Patents

Literature

82 results about "Internal bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the internal bond test (Z-direction tensile test) the internal bond strength between layers is determined in accordance with TAPPI T 541 (or also ISO 15754). The bond strength between the layers of multi-layer materials (duplex or coated papers) is measured. This determines processability during printing or after coating.

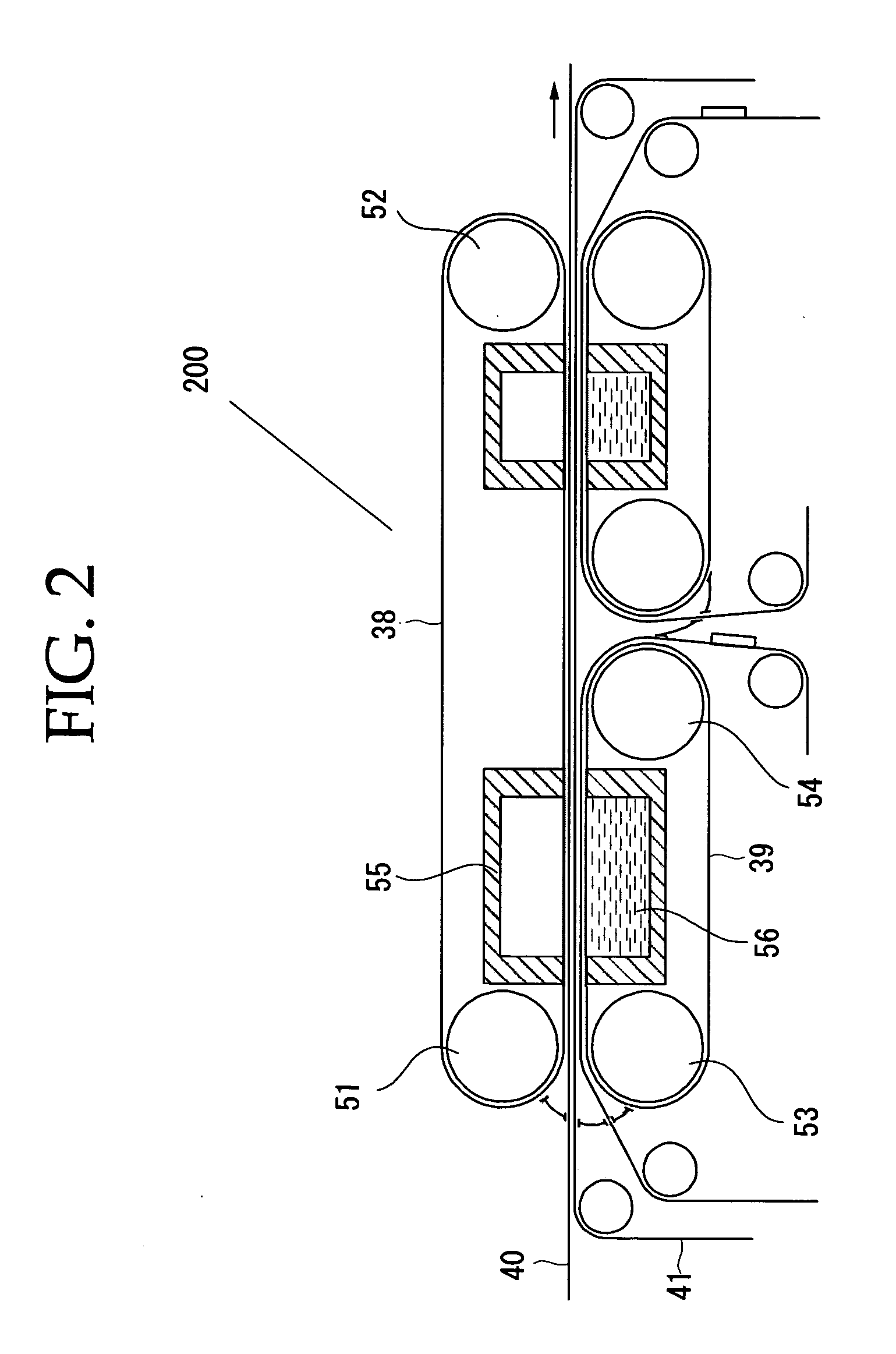

Wet crepe throughdry process for making absorbent sheet and novel fibrous products

InactiveUS20020148584A1Big cost advantageReduce air permeabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

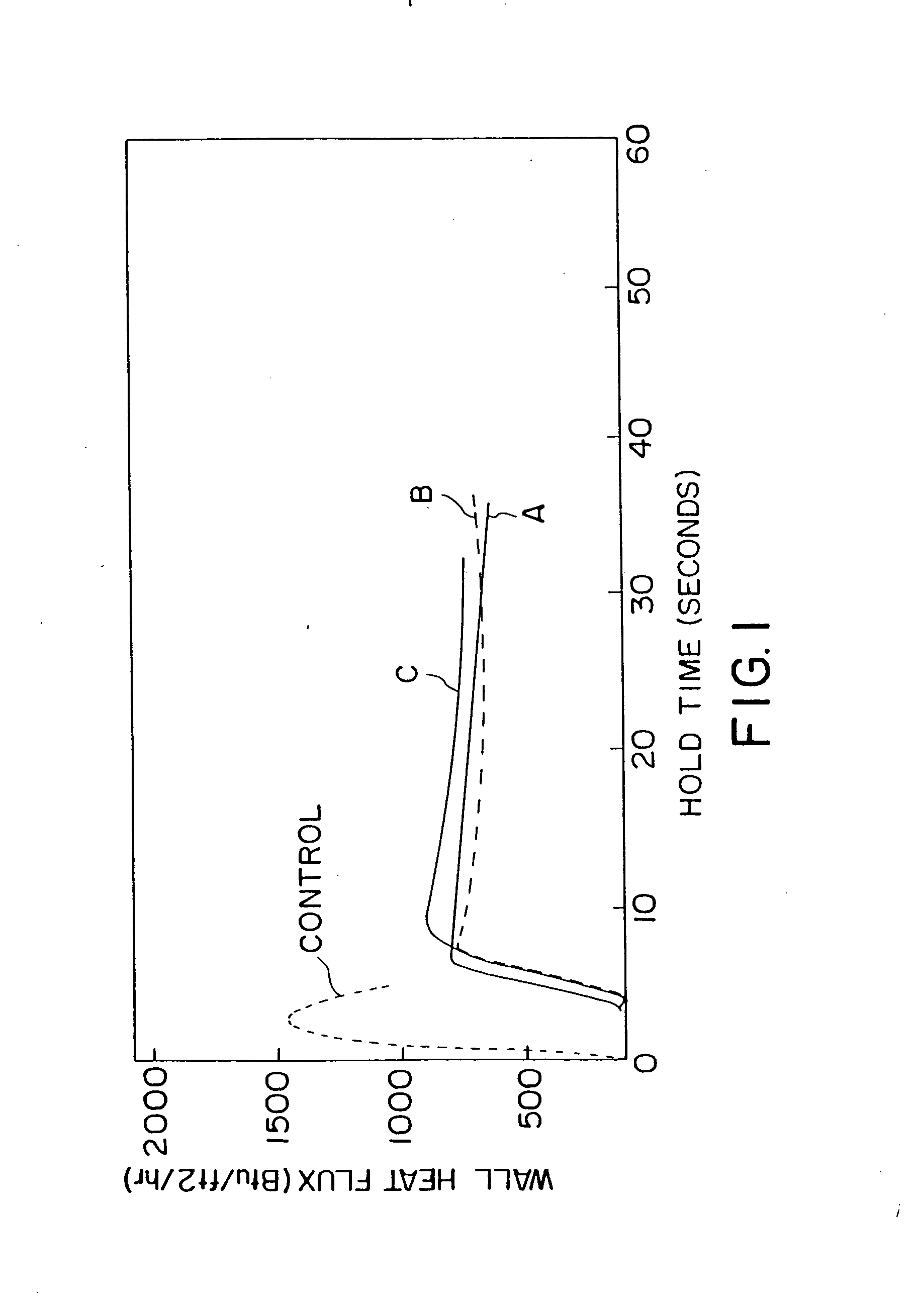

An improved process for making sheet from a fibrous furnish includes: depositing the furnish on a foraminous support; compactively dewatering the furnish to form a nascent web; drying the web on a heated cylinder; creping the web therefrom and throughdrying the web to a finished product. The microstructure of the web is controlled so as to facilitate throughdrying. The product exhibits a characteristic throughdrying coefficient of from 4 to 10 when the airflow through the sheet is characterized by a Reynolds Number of less than about 1. The novel products of the invention are characterized by wet springback ratio, hydraulic diameter and an internal bond strength parameter.

Owner:GPCP IP HLDG LLC

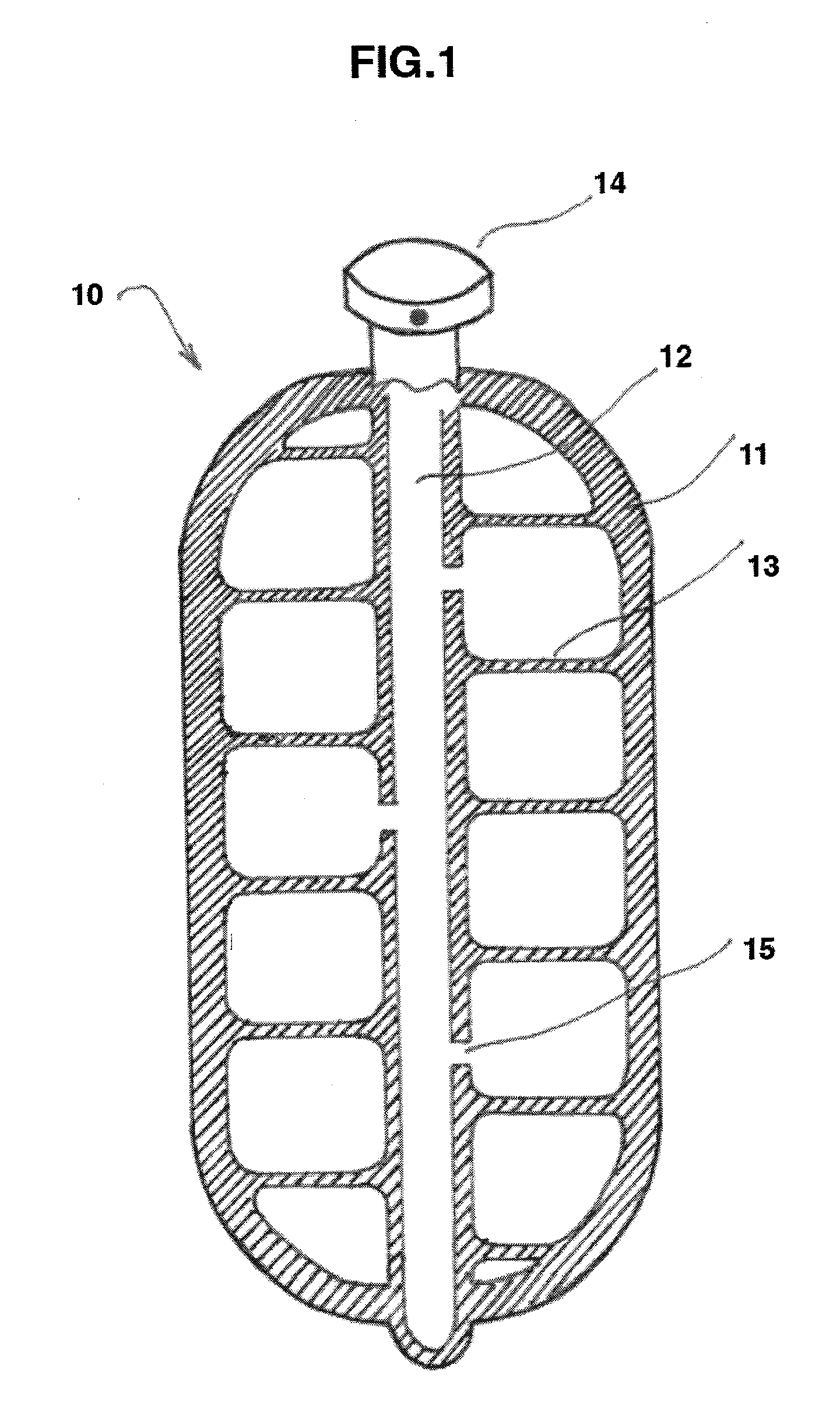

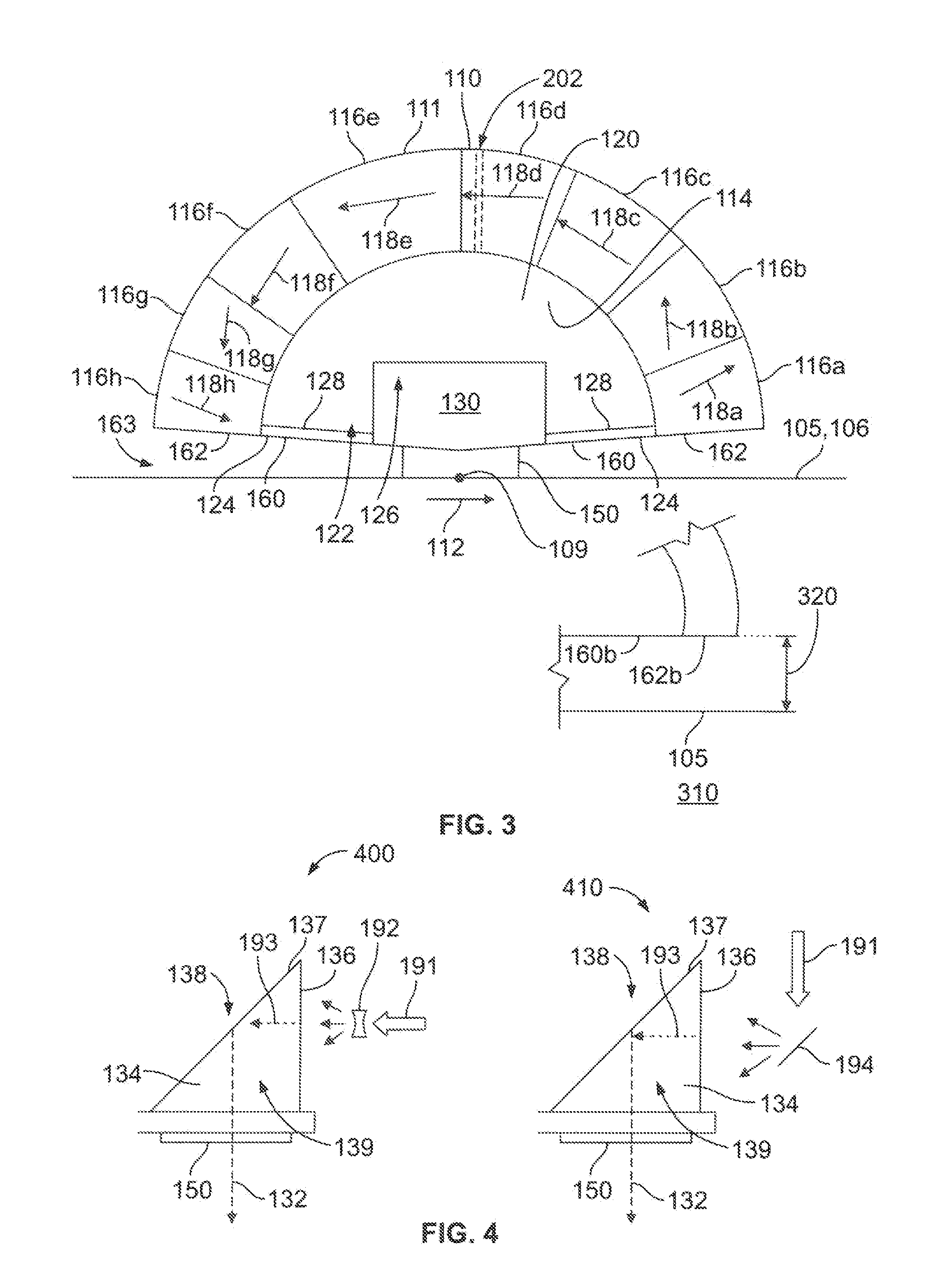

Pressure Vessels, Design and Method of Manufacturing Using Additive Printing

InactiveUS20160061381A1Less materialNo wasteLarge containersArc welding apparatusManufacturing technologyEngineering

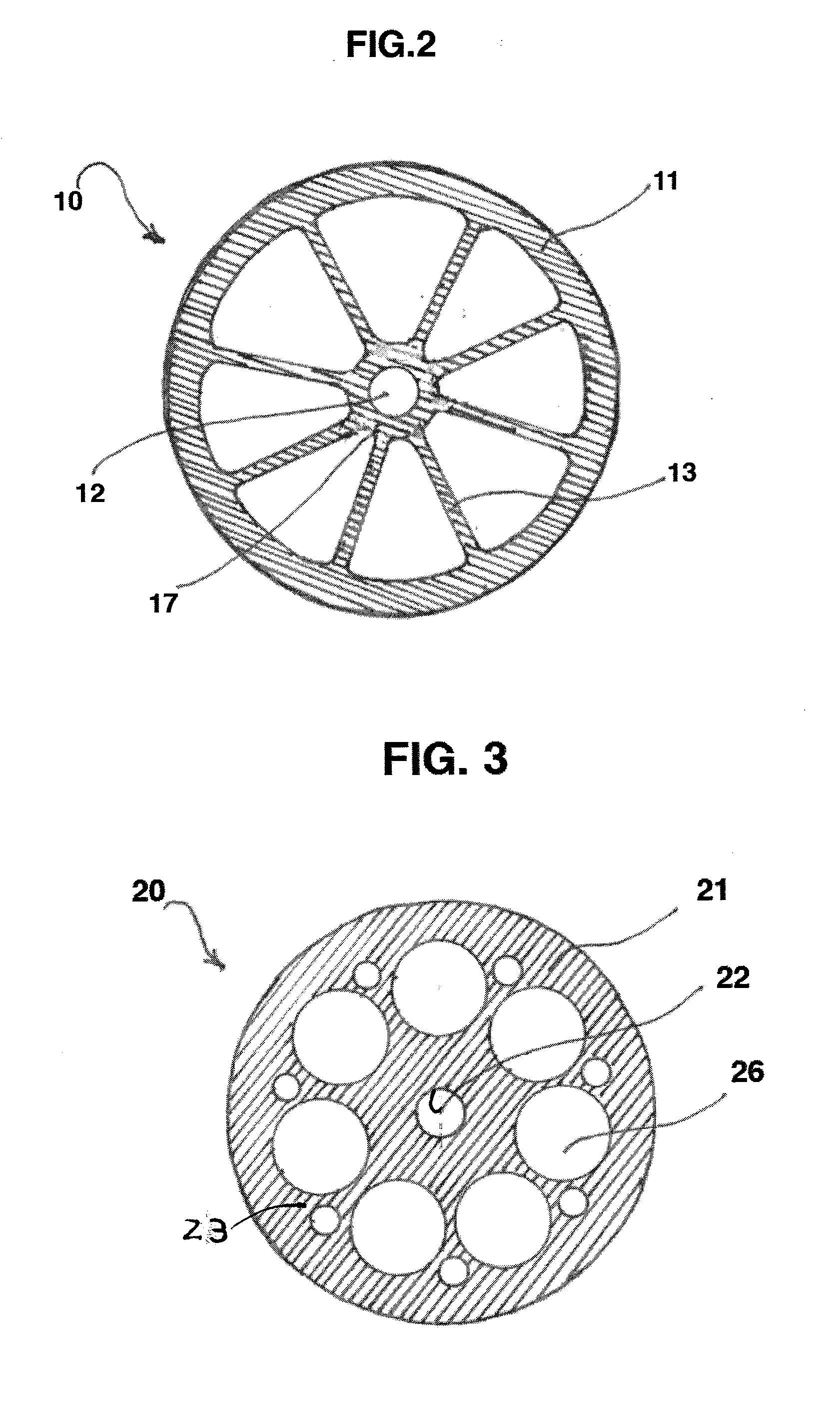

Method and design of a pressure vessel having an internal supportive structure that reduces pressure forces applied to the external shell of the vessel by distributing such forces via internal bonds mostly connected to a central supporting element. The method and design allow making much lighter and stronger pressure vessels and containers using additive manufacturing technology, known as 3D printing.

