Method for preparing lithium nickel cobalt manganese oxide by reverse positioning of power battery and application

A technology of nickel-cobalt-manganese lithium manganese oxide and nickel-cobalt-manganese oxide, which is applied in the field of reverse positioning of power batteries to prepare nickel-cobalt manganese oxide lithium, can solve the problems of high secondary pollutant treatment cost, large consumption of raw and auxiliary materials, and obvious limitations, and achieve Low processing cost, less consumption, and the effect of eliminating material stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

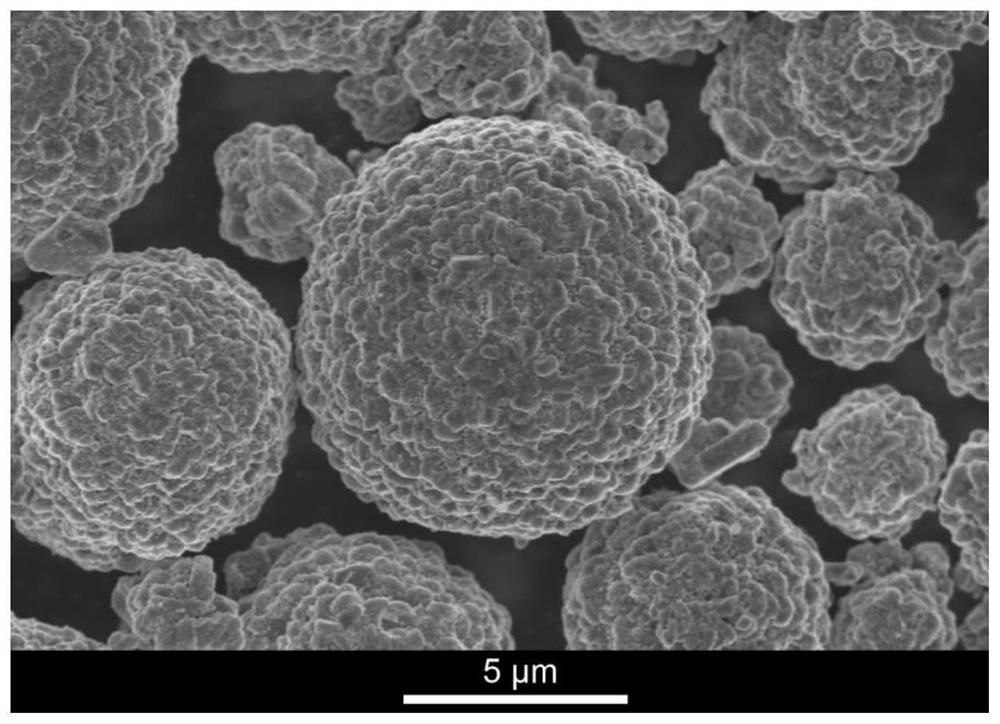

Image

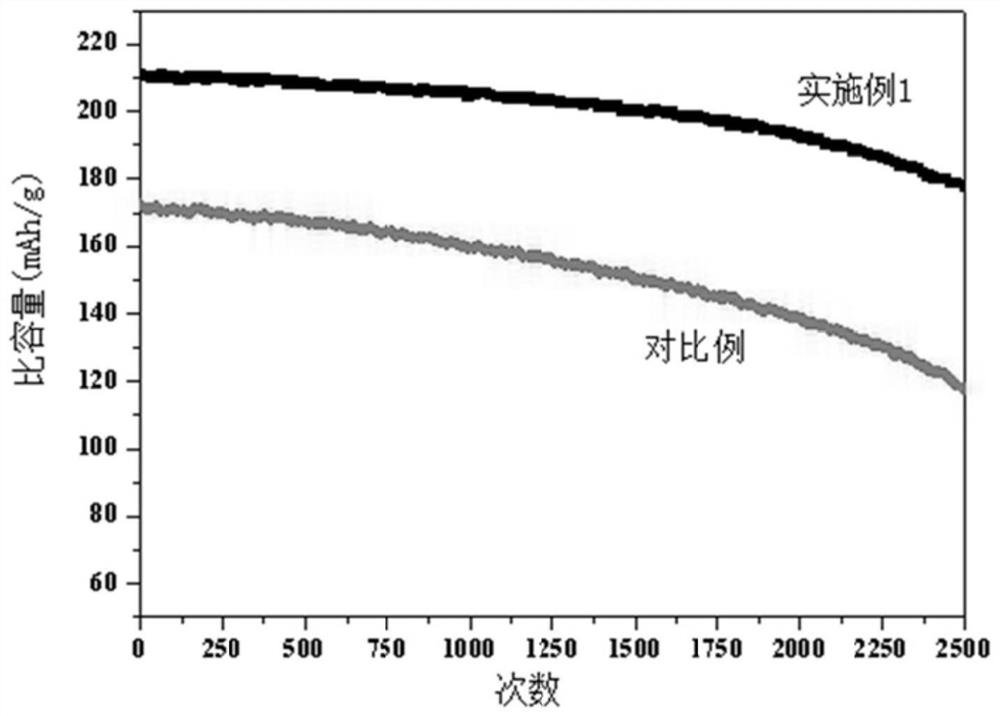

Examples

Embodiment 1

[0041] A method for preparing nickel-cobalt lithium manganese oxide by reverse positioning of a power battery, comprising the following specific steps:

[0042] (1) Disassemble the waste battery, obtain the battery cell, shell, and tab after separation, take the battery cell, disassemble the battery cell, and obtain the positive electrode sheet, negative electrode sheet, and diaphragm whose positive electrode material is nickel-cobalt lithium manganese oxide after separation;

[0043] (2) Mix the positive electrode sheet and the slagging agent calcium oxide at a weight ratio of 15:1, grind the positive electrode sheet to a particle size of 1mm, dry it at 100°C, and add metal at a weight ratio of 2:1 after cooling to room temperature. Aluminum powder, mixed well;

[0044] (3) Put the material mixed in step (2) in a self-propagating reaction furnace. Under a nitrogen atmosphere, ignite it with magnesium powder to initiate a self-propagating reaction. After cooling, remove the up...

Embodiment 2

[0051] A method for preparing nickel-cobalt lithium manganese oxide by reverse positioning of a power battery, comprising the following specific steps:

