Patents

Literature

45results about How to "Easy to cool down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

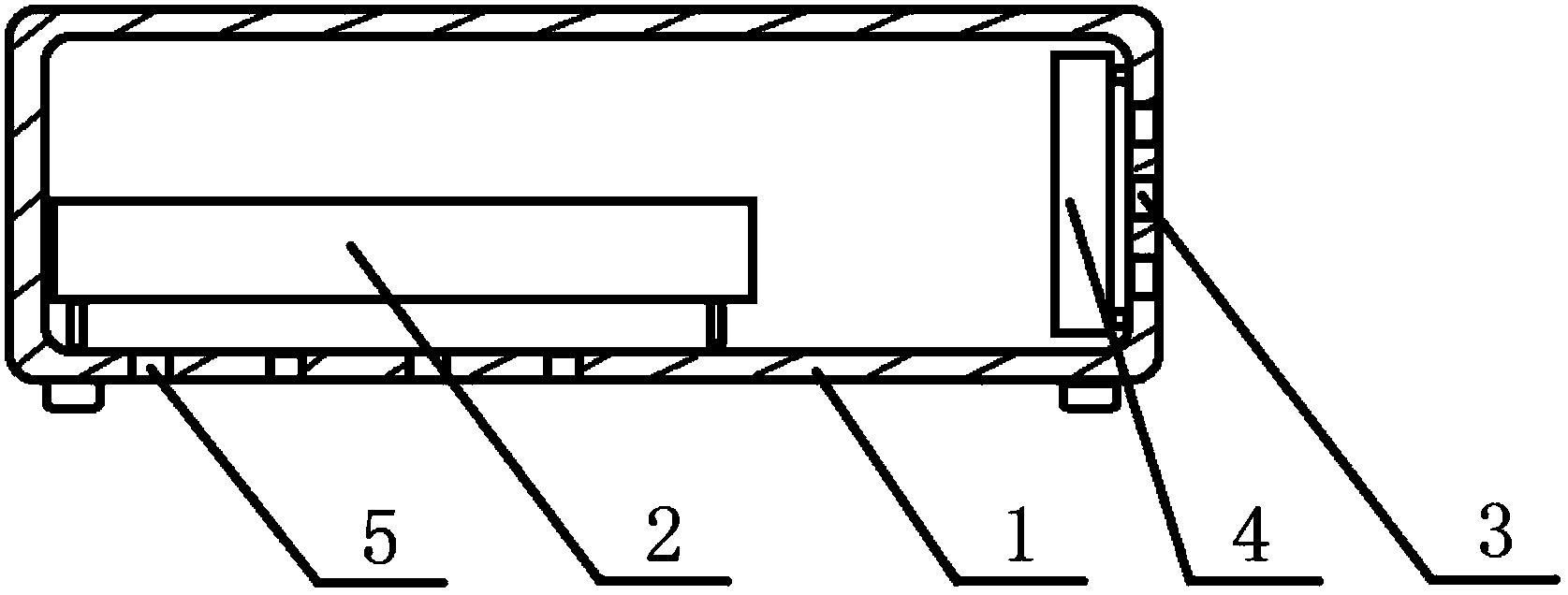

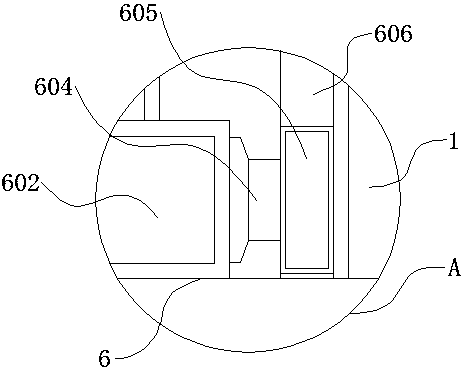

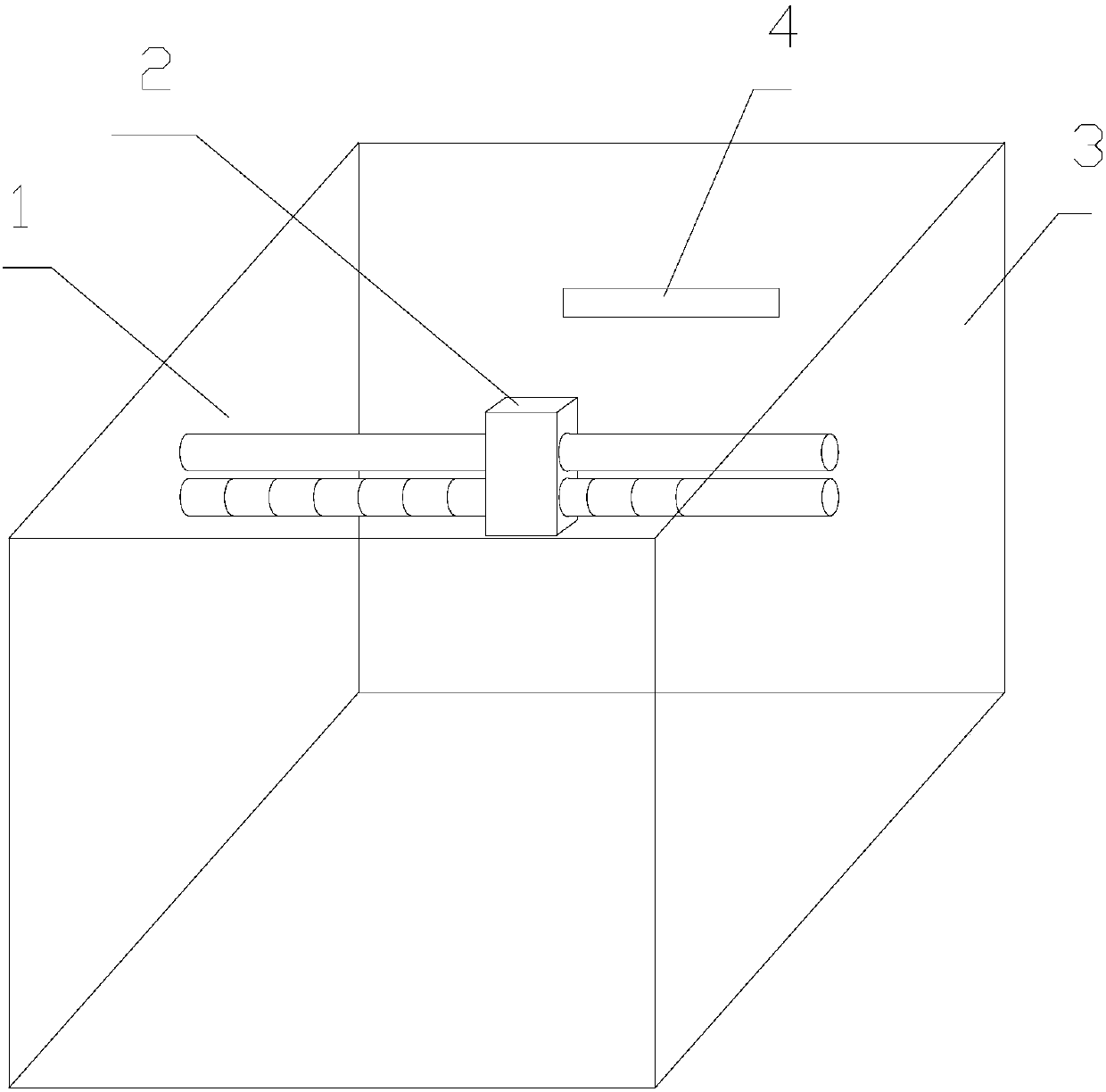

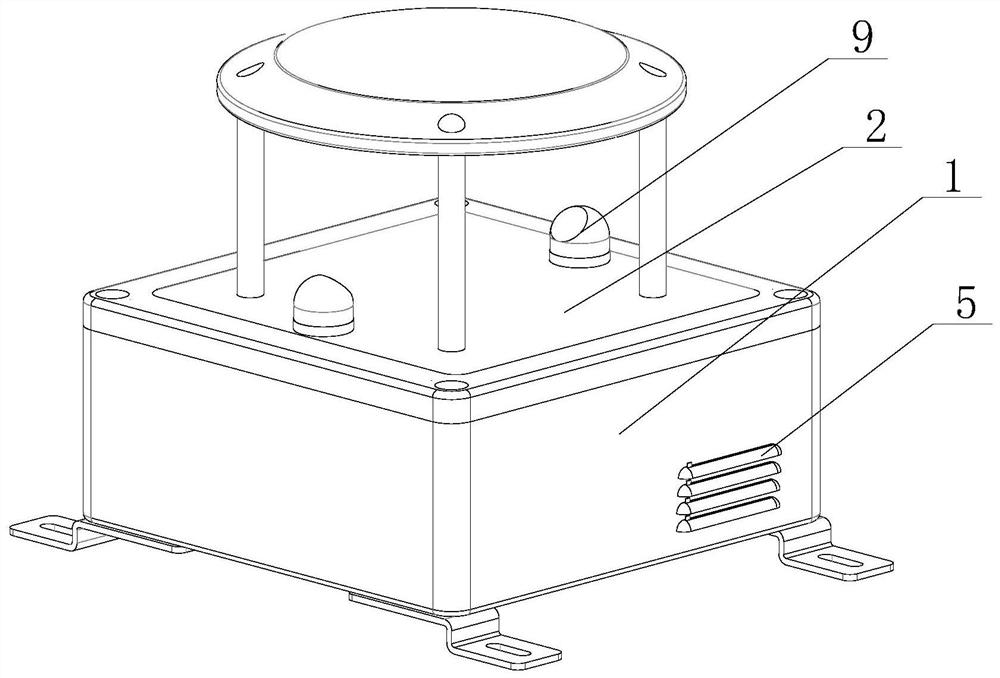

Router

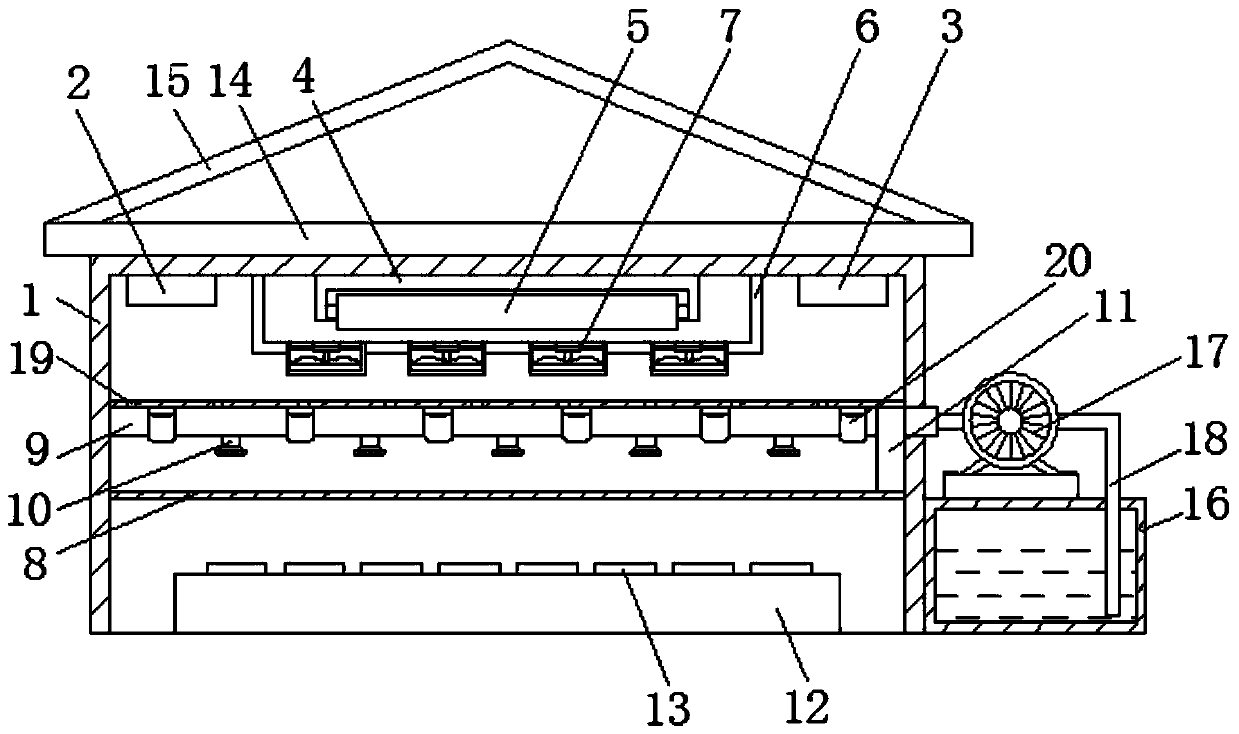

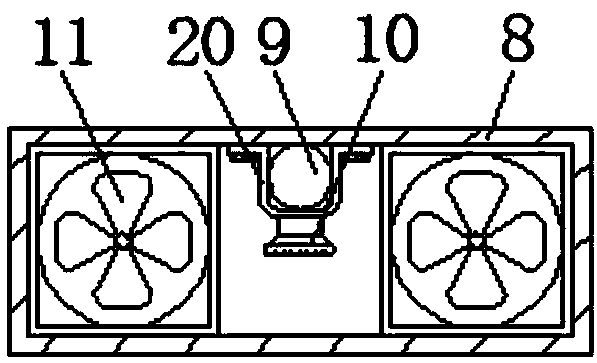

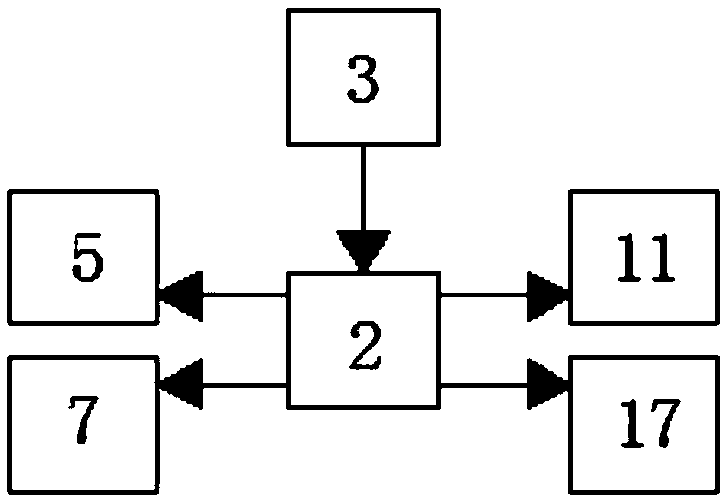

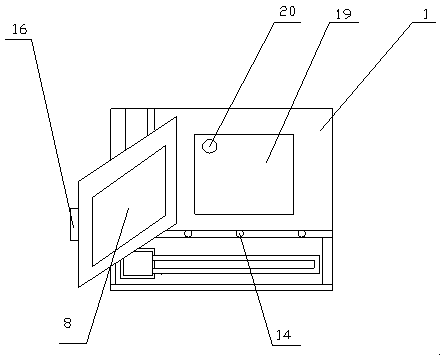

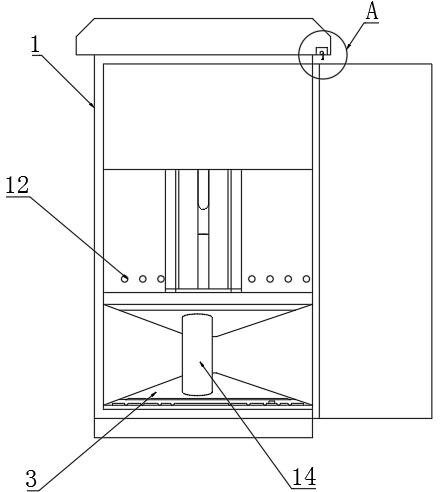

InactiveCN103685042AExtended service lifeEasy to cool downData switching networksCooling/ventilation/heating modificationsWorking temperatureComputer engineering

The invention provides a router. The router comprises a housing and a circuit board, wherein the circuit board is located in the housing and fixedly connected with the housing. The router is characterized in that ventilation holes are formed in the side wall of the housing; a fan is arranged on the inner side of the side wall; the fan is fixedly connected with the inner side wall of the housing. The router has the beneficial effects that the added ventilation holes and the fan can exhaust hot air in the housing in time to cool the circuit board, keep the circuit board at proper working temperature, and prolong the service life of the circuit board; air holes are added under the circuit board, and thus the air can be introduced in the housing through the air holes, which is convenient to cool the circuit board.

