Patents

Literature

313results about How to "Reduce air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

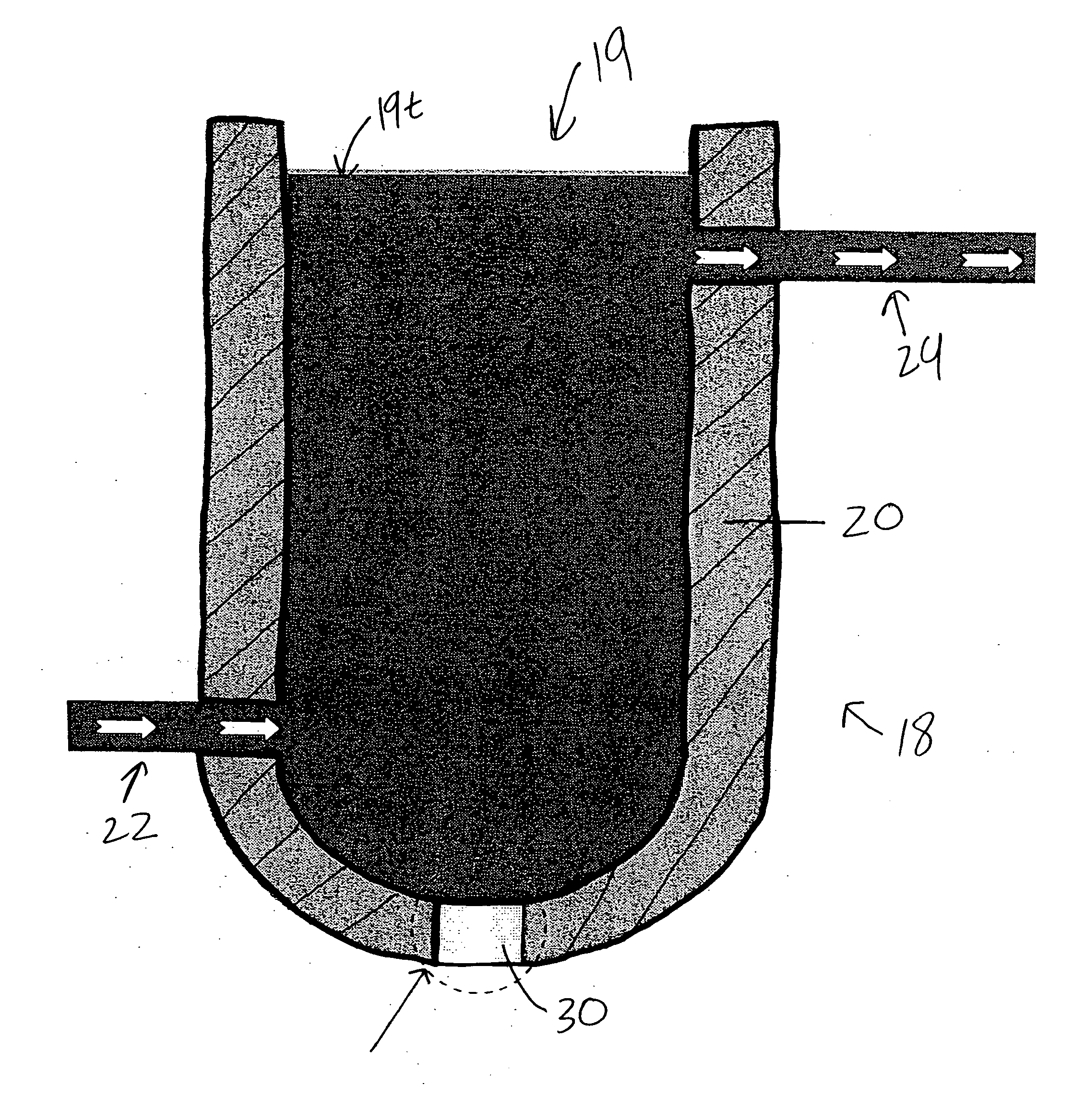

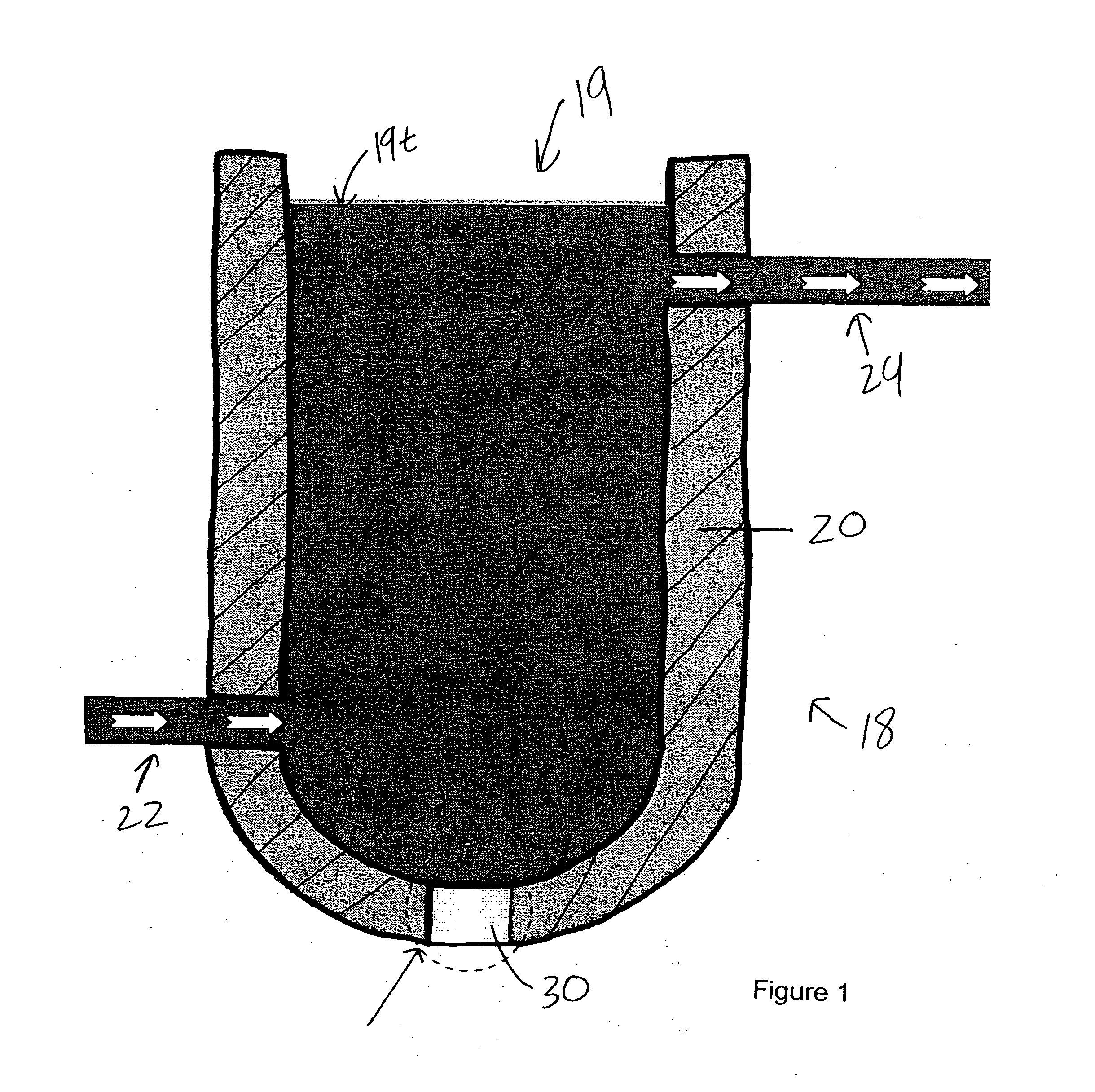

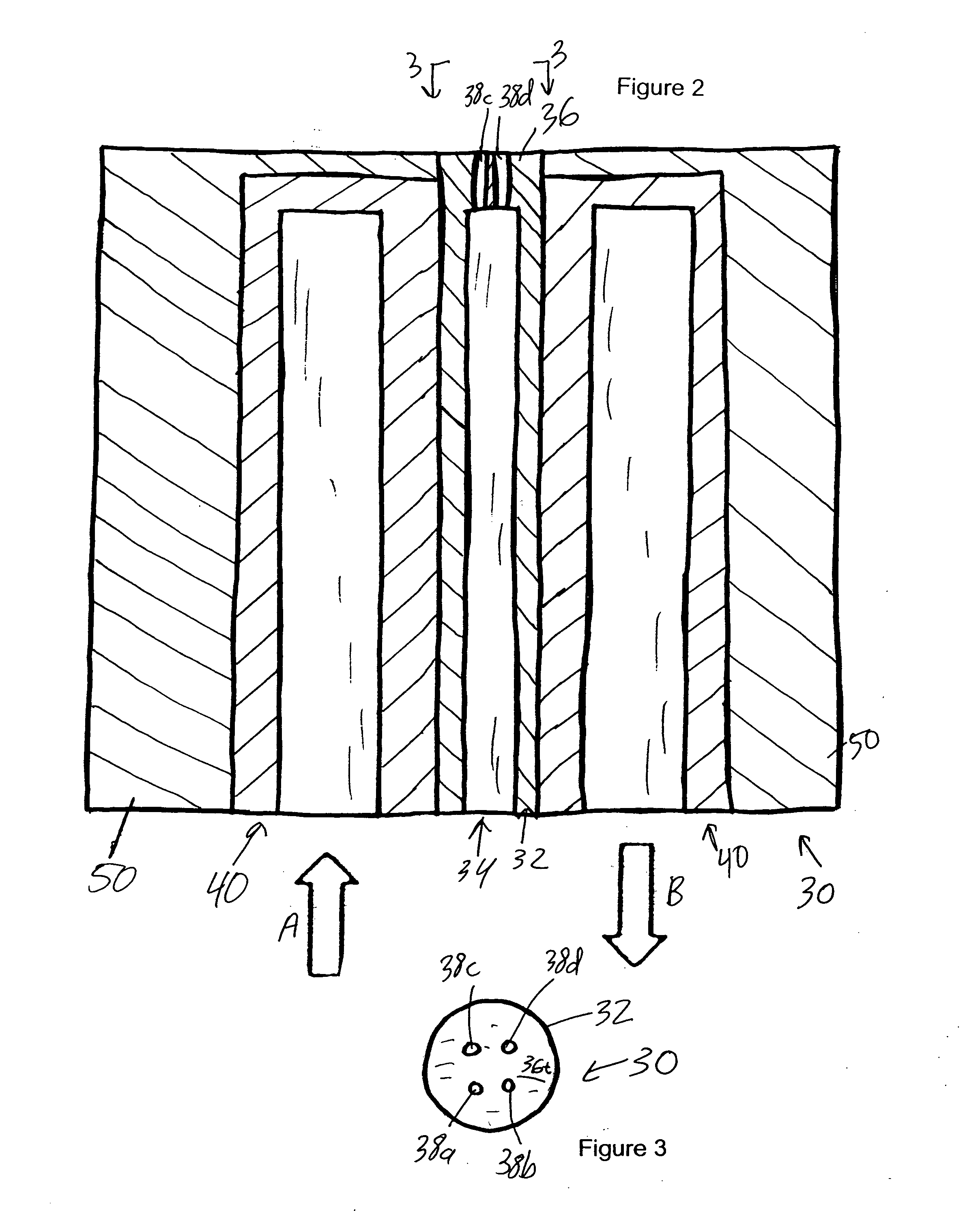

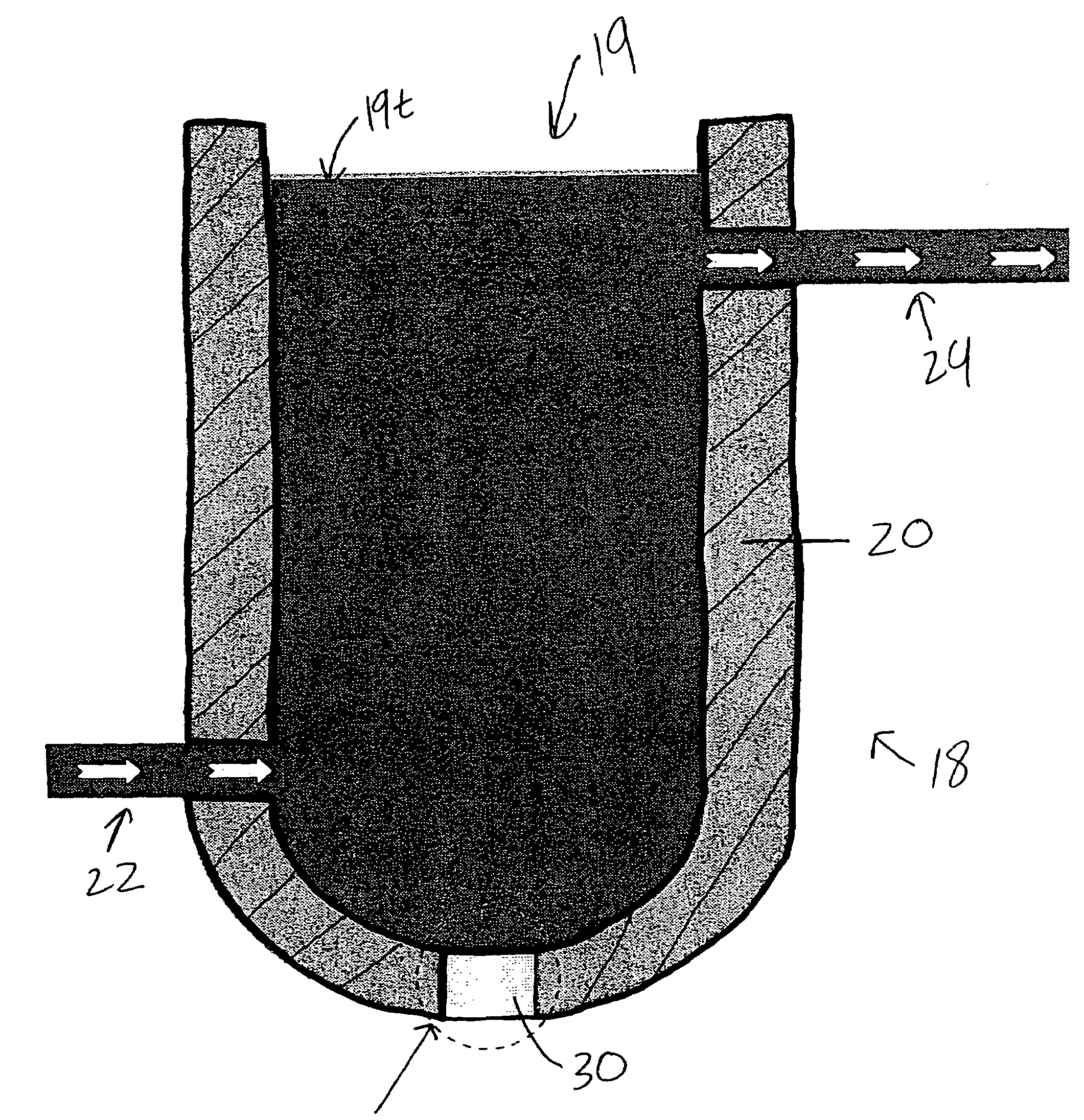

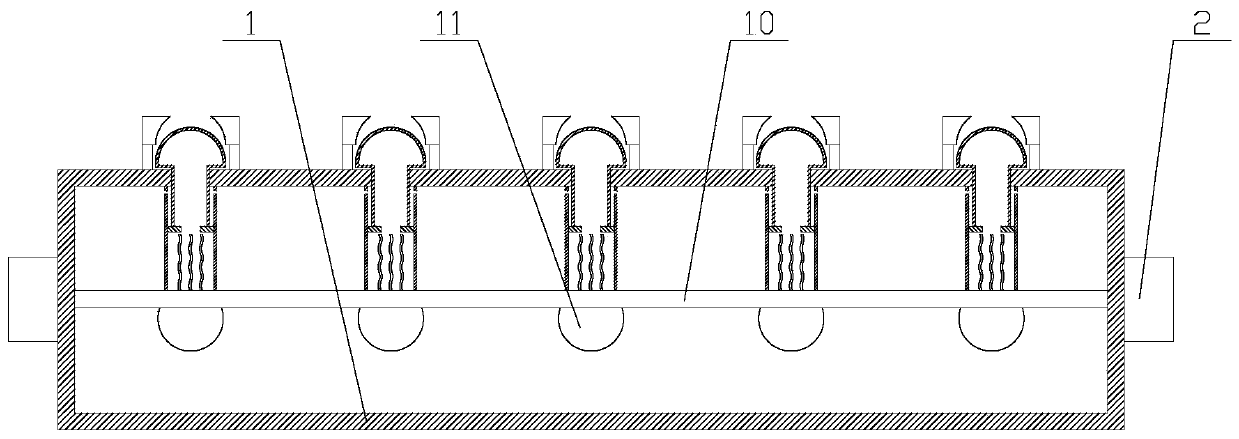

Degassing of molten alloys with the assistance of ultrasonic vibration

InactiveUS20070235159A1Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

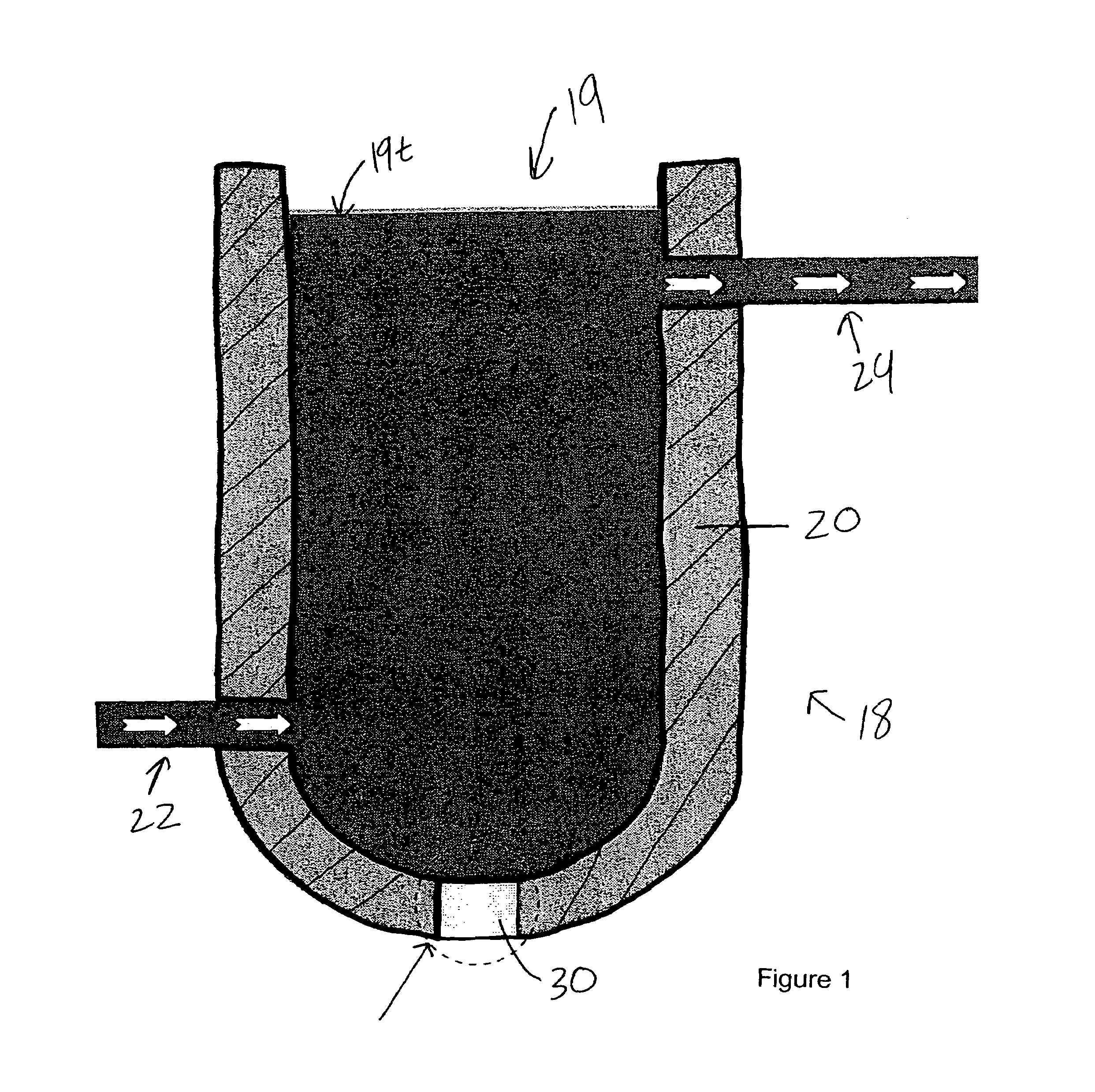

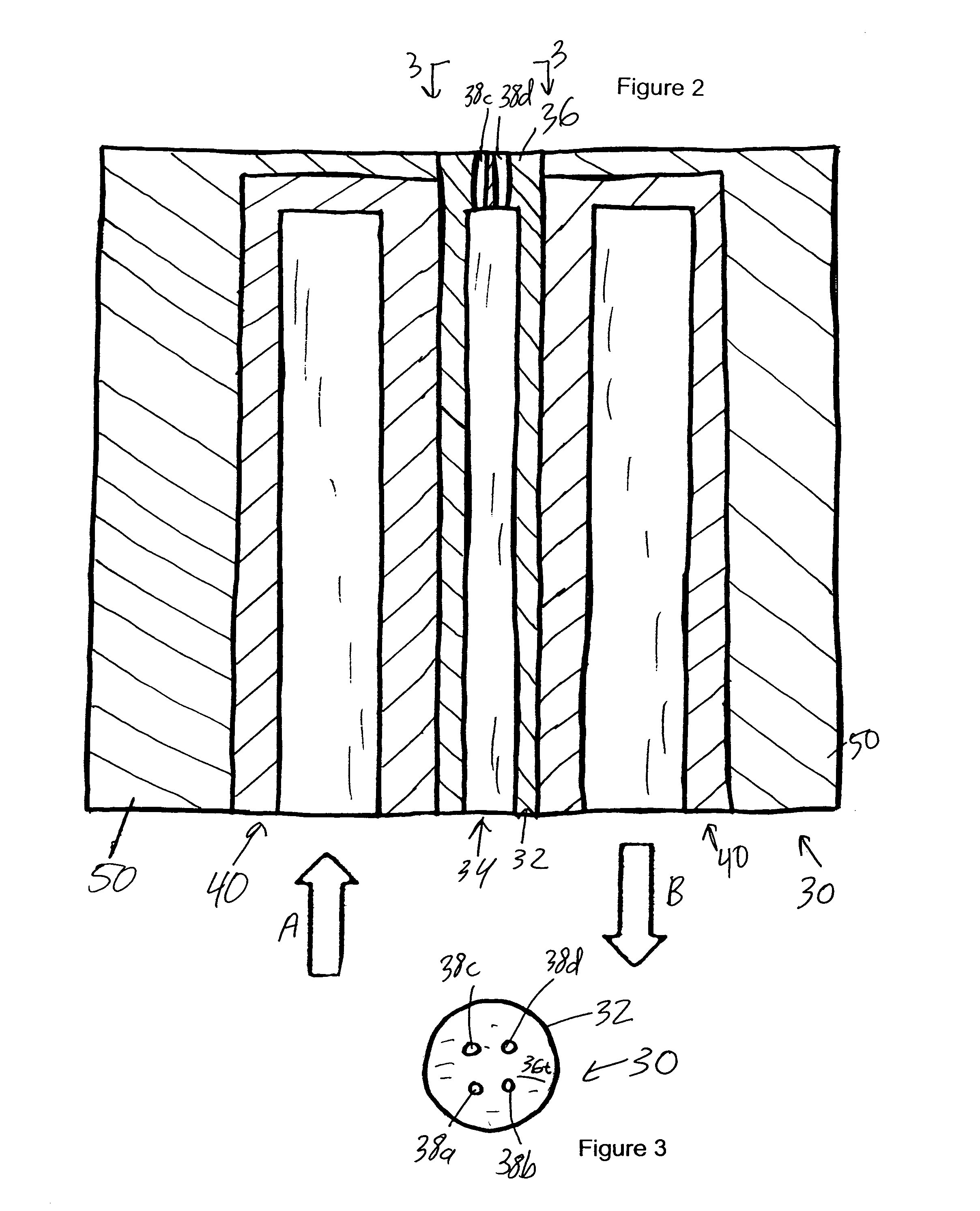

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

Degassing of molten alloys with the assistance of ultrasonic vibration

InactiveUS7682556B2Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

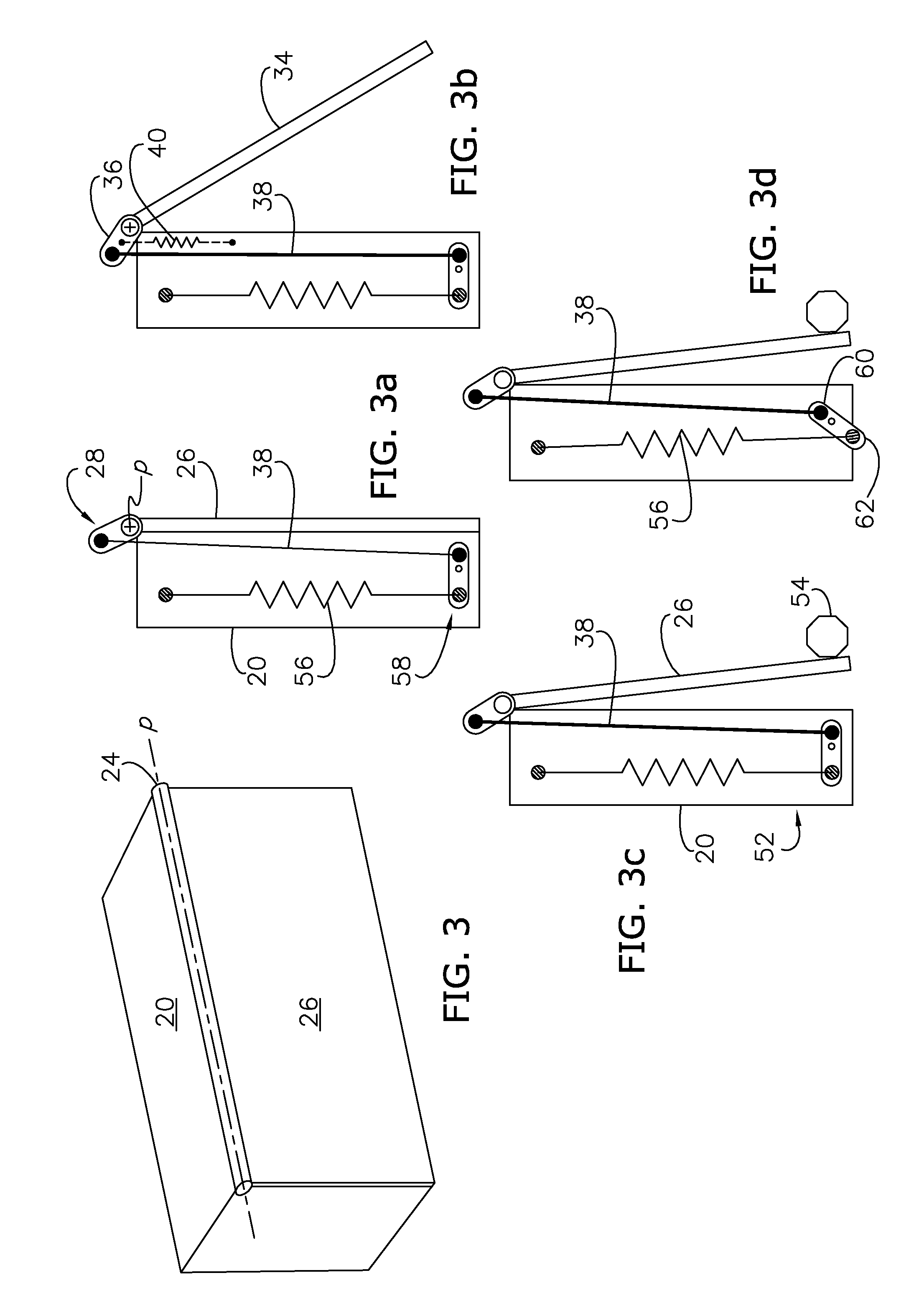

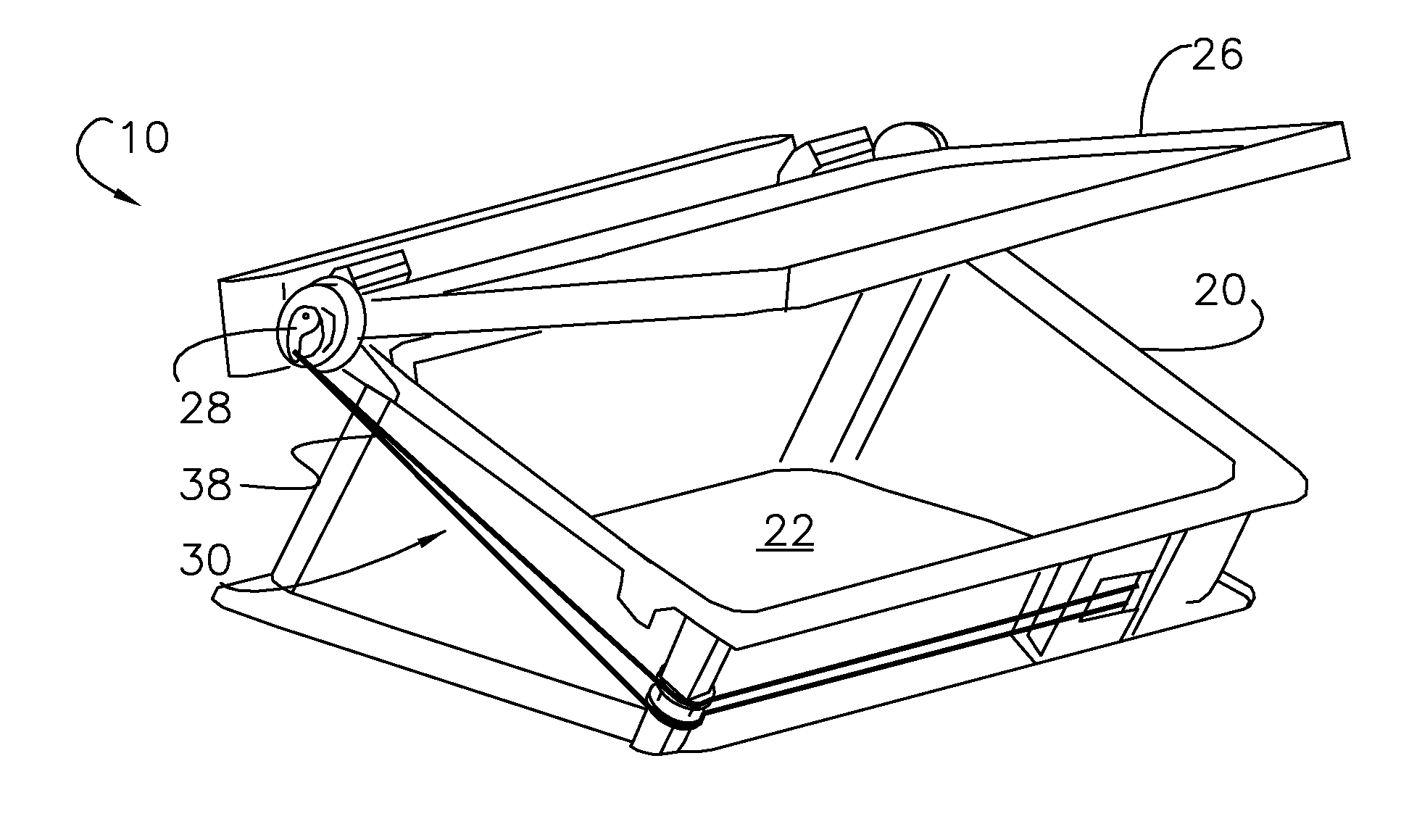

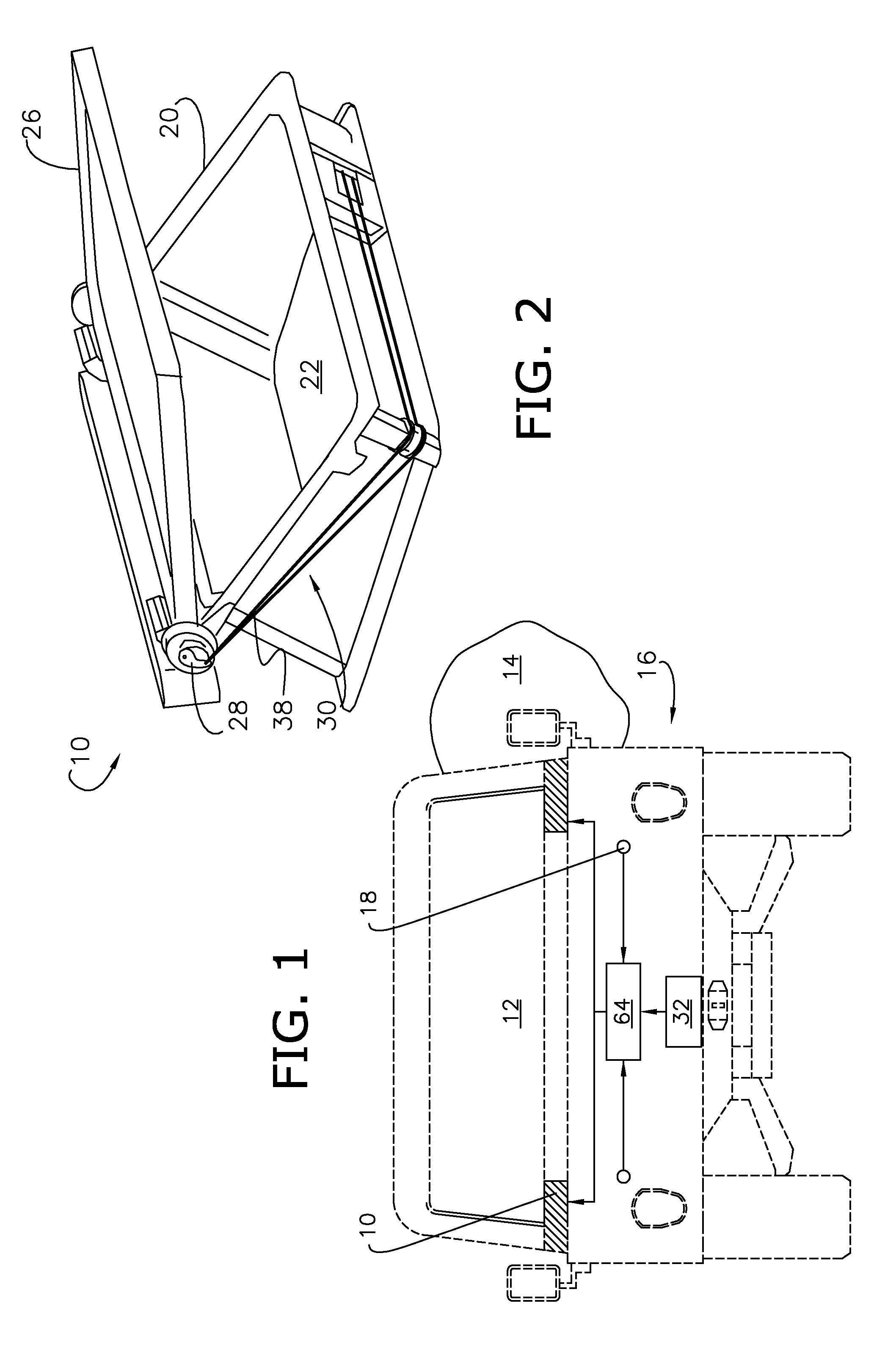

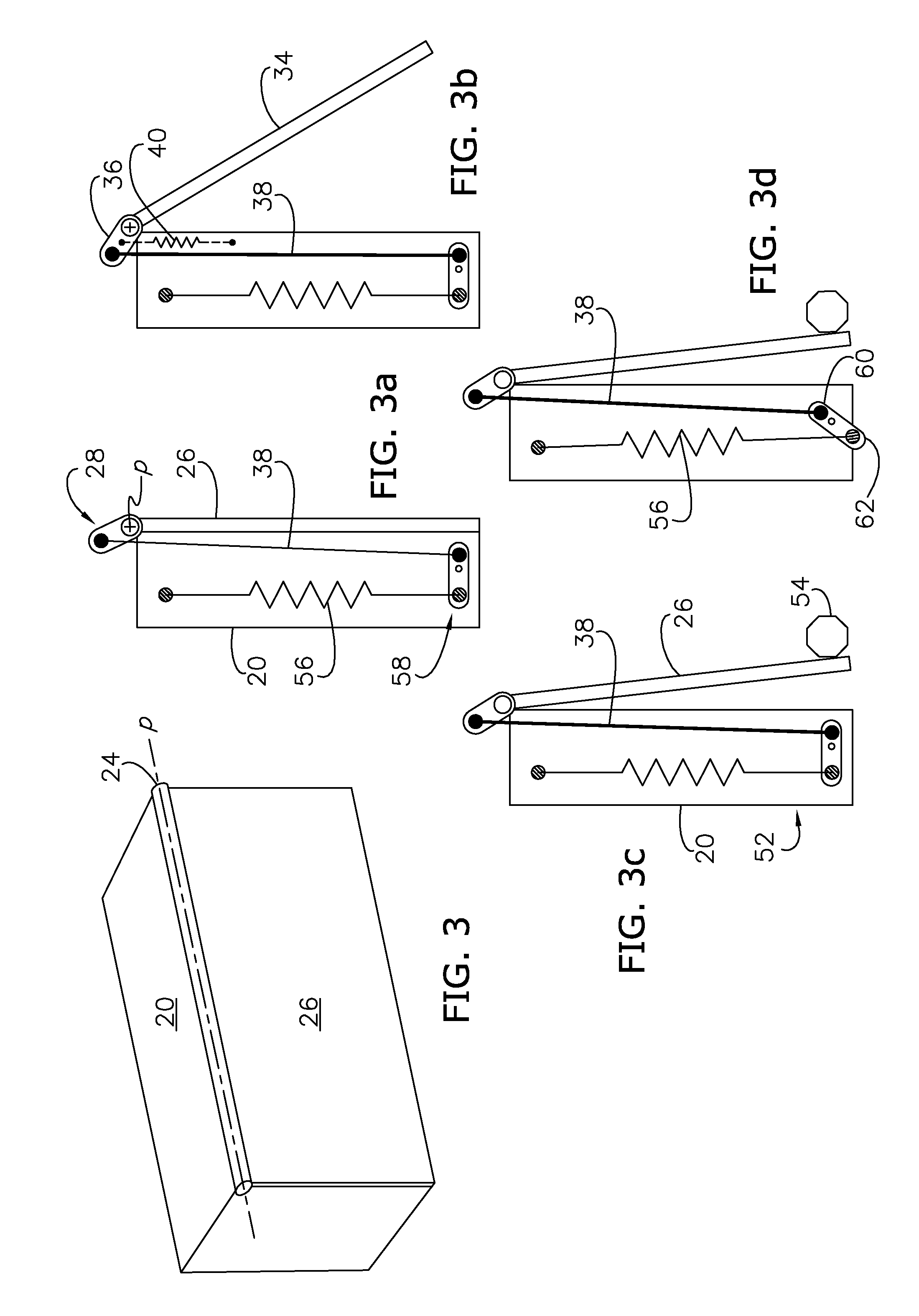

Active material enabled pressure release valves and methods of use

ActiveUS20100099346A1Reduce airReducing boomAir-treating devicesOperating means/releasing devices for valvesEngineeringActuator

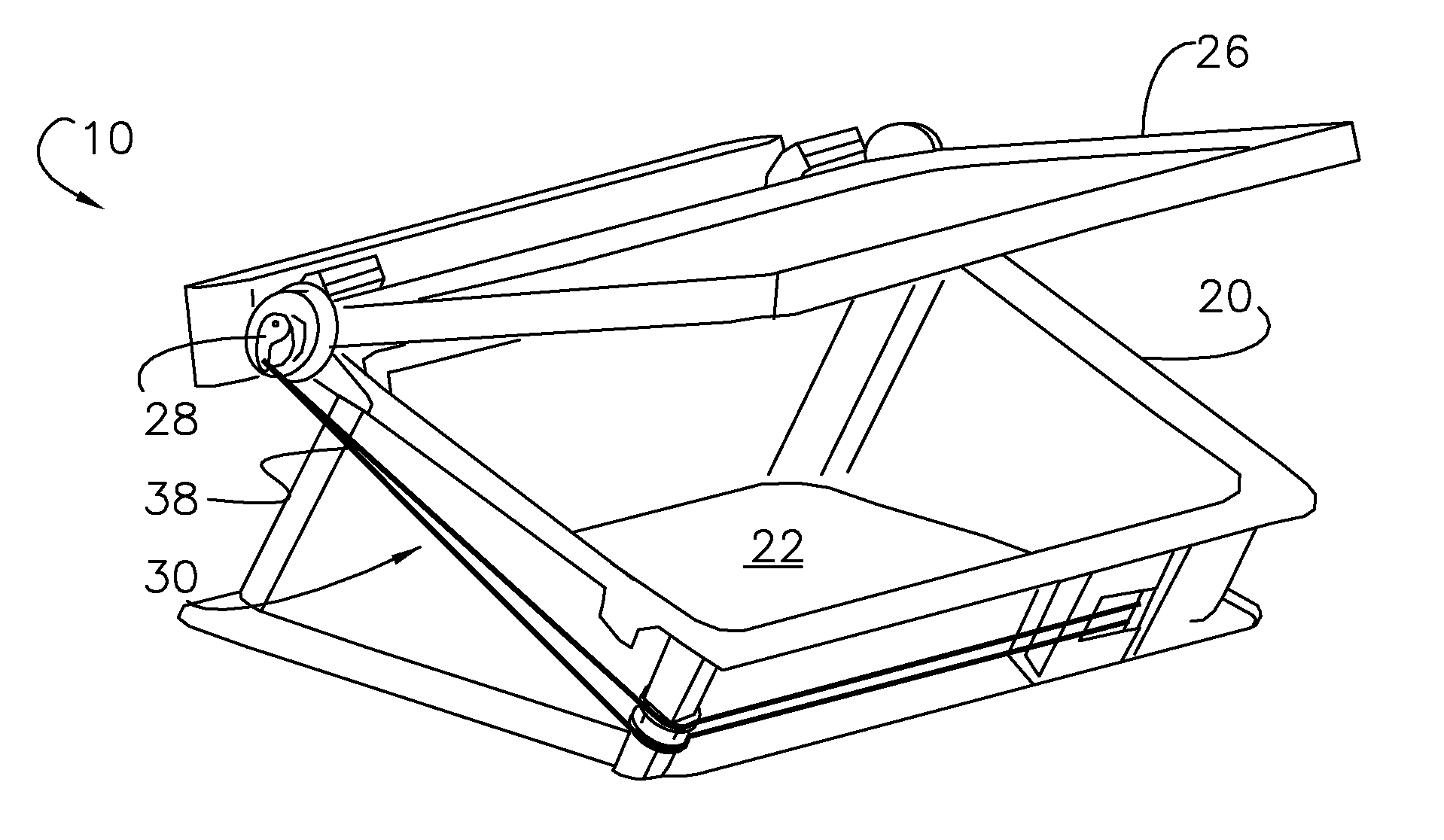

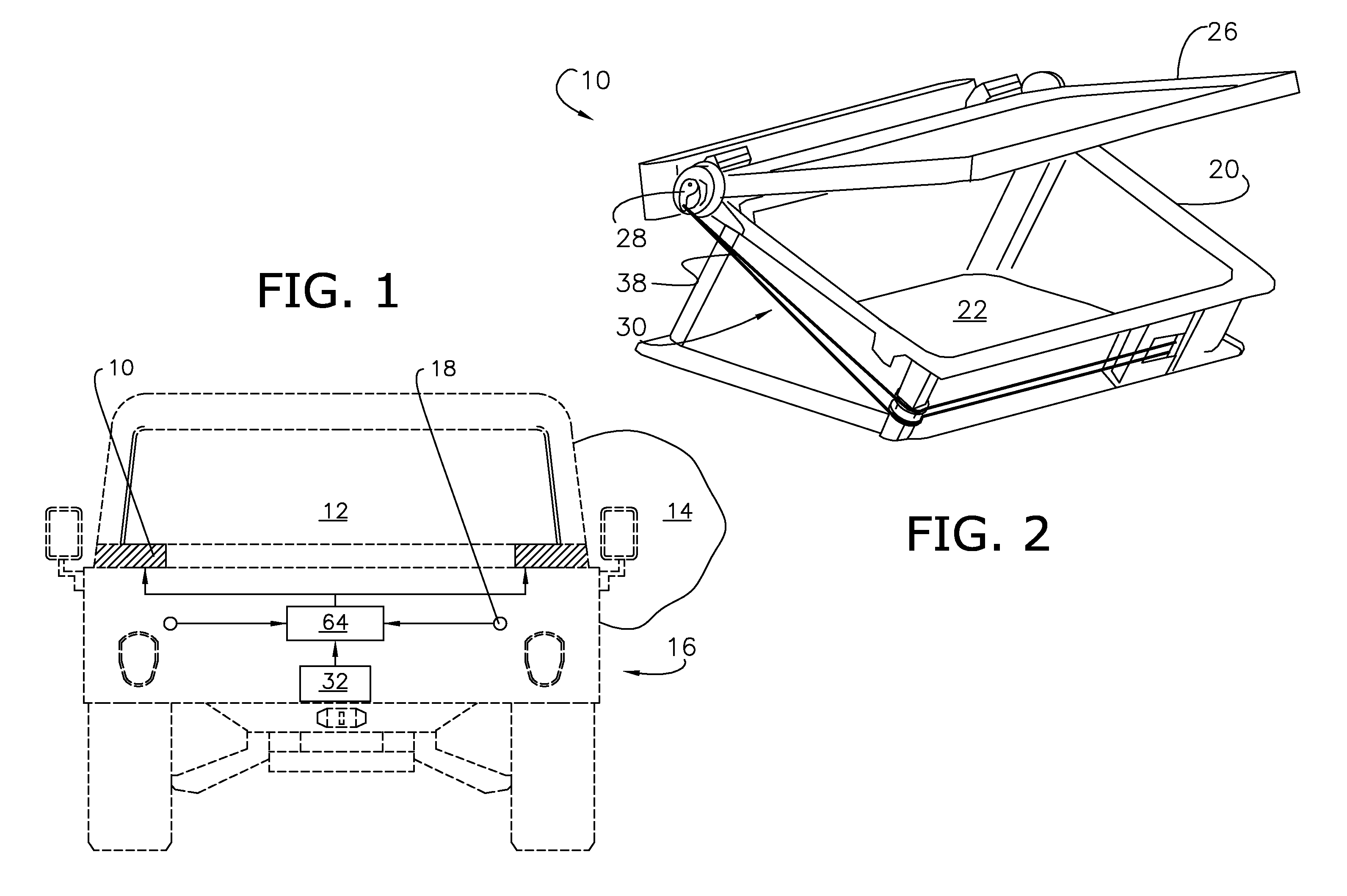

An active pressure relief valve adapted for selectively regulating a condition within an interior compartment generally includes a housing fluidly coupling the compartment to an external environment and defining an opening, an actuator including an active material element operable to effect movement of a flap relative to the opening, a load limit protector coupled to and configured to present a secondary output path for the element, when the flap is unable to move, and / or a latching mechanism coupled to, and configured to engage the flap, so as to retain the flap in a modified condition.

