Surface modification atomizing device for stone materials butted to pitch mixing floor and control method thereof

A technology of asphalt mixing and surface modification, which is applied in the direction of roads, road repairs, roads, etc., can solve problems such as lack, and achieve the effect of improving performance indicators and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

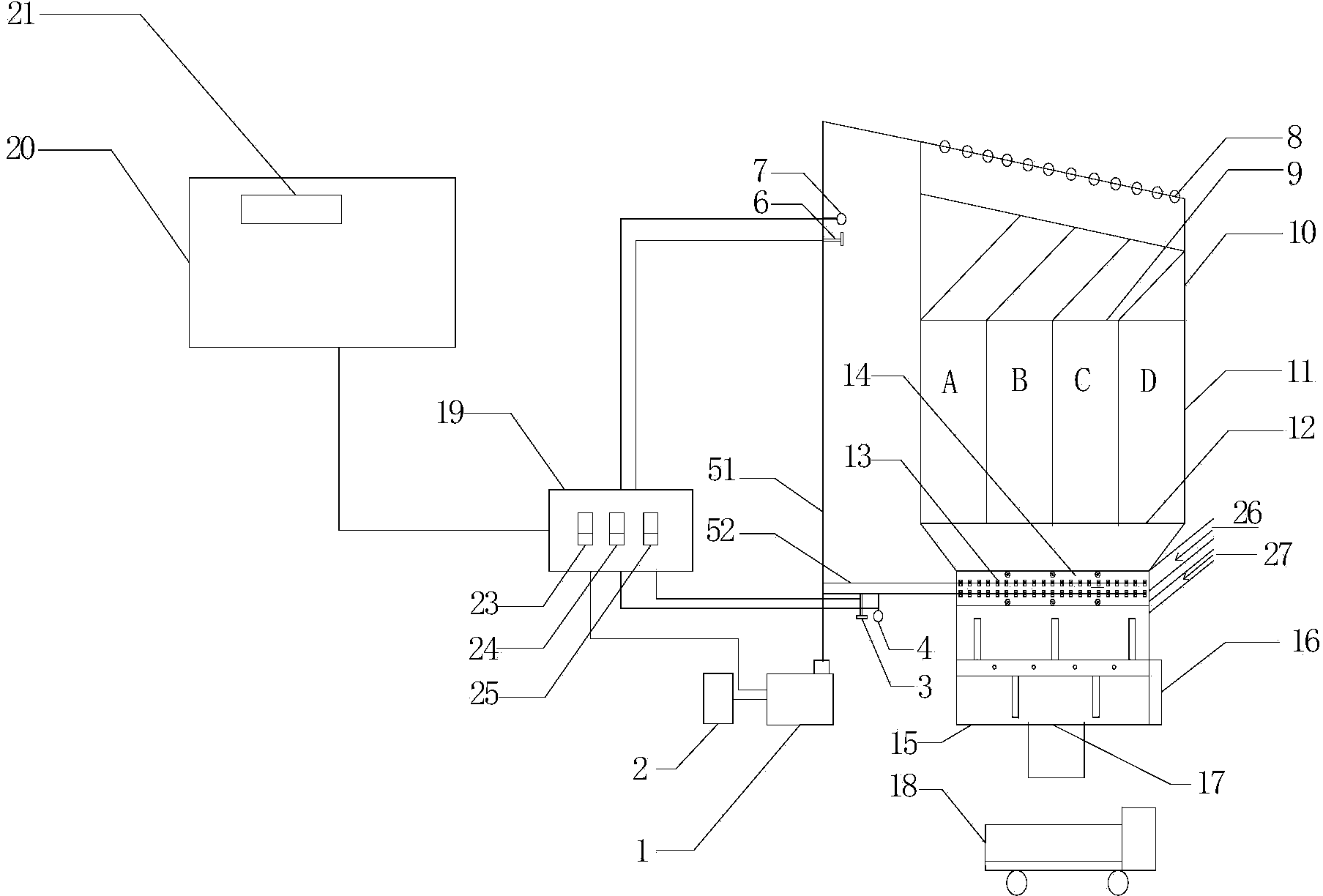

[0030] like figure 1 As shown, this embodiment discloses a stone surface modification atomization device connected to an asphalt mixing plant, including a control unit, a raw material barrel 2 for placing a stone surface modifier, a delivery pump 1, and a first electronic switch 23. The second electronic switch 24, the third electronic switch 25, the first atomizing nozzle device 8 and the second atomizing nozzle device 13; one end of the delivery pump 1 communicates with the raw material barrel 2; the other end of the delivery pump 1 passes through the first A pipeline 51 communicates with the first atomizing nozzle device 8, and the other end of the delivery pump 1 communicates with the second atomizing nozzle device 13 through a second pipeline 52; the first pipeline is provided with a first electric valve 6, and the second pipeline is provided with There is a second electric valve 3;

[0031] The delivery pump 1 and the first electric valve 6 are connected to the power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com