Owner:TIANJIN XINYUN NETWORK TECH

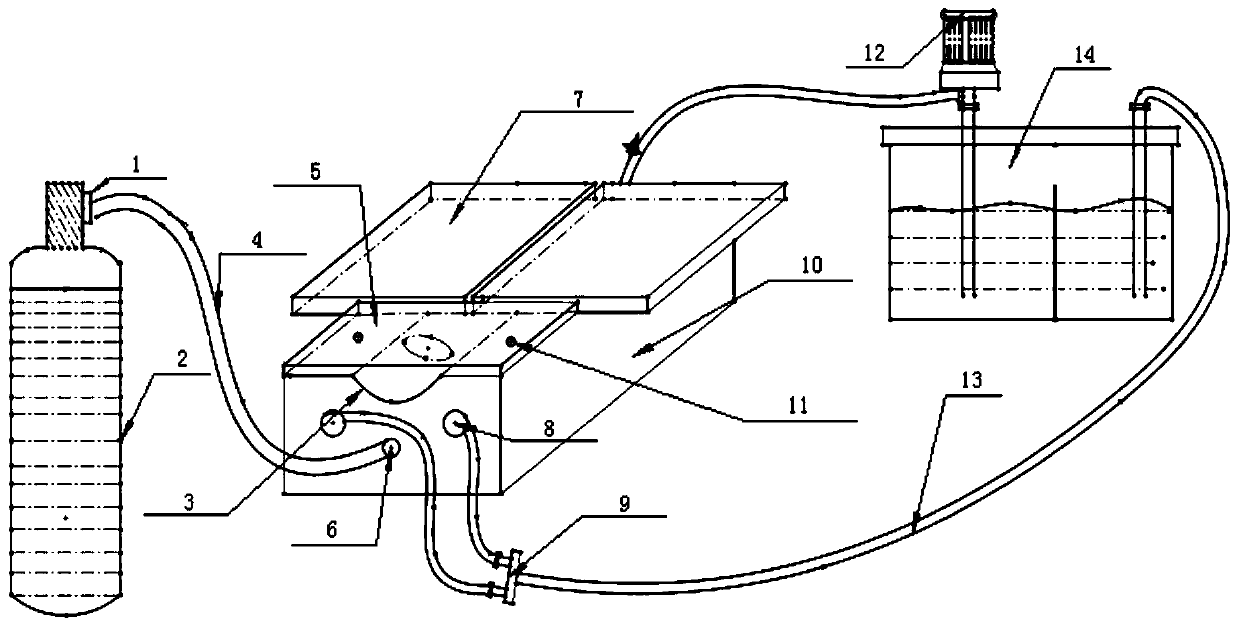

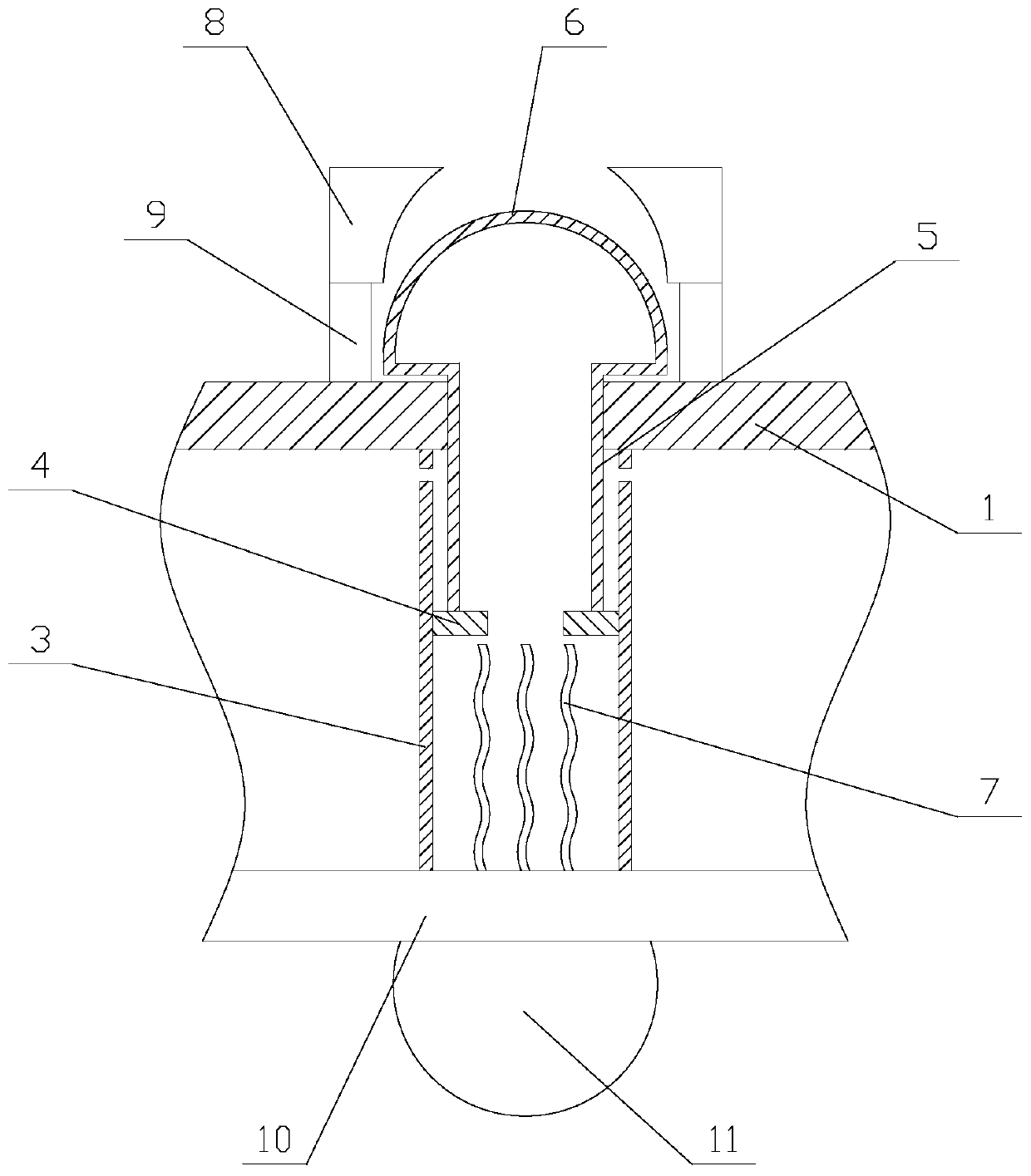

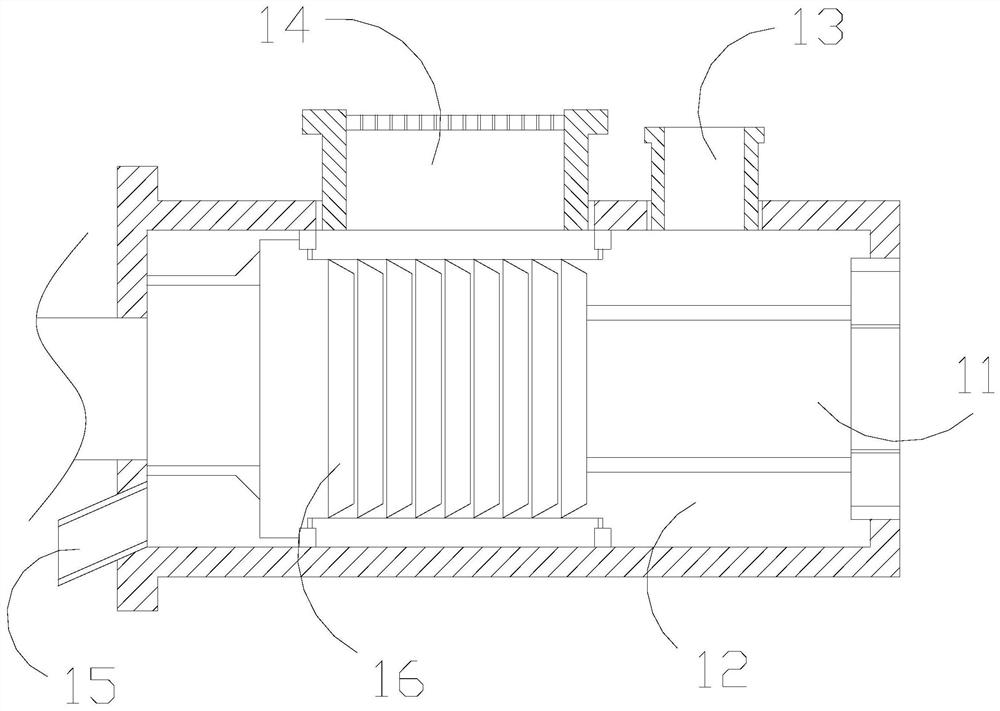

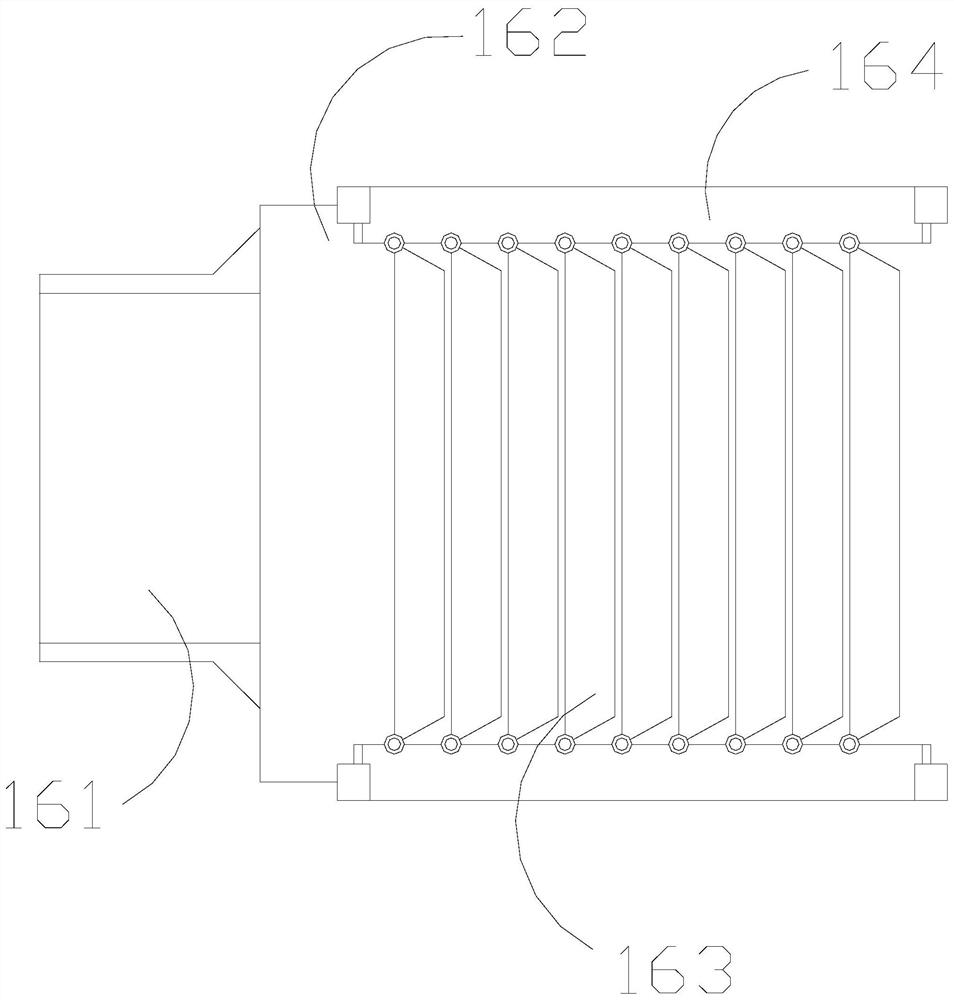

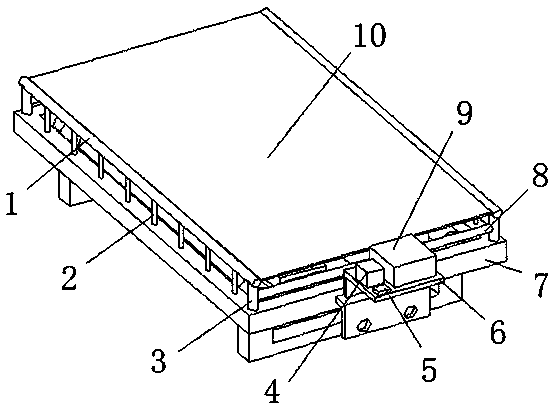

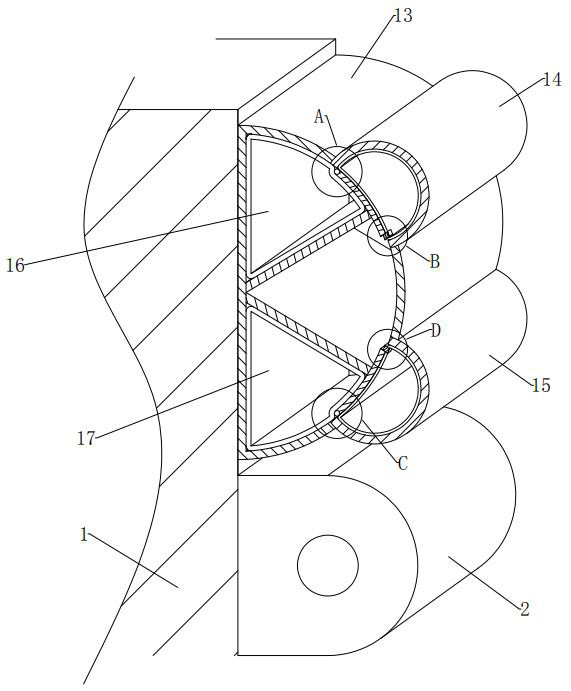

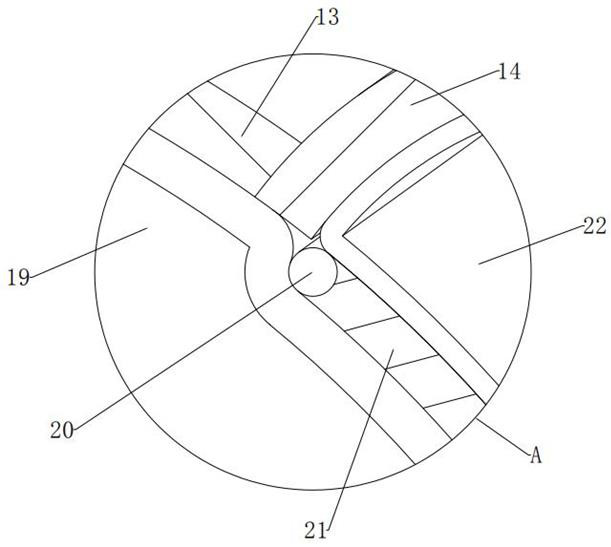

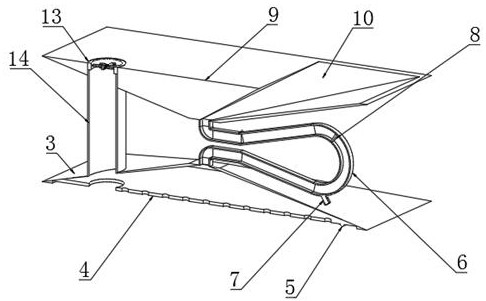

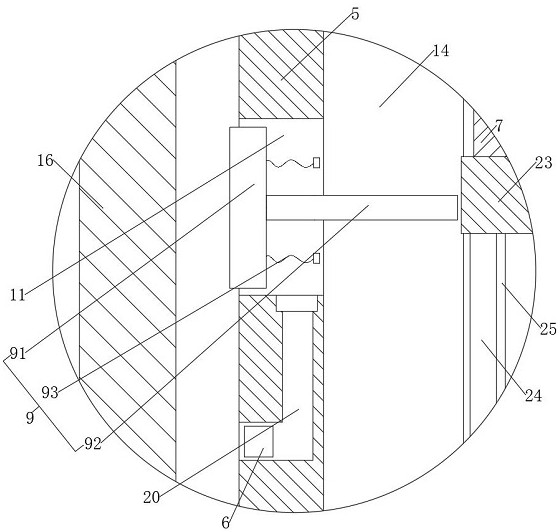

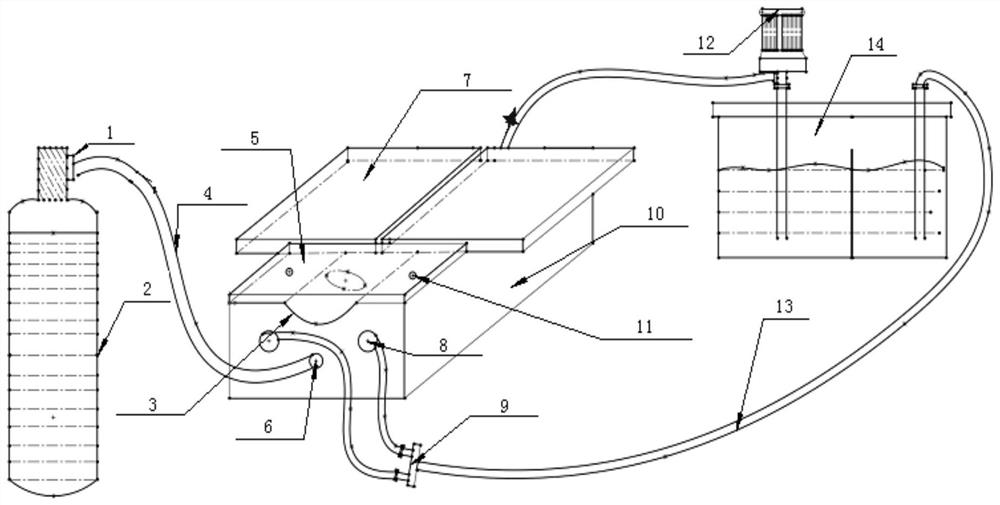

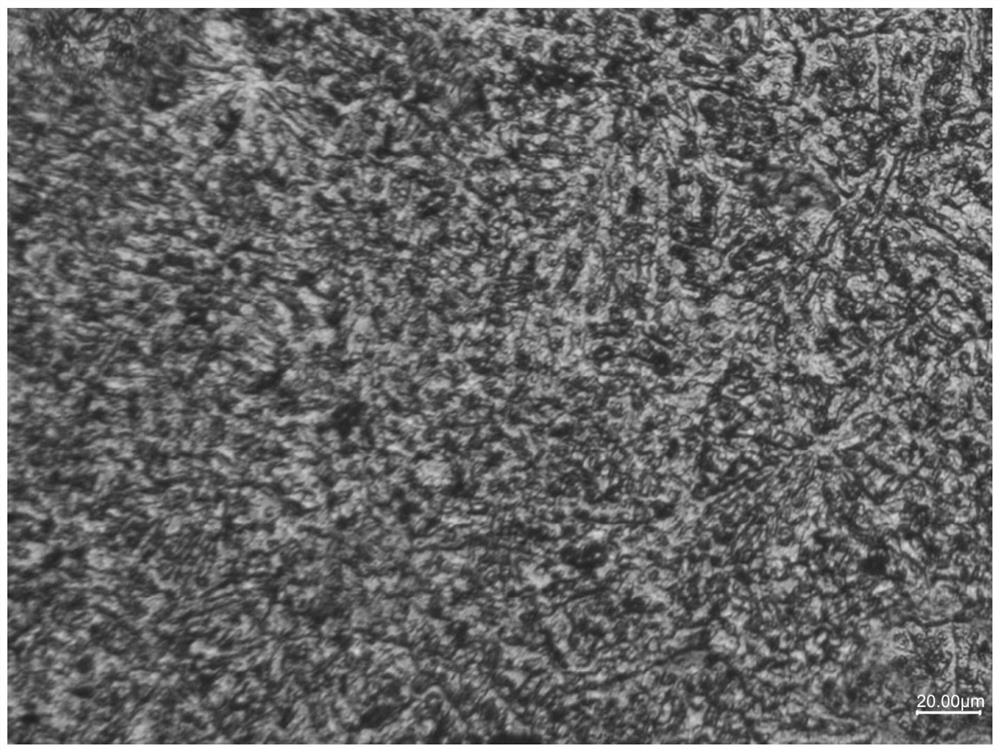

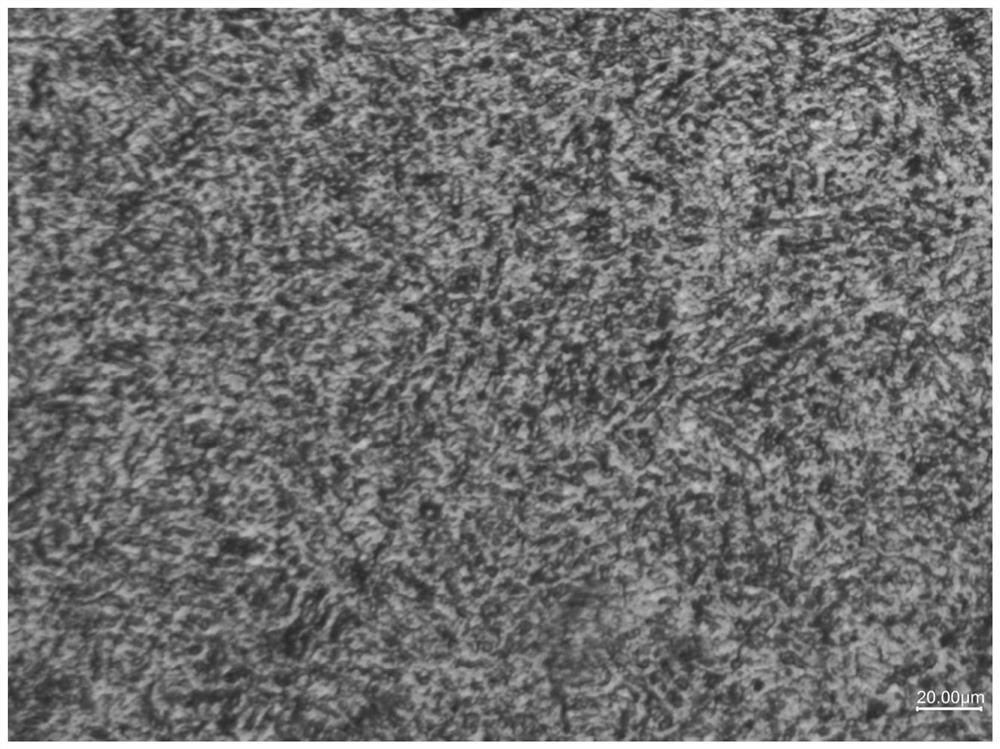

Single-sided welding copper liner device with water cooling and back protection and corresponding welding method

ActiveCN109865966ACompact structureReduce weightWelding/cutting auxillary devicesAuxillary welding devicesWeld seamElectric arc

The invention belongs to the technical field of welding, and particularly relates to a single-sided welding copper liner device with water cooling and back protection and a corresponding welding method. By circulating cooling water and shielding gas inside a copper liner, the good welding forming effect of workpieces to be welded is ensured, many beneficial effects of reducing welding deformation,prolonging the service life of the liner, preventing oxidation inclusion on the back of a weld seam, refining weld seam grains, improving the tensile strength of the weld seam and the like are realized, and the single-sided welding copper liner device is suitable for various electric-arc welding methods.

