Low-cost flue gas denitration catalyst and preparation and use methods thereof

A denitrification catalyst and low-cost technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of active component toxicity and high catalyst cost, achieve simple equipment and process, reduce denitrification cost, and high Effect of Catalytic Reduction on Denitrification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

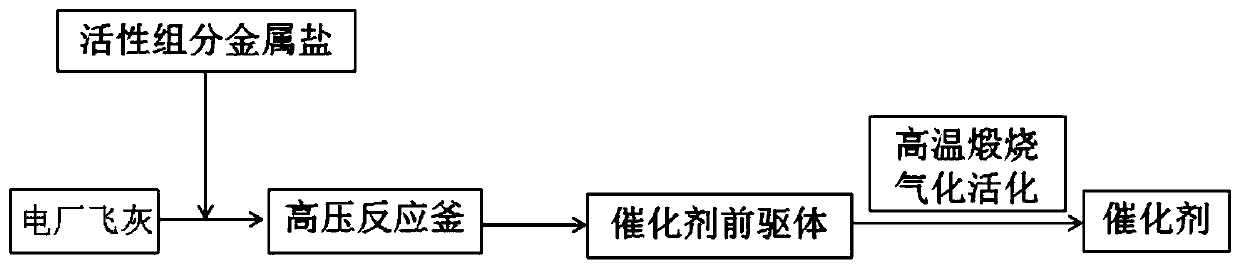

[0031] A method for preparing a low-cost flue gas denitrification catalyst, comprising the steps of:

[0032] 1) Dry the fly ash to constant weight;

[0033] 2) Dissolve the solid metal salt in deionized water to obtain a metal salt solution, mix the fly ash and the metal salt solution evenly in an autoclave, and soak the mixture for 20-40min at a pressure of 3-6MPa and a temperature of 40-60°C. Cool to room temperature, add ammonia water dropwise, until the pH of the solution is 9-10, continue mechanical stirring for 0.5-1h, take out the mixture for suction filtration, and dry again to constant weight;

[0034] 3) Put the dried product obtained in step 2) into a fixed-bed reactor, and under the protection of a nitrogen atmosphere, heat up to 600-700°C in a crucible furnace and pass in water vapor for calcination and gasification for 15-30min, and then cool down to room temperature. Get a catalyst.

[0035] In the metal salt solution, the mass-to-volume ratio of metal ions t...

