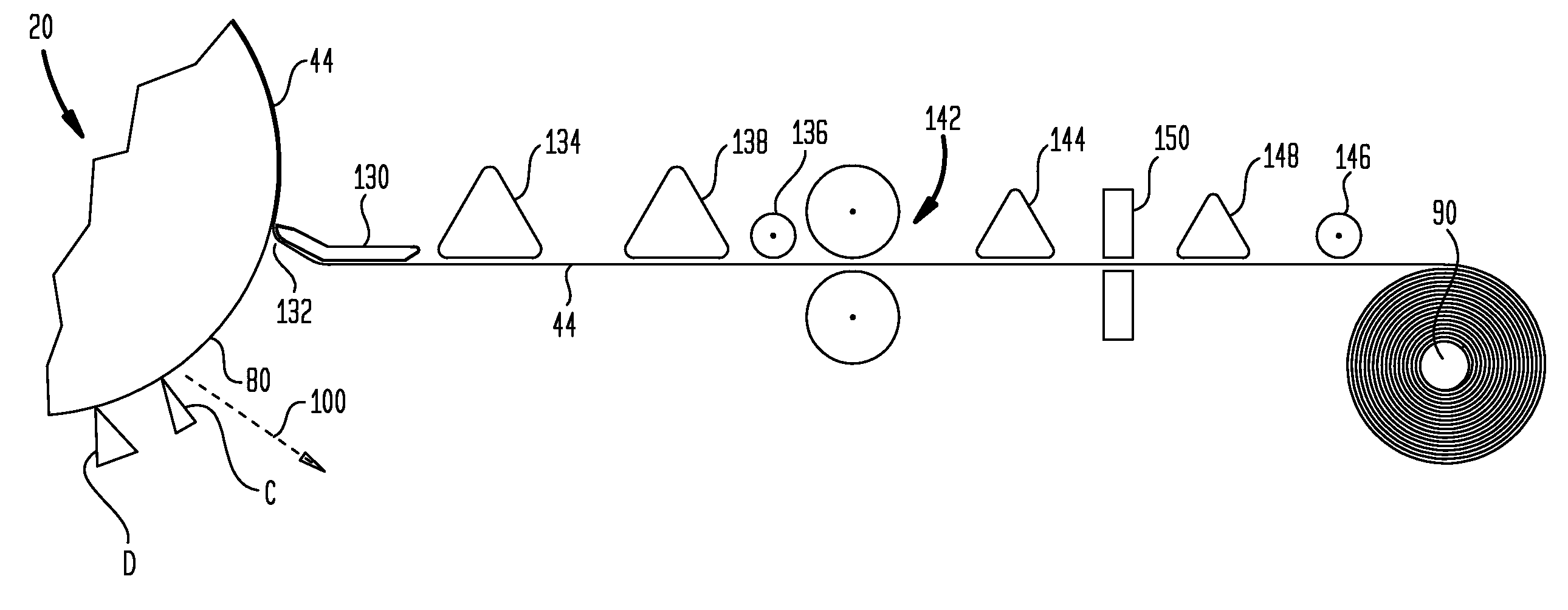

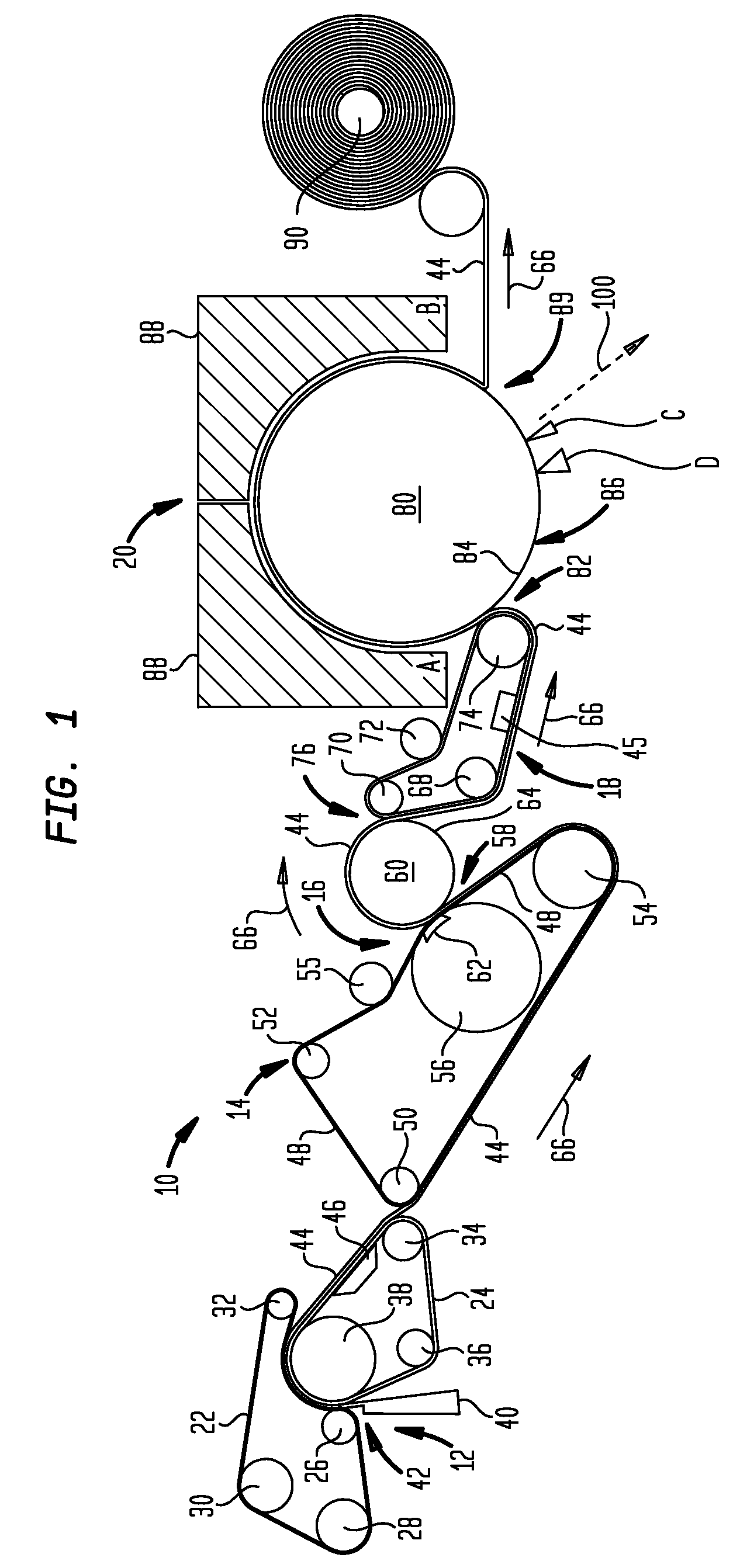

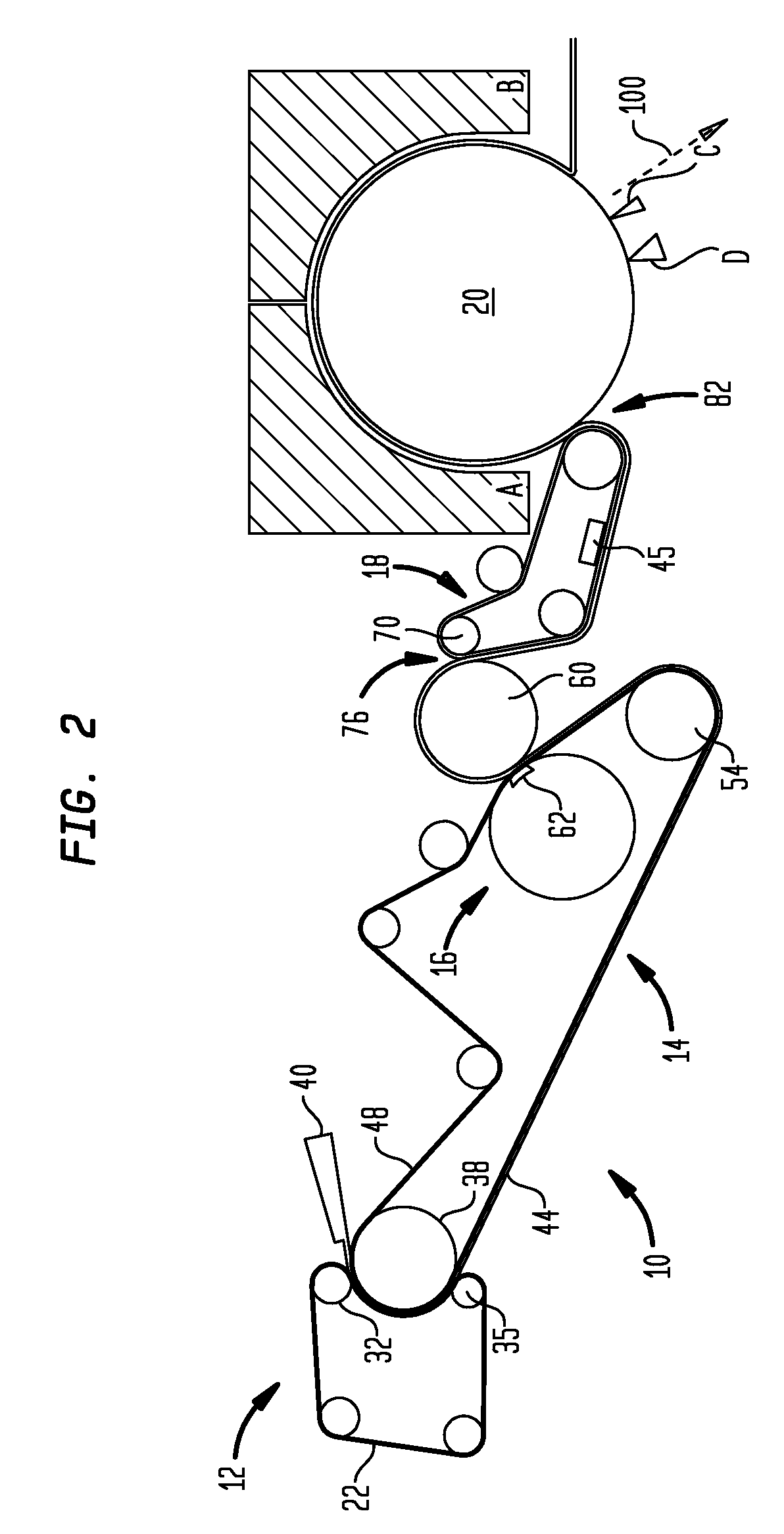

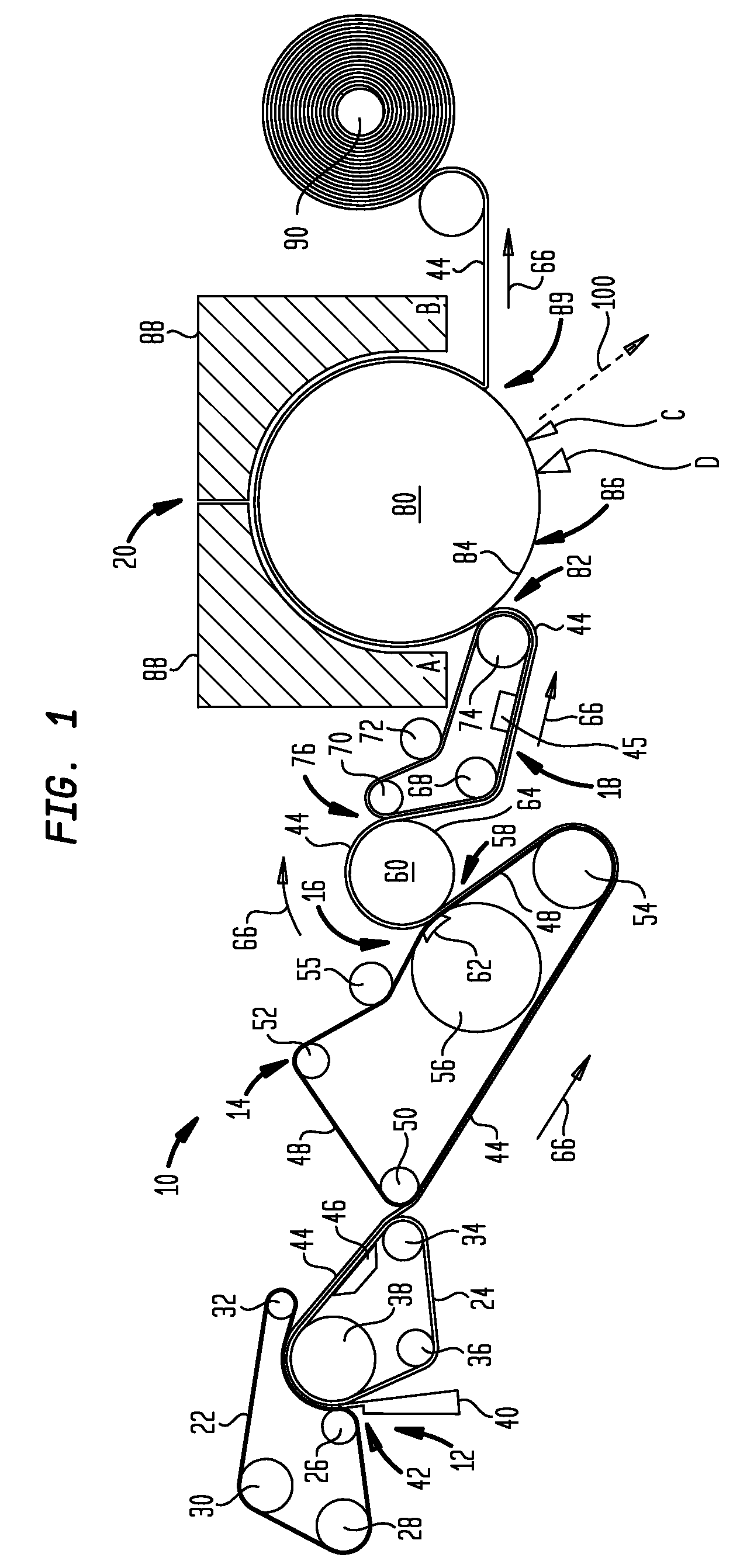

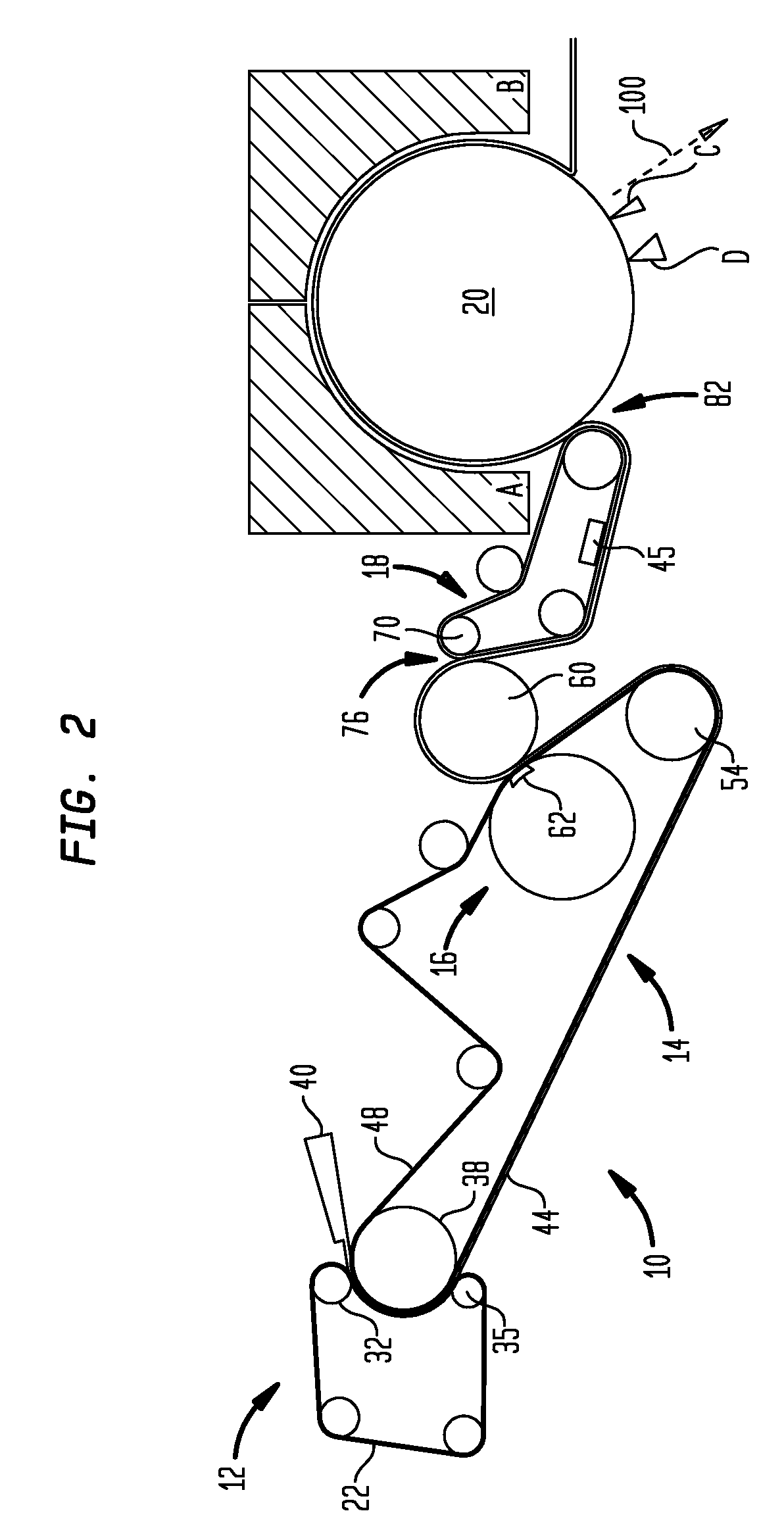

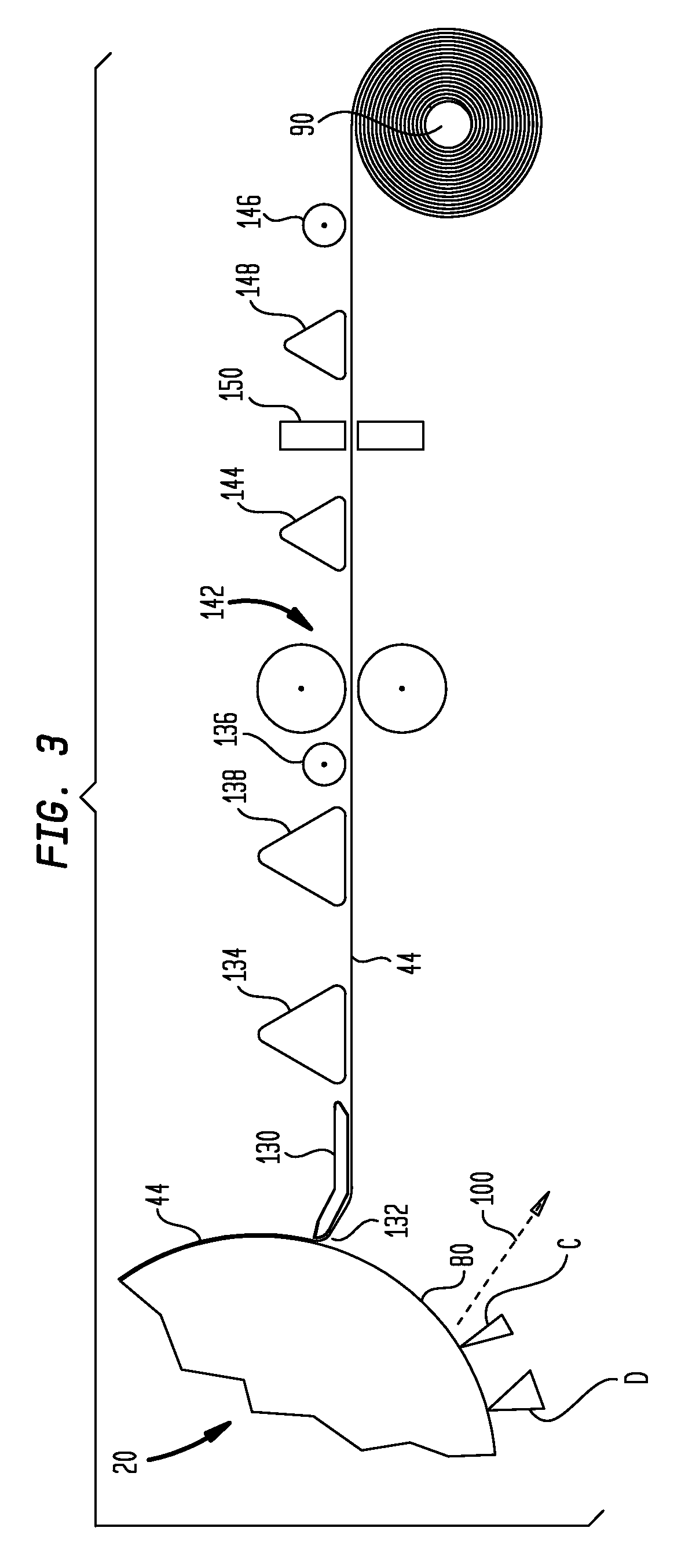

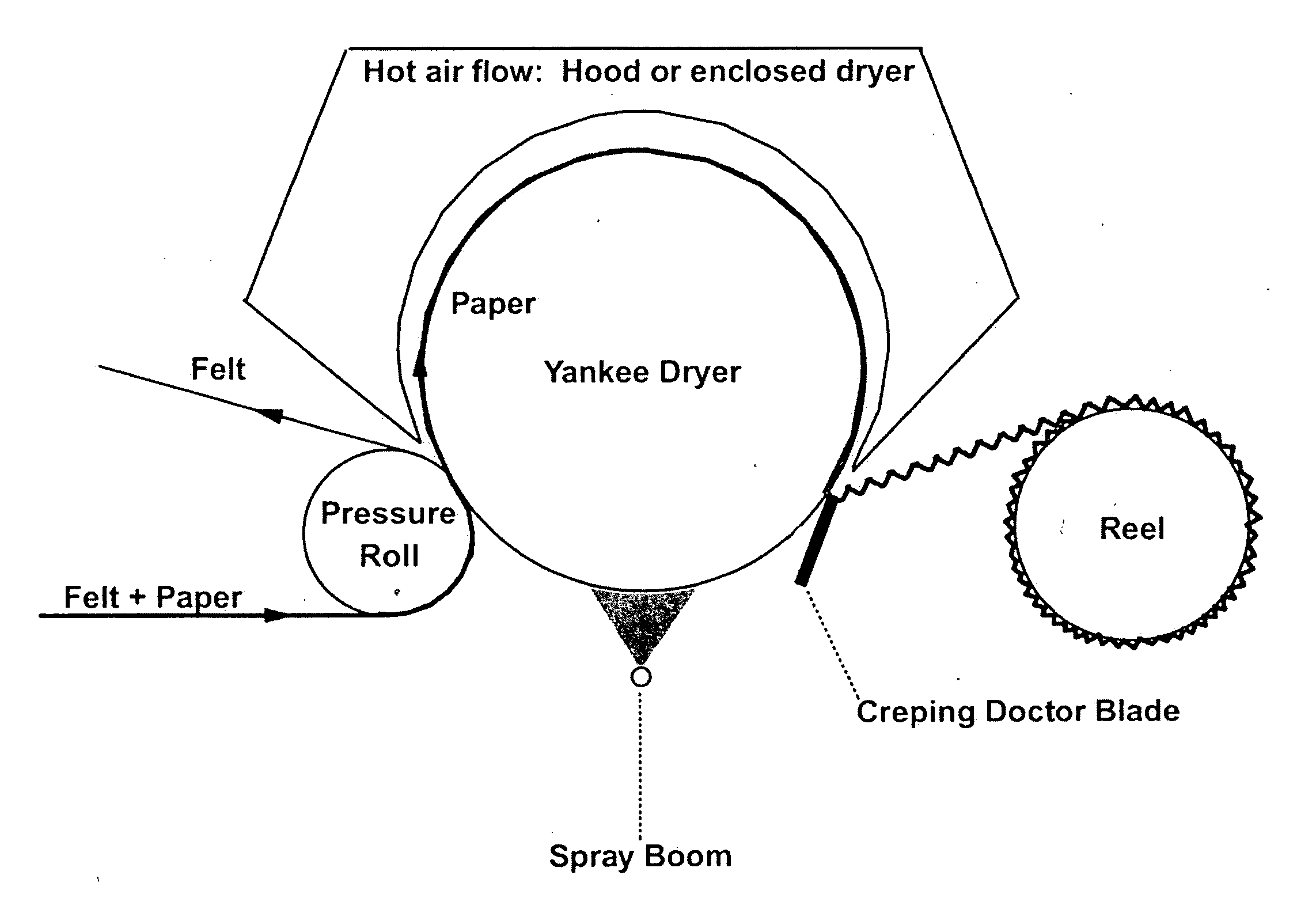

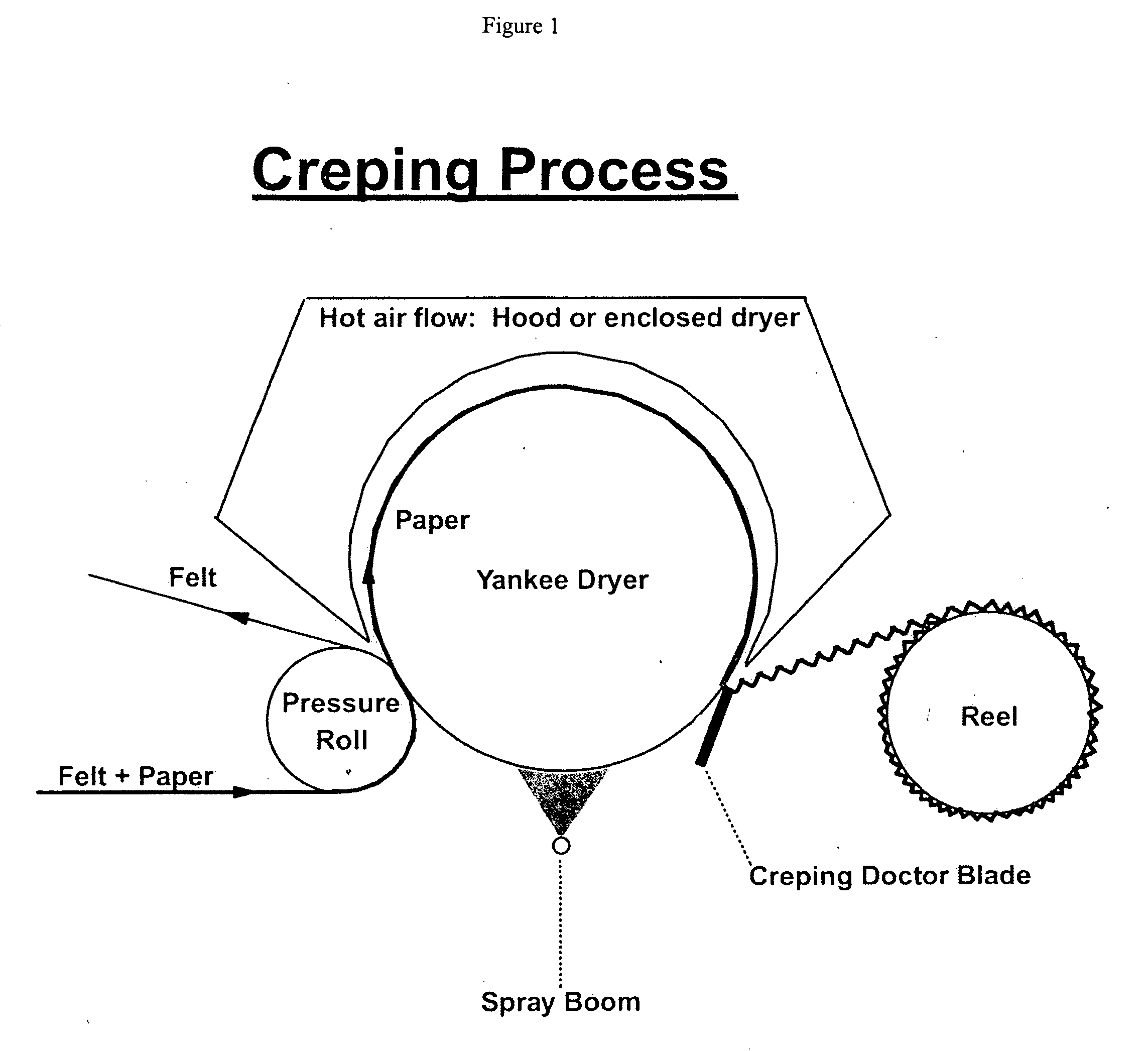

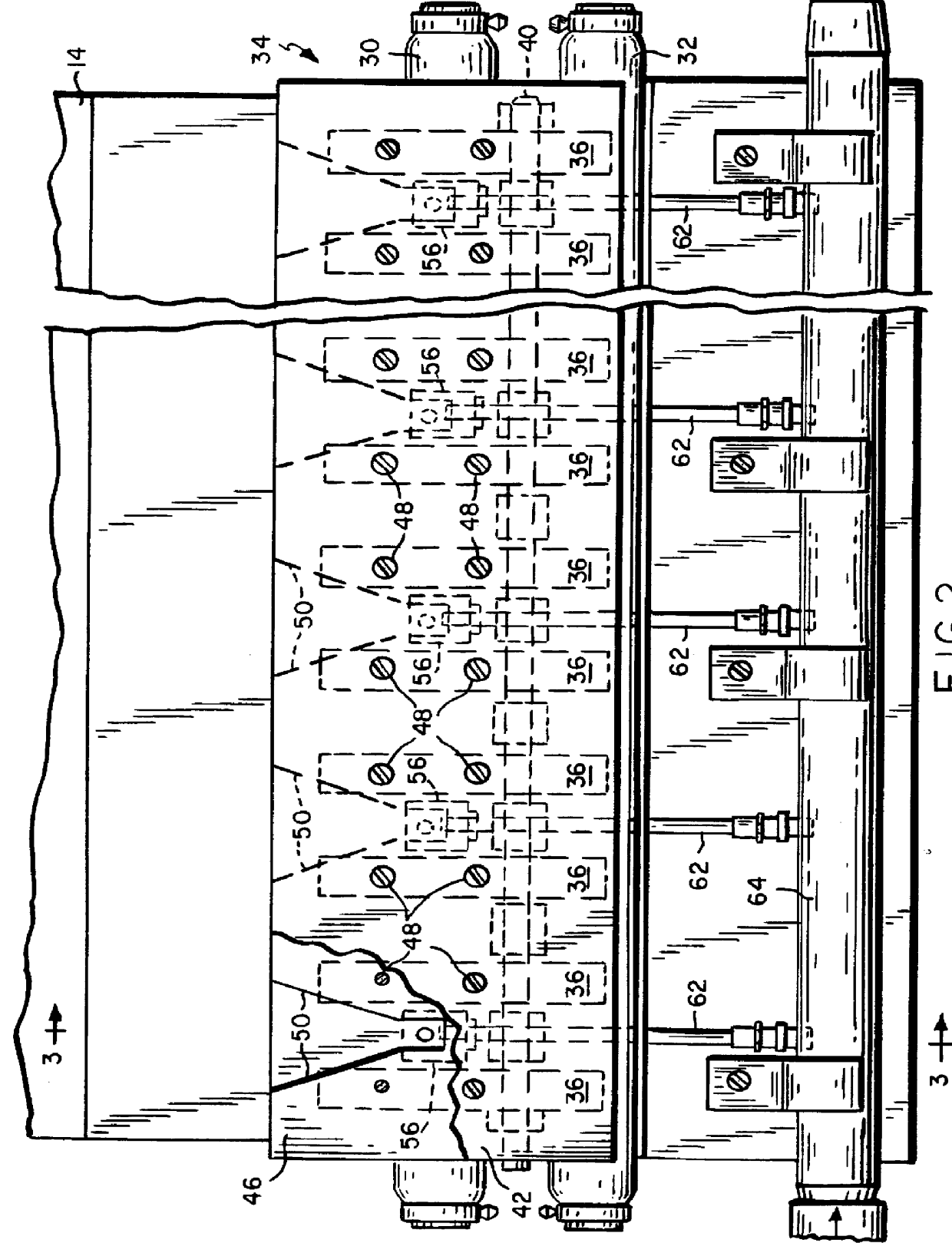

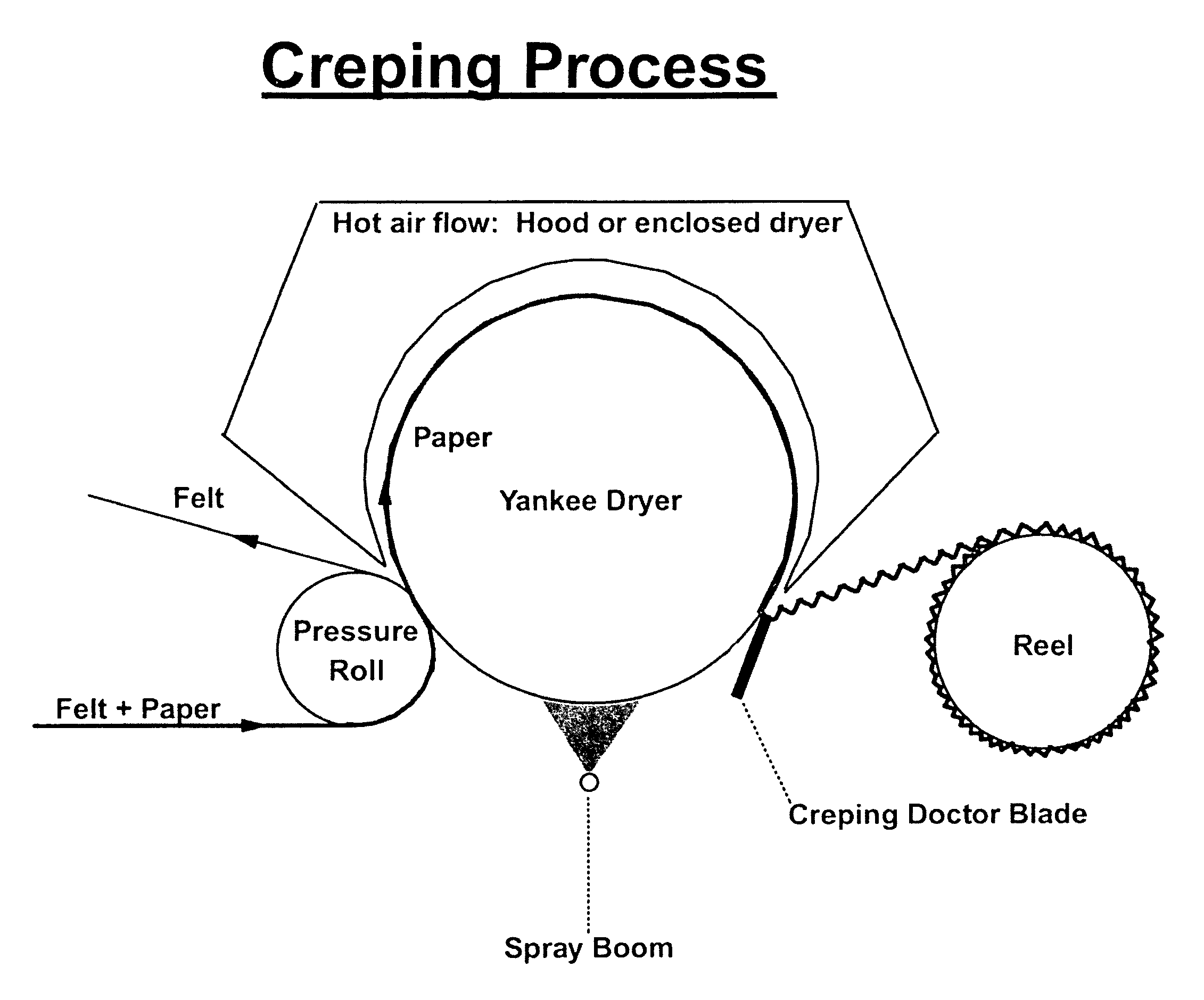

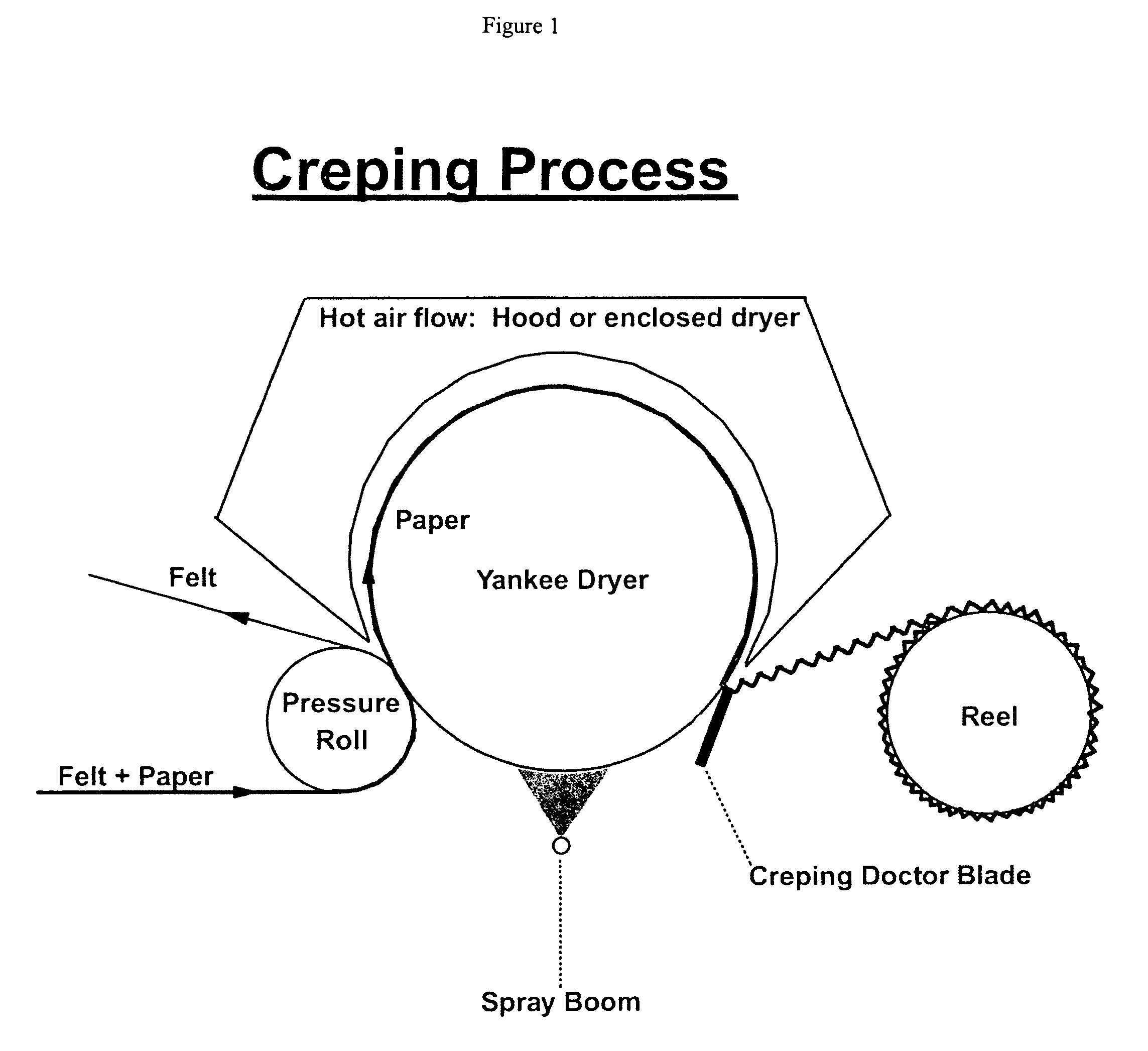

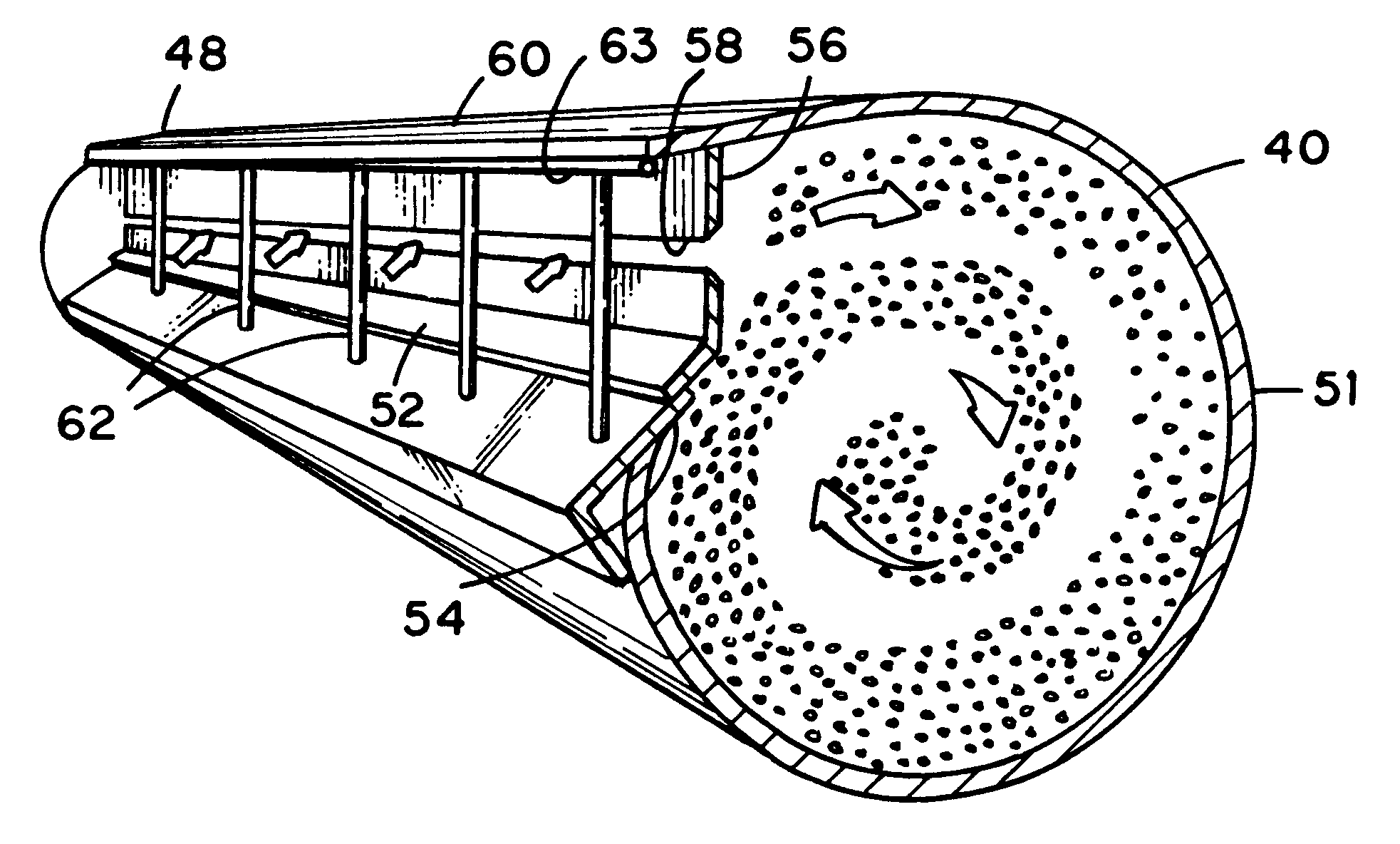

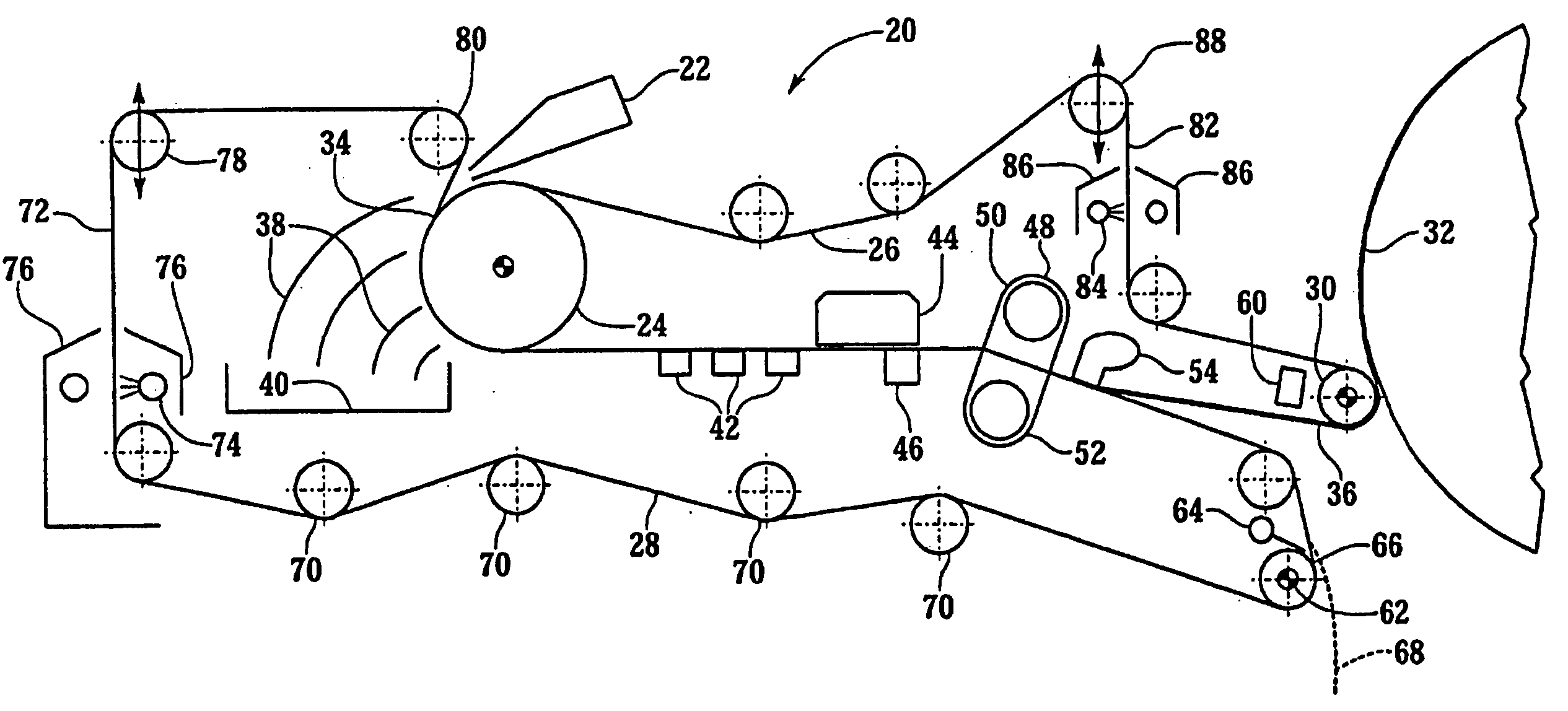

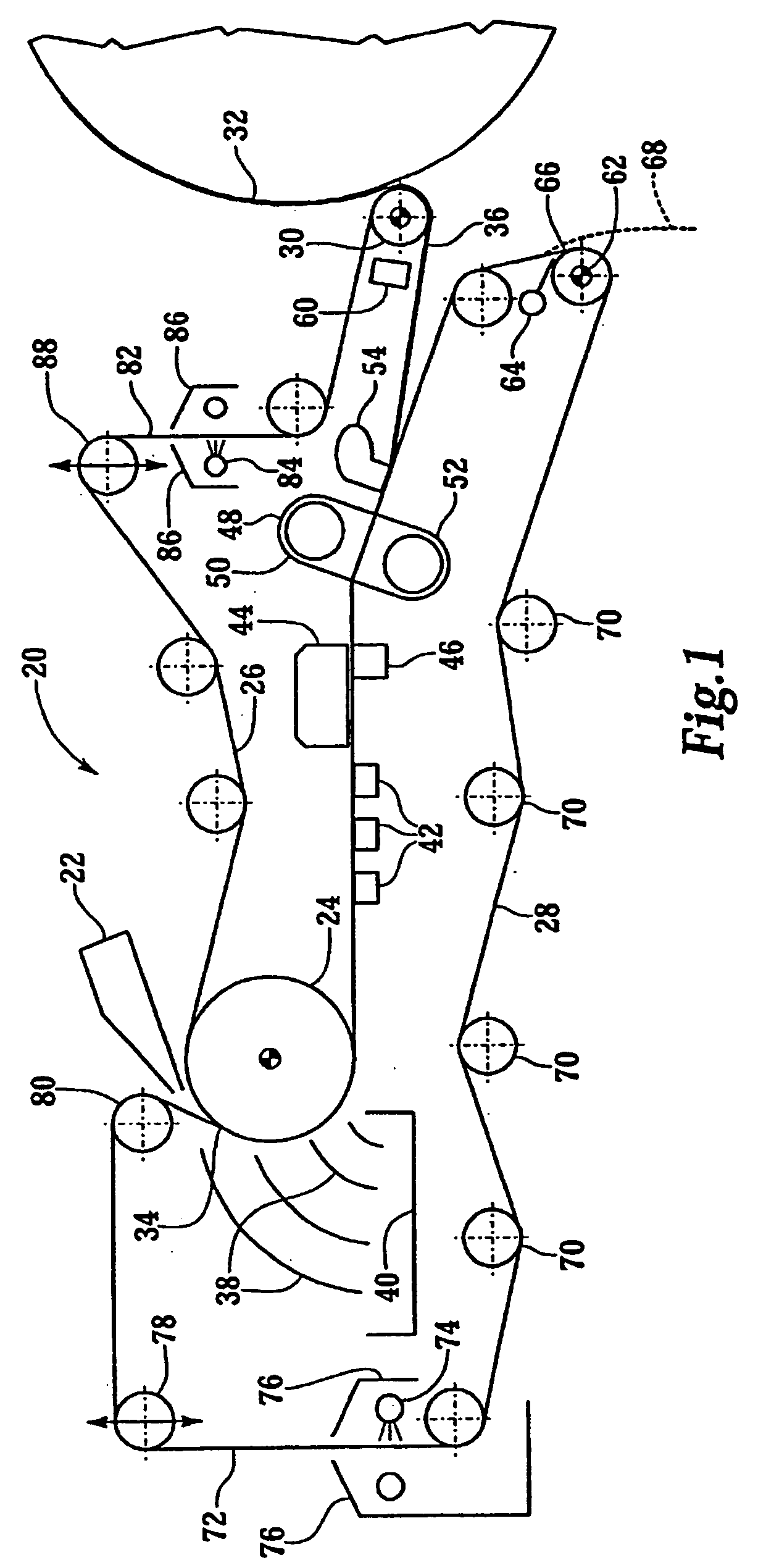

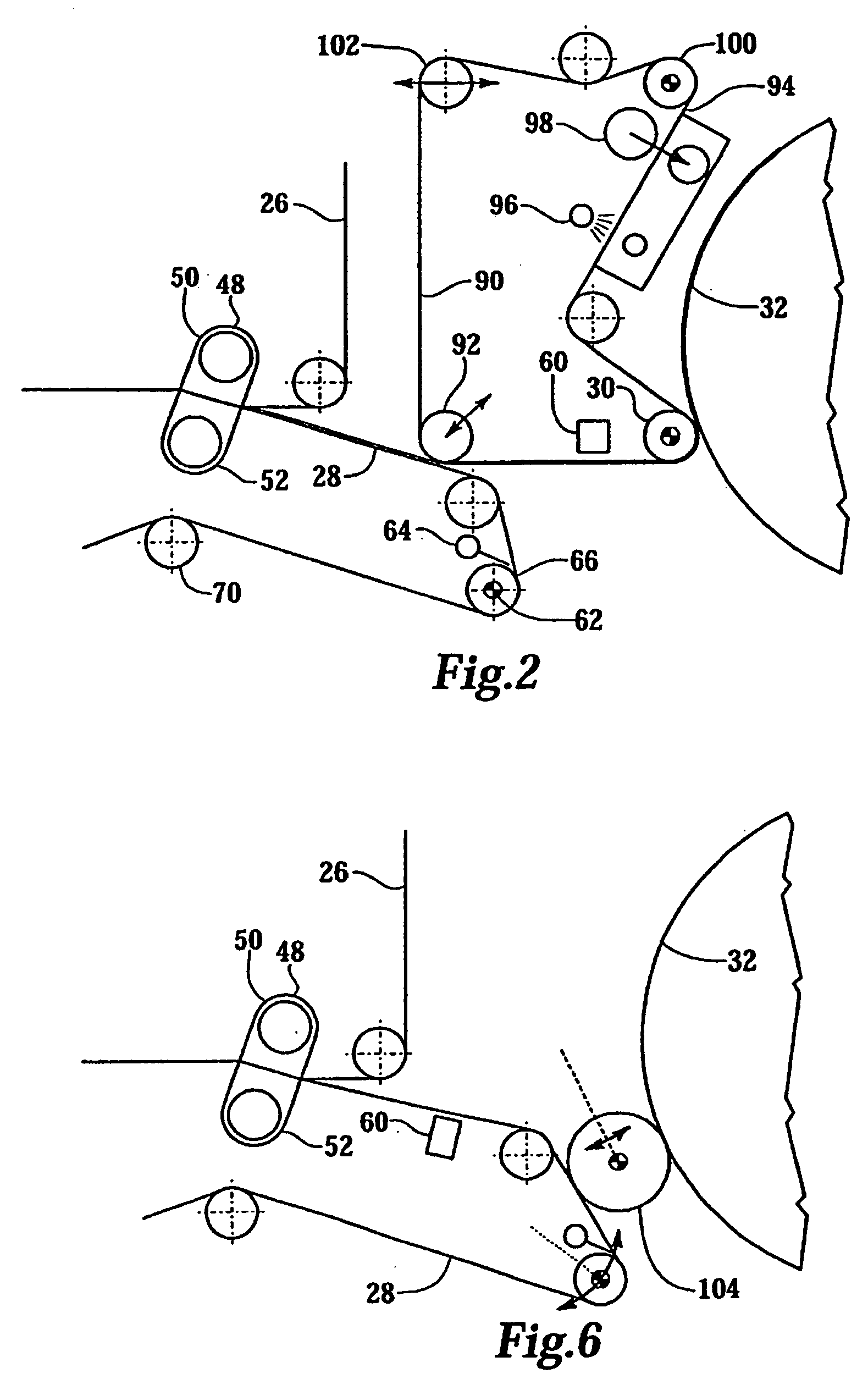

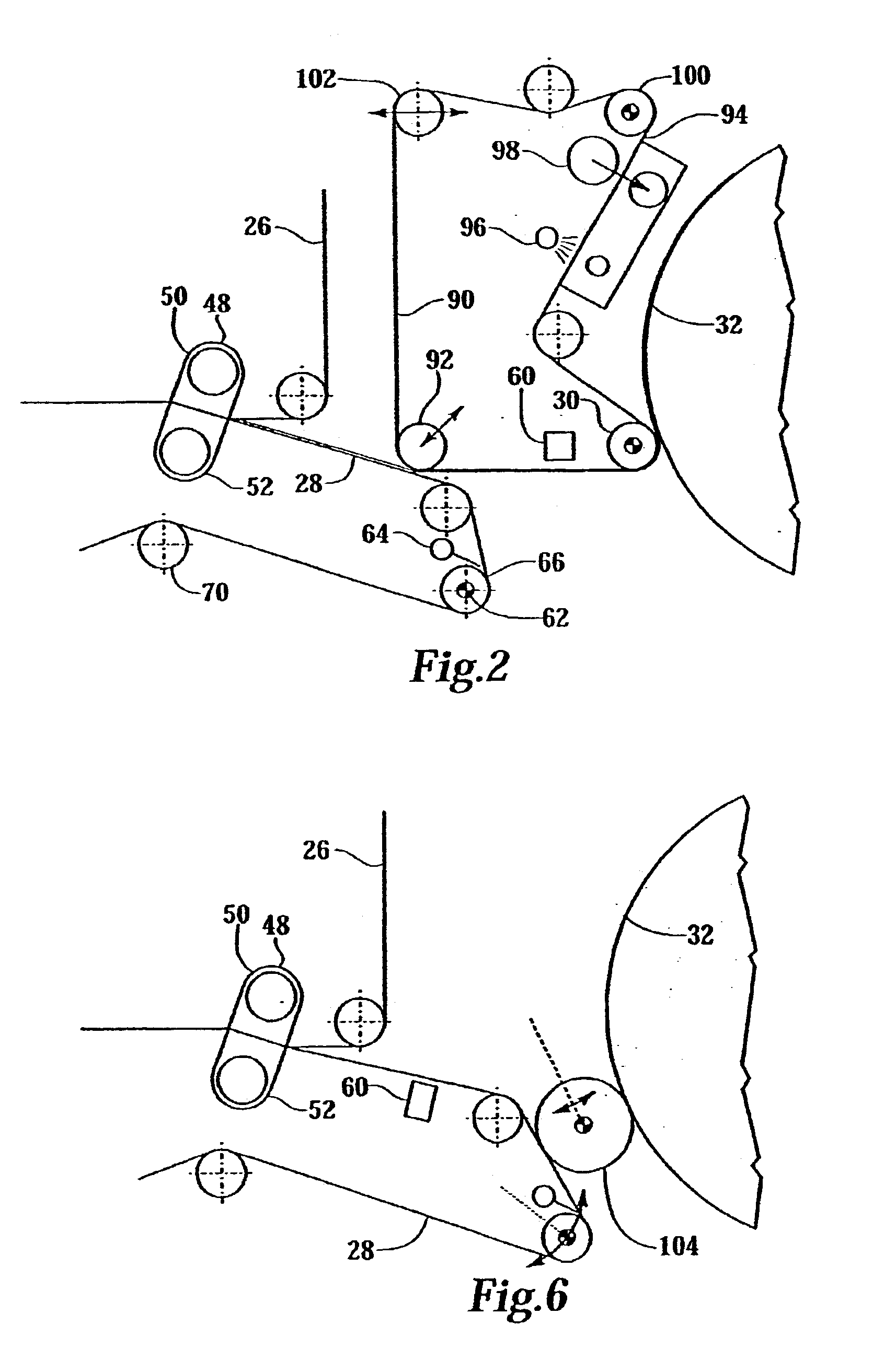