[0052] (1) Disassemble the waste battery, obtain the battery cell, shell, and tab after separation, take the battery cell, disassemble the battery cell, and obtain the positive electrode sheet, negative electrode sheet, and diaphragm whose positive electrode material is nickel-cobalt lithium manganese oxide after separation;

[0053] (2) Mix the positive electrode sheet and slagging agent calcium oxide at a weight ratio of 17:1, grind the positive electrode sheet to a particle size of 10mm, dry at 150°C, and add metal in a weight ratio of 3:1 after cooling to room temperature Aluminum powder, mixed well;

[0054] (3) placing the material in a self-propagating reaction furnace, under a nitrogen atmosphere, igniting with magnesium powder to initiate a self-propagating reaction, removing the upper layer of alumina-based smelting...

Embodiment 3

[0060] A method for preparing nickel-cobalt lithium manganese oxide by reverse positioning of a power battery, comprising the following specific steps:

[0061] (1) Disassemble the waste battery, obtain the battery cell, shell, and tab after separation, take the battery cell, disassemble the battery cell, and obtain the positive electrode sheet, negative electrode sheet, and diaphragm whose positive electrode material is nickel-cobalt lithium manganese oxide after separation;

[0062] (2) Mix the positive electrode sheet and slagging agent calcium oxide at a weight ratio of 20:1, grind the positive electrode sheet to a particle size of 20mm, dry at 180°C, cool to room temperature and add metal in a weight ratio of 5:1 Aluminum powder, mixed well;

[0063] (3) placing the material in a self-propagating reaction furnace, under a nitrogen atmosphere, igniting with magnesium powder to initiate a self-propagating reaction, removing the upper layer of alumina-based smelting slag aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com