Preparation method of low-compression permanent-deformation carboxylic acrylate rubber

A permanent deformation, acrylate technology, applied in the field of preparation of low compression set carboxylic acid acrylate rubber, can solve the problems of poor processing and extrusion performance, poor safety factor, poor compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

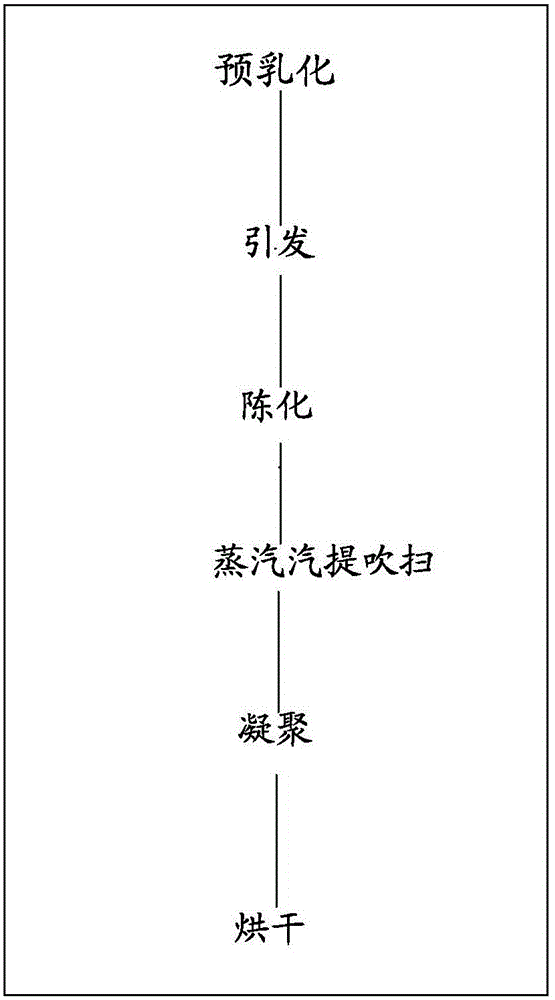

Embodiment 1

[0016] 70% of ethyl acrylate, 23% of butyl acrylate, 1% of maleic acid, 0.015% of regulator butyl, 2% of sodium dodecyl sulfonate, and deionized water as the balance, pre-heated at 48°C in nitrogen. emulsification. After the emulsification is uniform, lower the temperature to 43°C, initiate with 0.025% initiator, raise the temperature to 60°C at 1°C / min, add 1.4 times the initial amount of regulator D; continue to raise the temperature to 70°C at 1°C / min, and add 0.3% of the initial amount When heating up to 88°C at 1°C / min, add 0.3 times the initial amount of initiator; add 0.1 times the initial amount of initiator after holding for 50 minutes. The obtained polymer is aged, steam stripped and purged to remove residual monomers and low molecular substances; the acrylate rubber emulsion is diluted to 2 times the original, and coagulated with a total amount of 7% sodium chloride electrolyte After coagulation, it is washed continuously with deionized water until there is no emul...

Embodiment 2

[0018] 70% ethyl acrylate, 20% butyl acrylate, 5% methoxyethyl acrylate, 3% maleic acid, 0.025% regulator, 2.5% sodium lauryl sulfate, and deionized balance Water, pre-emulsified at 50°C under nitrogen. After the emulsification is uniform, lower the temperature to 44°C, initiate with 0.025% initiator, raise the temperature to 63°C at 1°C / min, add 1.5 times the initial amount of regulator D; continue to raise the temperature to 73°C at 1°C / min, add 0.5% of the initial amount When heating up to 90°C at 1°C / min, add 0.5 times the initial amount of initiator; add 0.2 times the initial amount of initiator after holding for 60 minutes. The resulting polymer is aged, steam stripped and purged to remove residual monomers and low-molecular substances; the acrylate rubber emulsion is diluted to 2.5 times the original, and coagulated with a total amount of 8% calcium chloride electrolyte After coagulation, it was washed continuously with deionized water until no emulsifier and electroly...

Embodiment 3

[0020] 80% ethyl acrylate, 15% methoxy ethyl acrylate, 4% maleic acid, using 0.035% regulator butadiene, adding 3% sodium lauryl sulfate, and the balance is deionized water, carried out in nitrogen Pre-emulsified at 53°C. After the emulsification is uniform, lower the temperature to 45°C, initiate with 0.026% initiator, raise the temperature to 65°C at 1°C / min, add 1.6 times the initial amount of regulator D; continue to raise the temperature to 75°C at 1°C / min, and add 0.6% of the initial amount When heating up to 92°C at 1°C / min, add 0.6 times the initial amount of initiator; add 0.3 times the initial amount of initiator after keeping warm for 60 minutes. The obtained polymer is aged, steam stripped and purged to remove residual monomers and low-molecular substances; the acrylate rubber emulsion is diluted to 3 times the original, and coagulated with 10% of the total amount of calcium chloride electrolyte After coagulation, it is washed continuously with deionized water unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com