Owner:KOTLIAR IGOR K

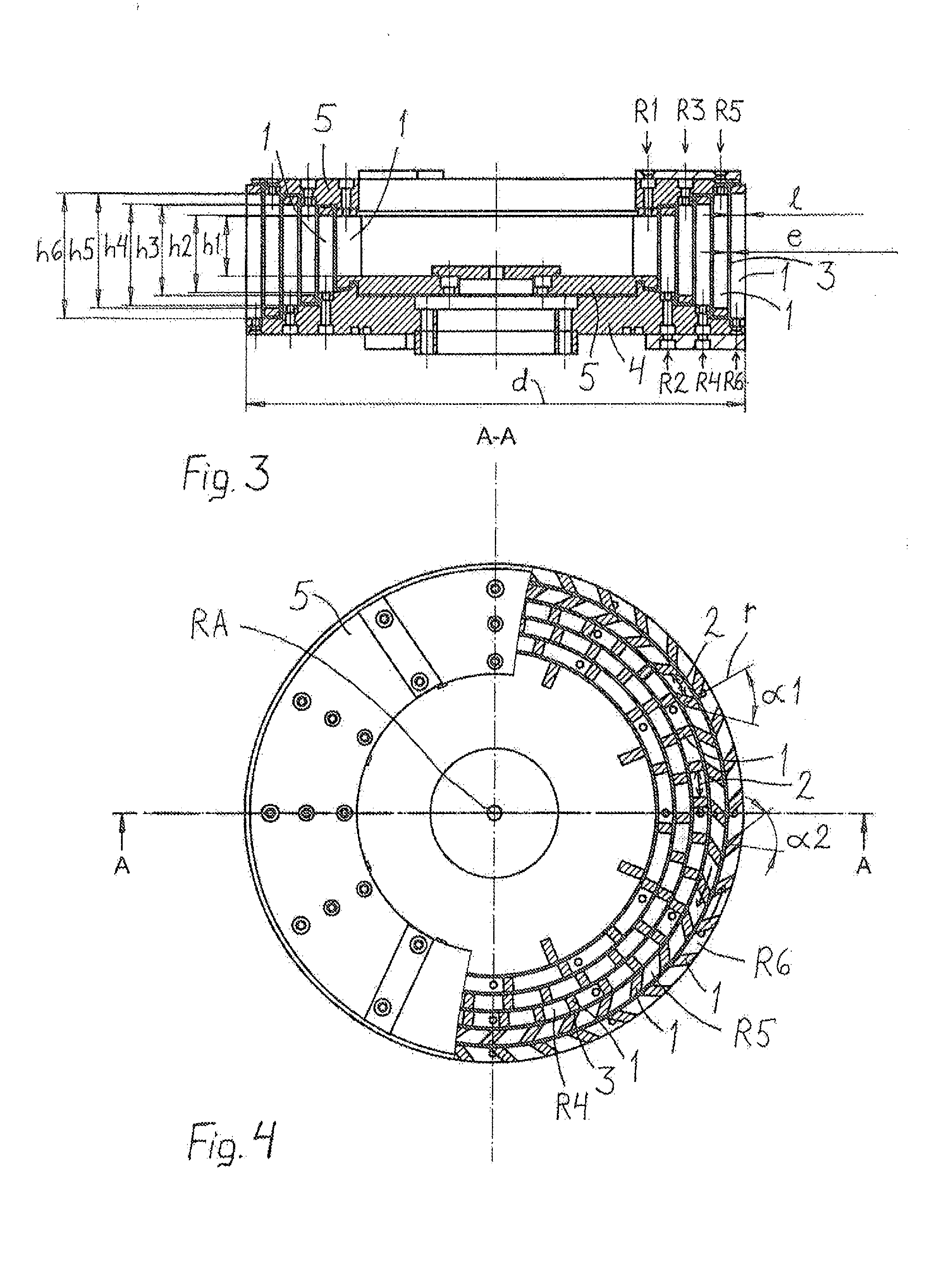

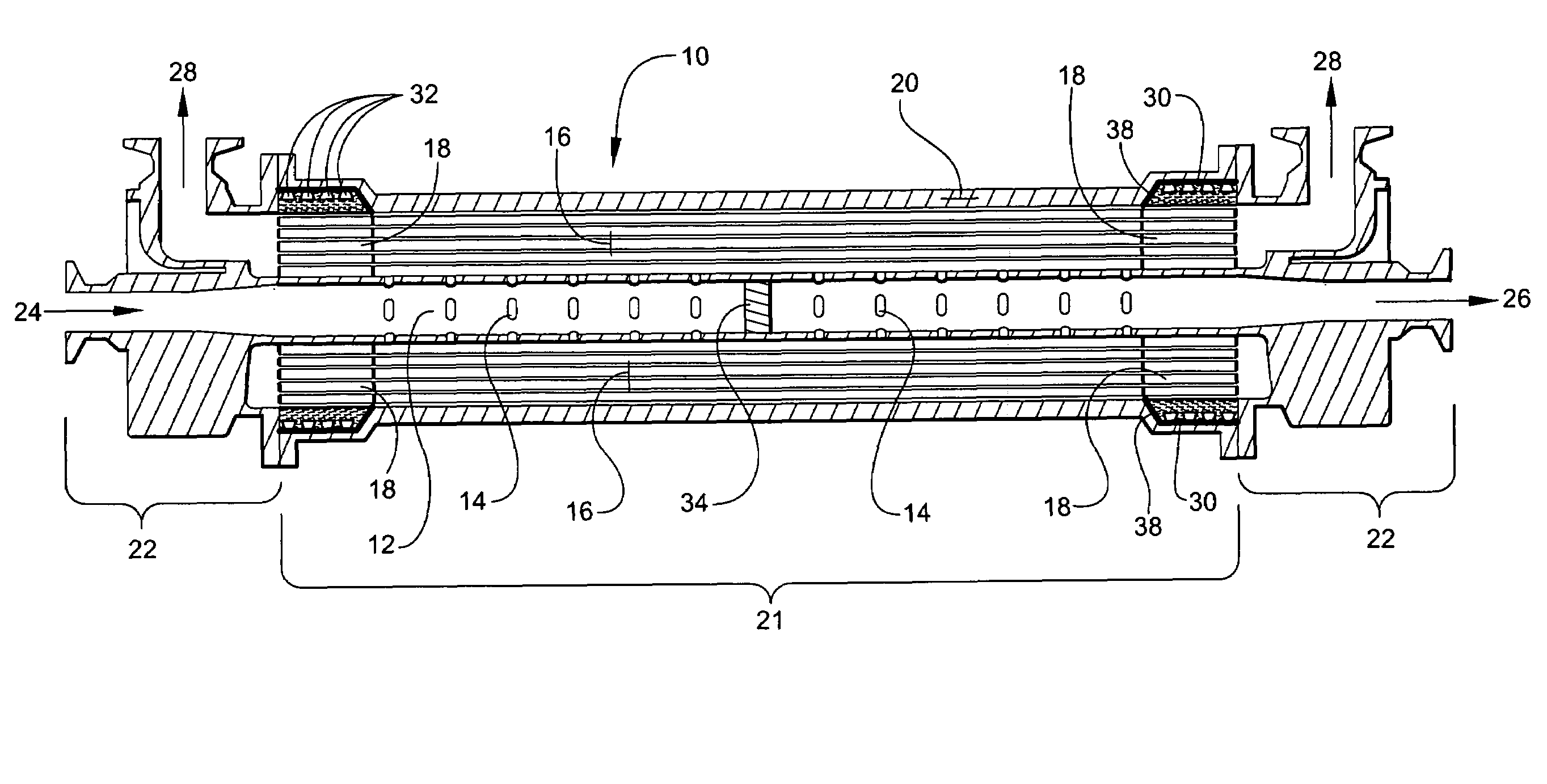

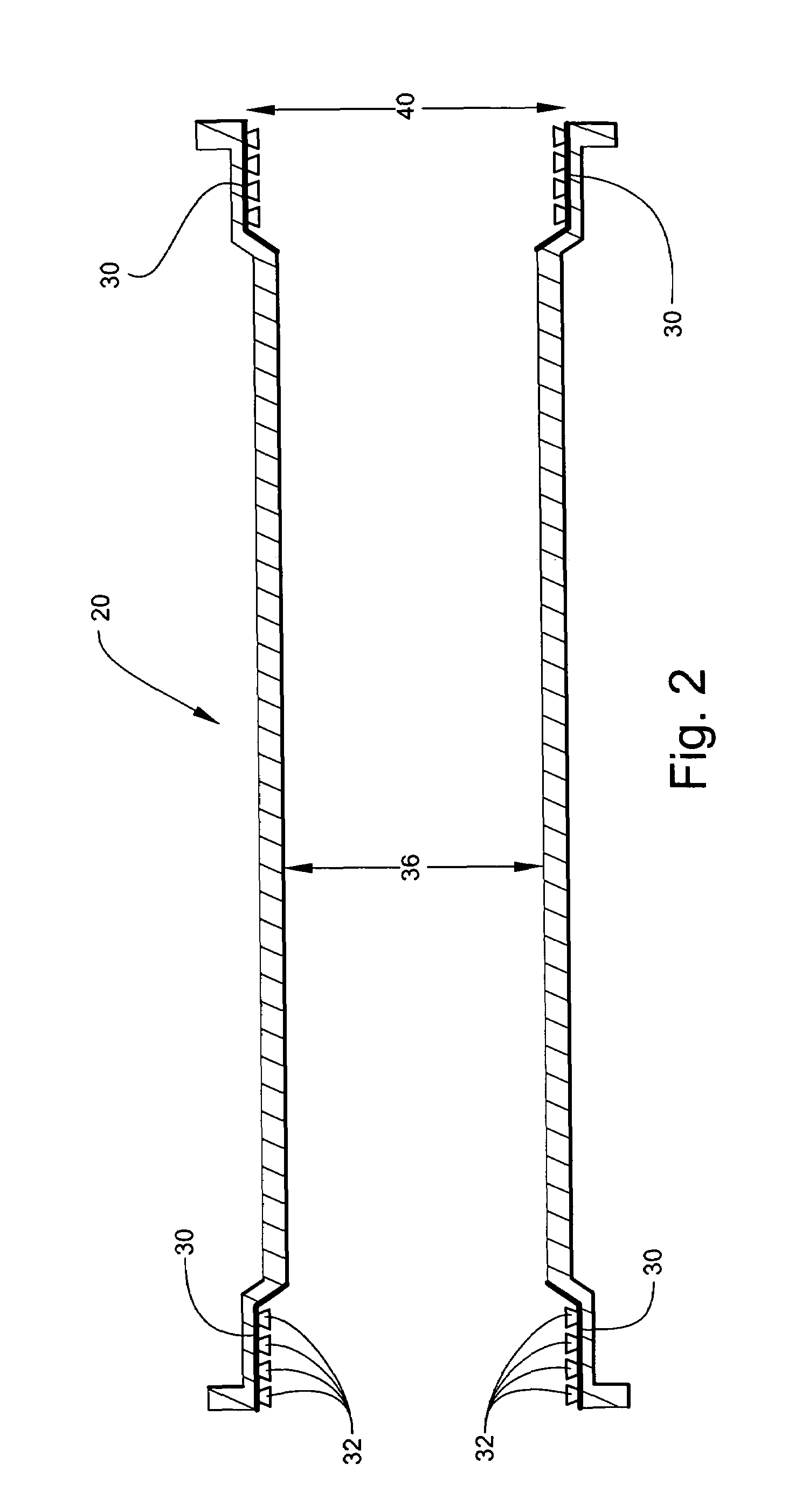

Hollow fiber membrane contactor and method of making same

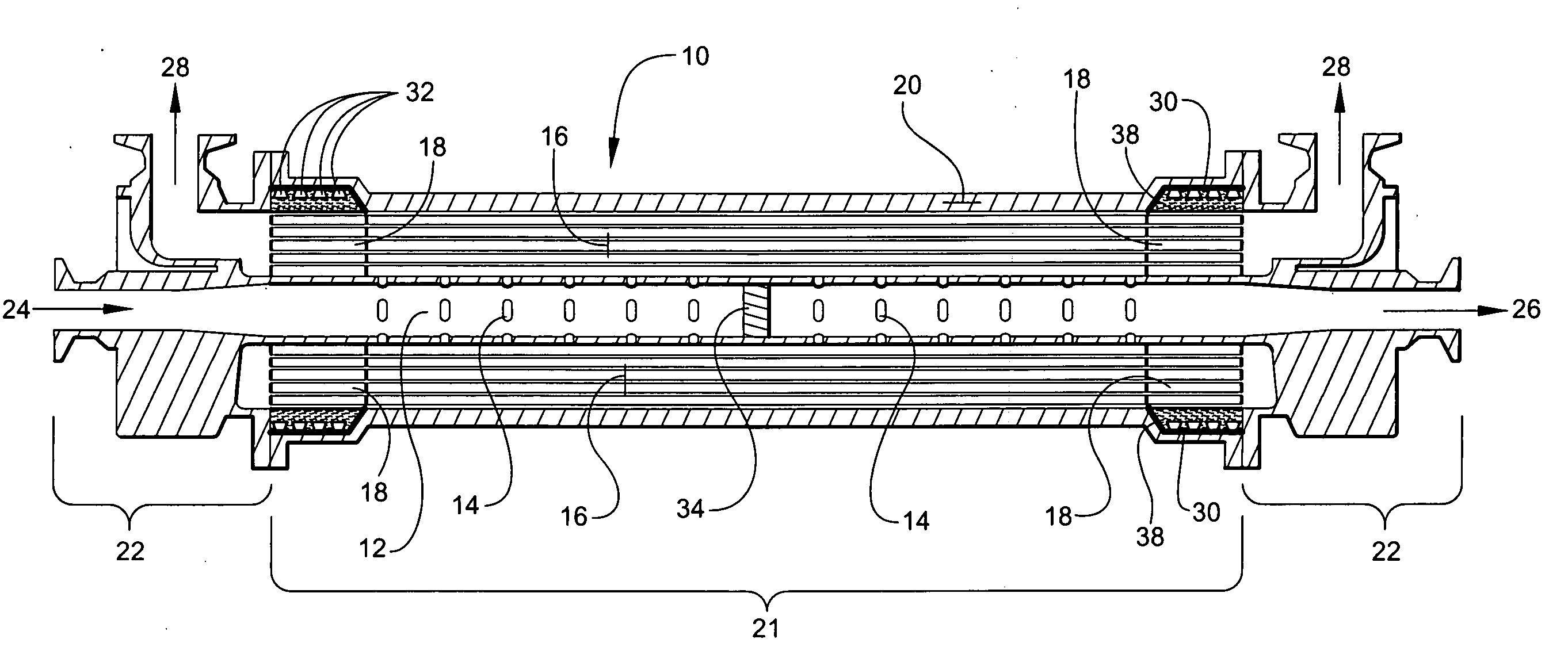

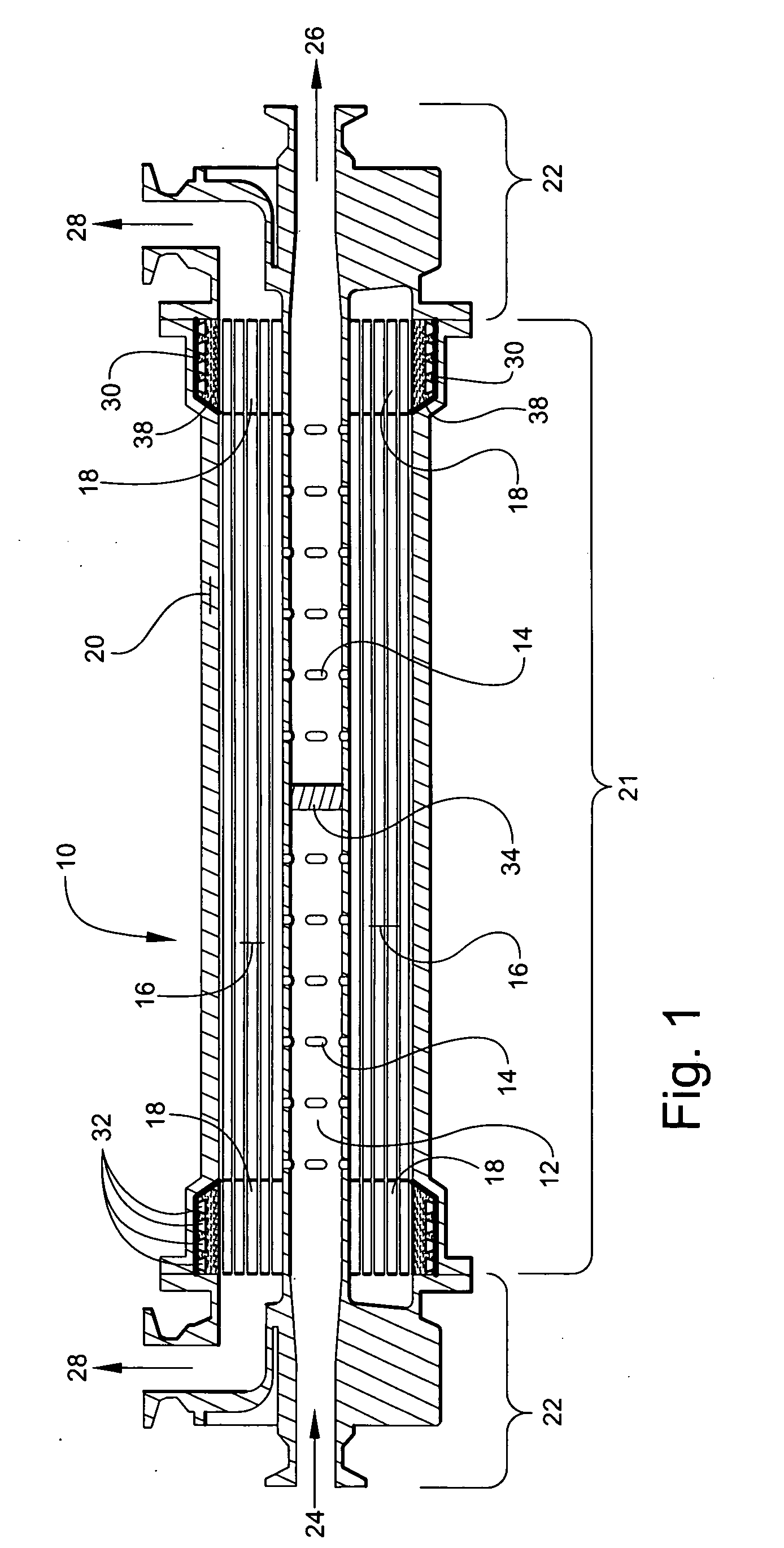

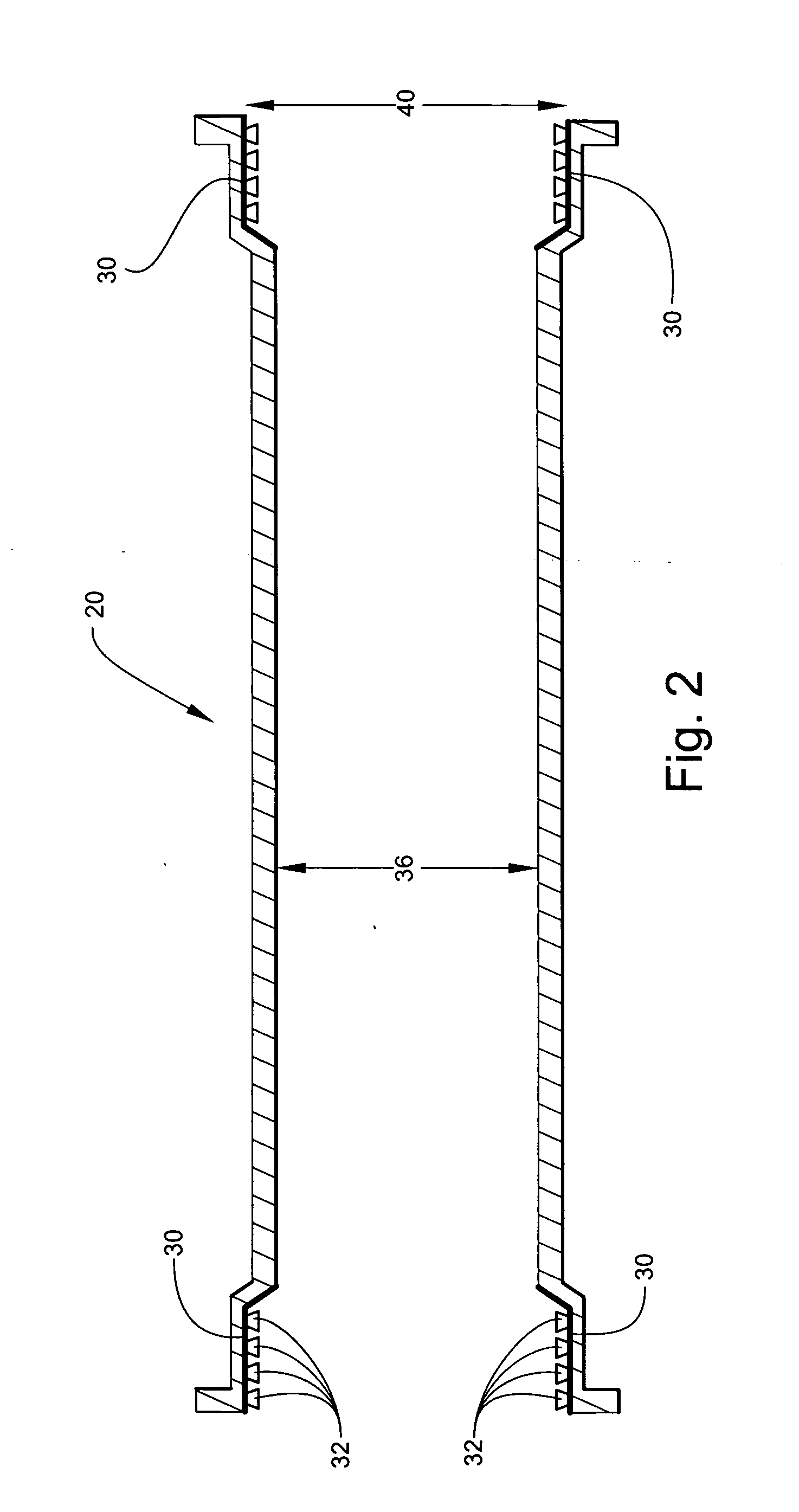

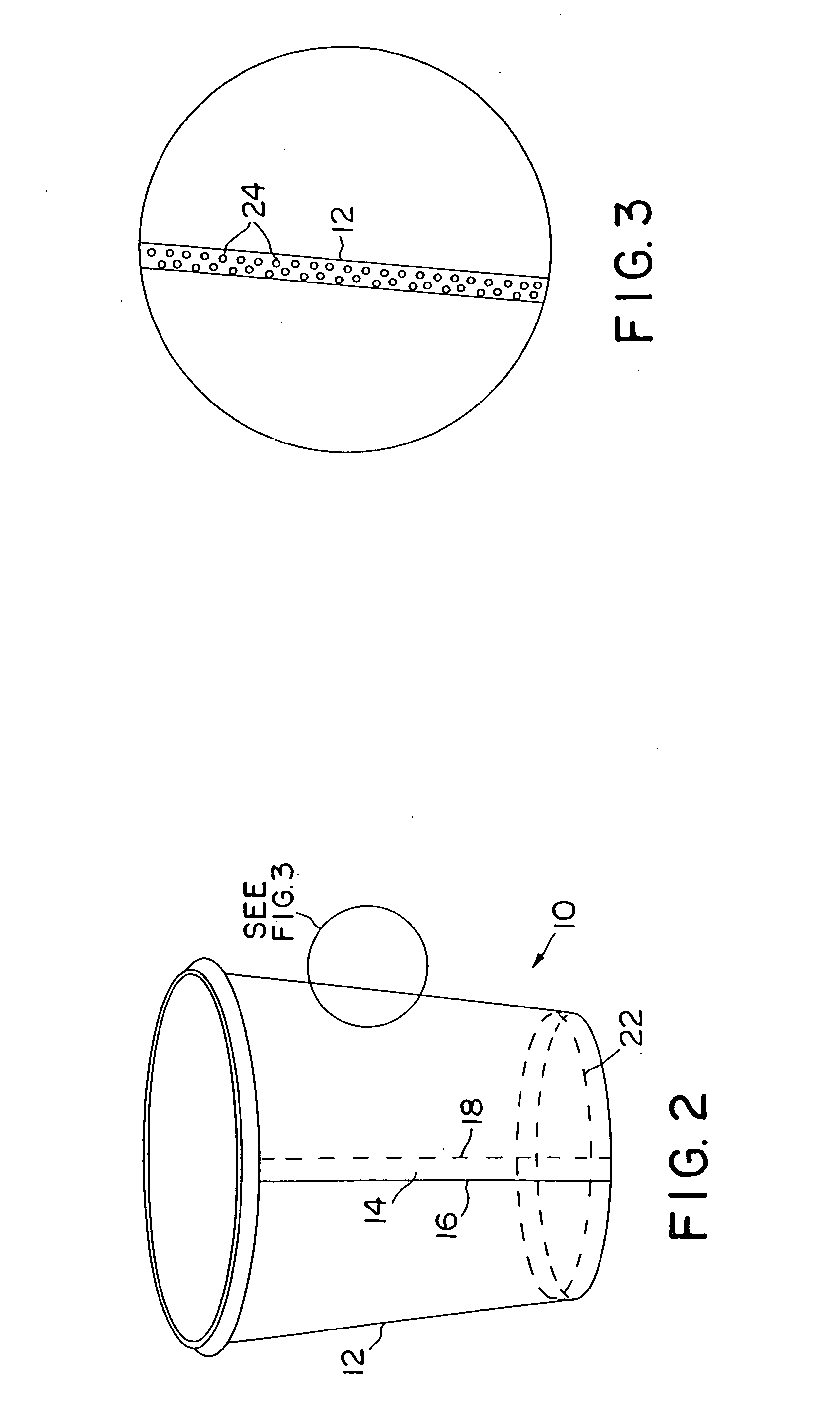

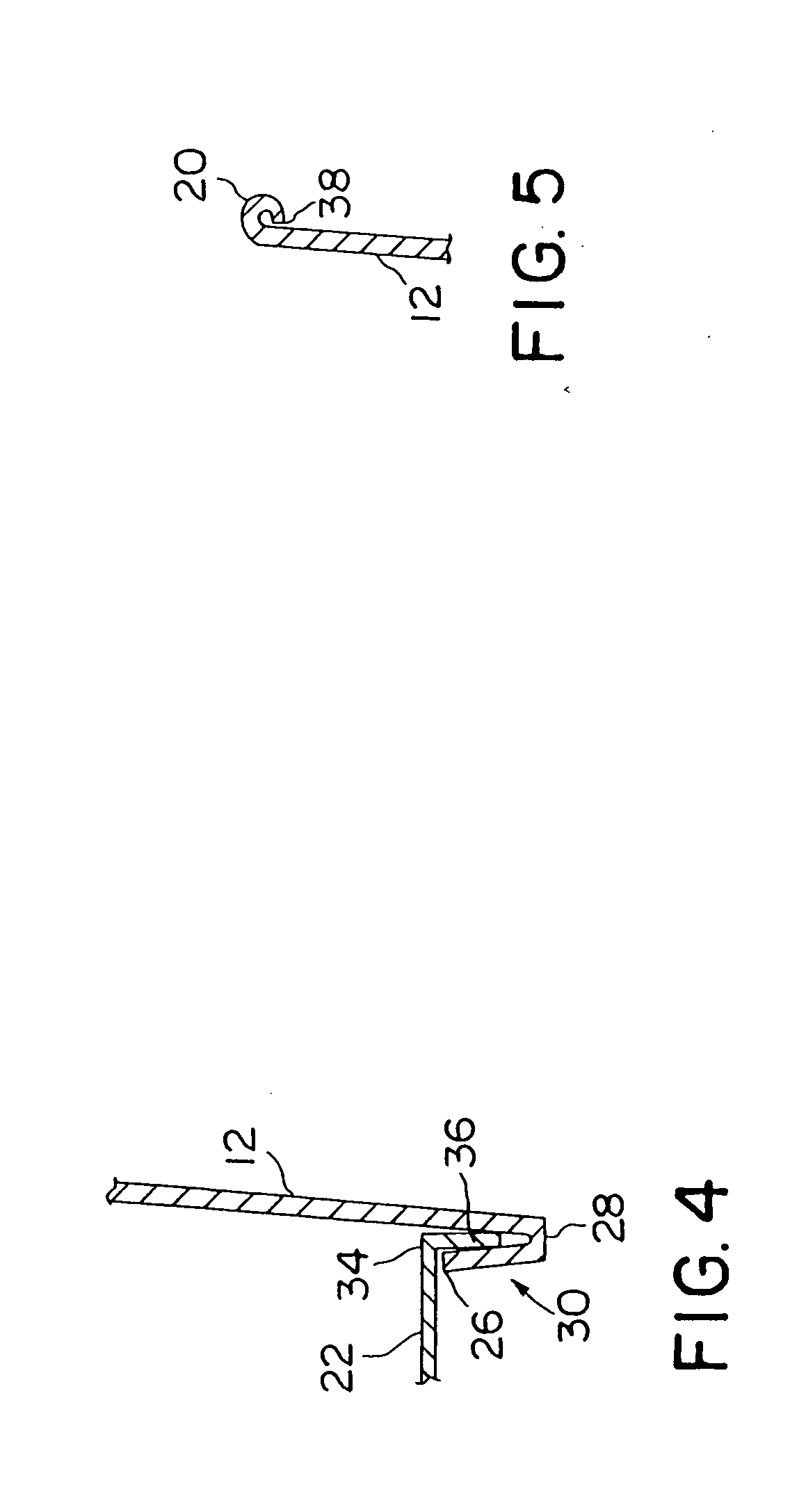

The instant invention is a hollow fiber membrane contactor, and method of making same. The hollow fiber membrane contactor includes (1) a shell, said shell having a internal bonding surface, an interlocking geometry ring being provided on said internal bonding surface; (2) a unitized structure; (3) a potting material joining said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (4) end caps, said end caps being adjoined to lateral ends of said shell. The method of making a hollow fiber membrane contactor includes (1) providing a shell, said shell having a internal bonding surface; (2) providing an interlocking geometry ring on said internal bonding surface; (3) forming a unitized structure; (4) placing the unitized structure into said shell (5) potting said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (6) adjoining end caps to lateral ends of said shell.