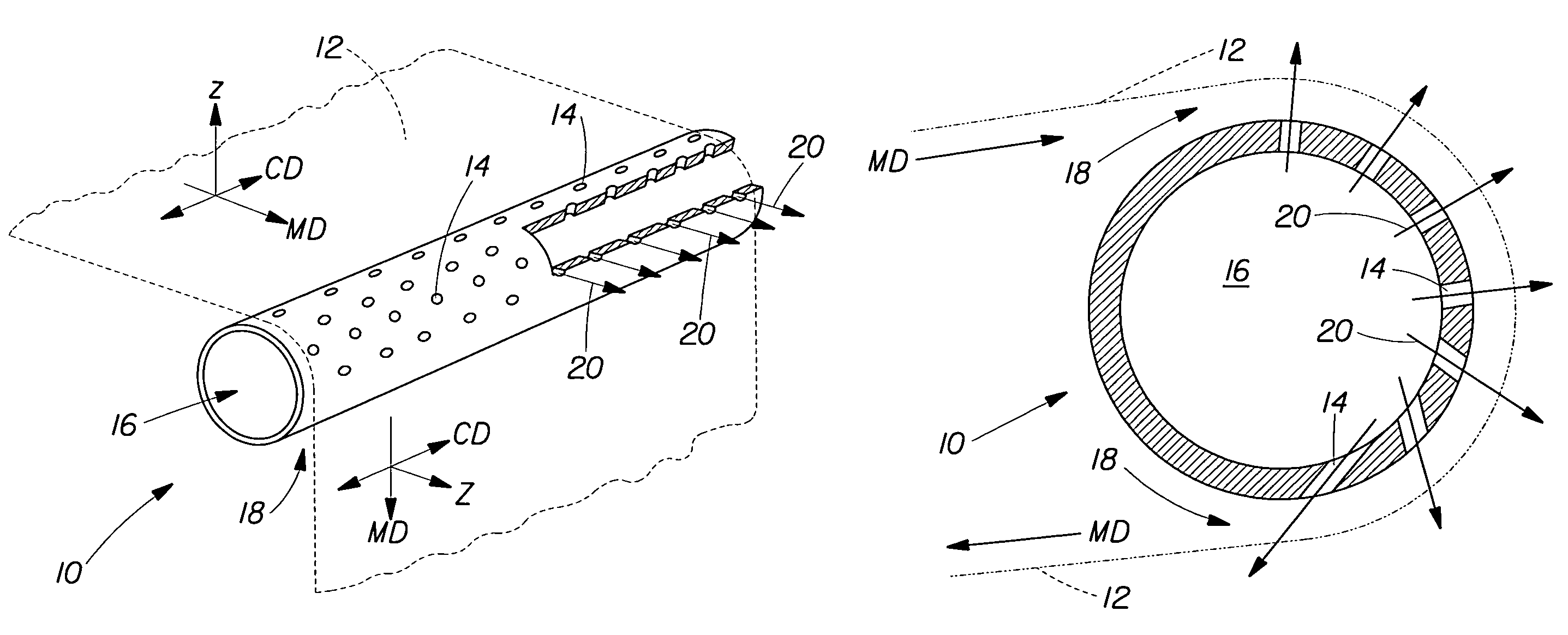

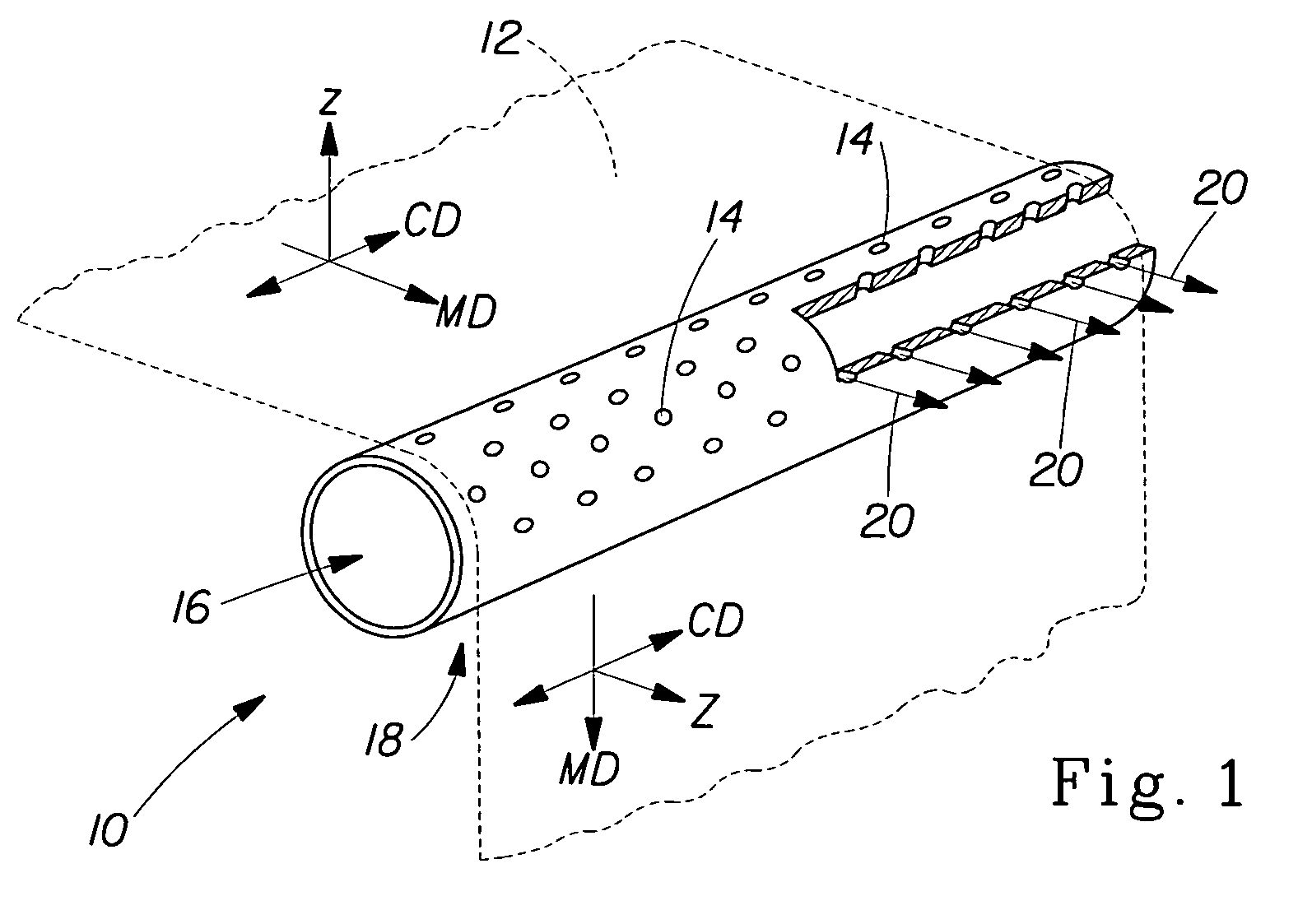

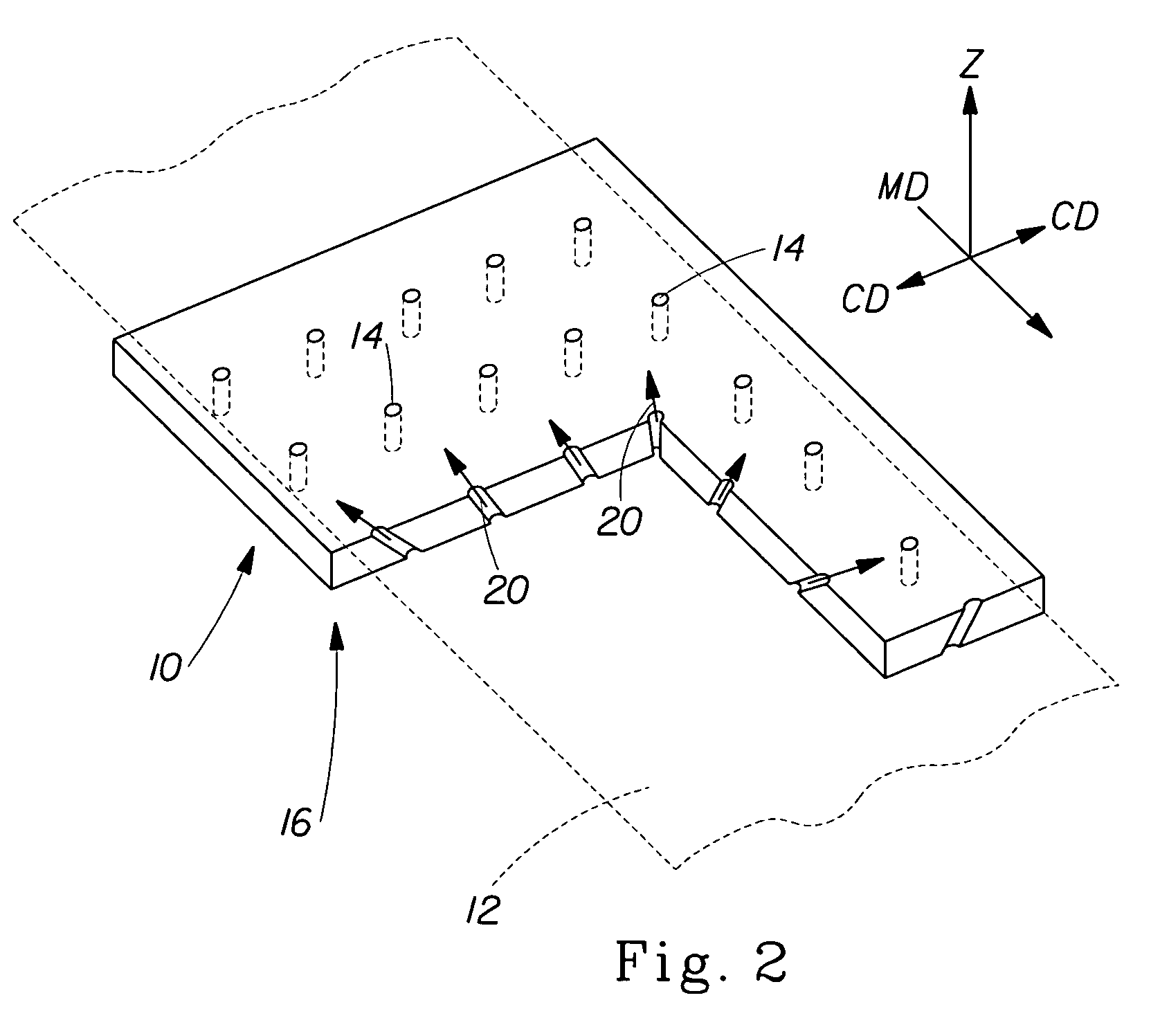

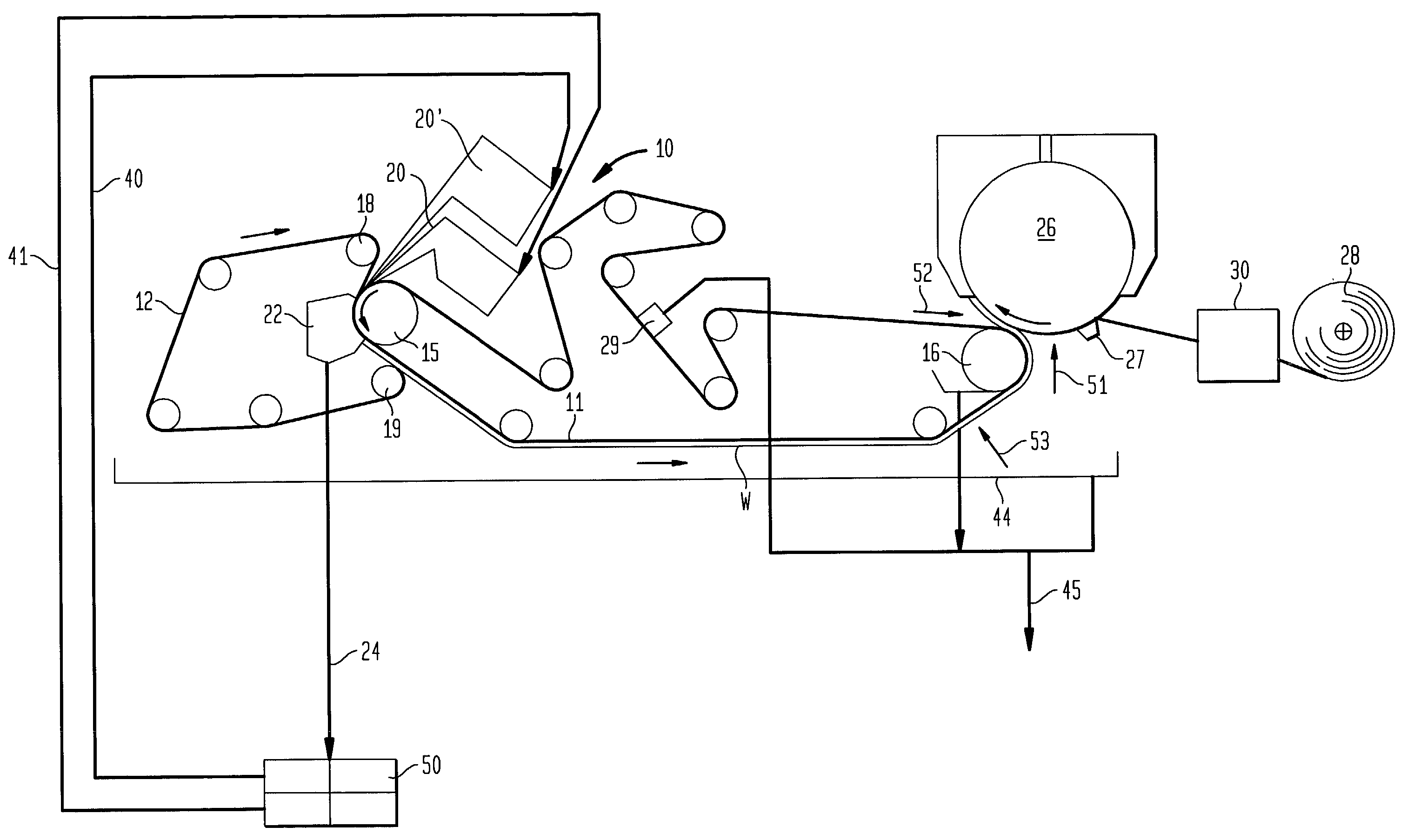

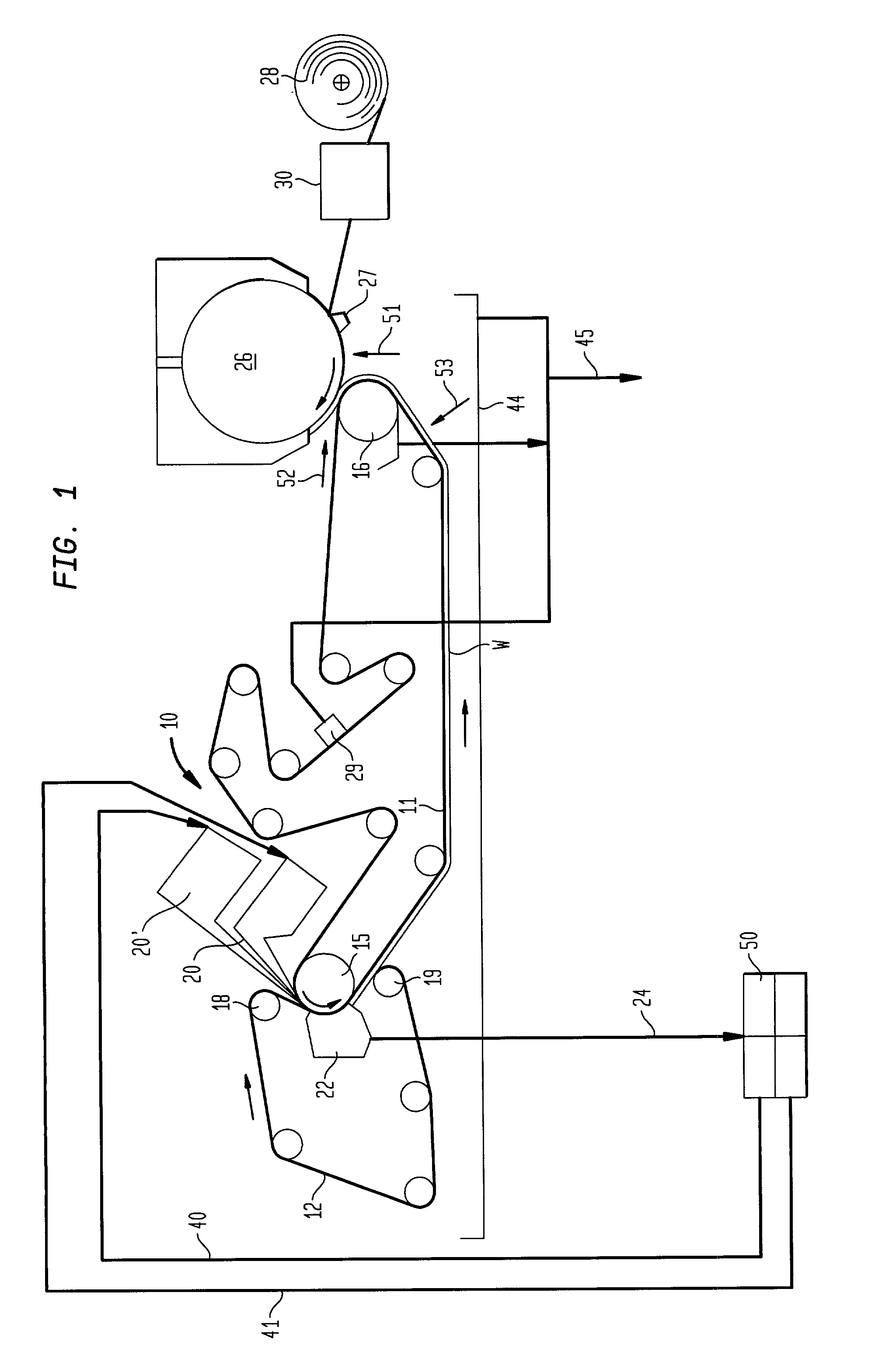

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

Method Of Controlling Adhesive Build-Up On A Yankee Dryer

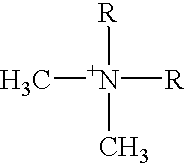

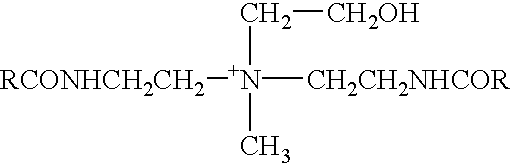

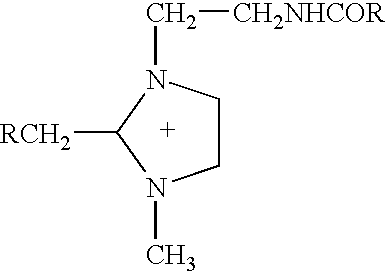

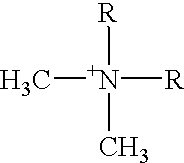

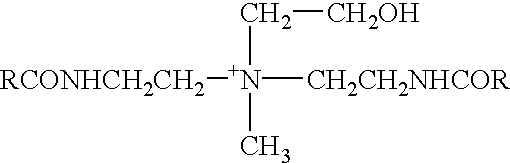

ActiveUS20070204966A1Reducing steady-state tensionReduce tensionNon-fibrous pulp additionNatural cellulose pulp/paperAdhesiveEngineering

