Non-woven fabric for semipermeable membrane support

A non-woven fabric and semi-permeable membrane technology, used in the field of non-woven fabrics, can solve the problems of poor air permeability, poor air permeability of the support body, and reduced sheet strength, etc., to improve adhesion, maintain smoothness, The effect of good thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

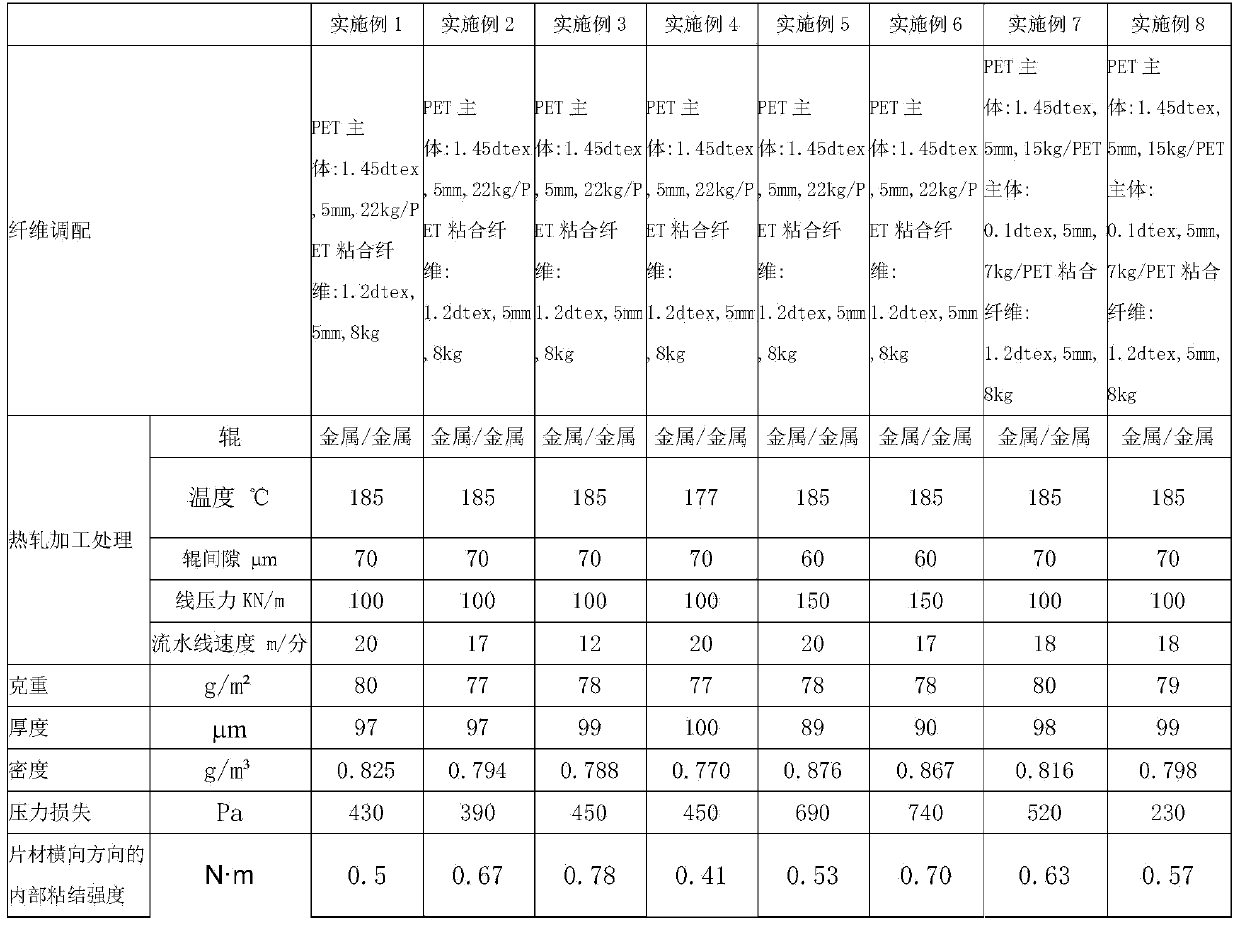

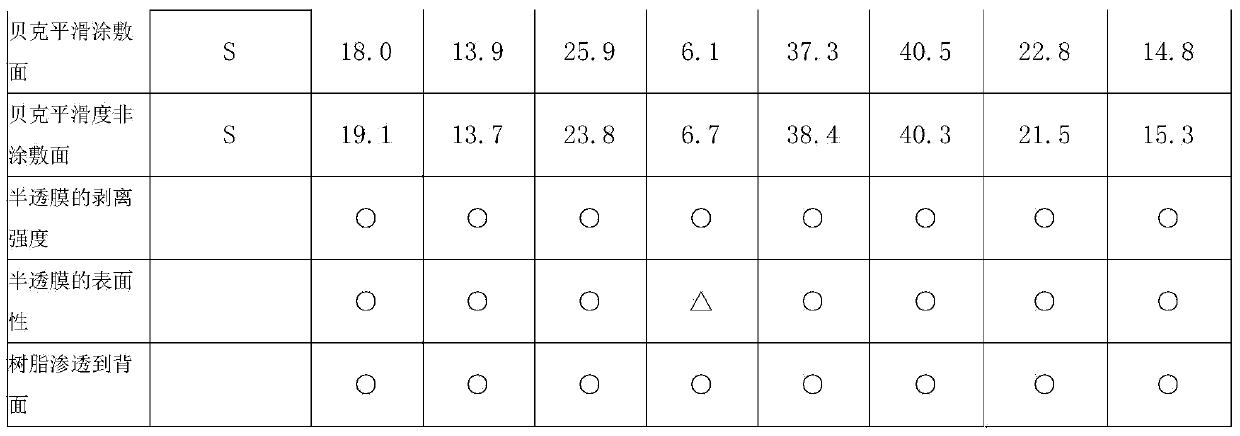

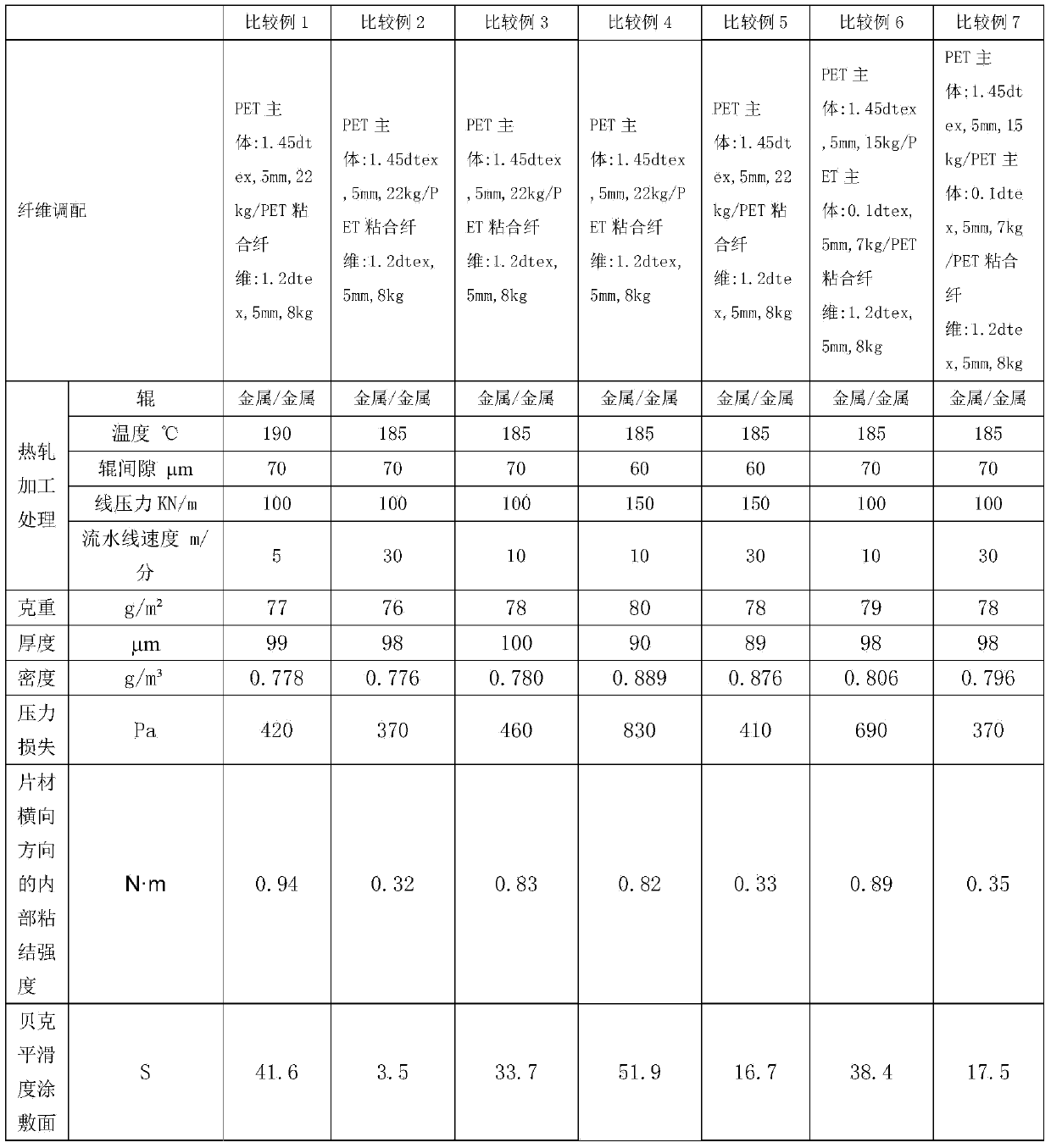

Embodiment 1

[0067]

[0068] 22 kg of a commercially available polyester main fiber (trade name: EP133, manufactured by Kuraray Co., Ltd.) having a thickness of 1.45 decitex and a cut length of 5 mm and a commercially available polyester fiber