Owner:3M INNOVATIVE PROPERTIES CO

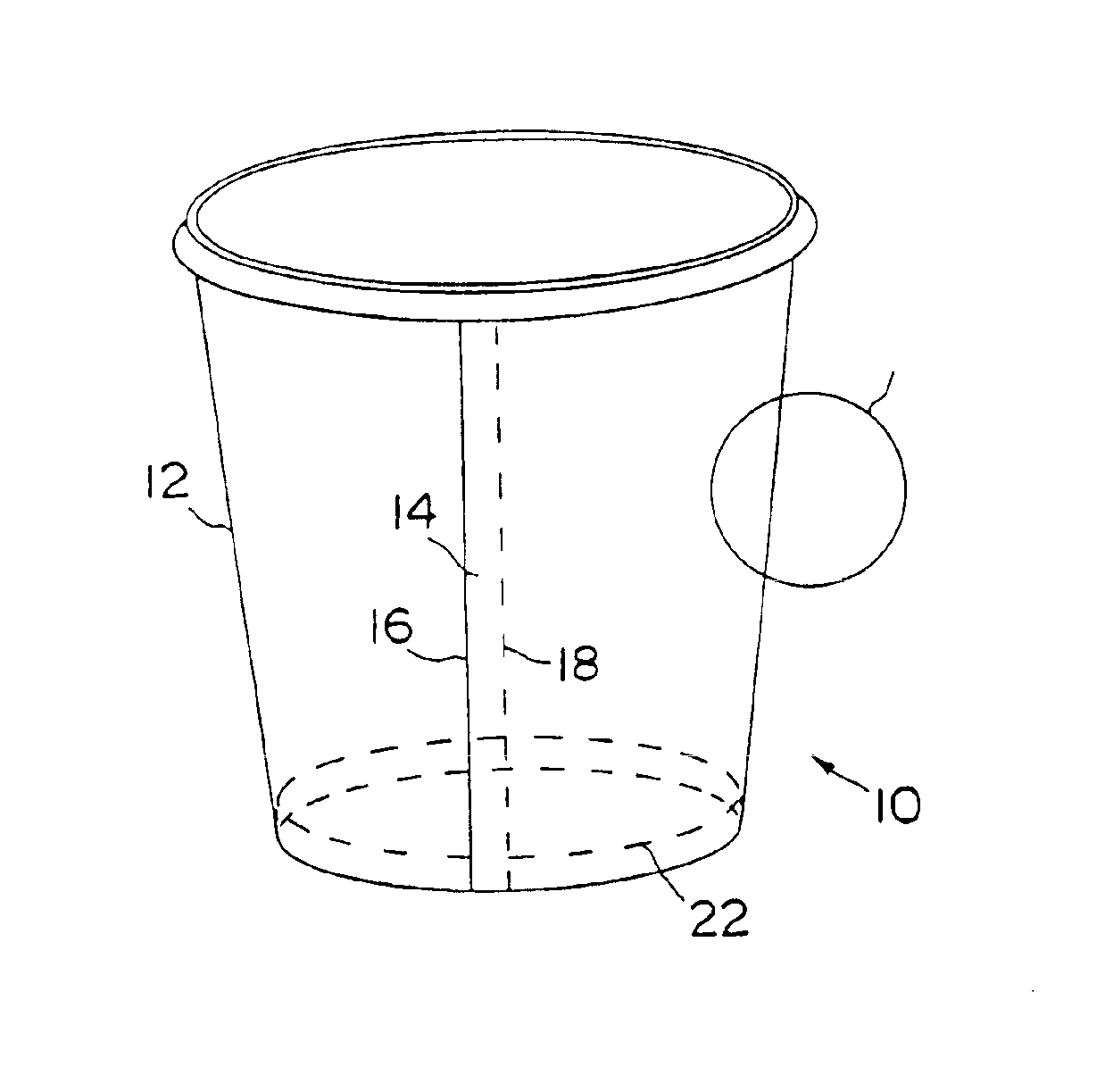

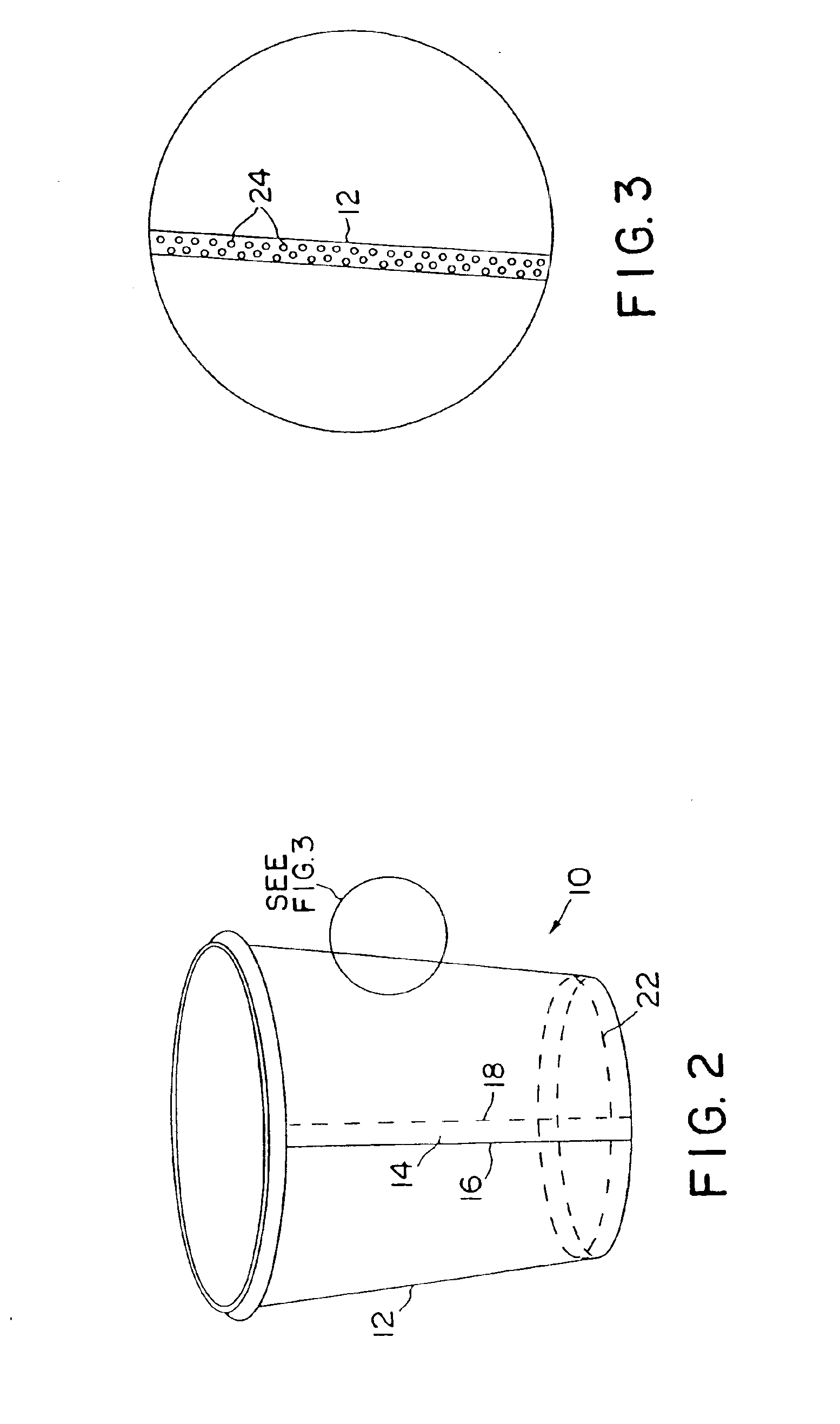

Low density paperboard articles

InactiveUS6846529B2Improve insulation performanceLess-expensive to produceNon-fibrous pulp additionNatural cellulose pulp/paperLow-density polyethyleneLinear low-density polyethylene

The invention provides a low density paperboard material for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft-lbf preferably at least 100×10−3 ft-lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and the surface of the low density board may have a Sheffield smoothness of 300 SU or greater.

Owner:GRAPHIC PACKAGING INT

Wet crepe throughdry process for making absorbent sheet and novel fibrous product

An improved process for making sheet from a fibrous furnish includes: depositing the furnish on a foraminous support; compactively dewatering the furnish to form a nascent web; drying the web on a heated cylinder; creping the web therefrom and throughdrying the web to a finished product. The microstructure of the web is controlled so as to facilitate throughdrying. The product exhibits a characteristic throughdrying coefficient of from 4 to 10 when the airflow through the sheet is characterized by a Reynolds Number of less than about 1. The novel products of the invention are characterized by wet springback ratio, hydraulic diameter and an internal bond strength parameter.

Owner:GPCP IP HLDG LLC

Ink jet recording method and ink jet recording paper

InactiveUS6880928B2Weaken expansion/shrinkage transmissionLess frizzSpecial paperMeasurement apparatus componentsFiberThird generation

In an ink jet recording method, a surface of a recording paper, in which a base paper contains a pulp fiber and a filler, one surface of the base paper being coated with a polyvalent metal salt in a coating amount of from 0.1 to 3 g / m2, having a basis weight of from 63 to 100 g / m2 and an internal bond strength of from 0.05 to 0.2 N·m is printed using an ink of at least one color made of at least a pigment, a water-soluble organic solvent, water and a surfactant and having a surface tension of from 25 to 37 mN / m. According to the method, the color reproduction is improved, the inter color bleeding and the feathering of characters are reduced, the double-sided printability is provided by reducing curling and cockling occurring immediately after printing, and curling and cockling occurring after allowing to stand and drying are also reduced.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Bonding Material for Semiconductor Devices

ActiveUS20130134591A1Improve reliabilityFew voidPorous dielectricsLayered productsMetallurgyInternal bond

A semiconductor device is provided which has internal bonds which do not melt at the time of mounting on a substrate. A bonding material is used for internal bonding of the semiconductor device. The bonding material is obtained by filling the pores of a porous metal body having a mesh-like structure and covering the surface thereof with Sn or an Sn-based solder alloy.

Owner:SENJU METAL IND CO LTD

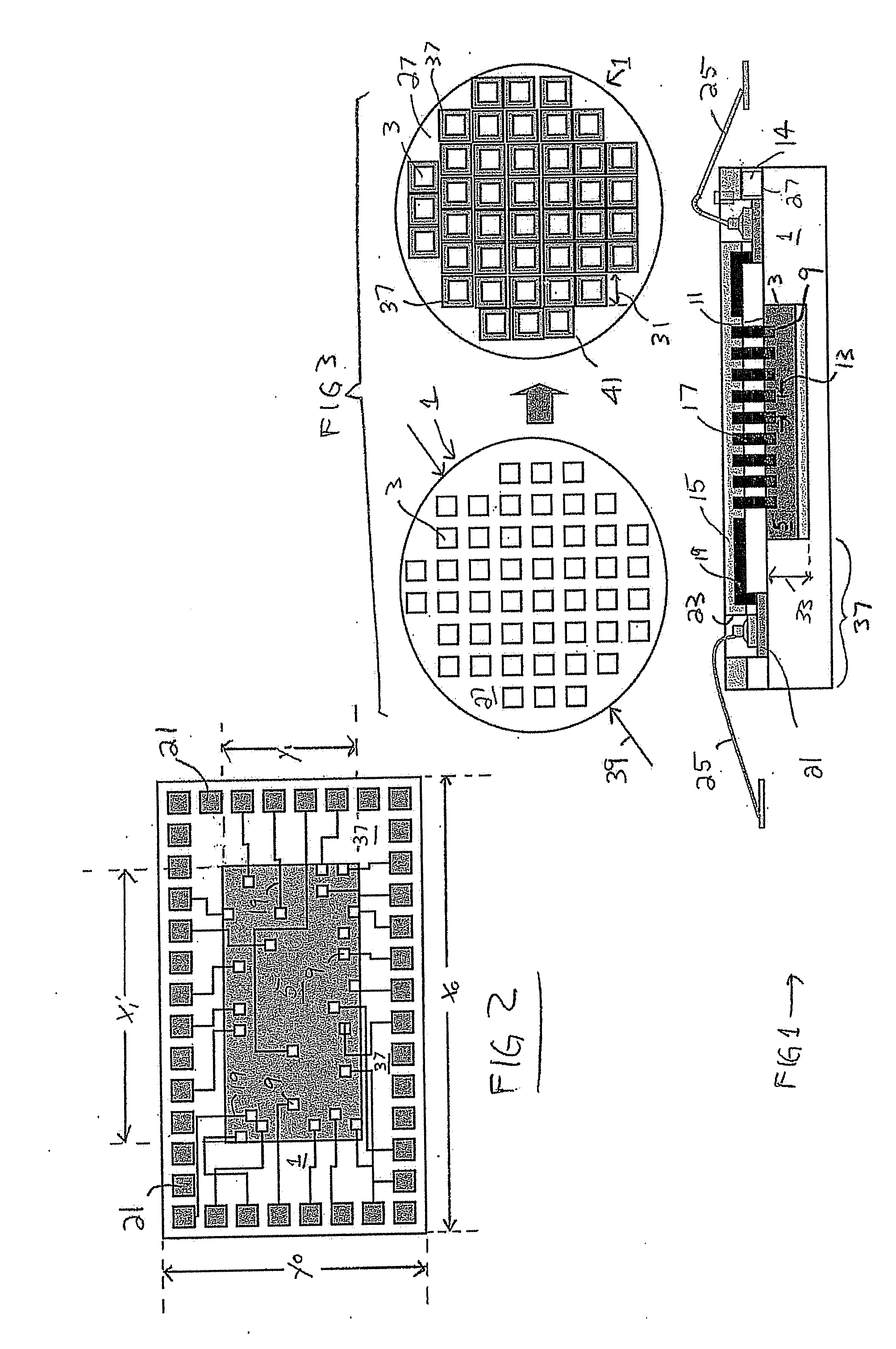

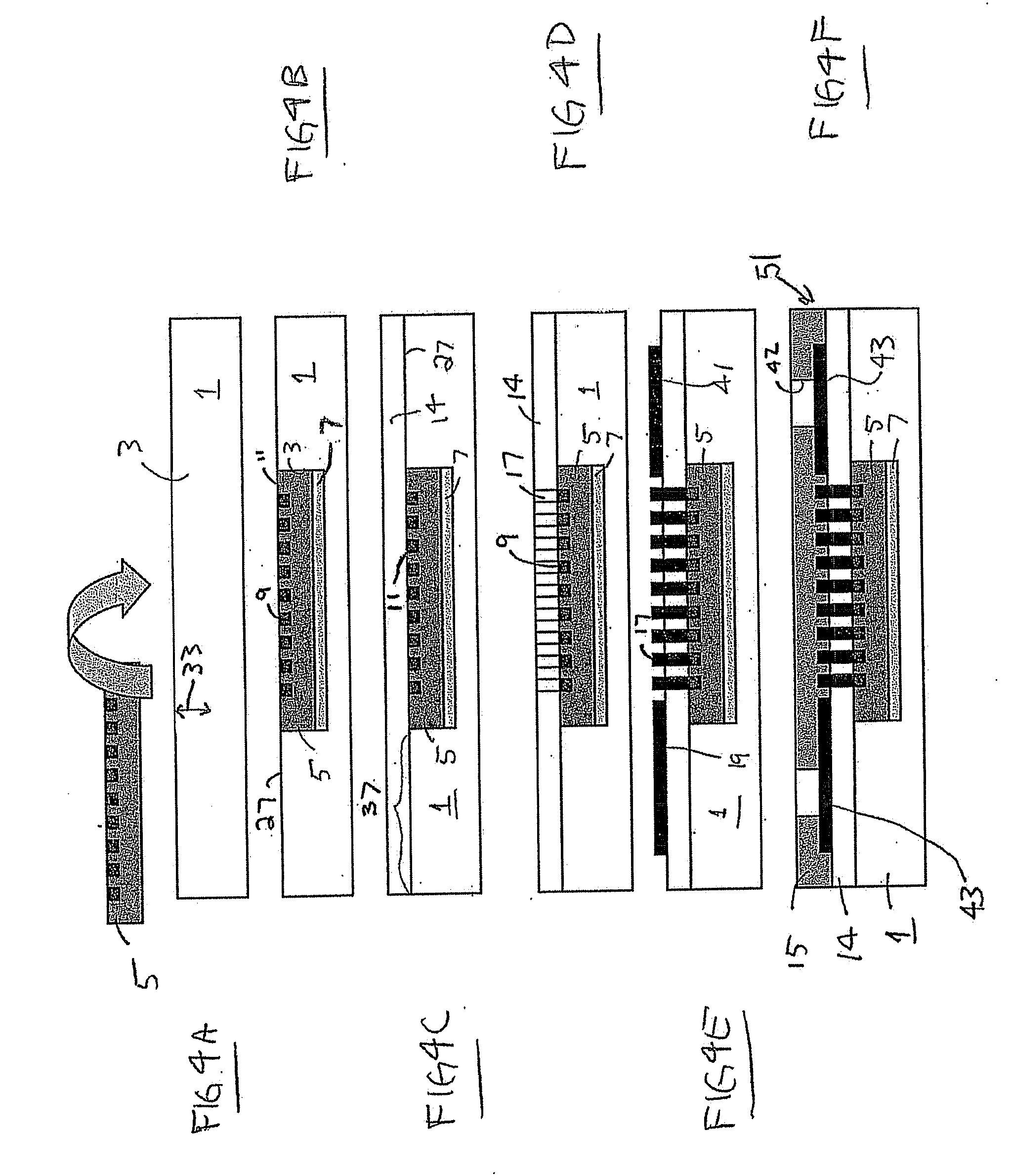

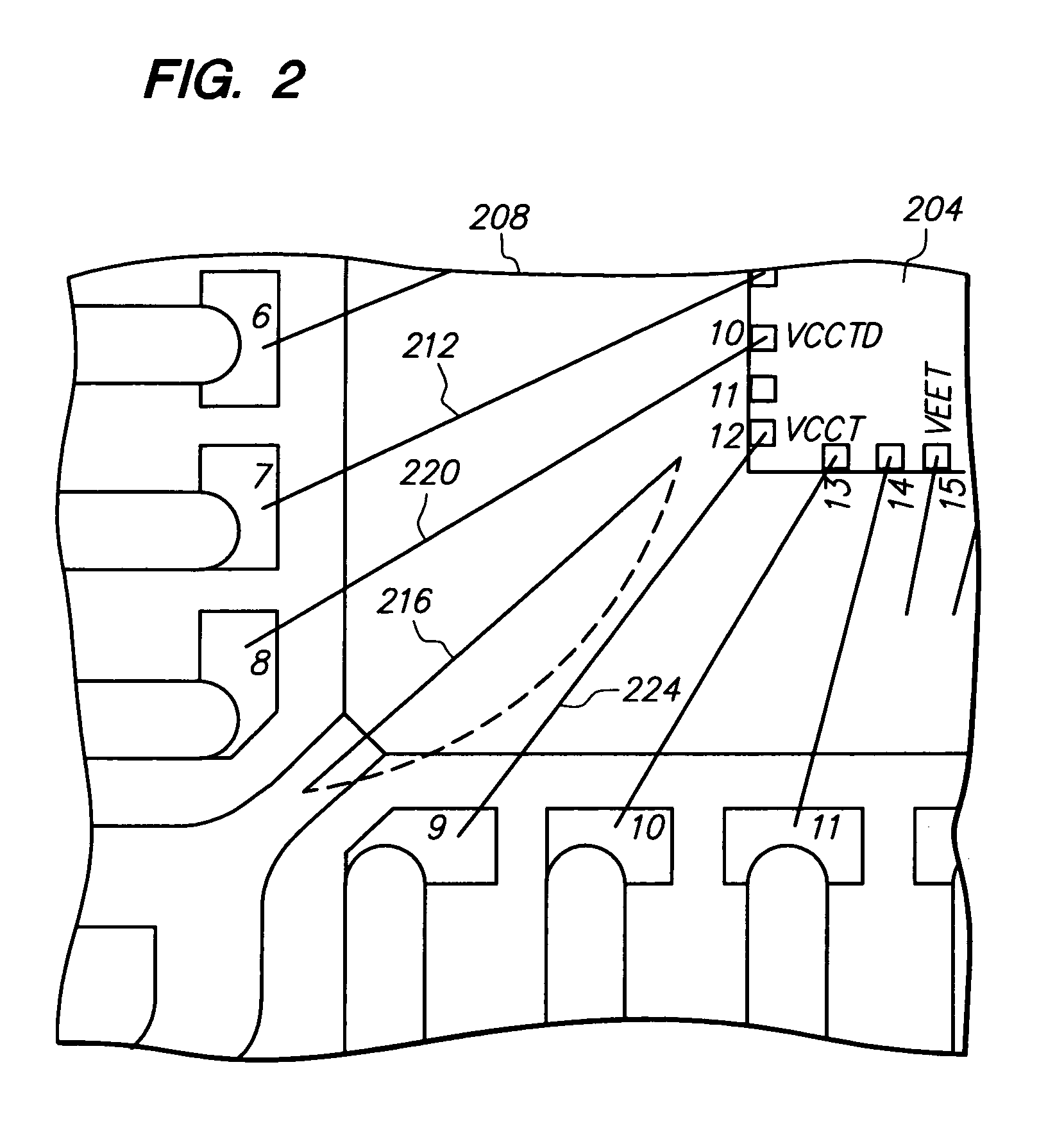

Semiconductor device, wiring substrate, and method for manufacturing wiring substrate

ActiveUS20060151870A1Improve reliabilityThermal expansion mismatchSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsDevice materialSemiconductor chip