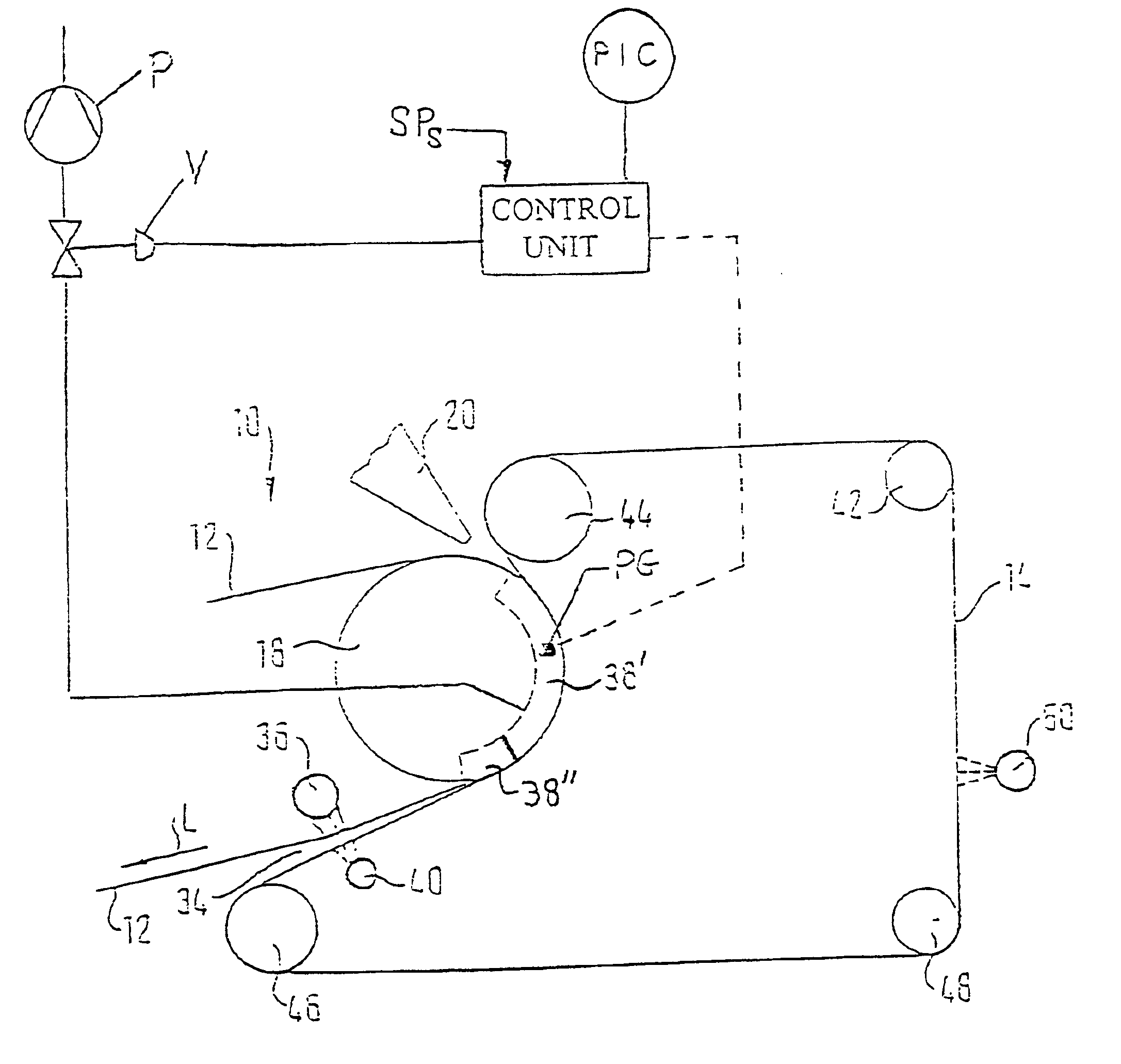

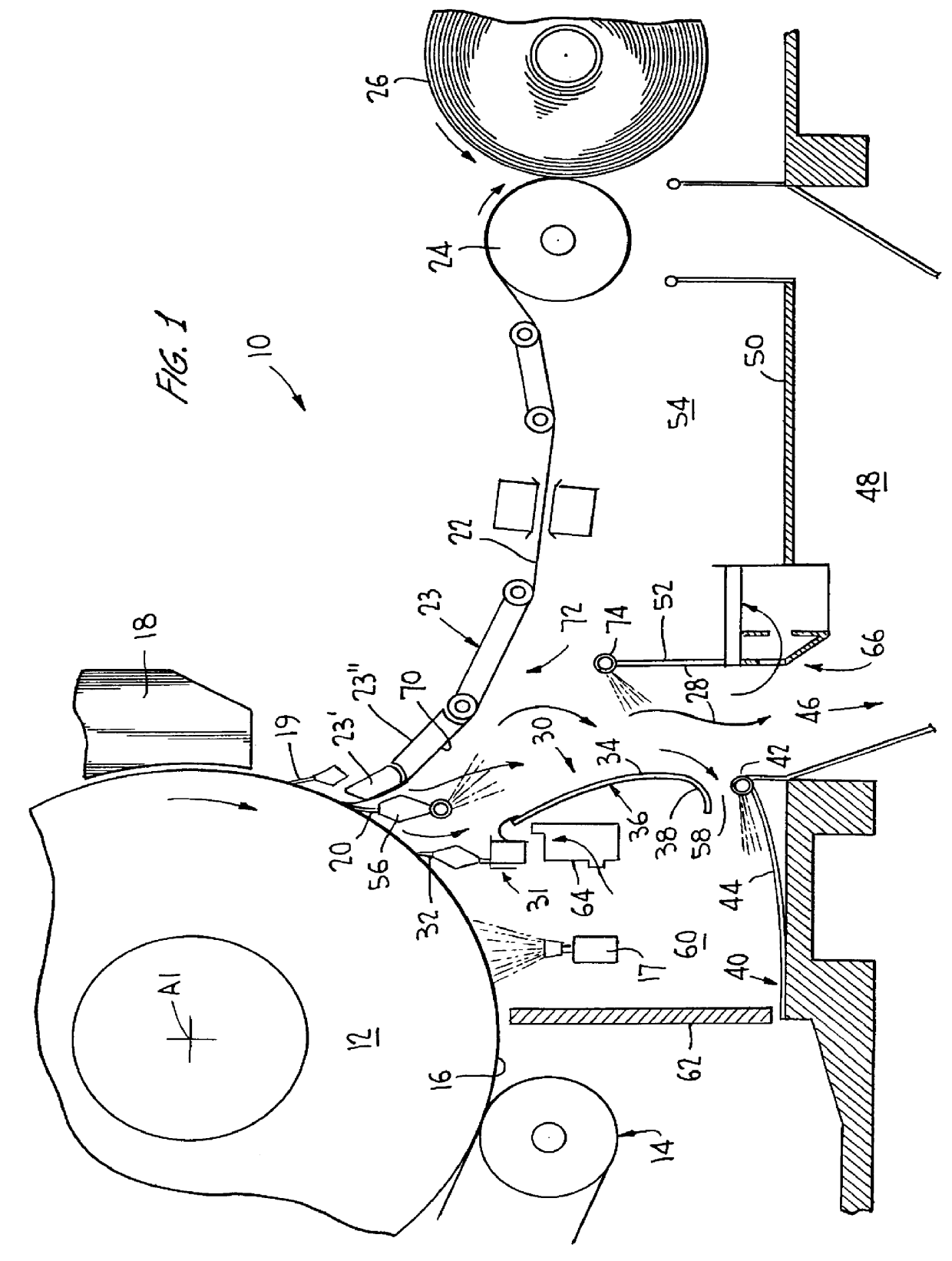

An improved method of controlling build-up of adhesive coating on a Yankee drying cylinder preferably includes intermittently: (a) increasing the add-on rate of resinous adhesive to the drying cylinder substantially above the steady-state add-on rate; (b) segregating the absorbent sheet product produced while the add-on rate of resinous adhesive to the drying cylinder is elevated above the steady-state add-on rate from absorbent sheet product accumulated during steady-state operation; and (c) while the add-on rate of resinous adhesive to the drying cylinder is increased above the steady-state add-on rate, stripping at least a portion of the adhesive coating from the drying cylinder with a cleaning doctor.

Owner:GPCP IP HLDG LLC

Method of controlling adhesive build-up on a yankee dryer

ActiveUS7850823B2Increase ratingsReduce the temperatureNon-fibrous pulp additionNatural cellulose pulp/paperAdhesiveEngineering

Owner:GPCP IP HLDG LLC

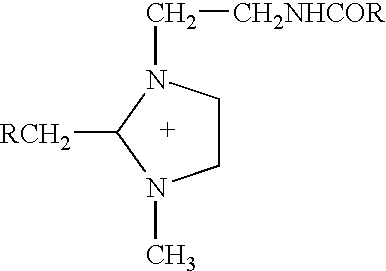

System for control of stickies in recovered and virgin paper processing

InactiveUS20060048908A1Good removal effectEasy to controlFats/resins/pitch/waxes removal in pulpMachine wet endPectinaseAmylase

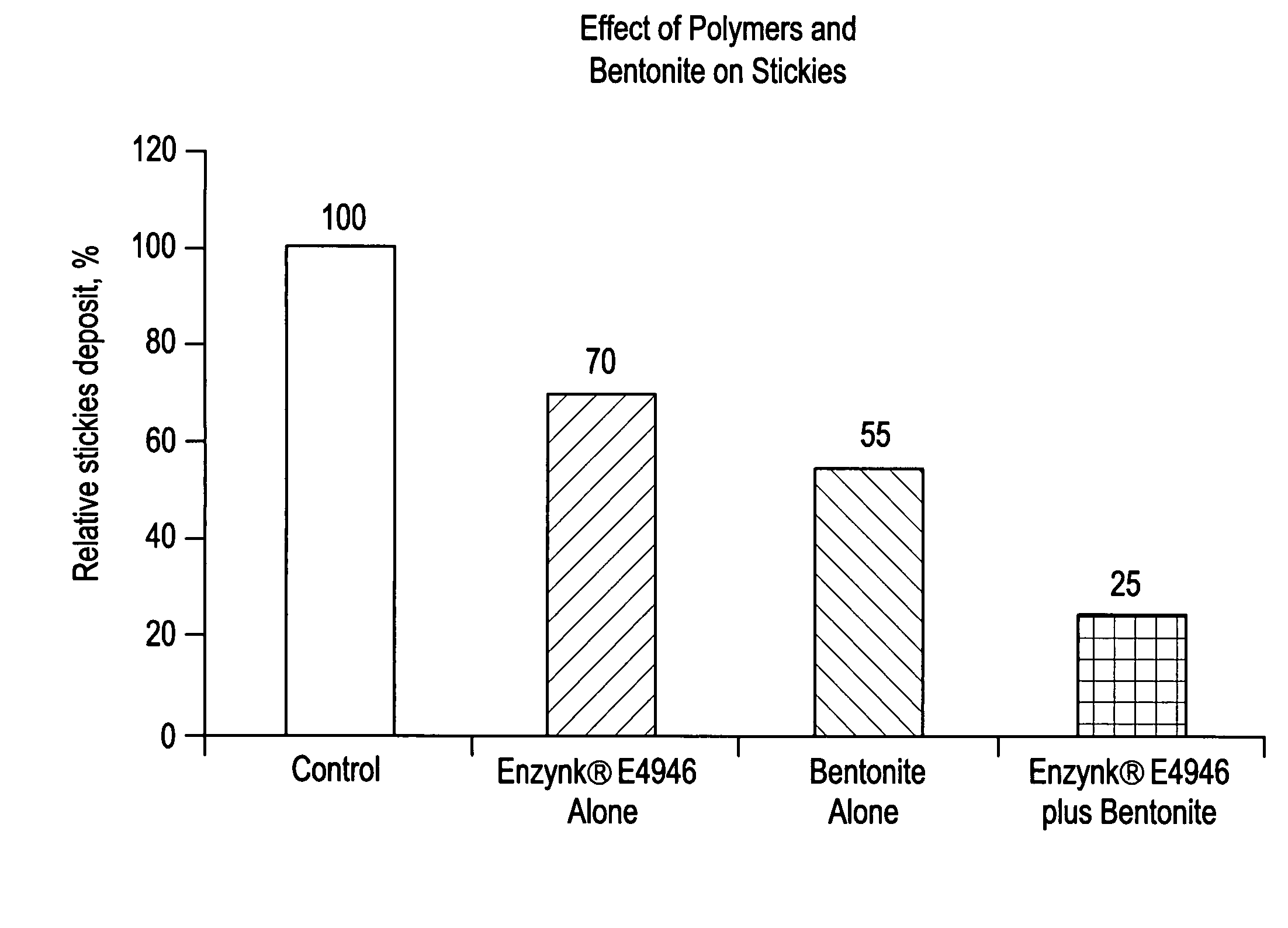

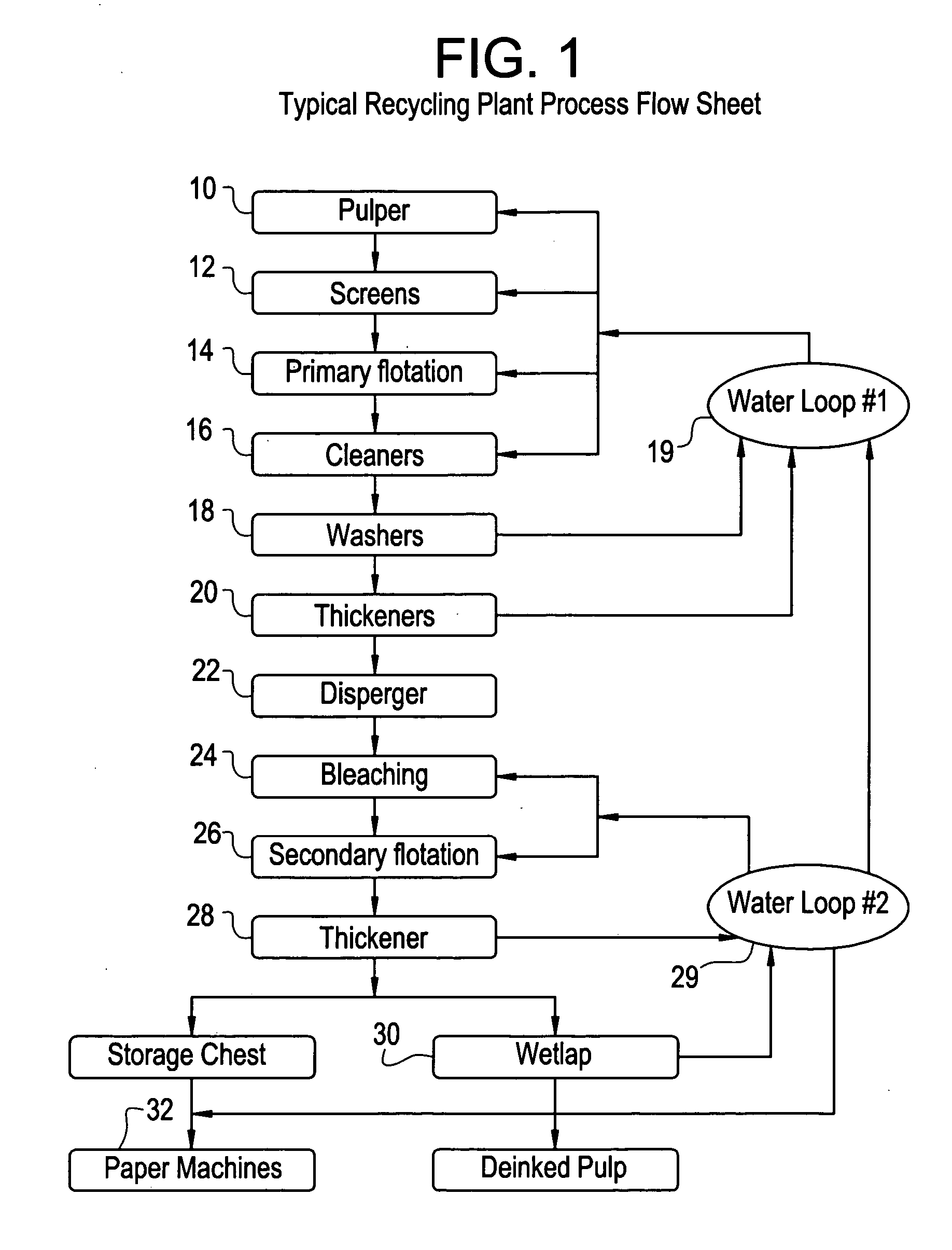

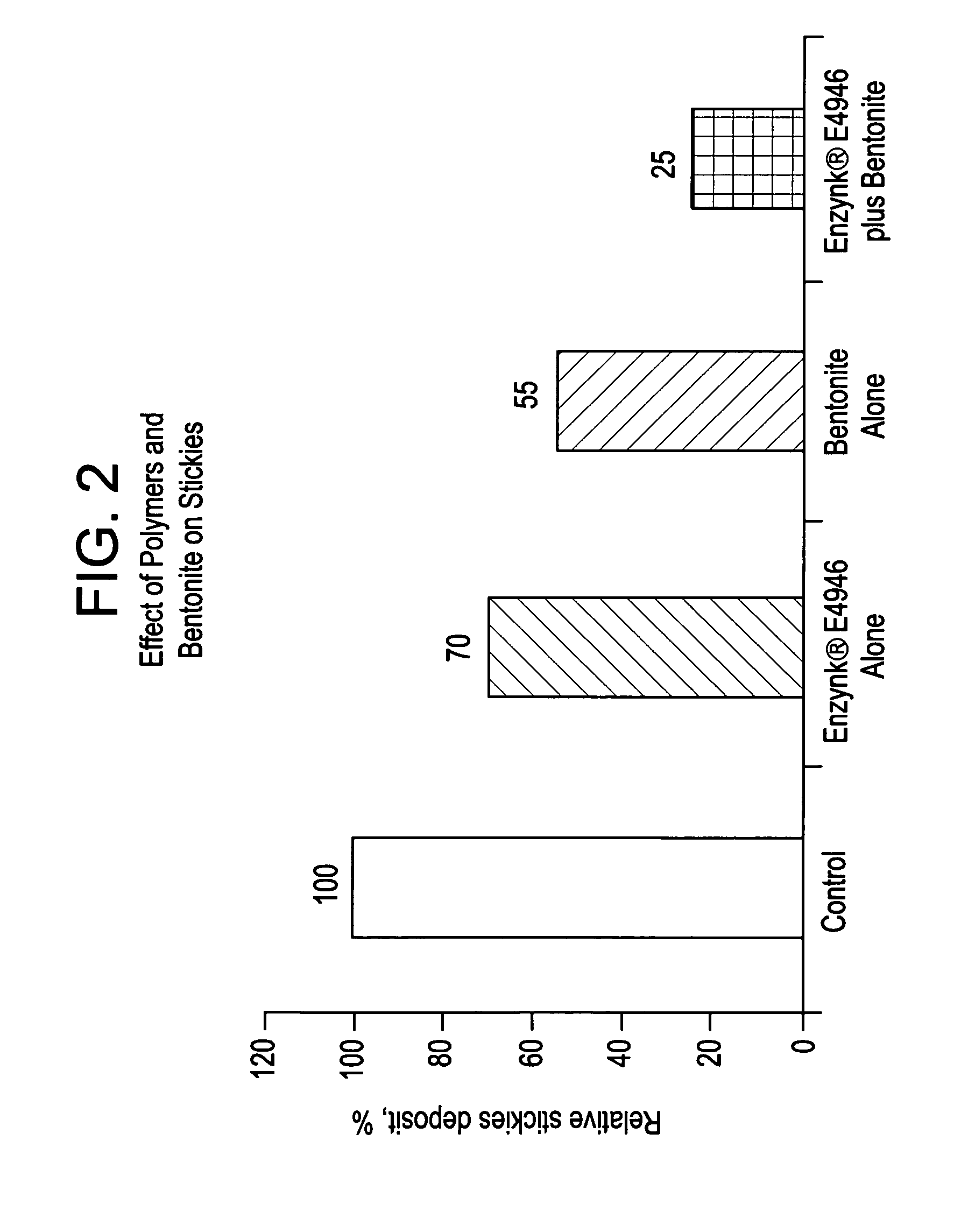

Enhanced removal and / or control of adhesives or sticky materials, “stickies”, from recovered paper stock or virgin pulp fibers is achieved using a combination of enzyme treatment with adsorbents and / or absorbents. Pulp stock to be treated is typically obtained from old magazines, newspapers, household waste, but may include corrugated boxes and office waste. Virgin pulps may include mechanical, chemical, or semi-chemical pulps. Enzymes typically include hydrolases such as cellulases, hemicellulases, pectinases, amylases, and lipases such as esterases, lyases such as pectate lyases, and oxidoreductases. Adsorbents include activated bentonite, microparticles, talc, clay and modified silica. Absorbents typically include water soluble polymers, dispersants, coagulatants and agglomerants.

Owner:ENZYMATIC DEINKING TECH LLC

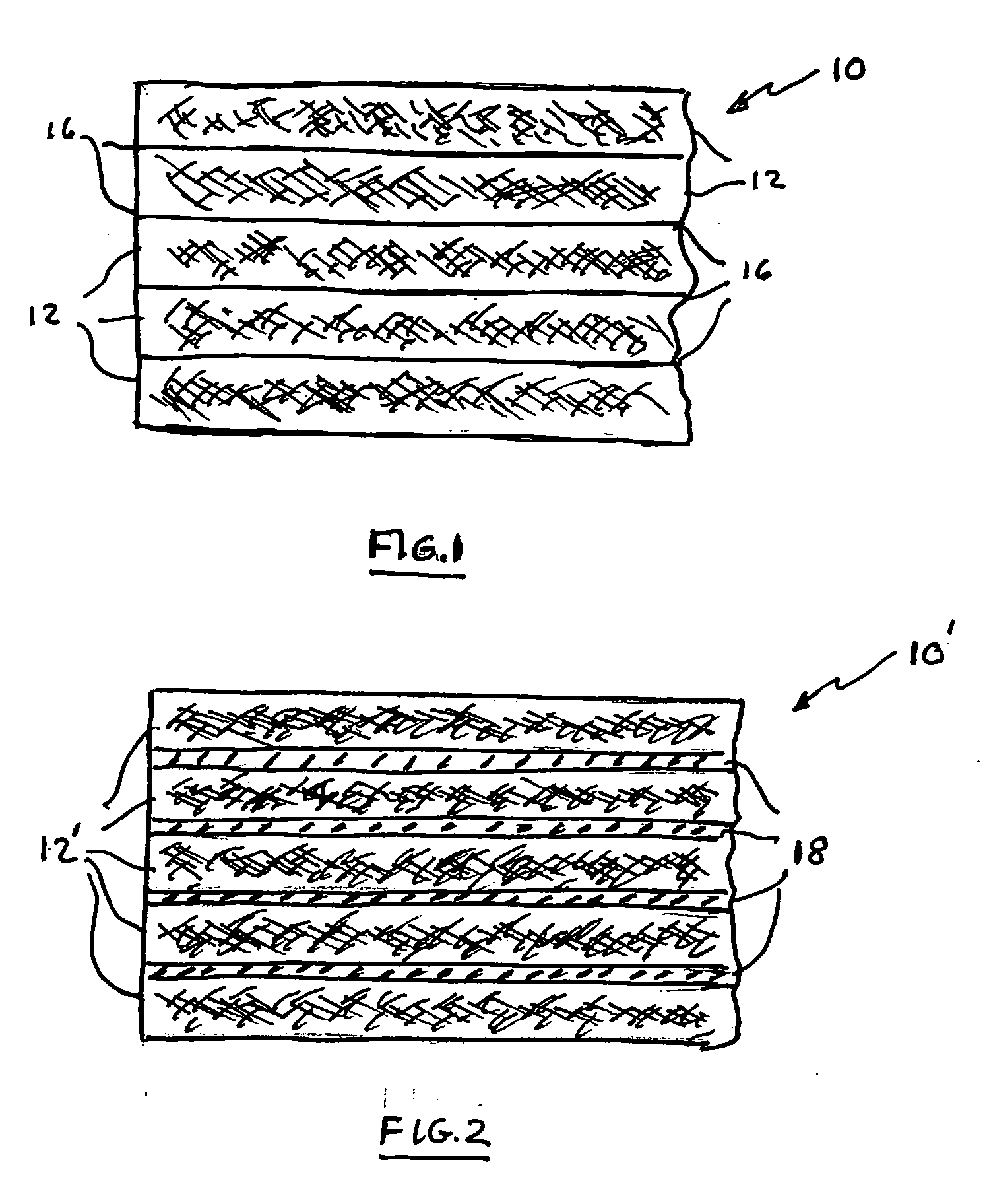

Wet crepe throughdry process for making absorbent sheet and novel fibrous products

InactiveUS20020148584A1Big cost advantageReduce air permeabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