Owner:GM GLOBAL TECH OPERATIONS LLC

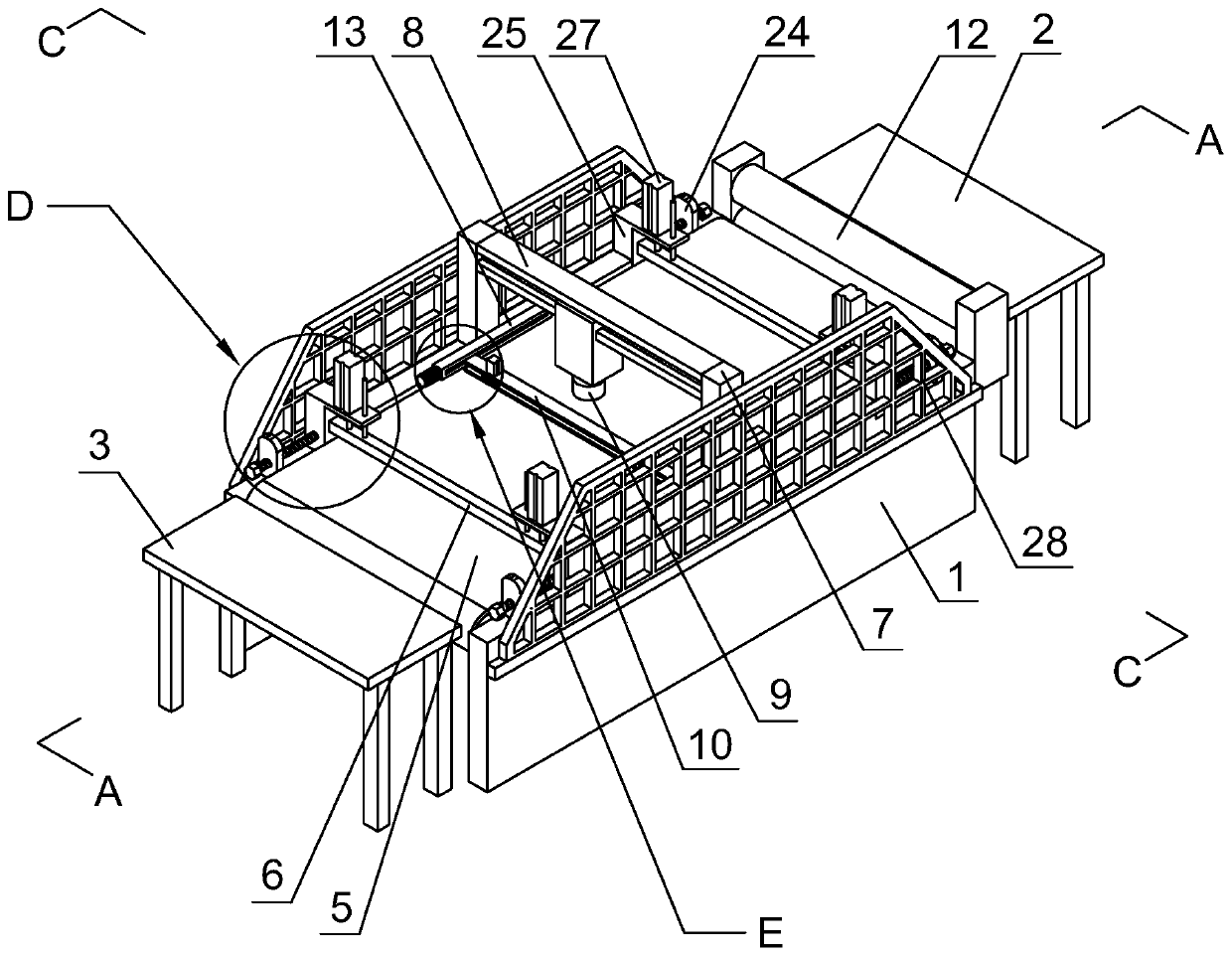

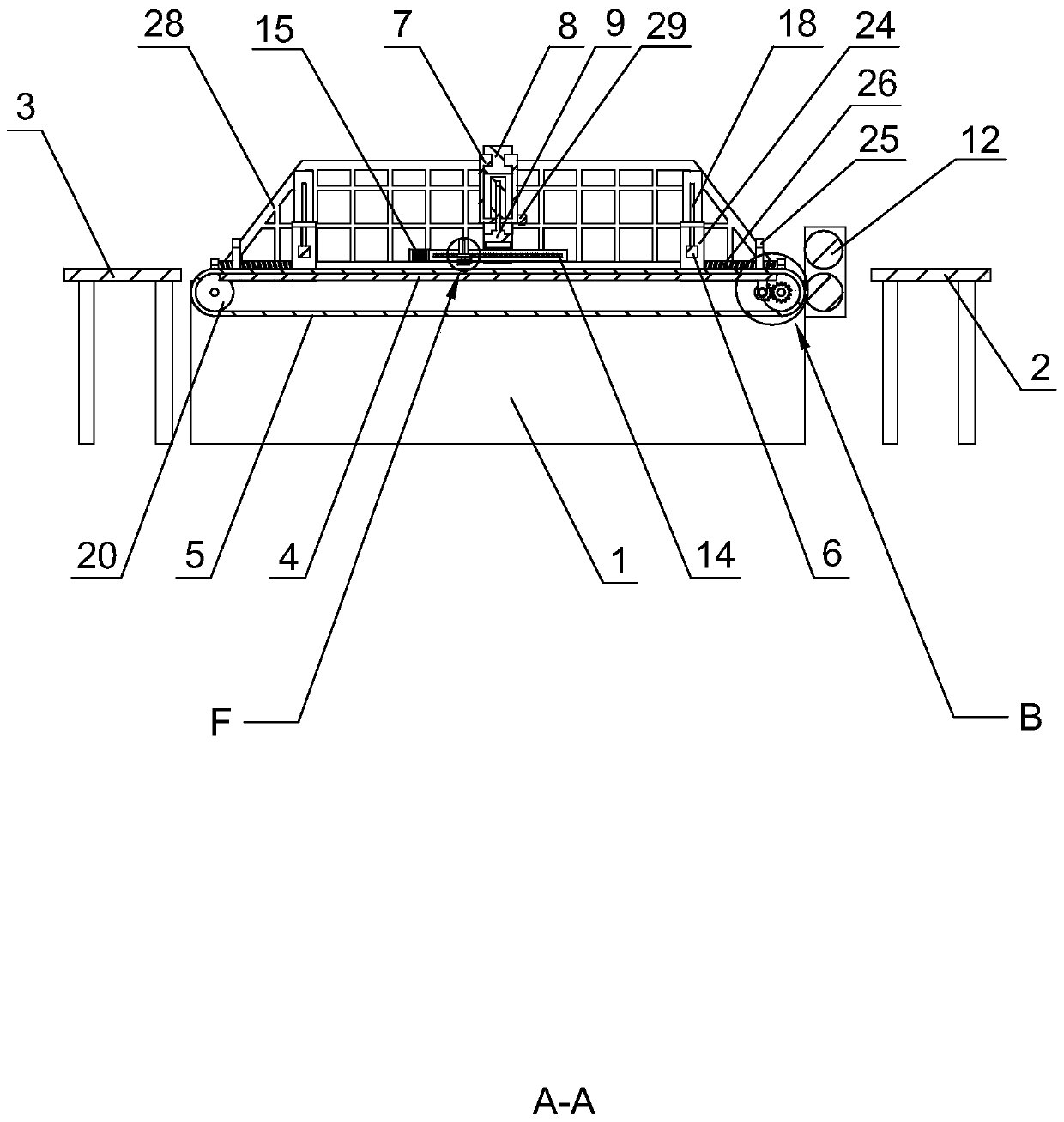

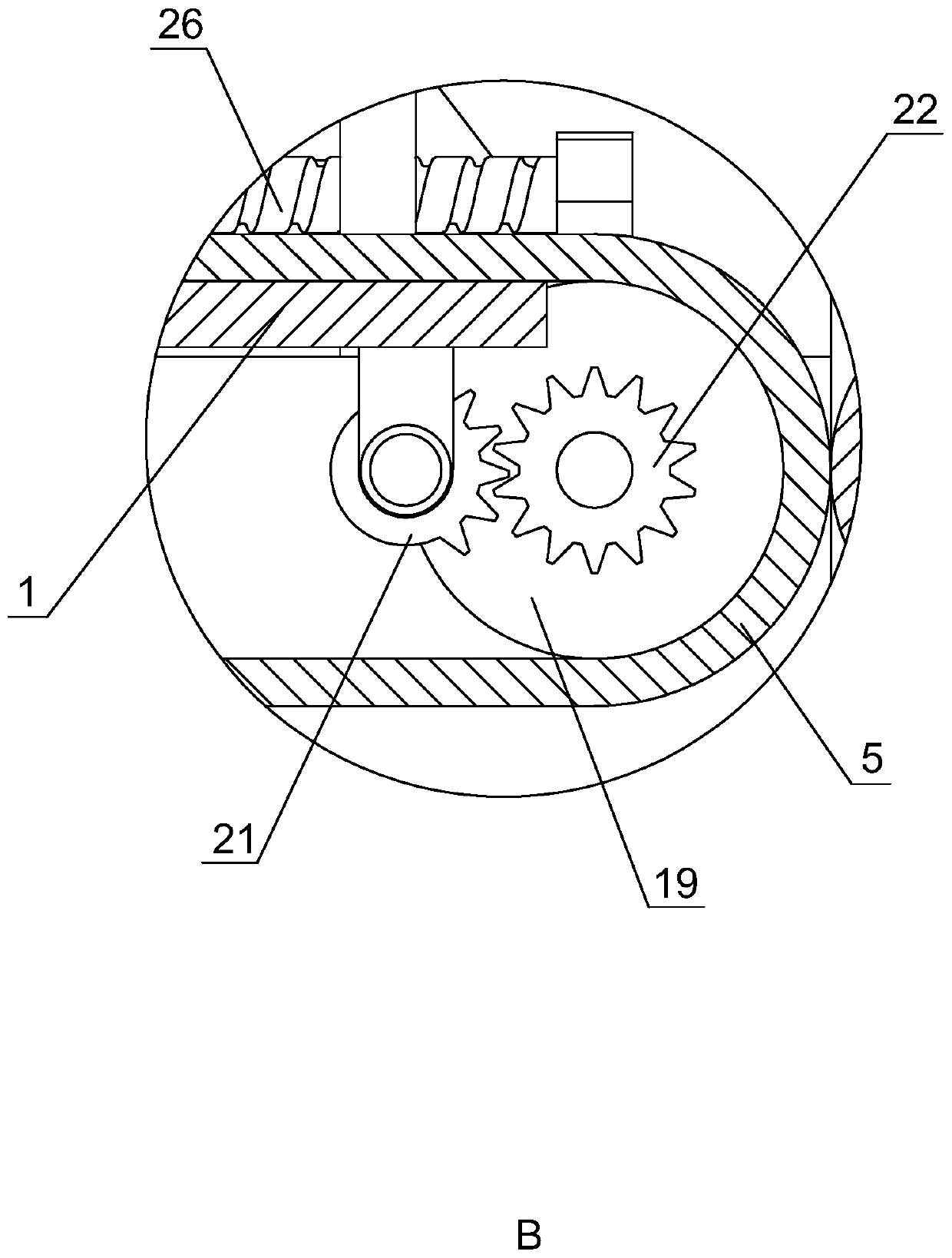

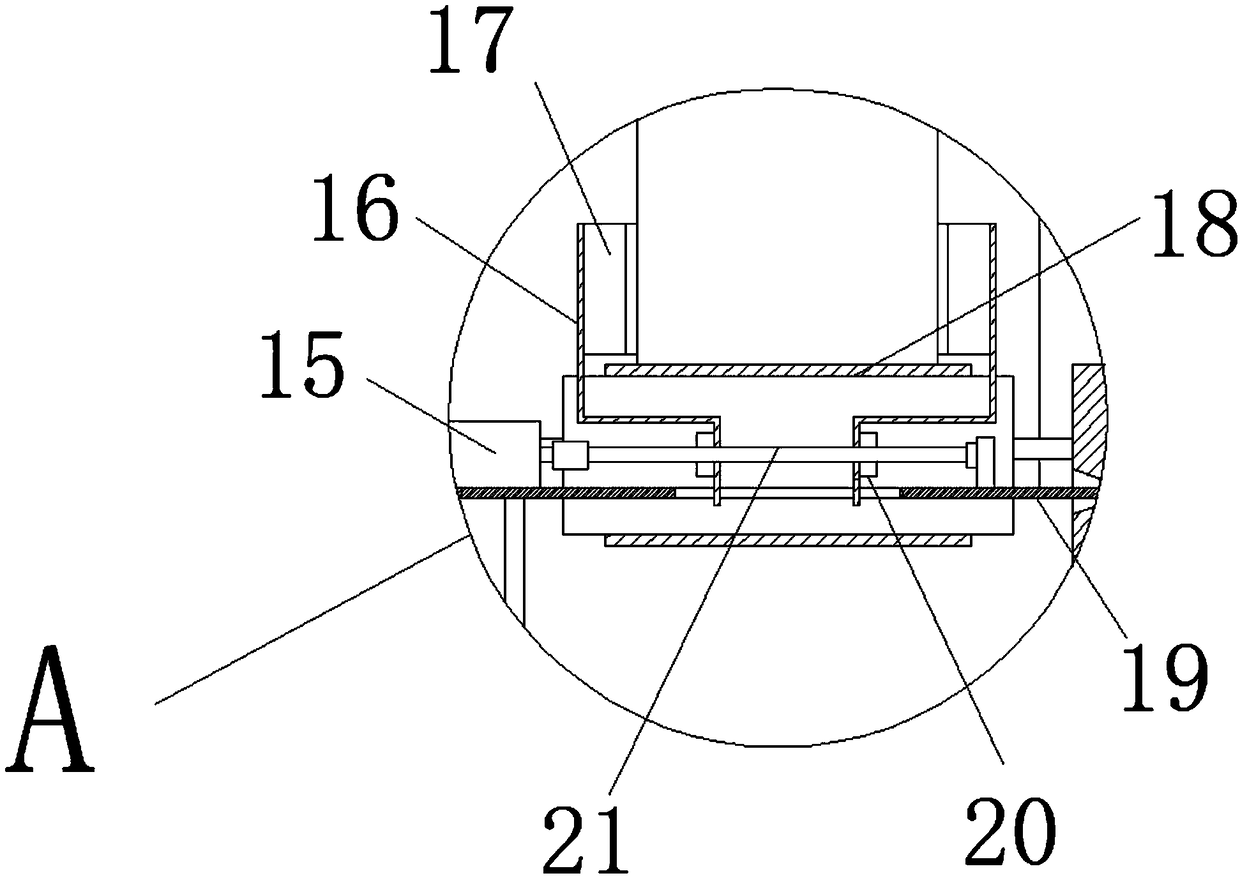

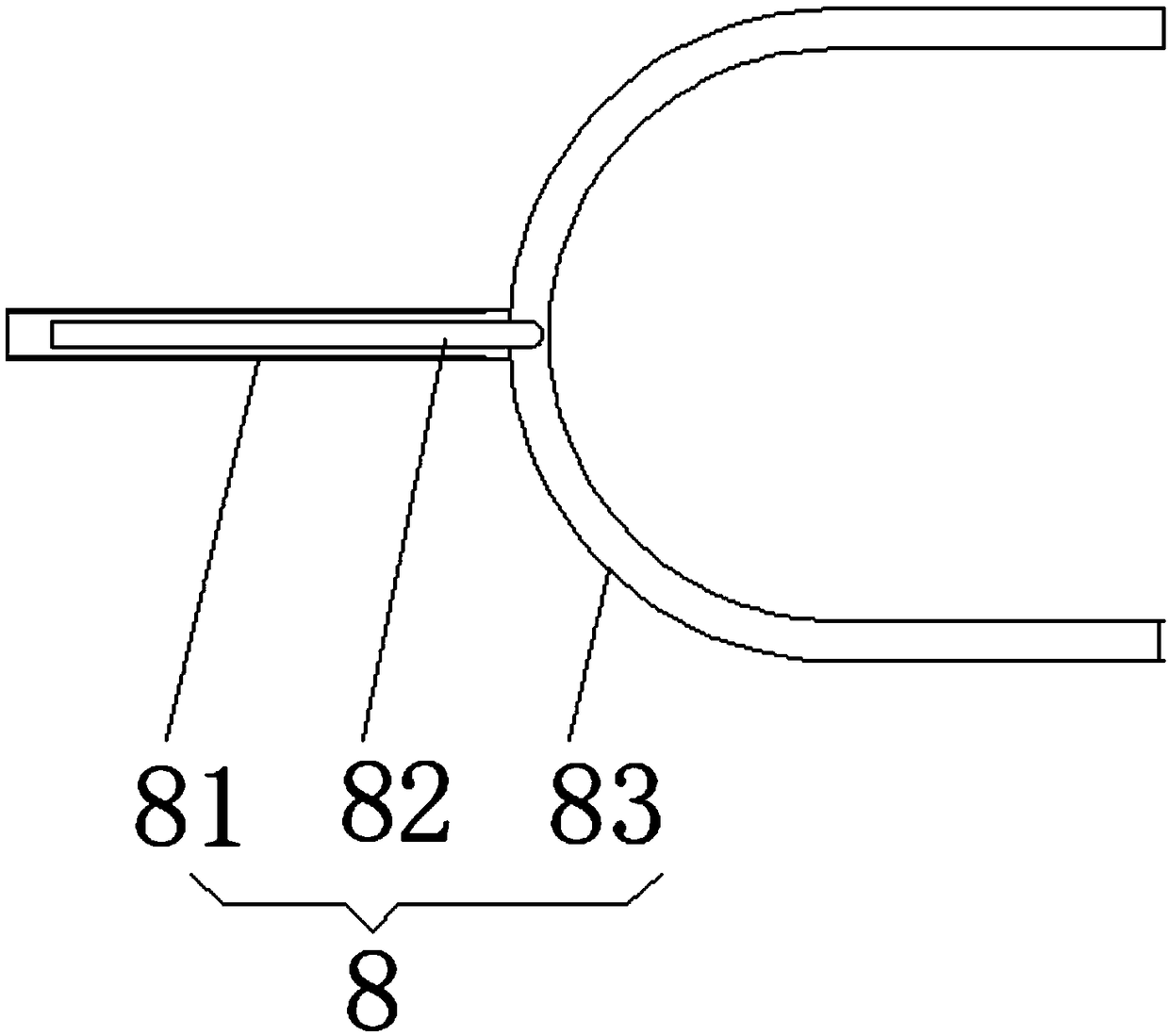

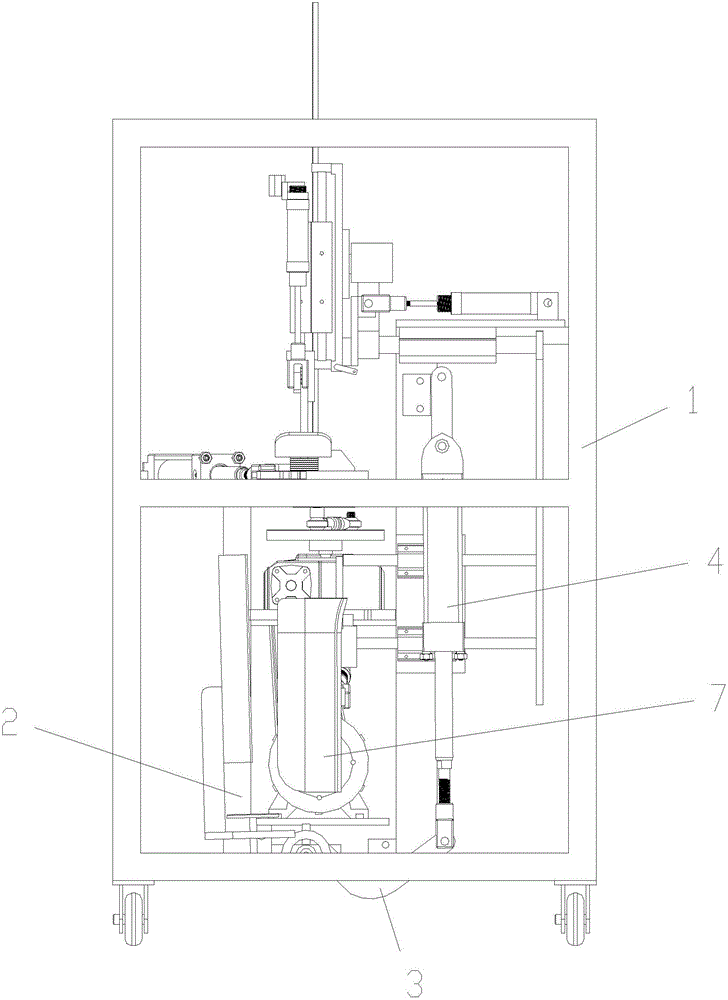

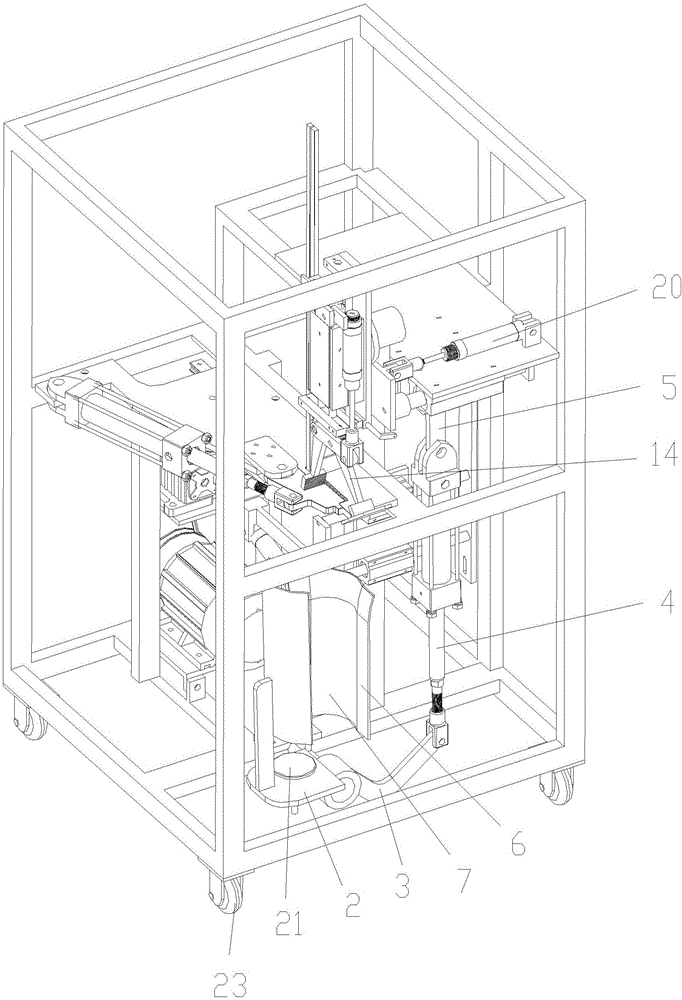

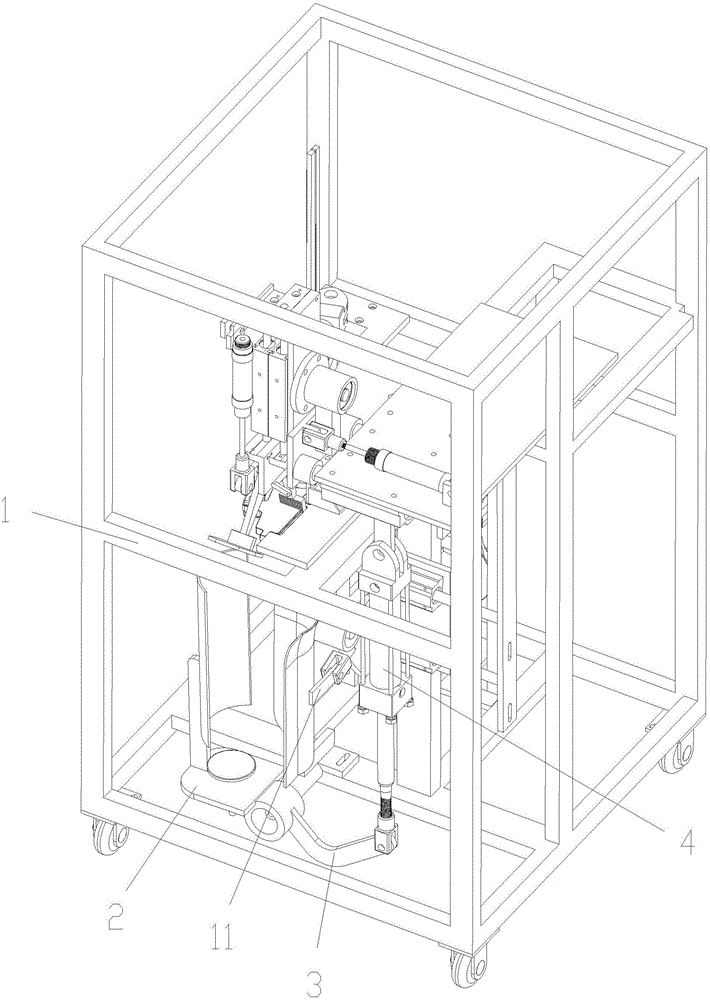

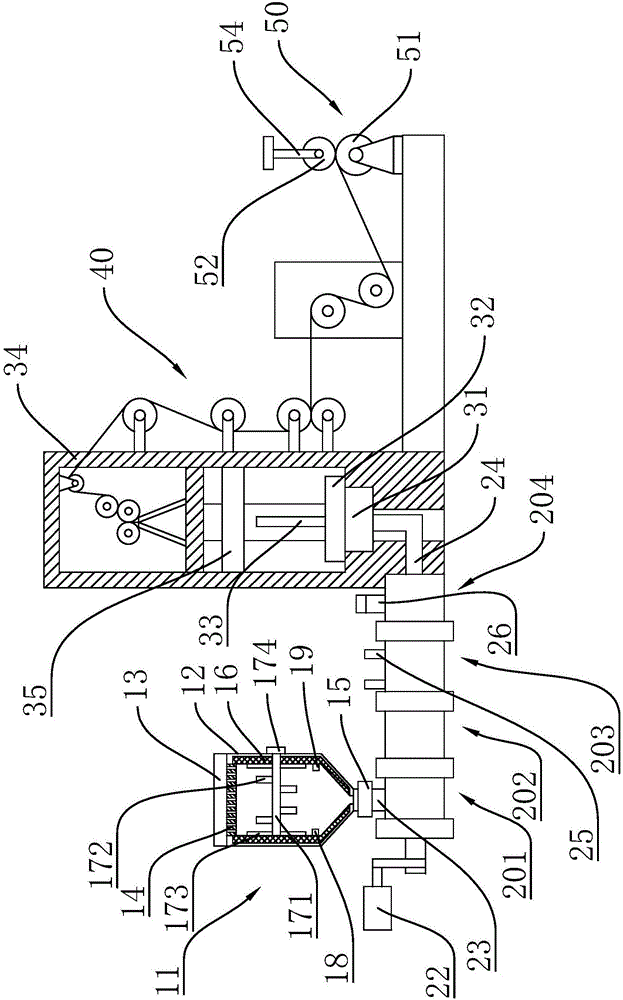

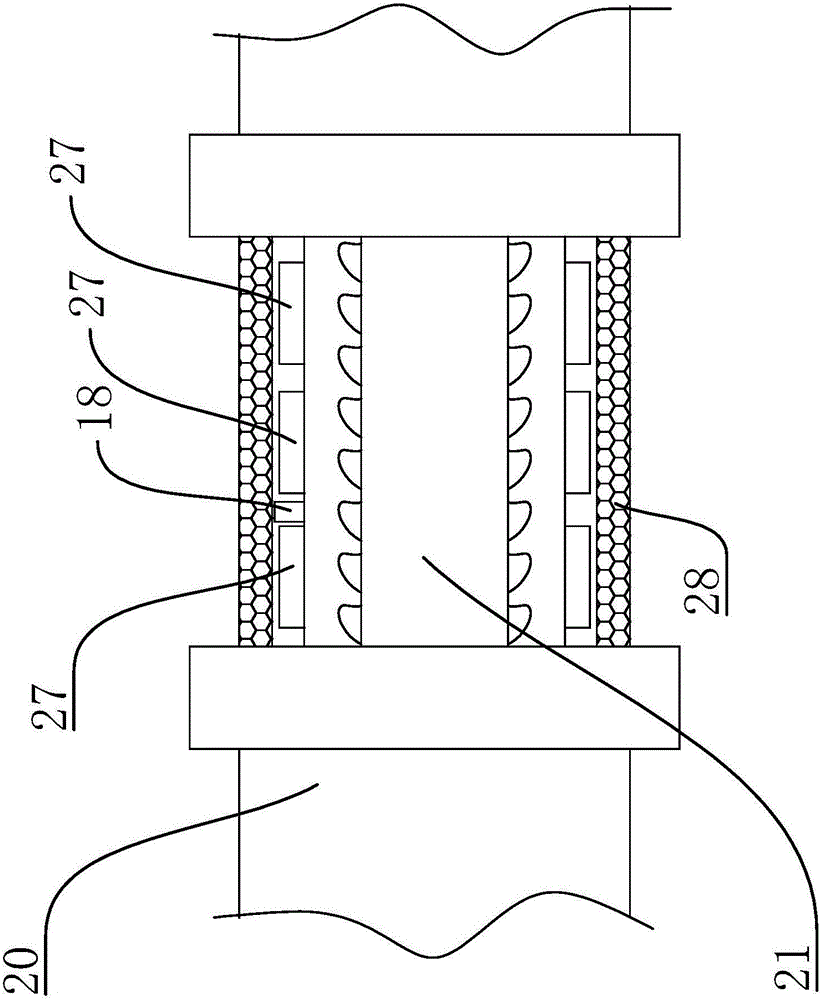

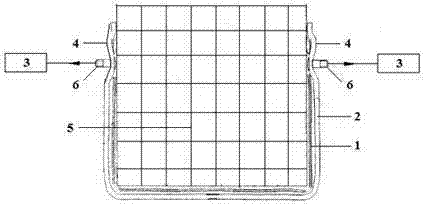

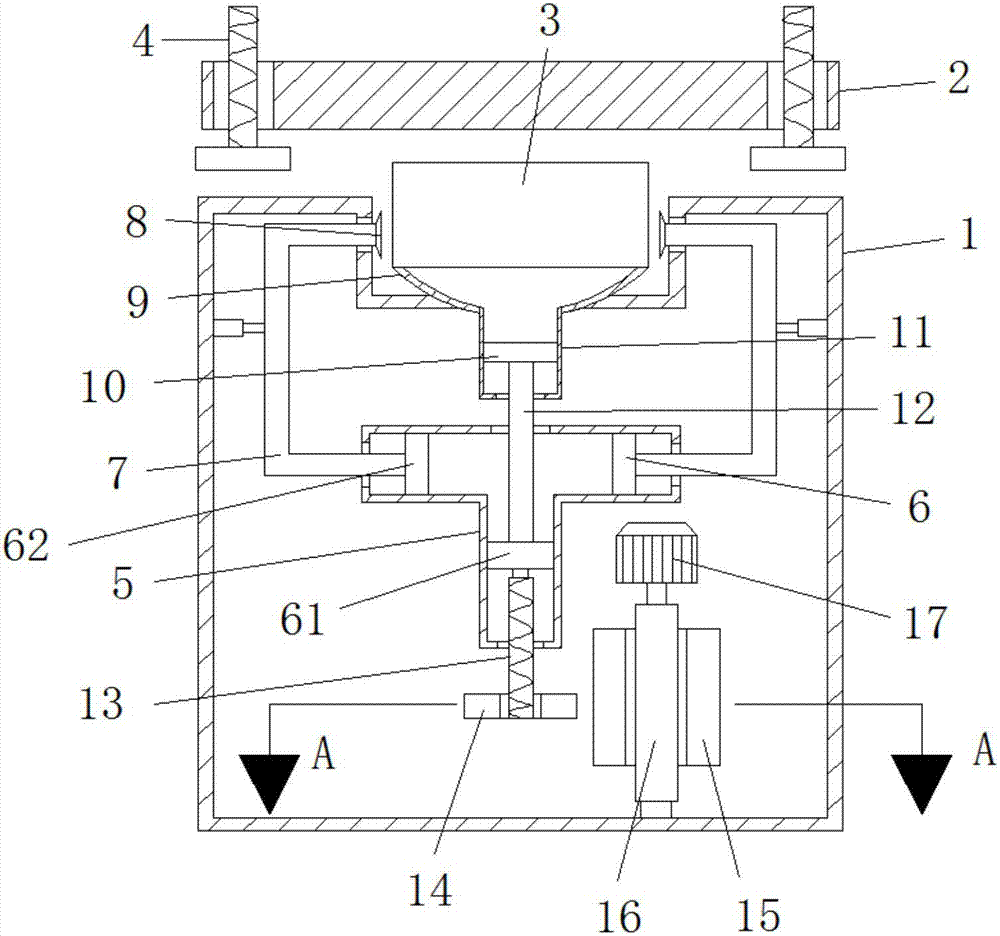

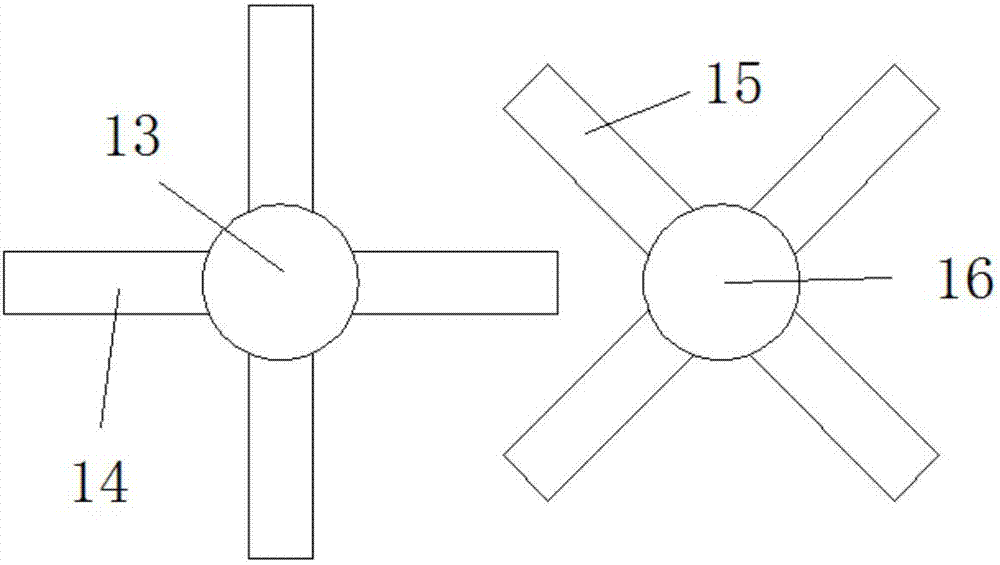

Automatic cutting machine for non-woven fabric

InactiveCN109825998AImprove detection accuracyImprove cutting accuracySevering textilesMetal working apparatusWoven fabricEngineering

The invention discloses an automatic cutting machine for a non-woven fabric, and relates to the technical field of mask fabric cutting devices. The problems that non-woven fabrics are loose, and the cutting positions of the non-woven fabrics are likely to shift, so that non-woven fabrics are wasted are solved. The machine comprises a machine body, a feeding table and a discharging table; a workbench is fixedly arranged inside the machine body, and a conveyor belt is intermittently and rotationally arranged on the workbench; two pressing plates are arranged inside the machine body in a liftingmode; the two sides of the workbench are each fixedly provided with a supporting base, the two supporting bases are jointly fixedly connected with a tool rest, and a cutter is slidably arranged on thetool rest; a transverse beam is slidably arranged between the two supporting bases, a stroking plate is arranged at one side of the beam in a lifting mode; two flattening rollers are rotationally arranged at one side of the machine body. The loose non-woven fabrics are compressed through the flattening rollers, the non-woven fabrics are stroked and compressed by sliding the stroking plate, the non-woven fabric is more flat, the cutting effect of the non-woven fabric is better, the phenomenon that non-woven fabrics are not cut through is avoided, and the mask fabric yield is increased.

