A method for preparing polyphenylene sulfide thermoplastic prepreg with improved permeability

A polyphenylene sulfide and prepreg technology, which is applied in the field of preparing polyphenylene sulfide thermoplastic prepregs, can solve the problems of difficult impregnation of thermoplastic resins and poor impregnation effects, and achieve the promotion of uniform dispersion time and uniform resin content , to promote the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

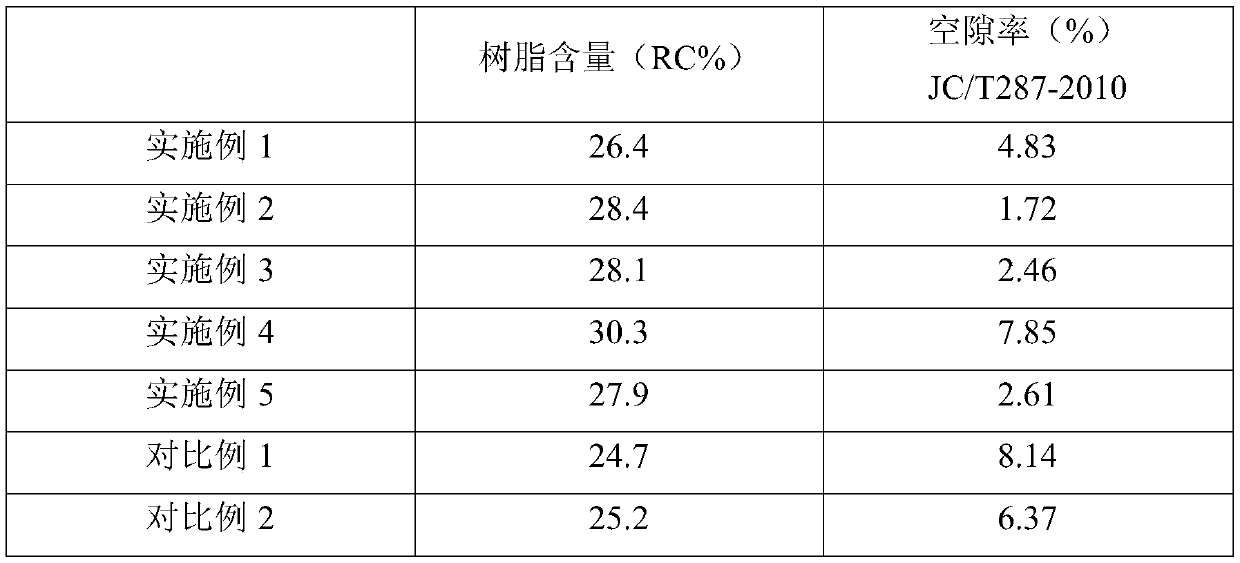

Examples

Embodiment 1

[0039] (1) The polyphenylene sulfide particles were ground in a liquid nitrogen pulverizer at -5°C for 30-120 minutes to obtain three powder particle sizes: 30um (R1), 75um (R2), and 120um (R3).

[0040] (2) Mix powders of three different particle sizes by a high-speed mixer in proportion, R1:R2:R3 (mass ratio)=1:2:7.

[0041] (3) Mix 50 parts of polyphenylene sulfide powder, 150 parts of deionized water, 3 parts of surfactant (fatty alcohol polyoxyethylene ether), 0.5 parts of defoamer BYK-A530, stir under mechanical stirring and ultrasonic vibration 40min. The conductivity of the deionized water used is 10us / cm.

[0042] (4) Preparation of carbon fiber thermoplastic prepreg: pour the above slurry into the dipping tank; carbon fiber (FAW: 100g / m 2 ) is drawn from the creel to weave the yarn, and the sizing agent on the surface of the carbon fiber is removed through a high-temperature furnace at 300°C, and passed through the dipping tank at a line speed of 3m / min to make the...

Embodiment 2

[0044] In this example, compared with Example 1, the amount of small particle size powder used is increased, and the amount of defoamer used is increased to improve the penetration effect of polyphenylene sulfide.

[0045] (1) The polyphenylene sulfide particles were ground in a liquid nitrogen pulverizer at -5°C for 30-120 minutes to obtain three powder particle sizes: 30um (R1), 75um (R2), and 120um (R3).

[0046] (2) Mix powders of three different particle sizes by a high-speed mixer according to the ratio, R1:R2:R3 (mass ratio)=4:3:3.

[0047] (3) Mix 50 parts of polyphenylene sulfide powder, 150 parts of deionized water, 3 parts of surfactant fatty alcohol polyoxyethylene ether, 2.5 parts of defoamer BYK-A 530, and stir for 40 minutes under mechanical stirring and ultrasonic vibration . The conductivity of the deionized water used is 10us / cm.

[0048] (4) Preparation of carbon fiber thermoplastic prepreg: pour the above slurry into the dipping tank; carbon fiber (FAW: 1...

Embodiment 3

[0050]Compared with Example 1, this example only increases the amount of powder with a small particle size. The ratio of polyphenylene sulfide powders with three different particle sizes is R1:R2:R3=4:3:3. Others are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com