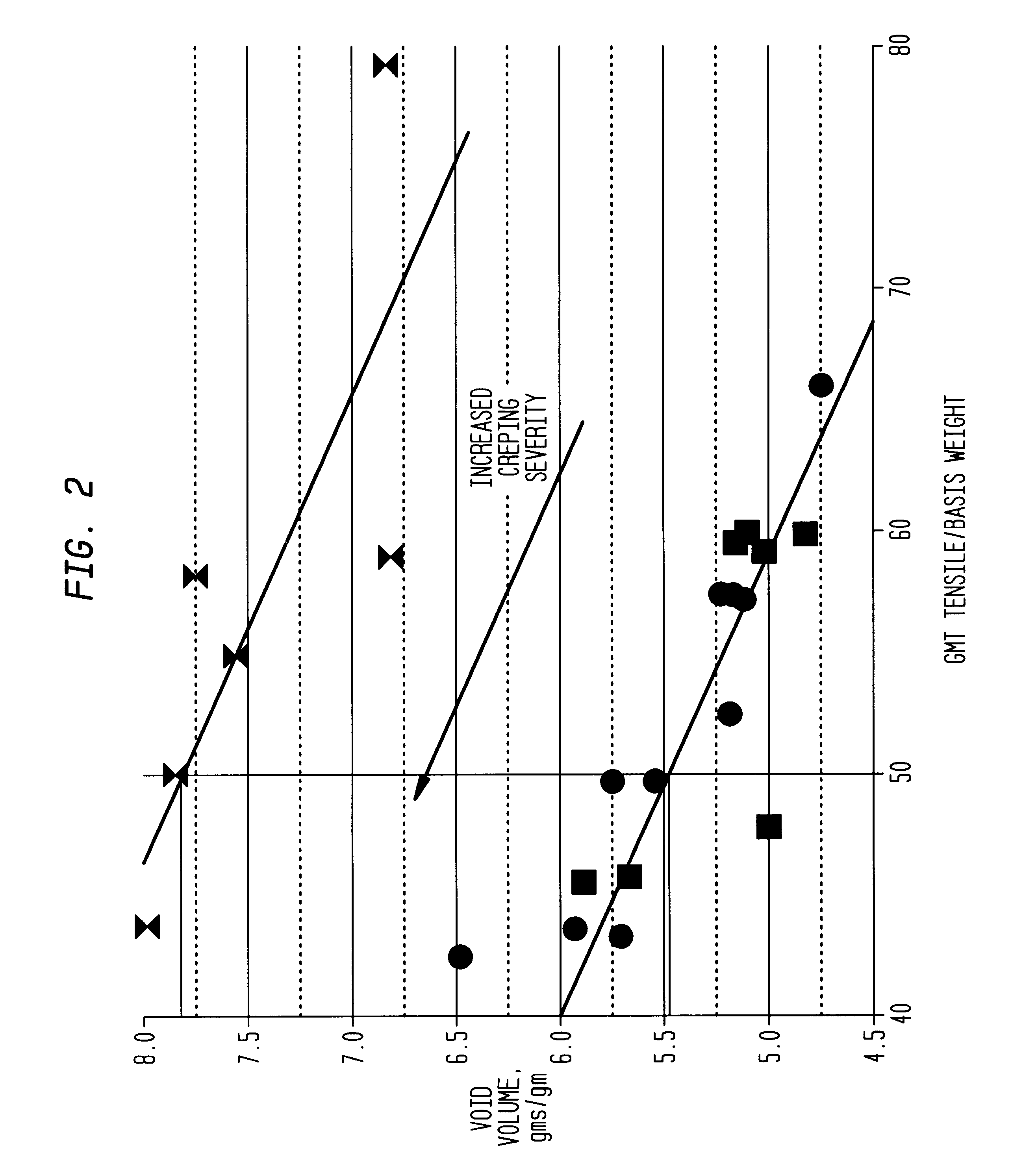

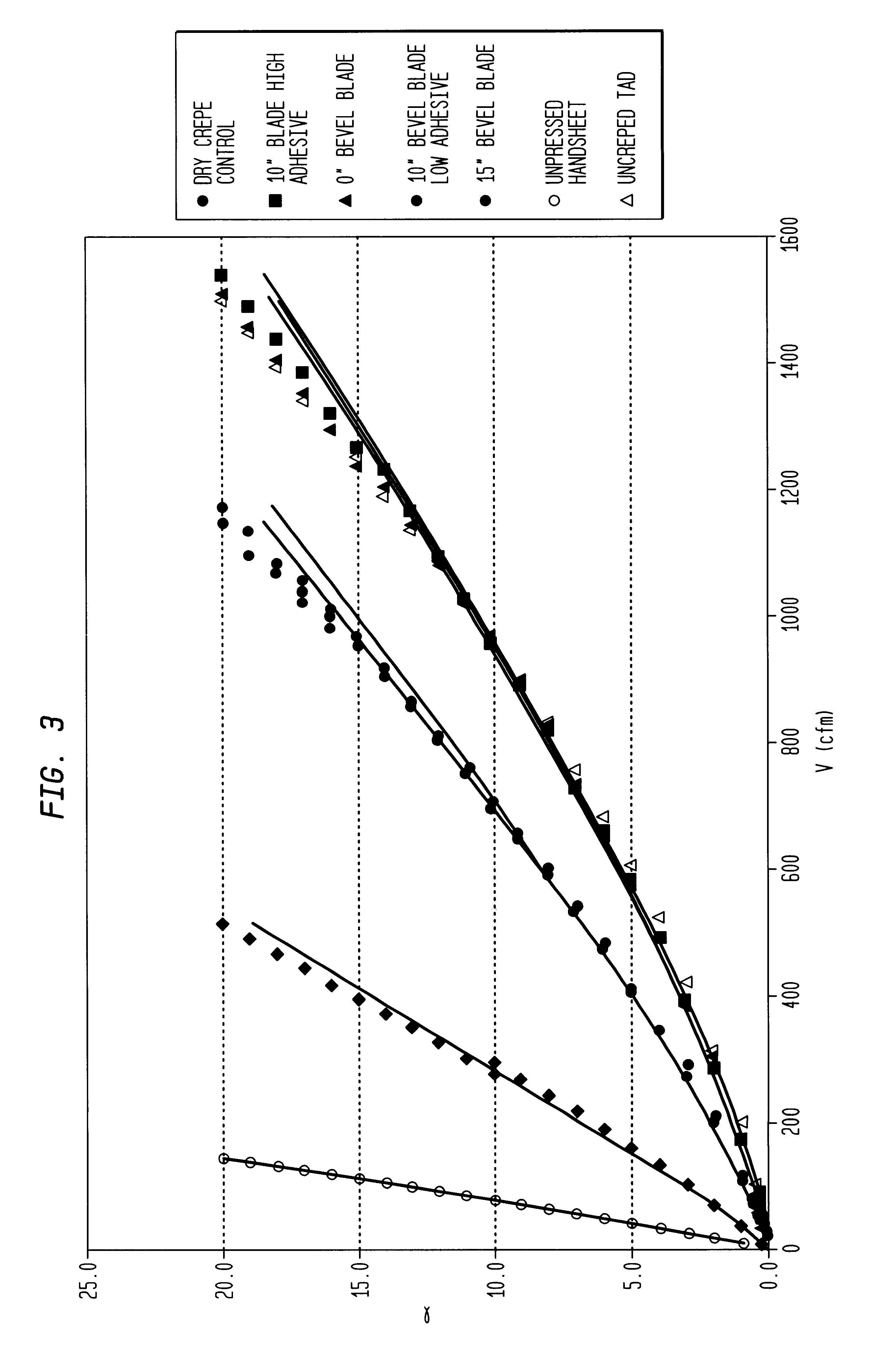

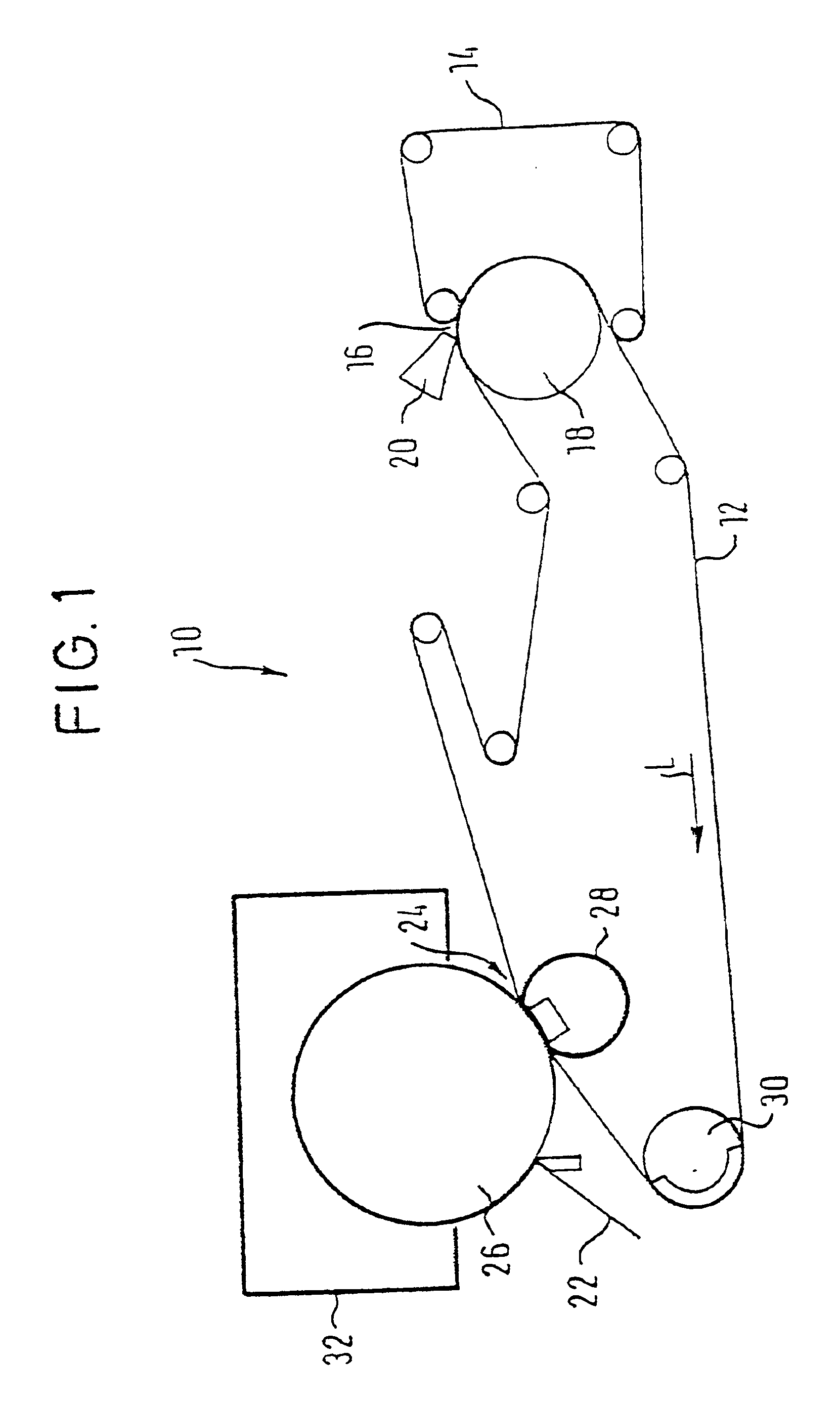

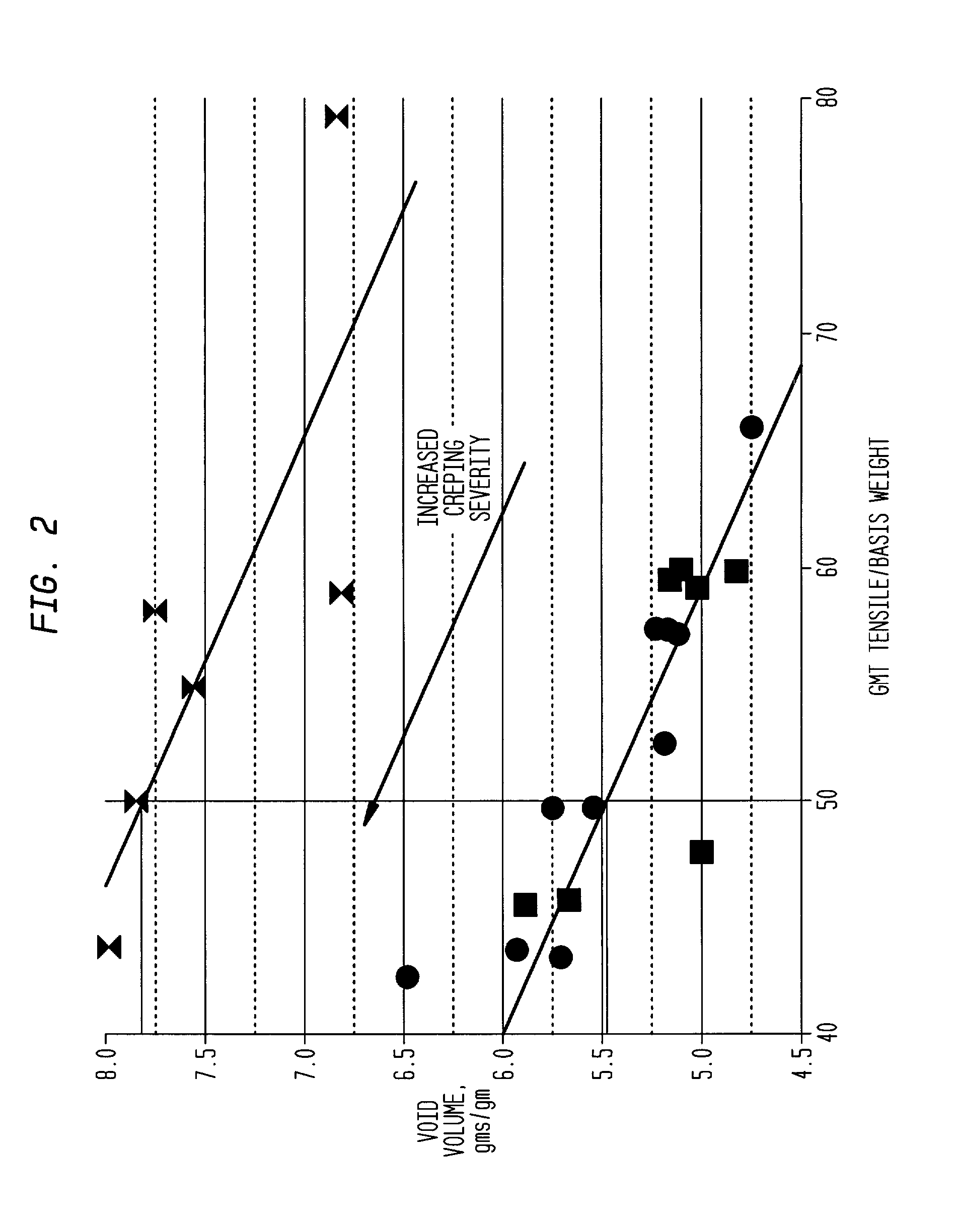

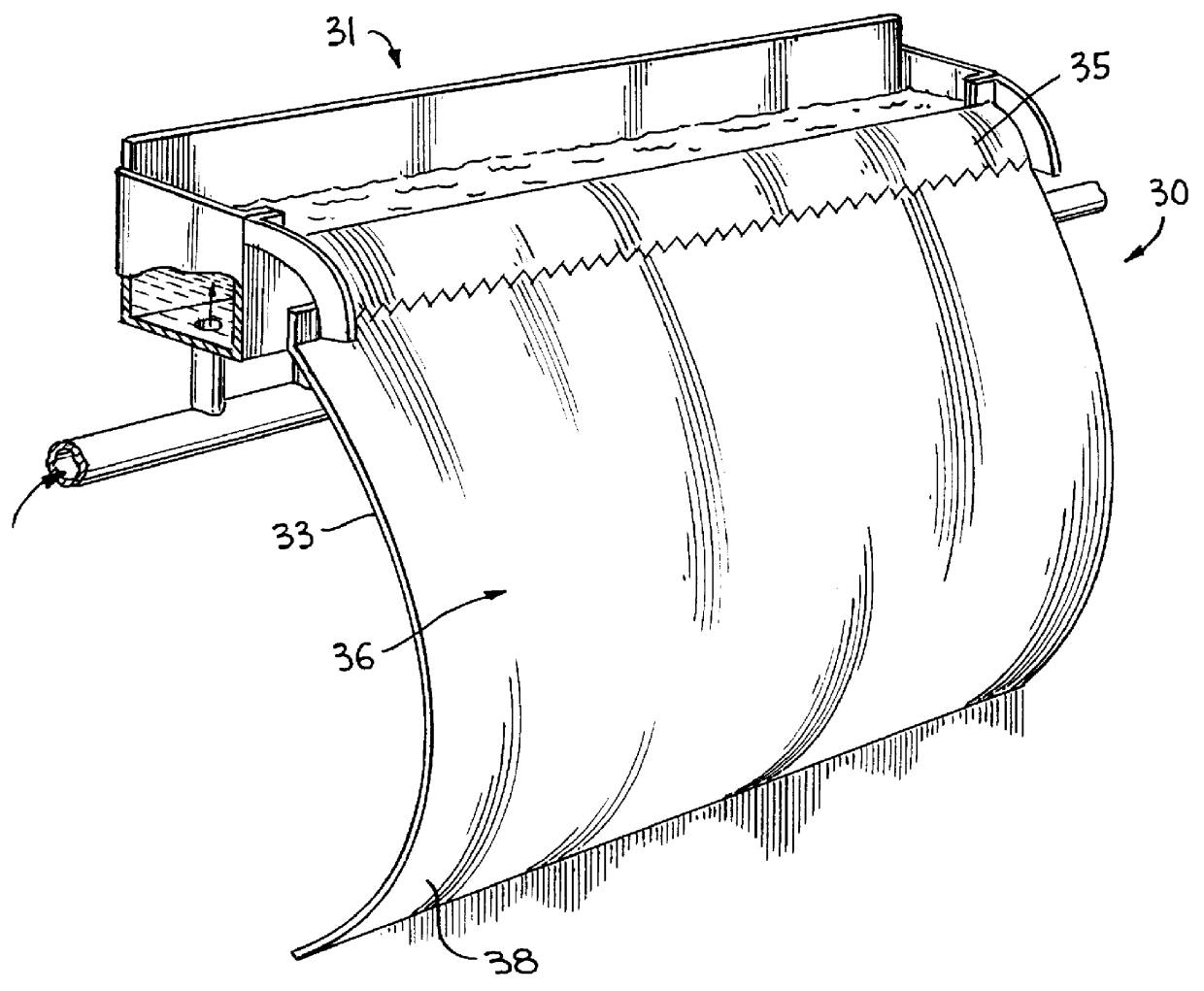

An improved process for making sheet from a fibrous furnish includes: depositing the furnish on a foraminous support; compactively dewatering the furnish to form a nascent web; drying the web on a heated cylinder; creping the web therefrom and throughdrying the web to a finished product. The microstructure of the web is controlled so as to facilitate throughdrying. The product exhibits a characteristic throughdrying coefficient of from 4 to 10 when the airflow through the sheet is characterized by a Reynolds Number of less than about 1. The novel products of the invention are characterized by wet springback ratio, hydraulic diameter and an internal bond strength parameter.

Owner:GPCP IP HLDG LLC

Modified creping adhesive composition and method of use thereof

ActiveUS20050245669A1Soften and plasticizeSoften and/or plasticize the creping adhesiveNon-fibrous pulp additionNatural cellulose pulp/paperPulp and paper industry

A modified creping adhesive composition, comprising an adhesive component and at least one terpene modifier, and its use in the production of creped paper products by a process which includes the steps of adhering a paper web to the surface of a drying cylinder and separating the paper web from the drying cylinder with a creping blade.

Owner:GPCP IP HLDG LLC

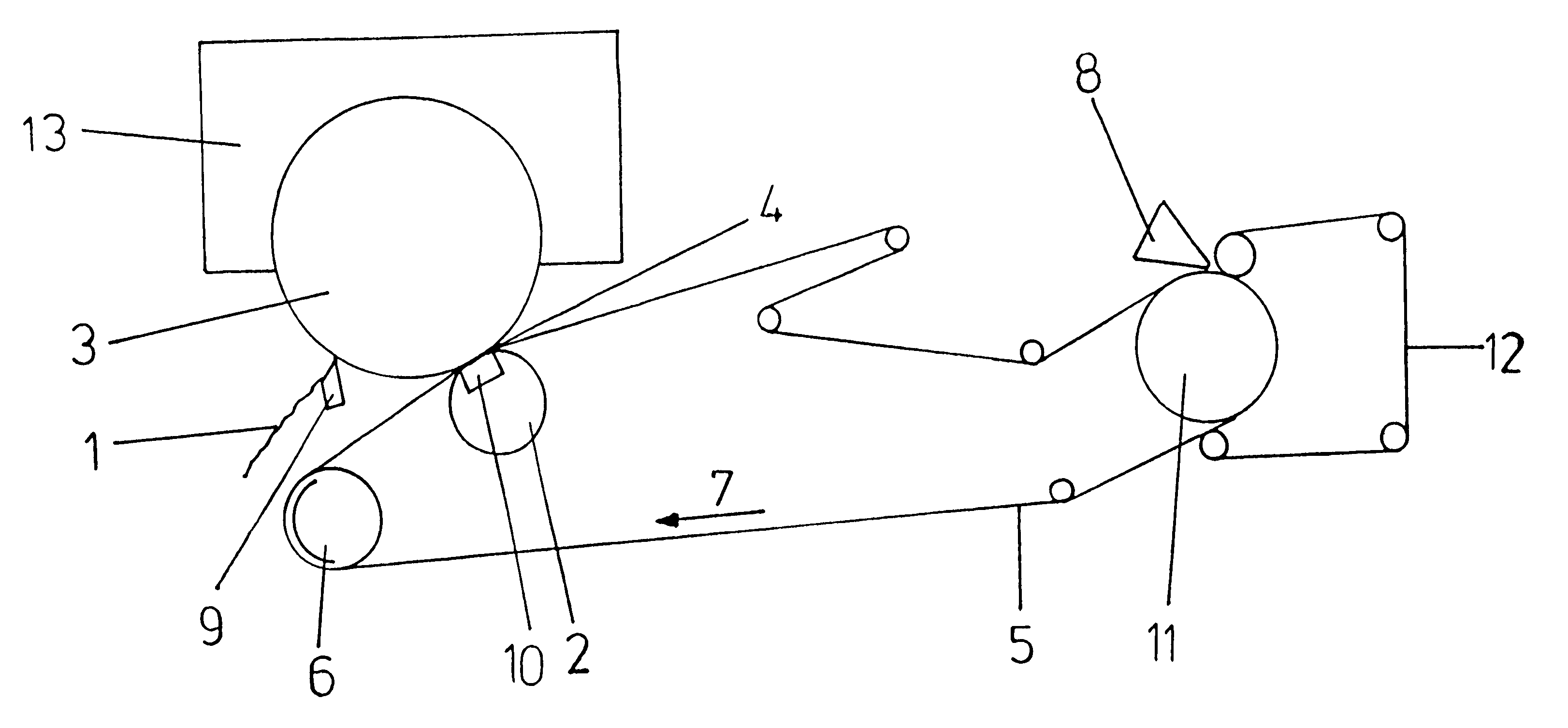

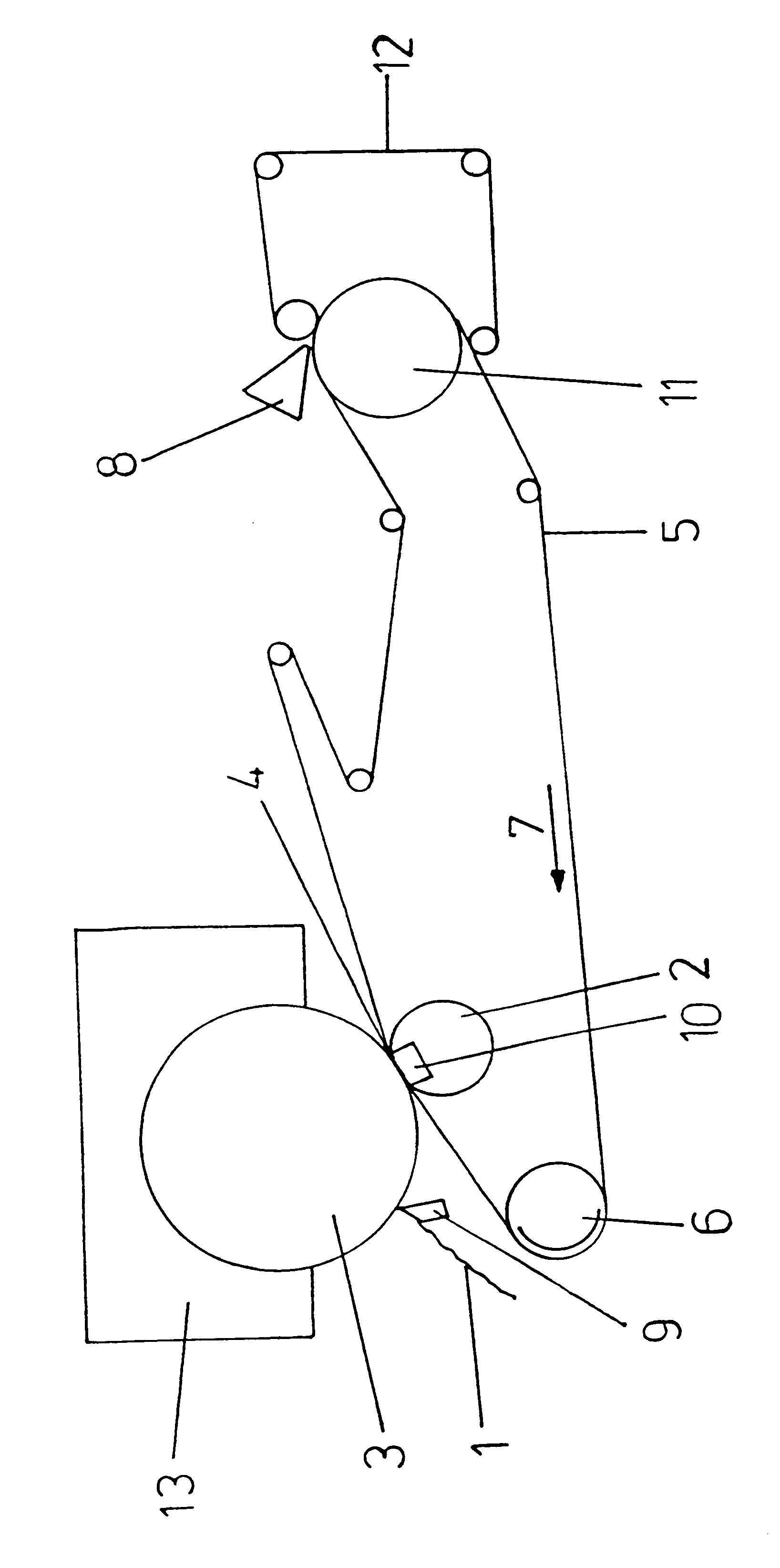

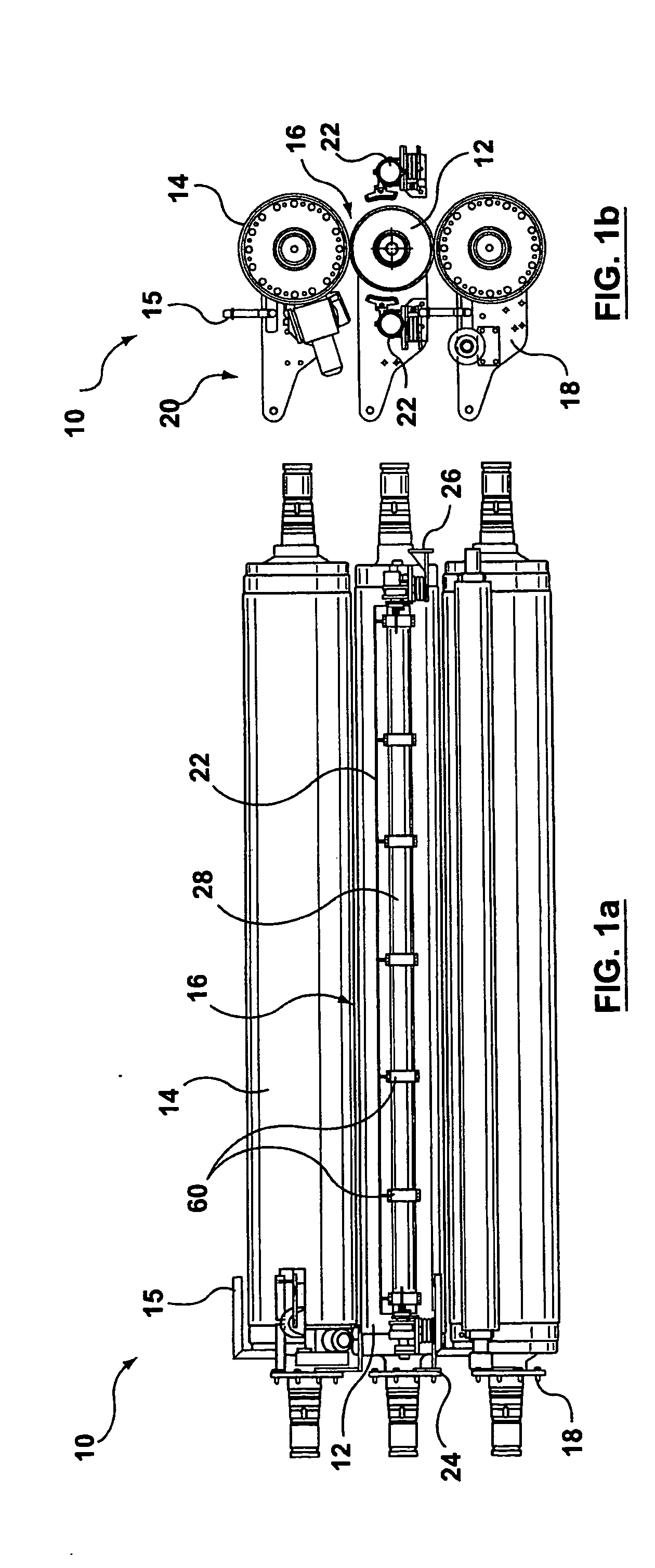

Former and process for producing a tissue web

InactiveUS6821391B2Improve adhesionIncrease vacuumNon-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineering

A former for producing a tissue web and a process of making a tissue web using the former. The former includes a forming element, an inner dewatering belt, and an outer dewatering belt. The inner and outer belts converge to form a stock inlet nip. The inner and outer belts are guided over the forming element and thereafter separating from one another in the area of a separation point. At least one suction element is positioned adjacent the inner belt on a side which is opposite the outer belt. Alternatively, a conditioning device is positioned adjacent the outer belt. The process includes forming the tissue web in the area of the forming element, guiding the inner and outer belts around the forming element, and separating the inner and outer belts in the area of the separation point. Alternatively, the process includes conditioning the outer belt.

Owner:VOITH PATENT GMBH

Wet crepe throughdry process for making absorbent sheet and novel fibrous product

An improved process for making sheet from a fibrous furnish includes: depositing the furnish on a foraminous support; compactively dewatering the furnish to form a nascent web; drying the web on a heated cylinder; creping the web therefrom and throughdrying the web to a finished product. The microstructure of the web is controlled so as to facilitate throughdrying. The product exhibits a characteristic throughdrying coefficient of from 4 to 10 when the airflow through the sheet is characterized by a Reynolds Number of less than about 1. The novel products of the invention are characterized by wet springback ratio, hydraulic diameter and an internal bond strength parameter.

Owner:GPCP IP HLDG LLC

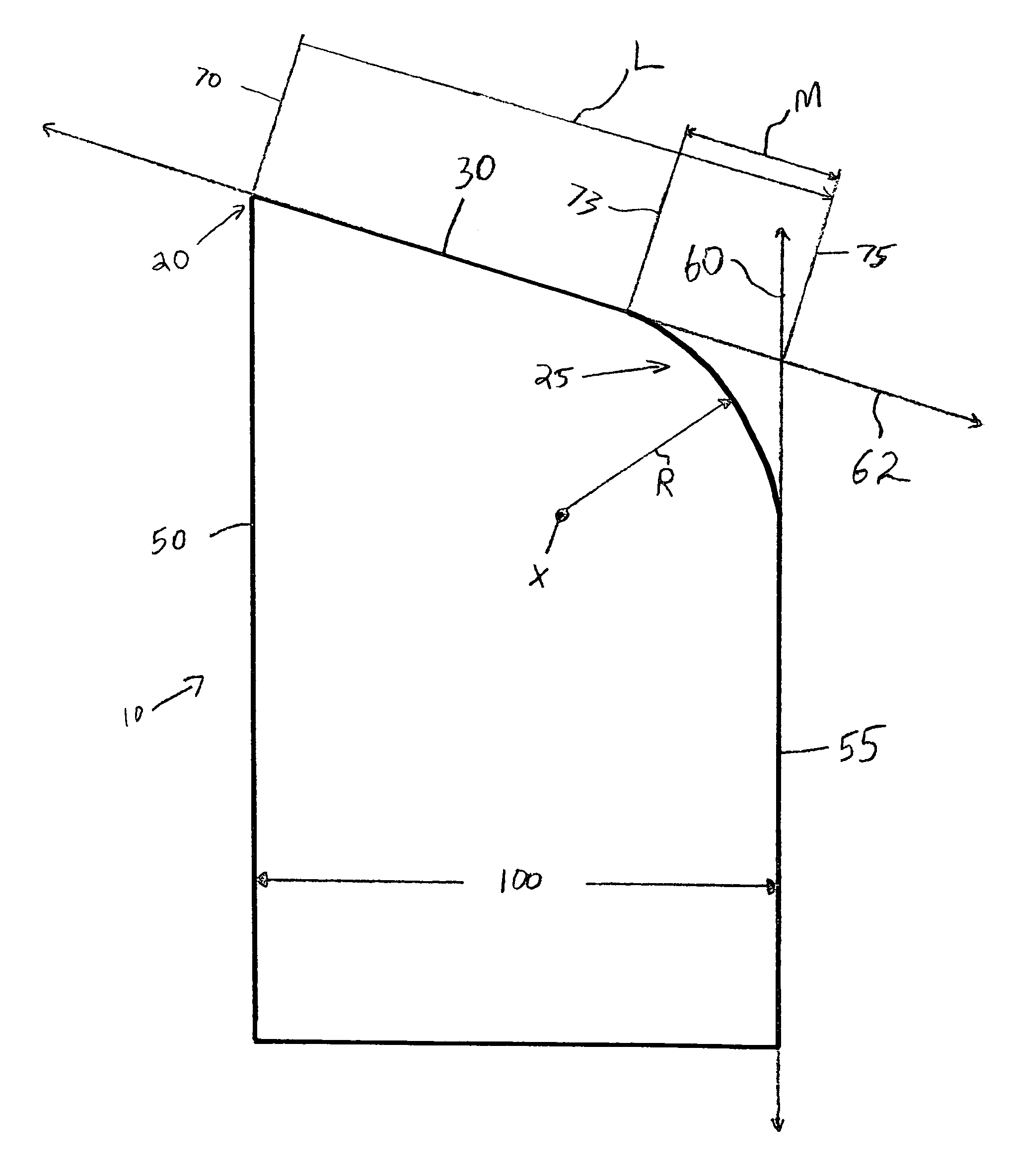

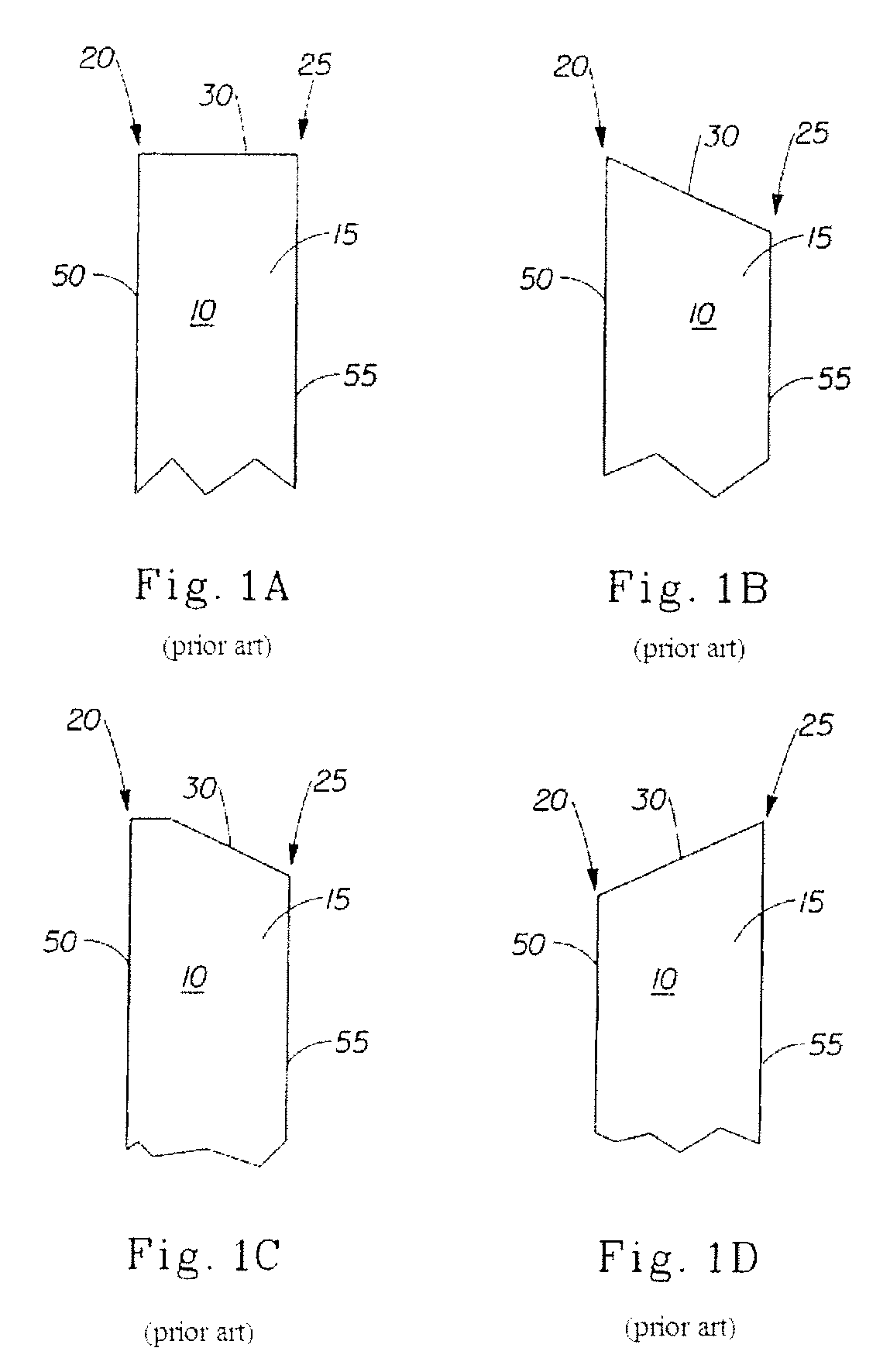

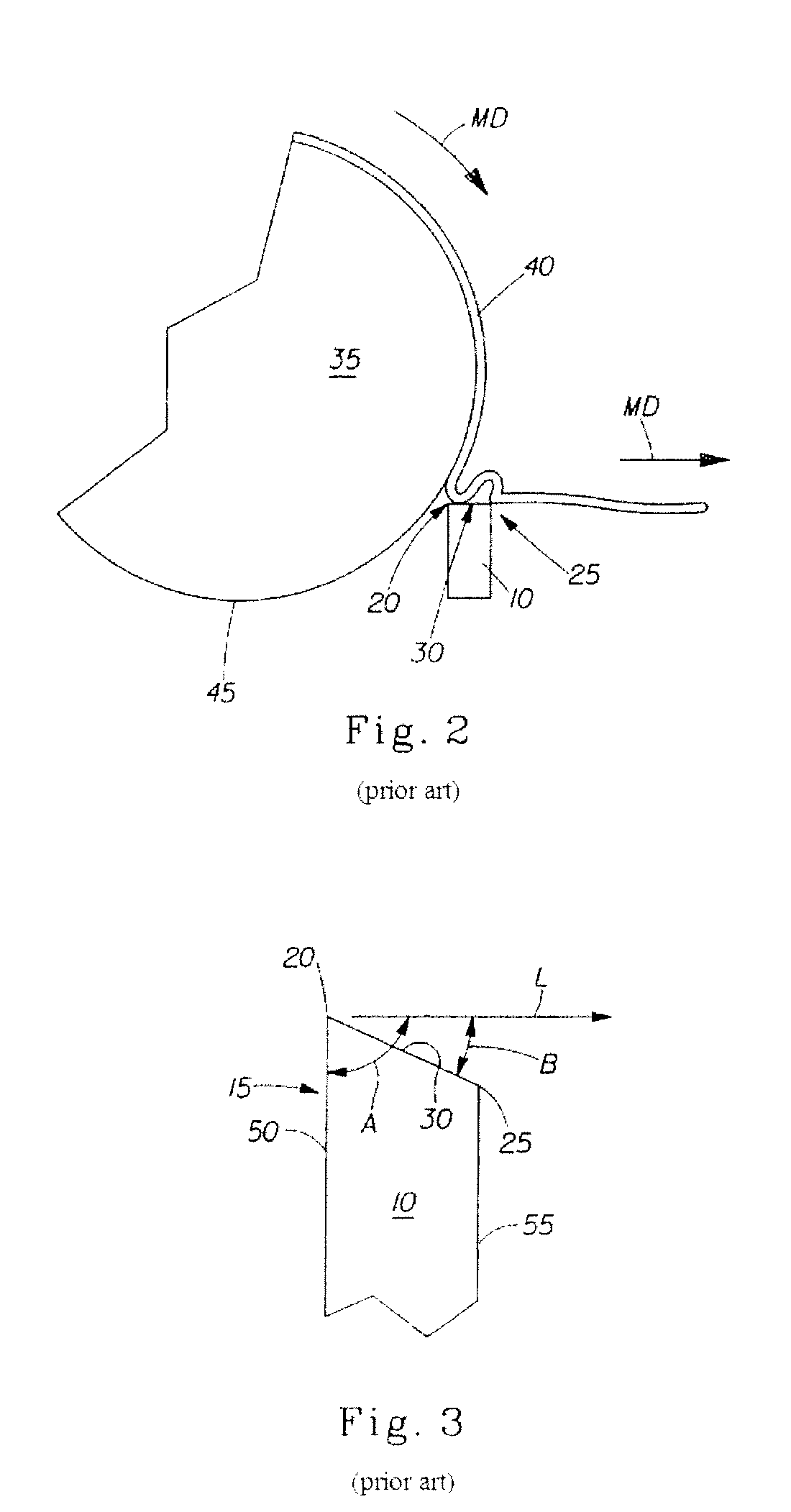

Creping blade

A creping blade including a body having a leading side, a trailing side, and working end including a bevel surface. The bevel surface is defined by a leading edge and a trailing edge, wherein the trailing edge of the creping blade has a trailing edge radius of greater than about 0.001 inches (about 0.0254 mm).