Owner:WUHAN UNIV OF TECH +1

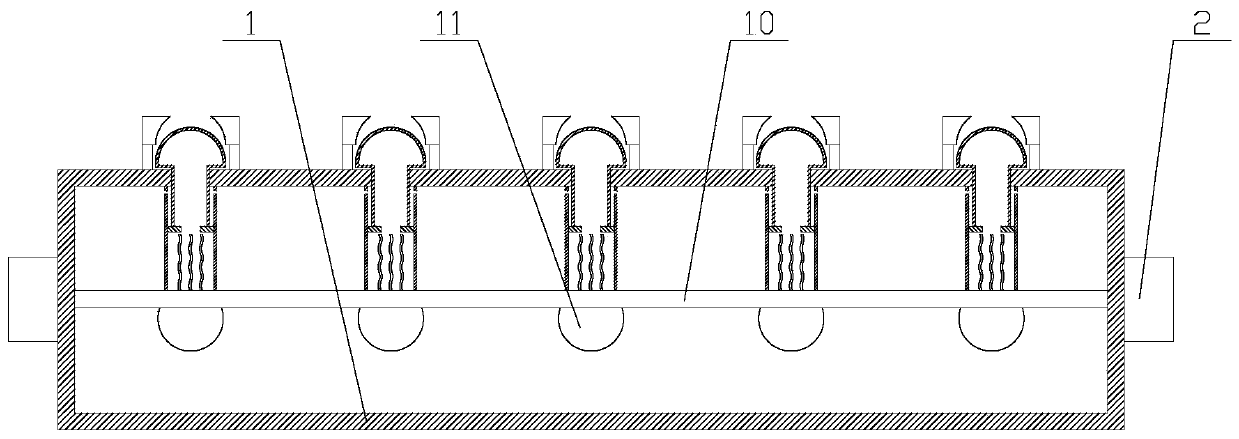

LED lamp tube with heat-dissipating function

ActiveCN109798456AIncrease cooling areaEasy to cool downLighting heating/cooling arrangementsSemiconductor devices for light sourcesEngineeringLED lamp

The invention relates to an LED lamp tube with a heat-dissipating function, comprising a housing and two connection blocks. A substrate and a plurality of LEDs are arranged in the housing. The side ofthe substrate far away from the LEDs is provided with a plurality of heat-dissipating components; each heat-dissipating component includes an opening, a sealing tube, a sealing plate, a heat-absorbing tube and a heat-dissipating block. When the LED lamp tube with the heat-dissipating function emits light continuously for lighting, the sealing plate is moved under expansion of heated air, and theheat-dissipating area of the heat-absorbing tube is enlarged. A heat transfer block gains contact with a heat-dissipating block to absorb heat, so that air in the heat-absorbing tube and in the heat-dissipating block is decreased; cooling of the substrate is facilitated, operation of the LEDs at a high temperature is avoided, the service life the LED lamp tube is extended, and the LED lamp tube ismore practical.