Owner:上海即索实业有限公司

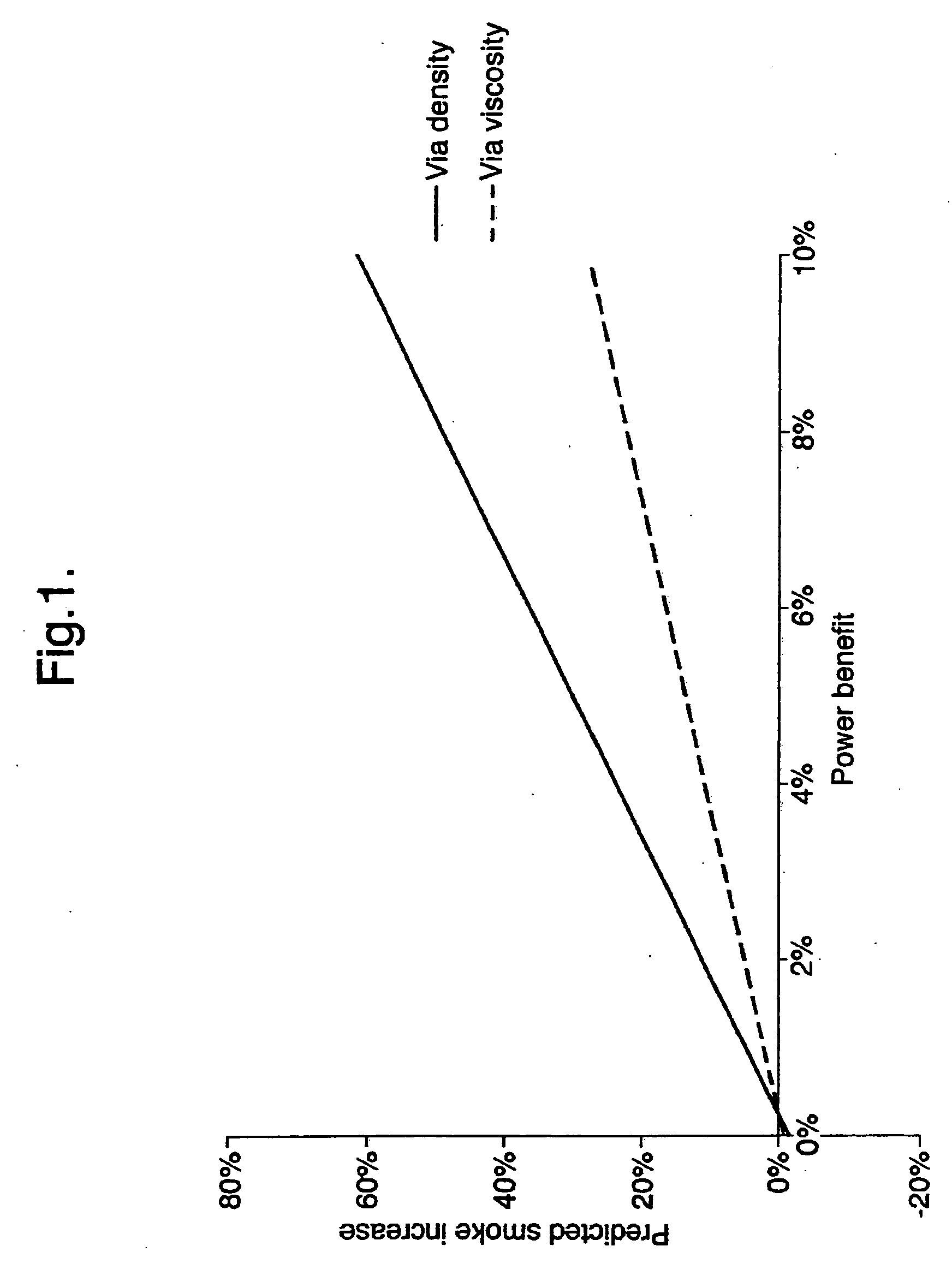

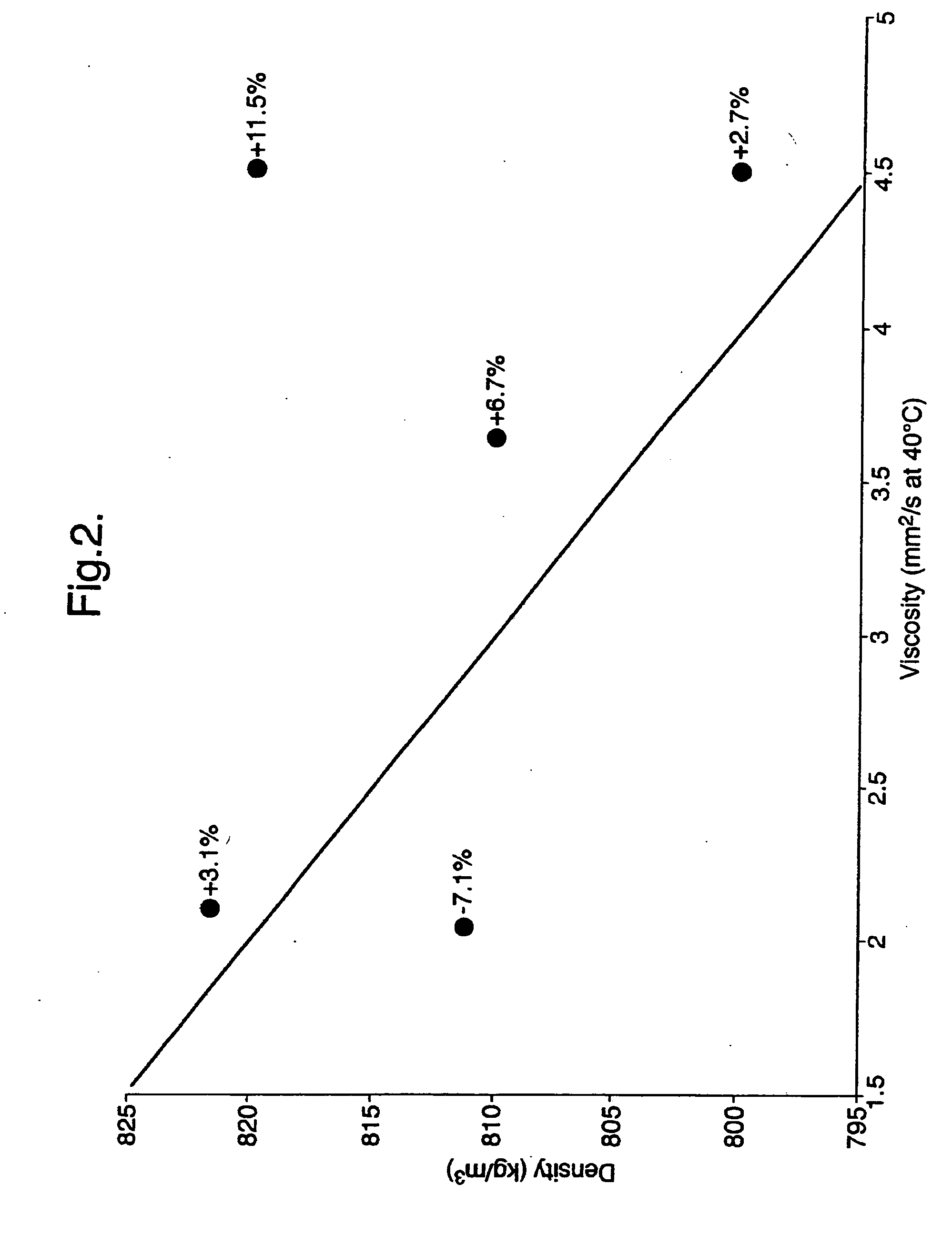

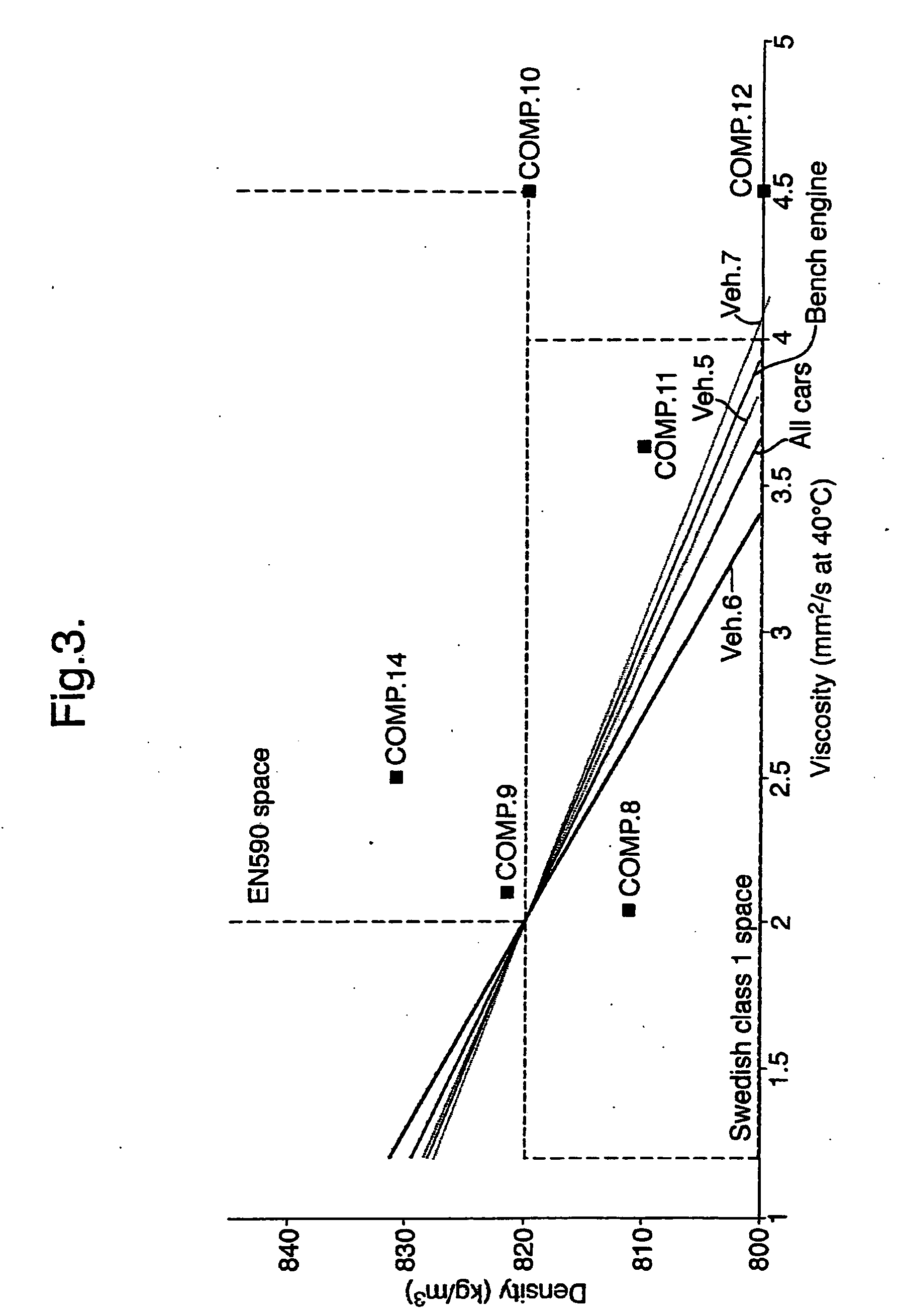

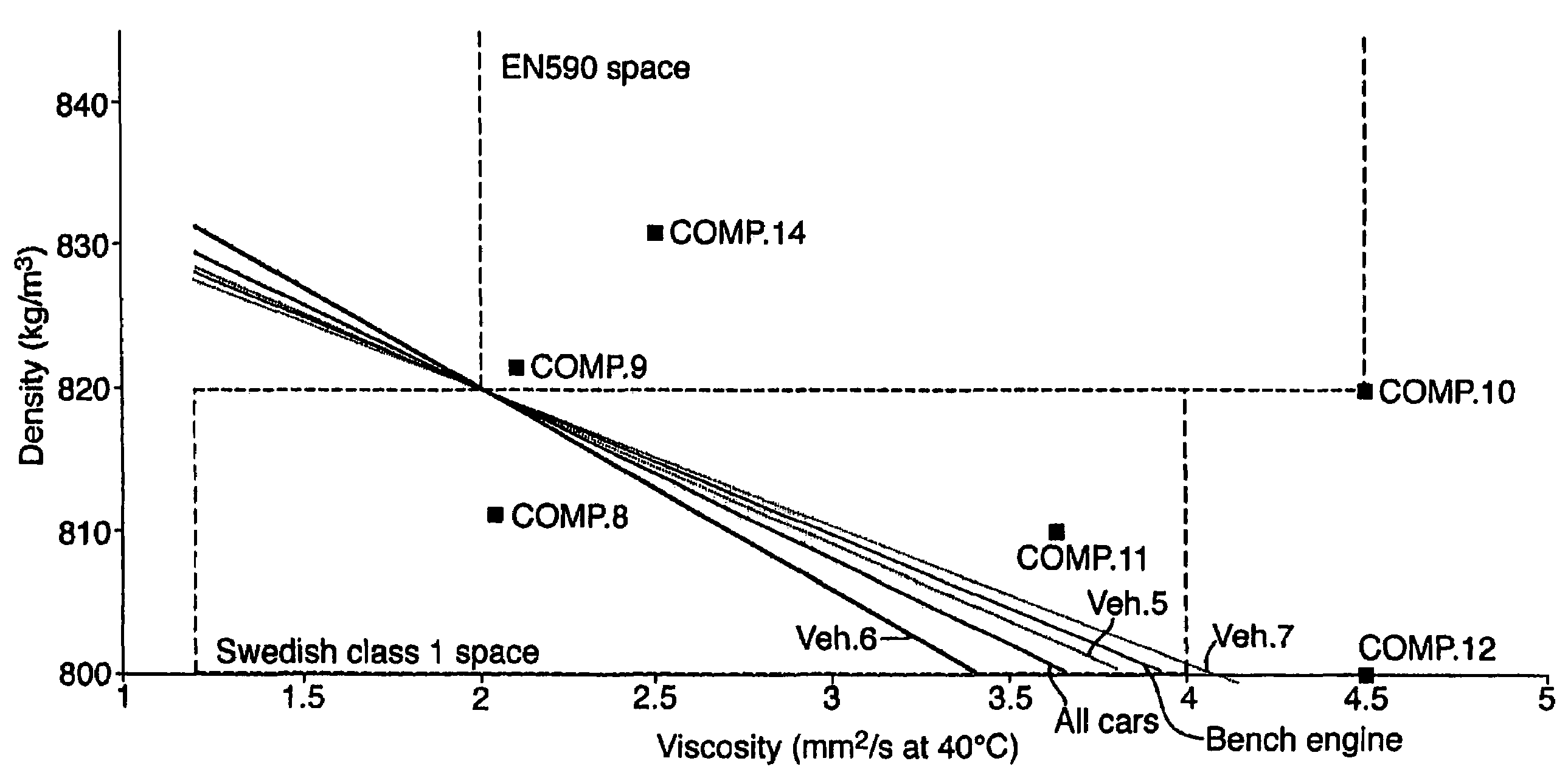

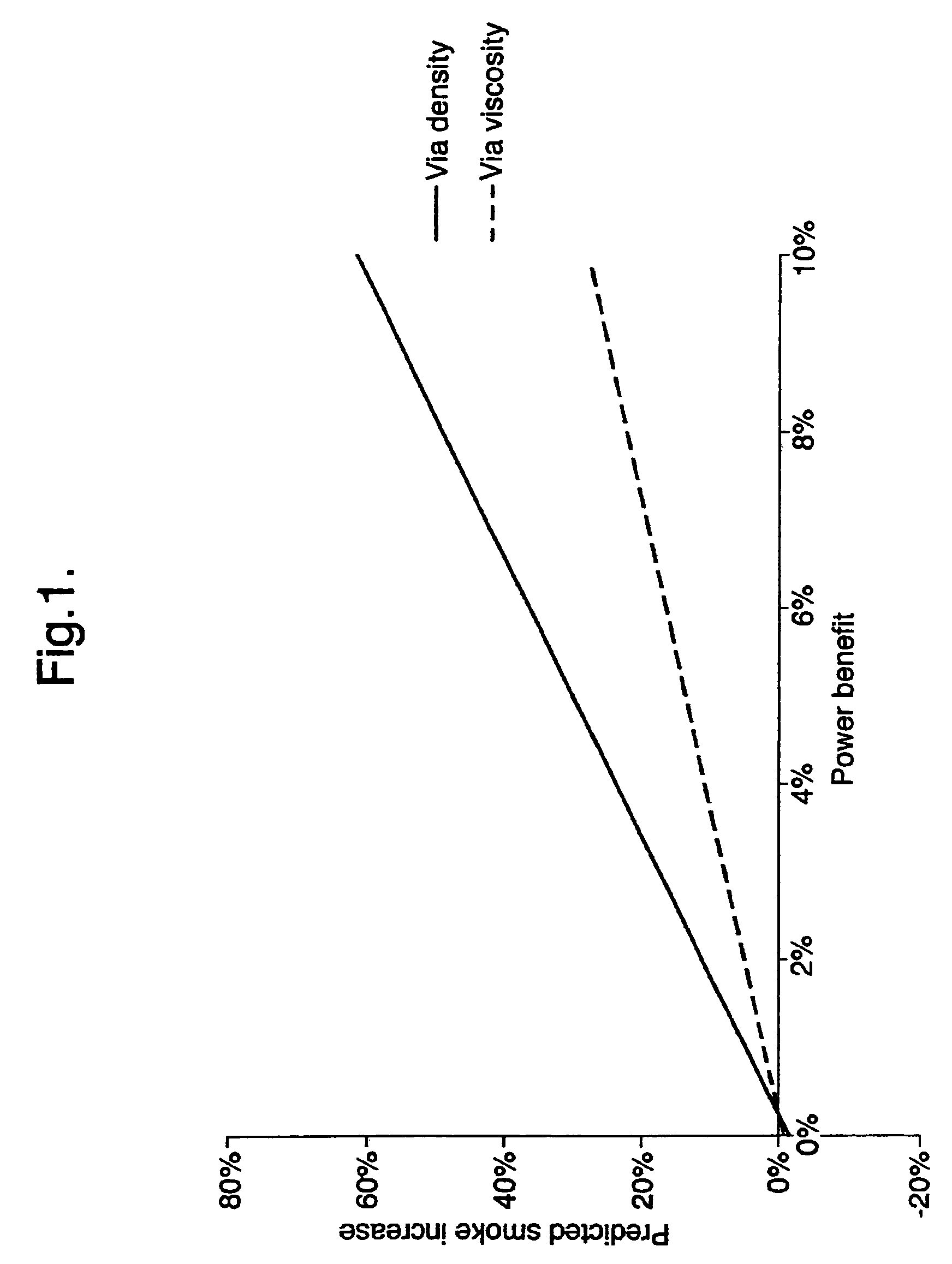

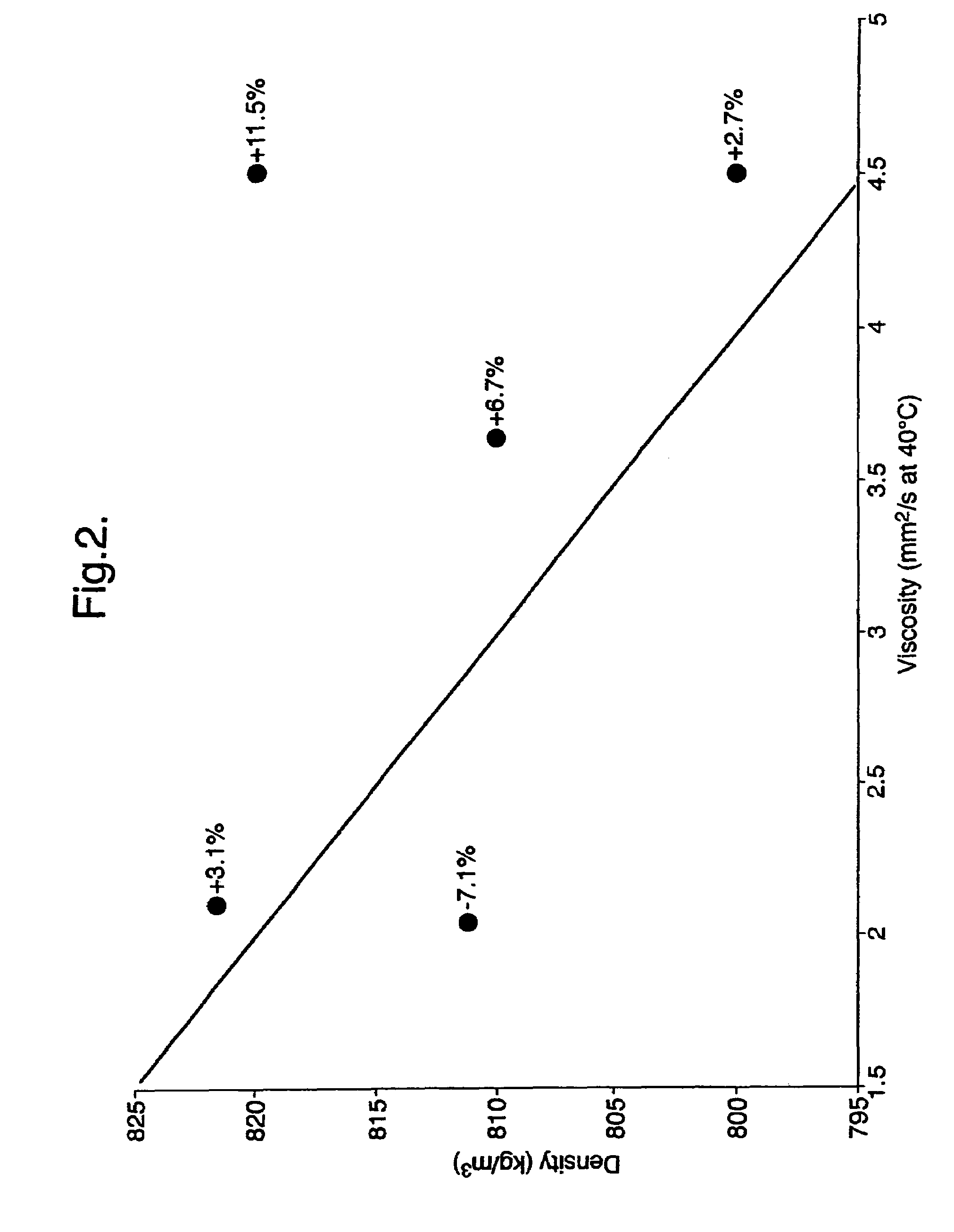

Power increase and increase in acceleration performance of diesel fuel compositions

ActiveUS20060112614A1High strengthAccelerate emissionsSolid fuelsLiquid carbonaceous fuelsViscosityTractive effort

Use of a viscosity increasing component (ii) in provided in a composition (i) of a diesel fuel for the purpose of: improving the vehicle tractive effort (VTE) and / or acceleration performance of a compression ignition engine or a vehicle powered by such an engine, into which engine the composition (i) is introduced, or mitigating decrease in the vehicle tractive effort (VTE) and / or acceleration performance, in the case of a diesel fuel composition (i) to which an additional component (iii) is introduced for the purpose of improving the emissions performance, of a compression ignition engine or a vehicle powered by such an engine, into which engine the composition (i) is introduced.