Owner:PROCTER & GAMBLE CO

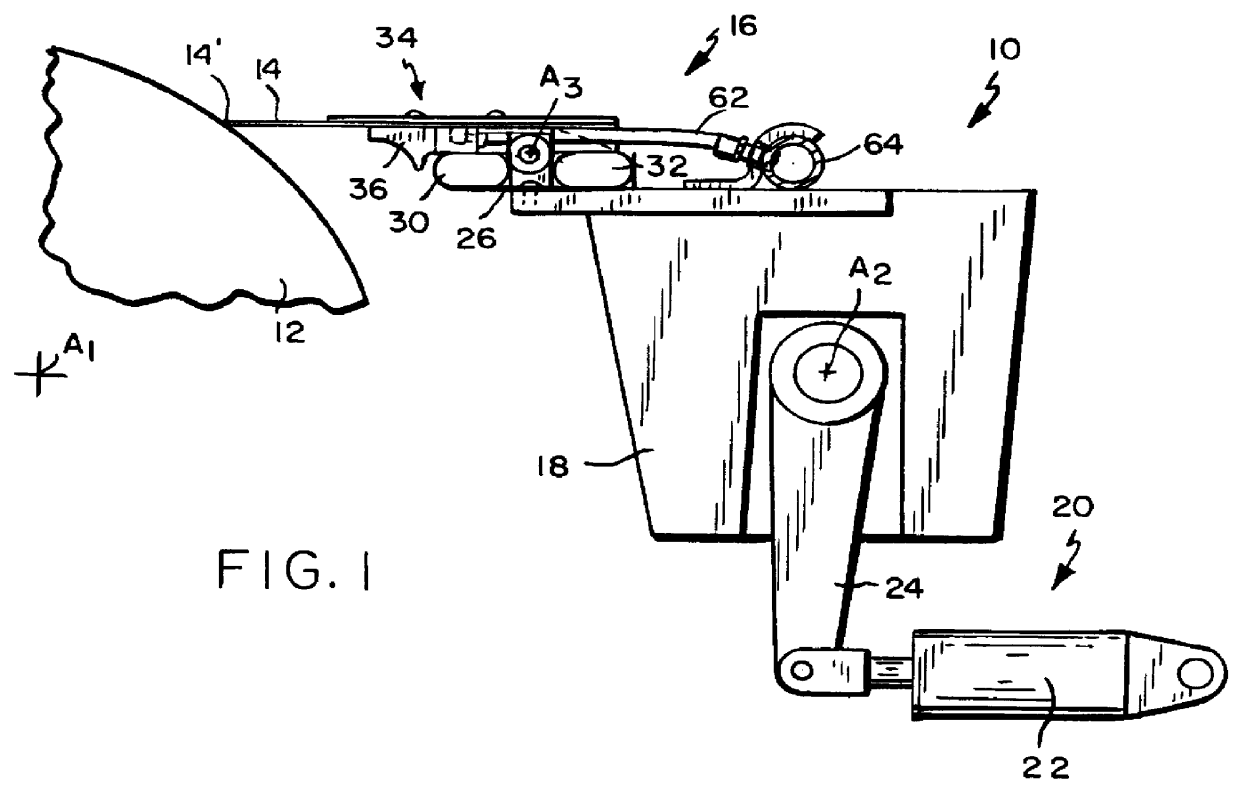

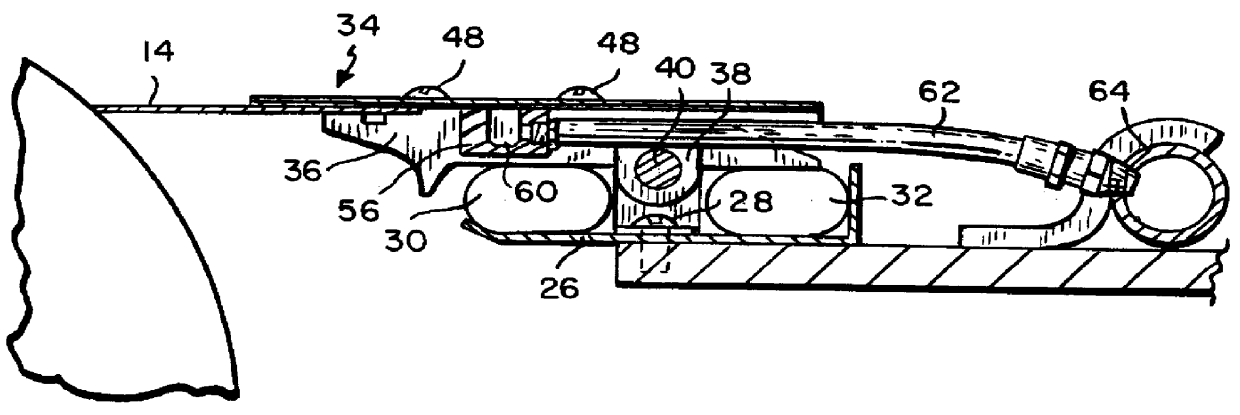

Fluid assisted doctor

InactiveUS6139638ALiquid surface applicatorsMechanical working/deformationMechanical engineeringEngineering

Owner:KADANT WEB SYSTEMS INC

Modified creping adhesive composition and method of use thereof

ActiveUS7404875B2Soften and/or plasticize the creping adhesiveNatural cellulose pulp/paperMechanical working/deformationPulp and paper industryPolymer science

A modified creping adhesive composition, comprising an adhesive component and at least one terpene modifier, and its use in the production of creped paper products by a process which includes the steps of adhering a paper web to the surface of a drying cylinder and separating the paper web from the drying cylinder with a creping blade.

Owner:GPCP IP HLDG LLC

Method and system for collecting and handling dust in a papermachine environment

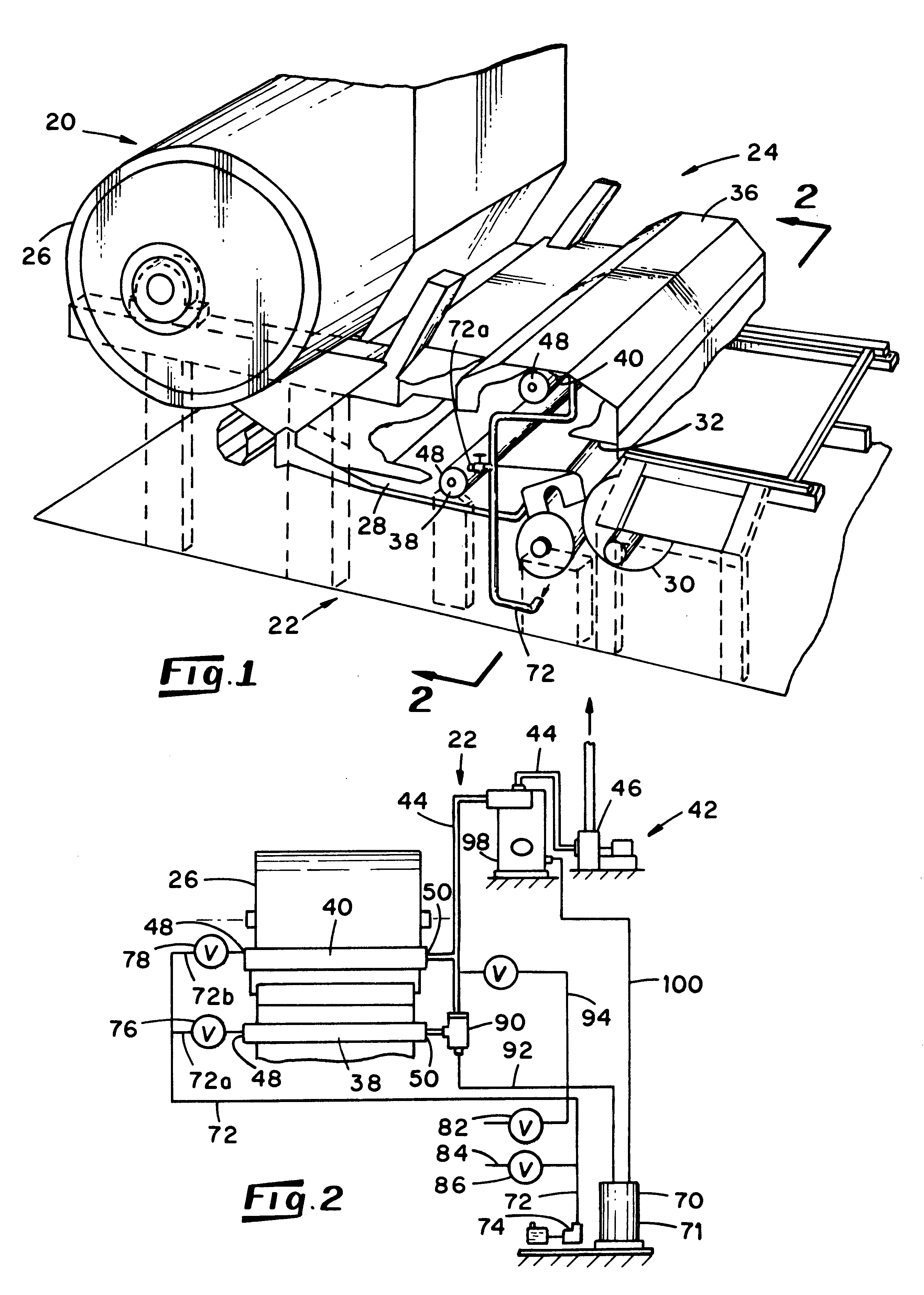

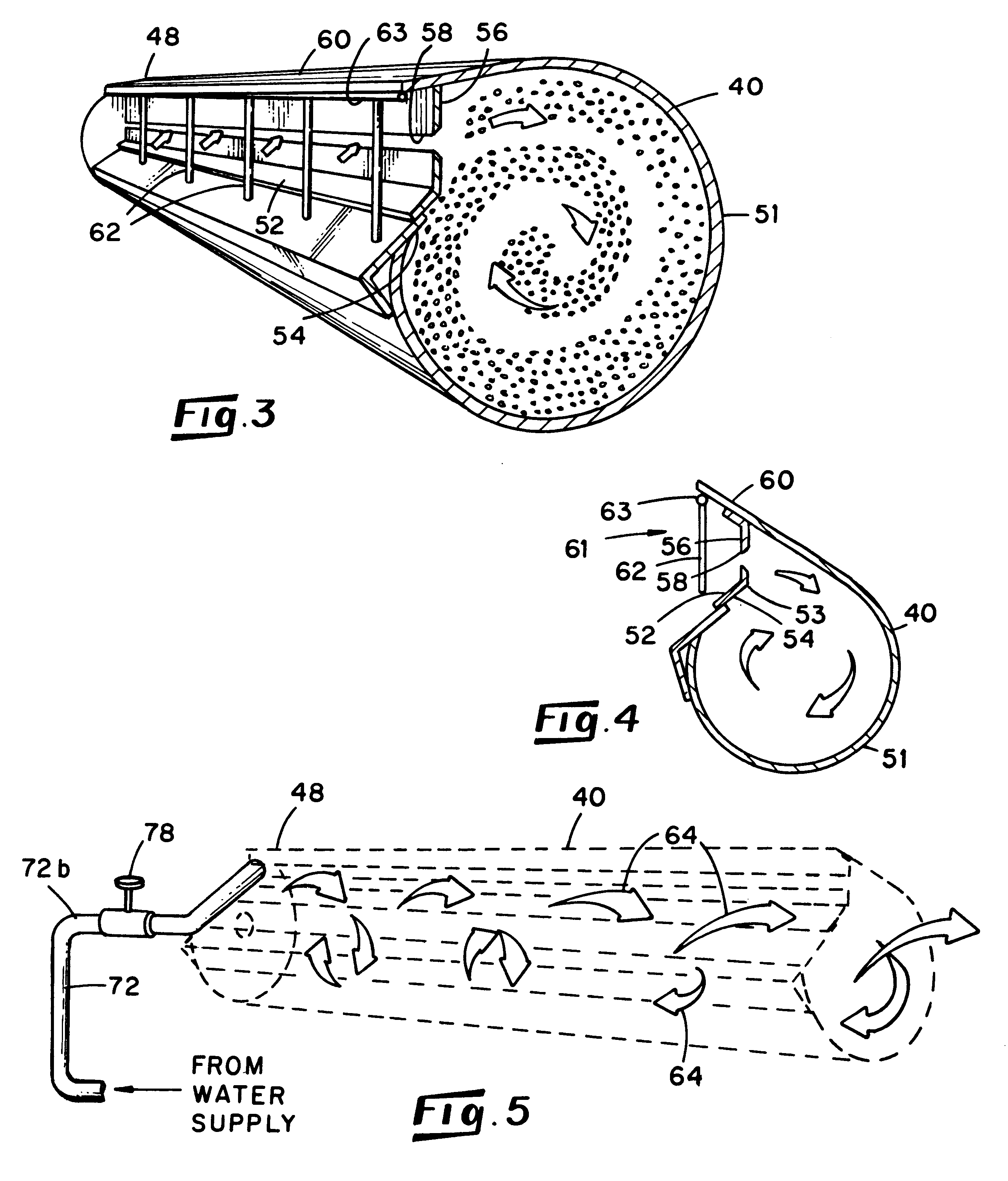

An improved process and system for collecting and handling dust in a papermaking machine environment wherein dust-laden air is drawn into and moves along an elongated collector by way of a vacuum-generating source connected to the collector involves the introduction of water into the collector so that the introduced water becomes entrained by the dust-laden air moving through the collector and wet-scrubs the dust-laden air upon entering the collector. With the dust being wet-scrubbed upon exiting the collector, the likelihood of ductwork fouling is substantially eliminated, and the risk of fire in the ductwork downstream of the collector is appreciably reduced.

Owner:VALMET OY

Papermaking machine for forming tissue employing an air press

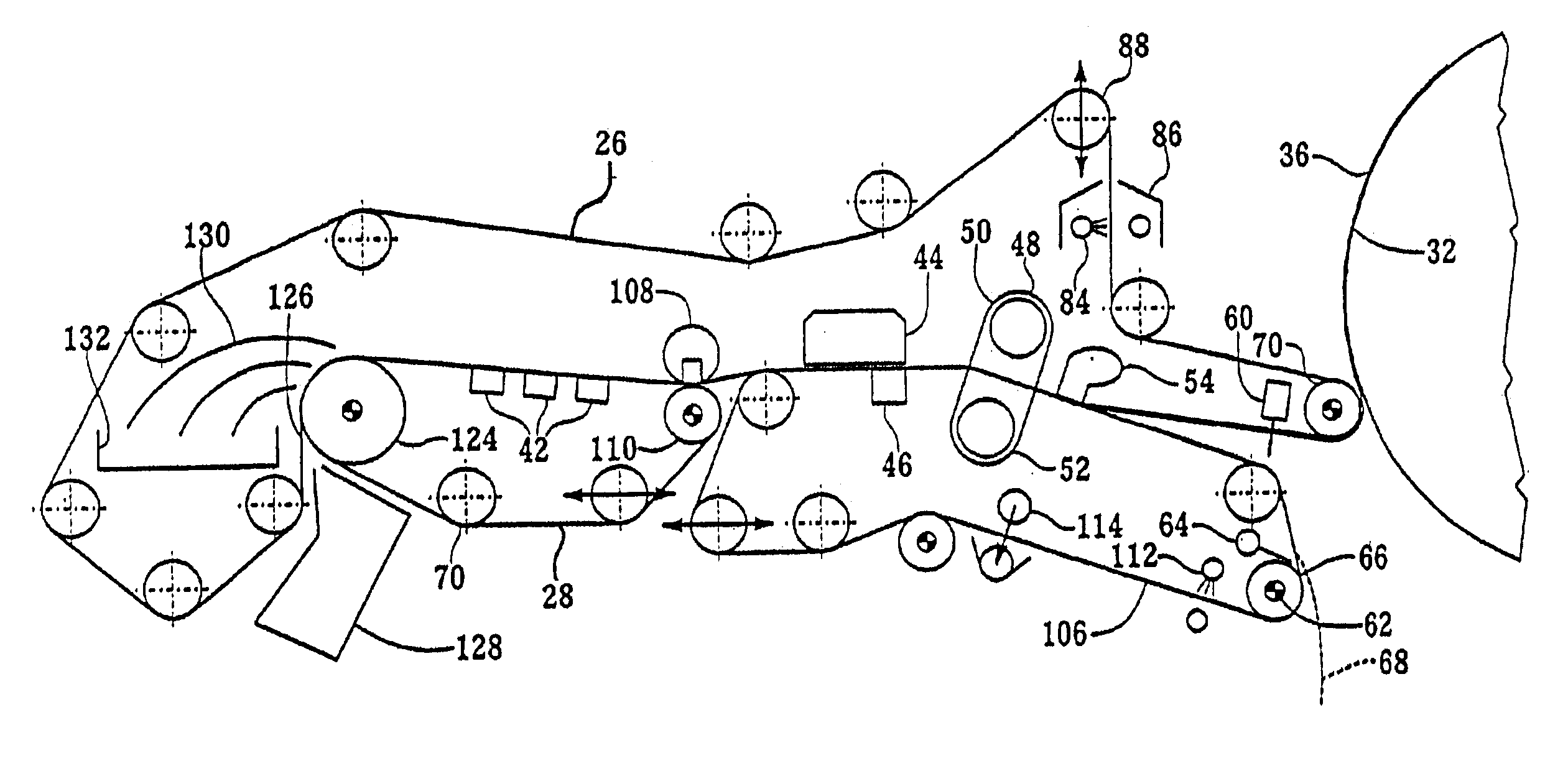

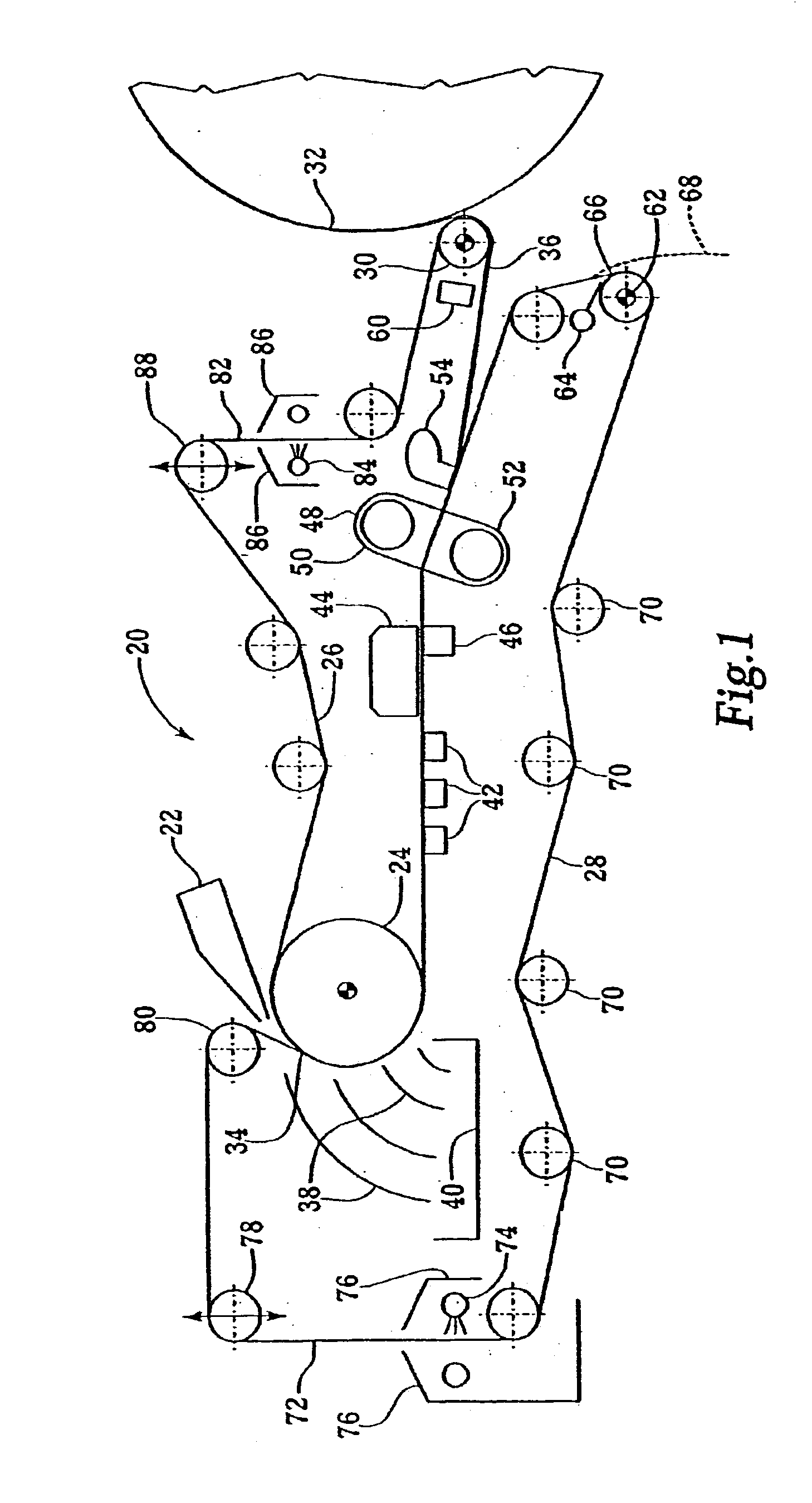

InactiveUS20050150626A1Shorten the lengthIncrease speedNon-fibrous pulp additionNatural cellulose pulp/paperLow vacuumPaper machine

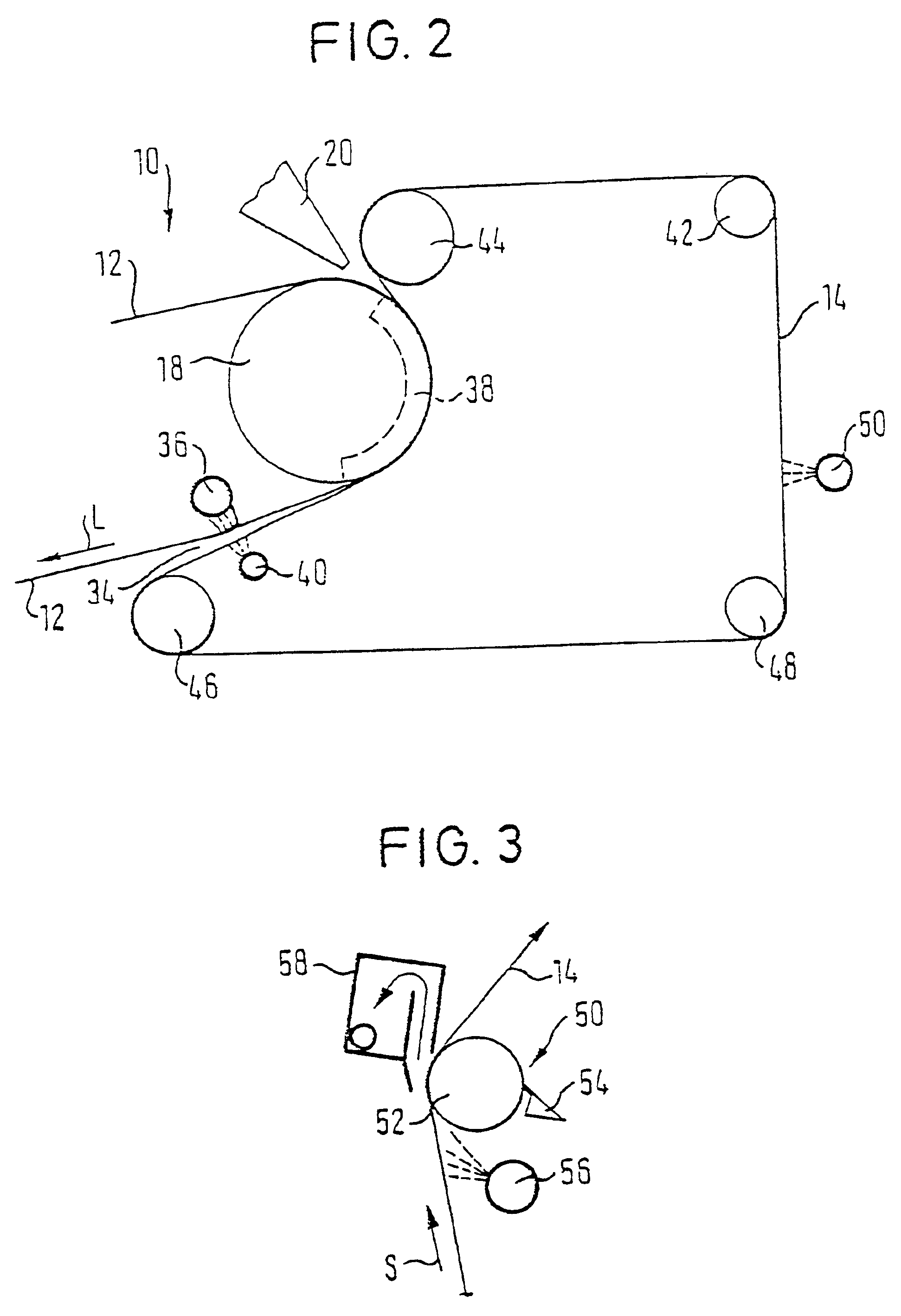

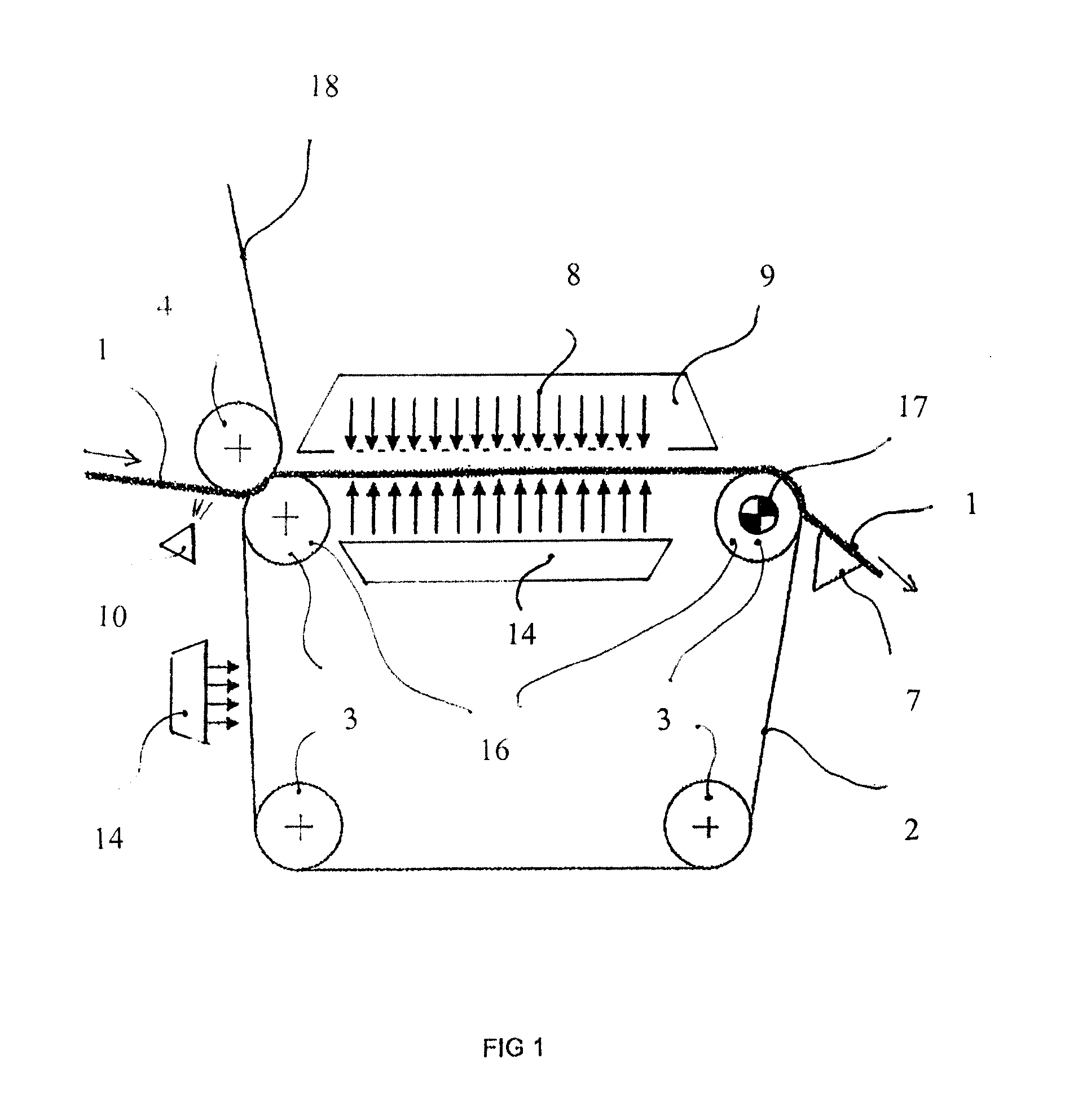

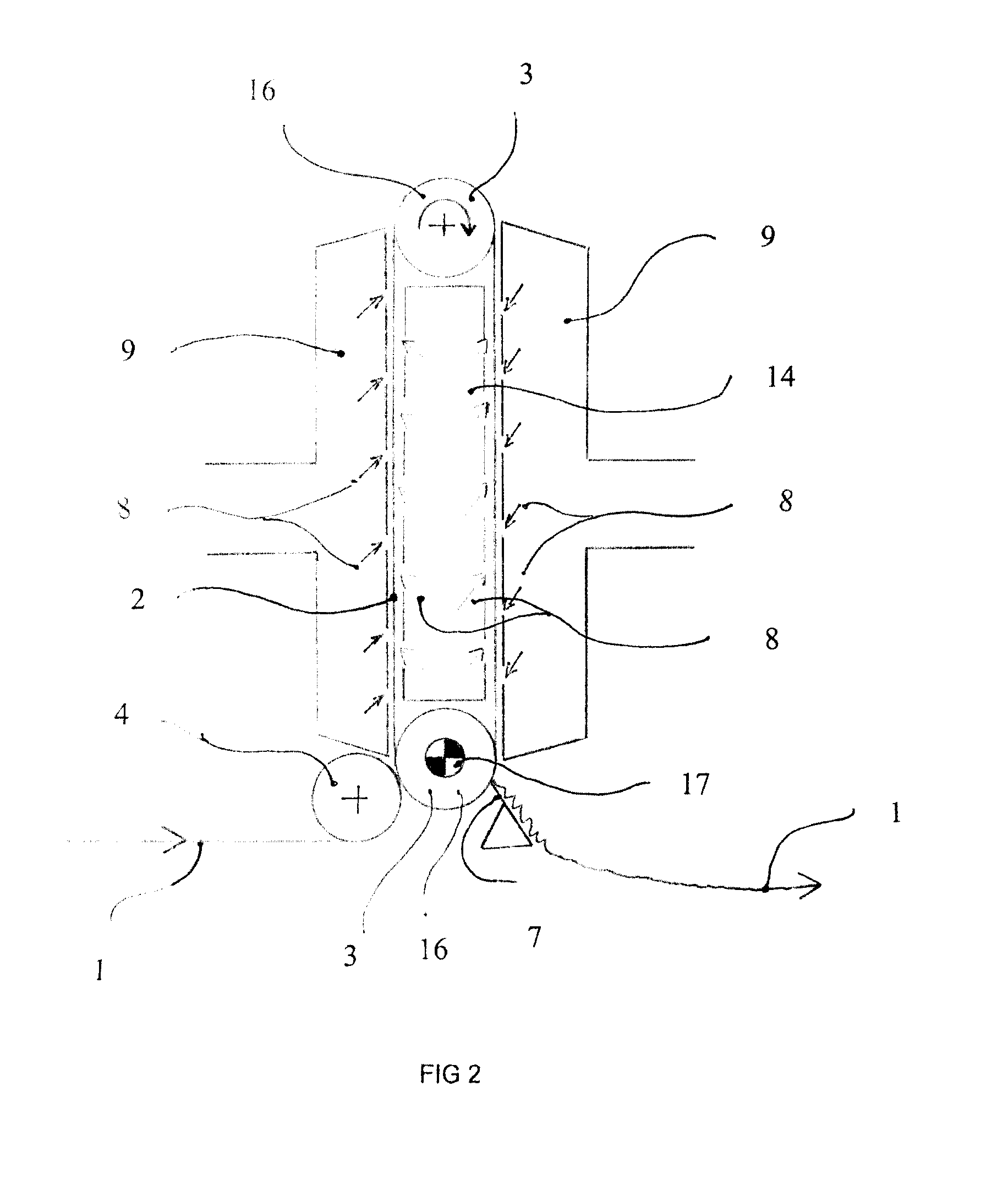

A web of tissue is formed in a twin wire former, followed by an air press for water removal in the pressing section, passing onto a Yankee dryer. A headbox injects stock between upper and lower dryer fabrics brought together on a breast roll. The fabrics moves over vacuum boxes, and the web is heated with steam and passed between an upper pressure box and a lower vacuum box forming an air press which dewaters the web. A sheet transfer pickup vacuum box holds the sheet to the upper fabric as the lower fabric diverges from the upper fabric. A pressure roller transfers the web onto a Yankee dryer. The fabrics are cleaned on vertical runs before returning to the breast roll. A final forming fabric is arranged to operated at a lower speed than the penultimate forming fabric so that a rush transfer and creping like action takes place.

Owner:VALMET TECH INC

Papermaking machine for forming tissue employing an air press

InactiveUS6863777B2Increases web bulk and absorbencyShorten the lengthNon-fibrous pulp additionNatural cellulose pulp/paperLow vacuumAirflow

A web of tissue is formed in a twin wire former, followed by an air press for water removal in the pressing section, passing onto a Yankee dryer. A headbox injects stock between upper and lower dryer fabrics brought together on a breast roll. The fabrics move over vacuum boxes, and the web is heated with steam and passed between an upper pressure box and a lower vacuum box forming an air press which dewaters the web. A sheet transfer pickup vacuum box holds the sheet to the upper fabric as the lower fabric diverges from the upper fabric. A pressure roller transfers the web onto a Yankee dryer. The fabrics are cleaned on vertical runs before returning to the breast roll.

