Automatic oil immersion device and oil immersion method for pipe fittings

An automatic and oil-immersed technology, which is applied to chemical instruments and methods, cleaning methods and utensils, and devices for coating liquid on the surface, etc., can solve the problems of low efficiency, incomplete oil immersion, and complicated operation steps of metal parts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

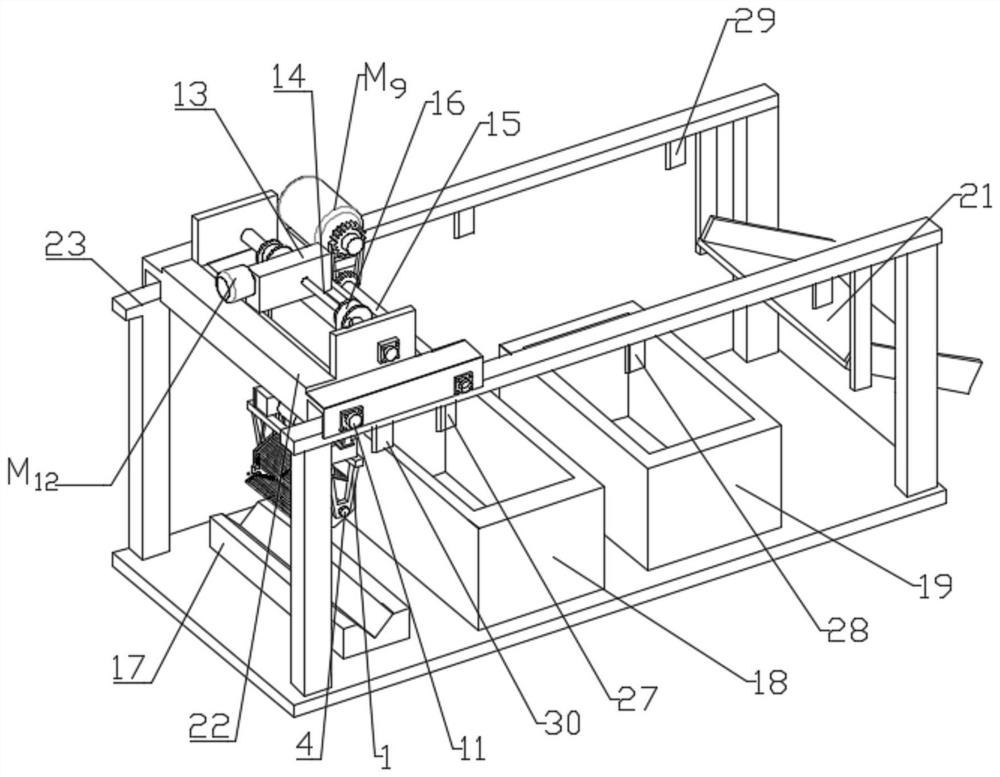

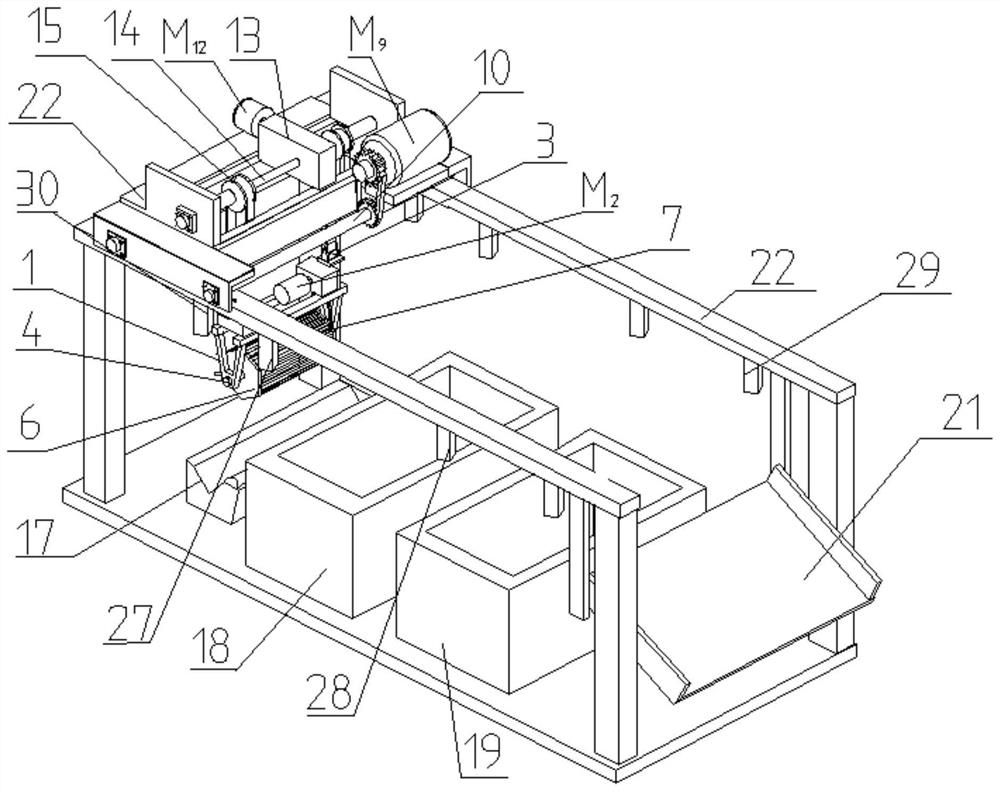

[0035] see figure 1 , 2 and image 3, the present invention comprises a lifting part, a sliding part, a roller part, an oiling pool 19 and a frame 23; the lifting part is assembled on the sliding part; the sliding part is assembled on the frame 23; the oiling pool 19 is set Below the