Speed oil filling device for pulse generator of wireless inclinometer and using method thereof

A pulse generator and wireless while-drilling technology, which is applied in engine lubrication, measurement, earthwork drilling and production, etc., can solve the problems of oil bag loss, difficult to distinguish joints, and easy air leakage, so as to achieve sufficient oil filling and reduce residual air bubbles Possibility, effect of reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is attached figure 1 And embodiment technical scheme of the present invention is described further.

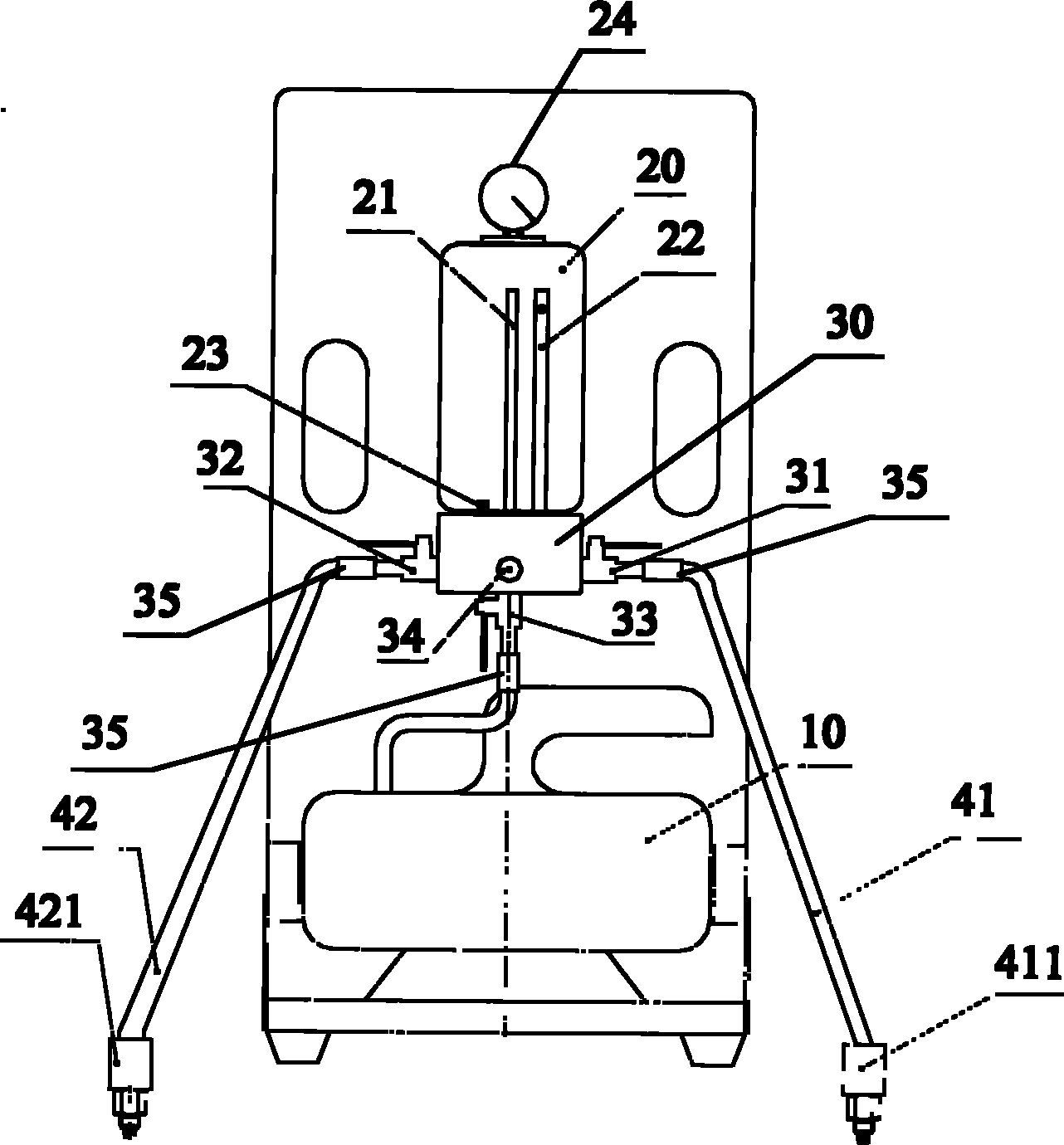

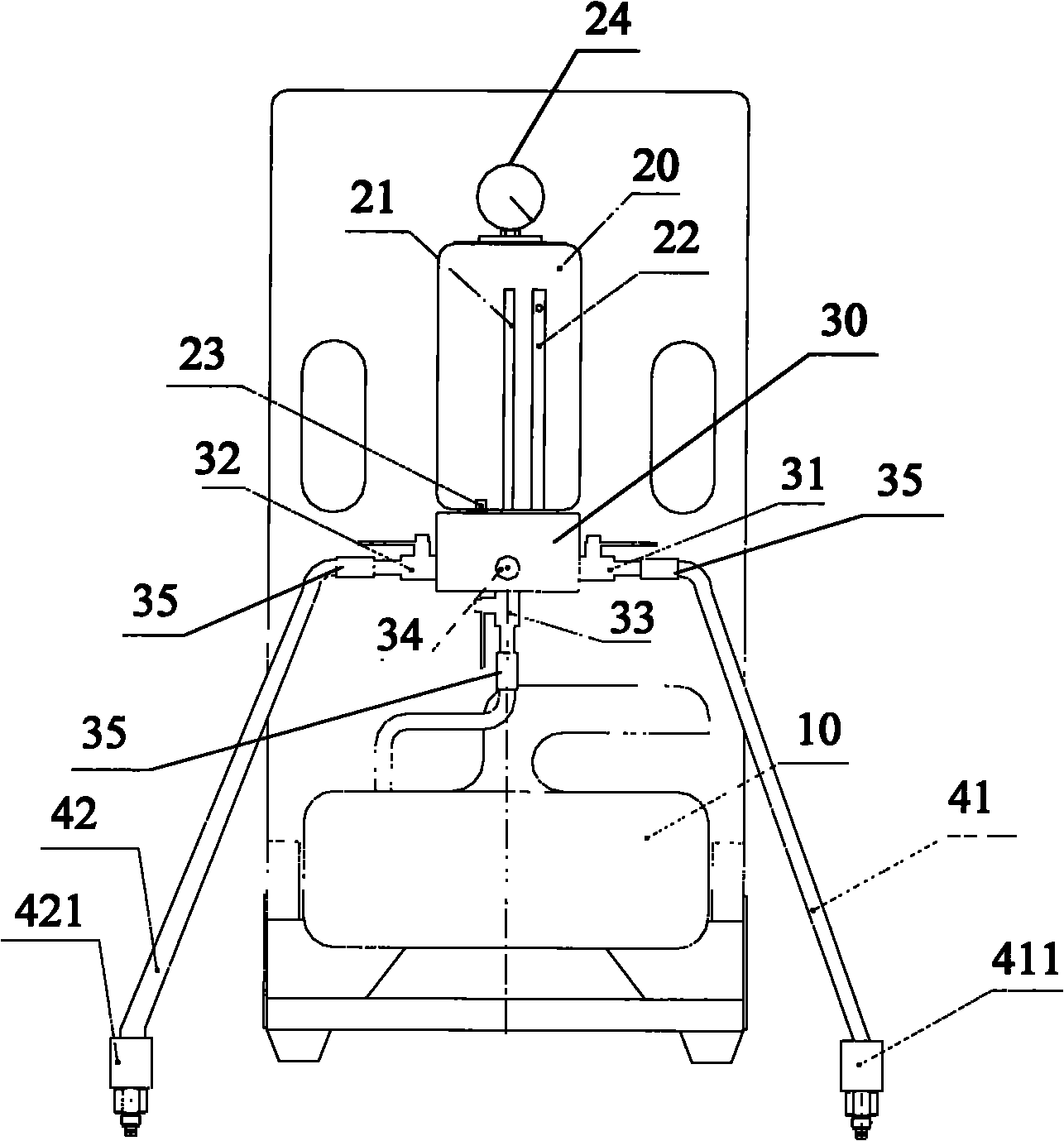

[0025] The present invention provides a rapid oil filling device for a pulse generator of a wireless inclinometer while drilling. The oil filling device includes: a vacuum pump 10 , an oil tank 20 , an oil inlet pipeline 41 and an oil outlet pipeline 42 .