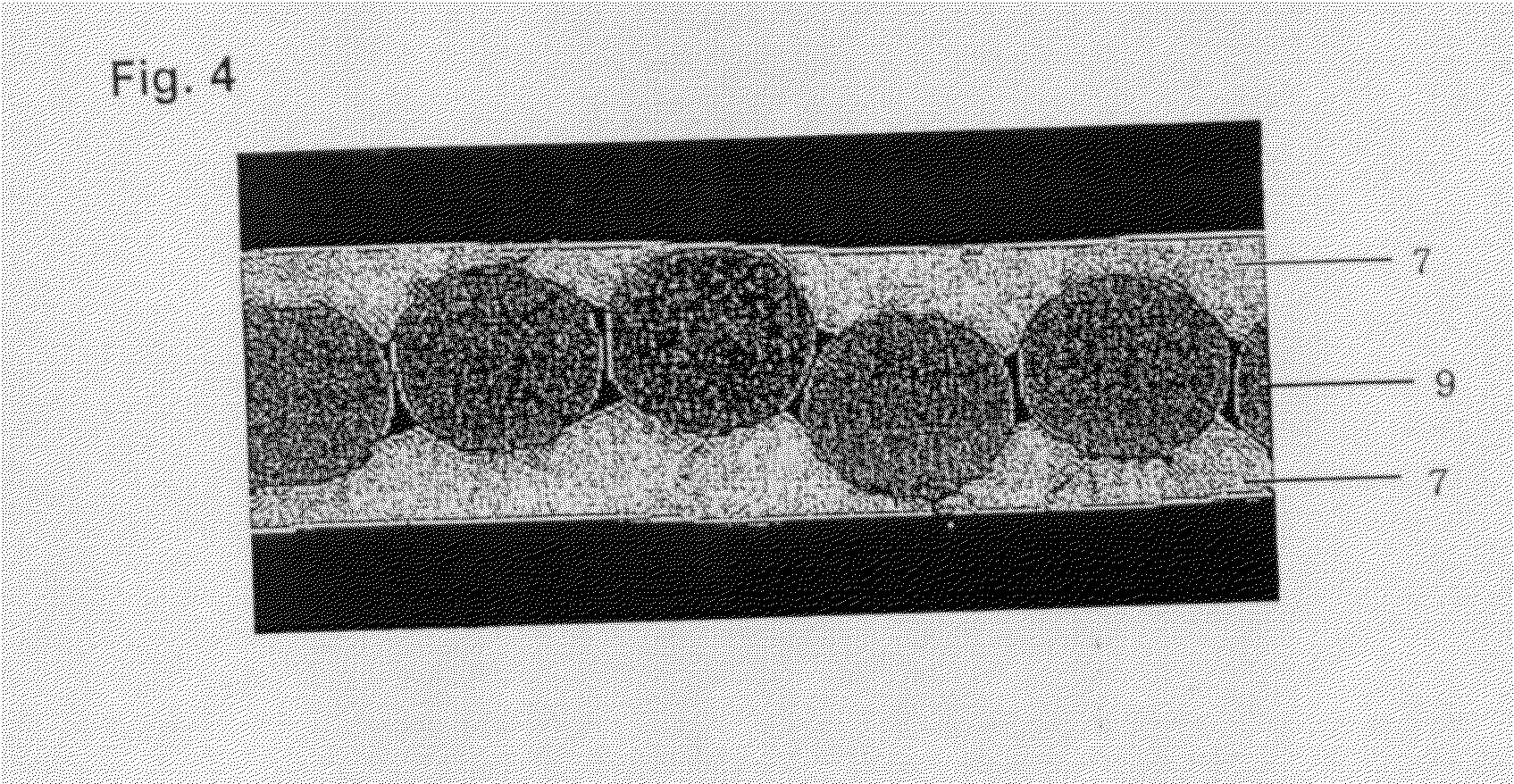

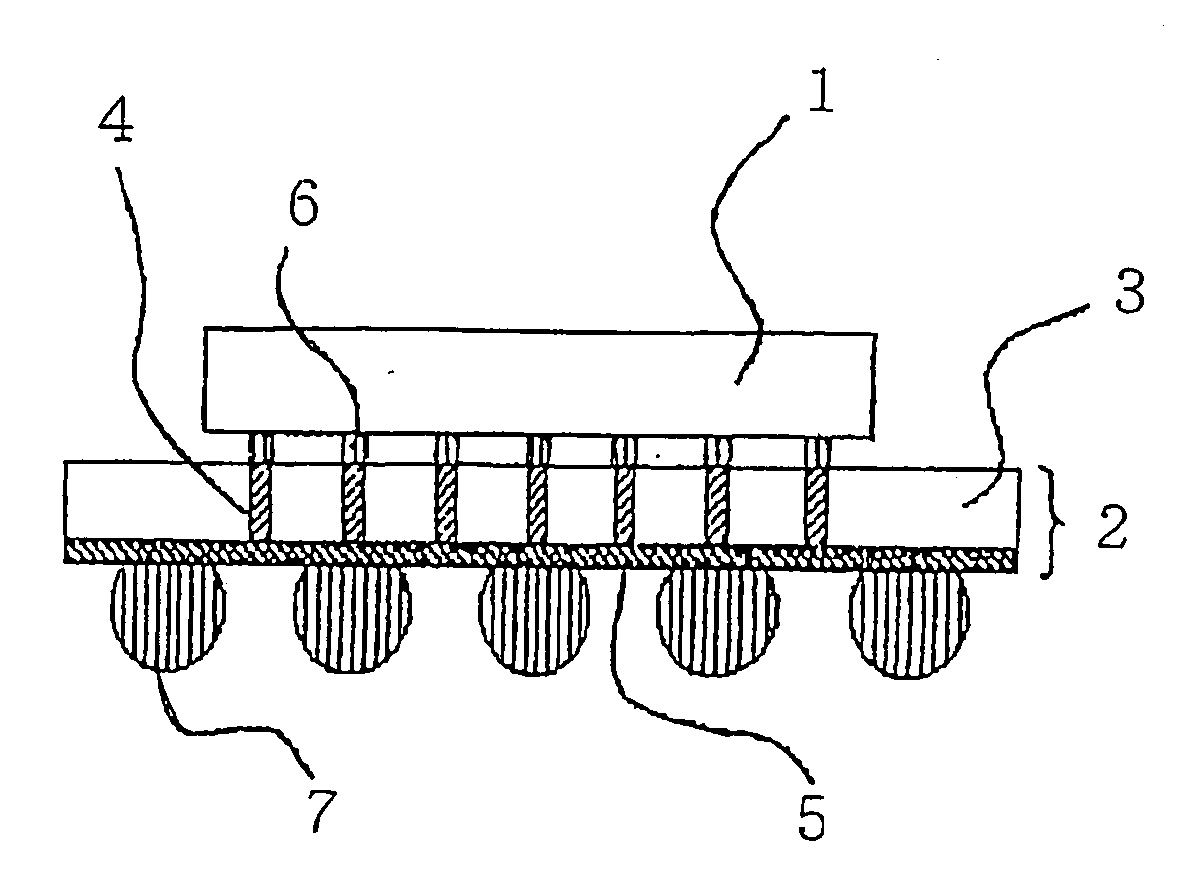

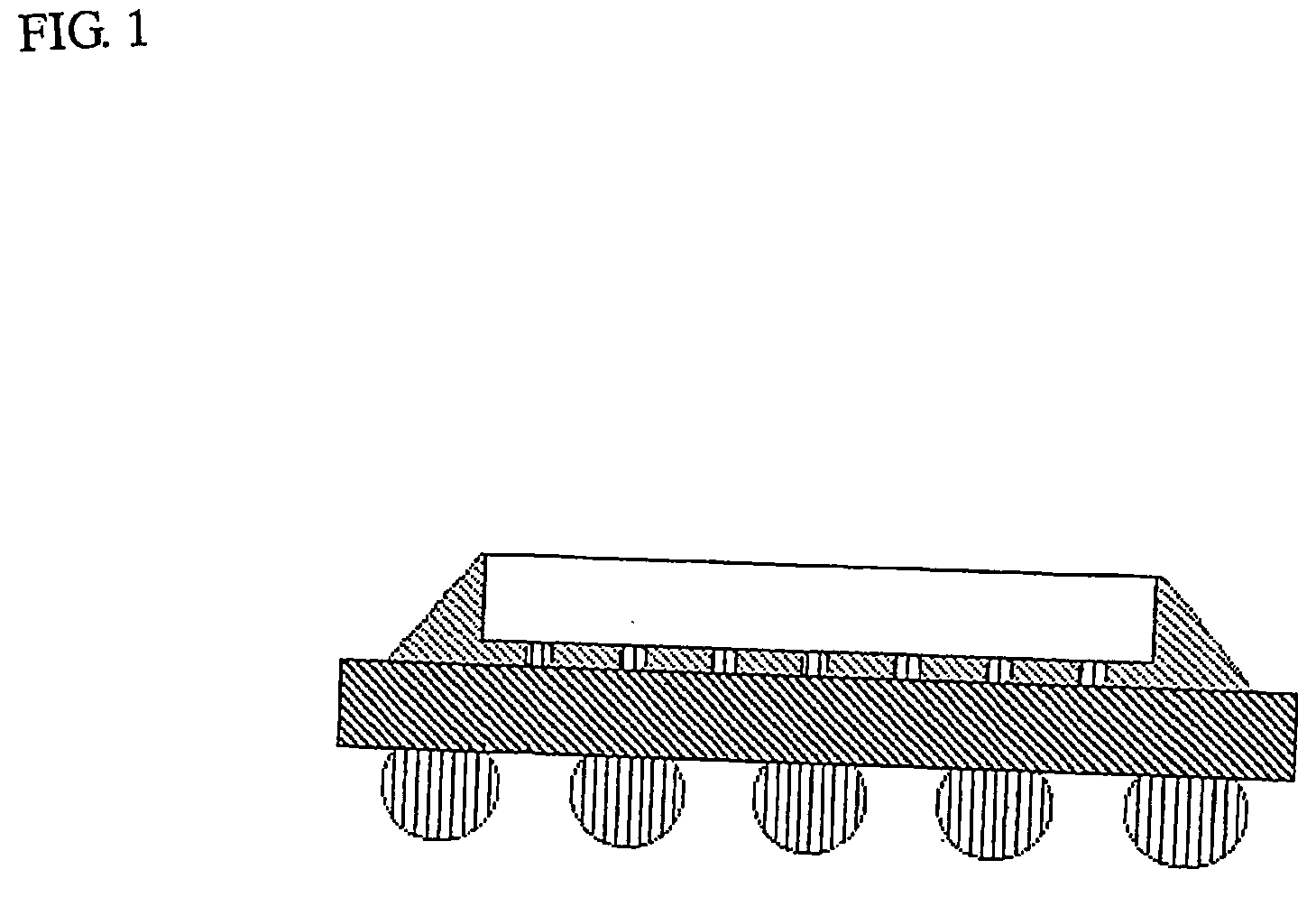

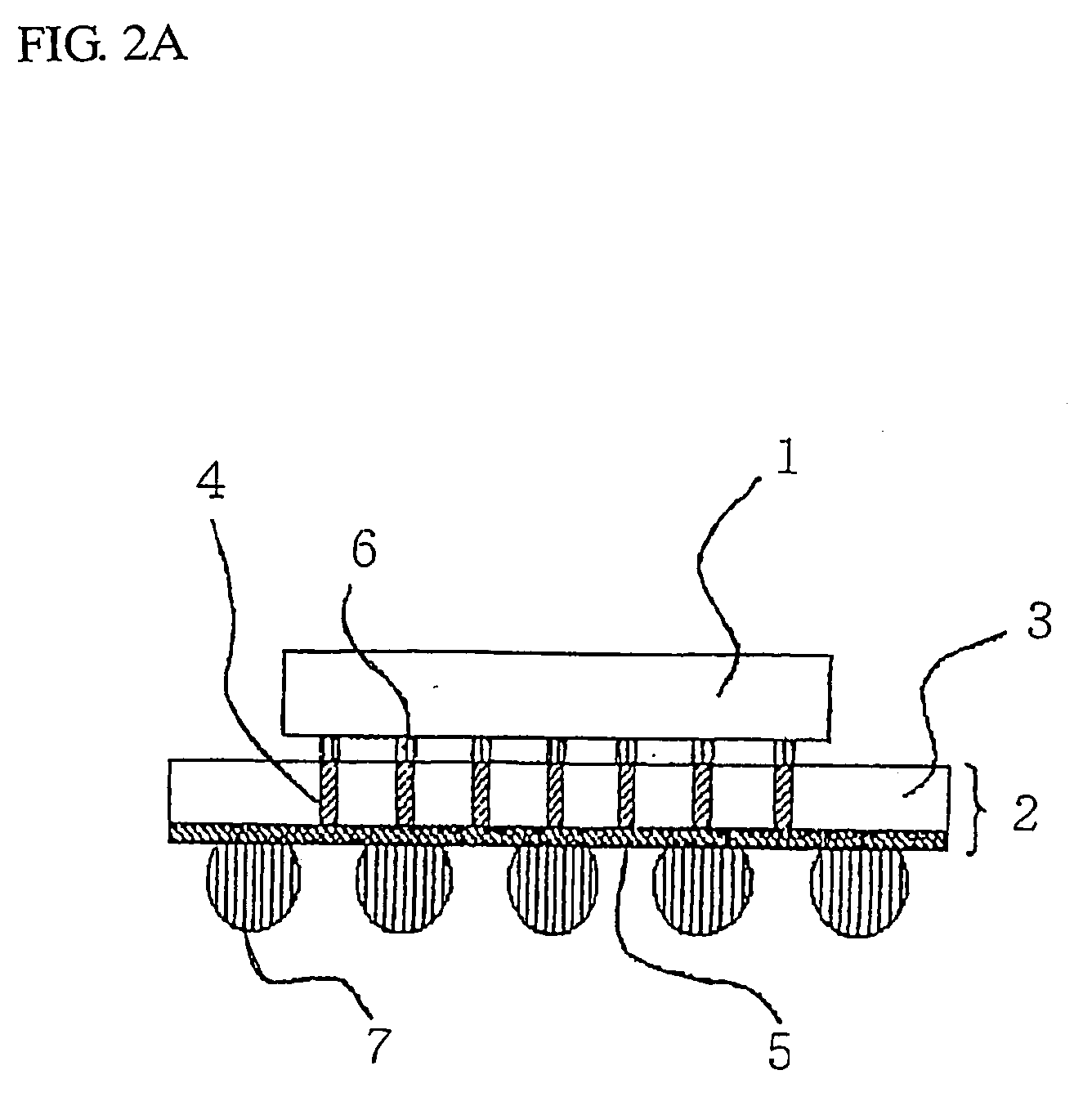

The reliabilities of a wiring substrate and a semiconductor apparatus are improved by reducing the internal stress caused by the difference of thermal expansion coefficients between a base substrate and a semiconductor chip. A wiring layer (5) is provided on one surface of a silicon base (3). An electrode as the uppermost layer of the wiring layer (5) is provided with an external bonding bump (7). A through-electrode (4) is formed in the base (3) for electrically connecting the wiring layer (5) and an electrode terminal. The electrode terminal on the chip mounting surface is bonded to an electrode terminal of a semiconductor chip (1) by an internal bonding bump (6). The thermal expansion coefficient of the silicon base (3) is equivalent to that of the semiconductor chip (1) and not more than that of the wiring layer (5).

Owner:GK BRIDGE 1

Low density paperboard articles

InactiveUS20050133183A1Improve thermal conductivityHigh densityDomestic cooling apparatusLighting and heating apparatusCardboardLow-density polyethylene

The invention provides a low density paperboard material and associated method for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft−lbf., preferably at least 100×10−3 lft−lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and exhibits insulative properties comparable to higher cost materials conventionally used to make cups. Also, the surface of the low density board may have a Sheffield smoothness of 300 SU or greater compared with the surface smoothness of 160 to 200 SU for conventional cupstock, the latter having been thought necessary for adequate print quality. However, it has been found that the low density board exhibits good printability on flexo printing machines despite its relatively rough surface, which is surprising and bonus effect realized along with the insulative and other properties of the board.

Owner:MOHAN KOSARAJU KRISHNA +3

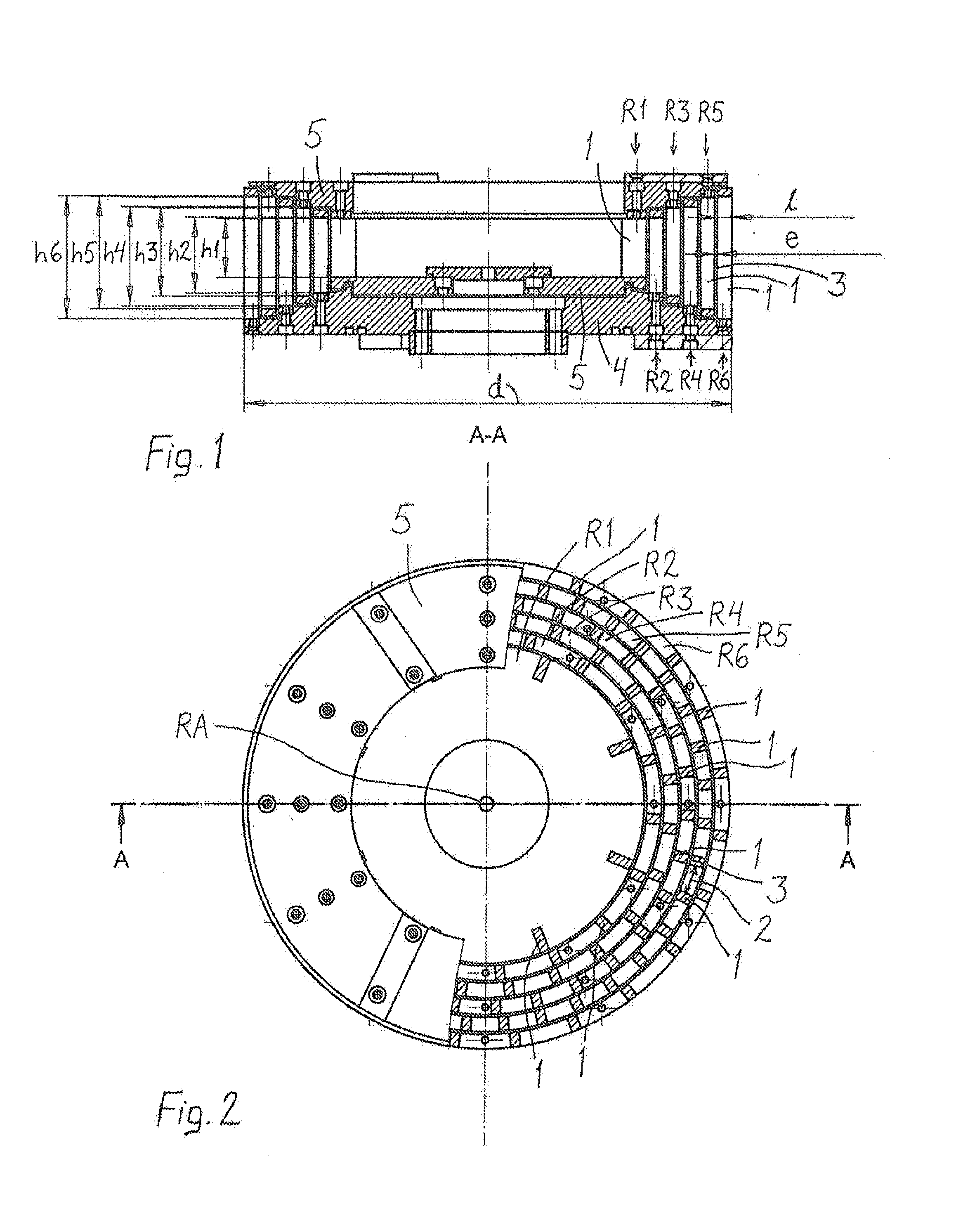

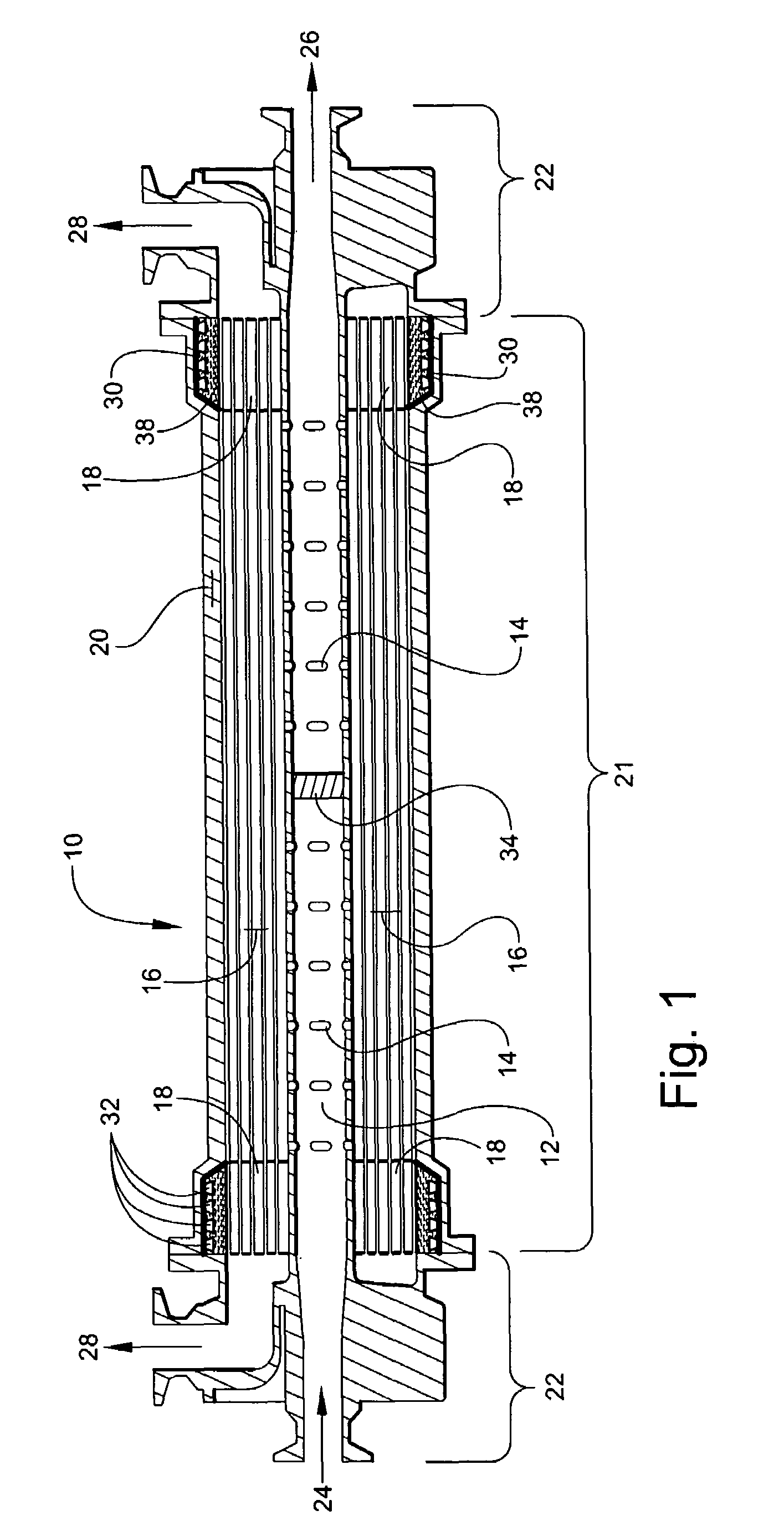

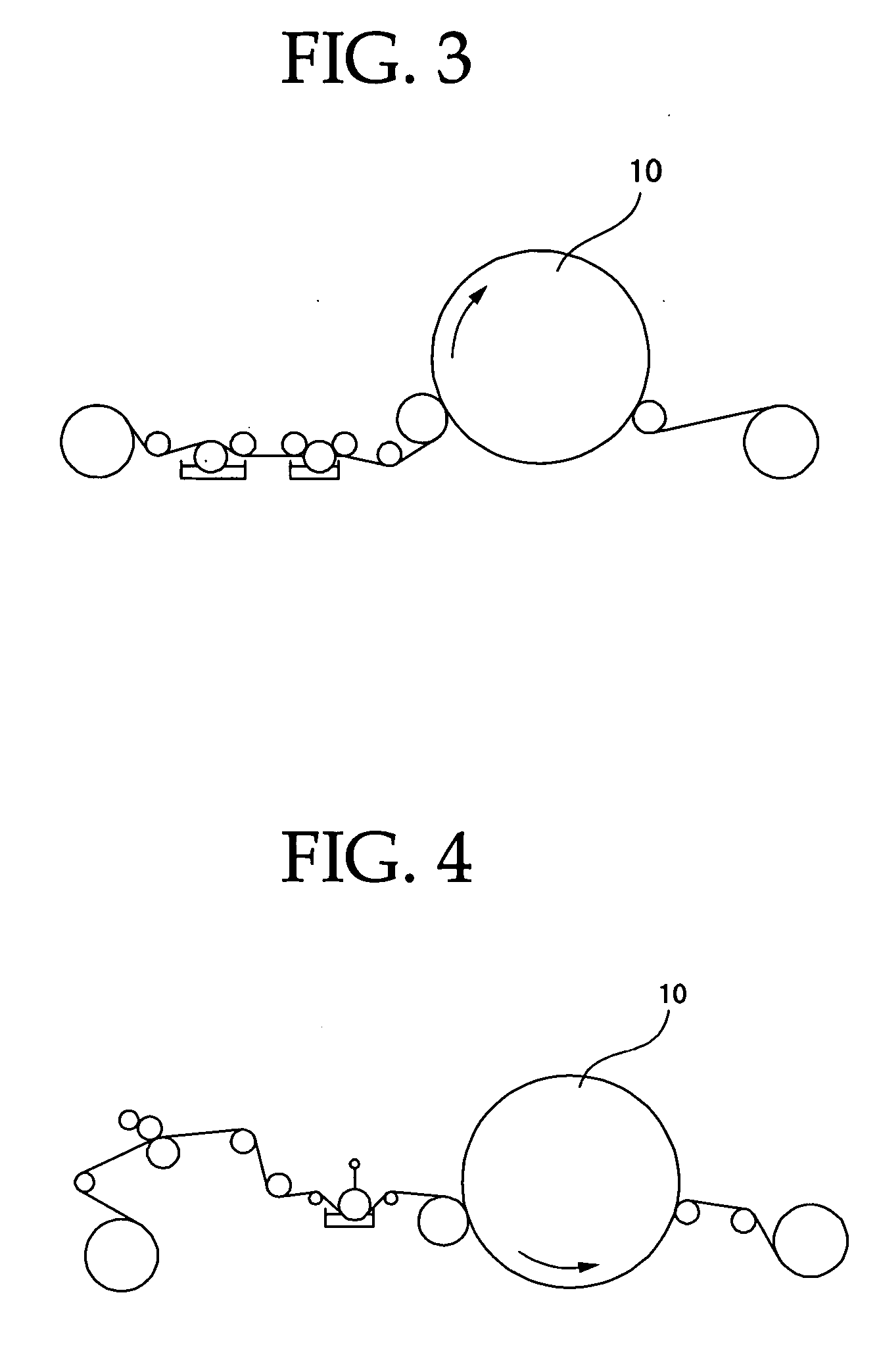

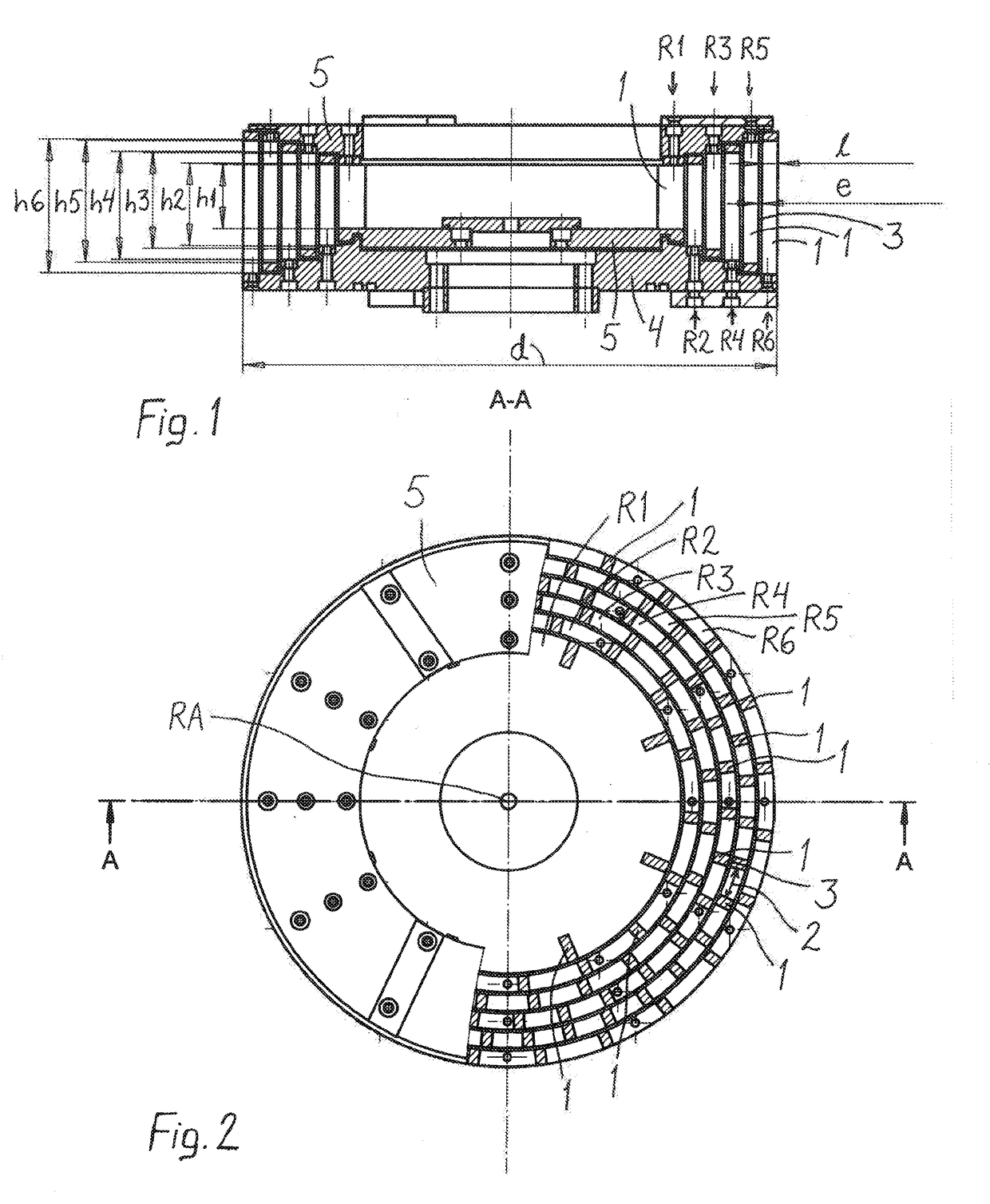

A method for producing nanofibrillar cellulose

ActiveUS20140284407A1Large capacityImprove consistencyFibrous raw materialsGrain treatmentsCelluloseFiber

In a method for producing nanofibril cellulose, cellulose based fibre material, in which internal bonds in the cellulose fibre have been weakened by chemical modification, are supplied, for separating fibrils, through several counter-rotating rotors outwards in the radial direction with respect to the rotation axis of the rotors in such a way that the material is repeatedly subjected to shearing and impacting forces by the effect of the blades of the different counter-rotating rotors, whereby it is simultaneously fibrillated.