frame 23; the part of the drum is set in cooperation with the lifting part; the part of the drum includes a loading bin, a connecting piece and a power part; the charging bin and the power part are all arranged on the connecting part, and the power part Drive the rotation of the loading bin.

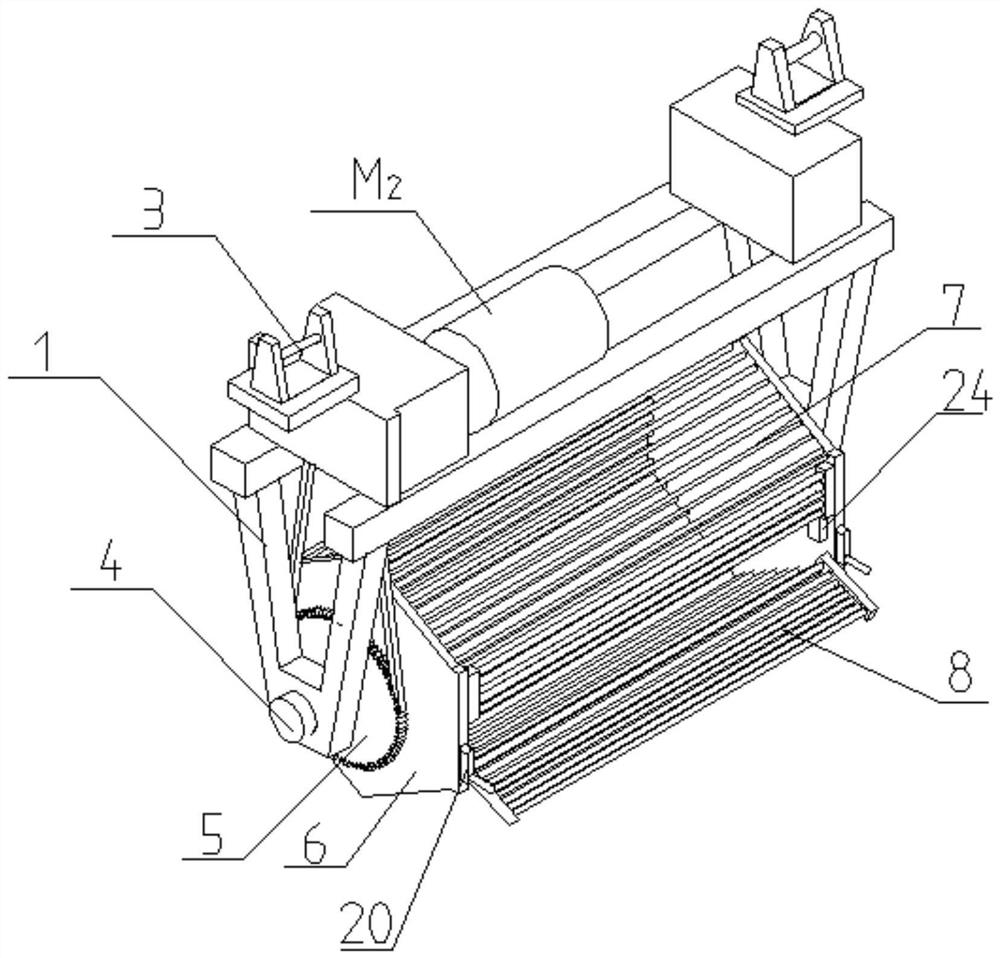

[0036] see figure 2 and image 3 In order to make the metal parts contact with the solution smoothly during the dipping and cleaning process, and after the metal parts are hoisted out of the pool containing the solution, the solution on the metal parts can be discharged smoothly, the present invention is additionally equipped with a loading bin; The charging bin includes a charging door 8, a steel pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com