Owner:VALMET TECH INC

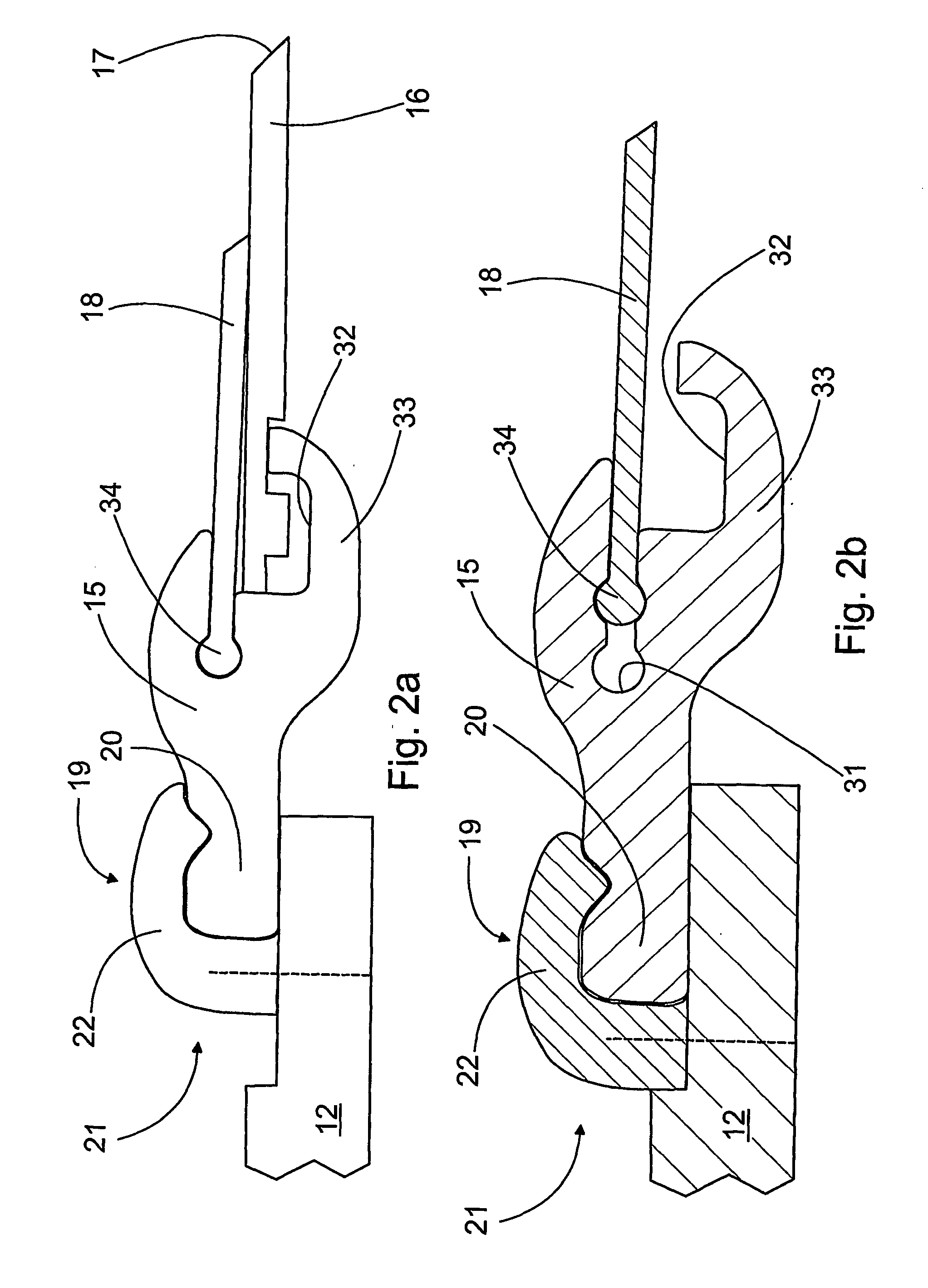

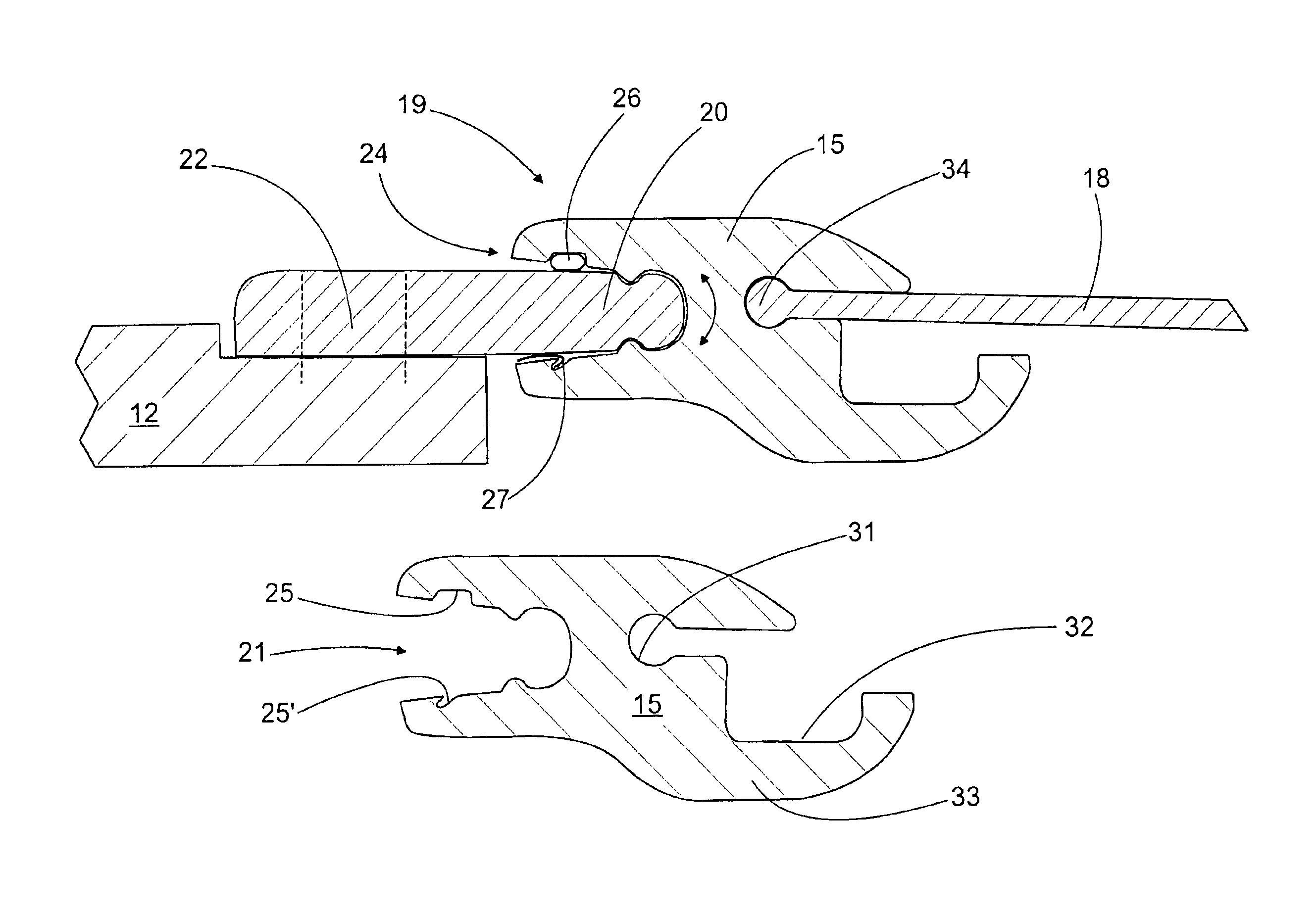

Composite-construction treatment equipment

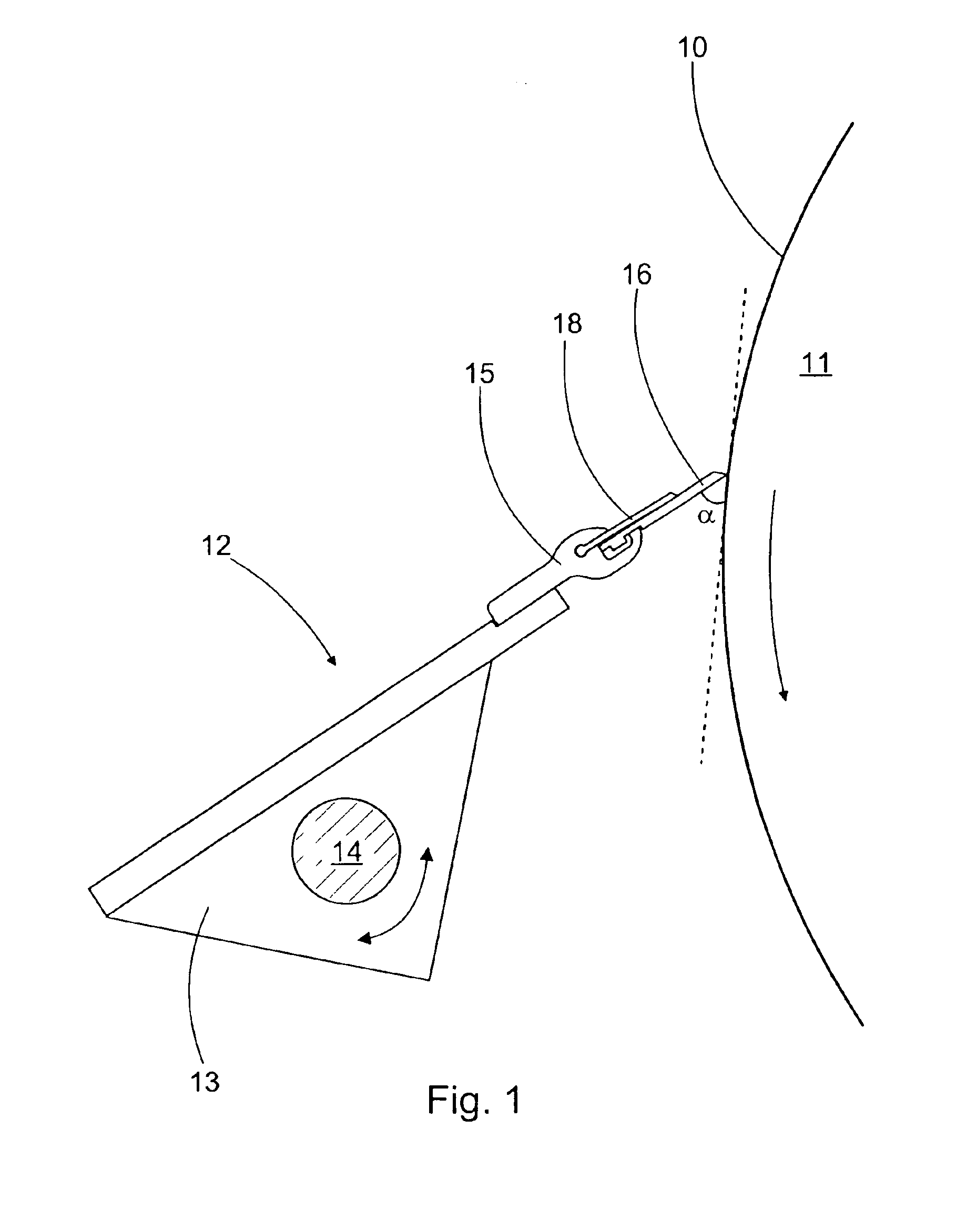

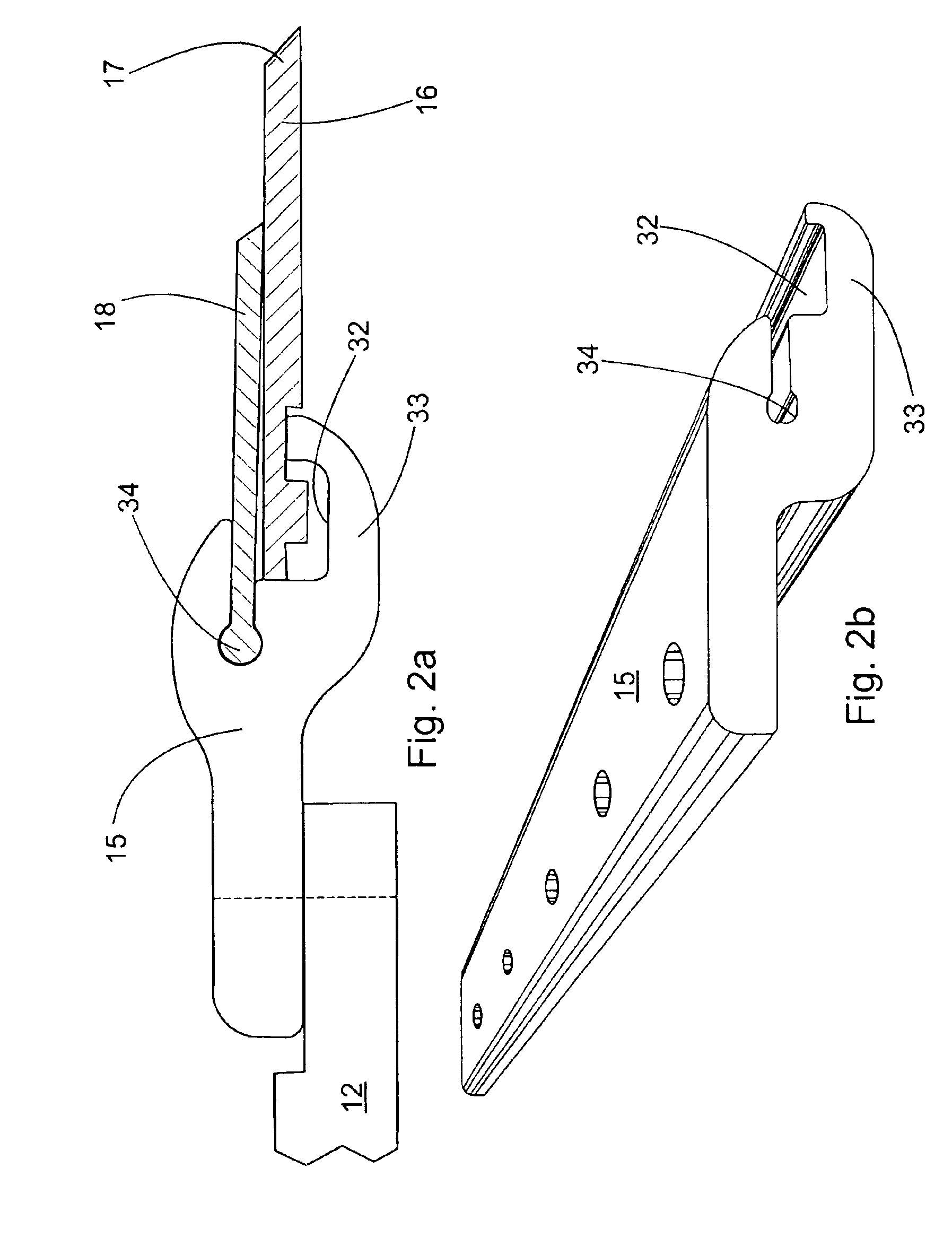

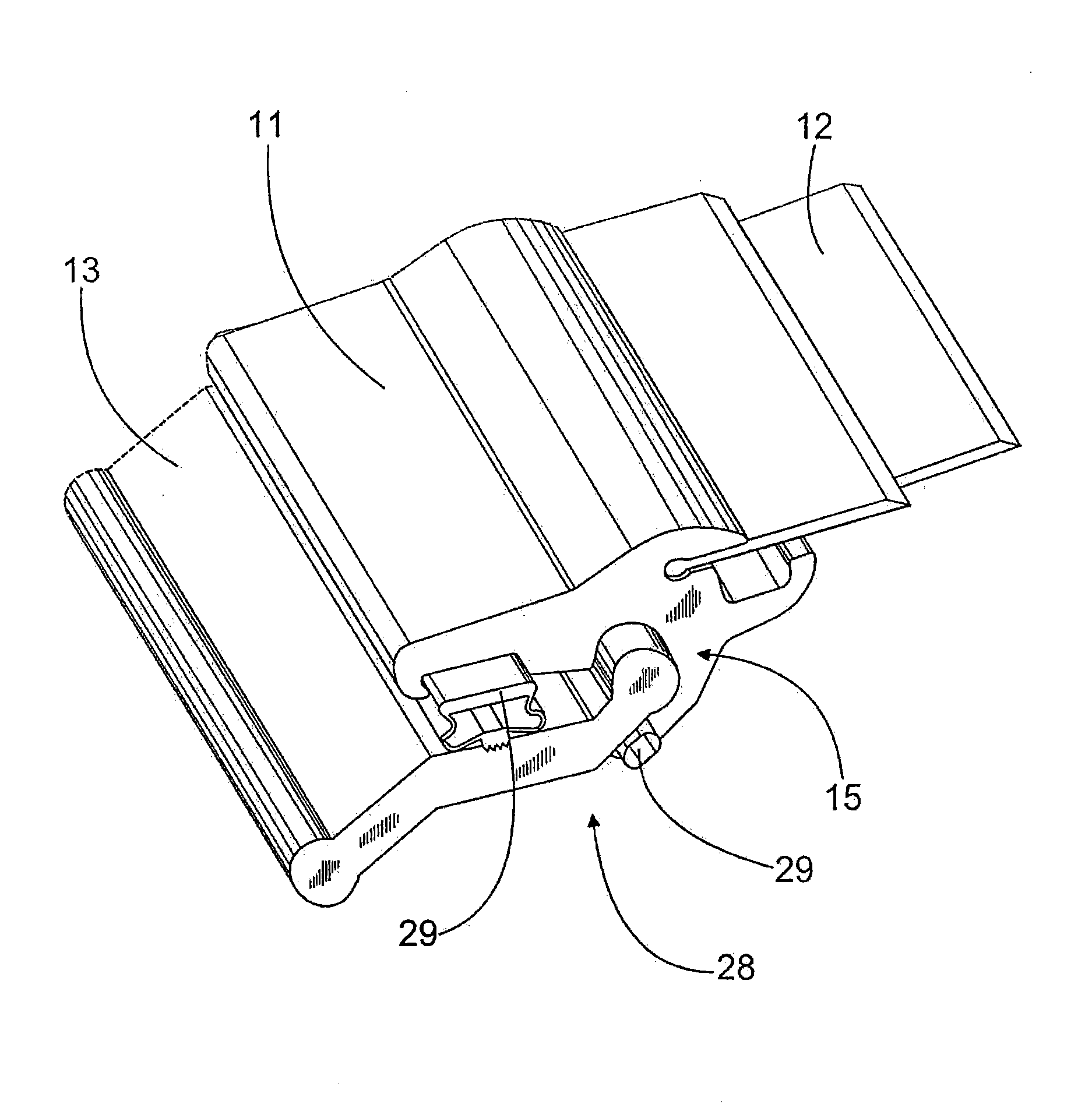

InactiveUS20060180291A1Easy to serviceEasy to useLiquid surface applicatorsMechanical working/deformationComposite constructionEngineering

A composite-construction treatment equipment has a frame (12) with a connected blade holder (15) made of a composite material. The blade holder (15) has a blade (16) and a separate backing blade (18). The blade holder (15) is removably adapted to the frame (12) using a pair of form-locking counter clamps (19). The form-lock is arranged tight in the lateral direction of the blade (16) and essentially free in the axial direction of the blade (16).

Owner:VALMET TECH INC

Planar elements for use in papermaking machines

InactiveUS20050279478A1Improve ultraviolet ray blocking propertyImprove performanceMaterial nanotechnologyLiquid surface applicatorsPolymer resinNanoparticle

A planar element for use in a papermaking machine comprising a synthetic construction incorporating nanoparticles in a polymeric resin matrix.

Owner:KADANT WEB SYSTEMS INC

Machine and process for producing a fiber material web

InactiveUS6235160B1Reduce materialSimple designNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

Machine and process for producing a fiber material web that includes at least one press device having a shoe press unit and a drying drum, such that the shoe press unit and the drying drum are positioned to form an elongated press nip. The machine also includes at least one belt that is water-permeable and water-absorbent and that is adapted to guide the fiber material web through the press nip, and at least one suction device located ahead of the elongated press nip, relative to a belt travel direction. The at least one belt is guided over the at least one suction device. The process includes guiding the at least one belt over the at least one suction device and suctioning the at least one belt, such that moisture is removed from the at least one belt, and guiding the fiber material web and the suctioned at least one belt through the extended press nip.

Owner:VOITH PATENT GMBH

Treatment equipment

InactiveUS6942734B2Easy to installEasy to changeLiquid surface applicatorsDoctorsTherapeutic DevicesMechanical engineering

A treatment equipment, which is intended to be installed in connection with a moving surface. The treatment equipment includes a frame and a blade holder formed from composite material as a single piece and connected to the frame. In addition, a blade is fitted to the blade holder, the bevelled edge belonging to which is arranged to be brought into contact with the moving surface by moving the blade holder. In the blade holder, there is also a separate backing blade, which is fitted at one edge into the blade holder, the other edge extending closer than the blade holder to the said bevelled edge.

Owner:VALMET TECH INC

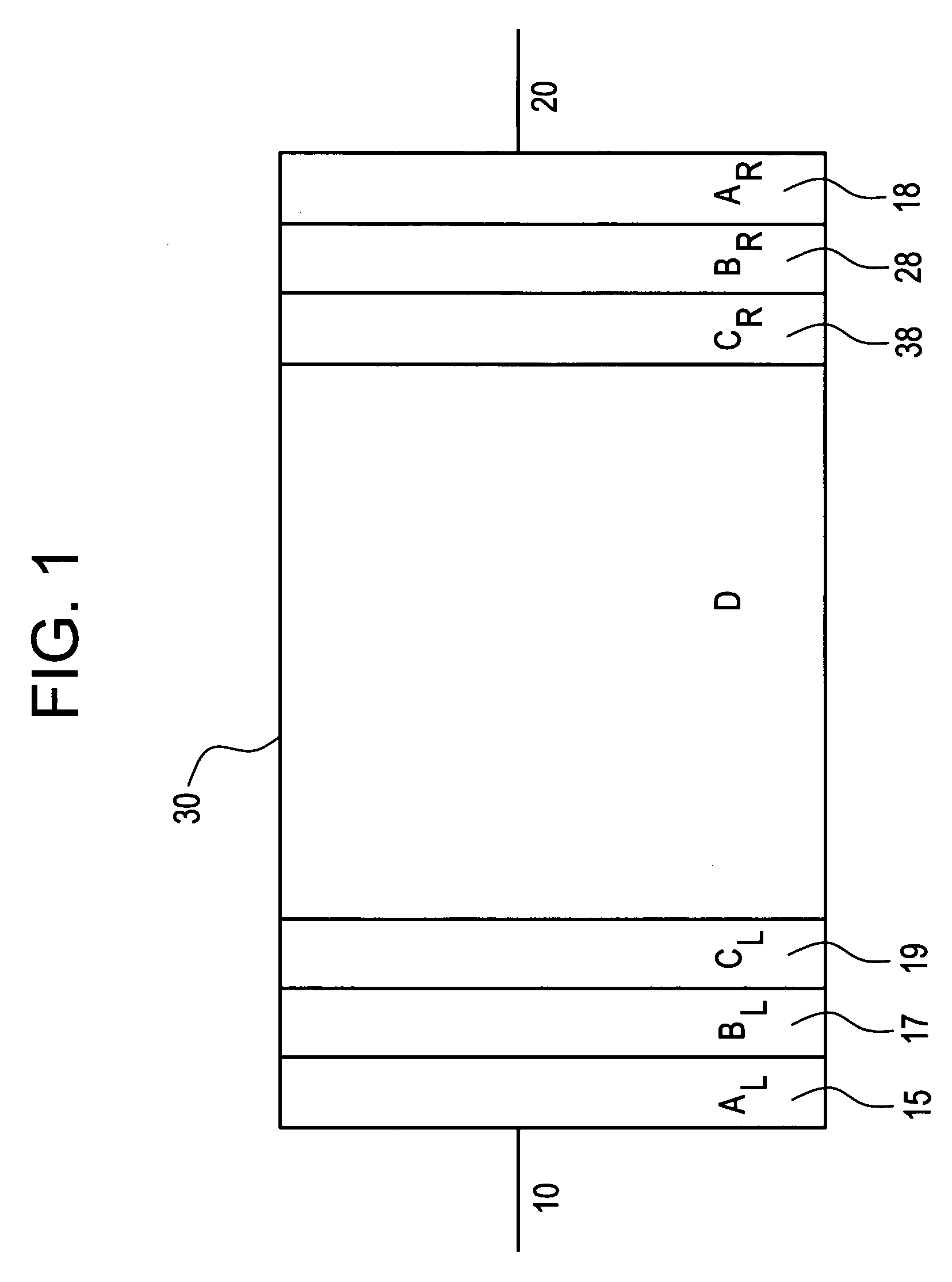

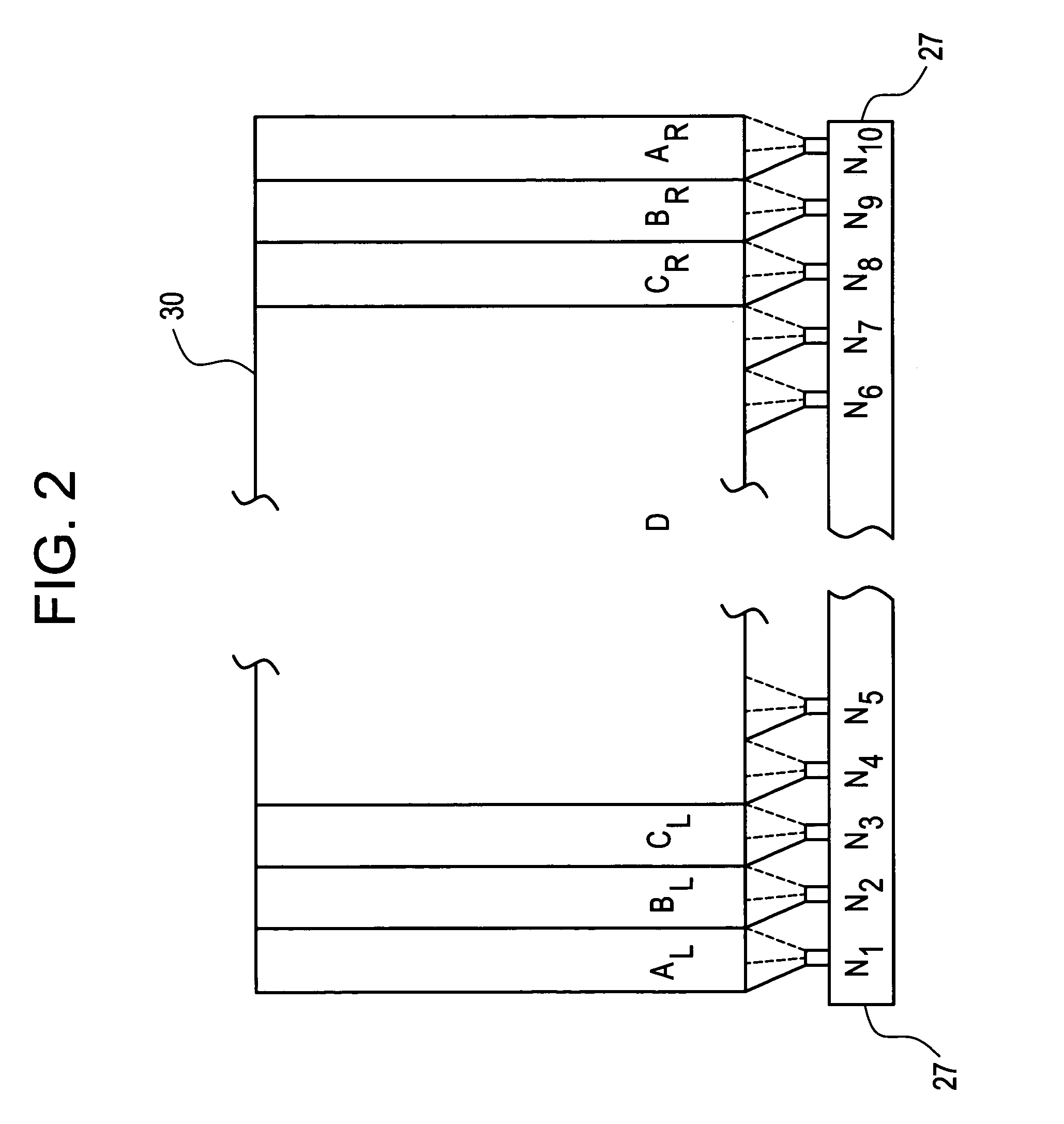

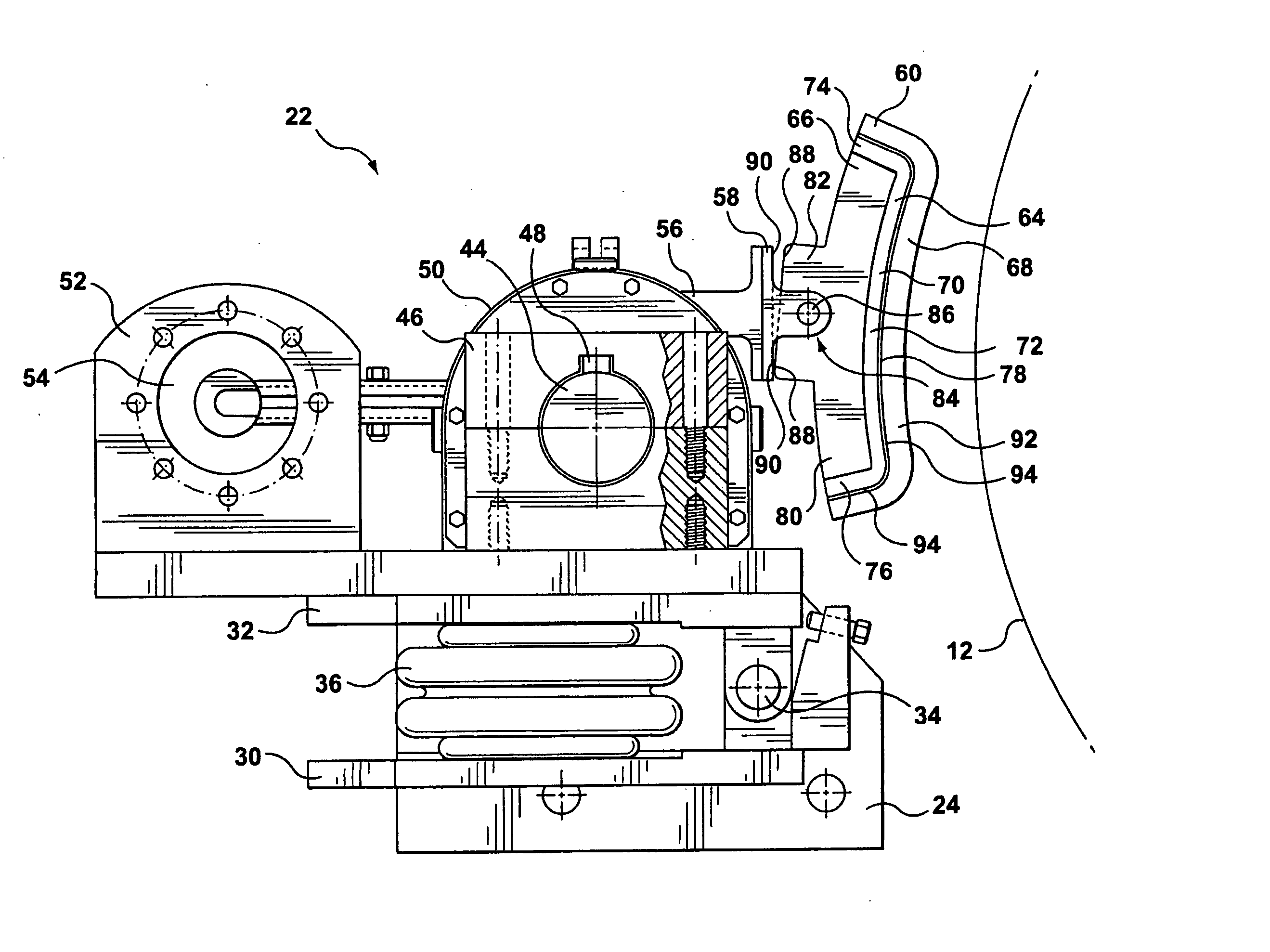

Method for targeted application of performance enhancing materials to a creping cylinder

InactiveUS7048826B2Non-fibrous pulp additionNatural cellulose pulp/paperEngineeringFluorescent tracer

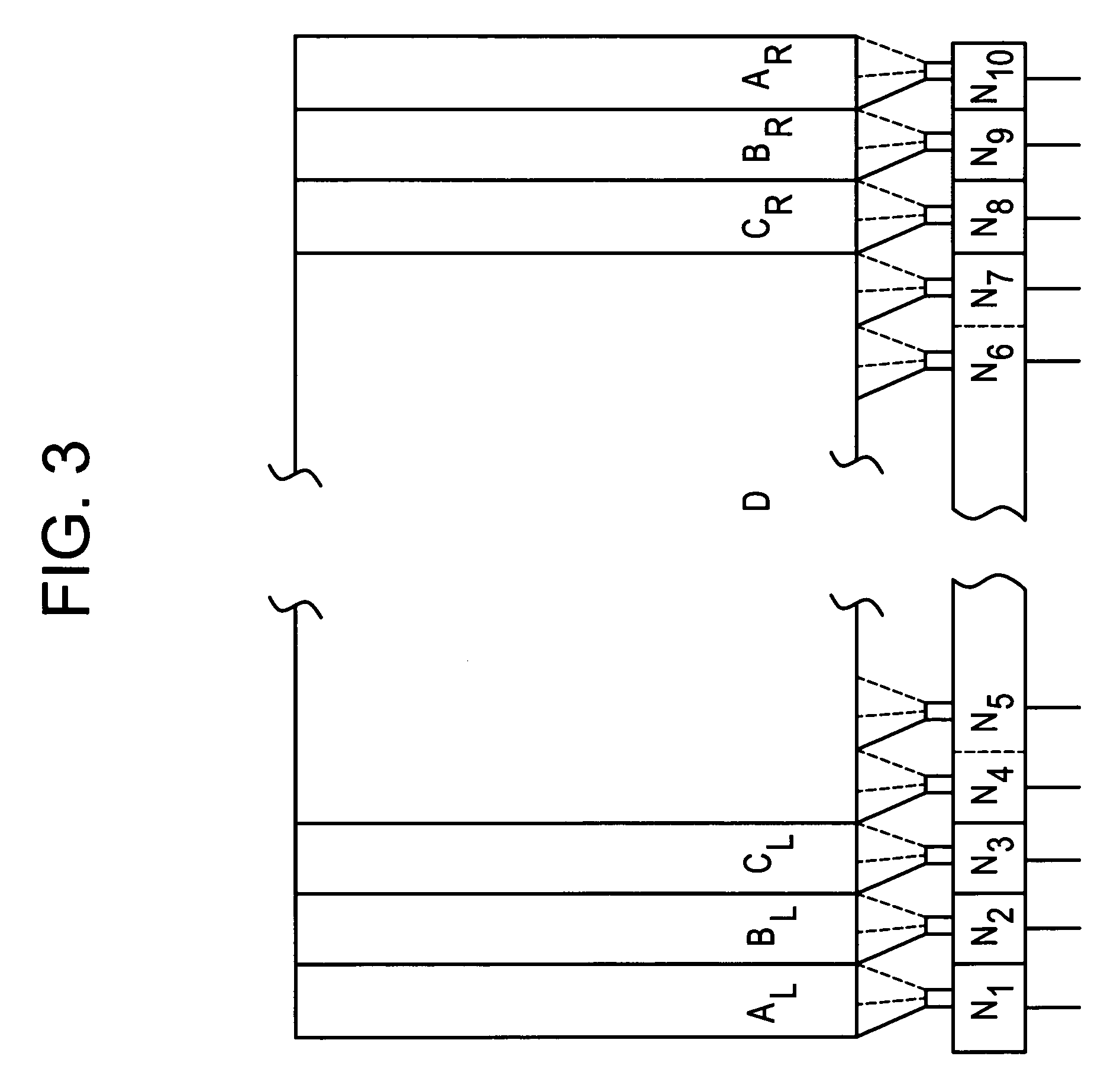

A method for target application of a Performance Enhancing Material to a creping cylinder in order to improve a tissue making operation is described and claimed. The method involves dividing the creping cylinder into Zones and then applying the desired Performance Enhancing Material on a Zone by Zone basis such that each Zone has the optimal Performance Enhancing Material present. Furthermore, a method to ascertain the amount and pattern of application of the Performance Enhancing Material used on the creping cylinder is described and claimed. This method involves adding an inert fluorescent tracer to said Performance Enhancing Material and then to use a fluorometer to look for the tracer on the creping cylinder, and / or on the creped tissue product and / or in the water removed from the felt.

Owner:ECOLAB USA INC

Vectored air web handling apparatus

Owner:THE PROCTER & GAMBLE COMPANY

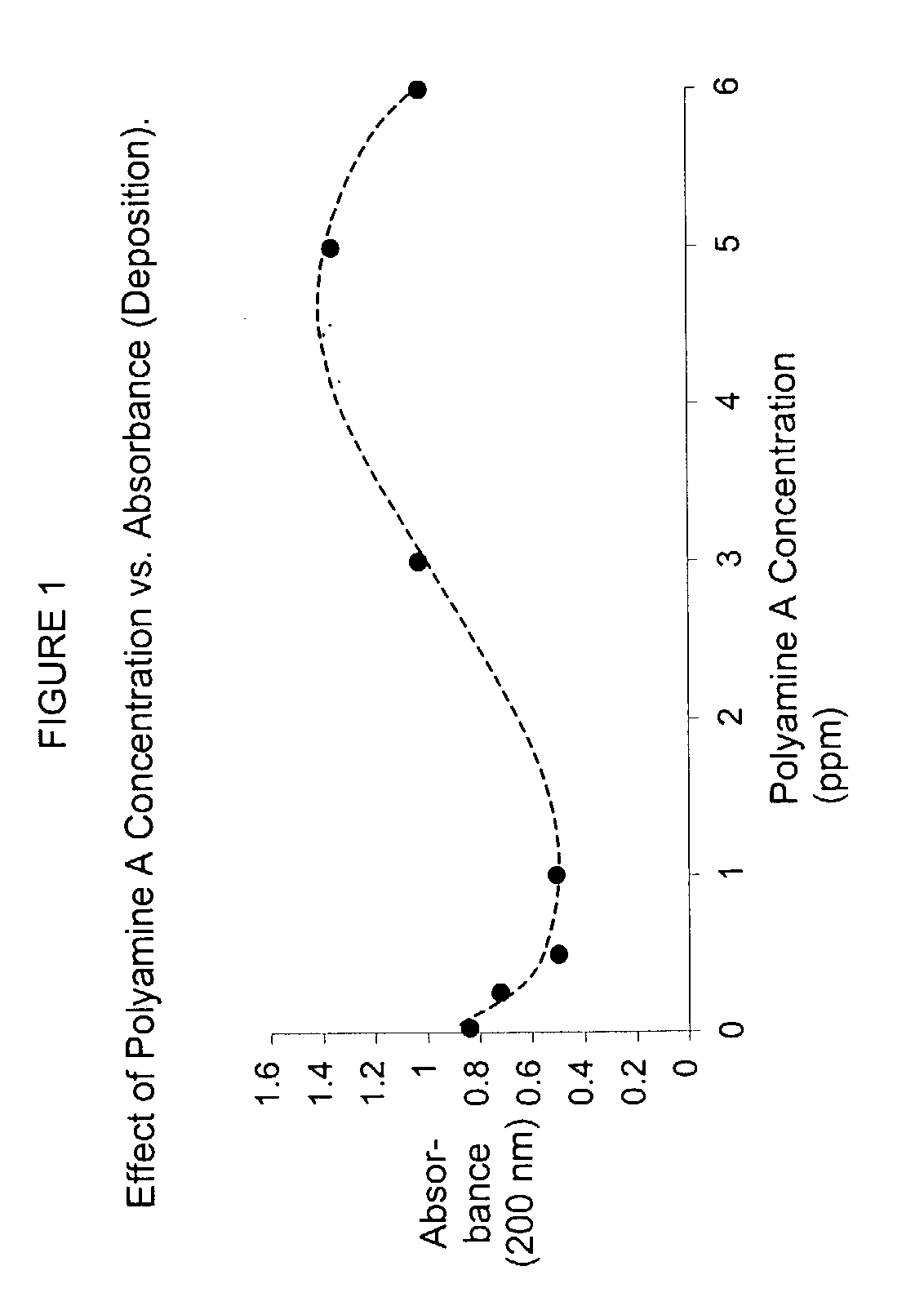

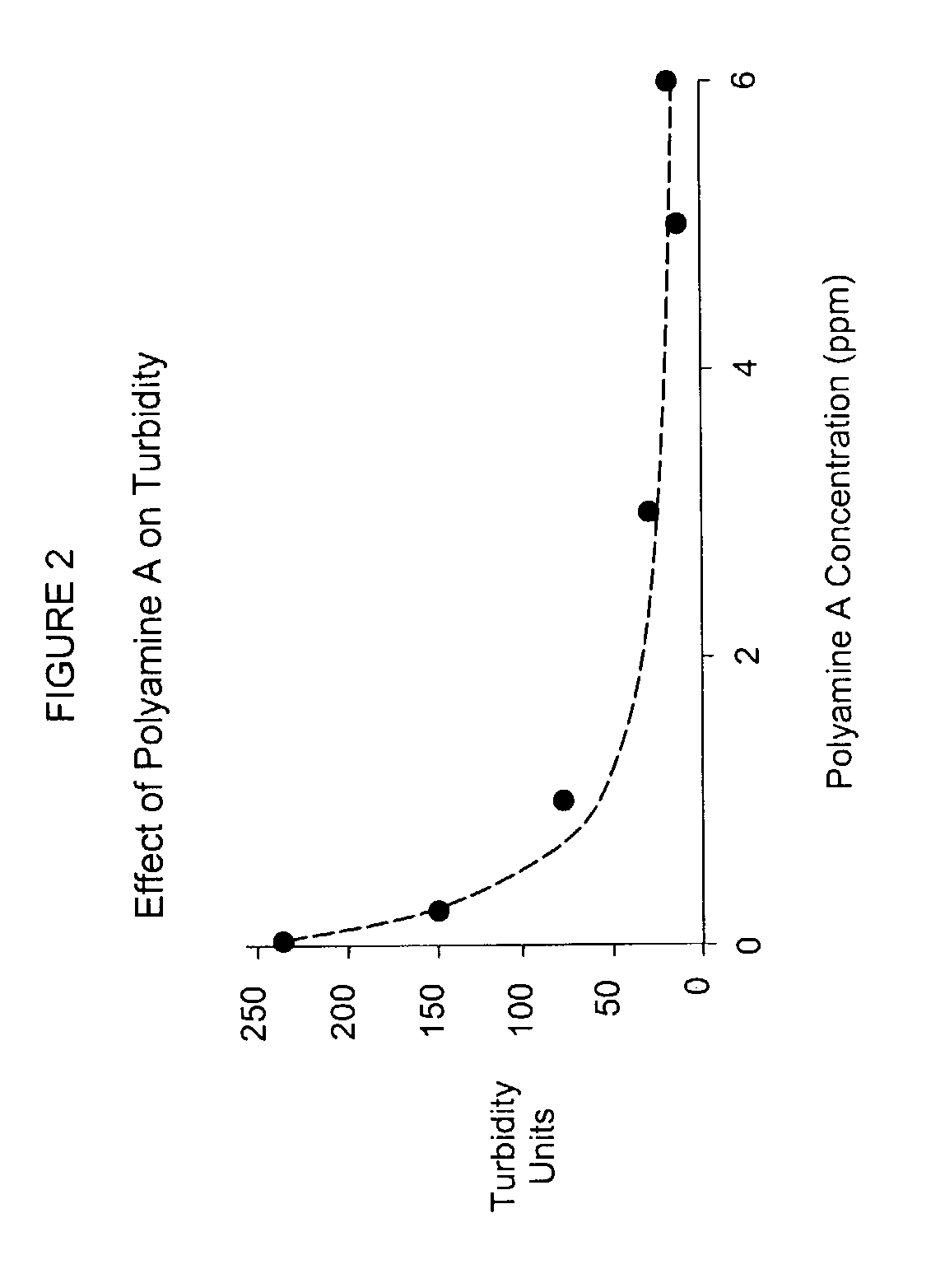

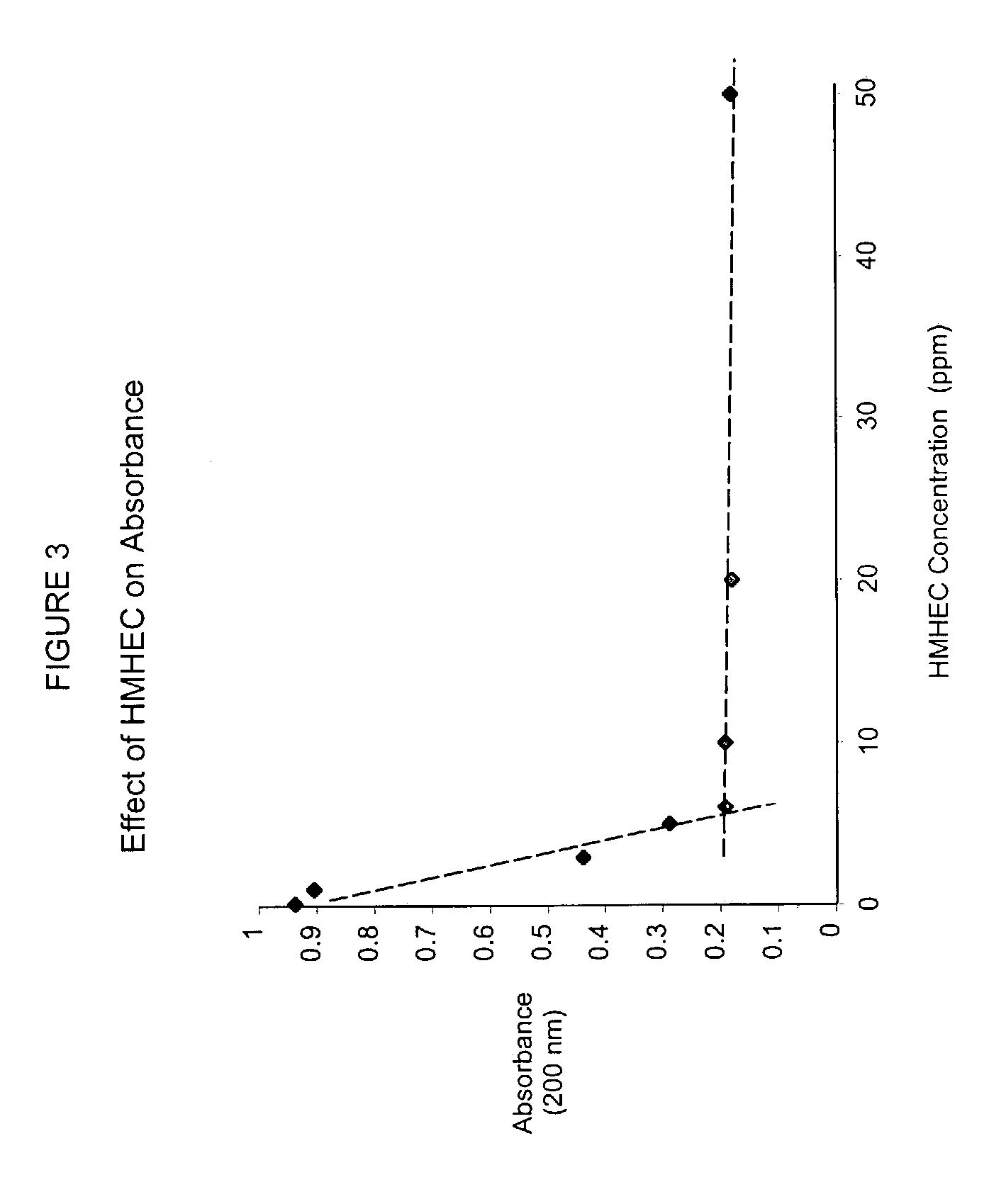

Method for controlling pitch and stickies deposition

ActiveUS7166192B2Improve retentionImprove usage activityNon-fibrous pulp additionNatural cellulose pulp/paperSlurryCellulose fiber