Owner:UPM-KYMMENE OYJ

Hollow fiber membrane contactor and method of making same

The instant invention is a hollow fiber membrane contactor, and method of making same. The hollow fiber membrane contactor includes (1) a shell, said shell having a internal bonding surface, an interlocking geometry ring being provided on said internal bonding surface; (2) a unitized structure; (3) a potting material joining said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (4) end caps, said end caps being adjoined to lateral ends of said shell. The method of making a hollow fiber membrane contactor includes (1) providing a shell, said shell having a internal bonding surface; (2) providing an interlocking geometry ring on said internal bonding surface; (3) forming a unitized structure; (4) placing the unitized structure into said shell (5) potting said unitized structure to said shell at said interlocking geometry ring thereby forming an interlocking seal therebetween; and (6) adjoining end caps to lateral ends of said shell.

Owner:3M INNOVATIVE PROPERTIES CO

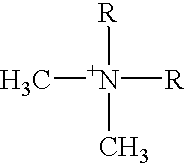

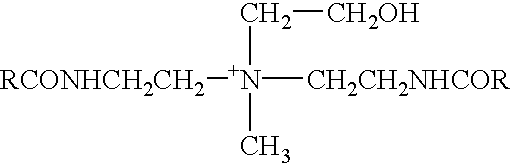

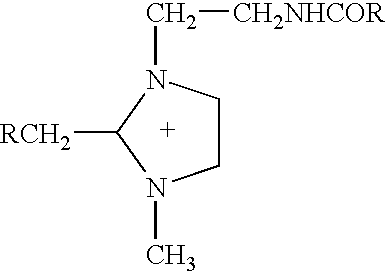

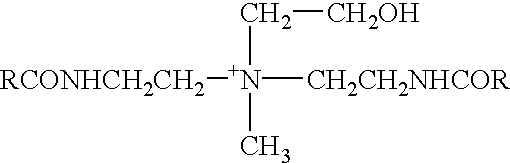

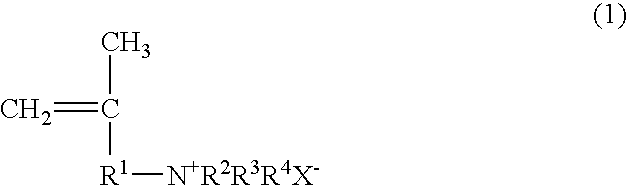

Papermaking chemical, method for manufacturing same, and paper containing same

Owner:SEIKO PMC CORP

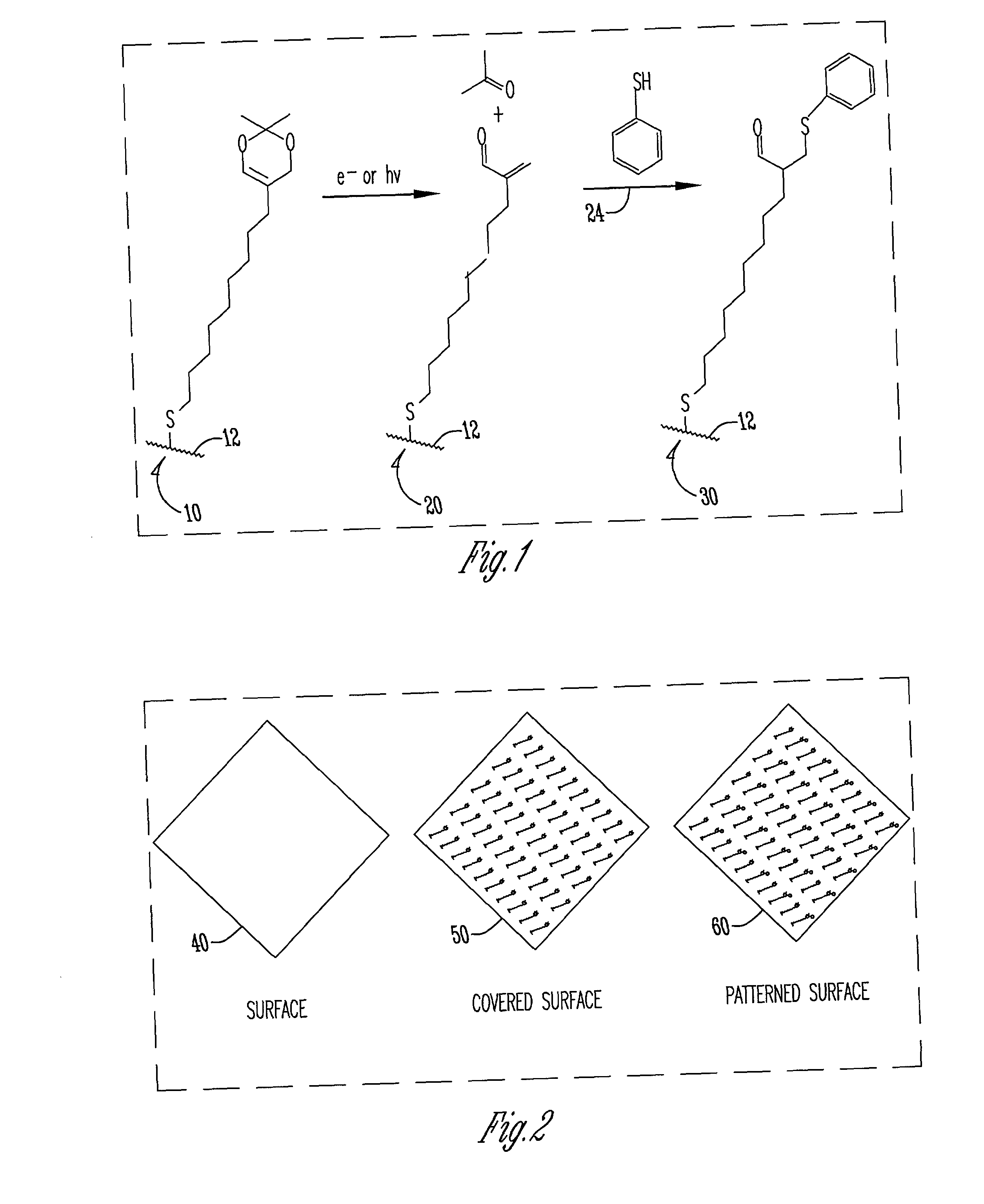

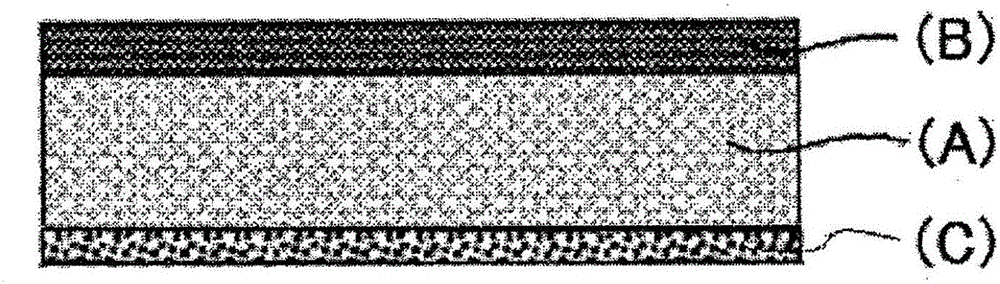

Chemical functionalization nanolithography

InactiveUS20020127491A1Property is limitedLiquid surface applicatorsElectric discharge tubesNanolithographyChemical functionalization

The present invention discloses devices and methods relating to patterning substrates using chemical functionalization. The methods include covering the surface of a substrate with a first plurality of molecules, selecting at least one internal bond from the plurality of molecules, and reacting the at least one internal bond to form at least one second functional group. Either or both of the functional groups can then be further reacted.

Owner:PENN STATE RES FOUND

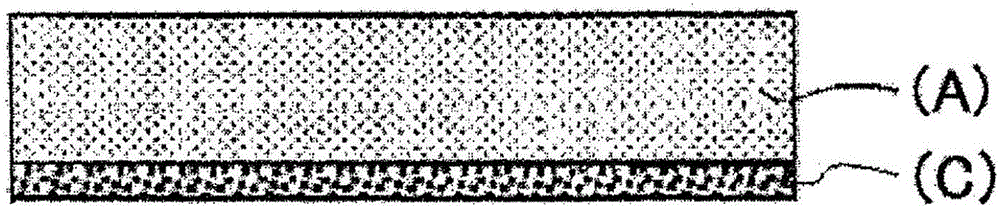

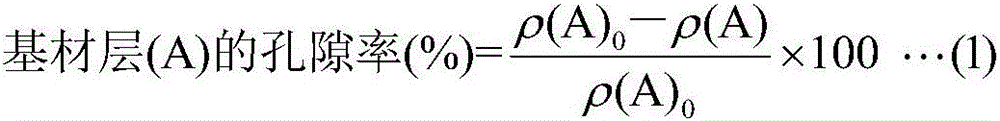

Label, method for manufacturing label, method for using label, and body with label

ActiveCN106575491AEasy to distinguishEasy to manufactureStampsPaper/cardboard articlesUltimate tensile strengthInternal bond

A label including a base material layer (A) and an adhesive layer (C) provided so as to be in contact with one surface of the foregoing, wherein the label is characterized in that the base material layer (A) includes a thermoplastic resin and inorganic fine powder and / or an organic filler, the base material layer (A) being stretched in at least one axial direction; and the internal bond strength of a film, measured in accordance with TAPPI T569, is 0.4-0.95 kg cm on the adhesive layer (C) side and 0.4-1.5 kg*cm on a side opposite thereto, the label being easily determined with the naked eye to have been separated from a body to which the label was stuck and, once separated, being difficult to be restored by re-sticking.

Owner:YUPO CORP

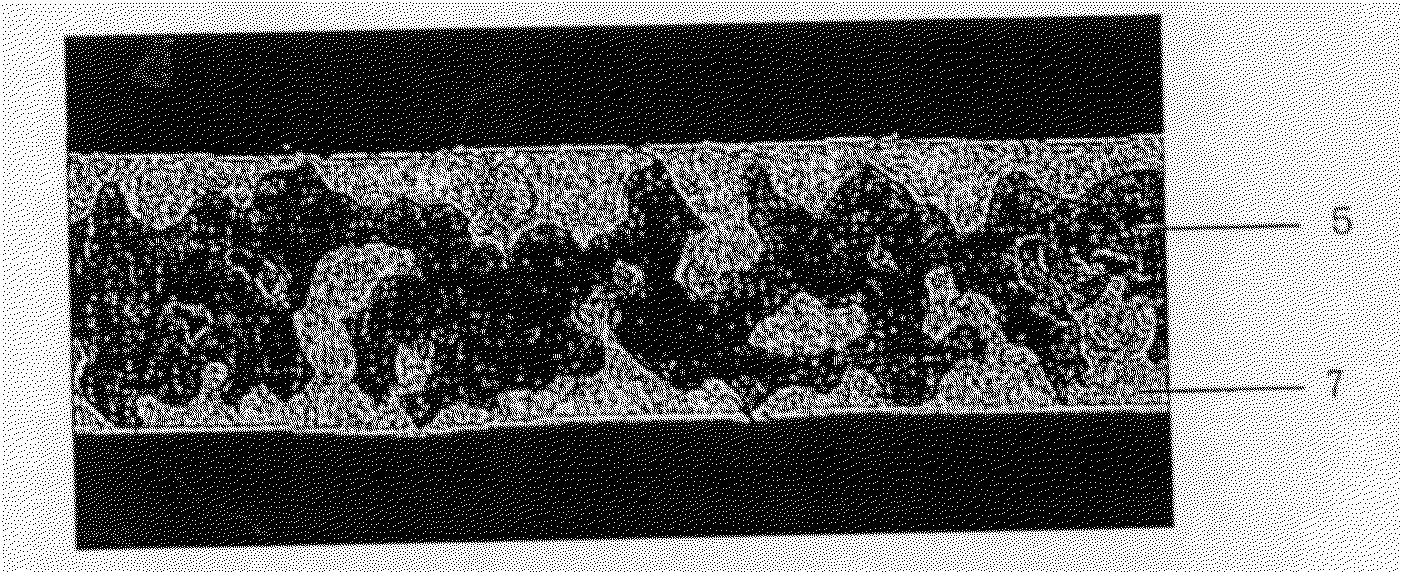

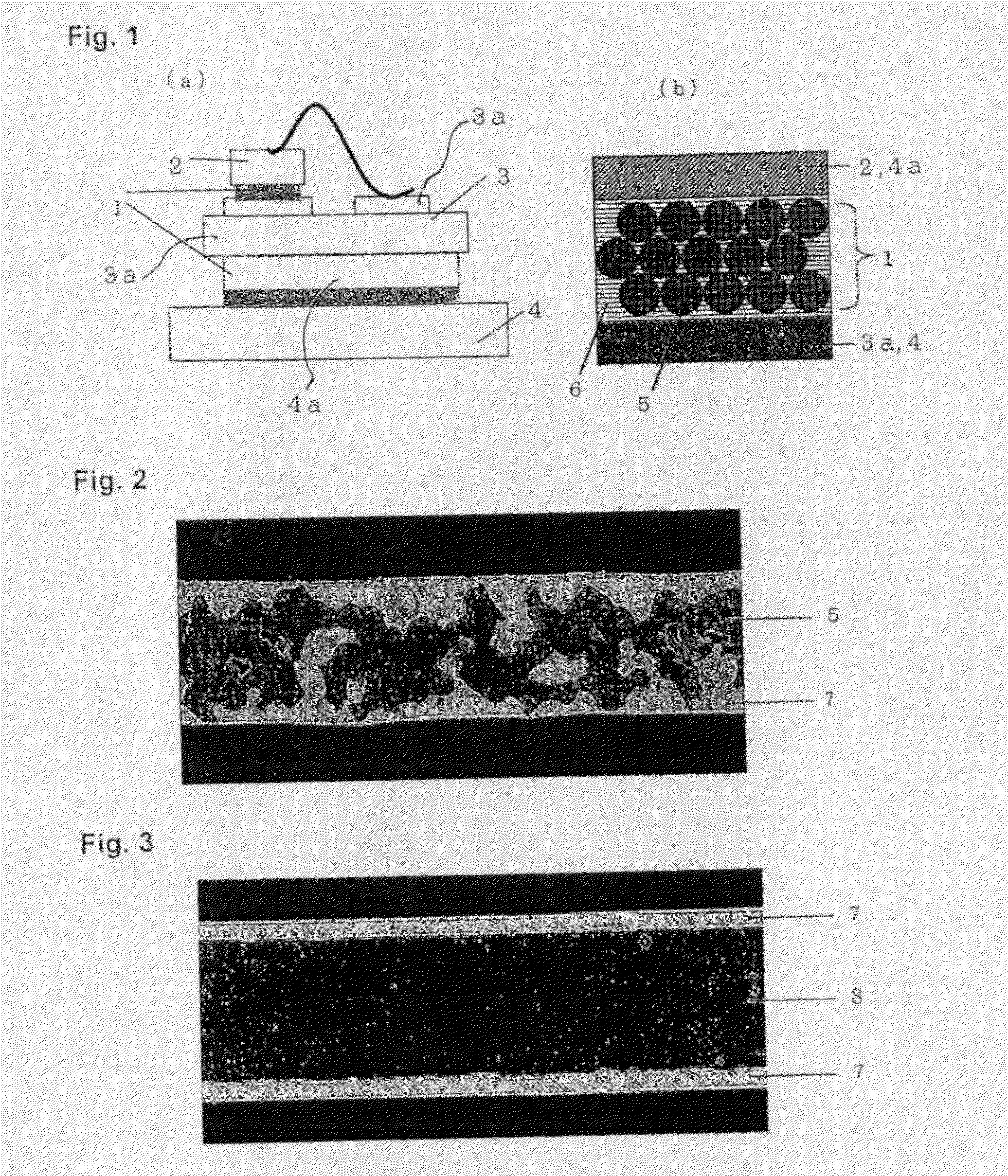

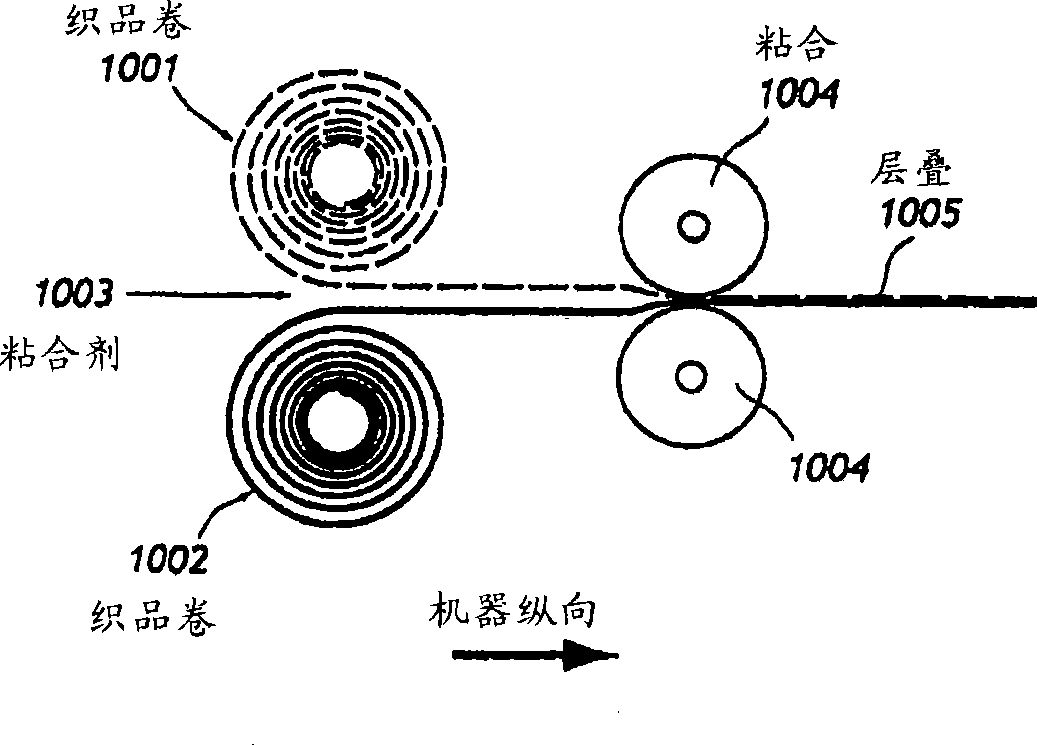

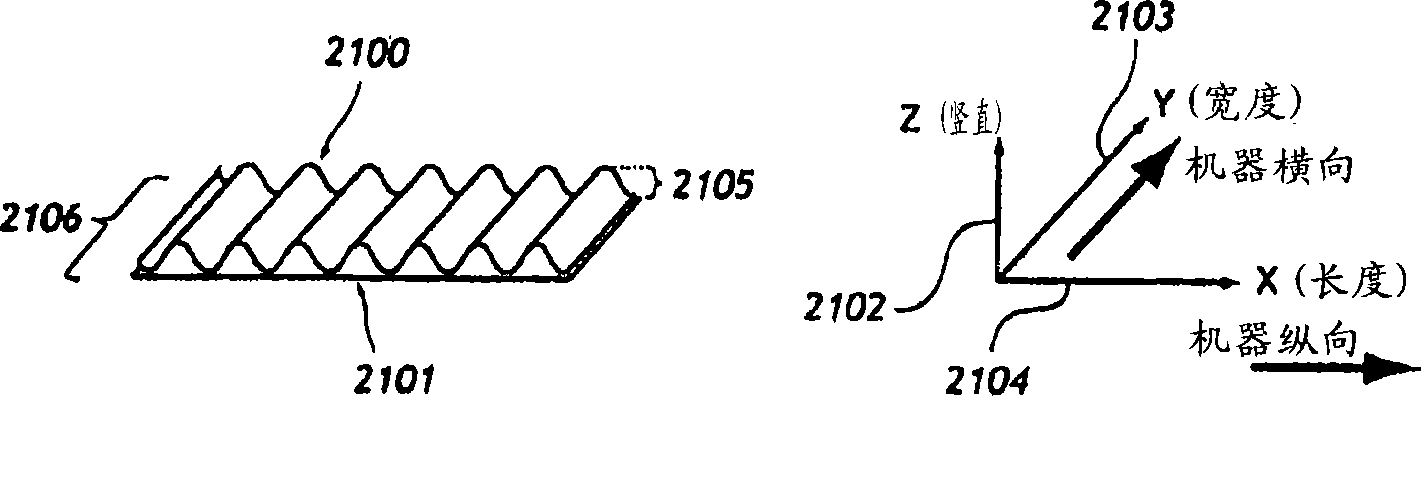

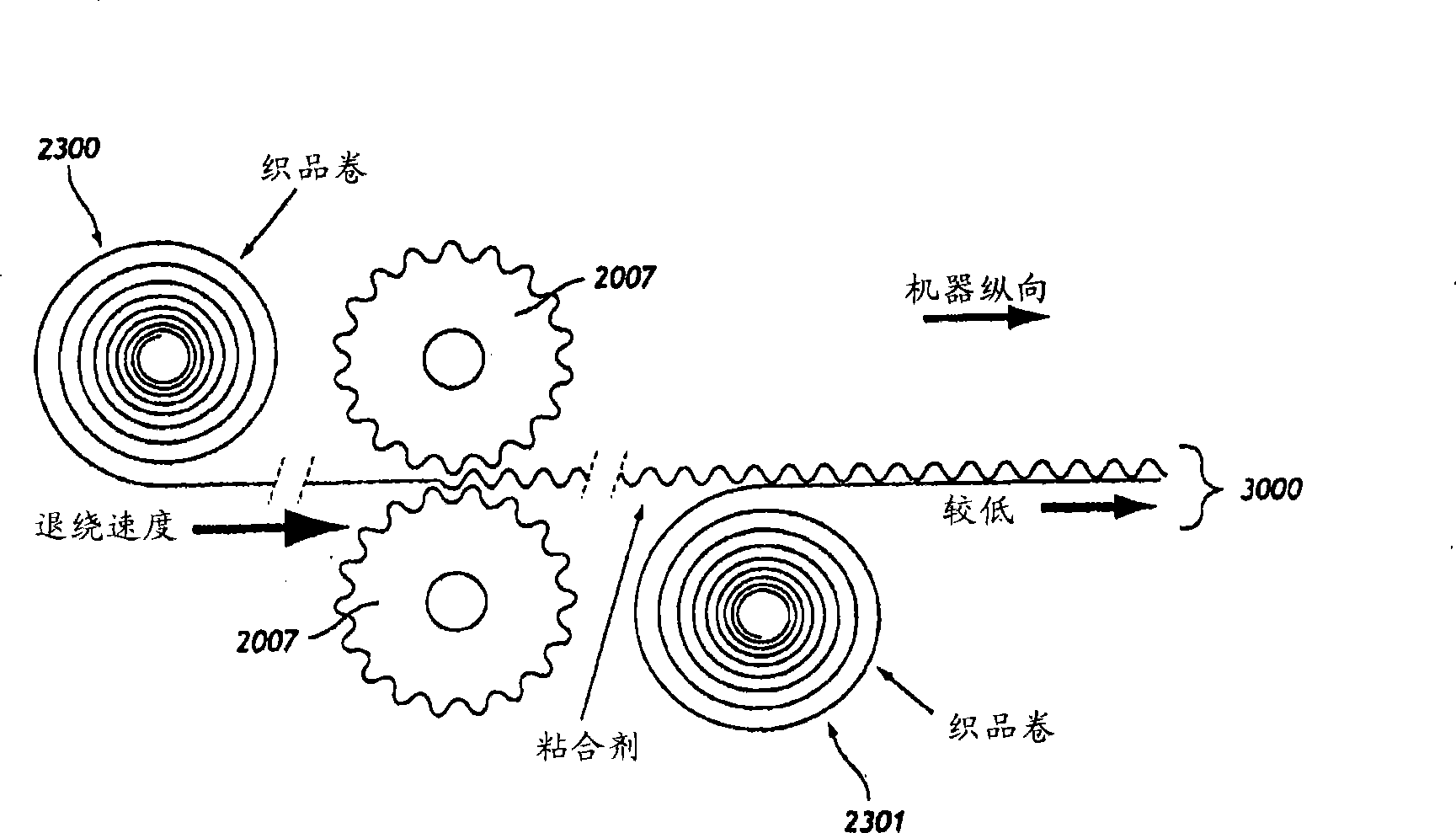

Wave-like structures bonded to flat surfaces in unitized composites and methods for making same

InactiveCN101500790AIncrease stiffnessImprove puncture resistanceLayered productsFiberManufacturing technology

Owner:MARKETING TECH SERVICE

Paper, image-recording material support, and image-recording material

InactiveUS20050020448A1Improve surface flatnessHigh glossPhotosensitive materialsPaper coatingImage recordingSurface roughness

Paper and an image-recording material support which have high surface planarity and excellent gloss are disclosed. Moreover, an image-recording material is disclosed which uses the image-recording material support and is capable of obtaining high quality image. The paper includes raw paper. The paper satisfies at least one of the following conditions (i) and (ii): (i) the paper has an inner bonding strength of 160 mJ or more specified in Japan Technical Association of the Pulp and Paper Industry No. 54, and an average center surface roughness (SRa) on at least one face of the paper is 0.9 μm or less at a cutoff wavelength of 0.3 mm to 0.4 mm, and (ii) an Oken type smoothness S (second) on the at least one face of the paper, and a density ρ (g / cm3) of the paper satisfy an expression S1 / 2 / ρ3≧15.