Owner:永康市恒纽工贸有限公司

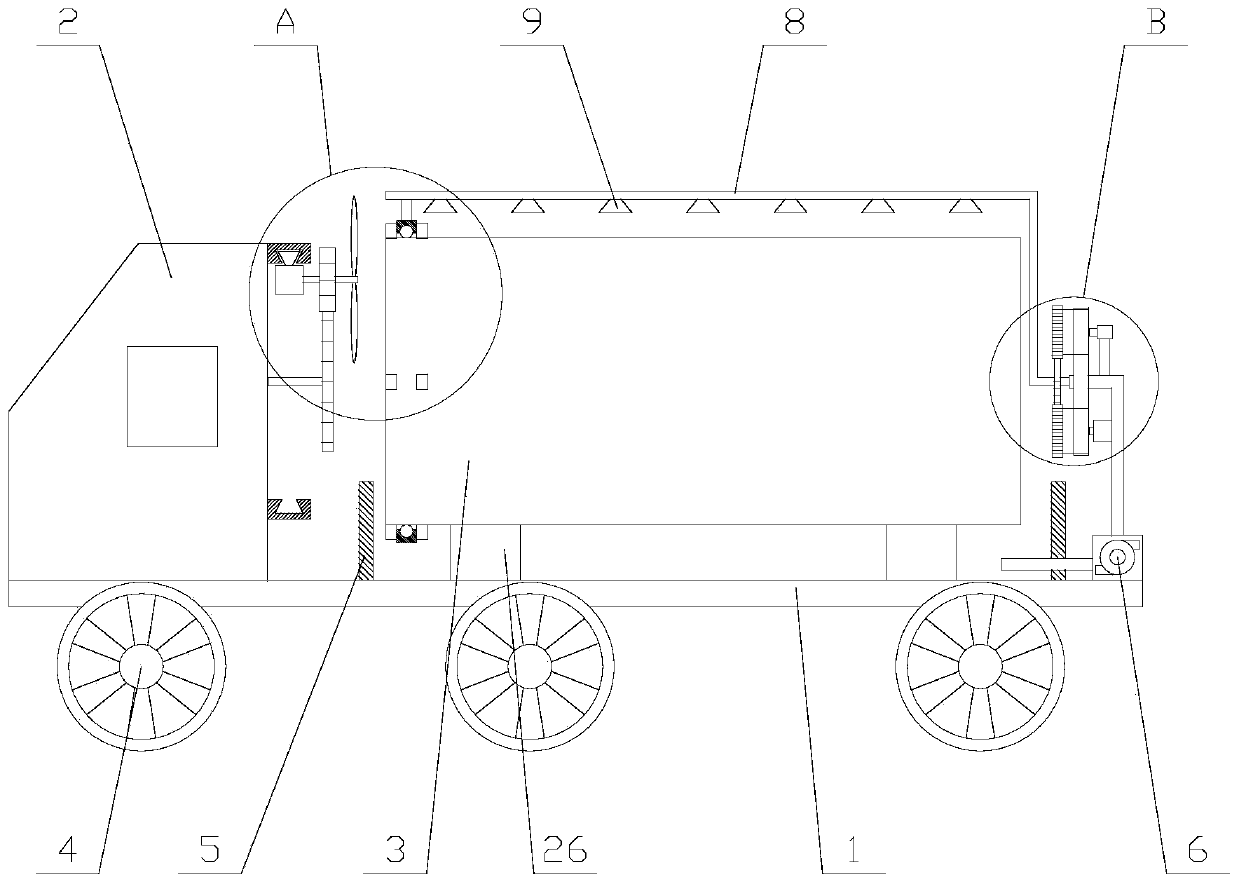

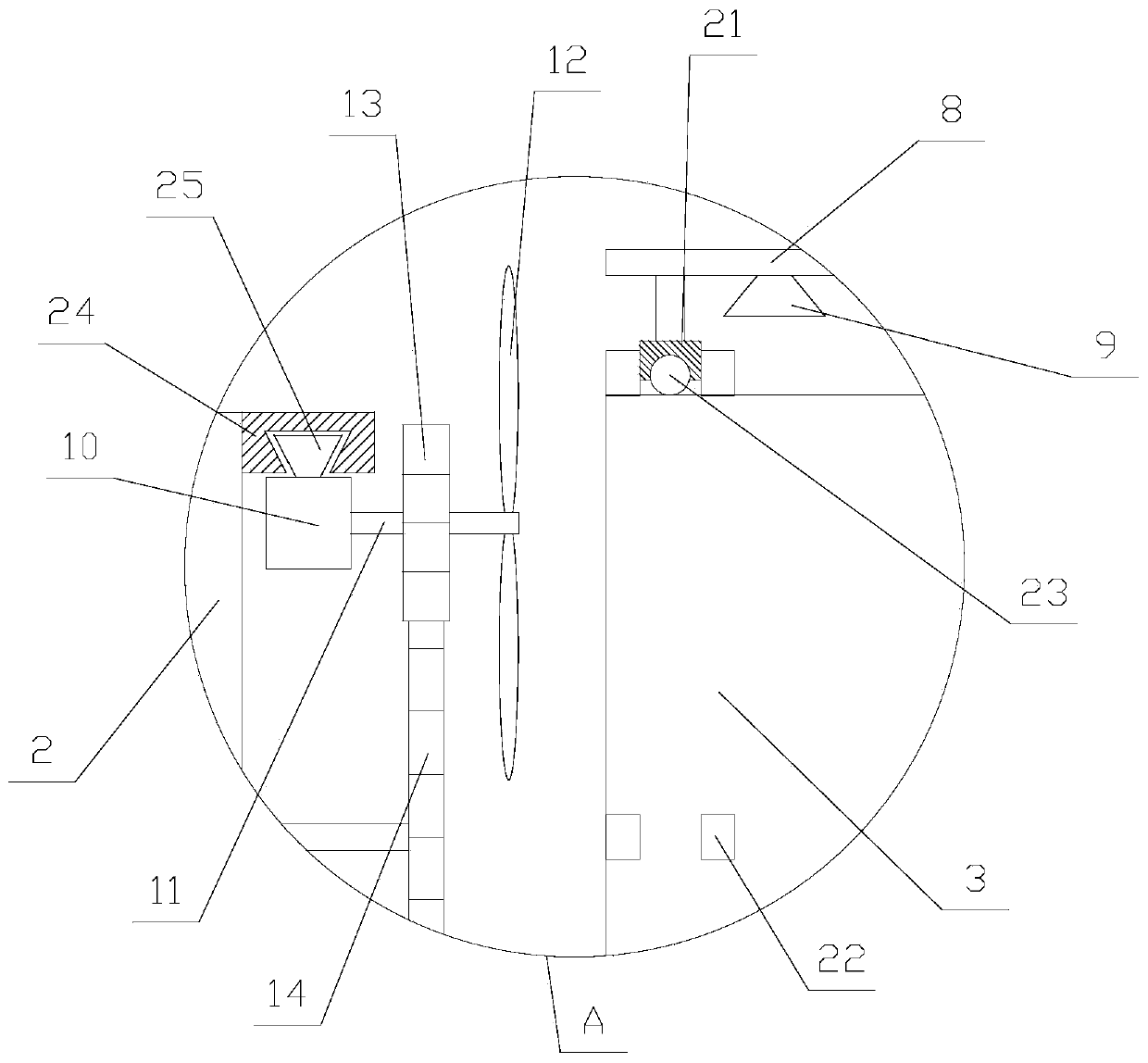

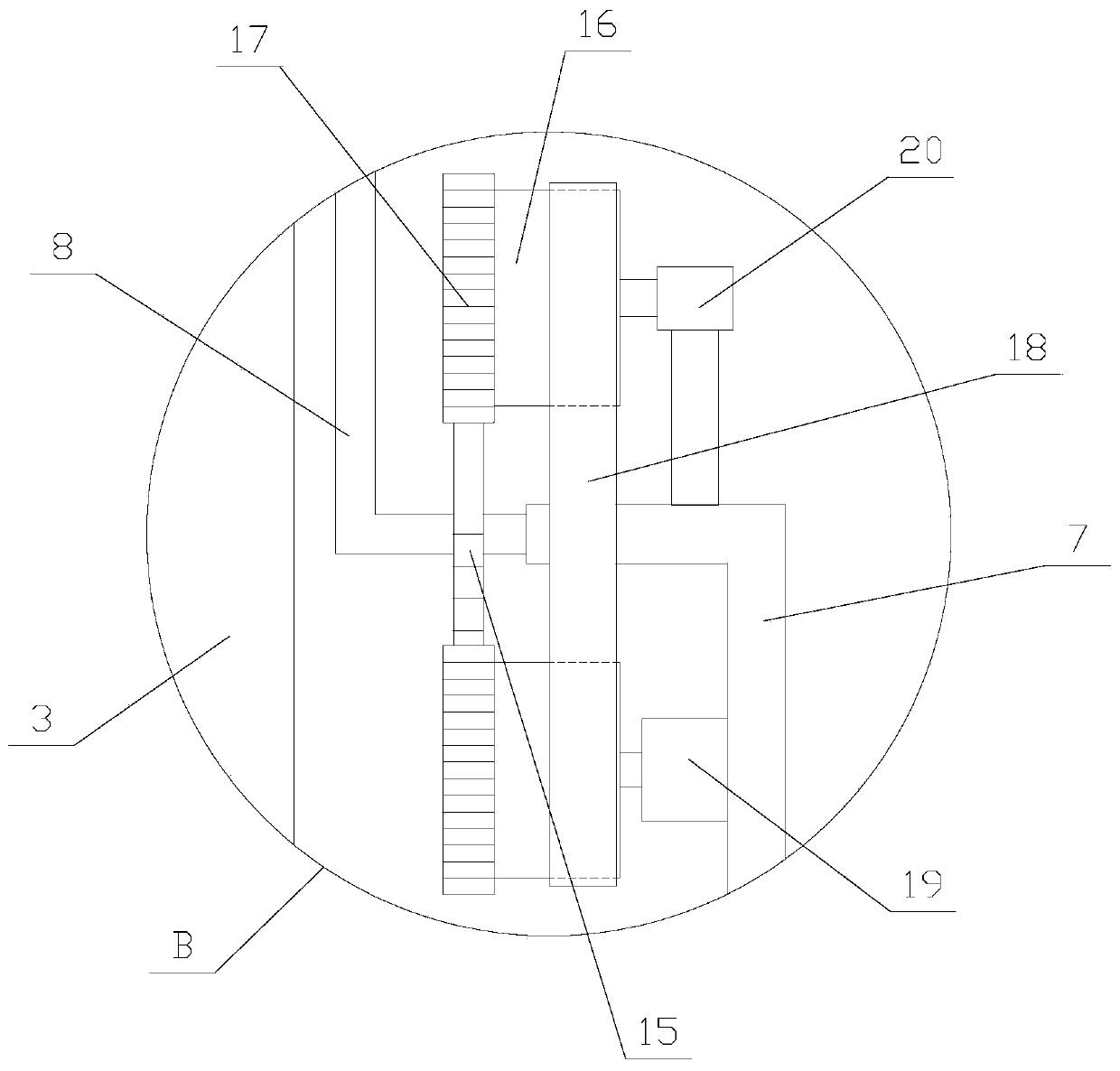

Safe and reliable natural gas transport vehicle convenient to cool

InactiveCN111532194AEasy to cool downGuaranteed safety and reliabilityTank vehiclesItem transportation vehiclesGear wheelElectric machinery

The invention relates to a safe and reliable natural gas transport vehicle convenient to cool. The vehicle comprises a chassis, a cab arranged above the chassis, a storage tank and wheels arranged below the chassis. A cooling mechanism is arranged on one side, close to the storage tank, of the cab; a spraying mechanism is further arranged above the chassis; the spraying mechanism comprises a fixedframe, a water pump, a water conveying pipe, a spraying pipe, a driving assembly and a plurality of nozzles; the cooling mechanism comprises a first motor, a rotating shaft, fan blades and a transmission assembly; and the transmission assembly comprises a first gear, a second gear and a limiting unit. According to the safe and reliable natural gas transport vehicle convenient to cool, a water solution can be sprayed to a periphery of the storage tank through the spraying mechanism, and primary cooling of the storage tank is facilitated while static electricity is eliminated; and in addition,the cooling mechanism is used for blowing air to the periphery of the storage tank, the water solution is promoted to evaporate by accelerating air flowing, the storage tank is further cooled, safetyand reliability of natural gas transportation are guaranteed, and then the practicability of the equipment is improved.

Owner:葛军

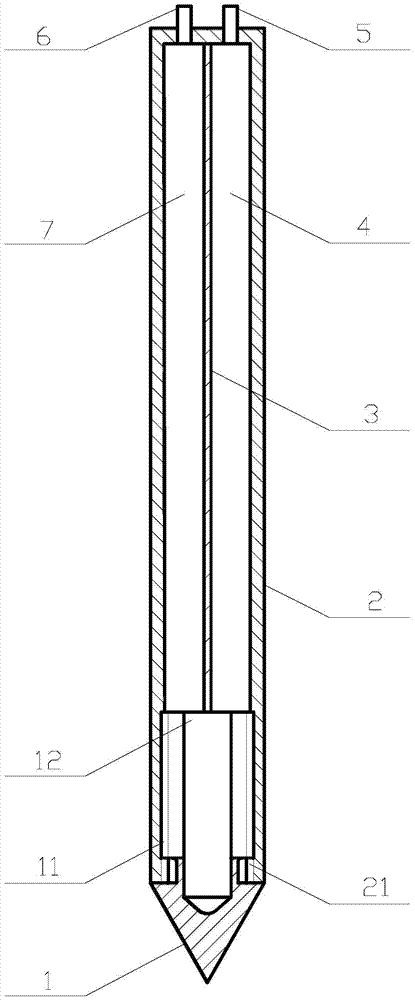

Copper tungsten arc gouging device

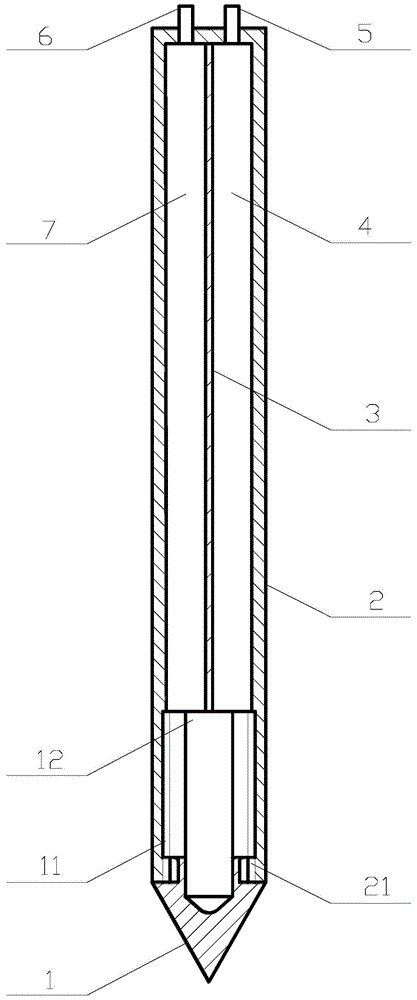

