Method for preparing semicoke supported multi-element nano metal oxide desulfurization and denitrification adsorbing agent

A nano-metal, desulfurization and denitrification technology, applied in the field of flue gas purification, can solve the problems of unsolved water consumption solid waste, secondary pollution of solid and liquid waste, poor pore structure of desulfurizer, etc. The effect of rich structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

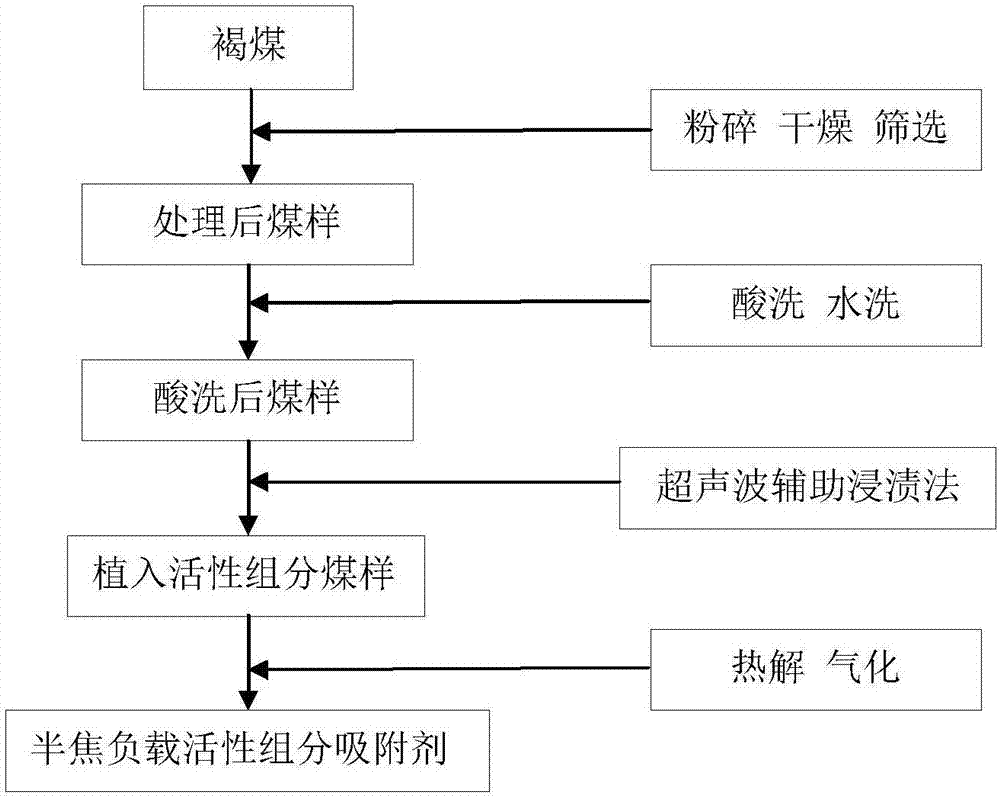

Method used

Image

Examples

Embodiment 1

[0039] Weigh analytically pure Fe(NO 3 ) 2 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O and Cu(NO 3 ) 2 ·5H 2 O, add 100ml deionized water, dissolve evenly, obtain the mixed solution that Fe, Zn and Cu content are respectively 4.33g, 1.37g, 0.38g / 100ml water. The lignite particles sieved to 125-200 mesh are placed in a vacuum oven, vacuum-dried at 105°C to constant weight, then acid-washed and water-washed, and vacuum-dried at 105°C to constant weight.

[0040] Weigh 10g of dried lignite sample, then put it into an ultrasonic cleaner together with 20ml of the above nitrate mixed solution, ultrasonically impregnate at 50°C for 5h, add a certain amount of ammonia water until the pH value of the solution reaches 10, continue ultrasonically impregnating for 1h, then Naturally cool to room temperature, take out, filter with suction, and dry again in a vacuum oven at 105°C to constant weight.