Owner:SHELL USA INC

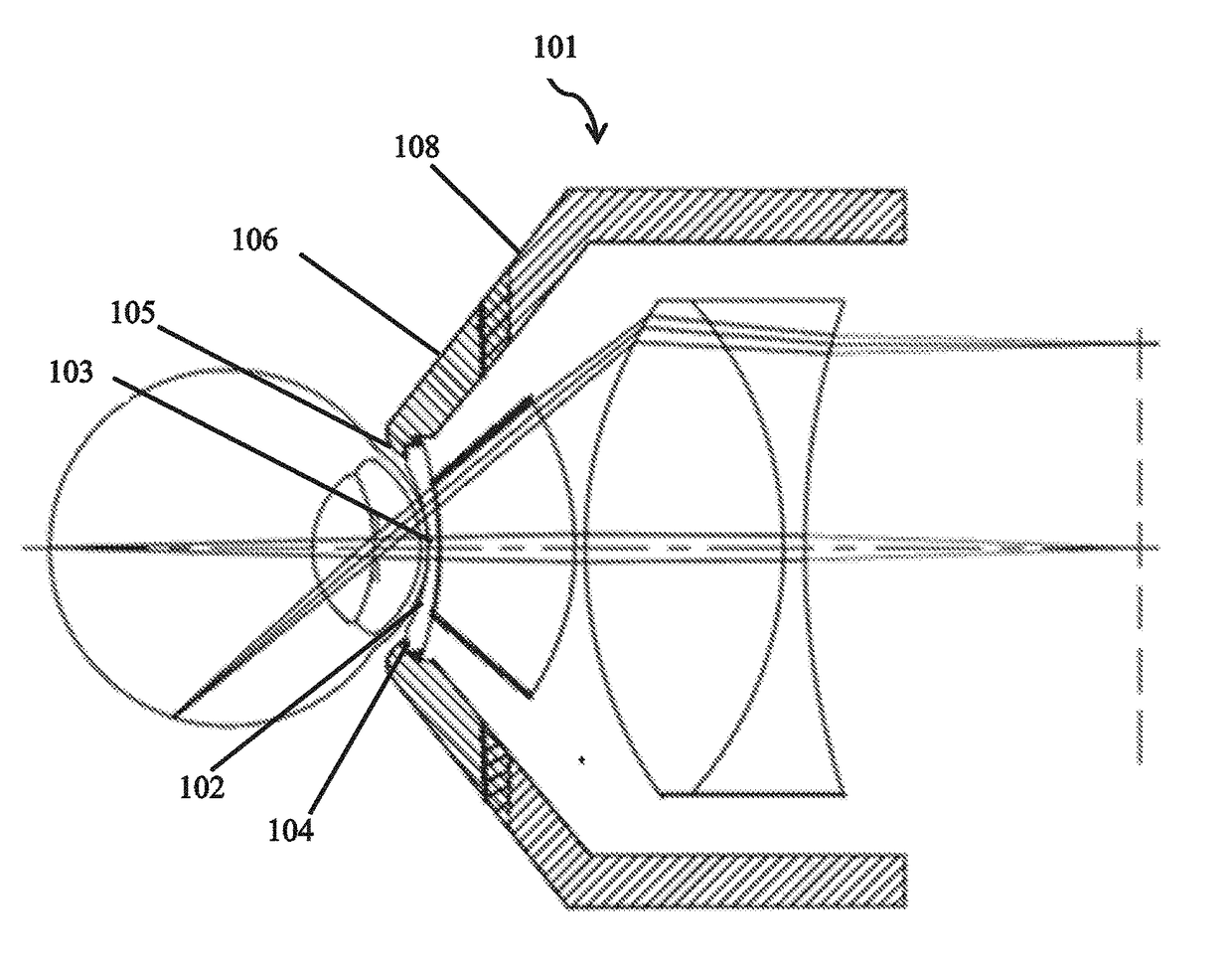

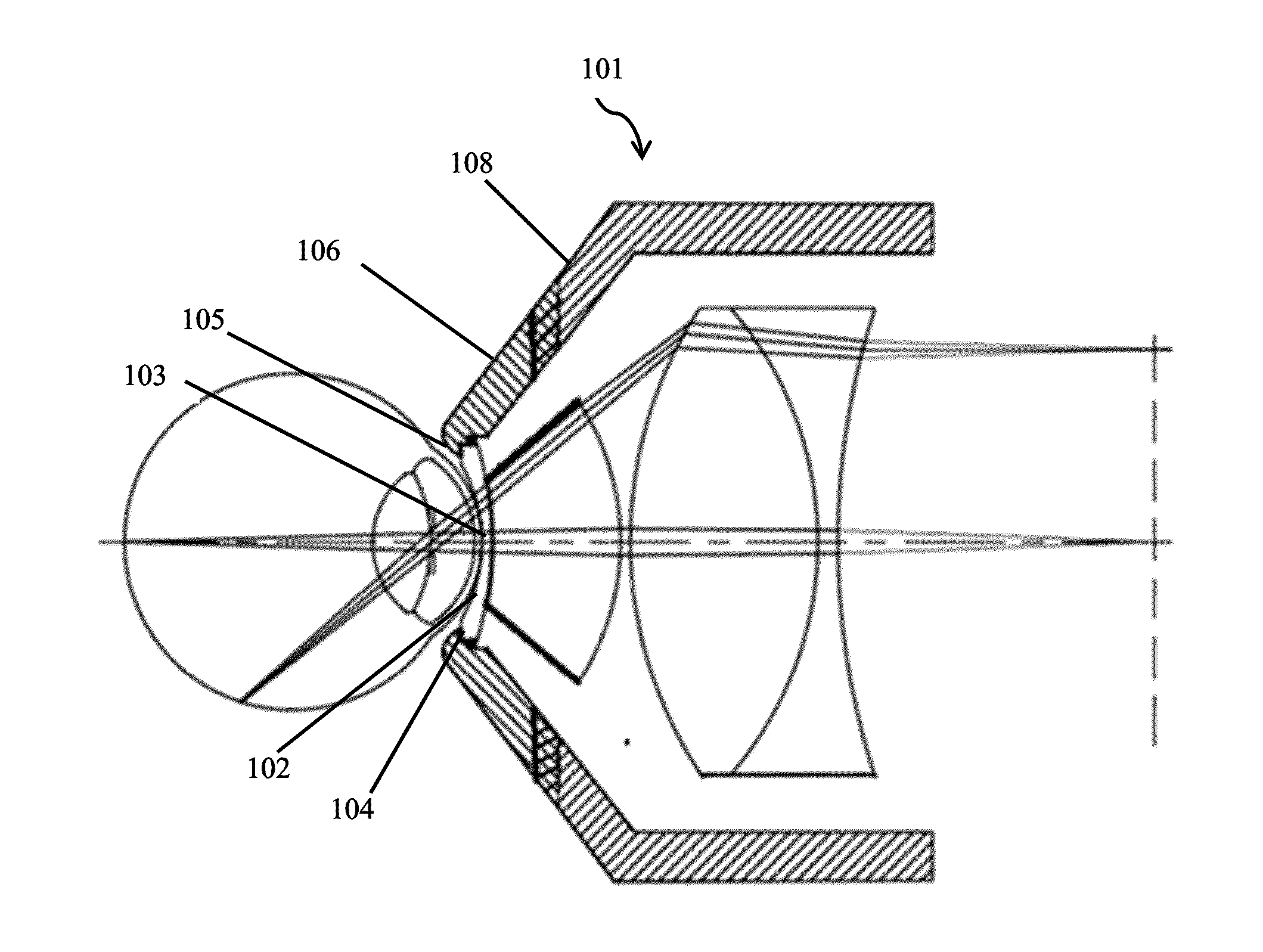

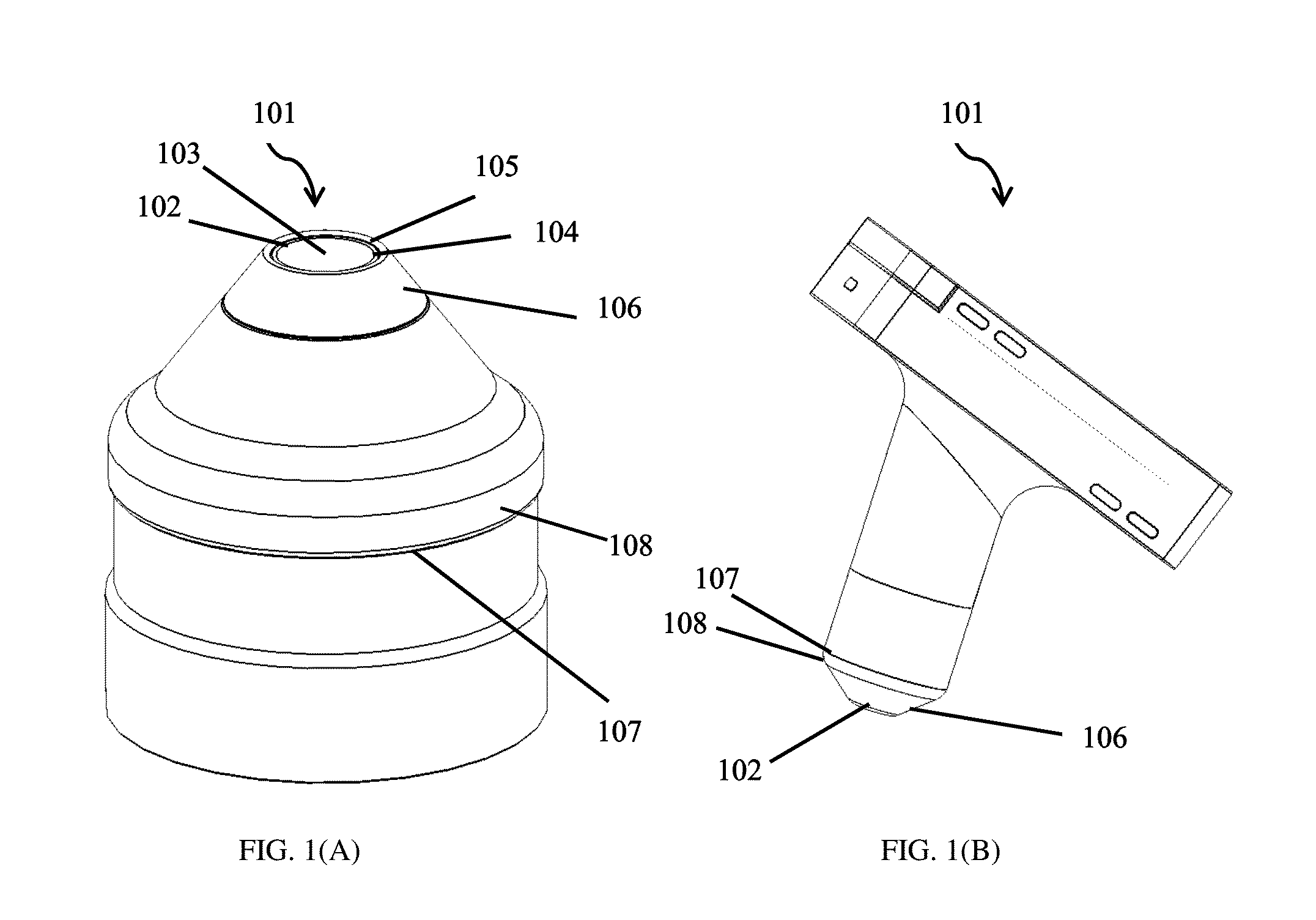

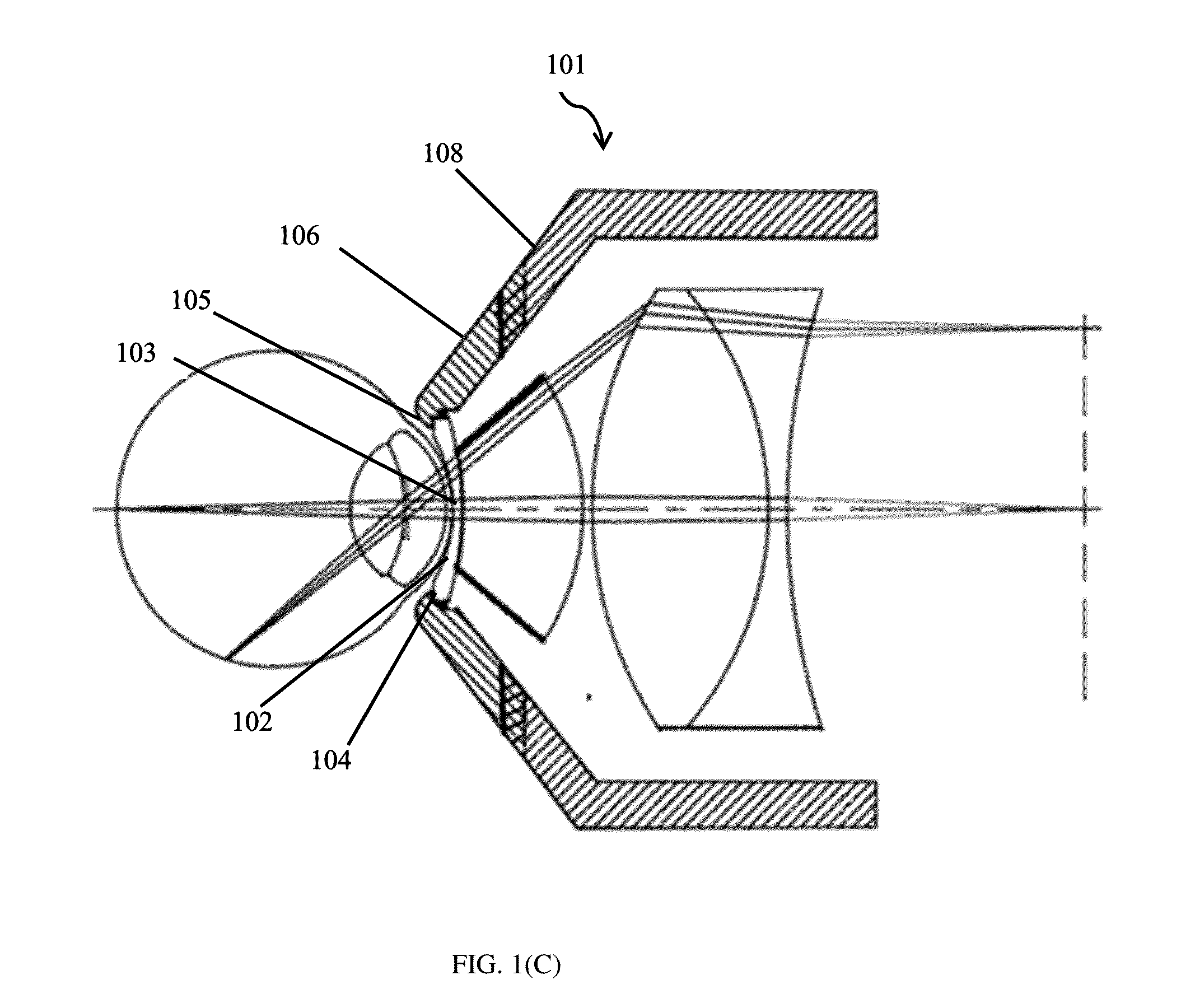

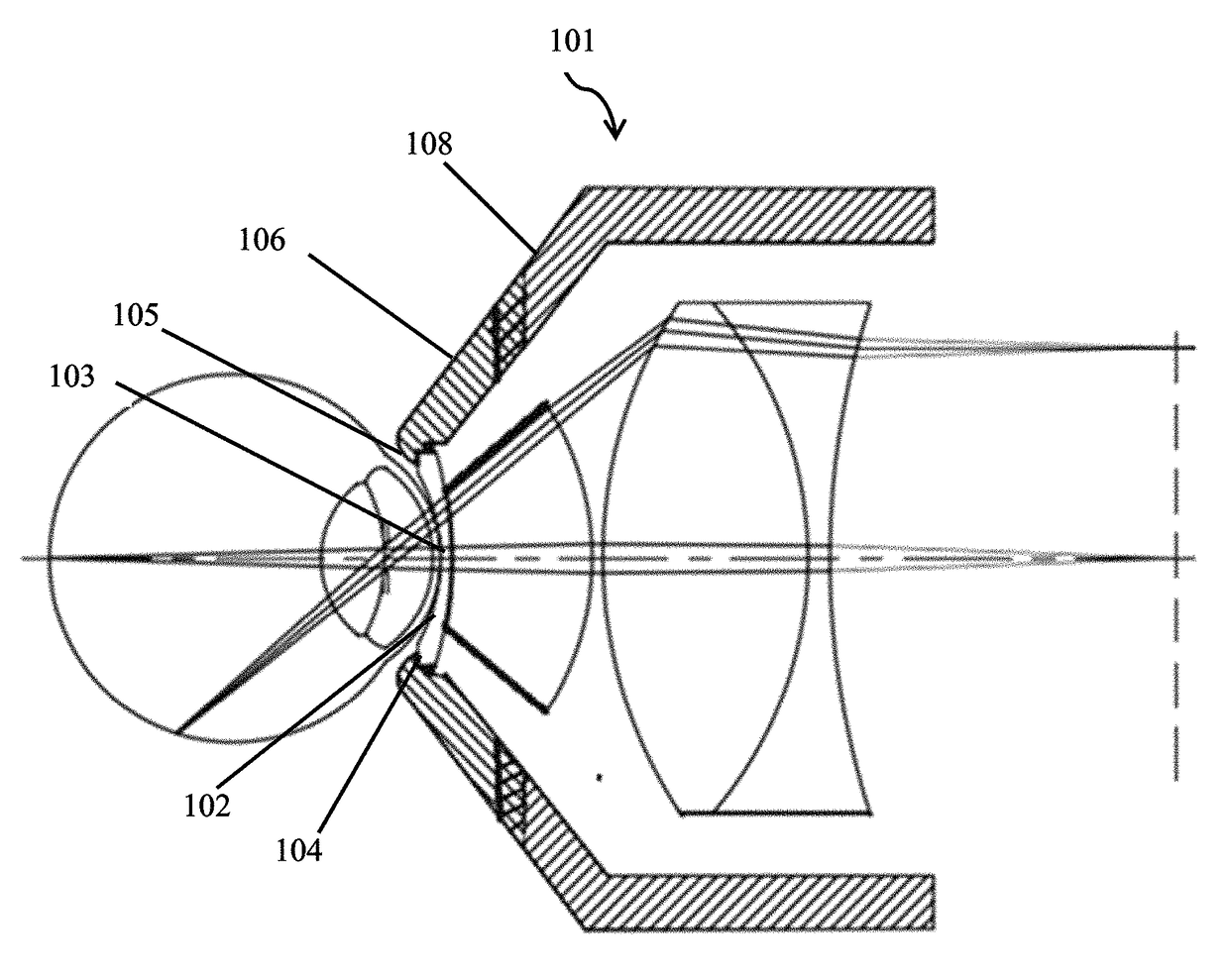

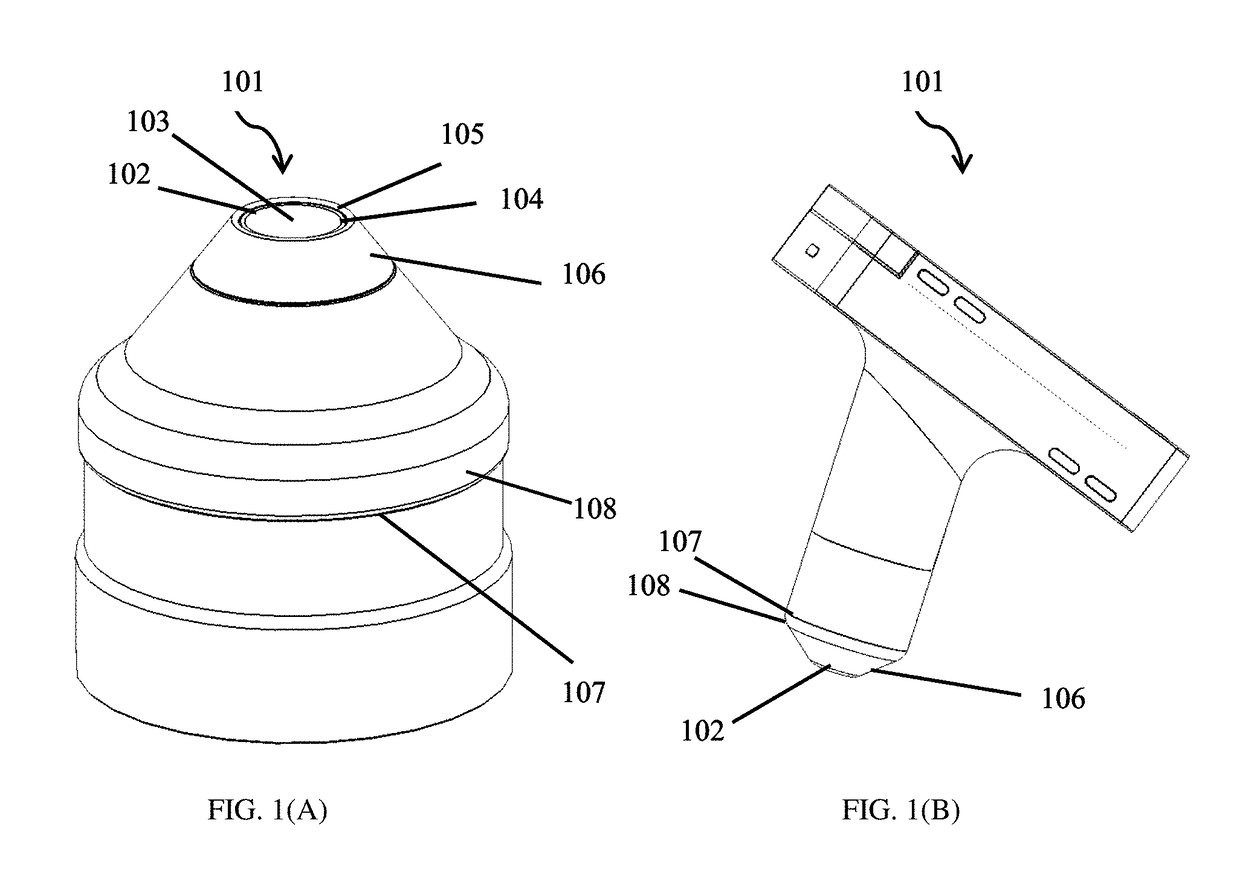

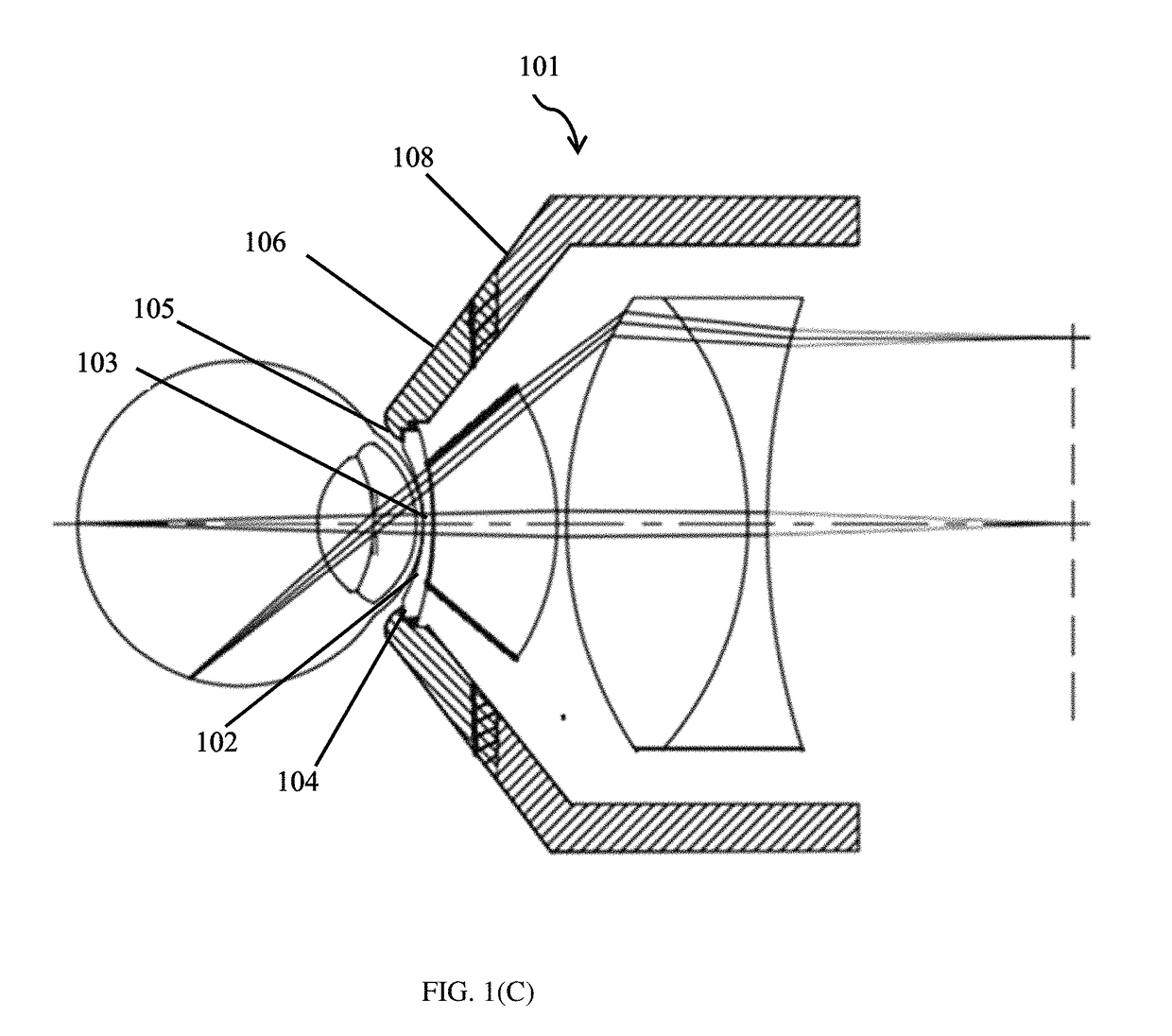

Disposable cap for an eye imaging apparatus and related methods

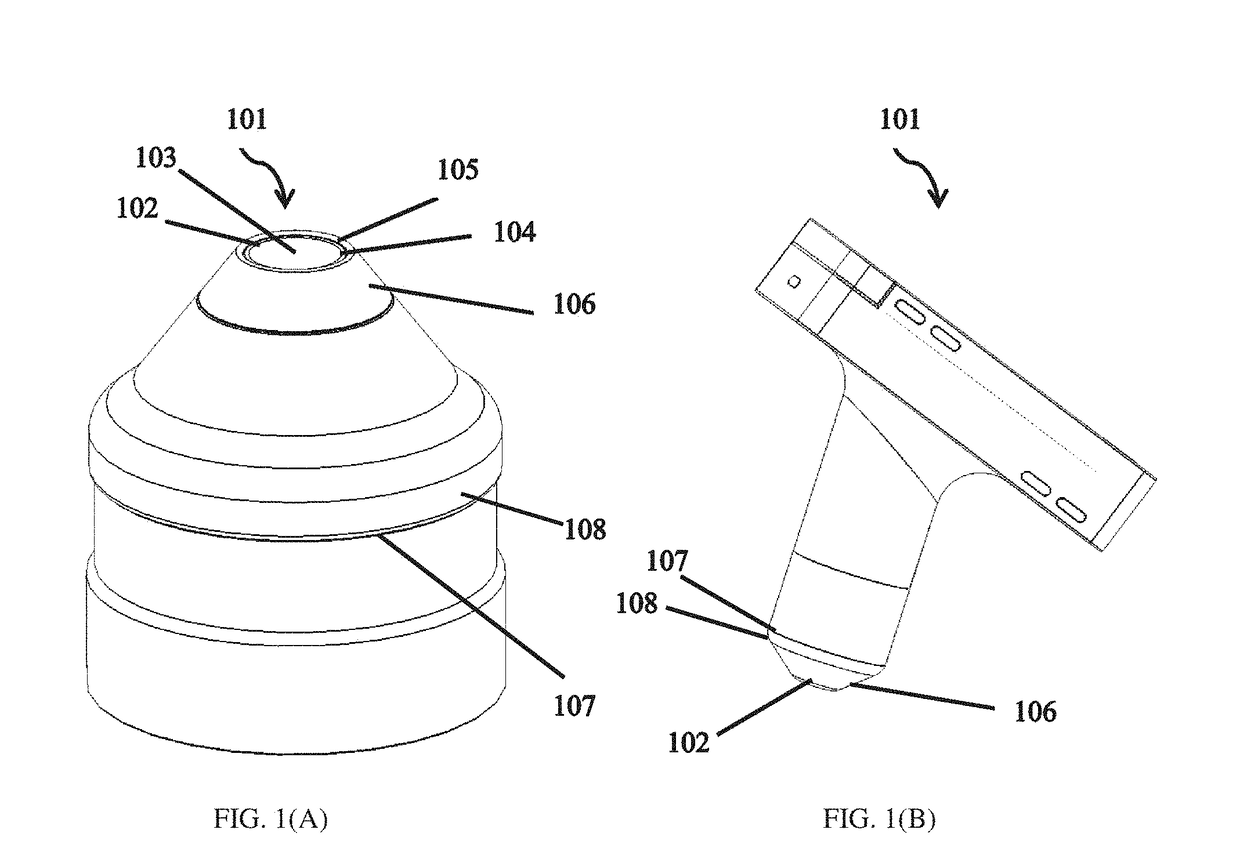

InactiveUS20180084994A1Good optical performanceReduce airSurgical furnitureSurgical drapesEngineeringBiomedical engineering

Disclosed herein is a disposable cap for an eye imaging apparatus with an optical window and related methods. The disposable cap can comprise an optically transparent window cover, a ridge, a side wall and a locking element. The window cover can comprise a convex back surface to match a concave shape of the optical window. The ridge of the disposable cap can extend distally and radially outward from the window cover and the side wall can extend proximally and radially outwardly from the ridge. The locking element can comprise one or more radially inward projections and one or more radially outward releasing tabs. A disposable packaging shell of the disposable cap also disclosed. Disclosed herein is also a plug-in disposable system comprising the disposable cap and the disposable packaging shell, configured to enable the disposable cap to be attached to and detached from the eye imaging apparatus.

Owner:VISUNEX MEDICAL SYST

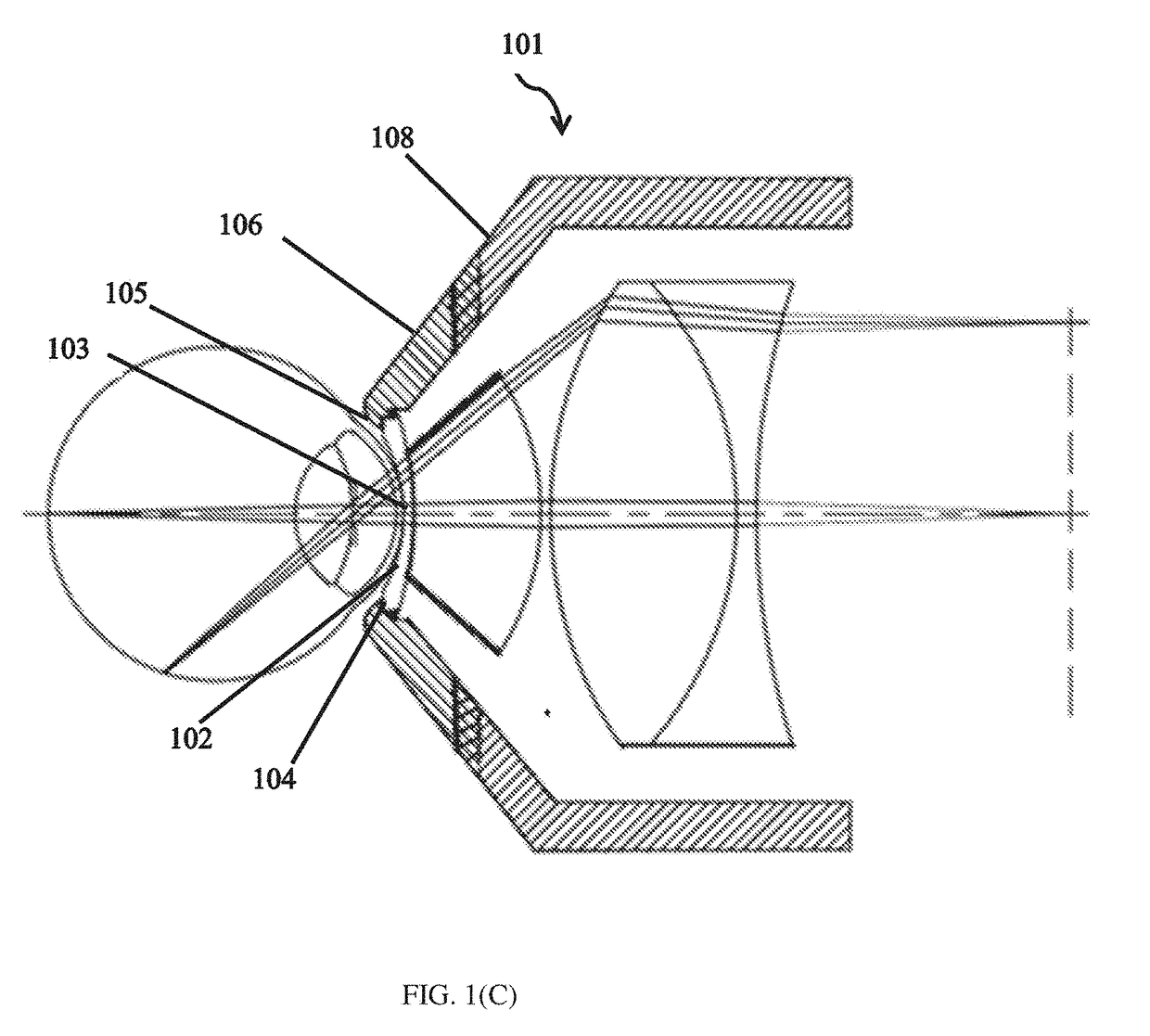

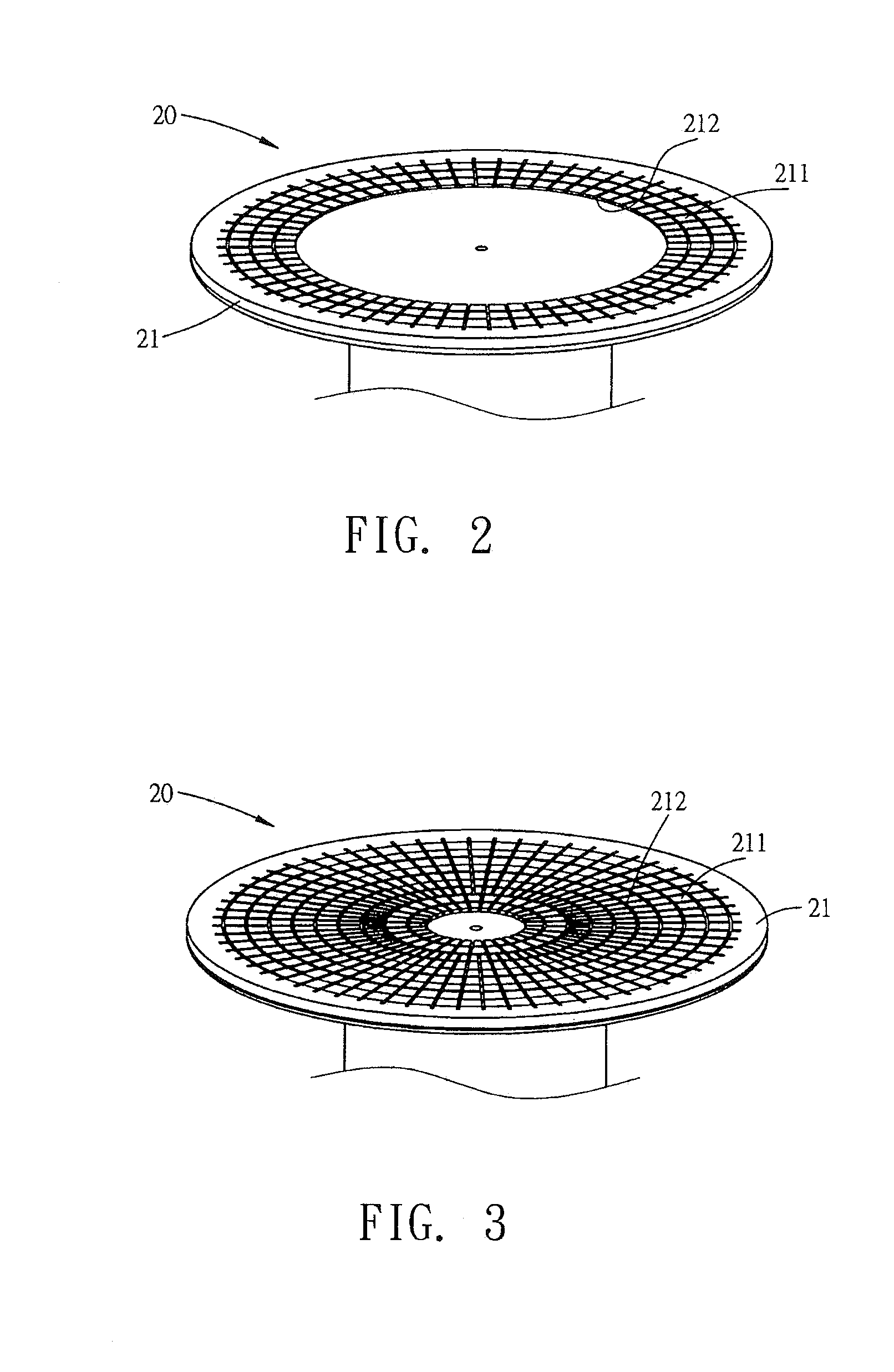

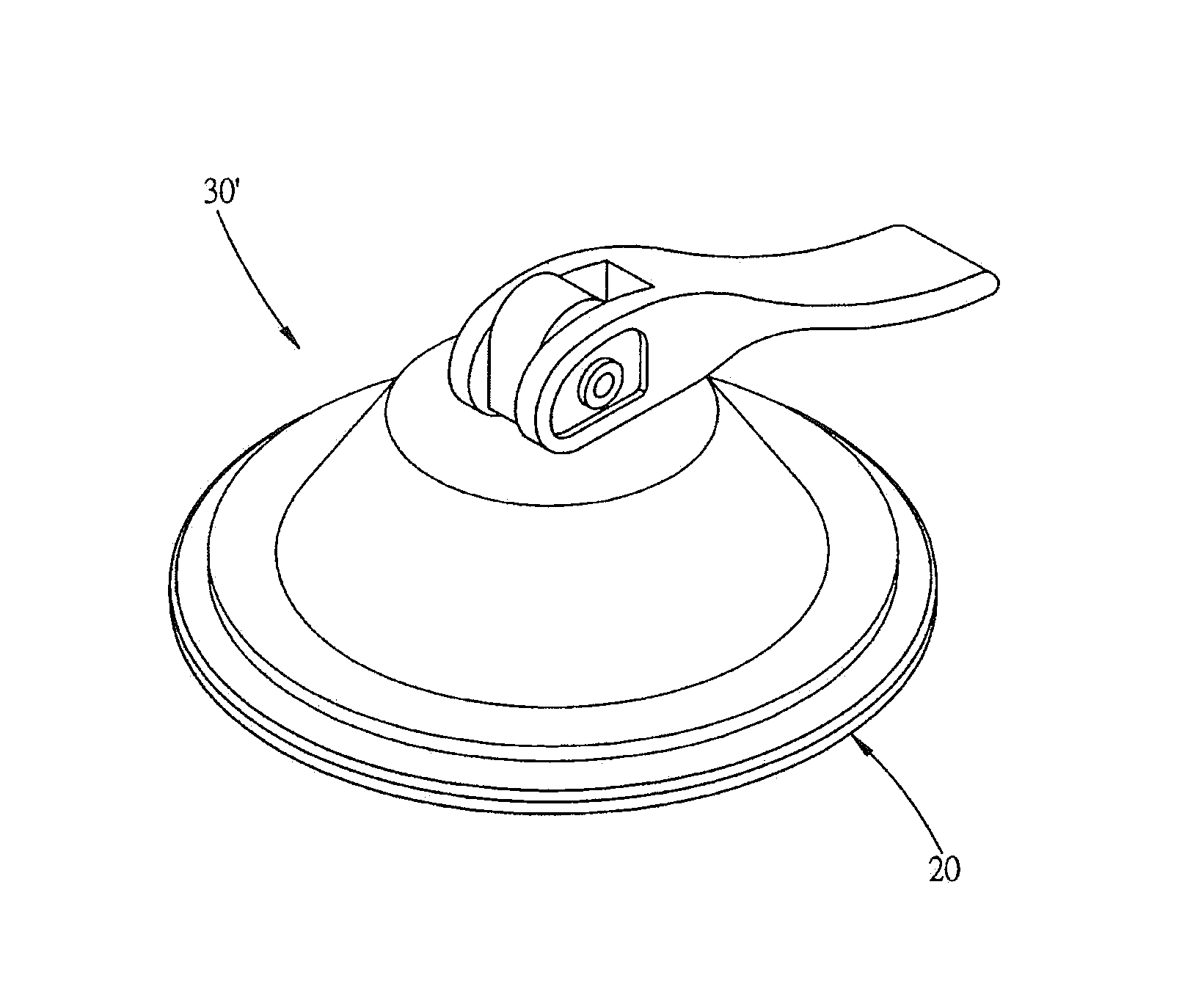

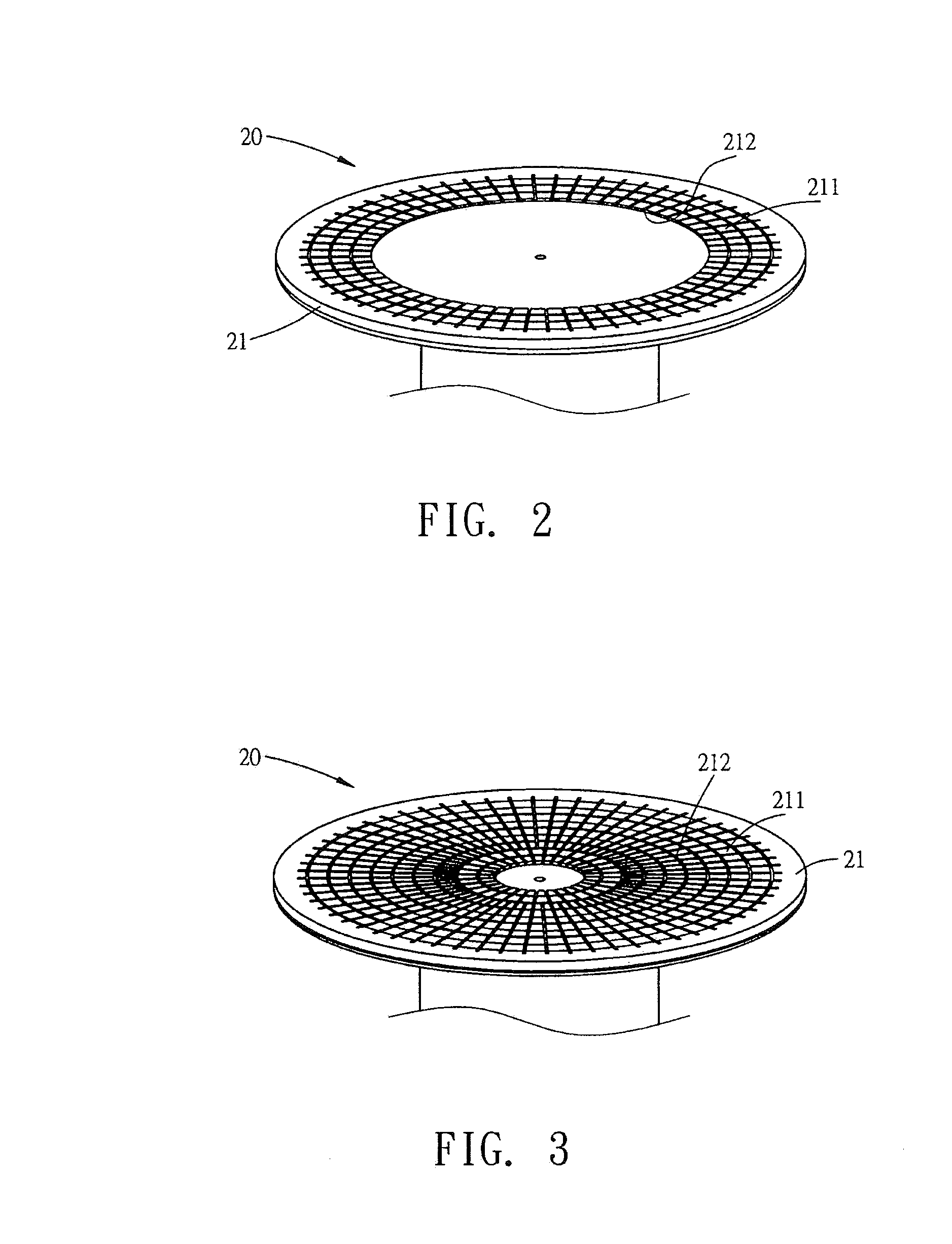

Sucker with Optimum Suction Attachment Effect

ActiveUS20140027588A1Reduce airReduce vacuum leakPicture framesDomestic mirrorsEngineeringAir tightness