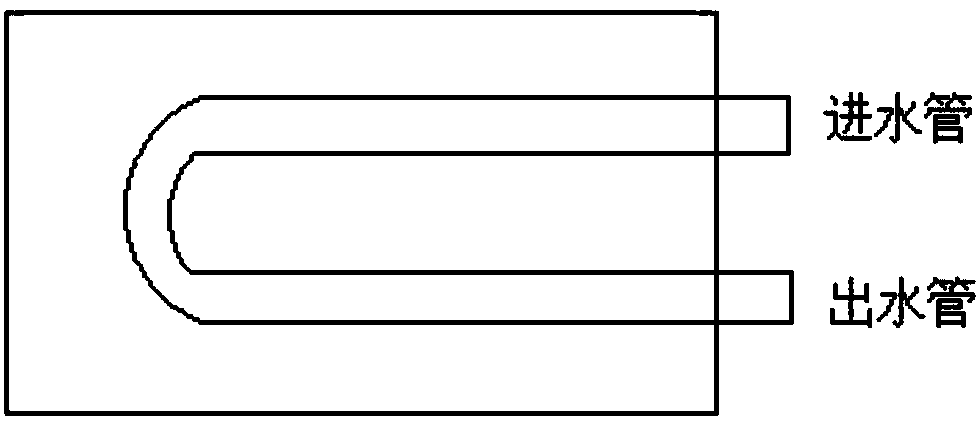

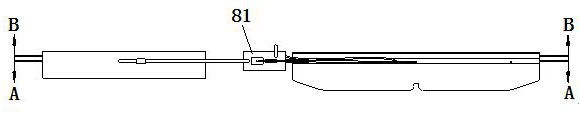

The invention belongs to the field of machining and particularly relates to a copper tungsten arc gouging device. The copper tungsten arc gouging device comprises a tungsten electrode tip, a copper pipe body, a separation plate, a water inlet pipe and a water outlet pipe. The lower end of the tungsten electrode tip is a cone. The upper end of the tungsten electrode tip is a cylinder. A tungsten electrode tip inner hole is formed in the tungsten electrode tip in the axial direction. The copper pipe body is a cylindrical shell with the sealed upper end and the open lower end. The lower end of the copper pipe body is fixedly connected with the cylinder of the tungsten electrode tip. The separation plate is arranged in the copper pipe body in the axial direction of the copper pipe body. The copper pipe body is divided into a water inlet cavity and a water outlet cavity through the separation plate in the axial direction of the copper pipe body. The sealed end of the copper pipe body is provided with the water inlet pipe and the water outlet pipe. The water inlet pipe is connected with the water inlet cavity. The water outlet pipe is connected with the water outlet cavity. The copper tungsten arc gouging device is simple in structure and convenient to use, and the copper pipe body is firmly connected with the tungsten electrode tip. A water circulation system is arranged in the device, and cooling is easy; and the tungsten electrode tip is adopted for discharging, an electric arc is stable, a formed groove of a notch is level, and mechanization of the back gouging process and the like is facilitated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Hot blast stove of drying equipment

