Steel rail surface treatment system using laminar plasma

A laminar plasma, surface treatment technology, applied in coating, metal material coating process, melt spraying and other directions, to achieve the effect of low friction, improved wear resistance, and obvious effect of hardness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

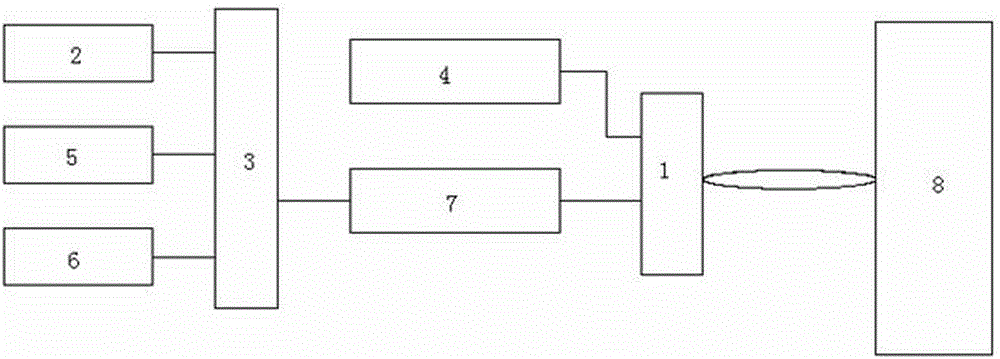

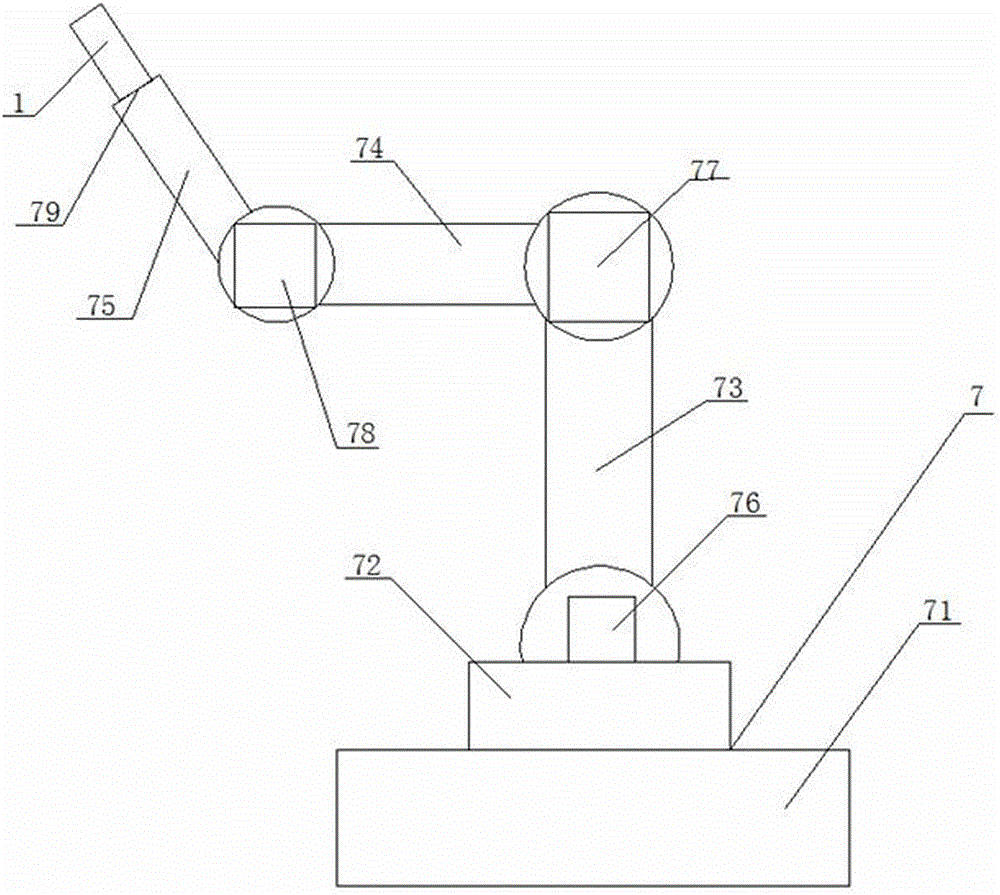

[0027] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0028] A rail surface treatment system using laminar plasma, including a non-transferred arc laminar plasma beam spray gun 1, a high-frequency rectifier power supply 2, a control cabinet 3, a wire feeding device 4, a circulating water cooling device 5, and a gas supply device 6. The industrial robot 7 and the rail installation platform 8; the non-transferred arc laminar flow plasma beam spray gun 1 is installed on the execution end 79 of the industrial robot 7; the circulating water cooling device 5 is controlled by the control cabinet 3 and the non-transferred arc laminar flow The plasma beam spray gun 1 is used for cooling the non-transferred arc laminar flow plasma beam spray gun 1; the gas supply device 6 is controlled by the control cabinet 3, and is used to provide the non-transferred arc laminar flow plasma beam spray gun 1 with working gas, Th...

Embodiment 2

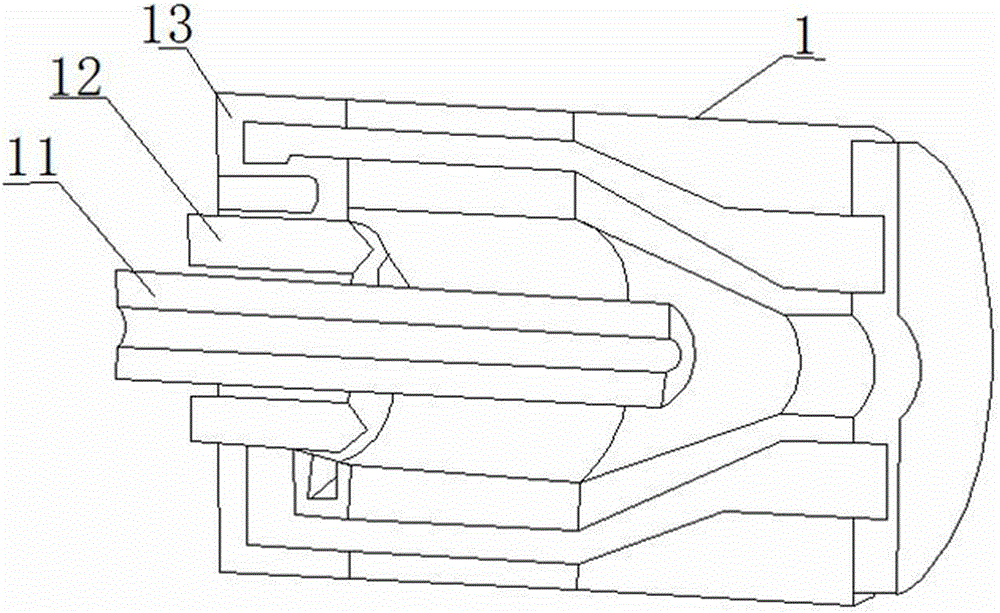