A sucker includes a sucker body having a rough suction layer which includes a plurality of protrusions which are juxtaposed to each other closely, and a plurality of grooves defined between the protrusions. When the rough suction layer presses an attached face and is disposed at a negative pressure state, the sucker body is pressed toward the attached face by a normal force from the ambient air, so that the rough suction layer is compressed, and the grooves form multiple independent negative pressure or vacuum zones, to increase a negative pressure of the rough suction layer, to decrease air existing in the rough suction layer, and to reduce a vacuum leak in the rough suction layer, so as to increase an air-tightness between the rough suction layer and the attached face.

Owner:TRU MILES HARDWARE

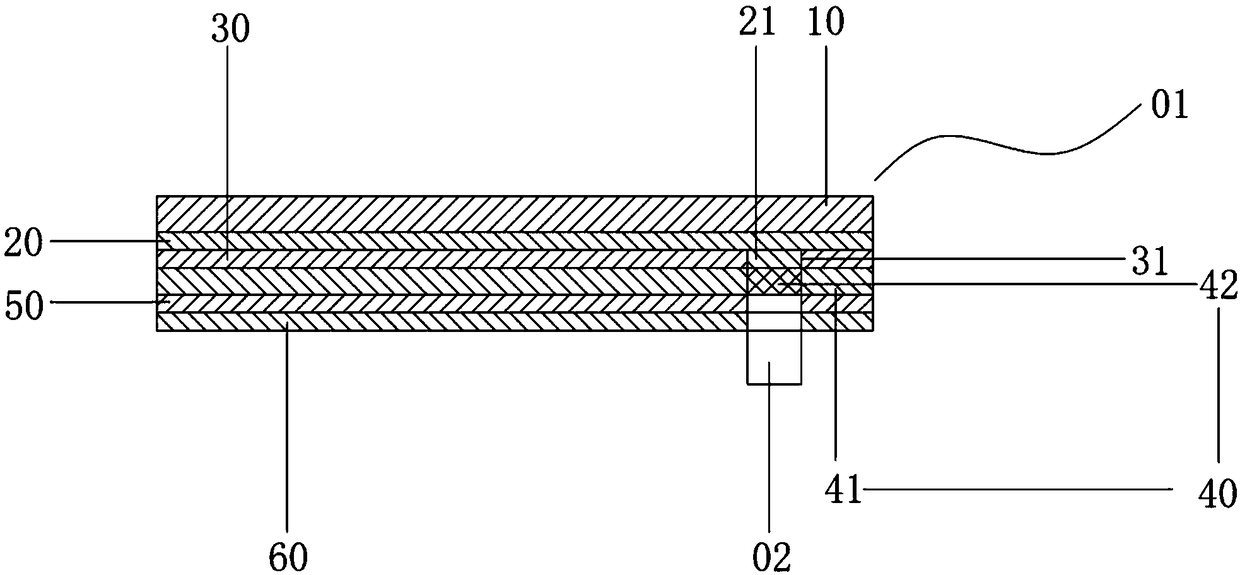

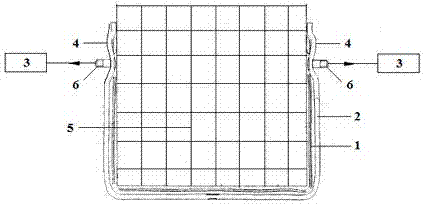

Display module structure used for front camera and laminating process thereof

PendingCN109194787AImprove efficiencyImprove yield rateTelephone set constructionsOrder formCamera module

The present invention provides a display module structure used for a front camera. The structure comprises a display module and a camera module arranged at the lower portion of the display module, thelens of the camera module is arranged facing the direction of the display module, the display module comprises a first optical gluing layer, an upper polaroid, a display screen, a lower polaroid anda back light in order form top to bottom, the display comprises a display area and a non-display area, the camera module is arranged below the non-display area, the upper polaroid is provided with a first light hole corresponding to the non-display area, the lower polaroid is provided with a second light hole corresponding to the non-display area, the back light is provided with a third light holecorresponding to the non-display area, and the first light hole is internally provided with a second optical gluing layer. The present invention further provides a display module laminating process used for a front camera used to display the laminating of the display module.