InactiveCN112378079AEasy to cool downAccelerated circulation mixingAir heatersSustainable buildingsThermodynamicsHot air oven

The invention discloses a hot blast stove of drying equipment. The hot blast stove structurally comprises a stove body, supports, an air inlet door and a combustor. Airflow generated by swinging of heat mixing bodies exerts airflow force on rotating bodies to enable the rotating bodies to continuously rotate around bearings, circulation of heat gas is disturbed in a certain flow direction at a flow discharging opening, circulation of spark foam carried in the gas is blocked on the inner side of a middle partition mechanism and stays and suspends for a long time, so that sparks are cooled and extinguished conveniently, inclined impact blocks deform obliquely under the action of airflow force to extinguish the spark foam carried in the gas, circulation and mixing of the gas are accelerated through hinged swing movement of the heat mixing bodies, swing of hinge swing plates has interaction force on airflow, at the moment when the hinge swing plates move in the opposite direction of the airflow, the spark foam can be extinguished through beating under elastic cooperation of springs, a displacement ring conducts multi-directional annular displacement movement to drive chisel columns tobe inserted in different positions in a radial cavity in a penetrating manner, the spark foam flowing through the chisel columns are extinguished through chisel columns, and therefore the spark foam in the mixed gas is eliminated.

Owner:南安昊捷商贸有限公司

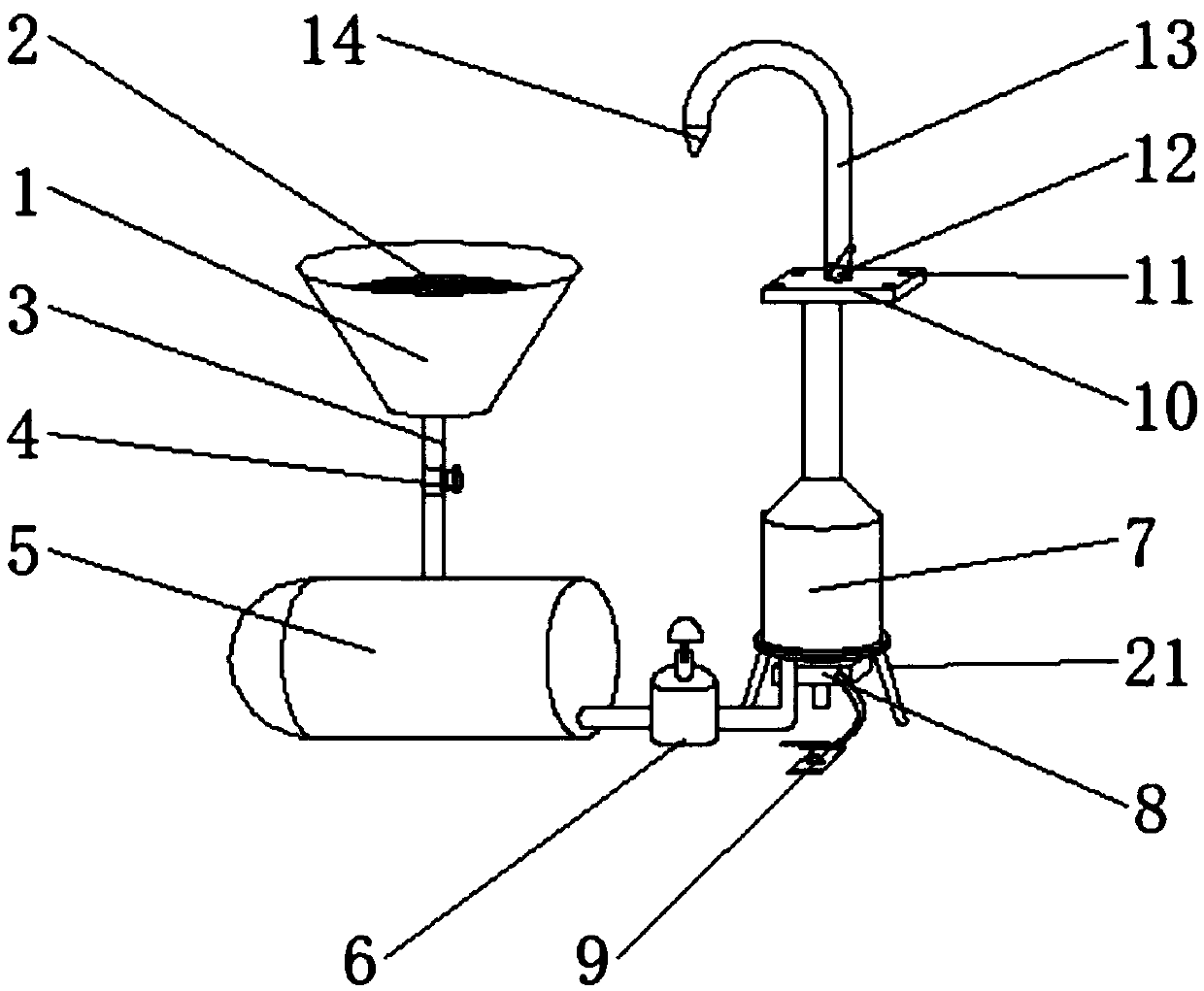