[0030] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0031]A rail surface treatment system using laminar plasma, including a non-transferred arc laminar plasma beam spray gun 1, a high-frequency rectifier power supply 2, a control cabinet 3, a wire feeding device 4, a circulating water cooling device 5, and a gas supply device 6. The industrial robot 7 and the rail installation platform 8; the non-transferred arc laminar flow plasma beam spray gun 1 is installed on the execution end 79 of the industrial robot 7; the circulating water cooling device 5 is controlled by the control cabinet 3 and the non-transferred arc laminar flow The plasma beam spray gun 1 is used for cooling the non-transferred arc laminar flow plasma beam spray gun 1; the gas supply device 6 is controlled by the control cabinet 3, and is used to provide the non-transferred arc laminar flow plasma beam spray gun 1 with work...

Embodiment 3

[0035] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0036] A rail surface treatment system using laminar plasma, including a non-transferred arc laminar plasma beam spray gun 1, a high-frequency rectifier power supply 2, a control cabinet 3, a wire feeding device 4, a circulating water cooling device 5, and a gas supply device 6. The industrial robot 7 and the rail installation platform 8; the non-transferred arc laminar flow plasma beam spray gun 1 is installed on the execution end 79 of the industrial robot 7; the circulating water cooling device 5 is controlled by the control cabinet 3 and the non-transferred arc laminar flow The plasma beam spray gun 1 is used for cooling the non-transferred arc laminar flow plasma beam spray gun 1; the gas supply device 6 is controlled by the control cabinet 3, and is used to provide the non-transferred arc laminar flow plasma beam spray gun 1 with wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com