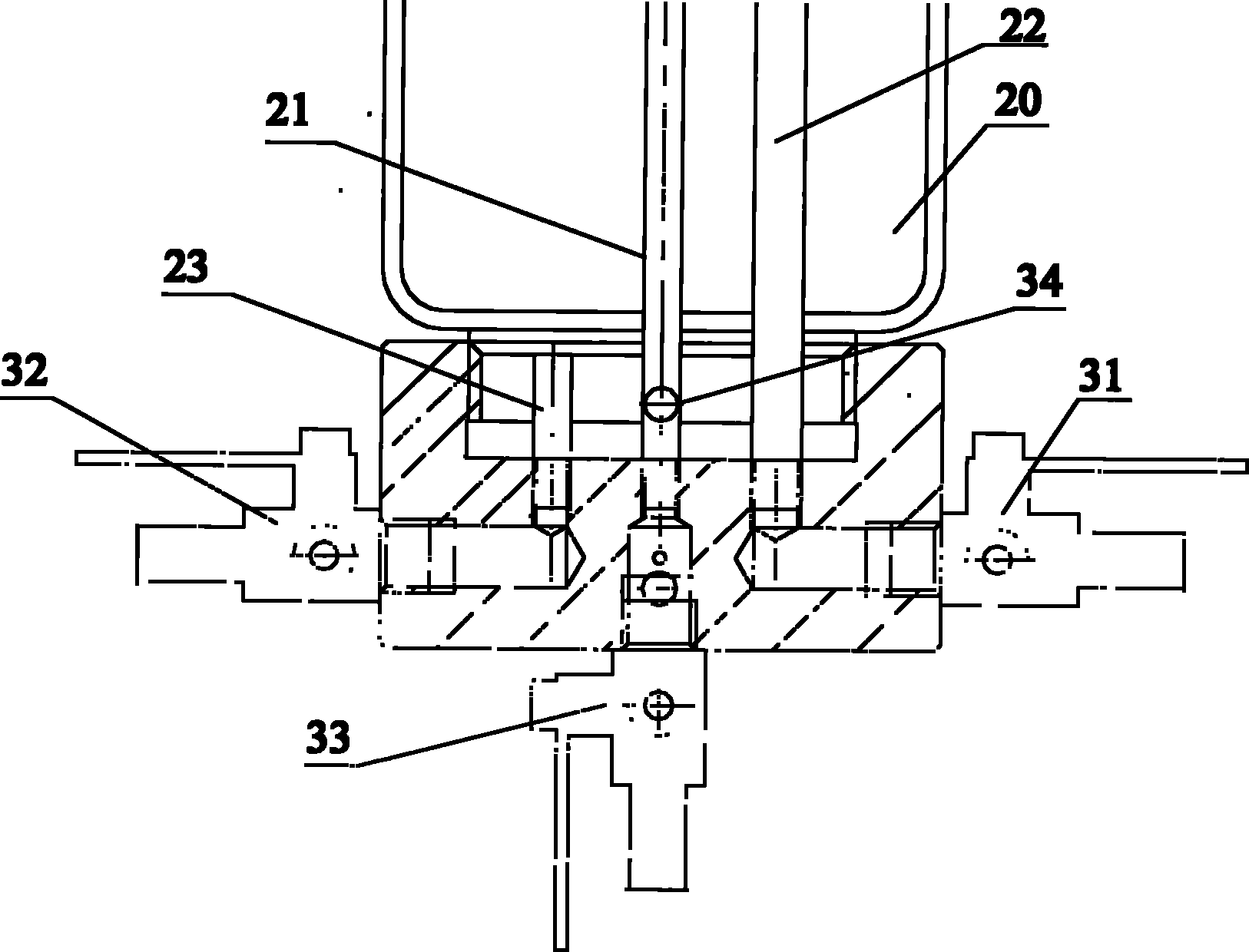

[0026] Such as figure 1 As shown, the oil filling device in this embodiment uses a high-strength vacuum oil tank 20 as an oil storage device, and is equipped with a rotary vane vacuum pump 10 with a pumping speed of 0.5 liters per second as a power. The vacuum oil tank 20 is provided with a suction pipe 21 connected with the vacuum pump 10 and controlled on and off by the third valve 33; Pipe 22, and the oil tank 20 is also provided with an oil filling pipe 23 that communicates with the oil outlet pipe 42 and controls the switch through the second valve 32. The above-mentioned first valve 31 , second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com