having a thickness of 1.2 dtex and a cut length of 5 mm were used. 8 kg of commercially available polyester binder fibers (trade name: TR07N, manufactured by Teijin Textile Co., Ltd.) were thrown into water, and dispersed by a disperser for 5 minutes to obtain a fiber raw material slurry with a fiber concentration of 1% by mass.

[0069]

[0070] Water was poured into the fiber raw material slurry 1, and after overall dilution, the fiber slurry with a fiber density|concentration of 0.03 mass % was obtained.

[0071]

[0072] The fiber pulp was put into the head box of the short-wire paper machine for papermaking, and then dried by a drum dryer with a surface temperature of 120° C. until the sheet was completely dry to obtain continuous winding b...

Embodiment 2

[0076]

[0077] Same as Example 1.

[0078]

[0079] Same as Example 1.

[0080]

[0081] Same as Example 1.

[0082]

[0083] In Example 1, the speed of the assembly line was adjusted to 17 m / min, and the rest was the same as in Example 1, thereby obtaining a nonwoven fabric for a semipermeable membrane support.

Embodiment 3

[0085]

[0086] Same as Example 1.

[0087]

[0088] Same as Example 1.

[0089]

[0090] Same as Example 1.

[0091]

[0092] In Example 1, the surface temperature of the metal roller was adjusted to 190° C., the speed of the assembly line was adjusted to 12 m / min, and the rest was the same as in Example 1, thereby obtaining a nonwoven fabric for a semipermeable membrane support.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com