Owner:厦门三德信科技股份有限公司

Disposable cap for an eye imaging apparatus and related methods

InactiveUS20160213250A1Avoid cross contaminationGood optical performanceSurgical furnitureSurgical drapesEngineeringOcular imaging

Disclosed herein is a disposable cap for an eye imaging apparatus with an optical window and related methods. The disposable cap can comprise an optically transparent window cover, a ridge, a side wall and a locking element. The window cover can comprise a convex back surface to match a concave shape of the optical window. The ridge of the disposable cap can extend distally and radially outward from the window cover and the side wall can extend proximally and radially outwardly from the ridge. The locking element can comprise one or more radially inward projections and one or more radially outward releasing tabs. A disposable packaging shell of the disposable cap also disclosed. Disclosed herein is also a plug-in disposable system comprising the disposable cap and the disposable packaging shell, configured to enable the disposable cap to be attached to and detached from the eye imaging apparatus.

Owner:VISUNEX MEDICAL SYST

Disposable cap for an eye imaging apparatus and related methods

InactiveUS9848773B2Good optical performanceReduce airSurgical furnitureSurgical drapesBiomedical engineeringRidge

Disclosed herein is a disposable cap for an eye imaging apparatus with an optical window and related methods. The disposable cap can comprise an optically transparent window cover, a ridge, a side wall and a locking element. The window cover can comprise a convex back surface to match a concave shape of the optical window. The ridge of the disposable cap can extend distally and radially outward from the window cover and the side wall can extend proximally and radially outwardly from the ridge. The locking element can comprise one or more radially inward projections and one or more radially outward releasing tabs. A disposable packaging shell of the disposable cap also disclosed. Disclosed herein is also a plug-in disposable system comprising the disposable cap and the disposable packaging shell, configured to enable the disposable cap to be attached to and detached from the eye imaging apparatus.

Owner:VISUNEX MEDICAL SYST

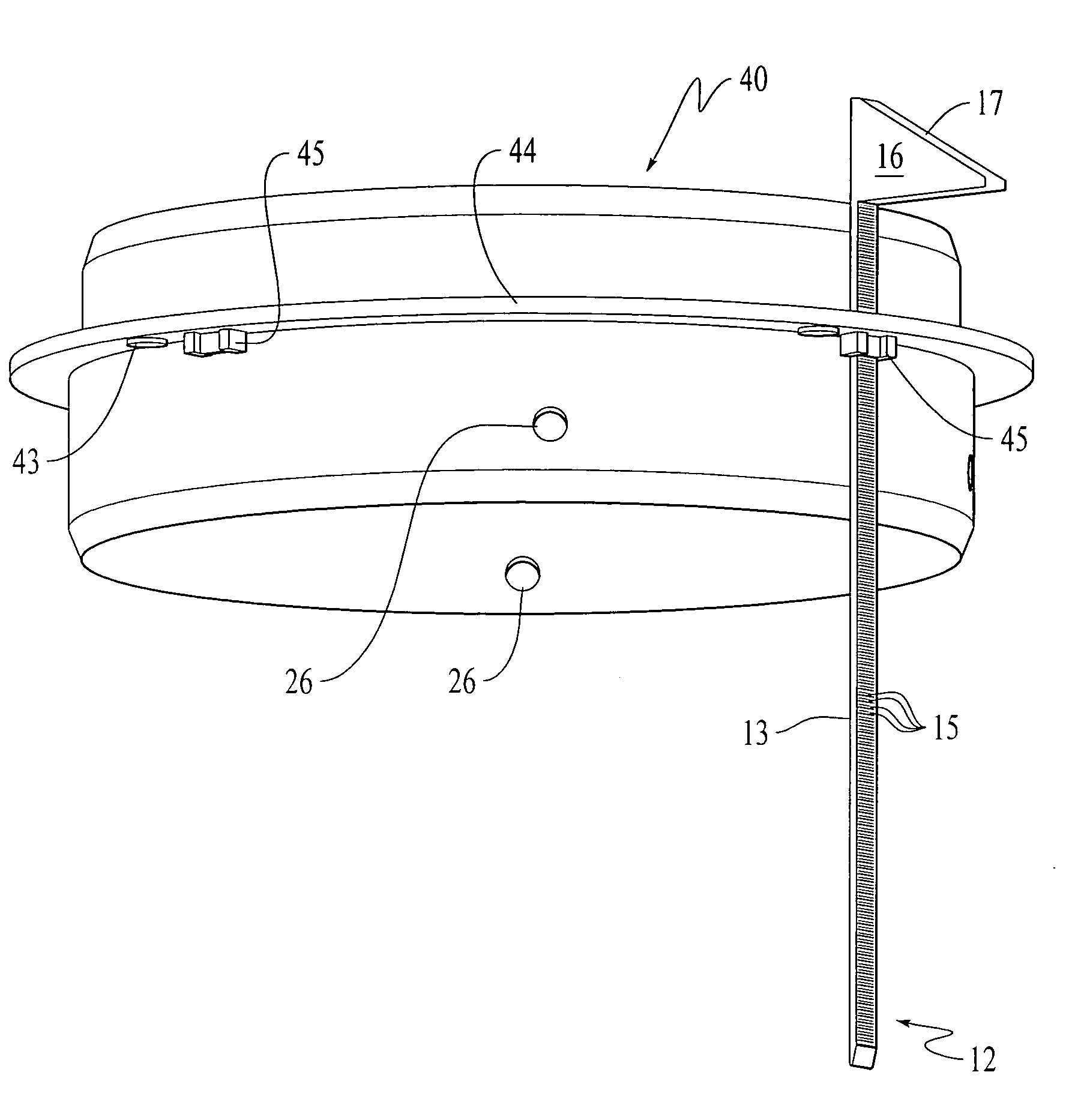

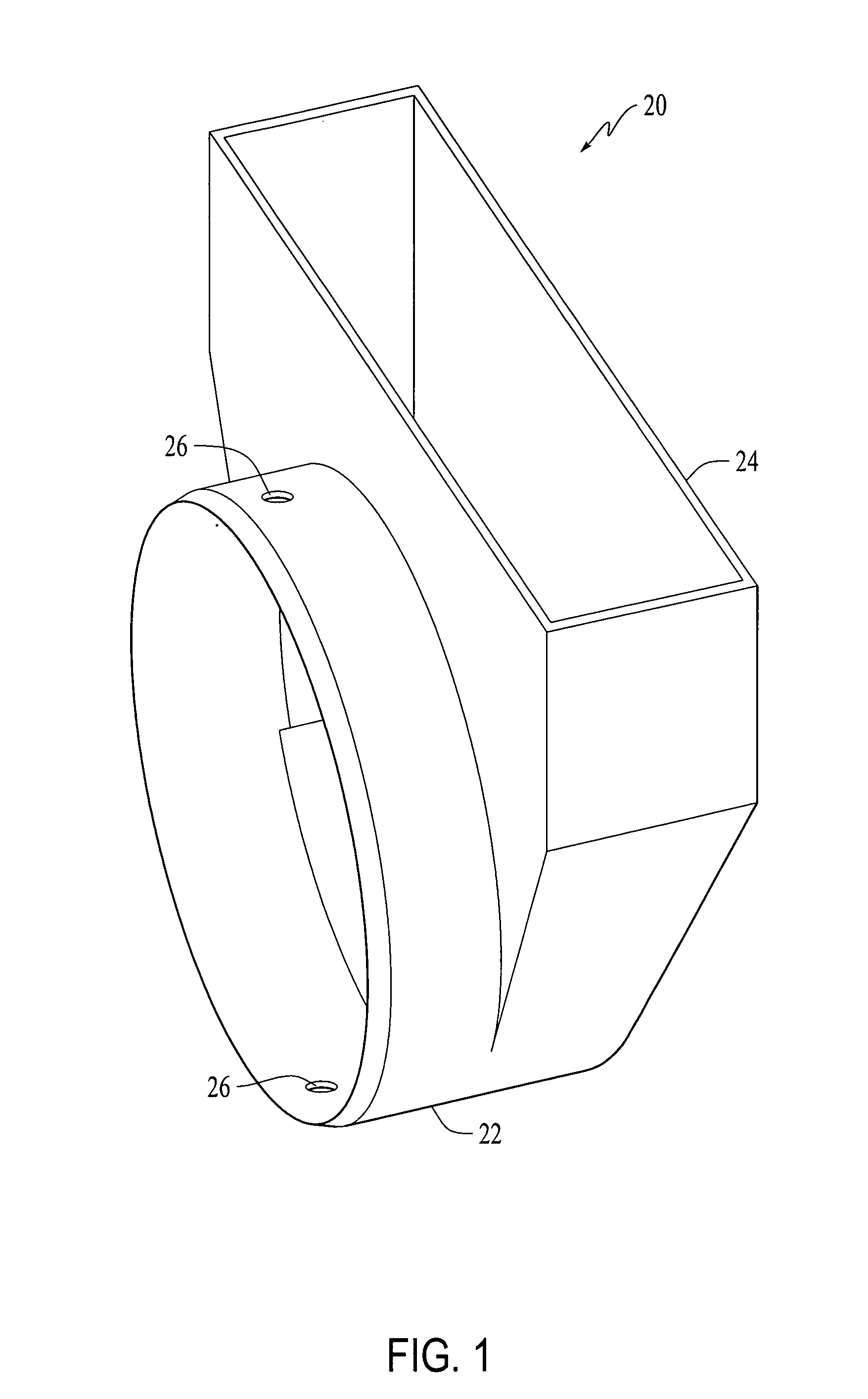

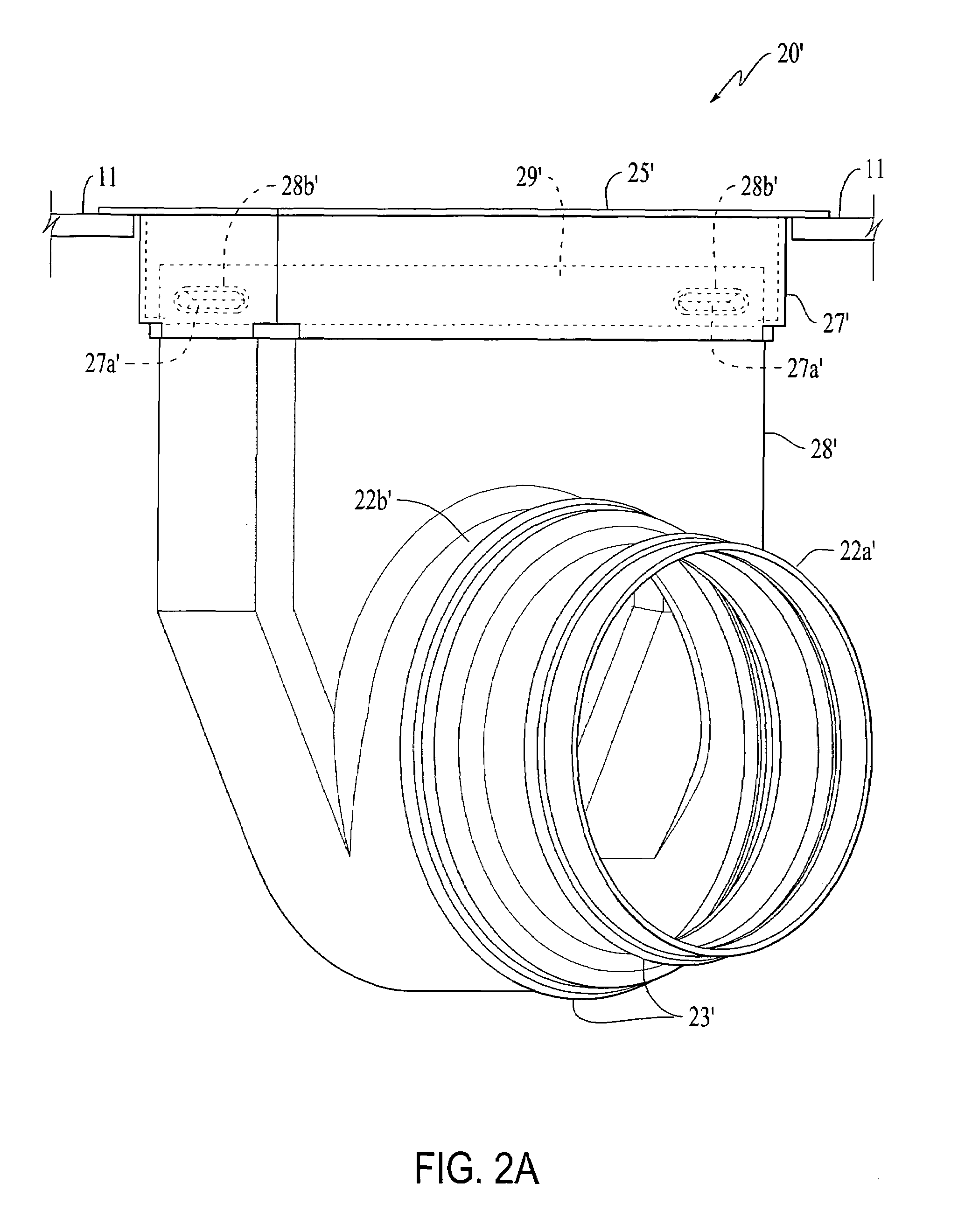

Plastic heating duct connectors

ActiveUS7338095B1Overcome deficienciesReduce lossesSleeve/socket jointsClosuresMaximum diameterEngineering

A connector for connecting a terminal end of a heating duct to a heating duct board, the connector including an annular cylindrical portion with an outer surface and a maximum outer diameter and a flange extending radially outwardly from the outer surface of the annular cylindrical portion. The flange has a dimension greater than the maximum diameter forming an abutment against which a lower edge of the heating duct board abuts. The flange also has at least one sleeve for receiving a zip tie. The connector includes retention means for securing the connector to the heating duct board with the heating duct board encircling the annular cylindrical portion and being in abutting engagement with the flange. The retention includes at least one zip tie mounted through the at least one sleeve of the flange and engageable in a mouth of the heating duct board to which the connector is secured.

Owner:DURA TITE SYST

Active material enabled pressure release valves and methods of use

ActiveUS8414366B2Reduce airReducing boomAir-treating devicesOperating means/releasing devices for valvesEngineeringActuator

An active pressure relief valve adapted for selectively regulating a condition within an interior compartment generally includes a housing fluidly coupling the compartment to an external environment and defining an opening, an actuator including an active material element operable to effect movement of a flap relative to the opening, a load limit protector coupled to and configured to present a secondary output path for the element, when the flap is unable to move, and / or a latching mechanism coupled to, and configured to engage the flap, so as to retain the flap in a modified condition.

Owner:GM GLOBAL TECH OPERATIONS LLC

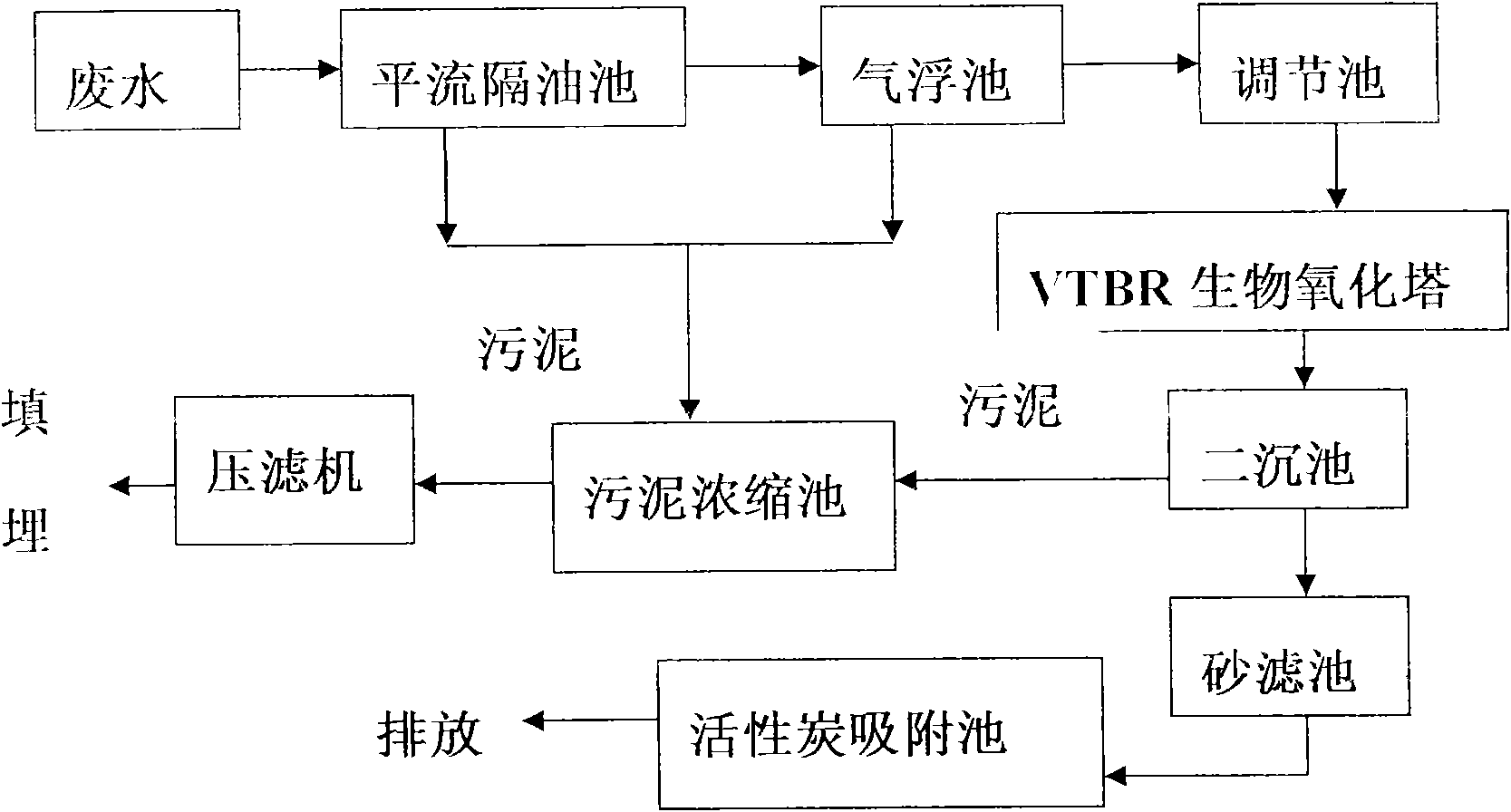

Method for treating coking wastewater

InactiveCN101643294AReduce airReduce energy consumptionFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processUltrafiltrationHazardous substance

The invention belongs to the technical field of wastewater treatment, and particularly relates to a method for treating coking wastewater. The invention provides the method for treating the coking wastewater, which has the advantages of simple operation, low cost and good treatment effect and can directly discharge effluent. The invention adopts the following technical scheme that (1) various wastewaters in a factory are discharged into a horizontal oil isolating tank through sewage pipelines, the oil isolating tank is provided with an oil scraper which periodically removes floating oil on thesurface, and the effluent of the oil isolating tank enters an air floating system for oil removal; (2) the effluent of the air floating system automatically flows into a wastewater mixing regulationtank to balance the water quality and water quantity; (3) the effluent of the mixing regulation tank enters a VTBR biological oxidation tower through a lift pump to be treated, most of COD is removed,phenol, cyanogen and other harmful substances are removed, and nitrogen is removed through nitration and denitrification; (4) the effluent enters a secondary sedimentation tank; and (5) the effluententers a sand filter and an active carbon adsorption device, then enters an ultra-filtration and reverse osmosis apparatus, and is discharged after reaching the standard.

Owner:何庆

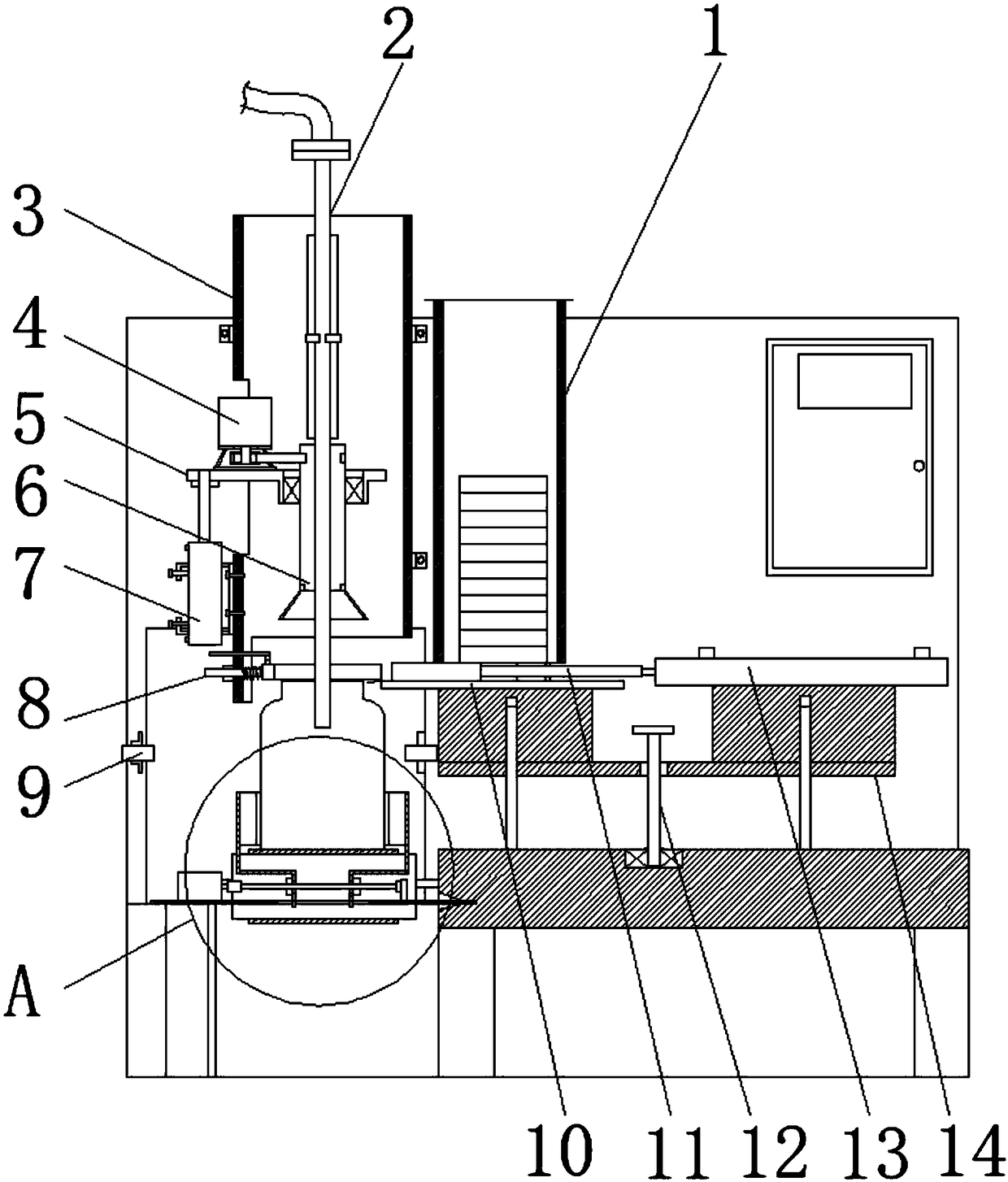

Food filling sealing device with steam sterilization function

InactiveCN108640064ARealize automatic capping operationExtended shelf lifeThreaded caps applicationPackage sterilisationHigh concentrationHeating time

The invention discloses a food filling sealing device with a steam sterilization function. The food filling sealing device comprises a cap screwing mechanism and a bottle cap storage cylinder, whereina conveying belt for conveying packaging bottles is arranged below the cap screwing mechanism, the conveying belt can pass through the lower portion of the cap screwing mechanism without obstructionwith the packaging bottles after cap screwing is finished, and meanwhile, a clamping mechanism is arranged at the position, corresponding to the cap screwing mechanism, of the conveying belt. According to the food filling sealing device with the steam sterilization function, the automatic cap sealing operation of canned food can be realized, meanwhile, before the capping operation is carried out,steam heating and disinfection of the food can be realized by utilizing a telescopic needle tube which can be connected with a steam generating device, and meanwhile, the internal air is reduced afterthe sealed canned food is cooled by utilizing the characteristics of thermal expansion and chilling contraction, so that the shelf life of the food is prolonged; and a high-concentration disinfectingand sealing mechanism is adopted, so that the heating time of the canned food in the actual packaging process is shortened, the heating frequency of the canned food in the actual packaging process, and the packaging cost is reduced.

Owner:张雪鸽

Automatic tying technology for edible fungus bags

The invention provides an automatic tying technology for edible fungus bags comprising following steps: 1. loading a fungus bag and placing the fungus bag in an automatic tying machine, wherein the fungus bag is made stand vertically and fungus sticks are clamped by the automatic tying machine; 2. the fungus bag mouth is clamped by a manipulator through moving downwards for some distance and then the manipulator moves downwards further to press the fungus in the fungus bag; 3. the manipulator moves upwards and clamps the fungus sticks and then slides to the right to place the fungus sticks in the tying machine; after a tying plate is tightly clamped, the manipulator moves upwards for some distance and then ties the fungus bag; 4. the tying plate in the typing machine is released and the manipulator is released and then the fungus sticks are popped up. According to the technology, when the fungus sticks are clamped, the manipulator presses the fungus sticks to compact the fungus in the fungus bag and expel air in the fungus bag; then the fungus sticks are lifted up and placed in the tying machine and the tying plates in the tying machine are folded, and then the manipulator lifts the fungus sticks; in this way, air in the fungus bag is expelled which guarantees that the fungus sticks are compacted after tying and air inside the fungus sticks is expelled.

Owner:庆元县菇星节能机械有限公司

Film blowing machine with improved winding mechanism

The invention provides a film blowing machine with an improved winding mechanism. Th film blowing machine comprises an extrusion mechanism, a film blowing mechanism, a traction mechanism and the winding mechanism. The film blowing mechanism comprises a die head, an air ring and a rack. The air ring is arranged on the die head. The die head and the air ring are fixedly arranged at the lower end of the rack. The traction mechanism is arranged at the upper end of the rack. The extrusion mechanism is provided with a discharge outlet connected with the die head. The winding mechanism comprises a winding shaft, a belt and a motor, wherein the winding shaft is used for winding thin films. The motor is in transmission connection with the winding shaft through the belt. The thin films blown out from the die head are conveyed to the winding shaft through the traction mechanism. A press shaft capable of pressing the thin films is arranged above the winding shaft. The winding mechanism further comprises a support frame and elastic suspended arms. The press shaft is connected to the support frame through the elastic suspended arms. According to the film blowing machine with the improved winding mechanism, deviation of the thin films in the winding process can be avoided, and dislocation of an upper layer and a lower layer of a thin film is prevented.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

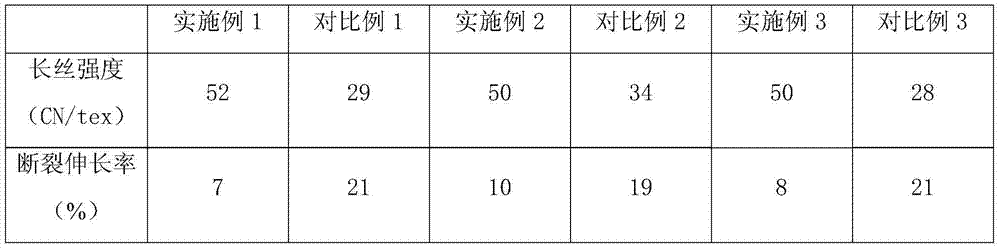

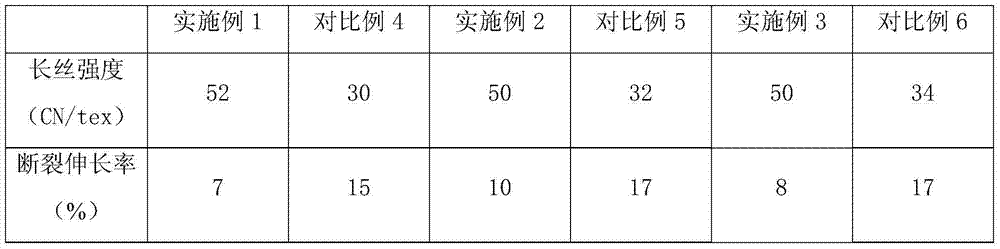

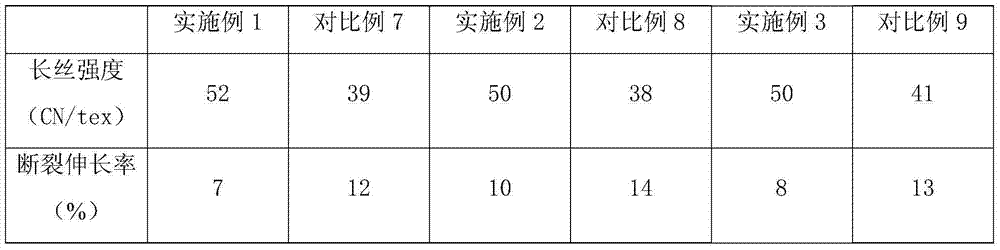

Process for manufacturing high-strength low-elongation polytetrafluoroethylene filaments

ActiveCN104294382AHigh strengthFilament quality improvement and breakthroughStretch-spinning methodsCompression moldingPolymer science

The invention belongs to the field of polytetrafluoroethylene functional material manufacturing, and particularly relates to a process for manufacturing high-strength low-elongation polytetrafluoroethylene filaments. The process comprises the steps that disperse polytetrafluoroethylene granules are processed in a low-temperature oil supply mode, cured and subjected to vacuum compression molding, material strips are extruded in a pushing and pressing mode, a thin film is obtained through compression, longitudinal heating stretching is conducted twice, the thin film is slit into flat filaments, the flat filaments are twisted into round filaments, heating stretching and forming are conducted on the round filaments, and the PTFE filaments of different specifications are manufactured. The filaments manufactured through the process meet the ideal indexes of high strength and low elongation, thereby being an improvement and breakthrough in the quality of polytetrafluoroethylene filaments.