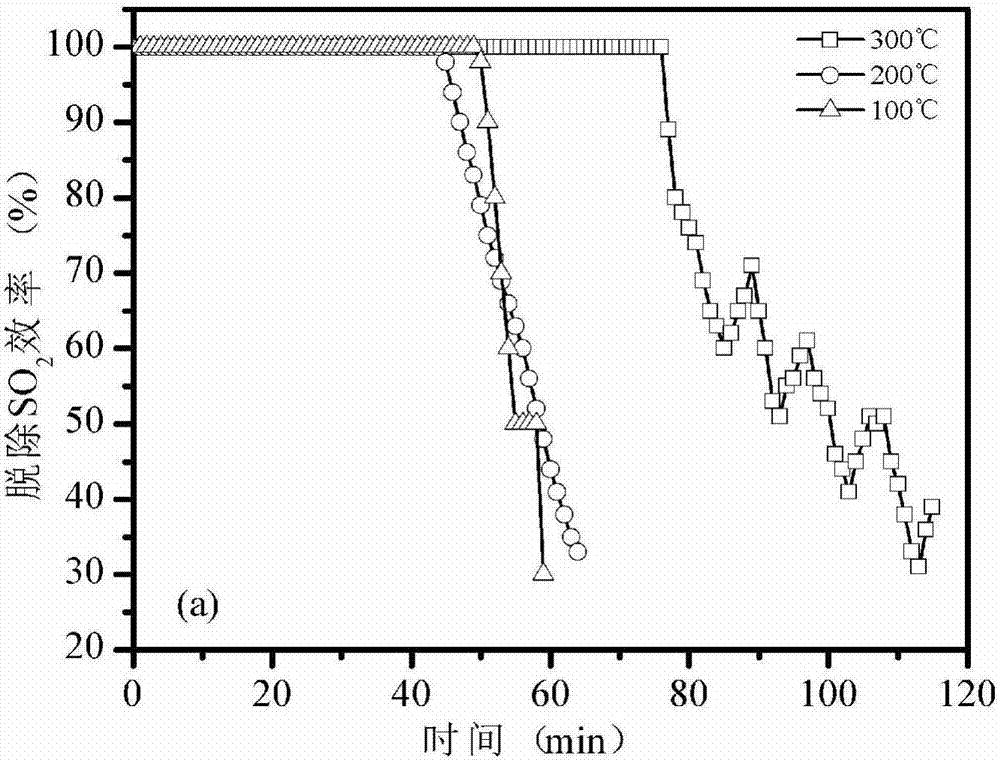

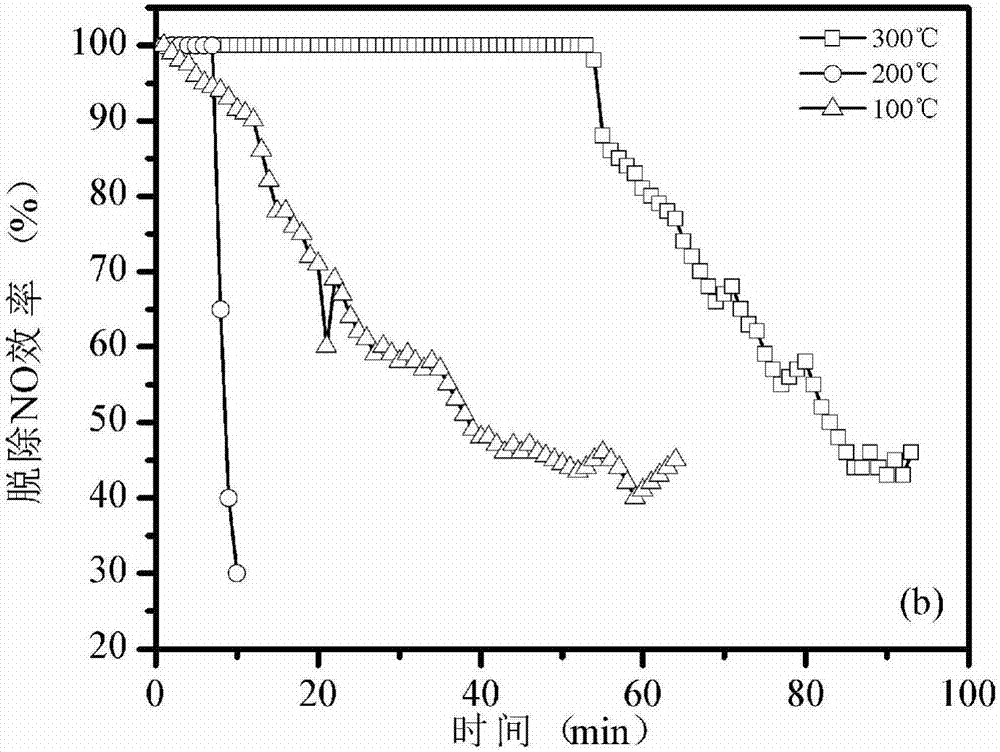

[0041] Put 2-3g of the dried lignite sample into the middle part of the quartz (fixed bed) reacto...

Embodiment 2

[0043] Weigh analytically pure Fe(NO 3 ) 2 9H 2 O, add 100ml deionized water, dissolve evenly, obtain the mixed solution that Fe content is 7.21g / 100ml water.

[0044] The lignite particles sieved to 125-200 mesh are put into a vacuum oven, and vacuum-dried at 105° C. until constant weight. Then the lignite was acid-washed and water-washed, and vacuum-dried at 105°C to constant weight.

[0045] Weigh 10g of dry lignite sample, put it into an ultrasonic cleaner together with 20ml of the above-mentioned nitrate mixed solution, ultrasonically impregnate at 50°C for 5h, add a certain amount of ammonia water until the pH value of the solution reaches 10, continue ultrasonically impregnating for 1h, and then naturally Cool to room temperature, take out, filter with suction, and dry again in a vacuum oven at 105°C to constant weight.

[0046] Put 2-3g of the dried lignite sample into the middle part of the quartz (fixed bed) reactor, feed N with the flow rate of 100ml / min 2 , un...

Embodiment 3

[0048] Weigh analytically pure Zn(NO 3 ) 2 ·6H 2 O, add 100ml deionized water, dissolve evenly, obtain the mixed solution that Zn content is 4.58g / 100ml water.

[0049] The lignite particles sieved to 125-200 mesh are put into a vacuum oven, and vacuum-dried at 105° C. until constant weight. Then the lignite was acid-washed and water-washed, and vacuum-dried at 105°C to constant weight.

[0050] Weigh 10g of dry lignite sample, put it into an ultrasonic cleaner together with 20ml of the above-mentioned nitrate mixed solution, ultrasonically impregnate at 50°C for 5h, add a certain amount of ammonia water until the pH value of the solution reaches 10, continue ultrasonically impregnating for 1h, and then naturally Cool to room temperature, take out, filter with suction, and dry again in a vacuum oven at 105°C to constant weight.

[0051] Put 2-3g of the dried lignite sample into the middle part of the quartz (fixed bed) reactor, feed N with the flow rate of 100ml / min 2 , u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com