Method for preparing recycle oil and pickling neutralizer thereof in preparation process

A technology of re-refining and pickling, which is applied in the field of oil refining, can solve the problems of difficult-to-mix re-refining, strong product odor, difficult re-refining, etc., and achieve the effects of avoiding single raw material structure, fully washing oil, and good neutralization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

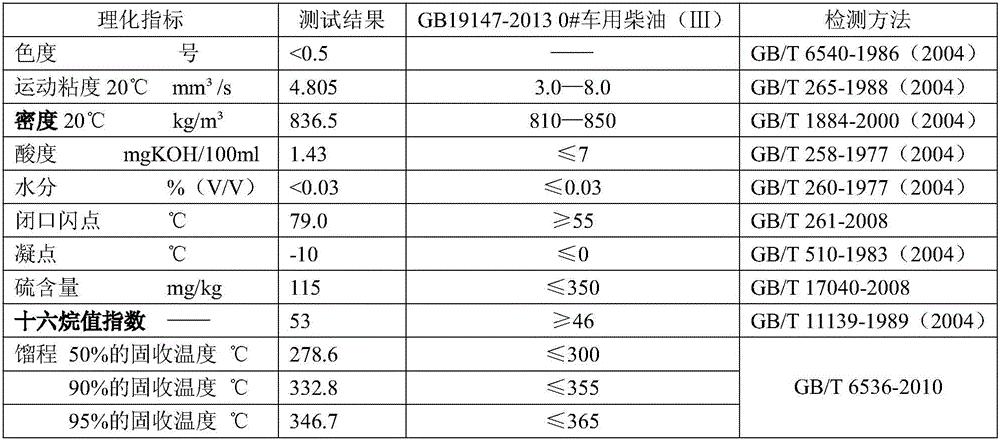

Image

Examples

Embodiment 1

[0032] Embodiment 1: 200ml of waste oil (edible kitchen waste oil) is used as raw material.

[0033] Step 1: mixing materials, sealing the inside of the waste oil distillation tank;

[0034] Step 2: heating, continuous heating after mixing, the heating temperature is between 300°C and 400°C;

[0035] Step 3: Condensation. After the mixture is liquefied and tumbling, the heated steam enters the condensation pipe, the condensed liquid is collected, and left to cool to form condensed oil; the cooling liquid presents a lighter transparent brown color.

[0036] The formula of pickling neutralizer corresponding to every 200ml of condensed oil is as follows: glacial acetic acid (liquid) 4ml, phosphoric acid (liquid) 6ml, oxalic acid (granule) 4g, absolute ethanol (liquid) 4ml, after stirring and mixing the above, Add concentrated sulfuric acid with a mass fraction of 92%-98% to 200ml, and then stir evenly.

[0037] Then take out 5% of the configured pickling neutralizer (that is, 1...

Embodiment 2

[0043] Embodiment 2: 200ml of waste engine oil (industrial equipment waste oil) is used as a raw material.

[0044] Step 1: Mix the materials, distill the inside of the waste engine oil tank, and seal it;

[0045] Step 2: heating, continuous heating after mixing, the heating temperature is between 360°C and 380°C;

[0046]Step 3: Condensation. After the mixture is liquefied and tumbling, the heated steam enters the condensation pipe, the condensed liquid is collected, and left to cool to form condensed oil; the cooling liquid is generally brown.

[0047] The formula of pickling neutralizer corresponding to every 200ml of condensed oil is as follows: glacial acetic acid (liquid) 8ml, phosphoric acid (liquid) 6ml, oxalic acid (granule) 6g, absolute ethanol (liquid) 6ml, after stirring and mixing the above, Add concentrated sulfuric acid with a mass fraction of 60%-75% to 200ml, and then stir evenly.

[0048] Then take out 8% of the configured pickling neutralizer (that is, 16m...

Embodiment 3

[0054] Embodiment 3: The raw material adopts waste plastics (solid 10kg).

[0055] Step 1: Mixing materials, putting waste plastic solids into the interior of the distillation tank, and sealing;

[0056] Step 2: heating, continuous heating after mixing, the heating temperature is between 380°C and 400°C;

[0057] Step 3: Condensation. After the mixture is liquefied and tumbling, the heated steam enters the condensation pipe, the condensed liquid is collected, and left to cool to form condensed oil;

[0058] Take out 200ml of coolant for later use; the coolant is dark brown in color.

[0059] The formula of pickling neutralizer corresponding to every 200ml of condensed oil is as follows: Glacial acetic acid (liquid) 10ml, phosphoric acid (liquid) 8ml, oxalic acid (granule) 8g, absolute ethanol (liquid) 8ml, after stirring and mixing the above, Add concentrated sulfuric acid with a mass fraction of 60%-75% to 200ml, and then stir evenly.

[0060] Then take out 10% of the conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com