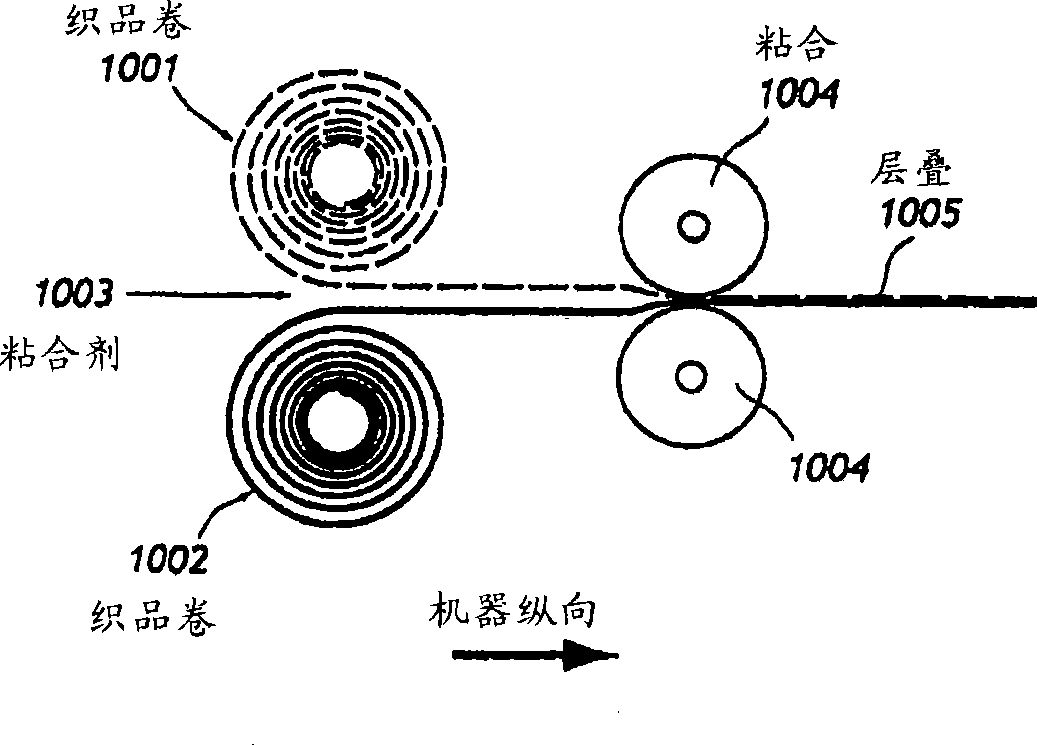

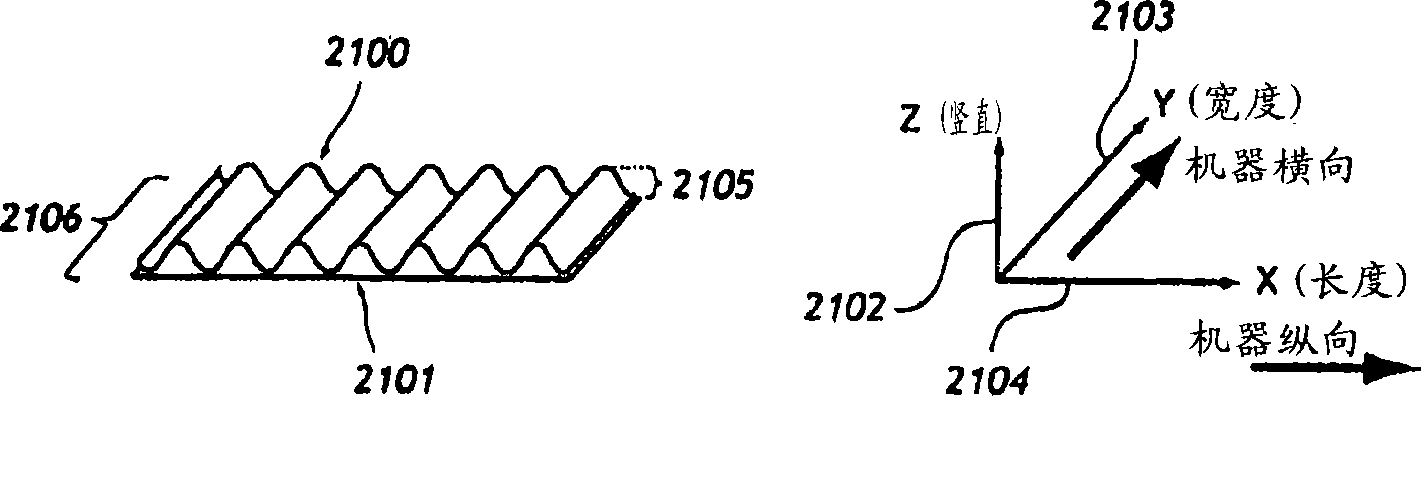

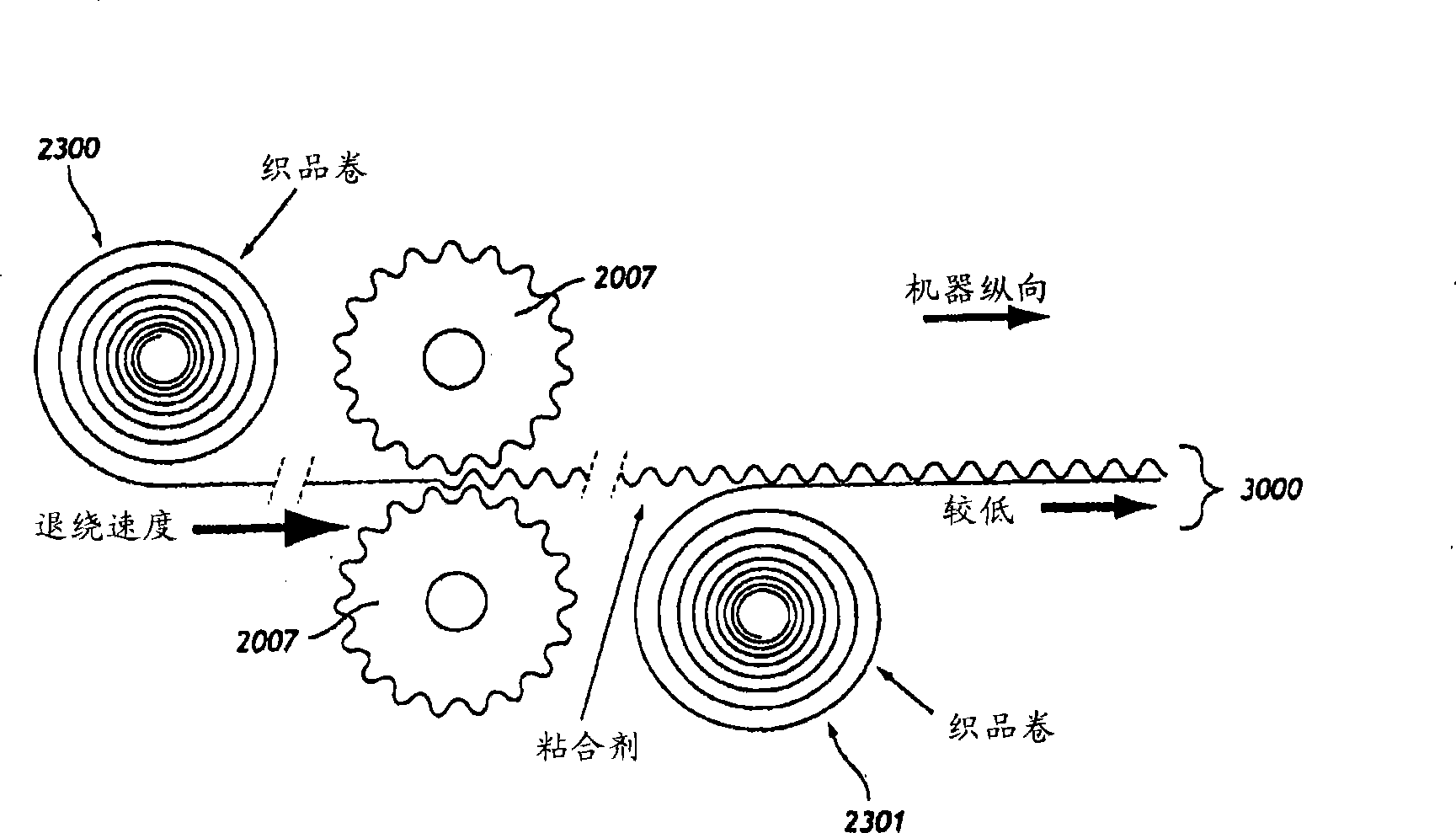

Wave-like structures bonded to flat surfaces in unitized composites and methods for making same

A composite, flat technique for the manufacture of synthetic composite fabric structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Although the invention has been shown and described herein with reference to specific embodiments, the invention is not limited to the details shown. On the contrary, various improvements can be implemented on this basis within the scope of equivalents of the claims without departing from the present invention. In addition, the embodiments used for illustration in the figures are not shown to scale and are not limited to the scales shown.

[0054] As used herein, the term "nonwoven" means a web of fibers having a structure made of interposed individual fibers, but which is not made in an orderly or discernible manner such as occurs in a woven or knitted web . As defined by INDA (Nonwovens Industry Association of America), the trade association representing the nonwoven fabrics industry, nonwoven fabrics generally refer to fibers or filaments entangled mechanically, thermally or chemically (and by perforation) and bonded together sheet structure or fiber network struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com