A method for controlling Pitch and Stickies is disclosed. The method comprises adding hydrophobically modified hydroxyethyl cellulose (HMHEC) and cationic polymers to a cellulosic fiber slurry (pulp) or to a paper process or to a paper making system and results in a higher degree of inhibiting organic deposition and retention of pitch on paper fiber as compared to the inhibition of the individual ingredients. The combination of HMHEC and cationic polymers surprising results in a synergistic effect.

Owner:SOLENIS TECH CAYMAN

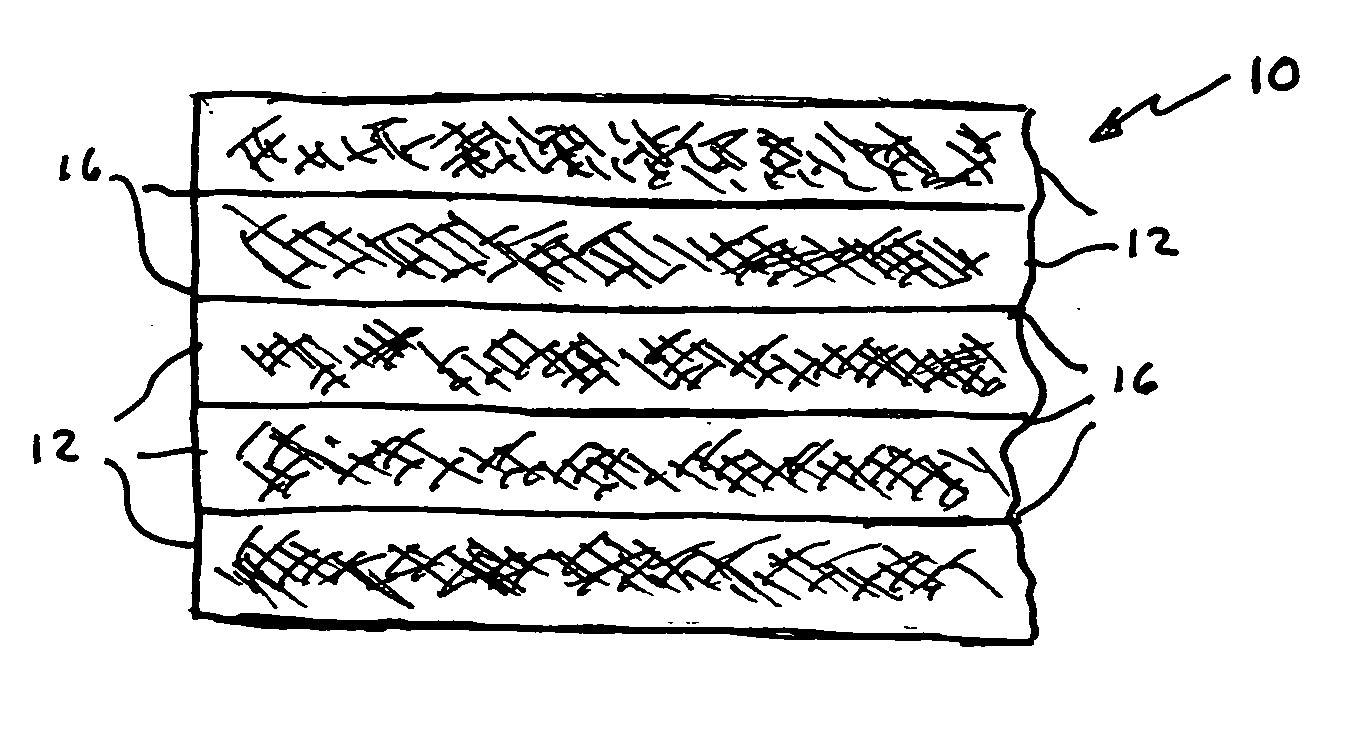

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS20020104628A1Reduce penetrationIncreased manufacturing flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

Dust-controlling apparatus, with a water curtain device, for a paper manufacturing machine

InactiveUS6068735AHighly efficient in removingEasy to captureMechanical working/deformationSpecial paperFiberDust control

A dust and fiber control device for paper making apparatus is described. The device includes a wall in conjunction with a feed spout for providing a water curtain. The water curtain serves to capture and remove air suspended dust and fiber particles from ambient air. The device is positioned transversely to the motion of a paper web underneath the web between a drying cylinder and a rewinder. The water curtain device is utilized in conjunction with air flow devices for assisting in controlling the collection of air suspended dust and fiber particles from the ambient air.

Owner:GEORGIA PACIFIC FRANCE SAS

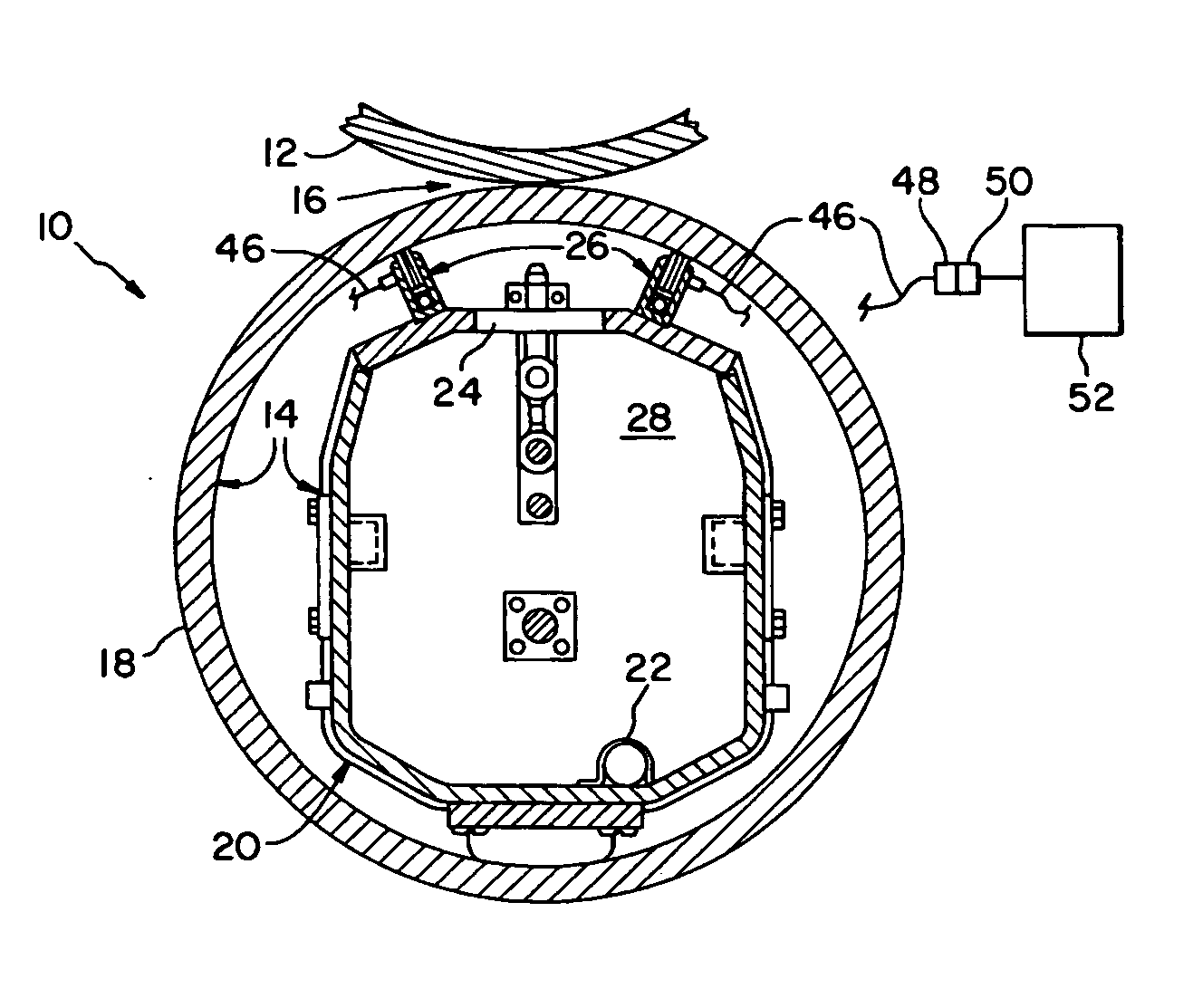

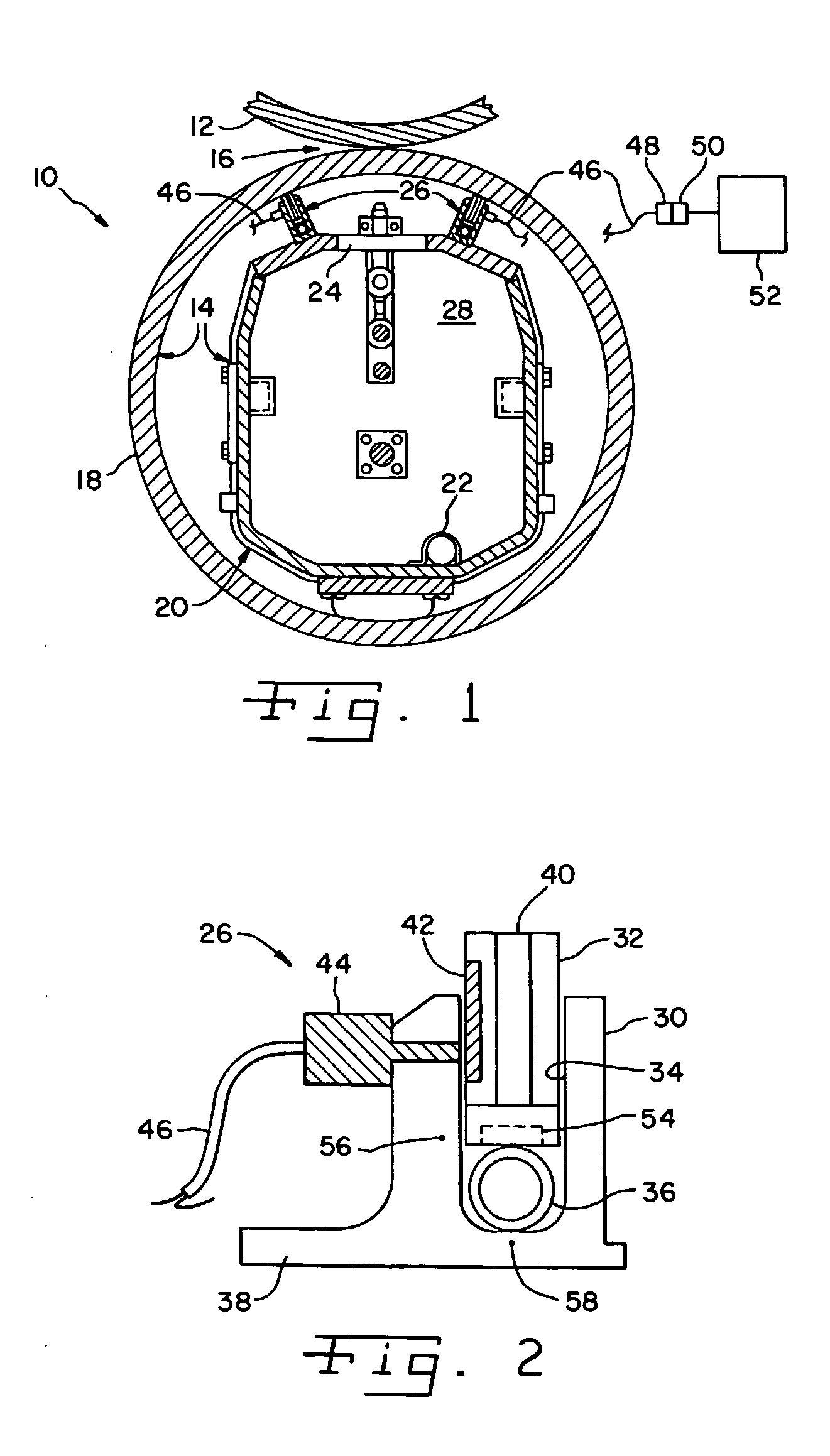

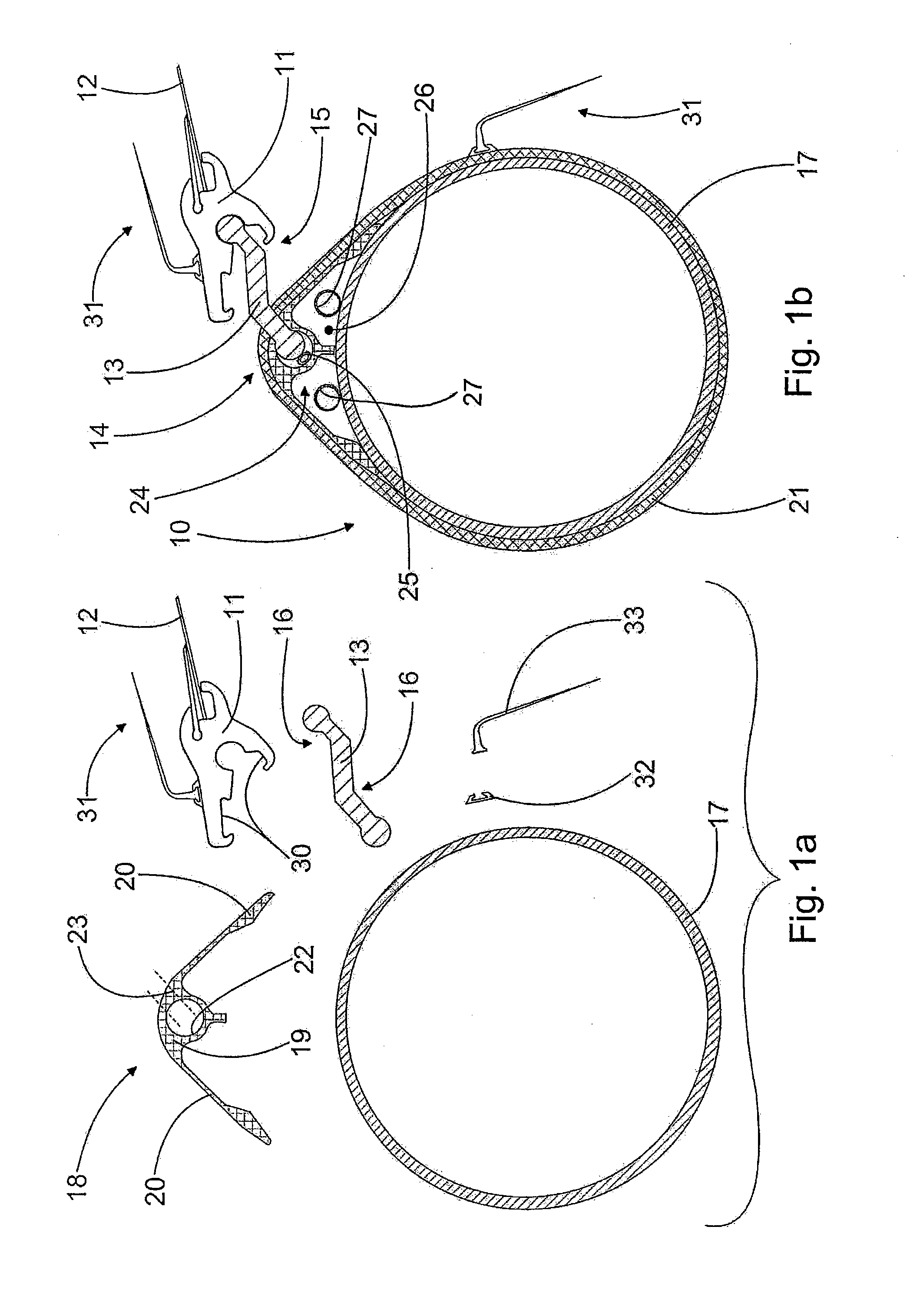

Suction roll seal strip with wear indicator

Seal strip for a hollow circular cylindrical screening device, which screening device is intended to be used in a paper or cardboard machine for the production of paper or cardboard, the seal strip having an indicator for indicating wear of the seal strip. The indicator is arranged to continuously give a measure of a remaining wear allowance and preferably also a wear rate, of the seal strip.

Owner:JOCELL

Wear indicator for seal strip in a suction box of a paper machine

InactiveUS20050126732A1Easy constructionAccurately indicatedEngine sealsPiston ringsEngineeringPaper machine

A suction roll assembly includes a suction roll having a perforated shell, and a suction box positioned within the suction roll. The suction box includes a holder, a seal strip adjacent the shell and carried by the holder, at least one target carried by the seal strip, and at least one sensor positioned in association with at least one target. Each sensor provides an output signal indicative of a position of at least one corresponding target.

Owner:VOITH PATENT GMBH

Roll cleaning apparatus

ActiveUS20050177971A1Surface cleaningRemove pollutantsBrushesWork treatment devicesEngineeringActuator

A paper making machine may having heated rolls for making high clay content papers. A roll cleaning apparatus may be mounted to the paper making machine. The roll cleaning apparatus may have a cleaning member that is mounted to a support member that extends lengthwise relative to a first roll of the paper making machine. The cleaning member may be a pad having a substantial area of the surface of the roll may be contacted. The cleaning member may be movable between an engaged position against the roll during operation, and a disengaged position spaced away from the roll in a non-operating condition, such as when replacement of the cleaning member is desired. The roll cleaning apparatus may include a drive connected to cause linear reciprocation of the cleaning member. The roll cleaning apparatus may have a drive or actuator mounted to move the cleaning member between the engaged and disengaged positions, and may be operable to bias the cleaning member against the roll in use.