Owner:FUJIFILM HLDG CORP +1

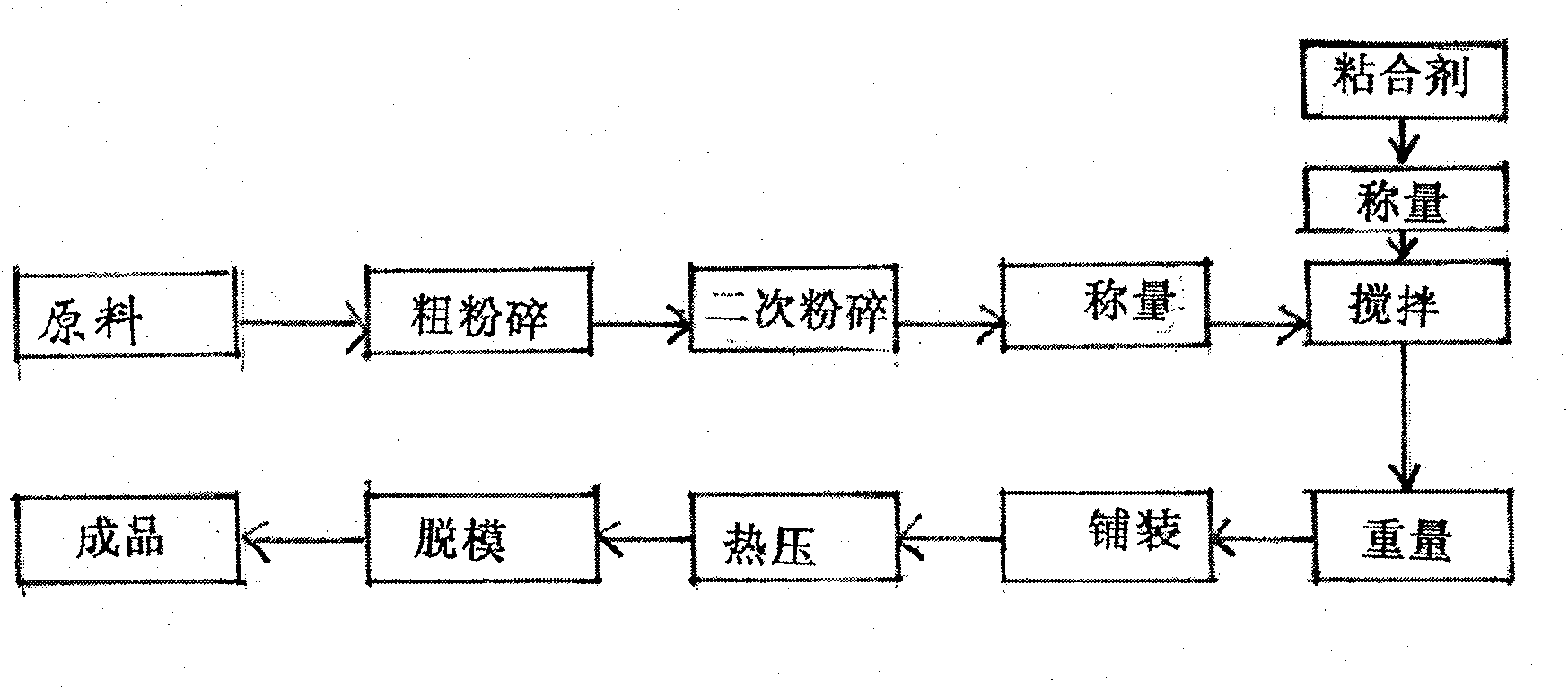

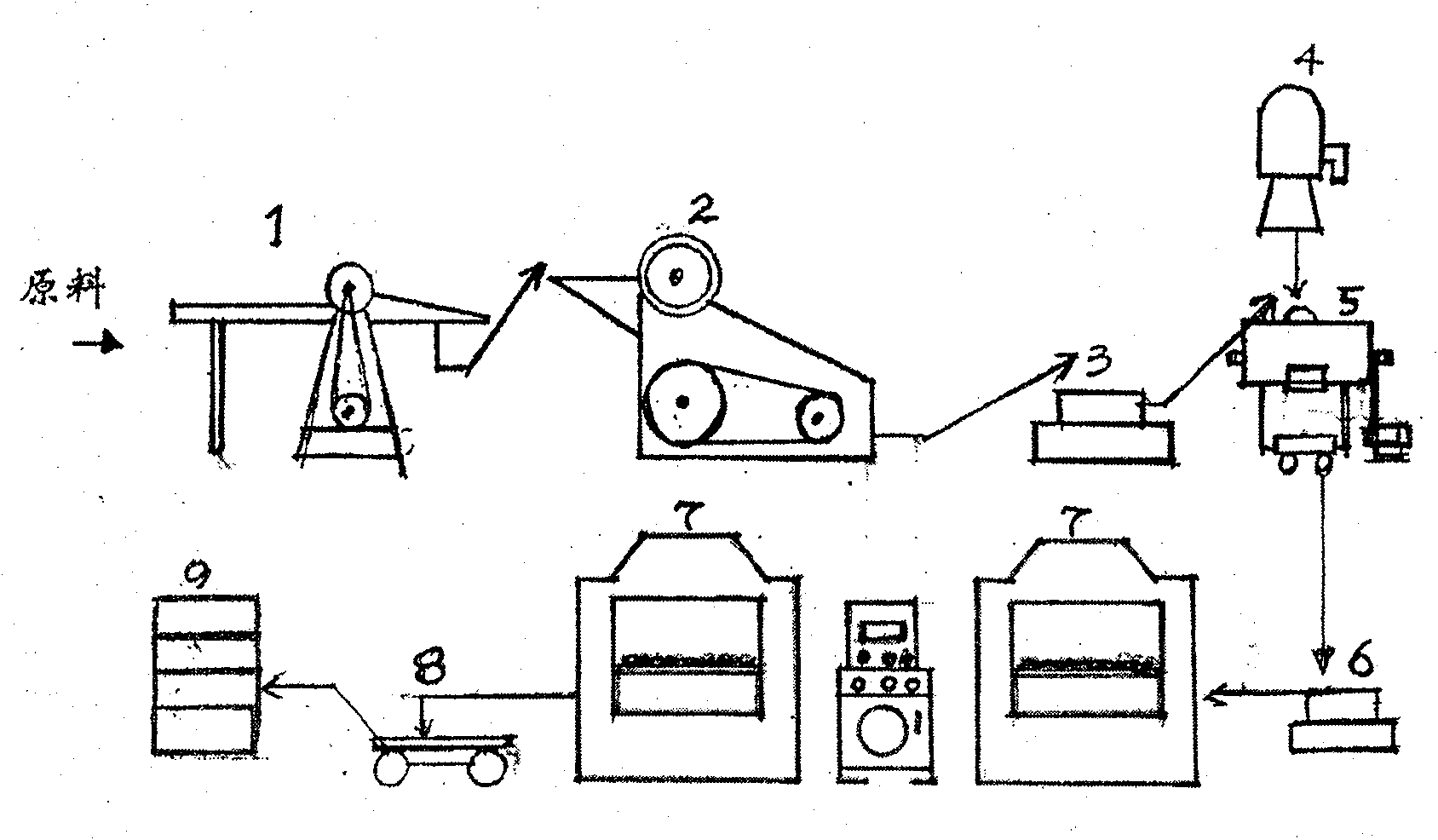

Production method and manufacturing technology for corn stalk moulded board

InactiveCN101898382AAvoid emissionsEvenly gradedWood working apparatusDomestic articlesManufacturing technologyMechanical index

The invention relates to a production method and manufacturing technology (attached drawings) for a moulded board from corn stalk serving as raw materials, and mainly solves the problems of energy consumption, three wastes, density, internal bond strength, expansion ratio and formaldehyde release in the prior art. The method is mainly characterized by comprising the following steps of: crushing the raw materials twice to achieve the grain diameter of 1 to 15 mm and the moisture content of 15 percent or below, and determining the apparent density of the raw materials to between 0.09 and 0.13 g / cm<3> after three kinds of size grading; determining the finished product density to between 0.4 and 0.55 g / cm<3> by contrasting the density of wood; solving the compression ratio of 2.5 to 4.5 by using the ratio of two densities; stirring 70 to 80 mass percent of raw materials and 20 to 30 mass percent of adhesive for 10 to 15 minutes, putting into a mould, and performing hot press molding at the temperature of between 135 and 170 DEG C for 25 to 40s / mm under the pressure of between 2.0 and 3.5 MPa. The method has the advantages that: by modifying parameters of a material preparing stage, and transforming crushing, stirring and hot-pressing equipment in the operation process and modifying the hot-pressing technological parameters, the method reduces the density deviation, improves the internal bond strength, reduces the expansion ratio and free formaldehyde release amount and makes physical and mechanical indexes of the finished products exceed the standard of the like products.

Owner:宋庆华

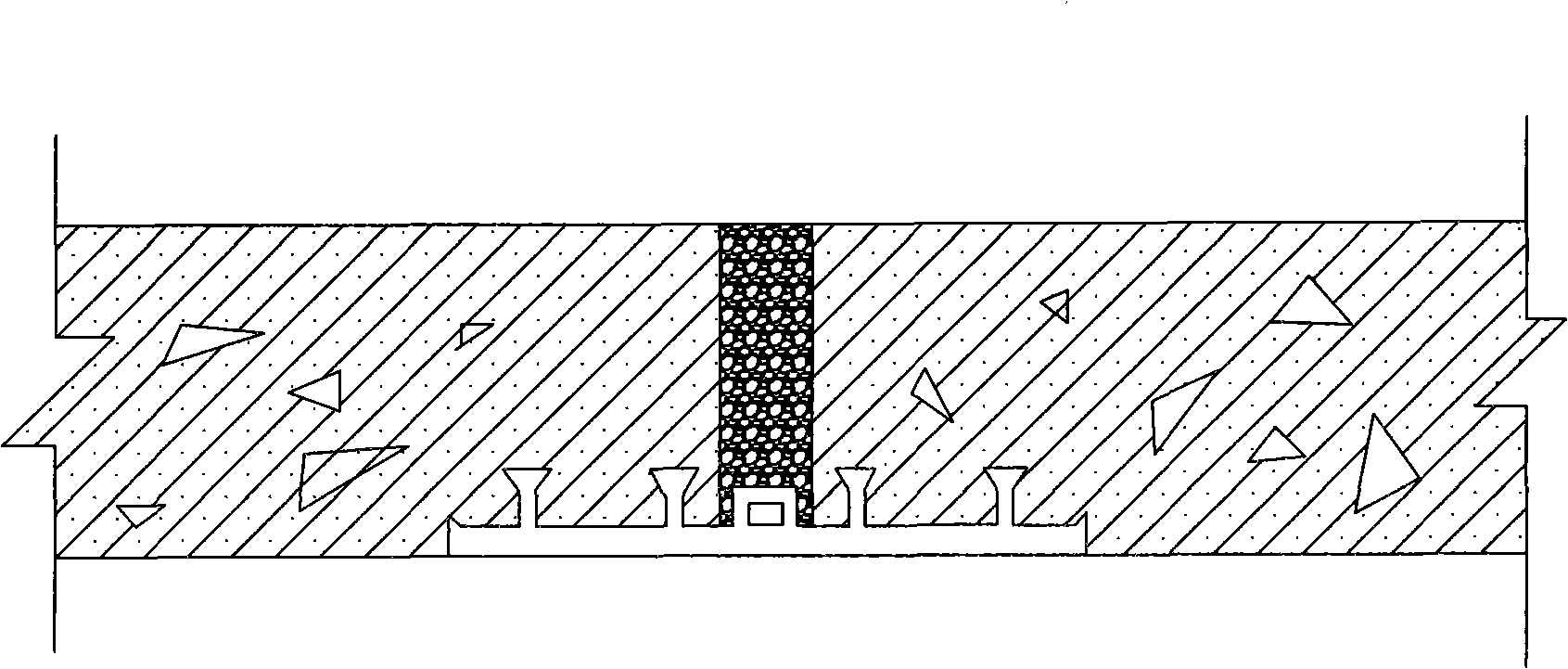

Internal-bonded water-proof technique for externally-bonded waterstop

InactiveCN101570973AAvoid damageStrong telescopic deformation abilityArtificial islandsUnderwater structuresSlurryRebar

The invention relates to an internal-bonded water-proof technique for externally-bonded waterstop, comprising steps as follows: (1) plugging a previous seam caused by damaged embedded-type waterstop primarily to plug water; (2) chiseling a groove at the leakage place on the inner lateral side of the concrete structure at two sides of an expansion joint; (3) planting anchored reinforcement with the same height at the bottom of the groove, placing the waterstop into the groove, and ensuring that the top end of the anchored reinforcement supports the waterstop; (4) setting a template on the groove surface, two ends of the template being tightly clipped to the inner lateral surface; (5) and pouring slurry materials into the groove, and removing films to an intensity. The invention finishes procedures of bonding, filling, sealing and enhancing at a time, can greatly enhance the tensile strength to ensure a level surface upon completion.

Owner:CHINA FIRST METALLURGICAL GROUP

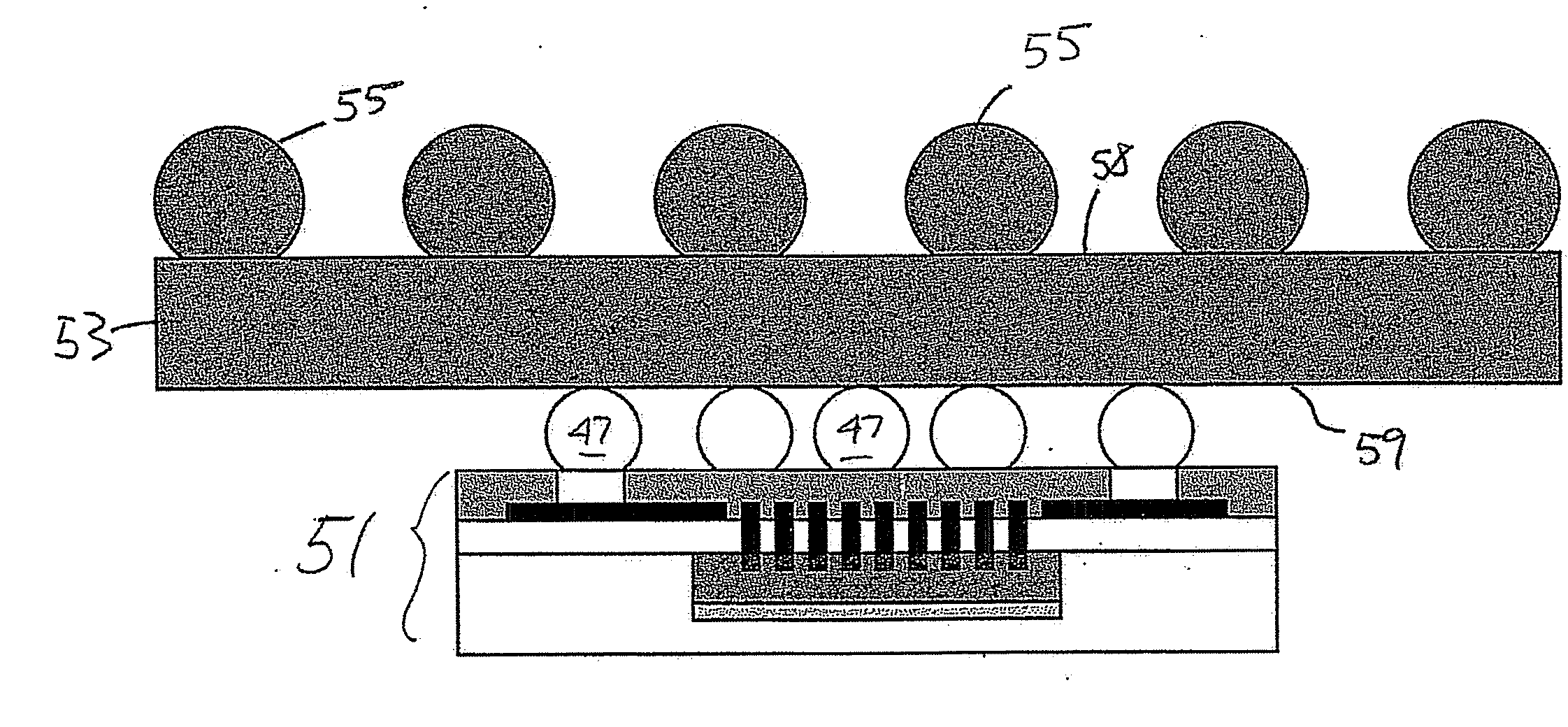

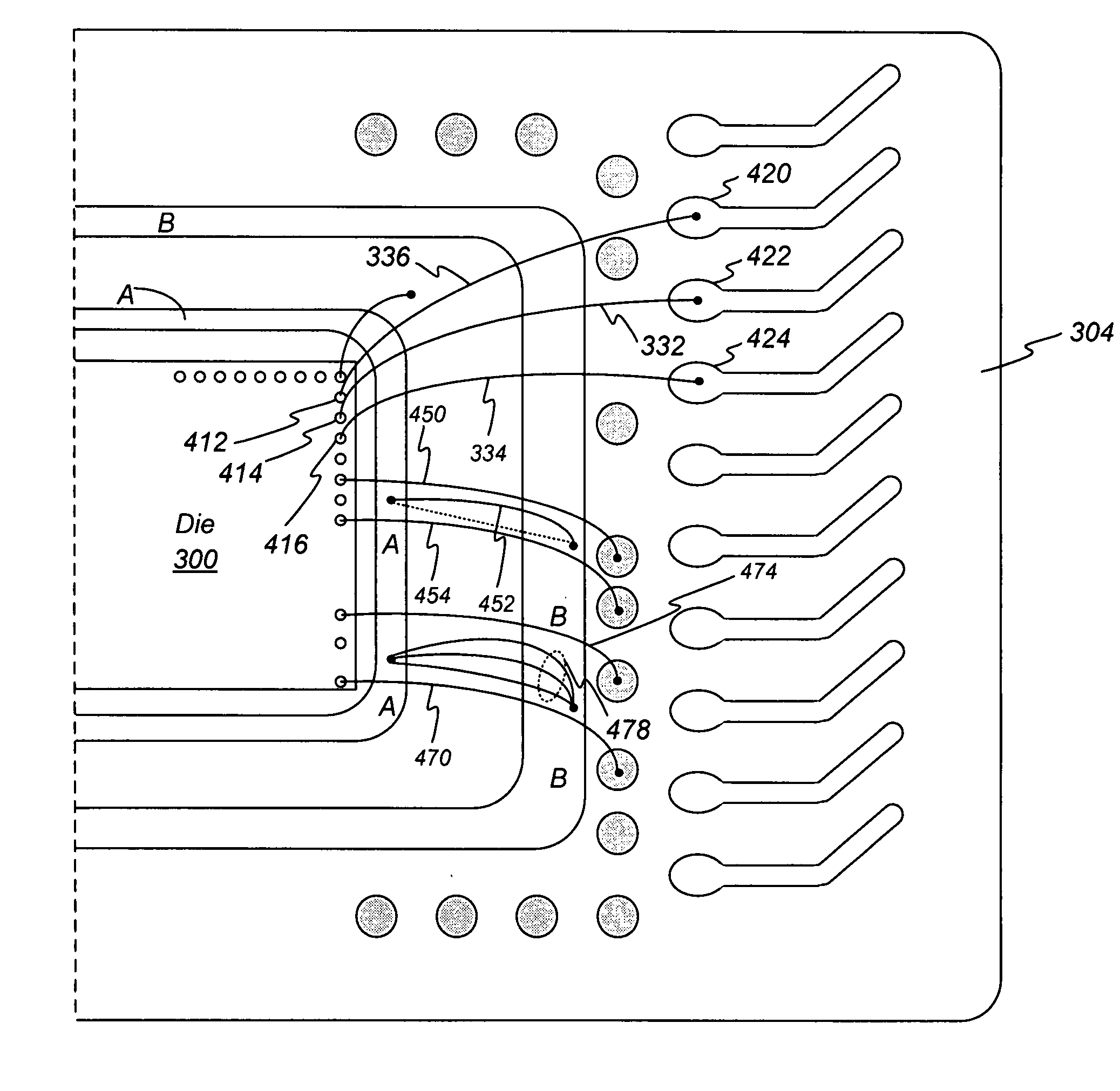

Chip holder with wafer level redistribution layer

InactiveUS20080197473A1Semiconductor/solid-state device detailsSolid-state devicesRedistribution layerSemiconductor chip

A chip holder formed of silicon, glass, other ceramics or other suitable materials includes a plurality of recesses for retaining semiconductor chips. The bond pads of the semiconductor chip are formed on or over an area of the chip holder that surrounds the semiconductor chip thus expanding the bonding area. The bond pads are coupled, using semiconductor wafer processing techniques, to internal bond pads formed directly on the semiconductor chip.

Owner:TAIWAN SEMICON MFG CO LTD

Polyolefin synthetic pulp and use thereof

InactiveUS6338772B1Large fiber breaking lengthImprove internal bond strengthNon-fibrous pulp additionSpecial paperPolymer sciencePolyolefin

A polyolefin synthetic pulp comprising a polyolefin resin graft-modified with an unsaturated carboxylic acid or a derivative thereof, and / or a polyolefin resin composition which comprises an ethylene / alpha,beta-unsaturated carboxylic acid copolymer and a polyethylene resin. Further, there is provided a heat sealing paper comprising a base fiber layer whose at least one surface is laminated and integrated with a layer of the polyolefin synthetic pulp. This polyolefin synthetic pulp has a large breaking length and an excellent internal bond strength, and exhibits stable heat sealing and hot tack properties over a wide temperature range from low to high temperature. The polyolefin synthetic pulp is suitable to use in battery separators, molding fiberboards, heat sealing papers and the like. The heat sealing papers have excellent heat sealing properties, and are characterized by having a large breaking length and an excellent internal bond strength and by exhibiting stable heat sealing and hot tack properties over a wide temperature range from low to high temperature.