Embodiment 1

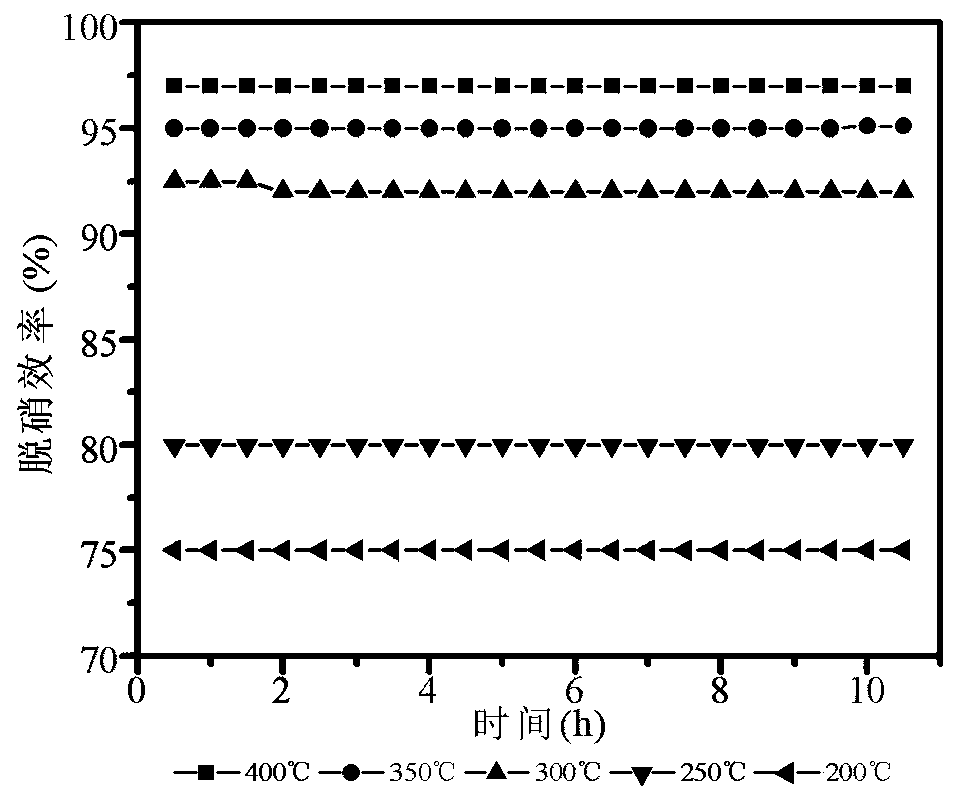

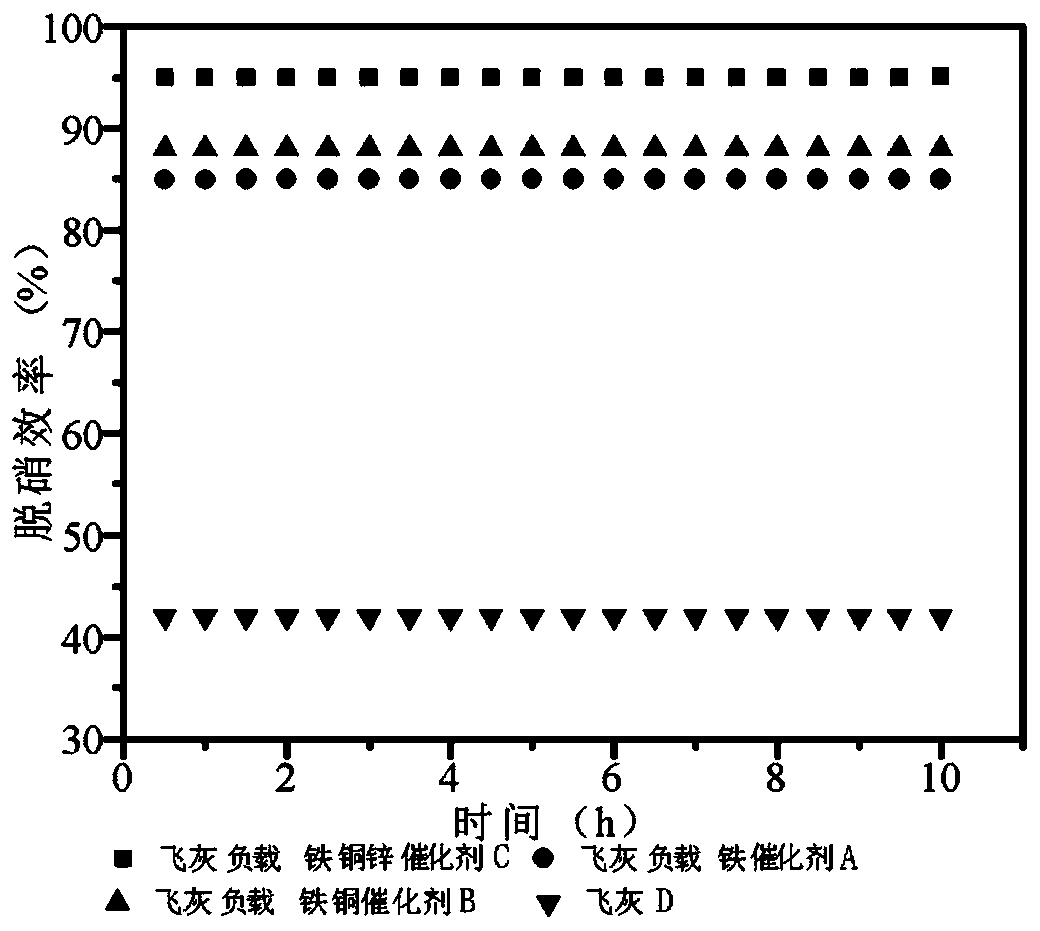

[0041] Weigh the analytically pure Fe(NO 3 ) 2 9H 2O was added into 100ml of deionized water and dissolved evenly to obtain ferric nitrate solutions with Fe contents of 10g / 100ml of water respectively. Put the fly ash with a particle size of 120-200 mesh into a vacuum oven, and vacuum-dry at 105°C until constant weight. Weigh 100g of dry fly ash, put it into the autoclave together with the ferric nitrate solution, soak it for 0.5h at a pressure of 5MPa and a temperature of 50°C, cool the sample to room temperature, add a certain amount of ammonia water, until the pH value of the solution reaches 9 -10, continue ultrasonic impregnation for 1 hour, then cool naturally to room temperature, take out, filter with suction, and dry again in a vacuum oven at 105°C to constant weight. Put 10g of the dried catalyst precursor sample into the fixed-bed reaction device, under the protection of nitrogen atmosphere, heat the fixed-bed reaction device to 700°C, and then pass in 0.015ml / min...

Embodiment 2

[0043] Weigh analytically pure Fe(NO 3 ) 2 9H 2 O and Cu(NO 3 ) 2 ·5H 2 O, add 100ml deionized water, dissolve evenly, obtain the mixed nitrate solution that Fe and Cu content are 9.5g / 100ml and 0.5g / 100ml water respectively. Put the fly ash sieved to 120-200 mesh into a vacuum oven, and vacuum dry at 105°C until constant weight. Weigh 100g of dry fly ash, put it into the autoclave together with the above-mentioned nitrate mixed solution, soak it for 0.5h at a pressure of 5MPa and a temperature of 50°C, cool the sample to room temperature, add a certain amount of ammonia water, until the pH of the solution reaches 9-10, continue ultrasonic impregnation for 1 hour, then cool naturally to room temperature, take out, filter with suction, and dry again in a vacuum oven at 105°C to constant weight. Put 10g of the dried catalyst precursor sample into the fixed-bed reaction device, under the protection of nitrogen atmosphere, heat the fixed-bed reaction device to 700°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com