Owner:常州华福环境科技股份有限公司

Thermoforming method of co-woven continuous fiber reinforced thermoplastic structural plate

The invention discloses a thermoforming method of a co-woven continuous fiber reinforced thermoplastic structural plate. The method comprises: first co-weaving prepreg into sheet or band prepreg on a braiding machine; spreading the prepreg on a die and conducting sealing with a vacuum bag or a polyester film; then raising the temperature, carrying out vacuum pumping to maintain a vacuum negative pressure, when the temperature reaches the melting point of thermoplastic resin, preserving the heat for a period of time, then performing cooling for molding; finally dismounting the vacuum bag or the polyester film so as to obtain a structural plate. The structural plate produced by the co-weaving method can expel air among the internal layers of the prepreg. Pressure is transmitted uniformly through fibers, so that shift in fiber direction can be avoided, and the structural plate also can be reinforced based on original enhanced fibers, thus substantially saving cost.

Owner:LIAONING LIAOJIE SCI & TECH

Energy-saving and environment-friendly lamp shell structure convenient for assembly

The invention discloses an energy-saving and environment-friendly lamp shell structure convenient for assembly. The energy-saving and environment-friendly lamp shell structure comprises a lamp shell body and an iron plate, and two symmetrically arranged screws are screwed into the lower end surface of the iron plate; the energy-saving and environment-friendly lamp shell structure is simple in structure, second fan blades are driven to rotate by a motor, the second fan blades are connected with first fan blades in a clamping mode, and a threaded rod is driven to rotate by the first fan blades;a second piston and a fourth piston are driven by the threaded rod to move downwards, then air inside a suction cup is reduced, a negative pressure is formed, so that the suction cup is more firmly connected with a permanent magnet; and when the second piston moves downwards, air flow in a T-shaped cylinder is changed, so that a first piston and a third piston are moved toward each other; and thentwo pressing plates press against the permanent magnet to increase the fixing force of the permanent magnet and the lamp shell body, and the permanent magnet is attracted to the iron plate so as to achieve the effect of easily assembling the energy-saving lamp shell body.

Owner:宁波华美斯车业有限公司

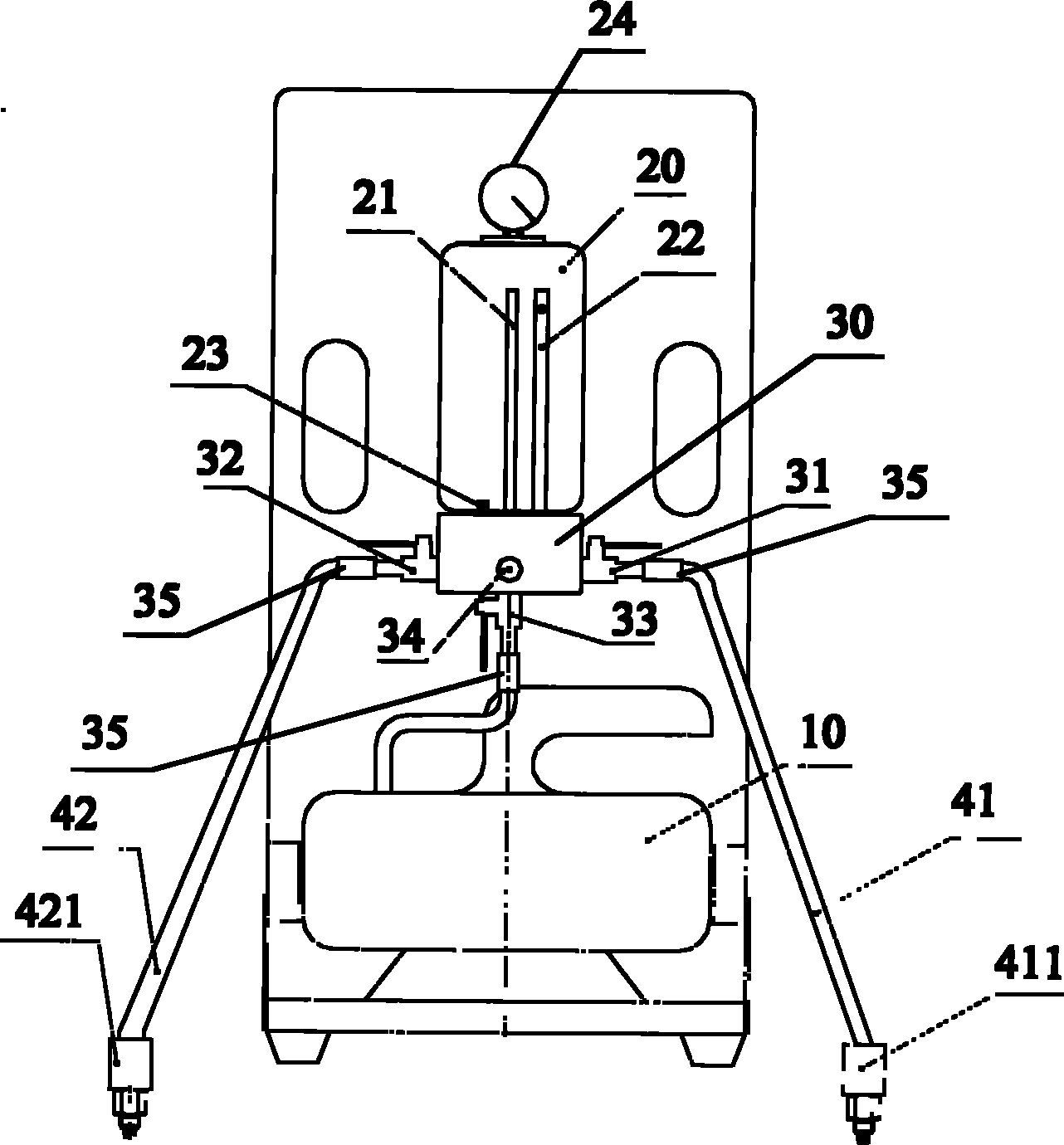

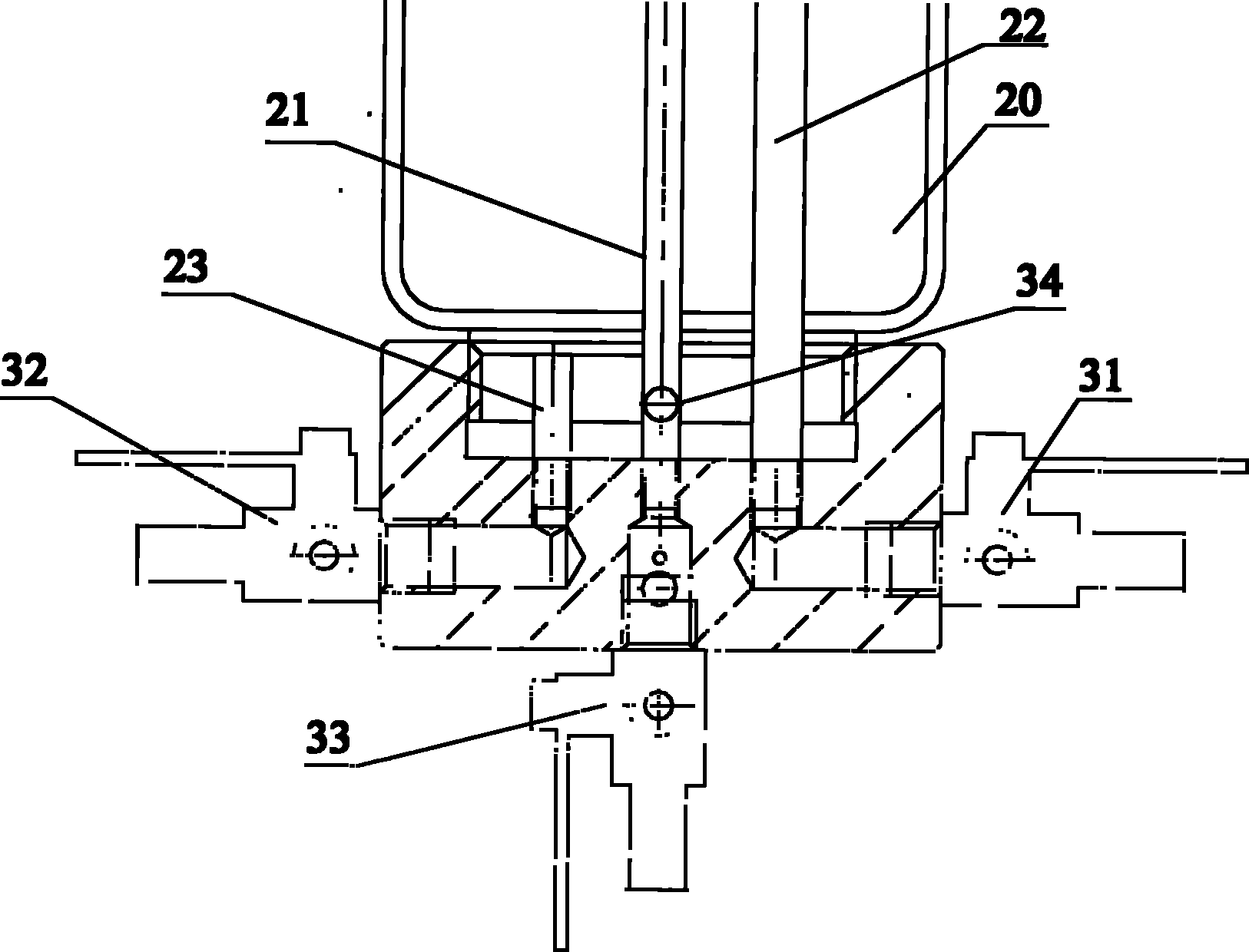

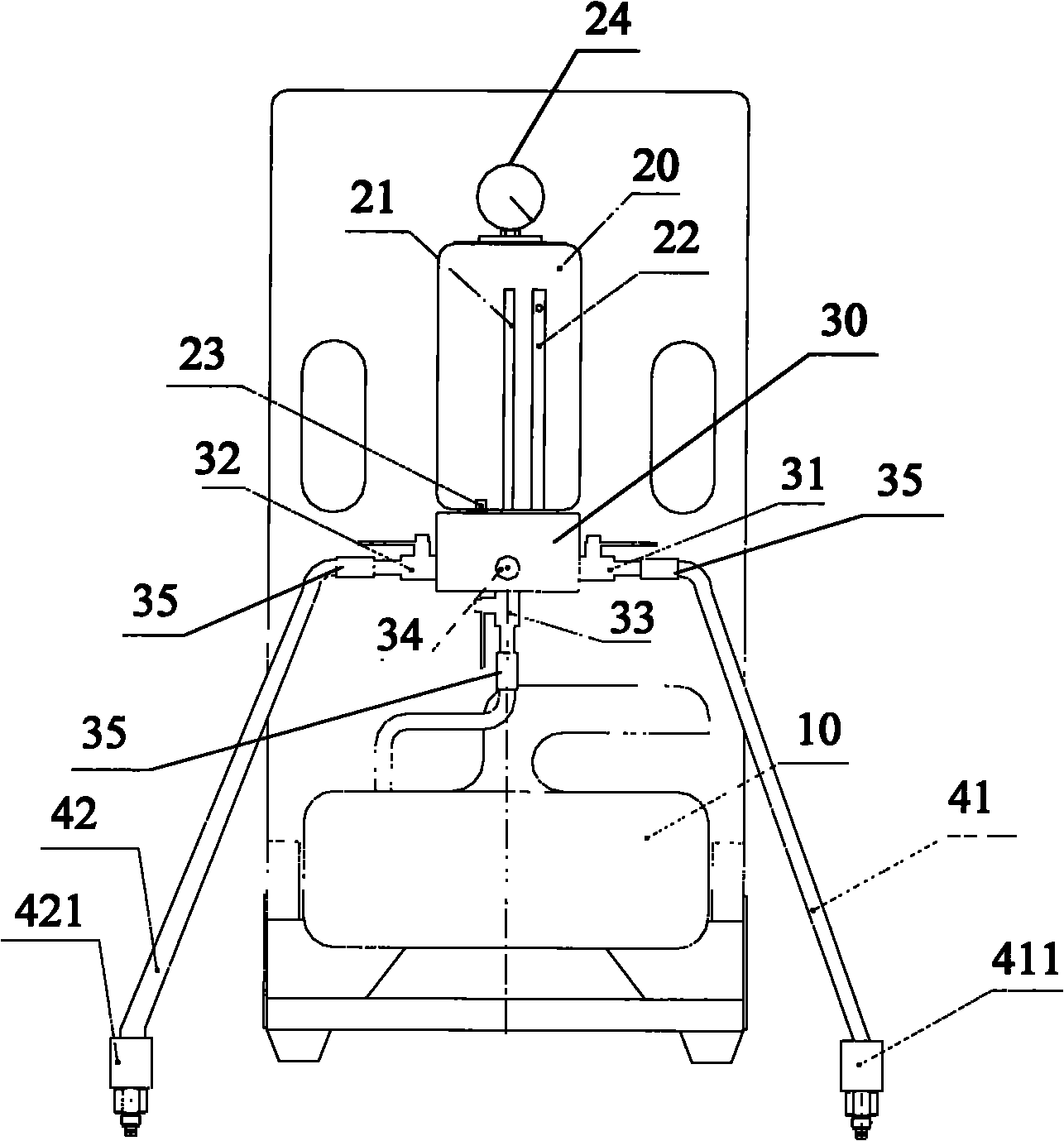

Speed oil filling device for pulse generator of wireless inclinometer and using method thereof

ActiveCN102080534AReduce residual air bubblesNo looseningSurveyLubrication check valvesVacuum pumpAtmosphere

The invention relates to a speed oil filling device for a pulse generator of a wireless inclinometer and a using method thereof, wherein the oil-filled device comprises a vacuum pump, an oil tank, an oil inlet pipeline and an oil outlet pipeline; the oil tank is internally provided with a suction pipe, an oil filling pipe and an oil charging pipe, wherein the suction pipe is connected with the vacuum pipe, and the communication is controlled by a third valve; the oil filling pipe is connected with the oil inlet pipeline, and the communication is controlled by a first valve; and the oil charging pipe is connected with the oil outlet pipeline, and the communication is controlled by a second valve; the lower end of the suction pipe is provided with a fourth valve for controlling the communication between the oil tank and the atmosphere; the ports of the oil inlet pipeline and the oil outlet pipeline are respectively provided with fast insertion type oil filling plugs; and each valve is in seal connection with the corresponding pipeline via a quick screwing type fast plug. The speed oil filling device provided by the invention has excellent sealing performance; a single-hole oil filling method or a double-hole oil filling method is provided; the air remained in an oil bag of the pulse generator is reduced as possible; and the oil is fast and conveniently filled in the pulse generator.

Owner:SHANGHAI GASOLINEEUM & CHEM EQUIP +1

Sucker with Optimum Suction Attachment Effect

InactiveUS20140263894A1Increase negative pressureReduce airStands/trestlesKitchen equipmentEngineeringAir tightness

A sucker includes a sucker body having a rough suction layer which includes a plurality of protrusions which are juxtaposed to each other closely, and a plurality of grooves defined between the protrusions. When the rough suction layer presses an attached face and is disposed at a negative pressure state, the sucker body is pressed toward the attached face by a normal force from the ambient air, so that the rough suction layer is compressed, and the grooves form multiple independent negative pressure or vacuum zones, to increase a negative pressure of the rough suction layer, to decrease air existing in the rough suction layer, and to reduce a vacuum leak in the rough suction layer, so as to increase an air-tightness between the rough suction layer and the attached face.

Owner:TRU MILES HARDWARE

Graphene concrete and preparation process thereof

The invention relates to graphene concrete and a preparation process thereof and solves technical problems of poor durability and proneness to corrosion of concrete in the prior art. The graphene concrete is prepared from, by weight, 150-220 parts of cement, 150-220 parts of sea sand, 225-330 parts of gravels, 5-18 parts of lignosulfonate, 40-100 parts of water, 10-40 parts of silicon powder, 15-45 parts of coal ash, 2-5 parts of graphene, 3-6 parts of oxidized graphene, 1-2.5 parts of magnesium powder, 2-12 parts of polypropylene fibers, 5-15 parts of carbon fibers and 0.5-1 part of ethyleneglycol. The graphene concrete is widely applied to the field of building materials.

Owner:山东昇昀国际贸易有限公司

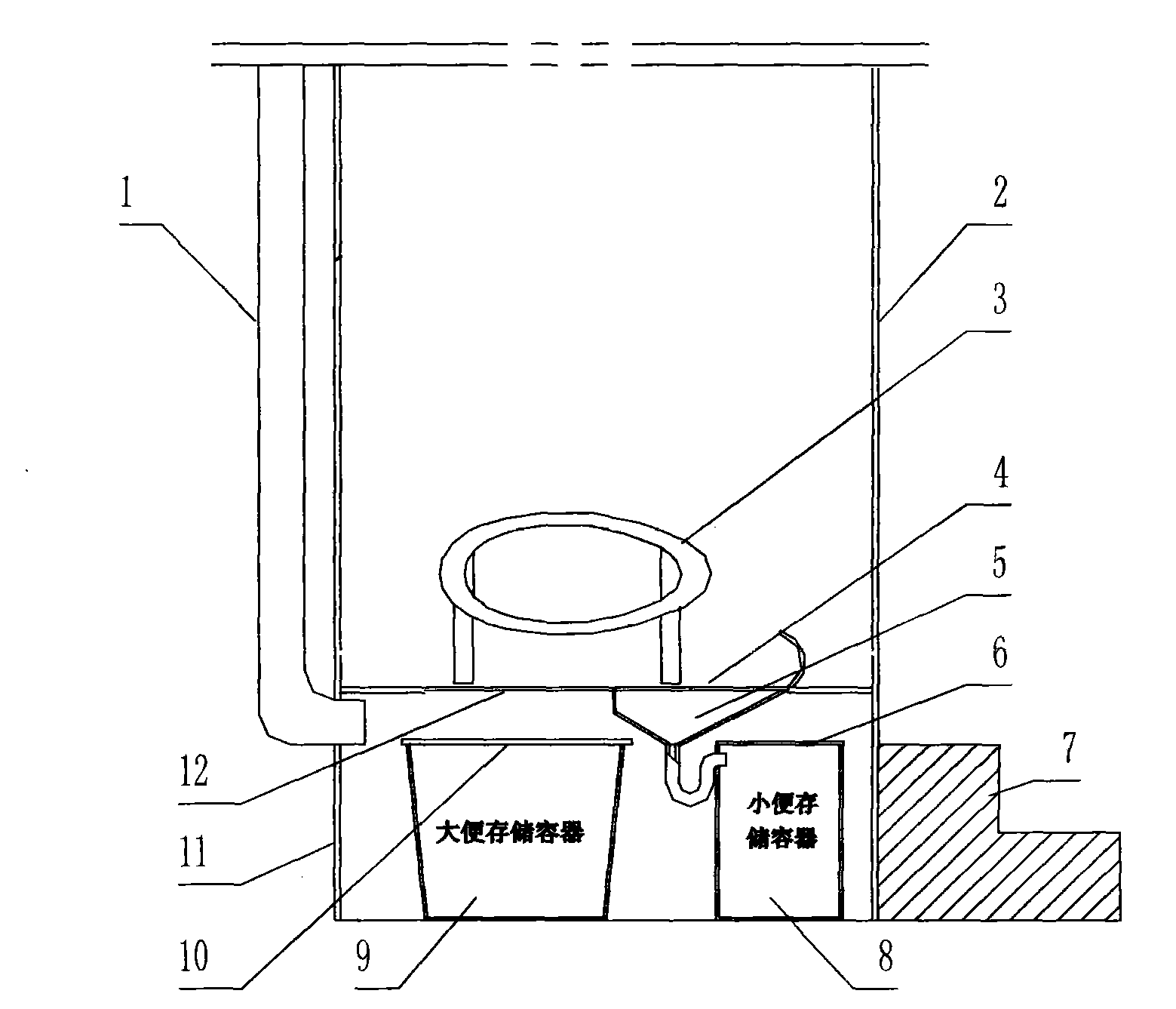

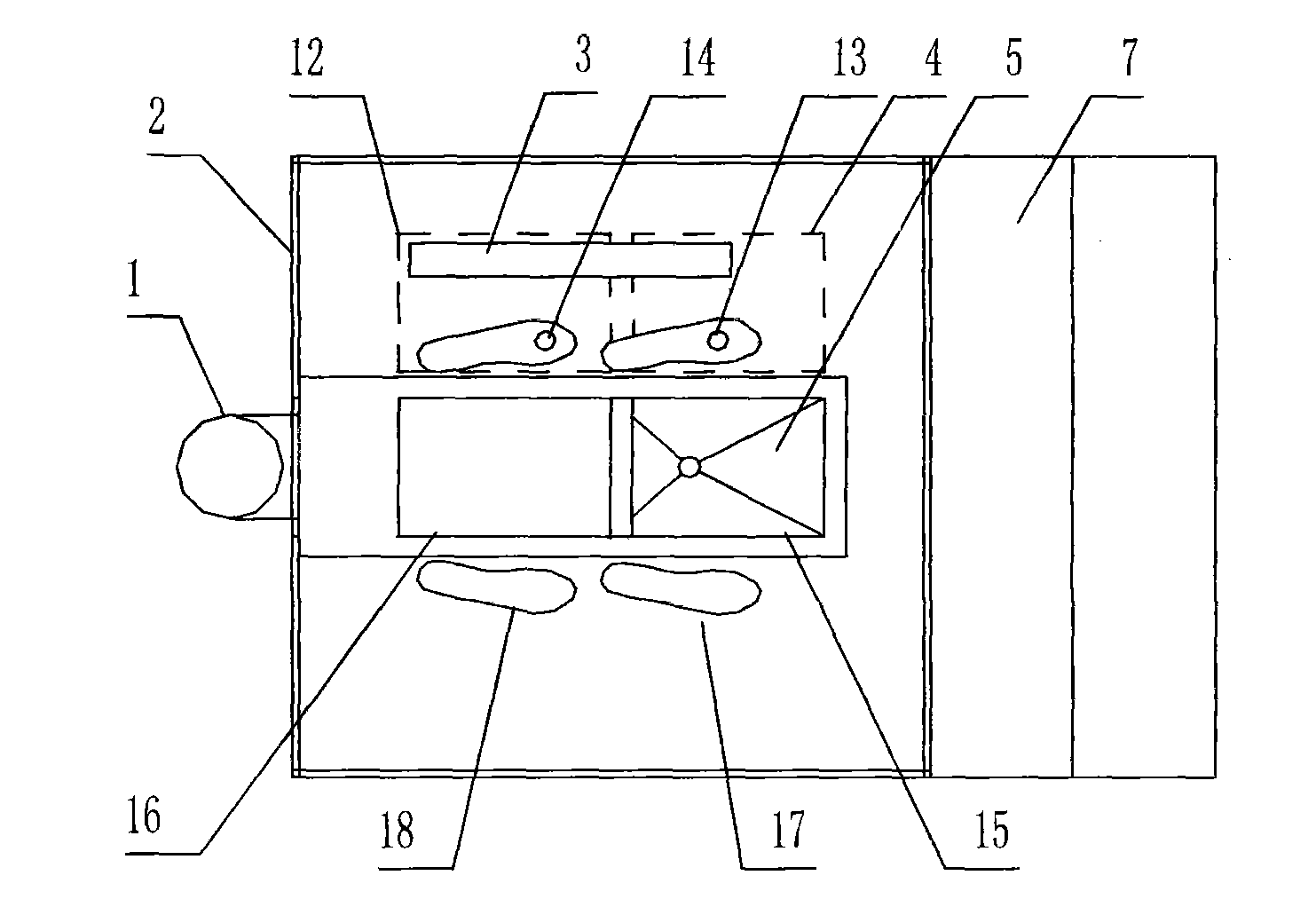

Waterless and environment-friendly manure collection toilet storing urine and shit separately

The invention discloses a waterless and environment-friendly manure collection toilet storing urine and shit separately. A bottom box is arranged; containers for storing urine and shit are arranged in the box; a box door is arranged on one side of the box, defecating and urinating openings and covers are arranged on an upper plate of the bottom box; a urine collection funnel is arranged below the urinating opening; an exhaust pipe and an exhaust fan are arranged at the upper part of a side plate of the bottom box; an upper surrounding plate and a switch door are arranged above the bottom box; steps are arranged beside the bottom box below the switch door; a ventilation fan is arranged at the upper part of the upper surrounding plate; peripheries of box plates and the door of the bottom box are sealed, and peripheries of the covers of the defecating and urinating openings are also sealed; sealing covers controlled by switches are arranged at upper ports of the containers for storing urine and shit, and the covers of the defecating and urinating openings are sealing covers controlled by switches; a front pedal indicating platform, a rear pedal indicating platform and a pedal switch are arranged on the upper plate of the bottom box; and plastic bags are arranged in the containers for storing urine and shit, and a seat support and a disinfecting deodorant sprayer are also arranged on the upper plate of the bottom box. The waterless and environment-friendly manure collection toilet is suitable for construction sites, country areas, water-deficient areas and even water-deficient cities, the structure is simple and complete, the use is convenient, the cost is low, and functions of saving water, protecting environment and collecting manure are particularly prominent.

Owner:TAIYUAN FIRST BUILDING & ENG GRP

Power increase and increase in acceleration performance of diesel fuel compositions

ActiveUS7638661B2High strengthAccelerate emissionsSolid fuelsLiquid carbonaceous fuelsEngineeringControl theory

Use of a viscosity increasing component (ii) in provided in a composition (i) of a diesel fuel for the purpose of: improving the vehicle tractive effort (VTE) and / or acceleration performance of a compression ignition engine or a vehicle powered by such an engine, into which engine the composition (i) is introduced, ormitigating decrease in the vehicle tractive effort (VTE) and / or acceleration performance, in the case of a diesel fuel composition (i) to which an additional component (iii) is introduced for the purpose of improving the emissions performance, of a compression ignition engine or a vehicle powered by such an engine, into which engine the composition (i) is introduced.

Owner:SHELL USA INC

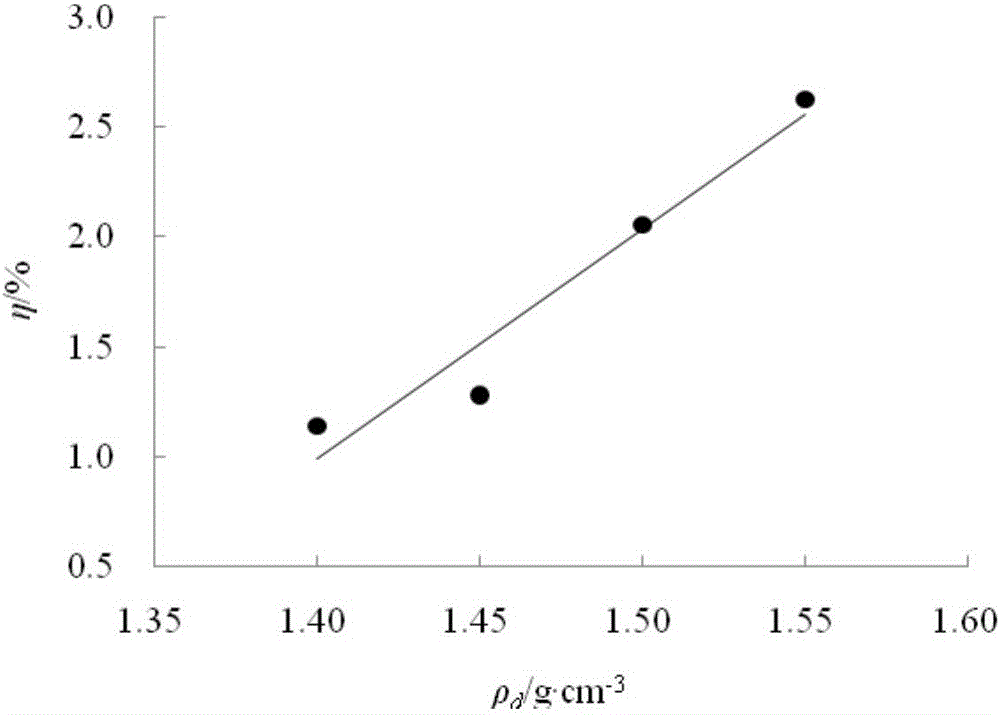

A soil body volumetric water content testing method based on electromagnetic wave time domain reflectometry

ActiveCN106053554AEliminate the effect of accumulated moisture contentReduce mistakesMaterial capacitanceTime-domain reflectometryLinear regression function

A soil body volumetric water content testing method based on electromagnetic wave time domain reflectometry is disclosed. The method includes preparing 3-5 soil body samples with different dry densities, measuring a series of gravimetric water content standard values, gravimetric water content equivalent values w by the electromagnetic wave time domain reflectometry and the dry densities, fitting to obtain a linear regression function about gravimetric water content relative errors [Eta] and the corresponding soil body dry densities [Rho]<di>, with the function being [Eta] = a[Rho]<di> + b, acquiring a water content standard value of a soil body and a calibration coefficient [Zeta] of an electromagnetic wave time domain reflectometry measuring value, with the [Zeta] being equal to 1-a[Rho]<d>-b, measuring a volumetric water content [Theta] of the soil body to be tested by using the electromagnetic wave time domain reflectometry, and further acquiring a calibrated volumetric water content [Theta]' of the soil body by the electromagnetic wave time domain reflectometry, wherein the [Theta]' is equal to [Zeta]*[Theta]. The method eliminates influences of different soil body types and dry density changes on volumetric water content testing by electromagnetic wave time domain reflectometry, obviously reduces test result errors and is accurate and reliable in test results, thus providing more accurate and more reliable test parameters for geotechnical engineering designing and construction.

Owner:SOUTHWEST JIAOTONG UNIV

LED lamp tube with heat-dissipating function

ActiveCN109798456AIncrease cooling areaEasy to cool downLighting heating/cooling arrangementsSemiconductor devices for light sourcesEngineeringLED lamp

The invention relates to an LED lamp tube with a heat-dissipating function, comprising a housing and two connection blocks. A substrate and a plurality of LEDs are arranged in the housing. The side ofthe substrate far away from the LEDs is provided with a plurality of heat-dissipating components; each heat-dissipating component includes an opening, a sealing tube, a sealing plate, a heat-absorbing tube and a heat-dissipating block. When the LED lamp tube with the heat-dissipating function emits light continuously for lighting, the sealing plate is moved under expansion of heated air, and theheat-dissipating area of the heat-absorbing tube is enlarged. A heat transfer block gains contact with a heat-dissipating block to absorb heat, so that air in the heat-absorbing tube and in the heat-dissipating block is decreased; cooling of the substrate is facilitated, operation of the LEDs at a high temperature is avoided, the service life the LED lamp tube is extended, and the LED lamp tube ismore practical.