Owner:MITSUI CHEM INC

Anti-Microbial Paper Substrates Useful in Wallboard Tape Applications

InactiveUS20110024067A1Natural cellulose pulp/paperWater-repelling agents additionJoint compoundPapermaking

This invention relates to paper products and / or substrates suitable for being made into wallboard tape (also may be known as joint tape and / or drywall tape) and having improved reduction or inhibition in the growth of microbes, mold and / or fungus. The paper substrate is characterized by its excellent physical properties including cross direction (CD) tensile, machine (MD) tensile, internal bond, wet tensile, hygroexpansivity, curl, bonding properties, bonding of joint tape to joint compound, etc. The paper product of the invention contains a sizing agent and an antimicrobial compound as well as other optional components including without limitation a binder. The paper product of the invention may be produced by contacting the plurality of cellulose fibers with each of the sizing agent, antimicrobial compound, and optional components at any point in the papermaking process, converting process, and / or post-converting process. Finally, the invention relates to methods of using the paper substrate.

Owner:INT PAPER CO

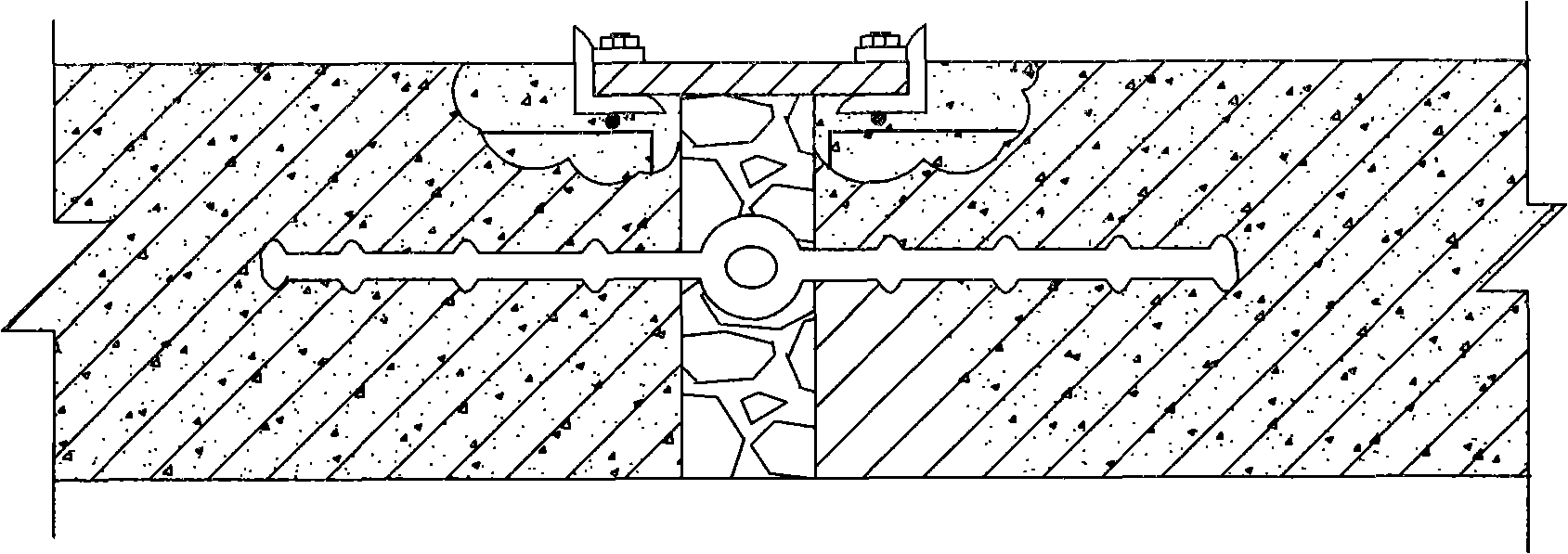

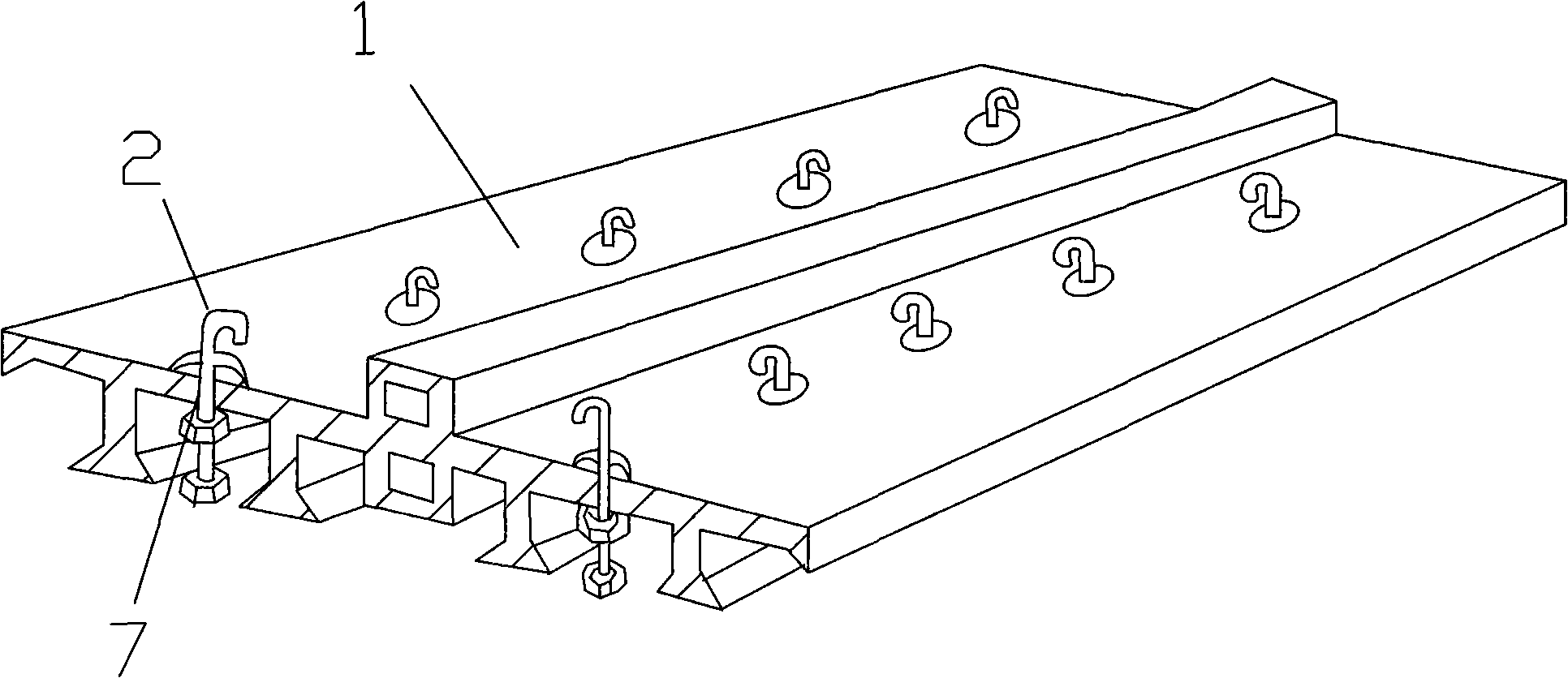

Scrimber and preparation method thereof

ActiveCN105196397AQuality assuranceHigh mechanical strengthFlat articlesDomestic articlesEconomic benefitsEngineering

The invention relates to scrimber and a preparation method thereof. According to the scrimber, logs and brush wood with a small diameter are taken as woody raw materials, the woody raw materials are cut off, soaked and ground to form wood bunches which are not broken in the longitudinal direction or loose in the transverse direction and are connected in a staggered manner, the wood bunches are separated, dried, glued, assembled, paved and hot-pressed through turning, pressing and twisting, and the scrimber is prepared. The scrimber has the main performance as follows: the thickness ranges from 15 mm to 25 mm, the density ranges from 1.1 g / cm<3>-1.2 g / cm<3>, the internal bond strength ranges from 4 MPa to 5 MPa, the static bending intensity ranges from 120 MPa to 130 MPa, the thickness swelling rate of the scrimber after water absorption is 4%-5%, and the formaldehyde emission ranges from 1.2 mg / L to 1.4 mg / L. The scrimber and the preparation method have the advantages that the scrimber product prepared with the simple and efficiency process has better mechanical strength and size stability and is suitable for large-scale production, the economic benefits are high, the utilization efficiency and the economic value of wood are improved, and convenience is provided for production, utilization and popularization of the scrimber.

Owner:泰州市龙洋木业有限公司

Hot pressing process for medium density fiberboards

InactiveCN104339435AImprove internal bond strengthAccurate thicknessWood working apparatusDomestic articlesMedium densityProcess engineering

The invention discloses a hot pressing process for medium density fiberboards. The hot pressing process comprises feeding, a first hot pressing stage, a second hot pressing stage, a third hot pressing stage and discharging. The hot pressing process is reasonable; by effectively controlling pressurizing time, pressure releasing time and pressure maintaining time of a hot press, the hot pressing time is shortened by 30-50 seconds compared with the time in the traditional hot pressing process, and the internal bond strength of slabs is improved by 20-30 percent; moreover, performance indexes of boards are strictly controlled, so that the thickness of the hot-pressed slabs is more accurate, the thickness of solidified layers of the boards after solidification is 0.3-0.8mm, and the manufacturing cost is reduced to the greatest degree; meanwhile, the problem of negative influence of steam pressure in core layers of the slabs on the performance of the boards is avoided, the stability of product quality is improved, the rejection rate of products is greatly reduced, and the production efficiency is improved; the method is also suitable for the hot pressing process for medium density fiberboards in different thicknesses, and is easily promoted on a large scale.

Owner:云南司珈尔木业股份有限公司

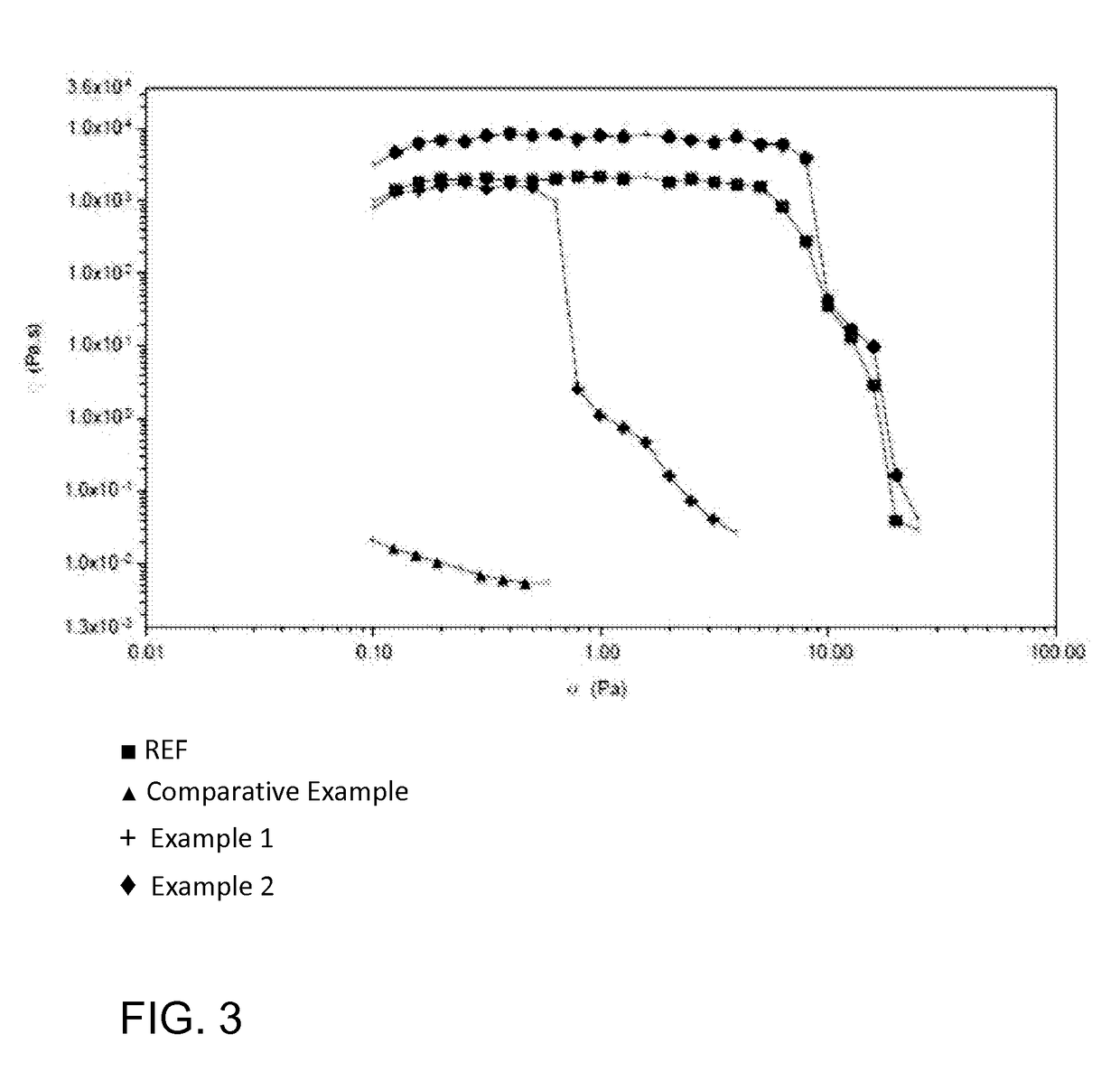

Using oil-based additives to improve lignocellulosic fibre bonding and dimensional performance

InactiveUS20070210473A1Improve bindingDomestic articlesFlat articlesGas chromatography measurementWax

About 78.0-91.4% refined lignocellulosic fibres were blended with 8.0-12.0% formaldehyde-based resin, 0.5-2.0% wax and 0.1-8.0% oil in a blowline or a blender before mat forming and panel pressing. Fibres can be from cereal straws or wood species. Wax can be slack or emulsified wax. Oil is selected from different groups including, but not being limited to, vegetable oils, tree oils and any kinds of oils and oil mixtures which consist of fatty acids with 12 to 24 carbon atoms. Inverse Gas Chromatography (IGC) measurement and MDF panel test results have shown that fibre adhesion characteristics have changed significantly, leading to significant panel internal bond (IB) and dimensional stability improvements.

Owner:ALBERTA RES COUNCIL INC

Coated paper sheet

InactiveUS7255918B2Increase resistanceImprove passabilityCoatings with pigmentsWater-repelling agents additionHigh resistanceAcrylic resin

A coated paper sheet provided with a coating layer formed on a paper sheet substrate and containing a pigment and a binder and optionally a pre-coated polyacrylamide-containing anionic acrylic resin layer formed between the substrate and coating layer, and having a 75° specular gloss of 70% or more, an air permeability of 4000 seconds or less, a Clark stiffness, in terms of critical strength L, of 12 cm or more in a cross direction and an internal bond strength of 200 mJ or more, exhibits high resistance to blistering, excellent printer-passing property, and high quality image-recording property and useful for both of offset printing and electrophotographic duplicating or printing.

Owner:OJI PAPER CO LTD

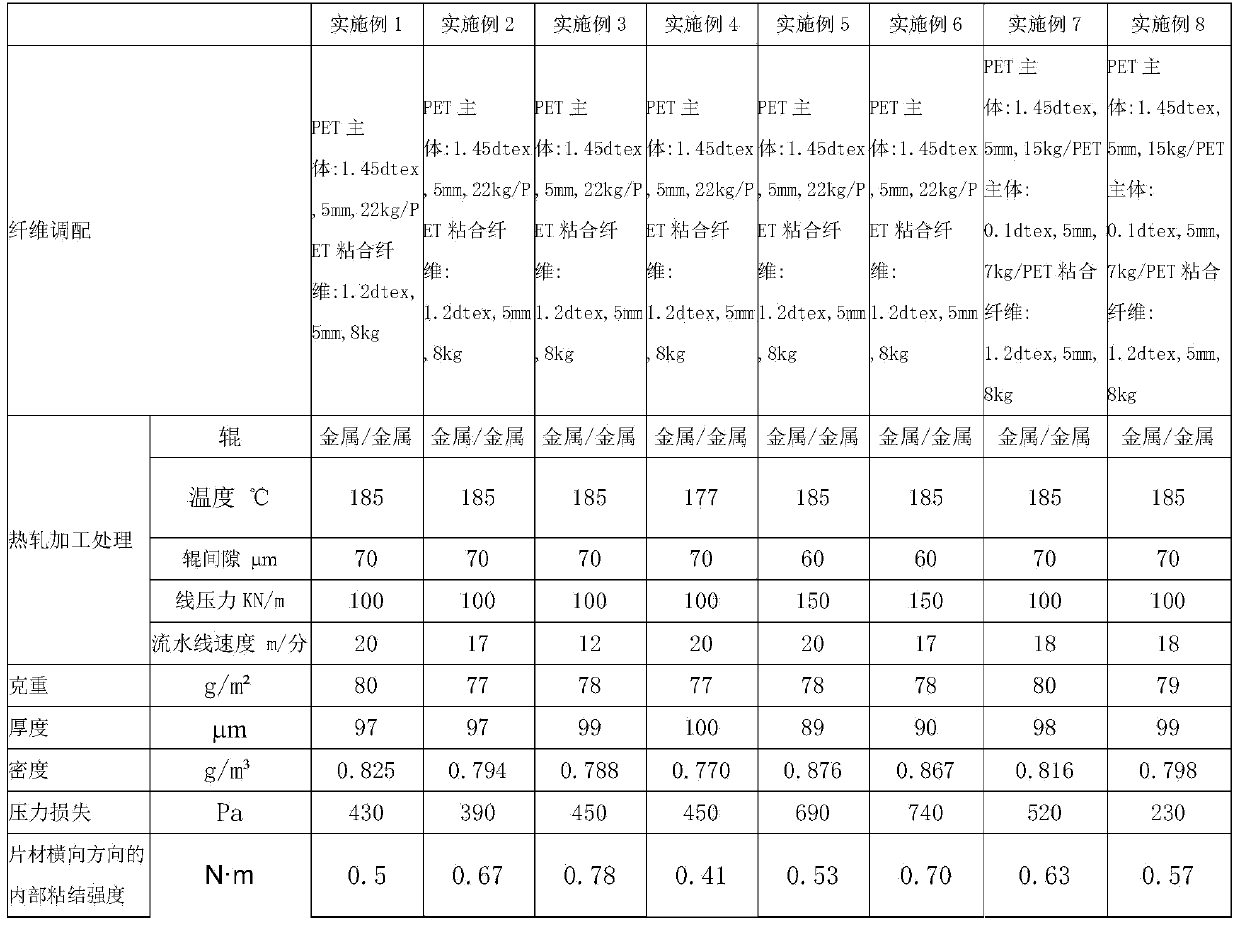

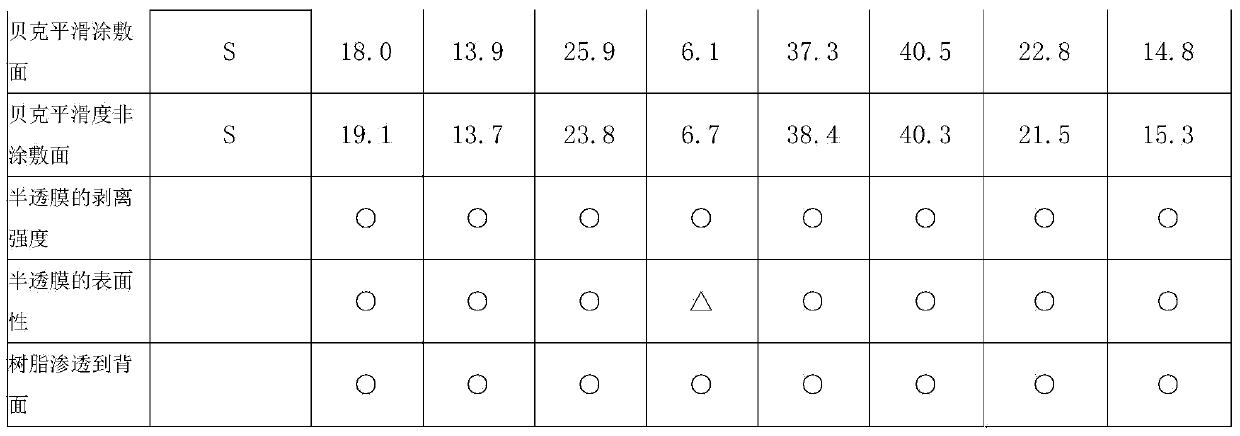

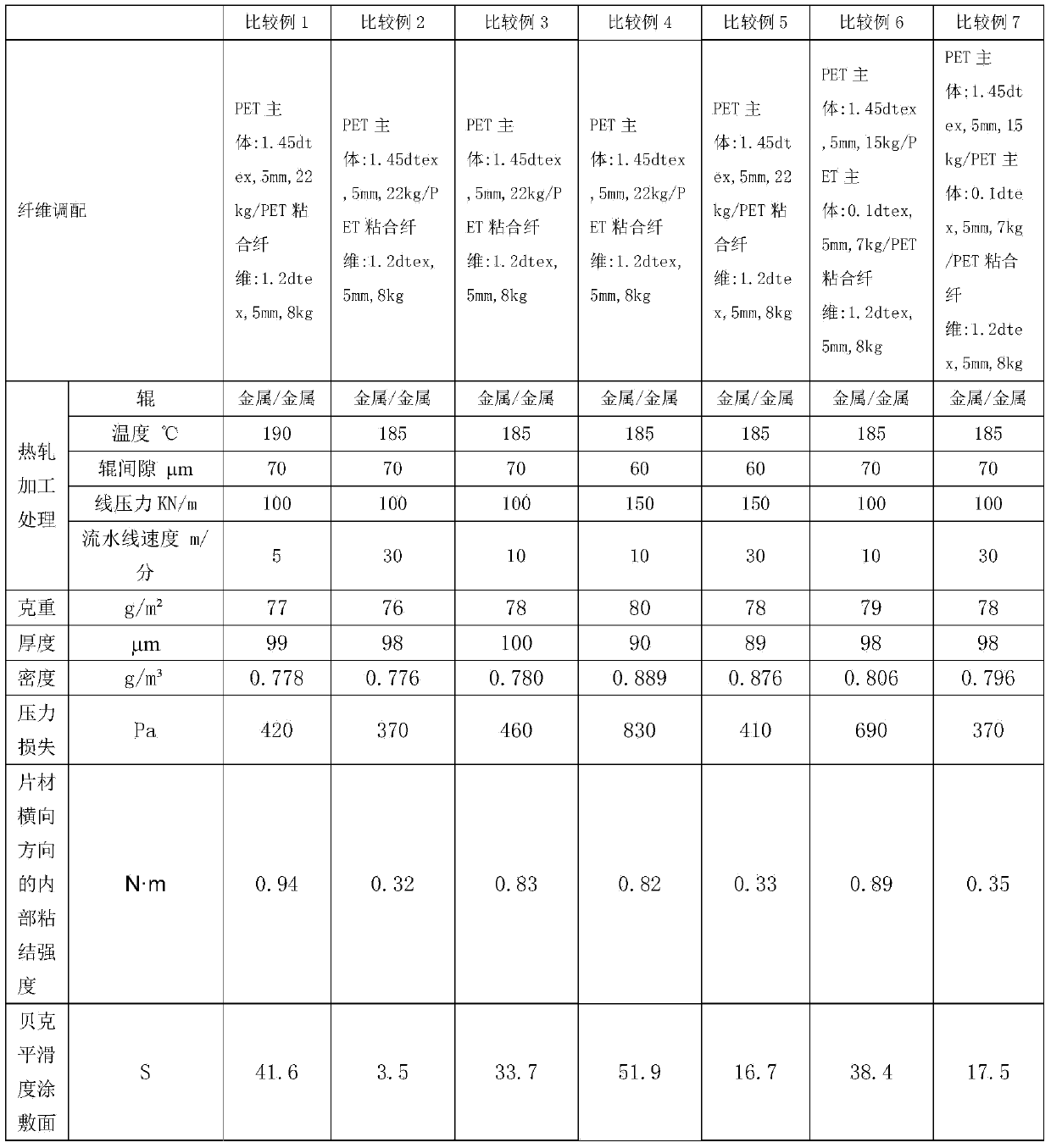

Non-woven fabric for semipermeable membrane support

ActiveCN104093479AImprove adhesionImprove thickness uniformitySemi-permeable membranesSynthetic resin layered productsUltimate tensile strengthInternal bond

The purpose of the present invention is to provide a non-woven fabric for a semipermeable membrane support, which can provide good adhesion of a semipermeable membrane to a support, can make the thickness of the semipermeable membrane uniform and does not undergo the penetration of a coating solution through the non-woven fabric. The non-woven fabric for a semipermeable membrane support according to the present invention is a non-woven fabric mainly composed of organic synthetic fibers and has a semipermeable membrane supported on one surface thereof, wherein each of a coating surface of the non-woven fabric, which is a surface to be coated with the semipermeable membrane, and a non-coating surface of the non-woven fabric, which is a surface opposed to the coating surface, has a Bekk smoothness degree of 5 seconds or more and the internal bond strength of the non-woven fabric falls within the range from 0.4 to 0.8 Nm as measured in the sheet lateral direction.