Owner:SUPERIOR INDAL SERVICES

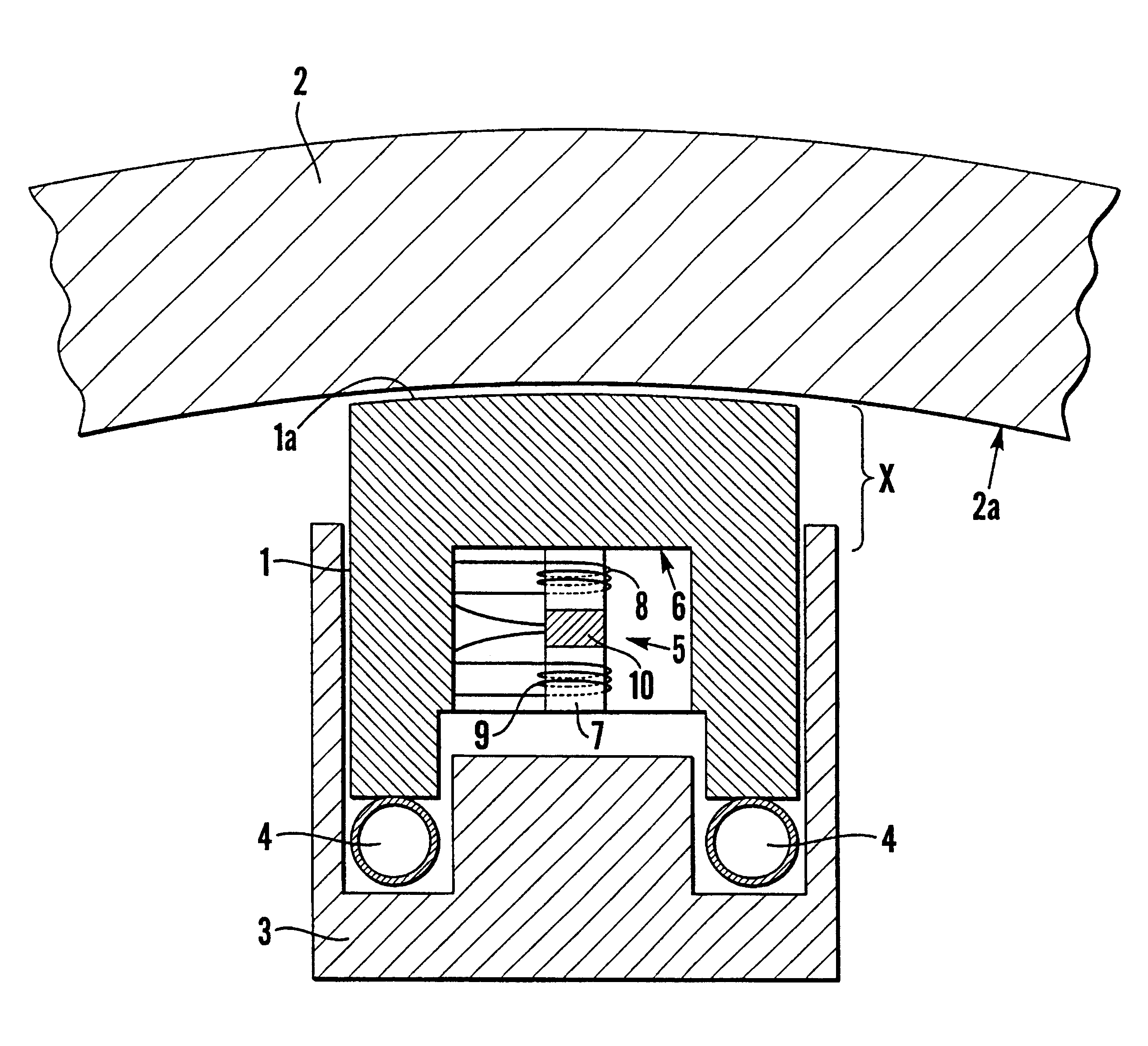

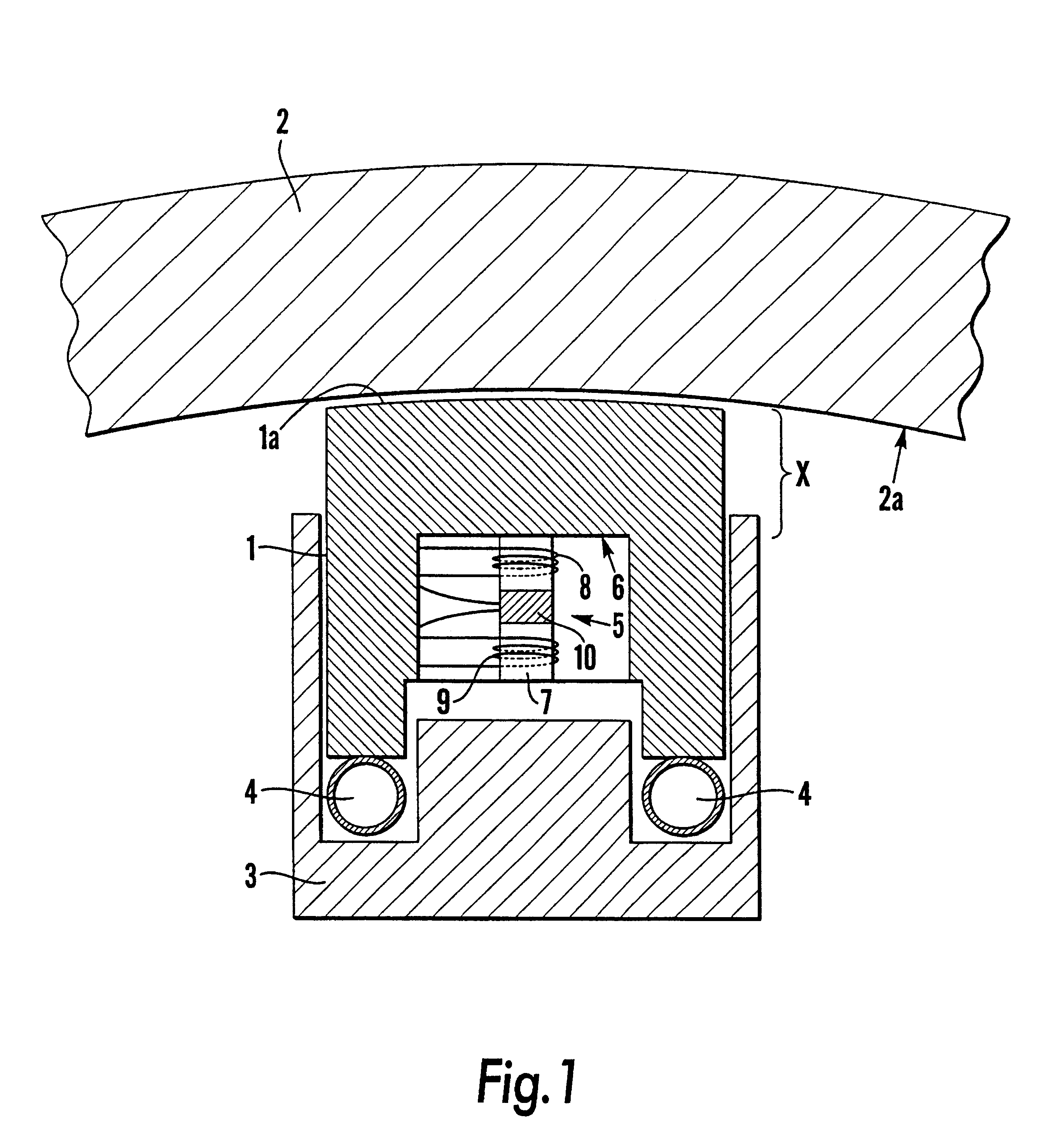

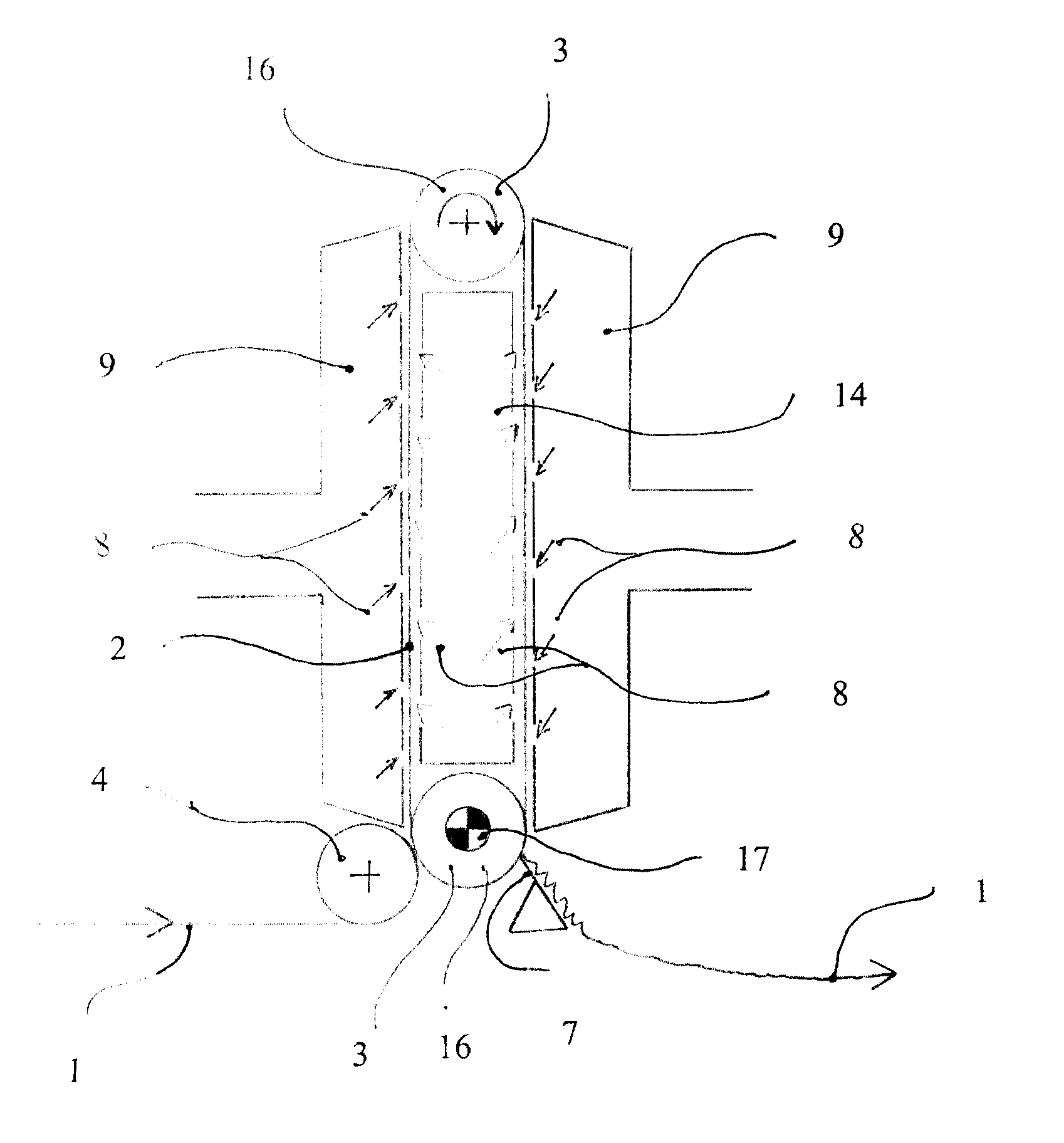

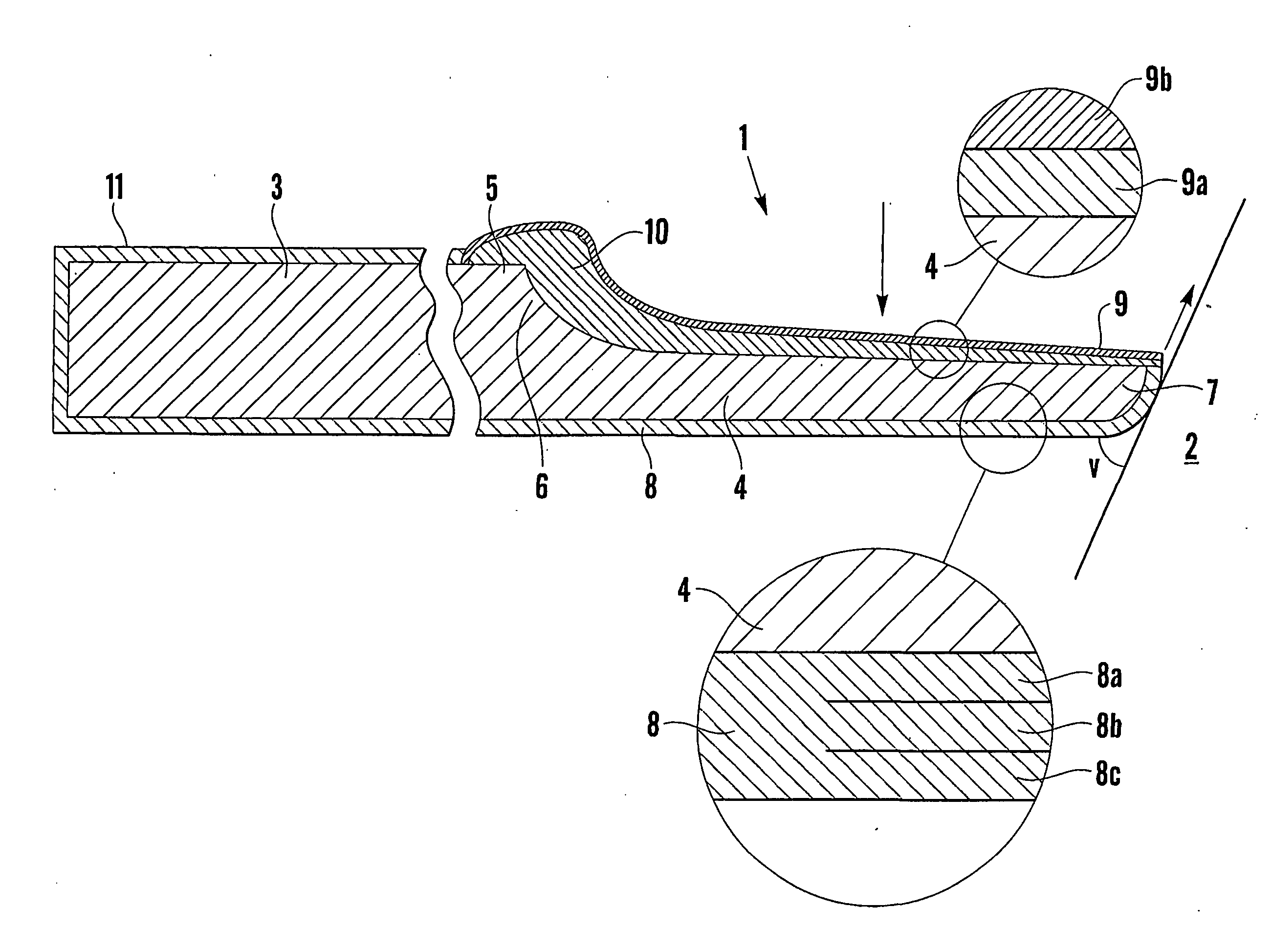

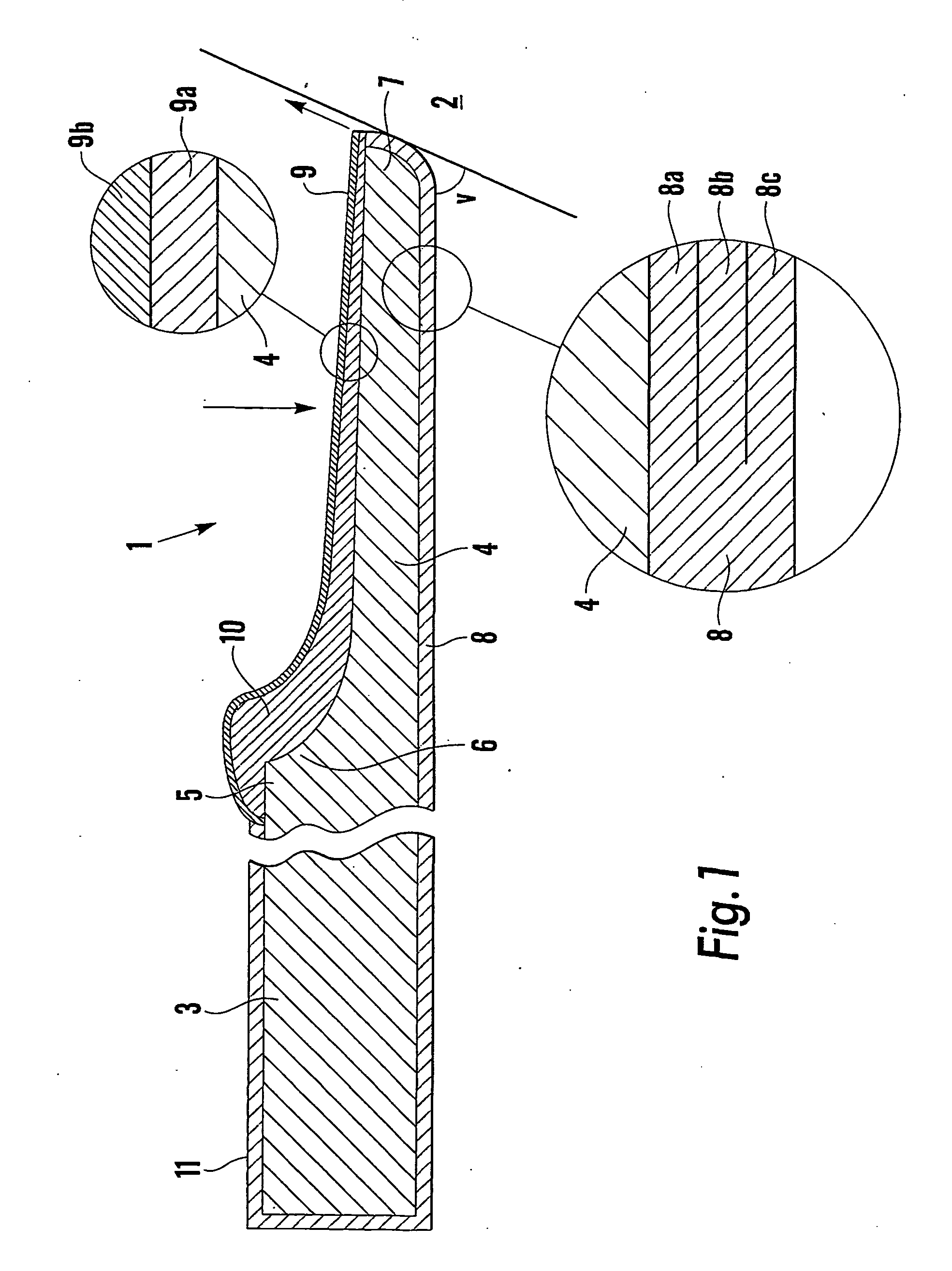

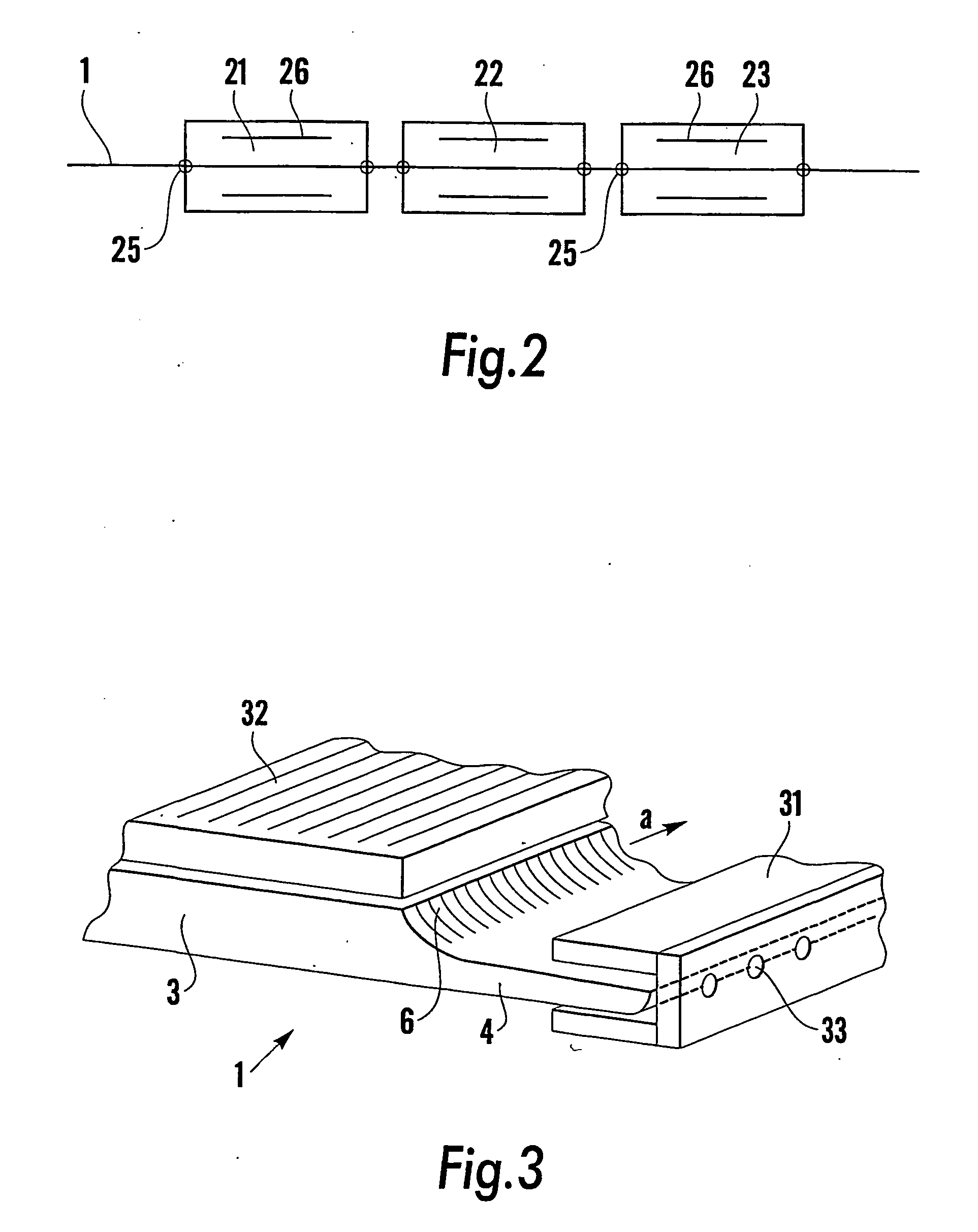

Device for drying and treating a tissue paper web

ActiveUS8486229B2Quality of the produced fiber productQuality of fiber productMechanical working/deformationDryer sectionFiberEngineering

A device for drying and treating a fiber-based moving fiber web (1) in a machine intended for producing tissue paper includes a metal belt (2) which is arranged to support the fiber web (1) and to transfer the fiber web (1) in the machine direction and which metal belt (2) is arranged as a continuous rotating cycle, at least one roll (3) the shell of which is in contact with the metal belt (2) arranged to rotate around, which roll (3) is for supporting and / or controlling the metal belt (2), and at least one counter element (5) arranged to create a contact area outside the metal belt (2) between the metal belt (2) and the counter element (5) for a process zone (6), via which process zone (6) the fiber web (1) is arranged to travel when using the device.

Owner:VALMET TECH INC

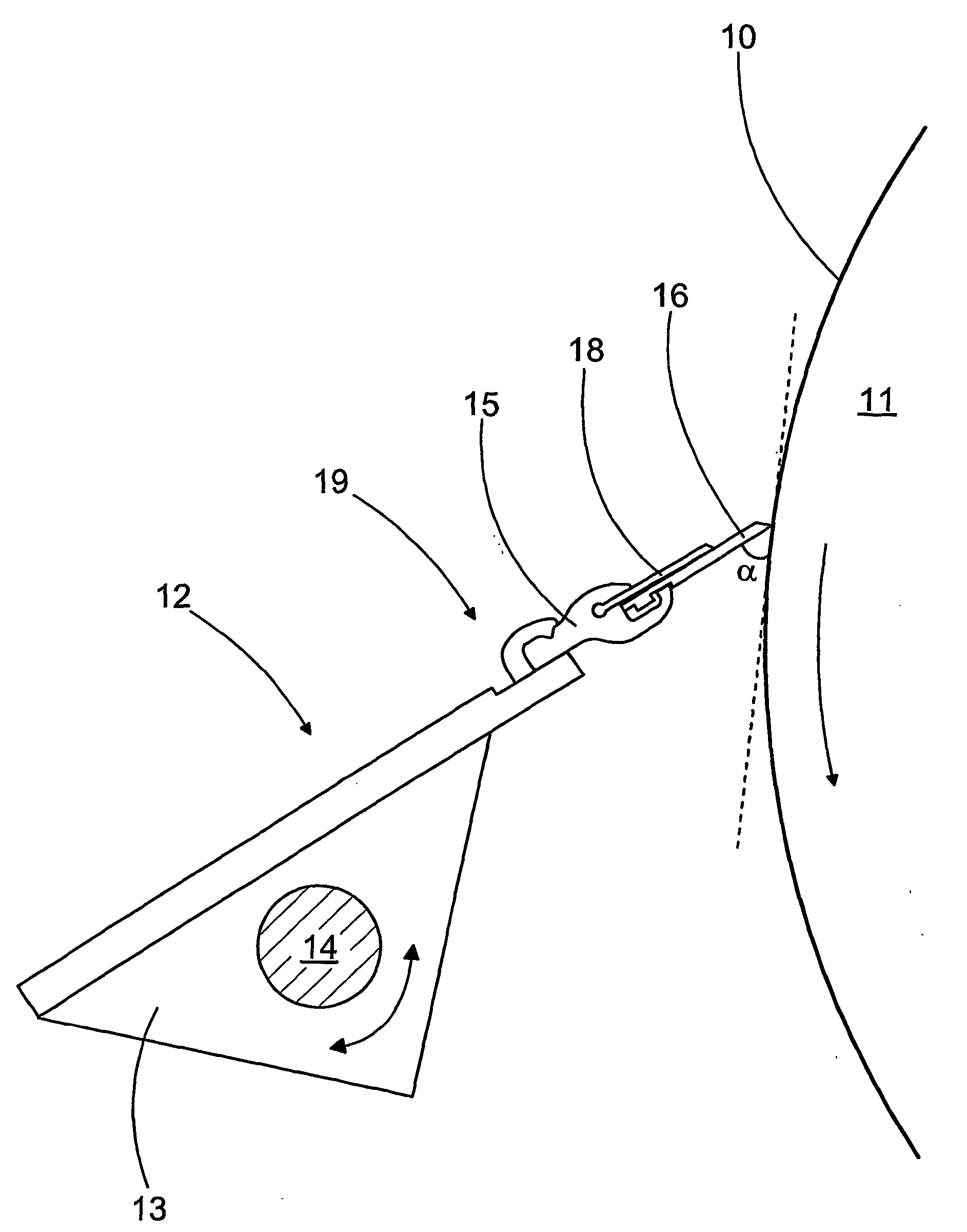

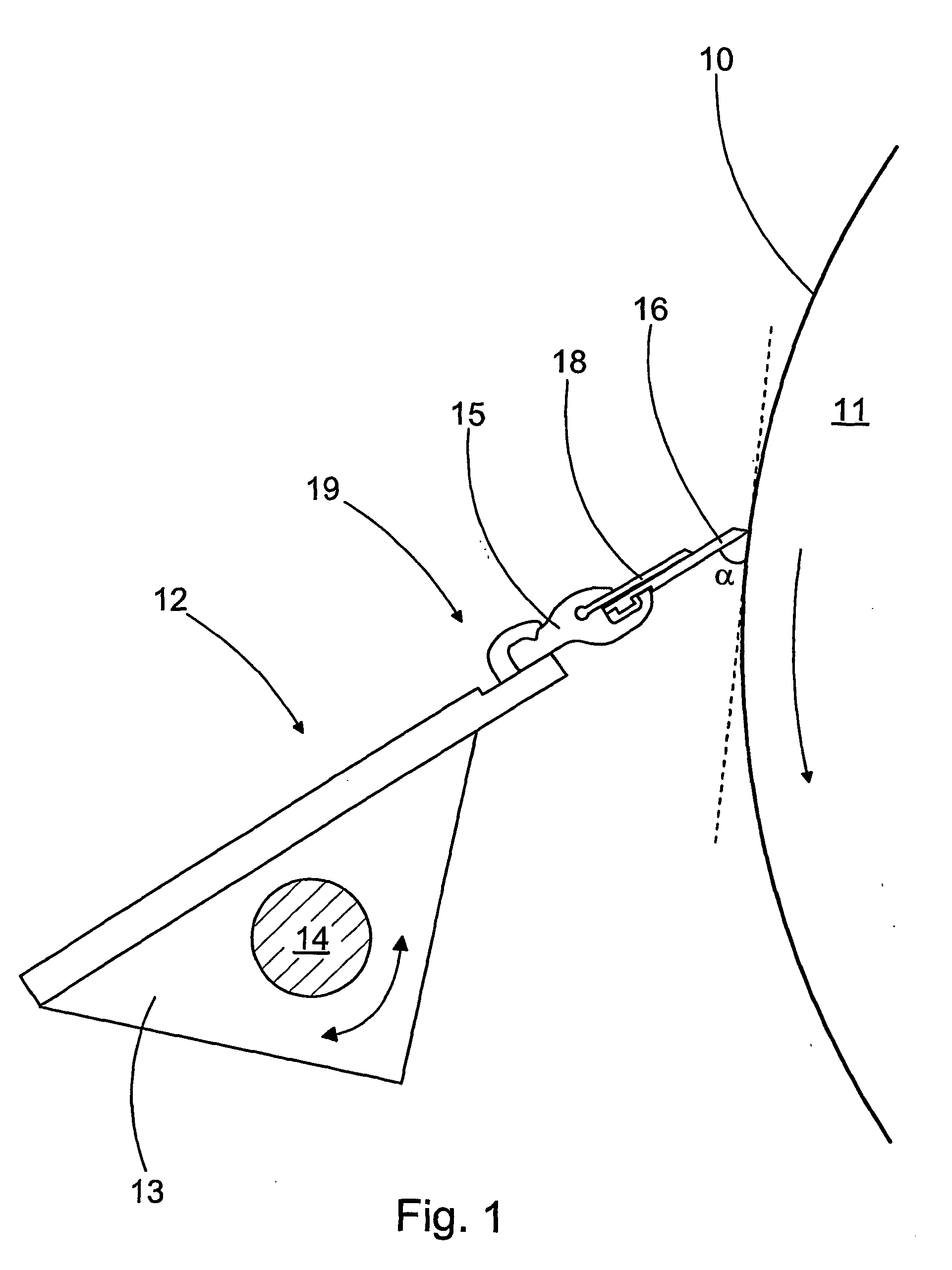

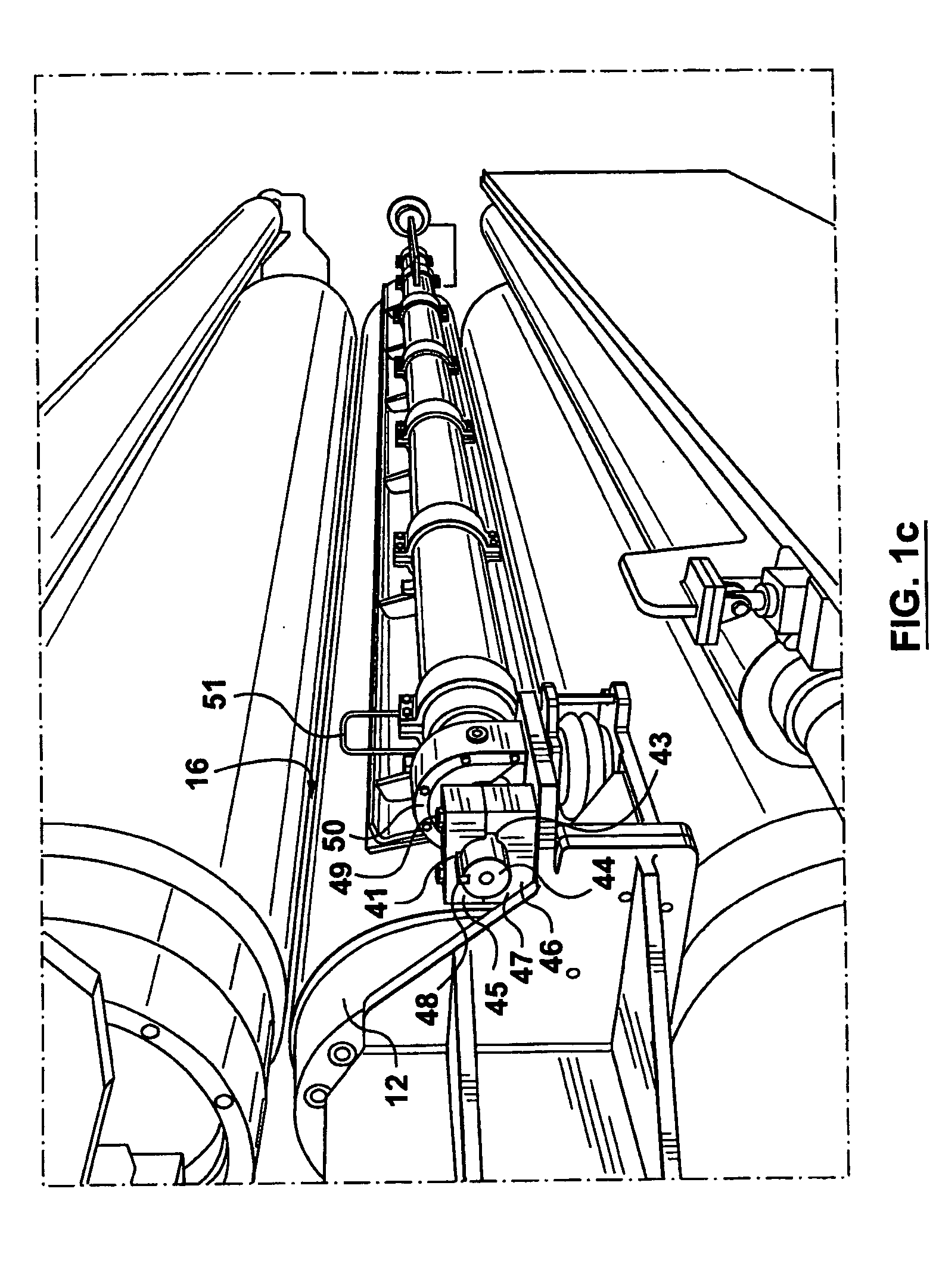

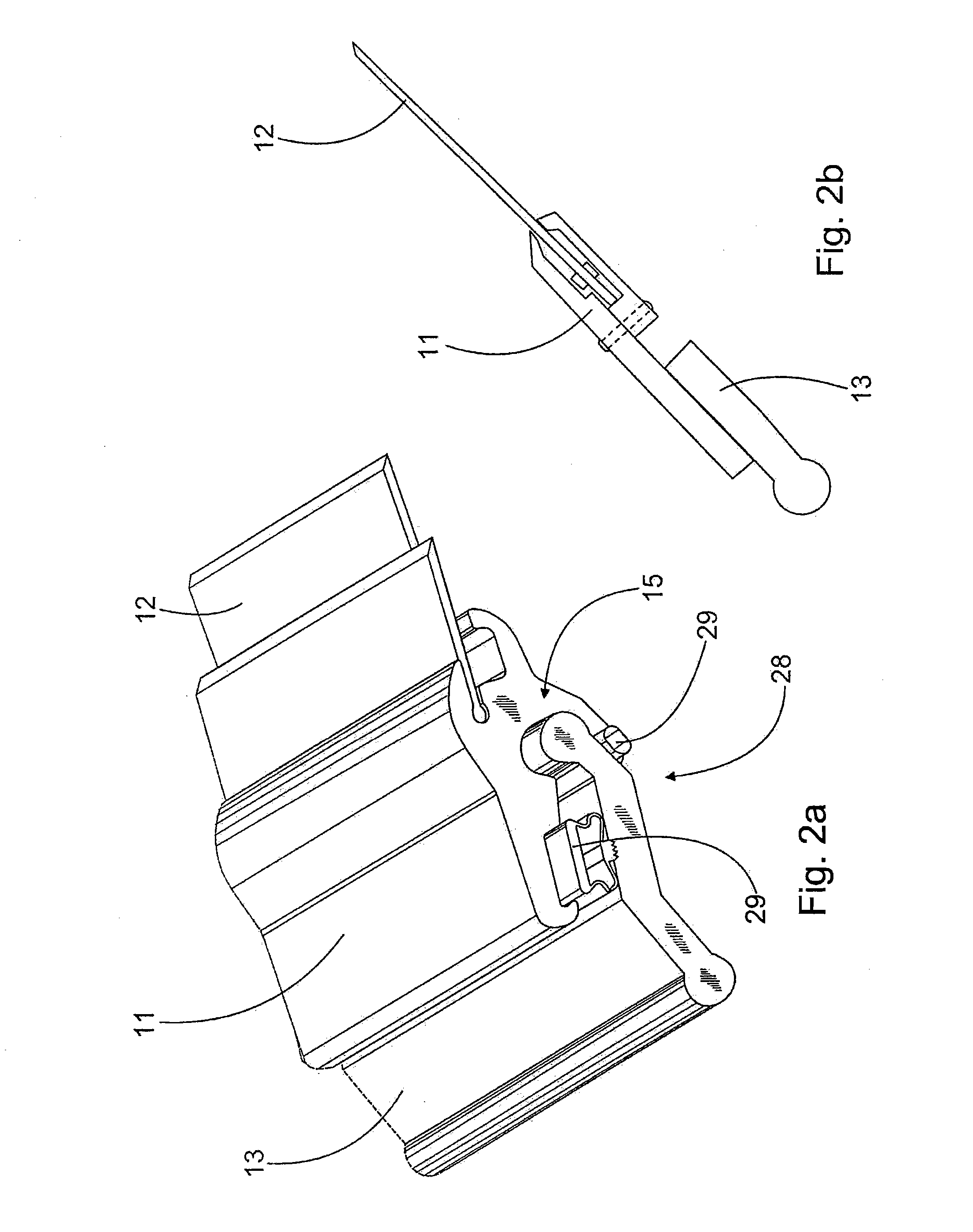

Composite Doctor Arrangement

InactiveUS20060289141A1Easy to fixImprove application versatilityLiquid surface applicatorsMechanical working/deformationWeb handling

A composite doctor arrangement for a web forming machine or web handling machine has a beam structure (10) with a mounting piece (13) fitted to it. A blade holder (11) is fitted to the mounting piece, with a blade (12) fitted to the blade holder (11). The mounting piece (13) is fitted axially and movably in the beam structure (10) by a form-locked mounting counterpiece (14), where the form locking is arranged so that it is fixed in the lateral direction of the blade (12) and essentially free in the longitudinal direction of the blade (12).

Owner:VALMET TECH INC

Doctor or coater blade and method in connection with its manufacturing

InactiveUS20040137261A1Improve wear resistanceEasy to wearLiquid surface applicatorsMechanical working/deformationNickel saltElectrolyte

The invention relates to a doctor or coater blade (1) of steel, having a nickel coating comprising abrasion resistant particles, said coating being constituted by an electrolytic nickel layer comprising abrasion resistant particles. The coating preferably comprises at least two electrolytic nickel layers having different composition, and may be formed differently in different sections of the blade. The invention also relates to a continuous process for electrolytic nickel coating in at least one electrolytic cell holding an electrolyte liquid comprising at least one nickel salt, and in at least one of these cells also comprising abrasion resistant particles.

Owner:SWEDEV

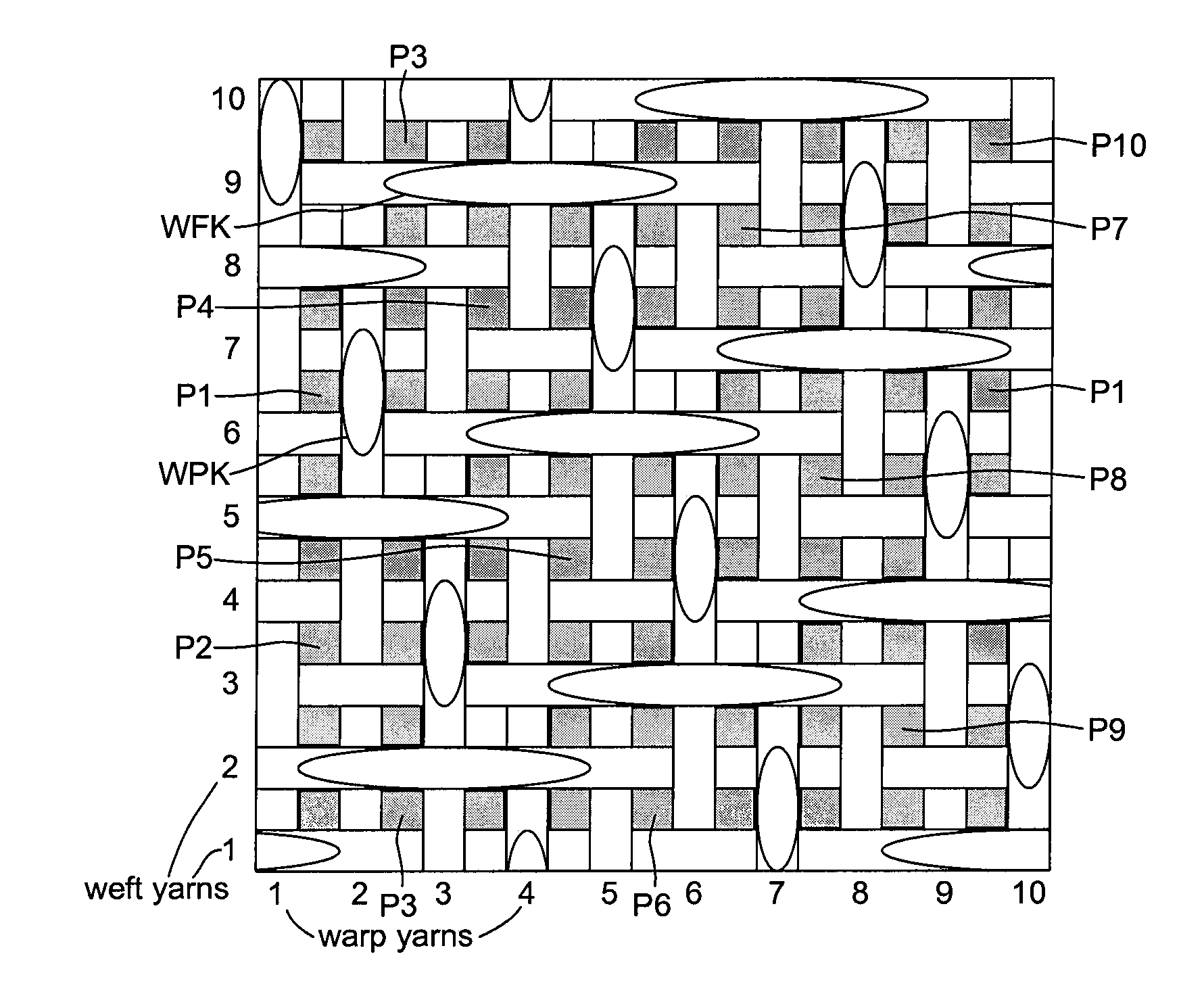

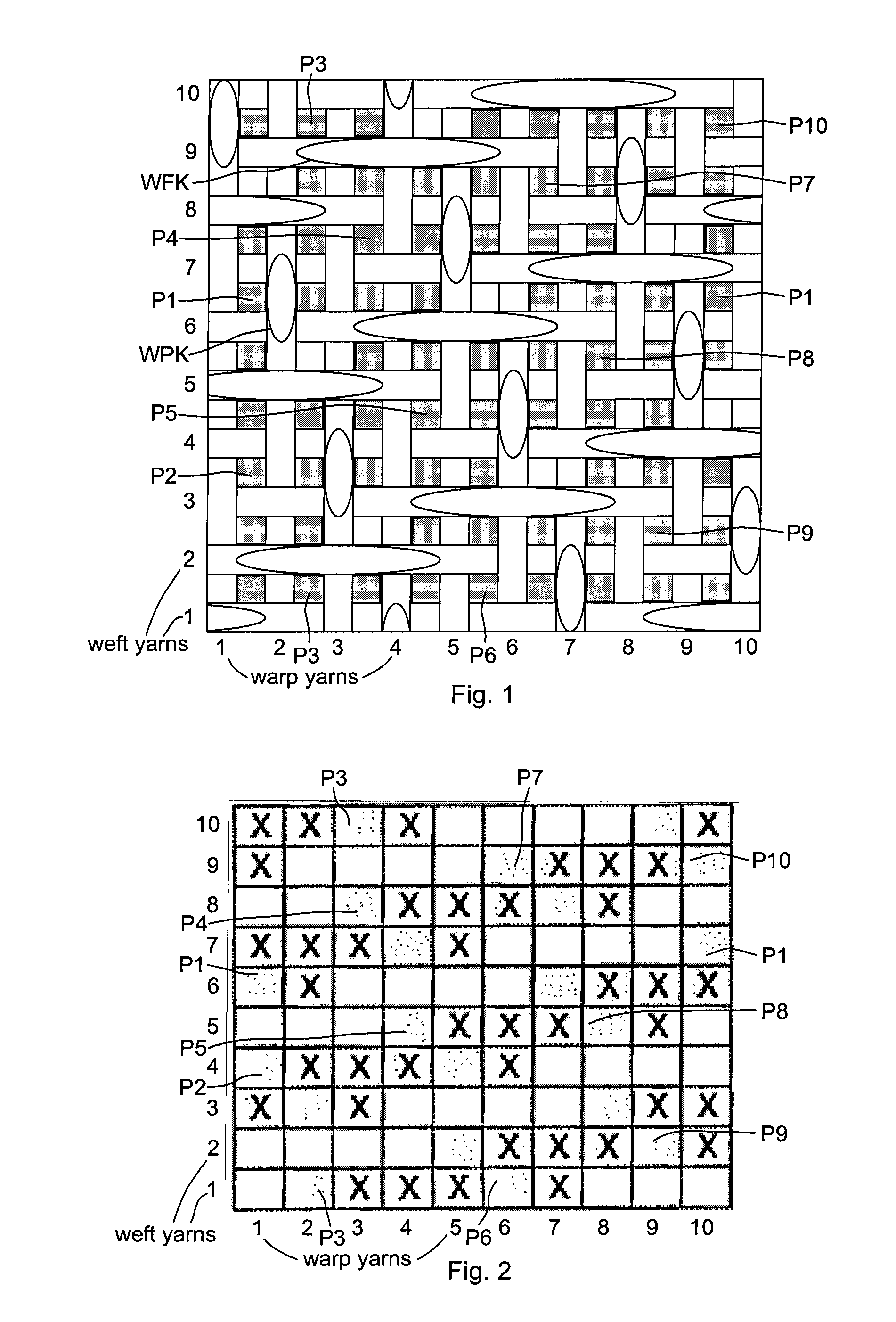

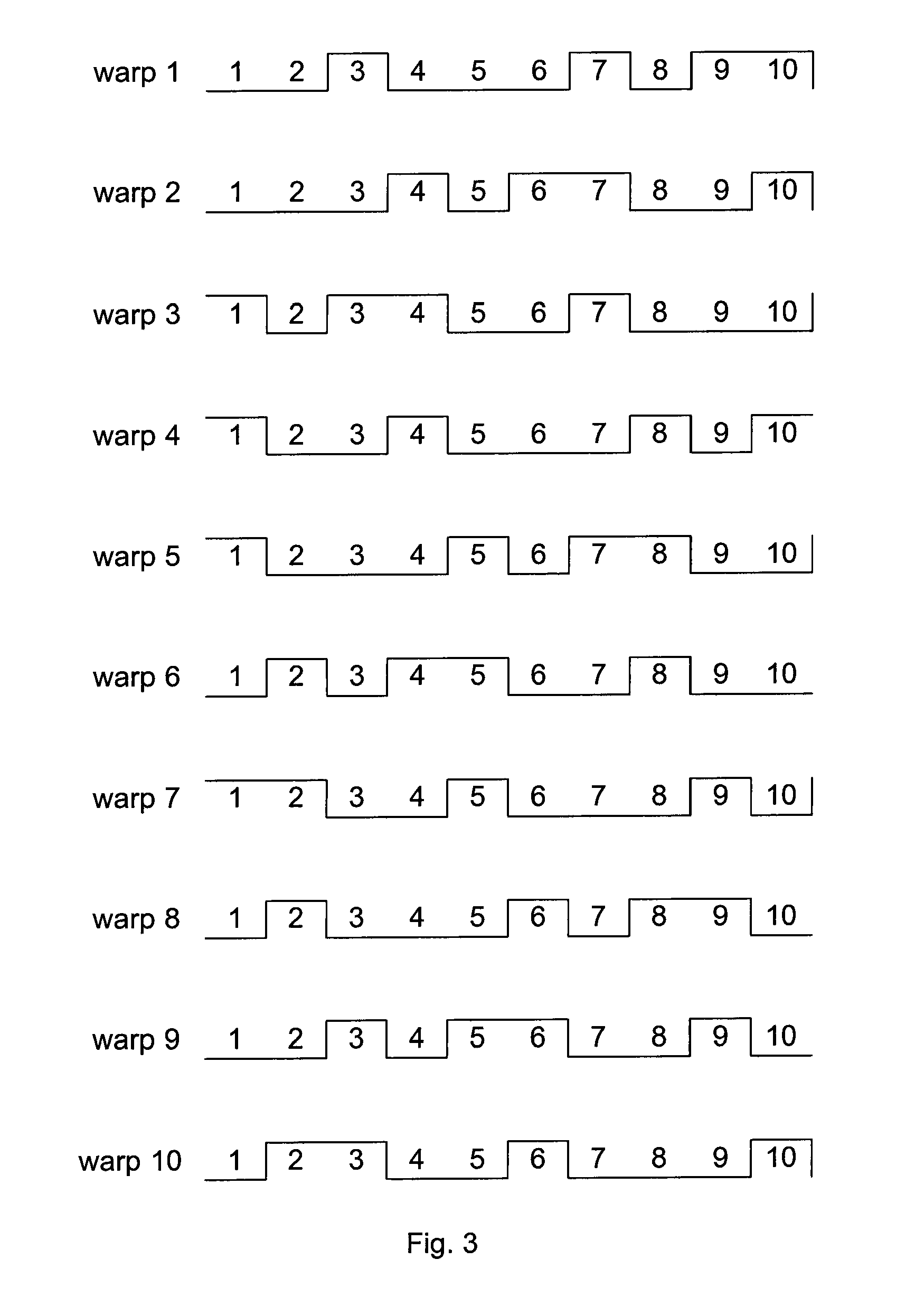

Structured Forming Fabric, Papermaking Machine, and Method

The present invention provides a fabric for a papermaking machine. The fabric includes a machine facing side and a web facing side having pockets formed by warp and weft yarns. Each pocket is defined by four sides on the web facing side, three of the four sides each being formed by a knuckle of a single yarn, and one of the sides being formed by a knuckle of a weft and of a warp yarn, wherein the weft yarn also defines a bottom surface of the pocket.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com