Owner:永康市恒纽工贸有限公司

Manufacturing technology of high-strength low-elongation polytetrafluoroethylene filaments

InactiveCN104894675AHigh strengthReduce airArtificial thread manufacturing machinesFilament/thread formingCompression moldingState of art

The invention belongs to the field of preparation of polytetrafluoroethylene functional materials and provides a manufacturing technology of high-strength low-elongation polytetrafluoroethylene filaments to solve the problems that the PTFE (polytetrafluoroethylene) filaments produced in the prior art generally are of low strength and excessively high elongation. The manufacturing technology includes: low-temperature oil treatment, curing treatment, compression molding, strip extruding, thermal elongating, slitting, filament manufacturing, and drawing and setting. The high-strength low-elongation polytetrafluoroethylene filaments are of strength up to 48-52 CN / tex and elongation at break, only 6% to 10%, the ideal indexes, high strength and low elongation, are achieved, and improvement and breakthrough on the quality of the polytetrafluoroethylene filaments are made; by the use of vacuum compression molding, the air in formed plastic is greatly reduced, the semi-finished products are higher in density and uniformity, and the manufacturing technology plays a key role in improving the quality of products made by the following pushing and rolling process.

Owner:常州万容新材料科技有限公司

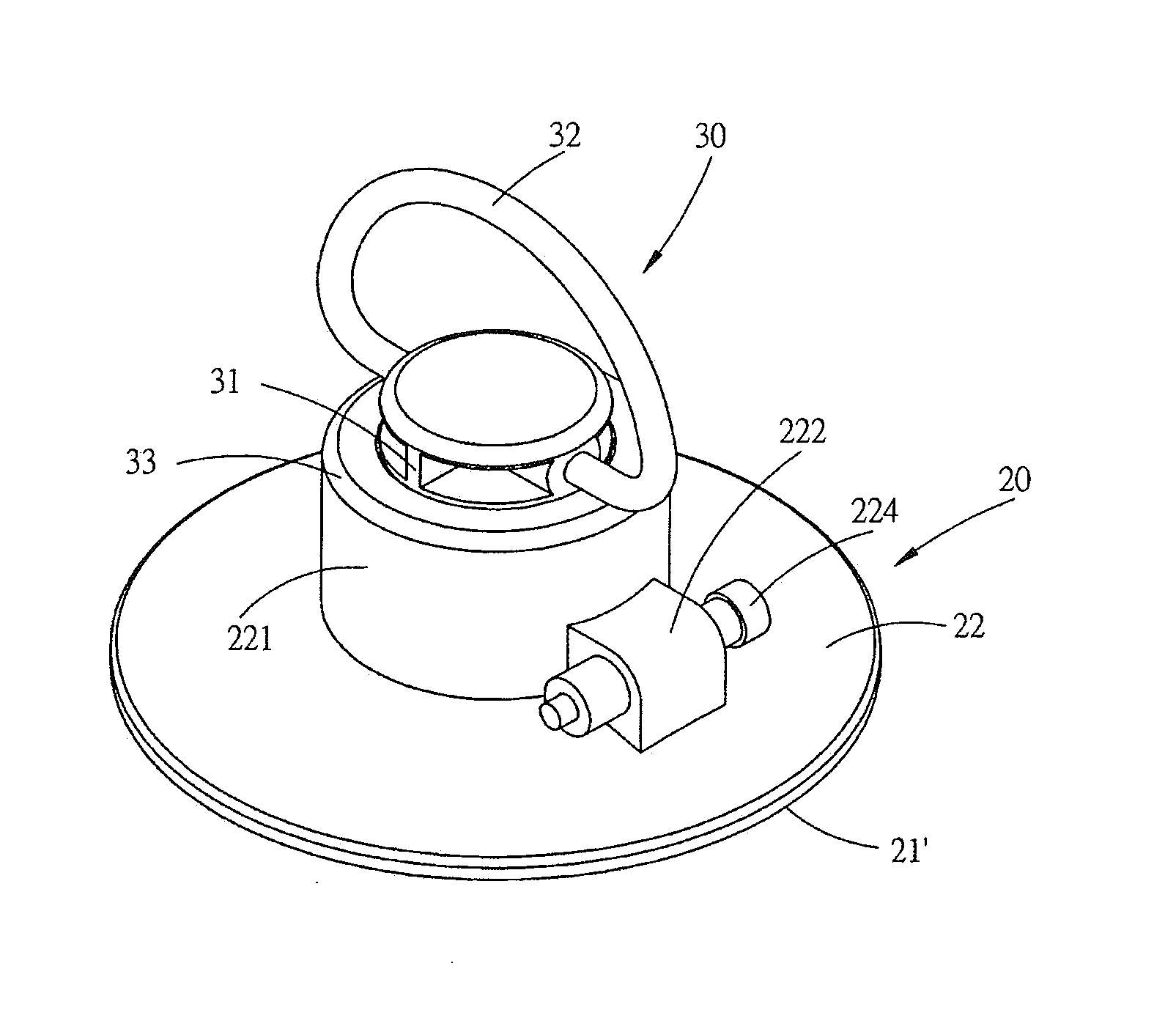

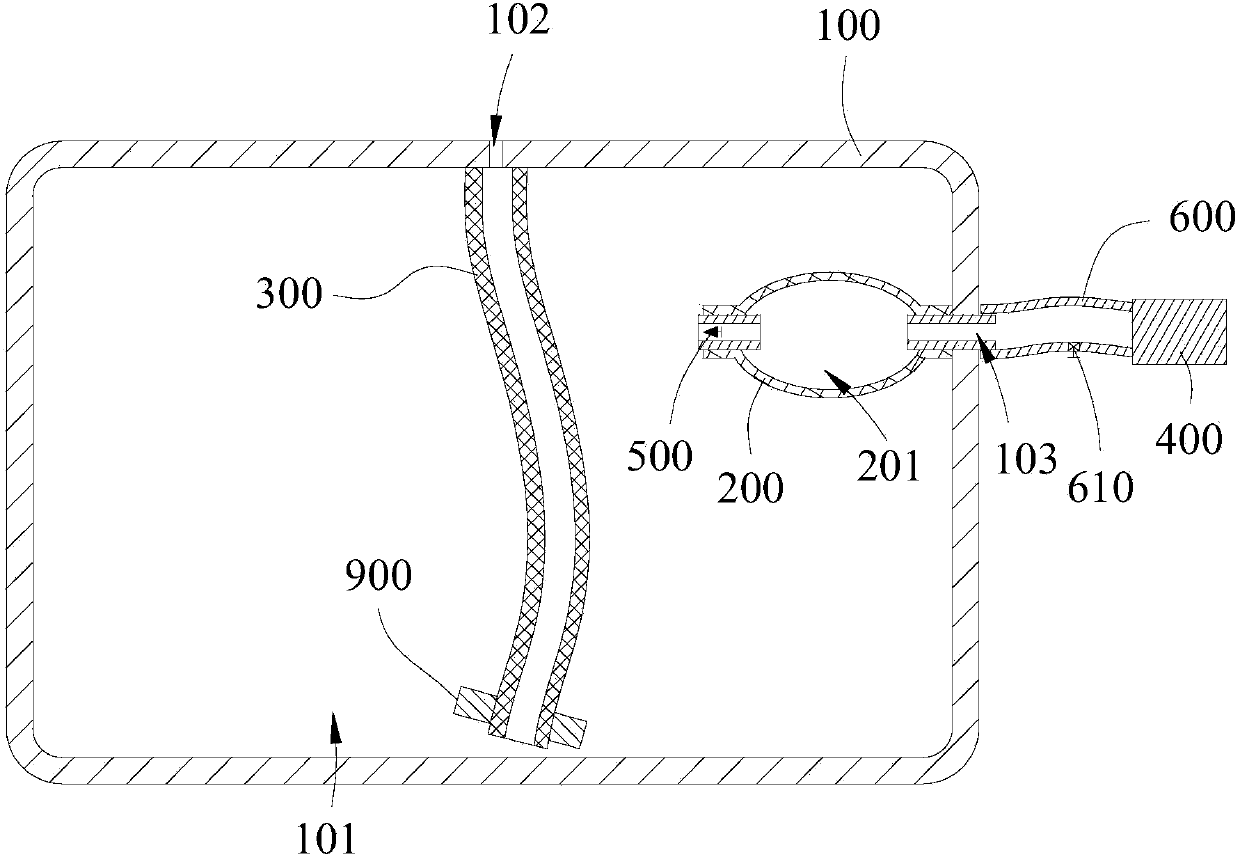

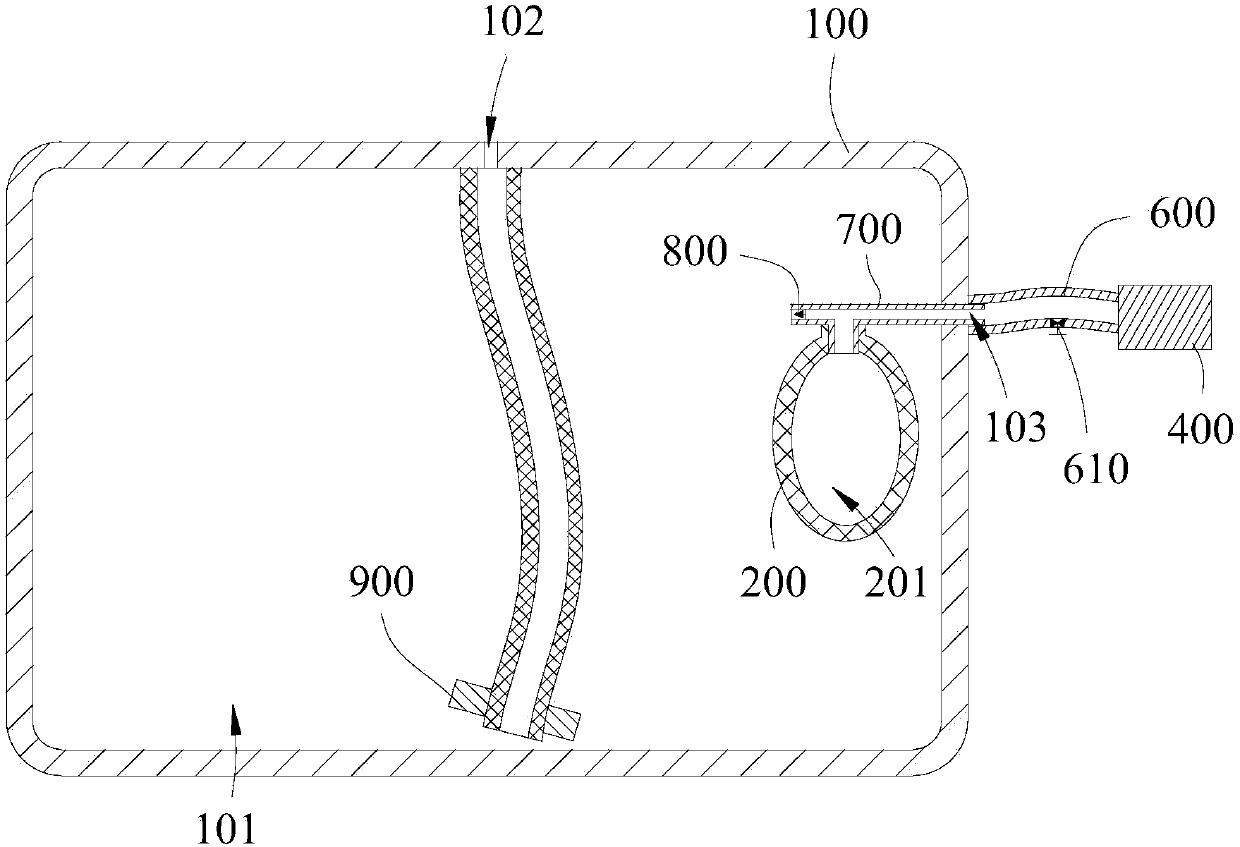

Feeding assembly and coating device

InactiveCN107899892AImprove the airReduce airLiquid surface applicatorsCoatingsButt jointEngineering

The invention discloses a feeding assembly and a coating device. The feeding assembly comprises a storing container (100), an air bag (200), a first connecting pipe (300) and an air pressure pump (400). The storing container (100) is provided with a container cavity (101) used for storing coating, and the container wall of the storing container (100) is provided with a discharging opening (102) and an air guiding hole (103) which both communicate with the container cavity (101). The air bag (200) is made of a flexible material, arranged in the container cavity (101), used for blocking communicating of the container cavity (101) and the air guiding hole (103), and provided with a bag cavity (201) used for storing air. The air guiding hole (103) communicates with the bag cavity (201), and the first connecting pipe (300) is arranged in the container cavity (101) and is in butt joint with the discharging opening (102). The air pressure pump (400) is used for conducting inflation / air exhaust on the bag cavity (201) through the air guiding hole (103). When the feeding assembly needs to stop feeding, the situation of continuous overflowing of the coating cannot occur.

Owner:梁涛

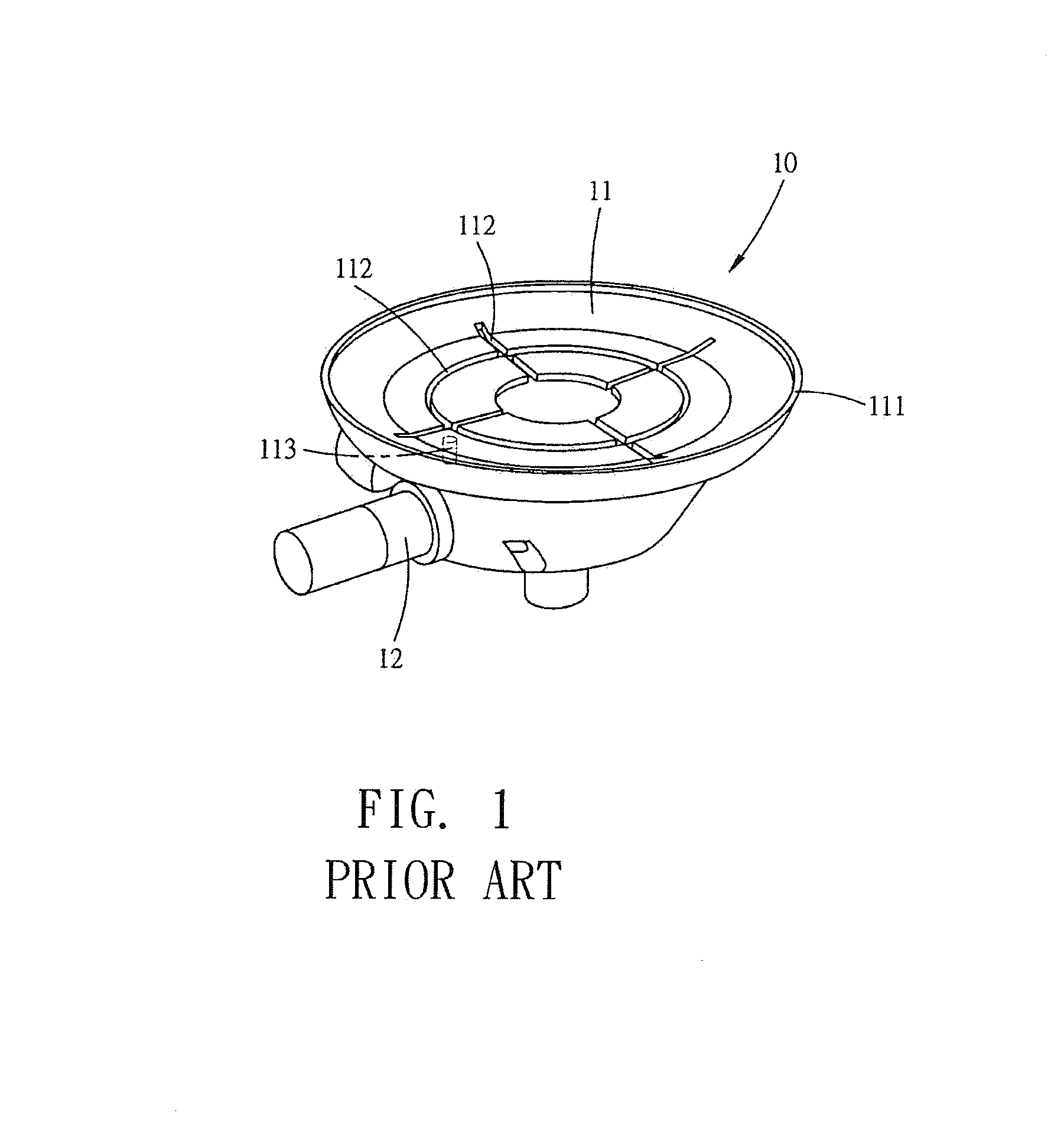

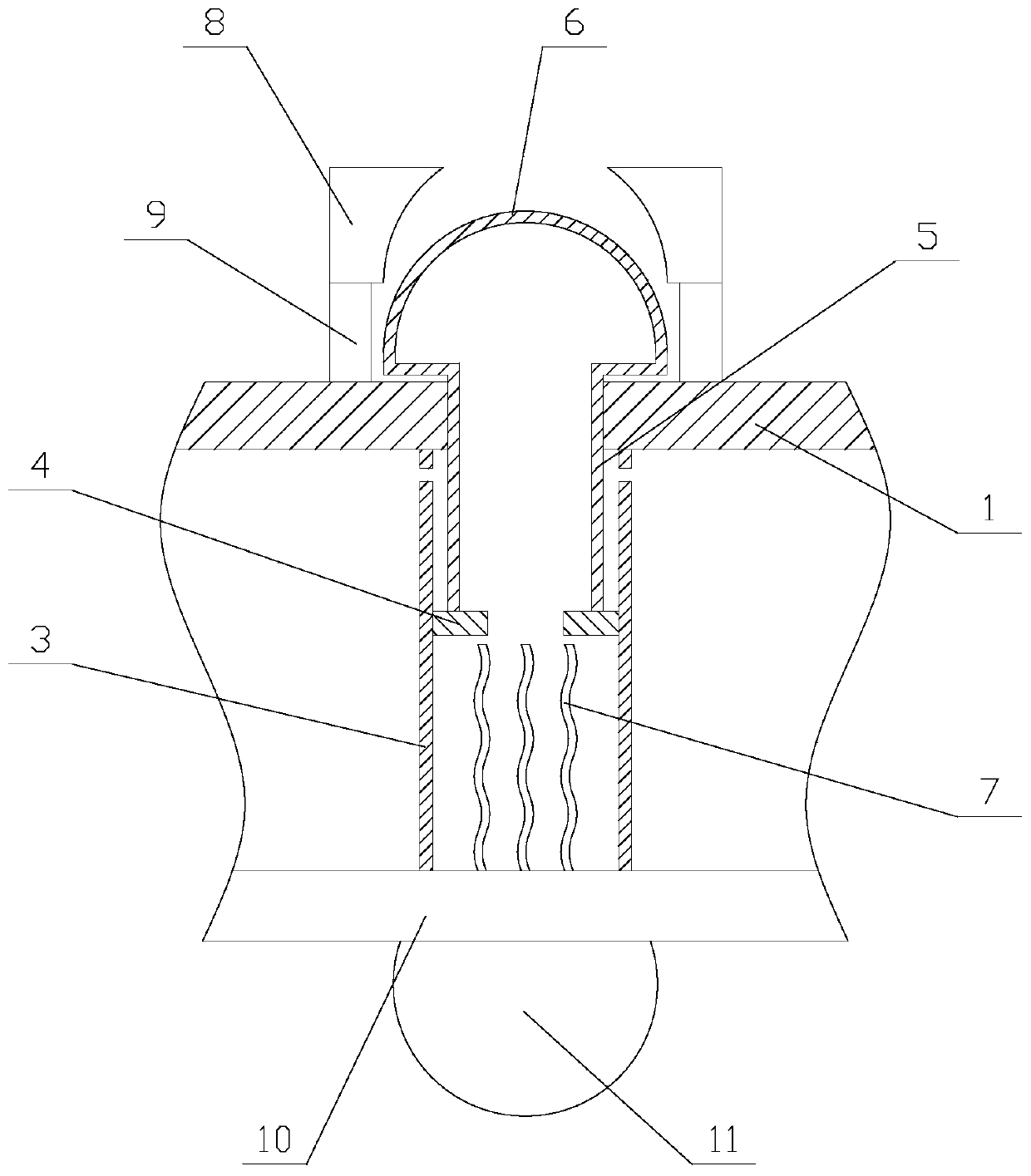

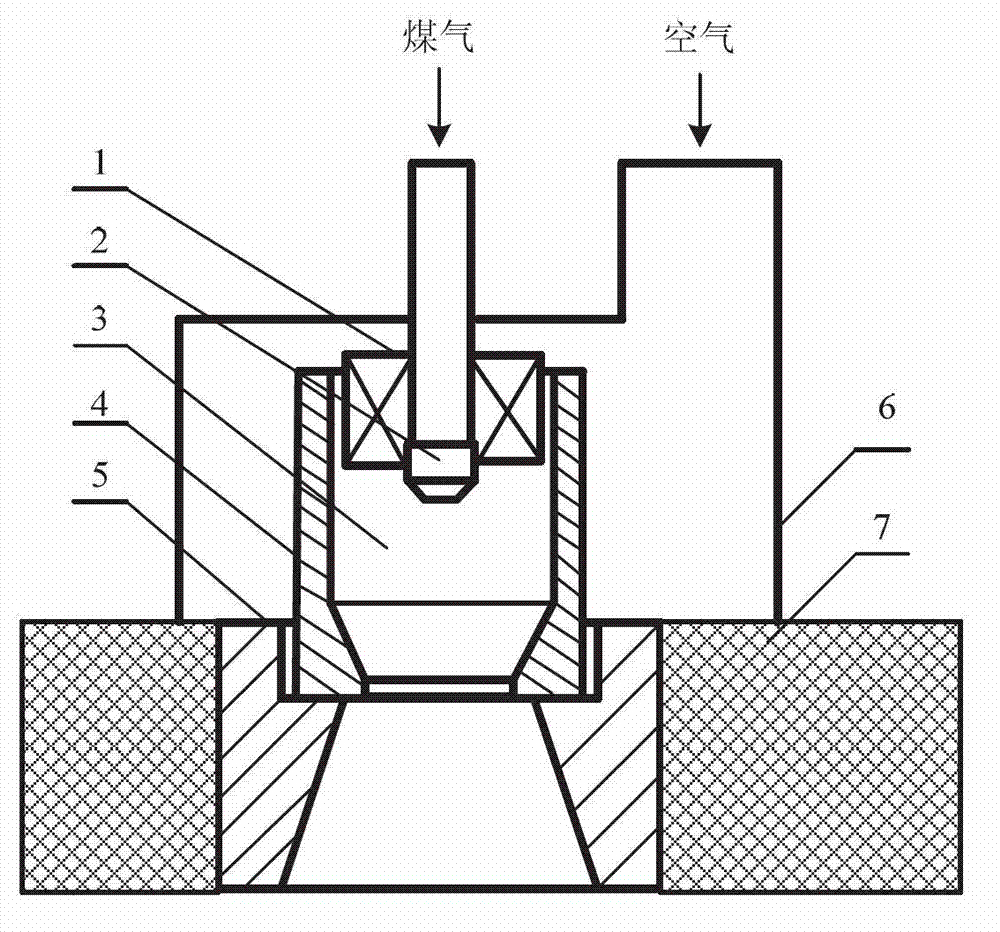

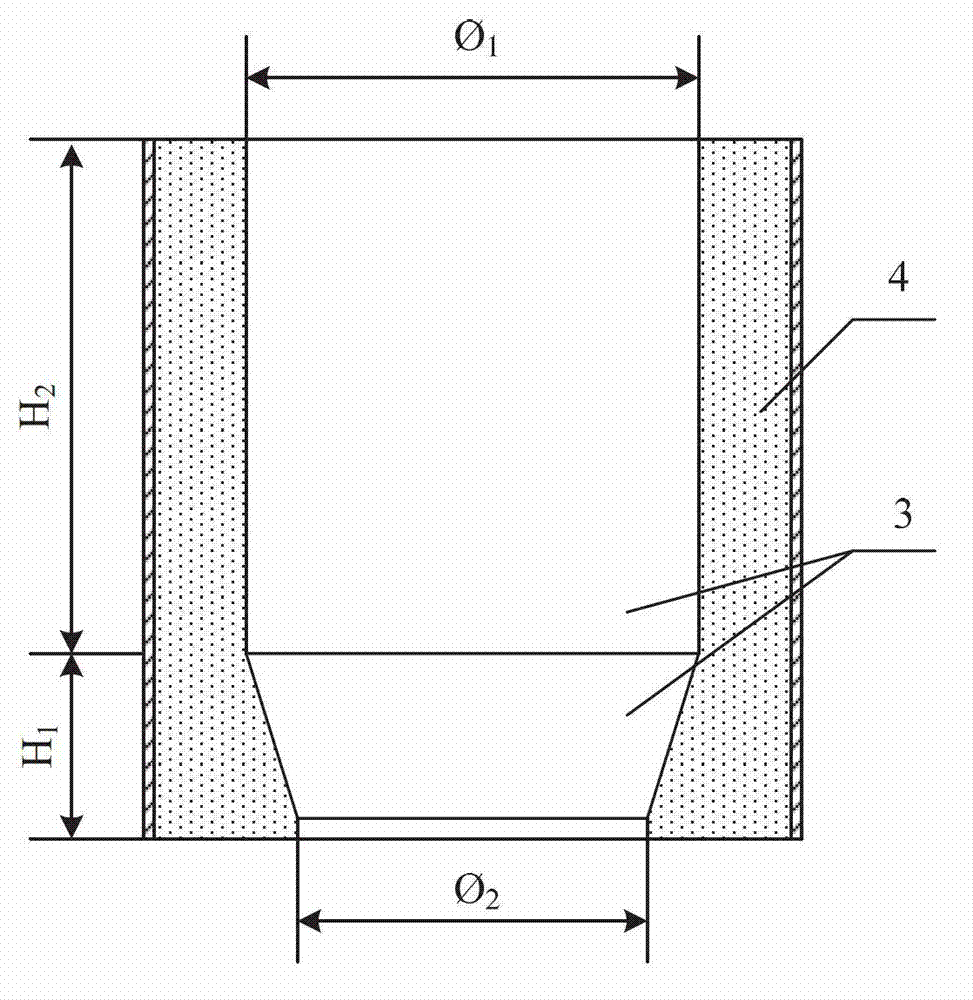

Swirling flow premixing type burner

The invention discloses a swirling flow premixing type burner. The swirling flow premixing type burner comprises a first burner brick, a second burner brick, a burning-supporting air chamber, an air swirler and a fuel gas nozzle, wherein a central hole is formed in the first burner brick; an upper section of the central hole is matched with the shape of the exterior outline and the dimension of the second burner brick; a lower section of the central hole is a cone-shaped hole with a large upper end aperture and small lower end aperture; a premixing chamber is arranged in a central part of the second burner brick; the fuel gas nozzle is a swirling flow nozzle and consists of a nozzle body and a gas inlet pipe which is connected with the nozzle body; the first burner brick is arranged on a furnace body; the second burner brick is arranged in the first burner brick; the air swirler is positioned at the inlet of the premixing chamber arranged in the second burner brick; the fuel gas nozzle is combined with the air swirler; the nozzle body of the fuel gas nozzle is positioned below the air swirler; and the burning-supporting air chamber is arranged on the furnace body.

Owner:SICHUAN UNIV

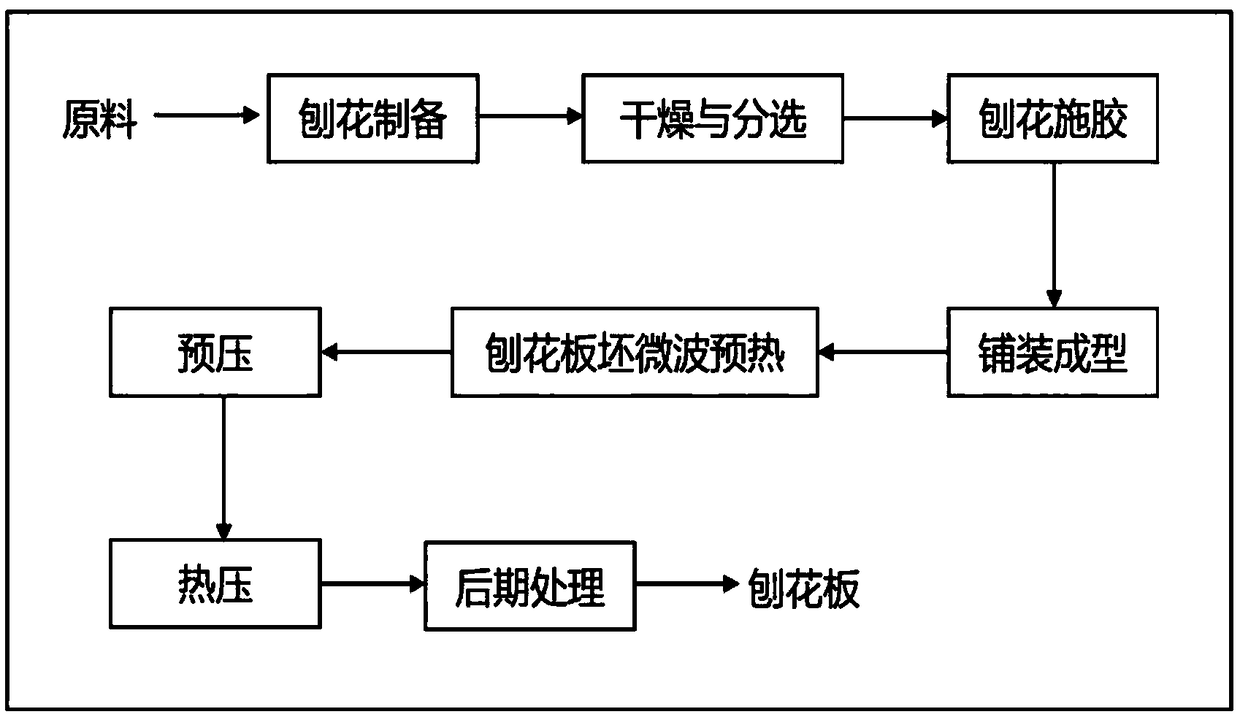

Chipboard making method through microwave preheating

InactiveCN109262795AImprove compactnessReduce airFlat articlesDomestic articlesWood shavingsMicrowave

The invention discloses a chipboard making method through microwave preheating. The method comprises the processes of wood shaving making, drying and screening, wood shaving gluing, laying and forming, prepressing, hot pressing and later processing. According to the chipboard making method, a chipboard microwave preheating process is additionally set between the laying process and the prepressingprocess, the chipboard is quickly preheated, a surface core layer of a plate blank is heated and subjected to temperature increase at the same time, the initial temperature of the laid chipboard blankduring prepressing and hot pressing is increased, air in the prepressed chipboard blank is reduced, and the heat transmission efficiency during hot press is improved; meanwhile, the heating and temperature increase time of the chipboard blank in a hot press is shortened, the curing speed of an adhesive is increased, the whole time of producing and making the chipboard is shortened, and the production efficiency is improved.

Owner:嘉木远景(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com