Owner:HOKUETSU KK

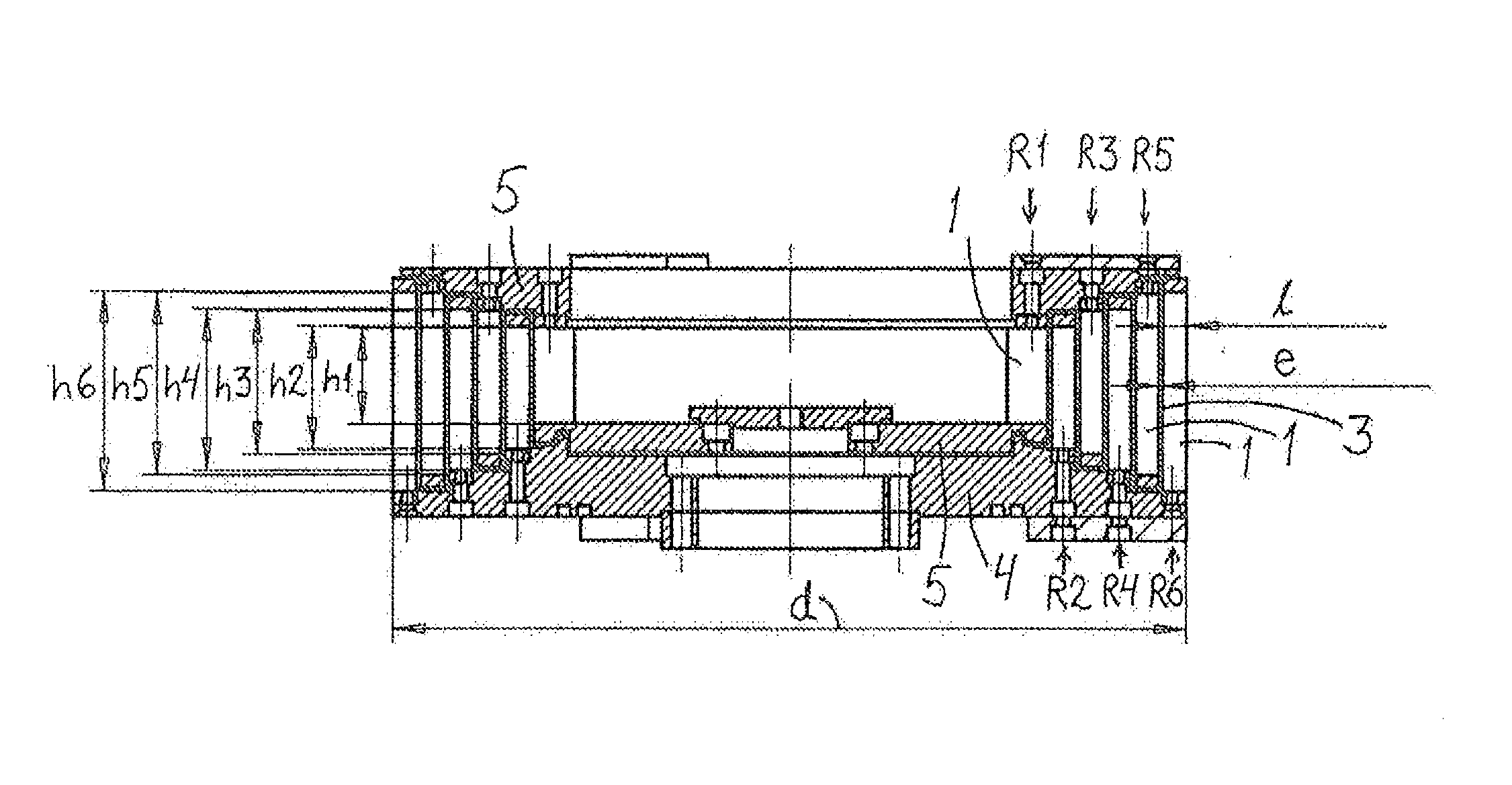

Method for producing nanofibrillar cellulose and nanofibrillar cellulose product

ActiveUS20170211230A1Large capacityImprove consistencyPaper/cardboardFibrous raw materialsCellulose fiberInternal bond

In a method for producing nanofibrillar cellulose, cellulose based fibre material, in which internal bonds in cellulose fibres have been weakened by preliminary modification of cellulose, is subjected to disintegration treatment in form of pulp comprising fibres and liquid. The fibre material is supplied at a consistency higher than 10 wt-%, preferably at least 15 wt-%, to a disintegration treatment where fibrils are detached from the fibre material by joint effect of repeated impacts to the fibre material by fast moving successive elements and the weakened internal bonds of the cellulose fibres. The nanofibrillar cellulose is withdrawn from the disintegration treatment at dry matter which is equal or higher than the consistency of the fibre material. In the disintegration treatment, the fibre material is supplied through several counter-rotating rotors (R1, R2, R3 . . . ) outwards in the radial direction with respect to the rotation axis (RA) of the rotors in such a way that the material is repeatedly subjected to shear and impact forces by the effect of the blades (1) of the different counter-rotating rotors.

Owner:UPM-KYMMENE OYJ

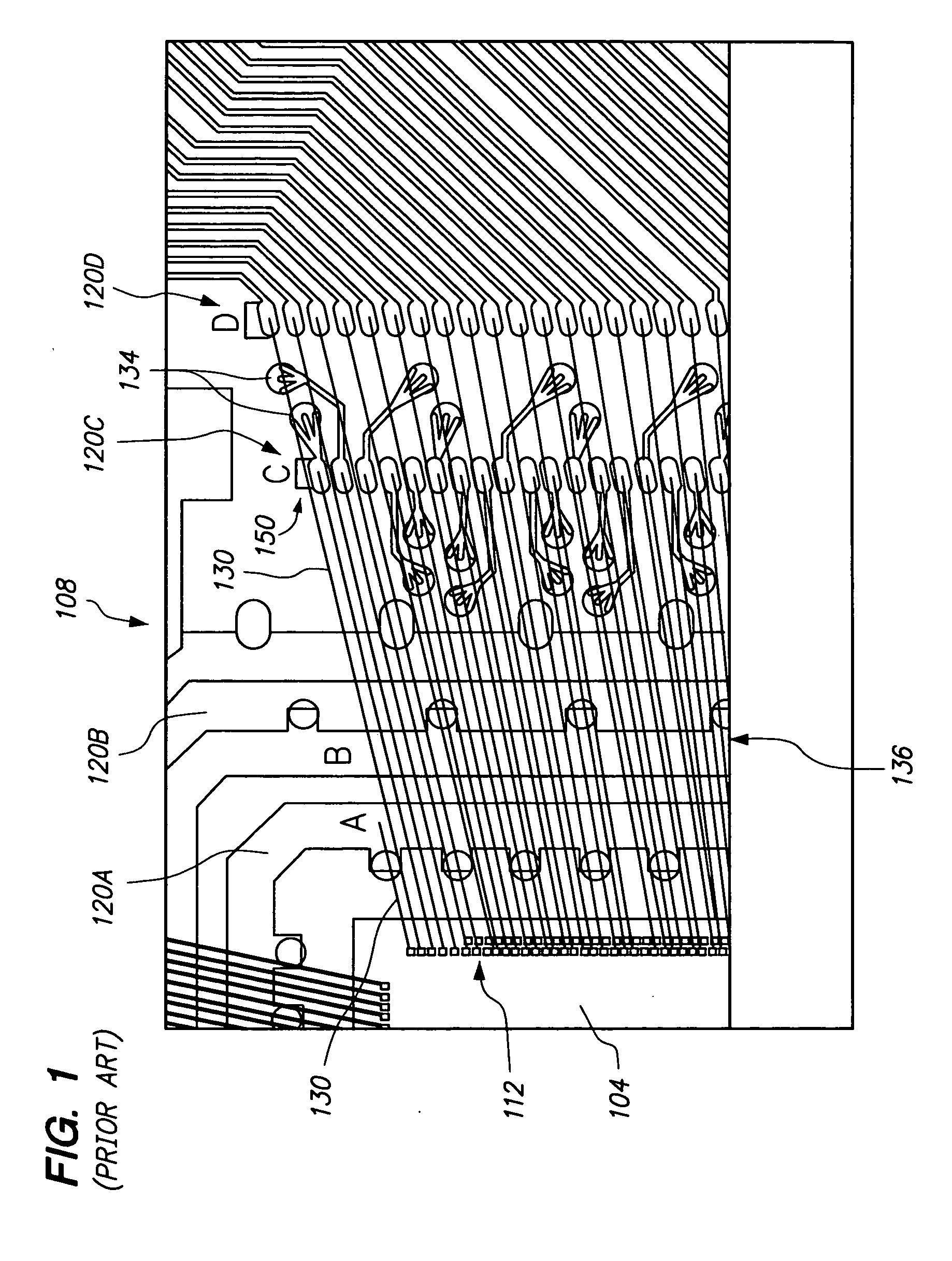

Methods for producing coating base papers and coated papers

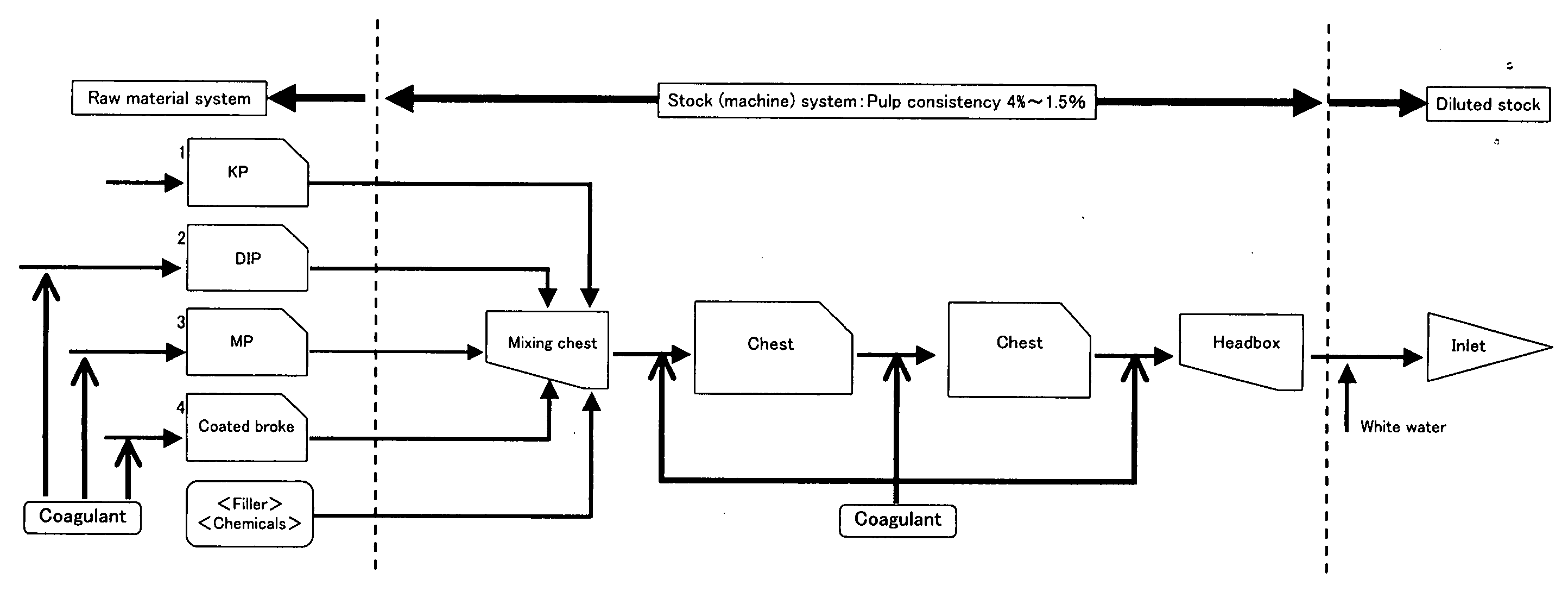

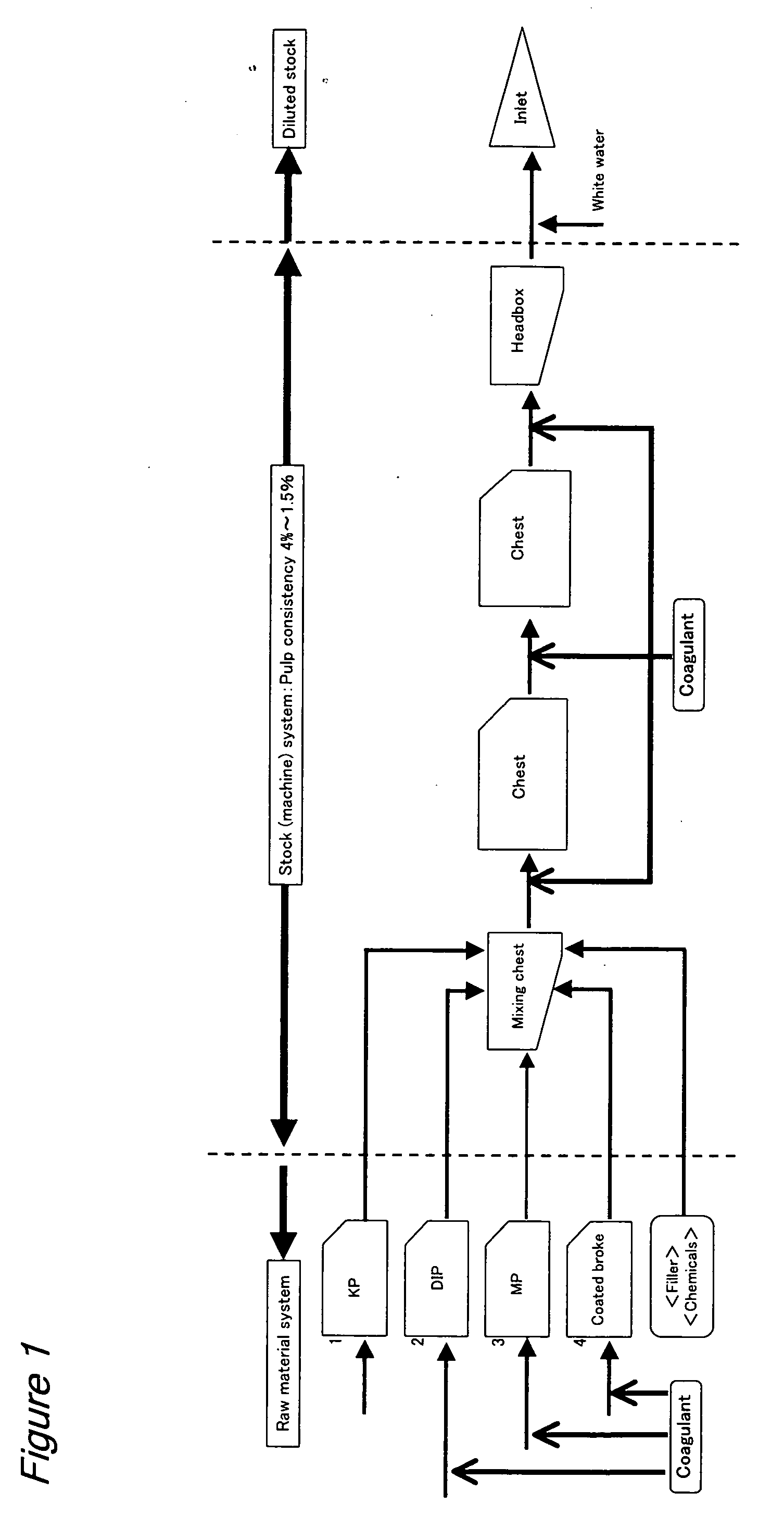

InactiveUS20100300633A1Promote formationHigh strengthNatural cellulose pulp/paperSpecial paperAcryditePapermaking

The present invention provides methods for producing a base paper for coated printing paper and a coated paper by neutral papermaking using a roll and blade gap former type paper machine including a drainage mechanism based on a drainage blade immediately downstream of initial drainage via a forming roll, comprising adding a cationic polyacrylamide-based material having a weight-average molecular weight of 10,000,000 or more determined by intrinsic viscosity measurement as a retention aid to a stock to convert it into paper. According to the present invention, the retention, formation and internal bond strength of the stock can be improved. In the present invention, an anionic microparticle and / or a coagulant can also be used.

Owner:NIPPON PAPER IND CO LTD

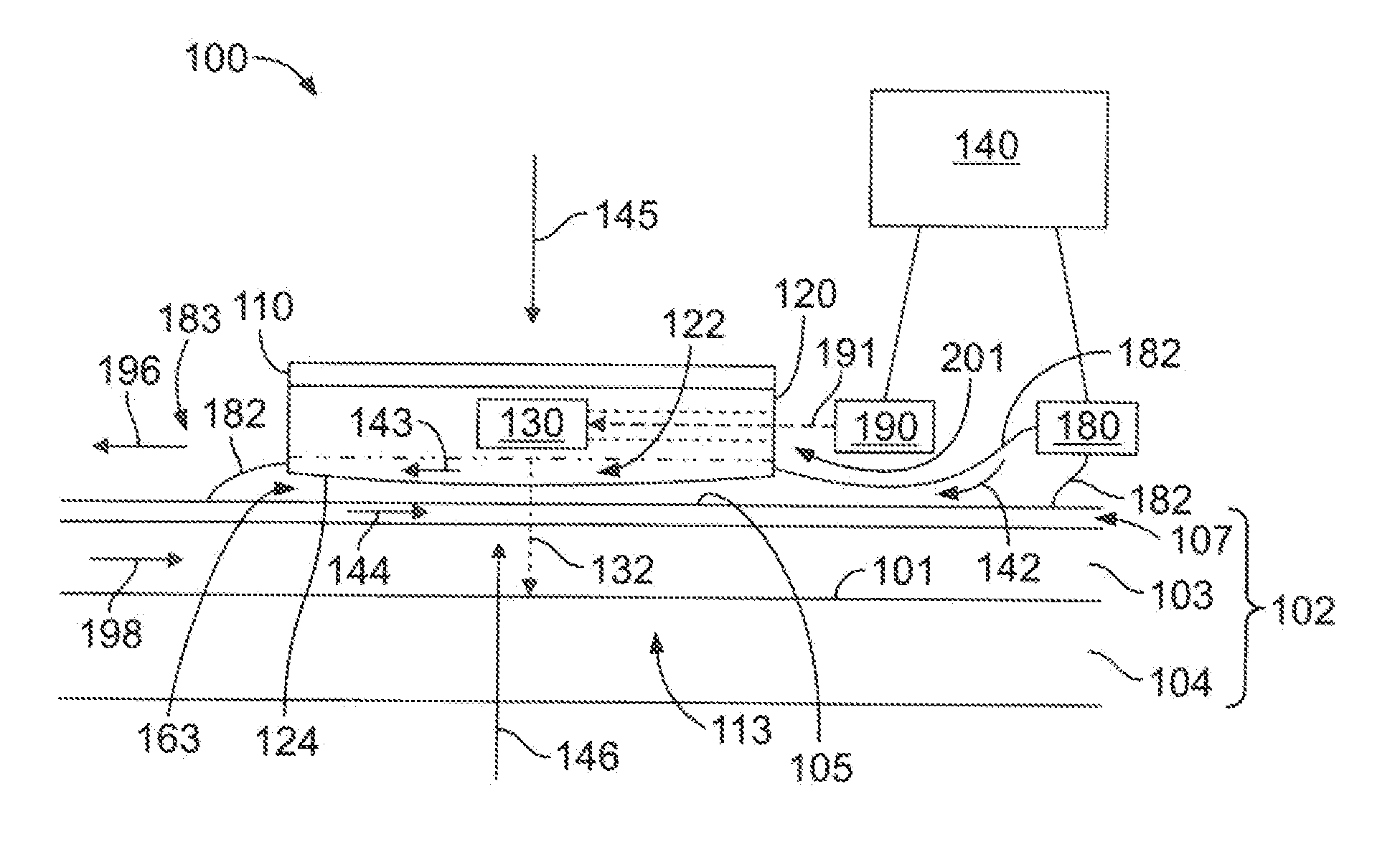

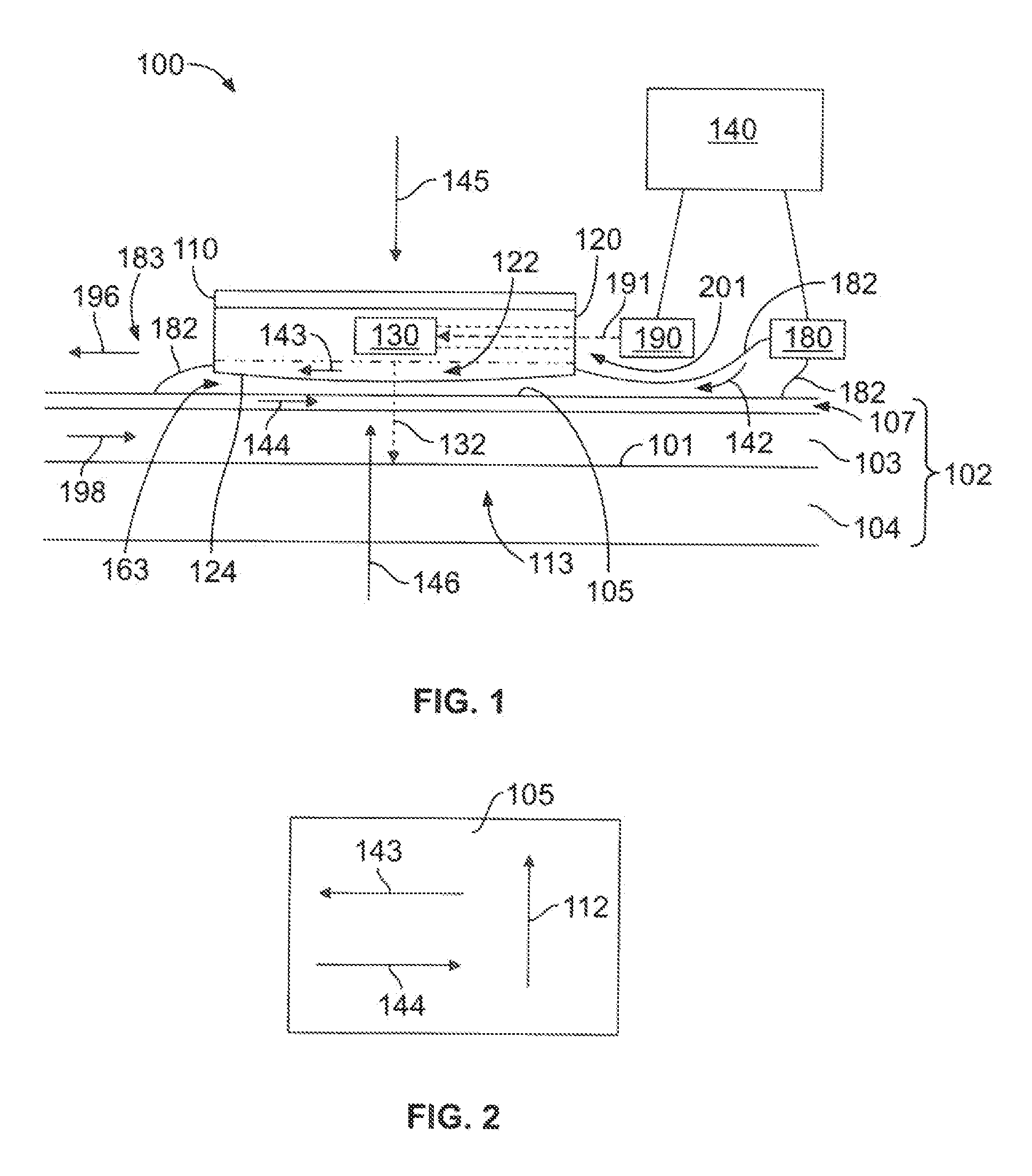

Systems and methods for testing internal bonds

ActiveUS20160349171A1Reduction of time and expenseUsing mechanical meansStrength propertiesPower flowTransducer

A transducer assembly is provided. The transducer assembly includes a magnetic portion, a body, a tensile pulse transmitter, and a pulse and current control unit. The magnetic portion is configured to provide a magnetic field. The body is disposed within an opening of the magnetic portion, and has a conductive portion configured to pass electric current near a body surface oriented toward the test surface. The tensile pulse transmitter is disposed within a cavity of the body and configured to transmit a tensile pulse into the test object. The pulse and current control unit is configured to control the tensile pulse transmitted by the tensile pulse transmitter, and to provide a current that passes through the conductive portion of the body and the test object, whereby a force urging the transducer assembly and the test object toward each other is generated responsive to the magnetic field and the current.

Owner:THE BOEING CO

Bond wire loop for high speed noise isolation

InactiveUS20090273074A1Reduce couplingSemiconductor/solid-state device detailsSolid-state devicesCircuit complexityElectricity

Semiconductor dies embodying electronic circuits are enclosed and protected within a package. To electrically access the die, the package includes external electrical leads which in turn connect to internal bond wires. The bond wires electrically connect the package to the die. As die density and circuit complexity increase, bond wire are placed in greater proximity. As a result, signal coupling between adjacent bond wires also increases and this coupling reduces circuit performance and input / output rates. A dissipation bond wire is provided adjacent the signal or supply bond wire acting as an aggressor. The dissipation bond wire has a first end connecting to the package and the second end connecting to the die or the package to form a conductive loop which dissipates unwanted coupling from an aggressor bond wire before the coupling couples into victim bond wire. The dissipation bond wire may be grounded.

Owner:MACOM TECH SOLUTIONS HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com