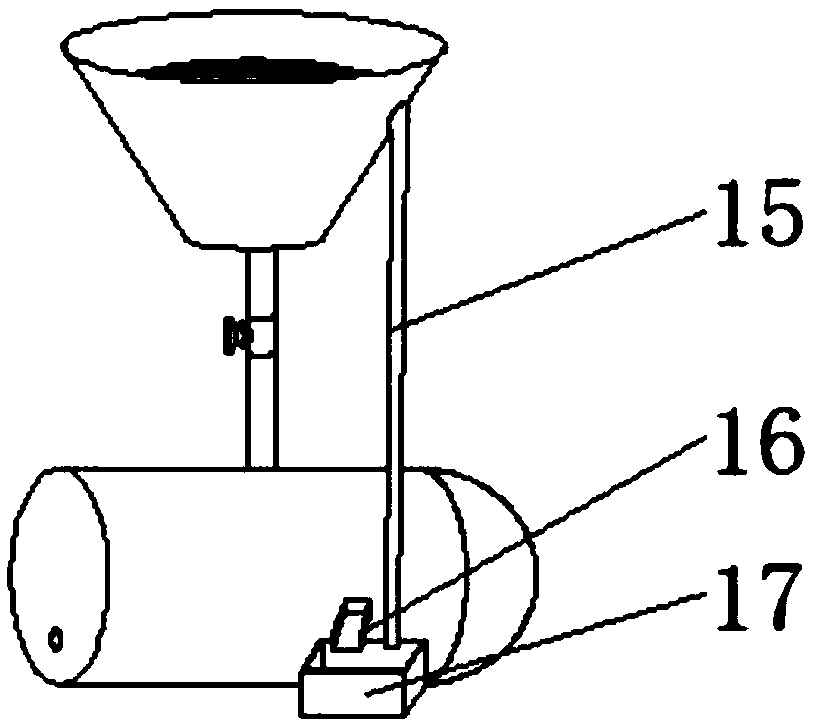

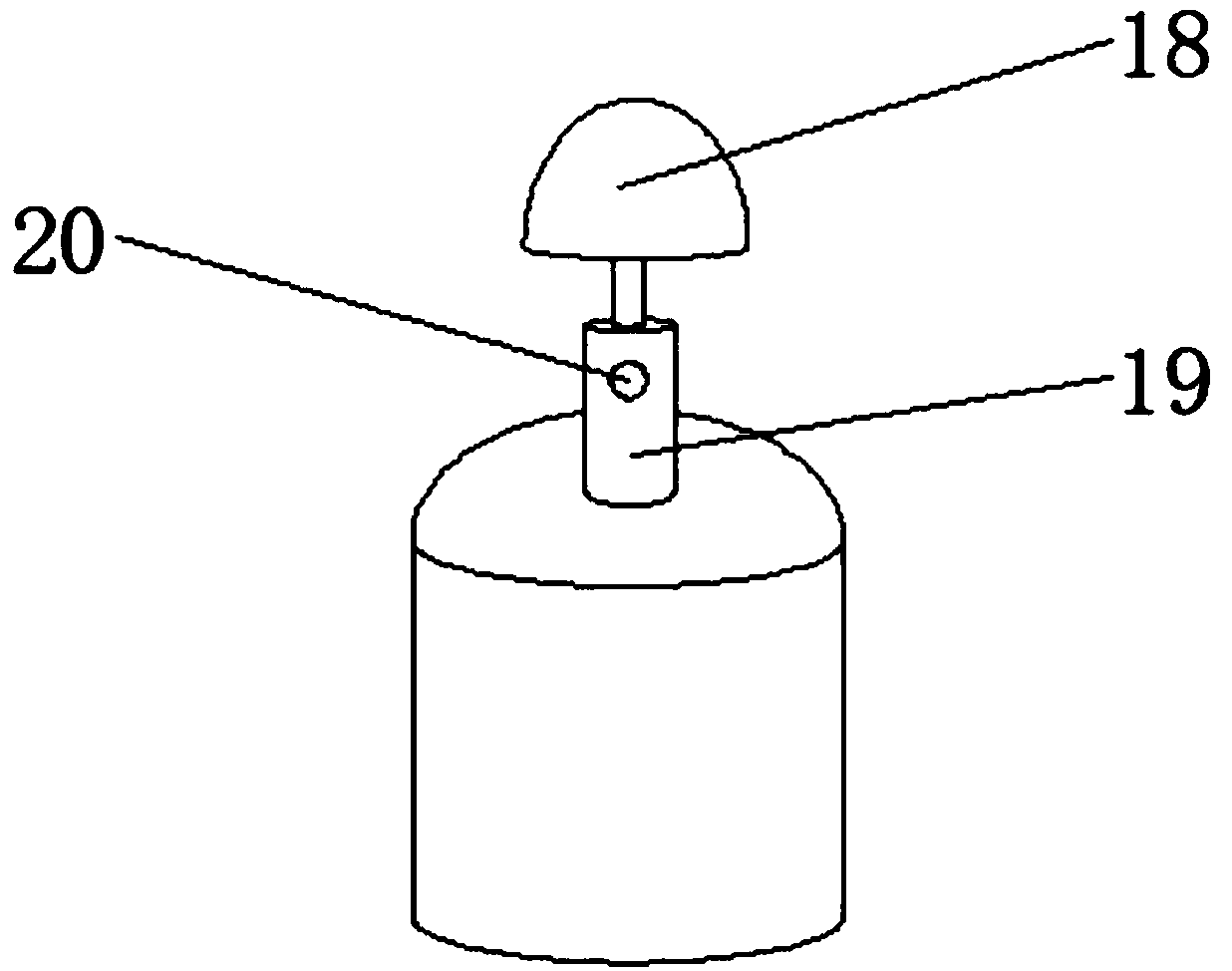

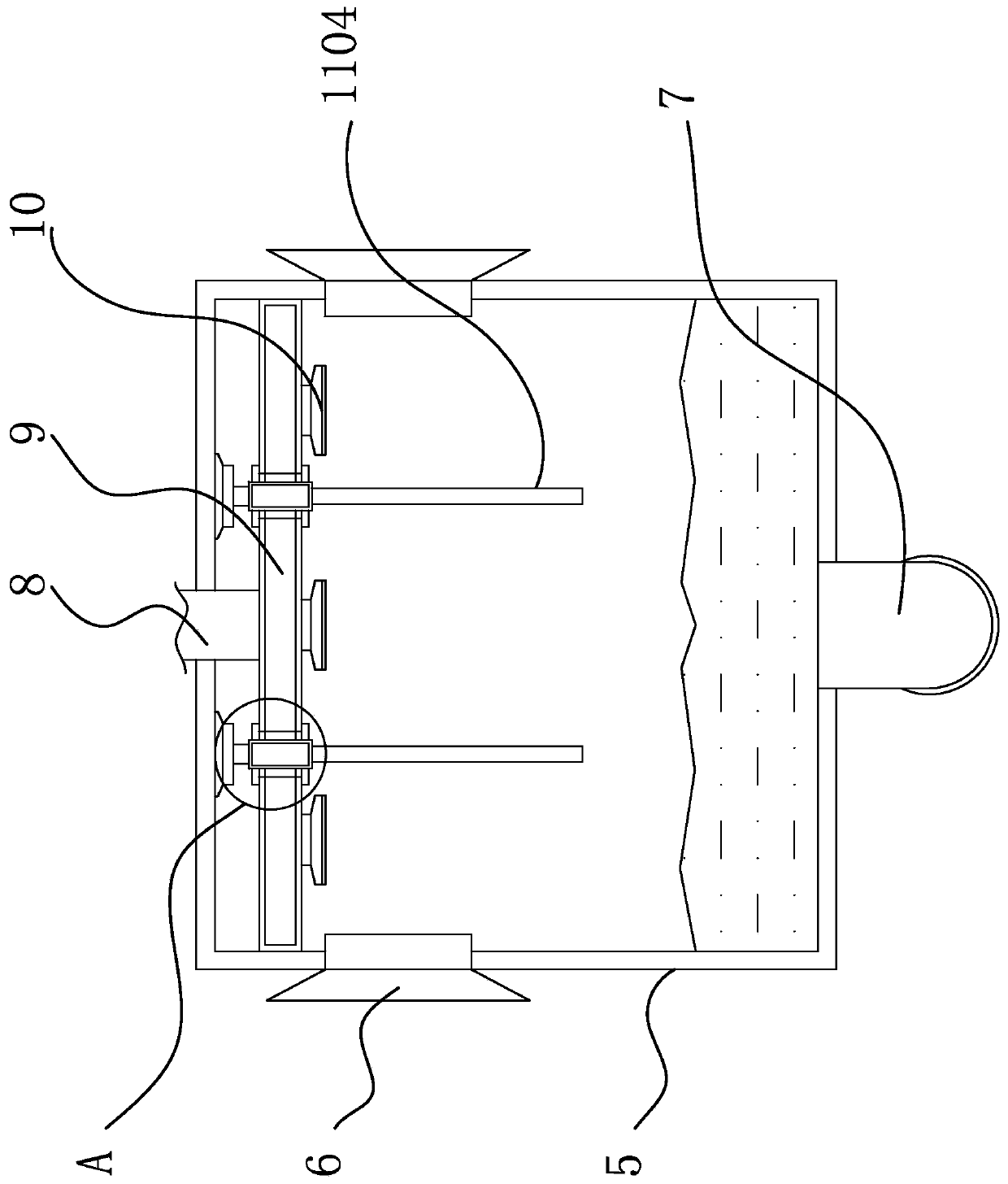

Novel backflow device for cooling liquid

PendingCN108015616AEasy to operateEasy to cool downMaintainance and safety accessoriesCooling fluidBackflow

The invention discloses a novel backflow device for a cooling liquid. The novel backflow device comprises a collecting bucket and an air pump; a filtering net is arranged in the collecting hopper, andthe filtering net is fixedly connected with the inner wall of the collecting hopper; the outer part of the collecting hopper is connected with a waste residue pipe; the lower end of the collecting hopper is connected with a conveying pipe, and the conveying pipe is fixedly connected with the collecting hopper; the tail end of the conveying pipe on the lower end of the collecting hopper is connected with a valve, a solid-liquid separator is arranged at the lower end of the valve, and the solid-liquid separator is connected with the valve through the conveying pipe; and a gas separator is arranged at the right end of the solid-liquid separator. According to the novel backflow device, impurities with relatively large size are filtered first by adopting the filter net, then are separated by the solid-liquid separator, so that the problem that blockage occurs due to the fact that the impurities cannot be removed is solved, and meanwhile, the cooling liquid at the rear end of a solid-liquidseparator further enters the air separator to discharge air in the cooling liquid.

Owner:无锡翔煌电气有限公司

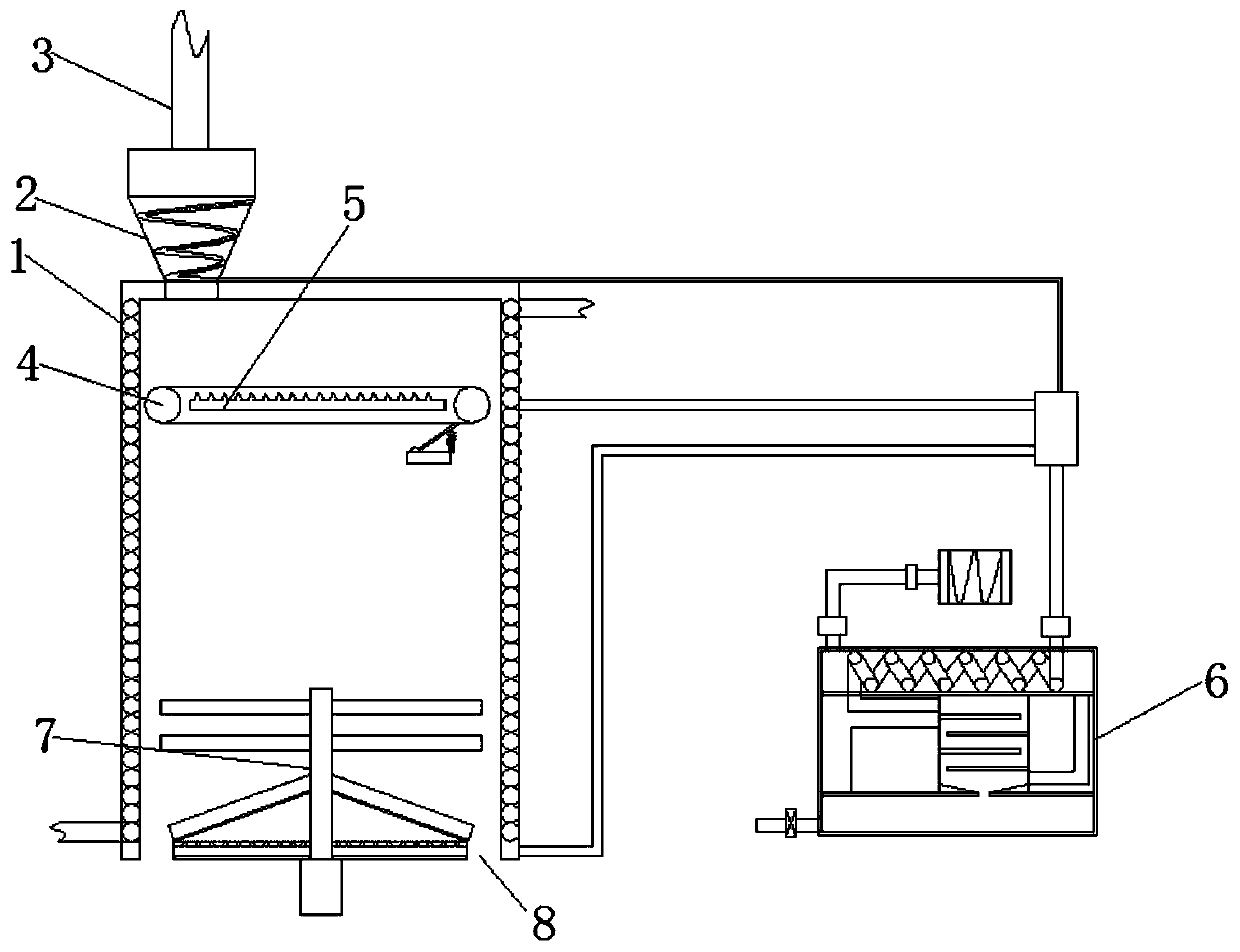

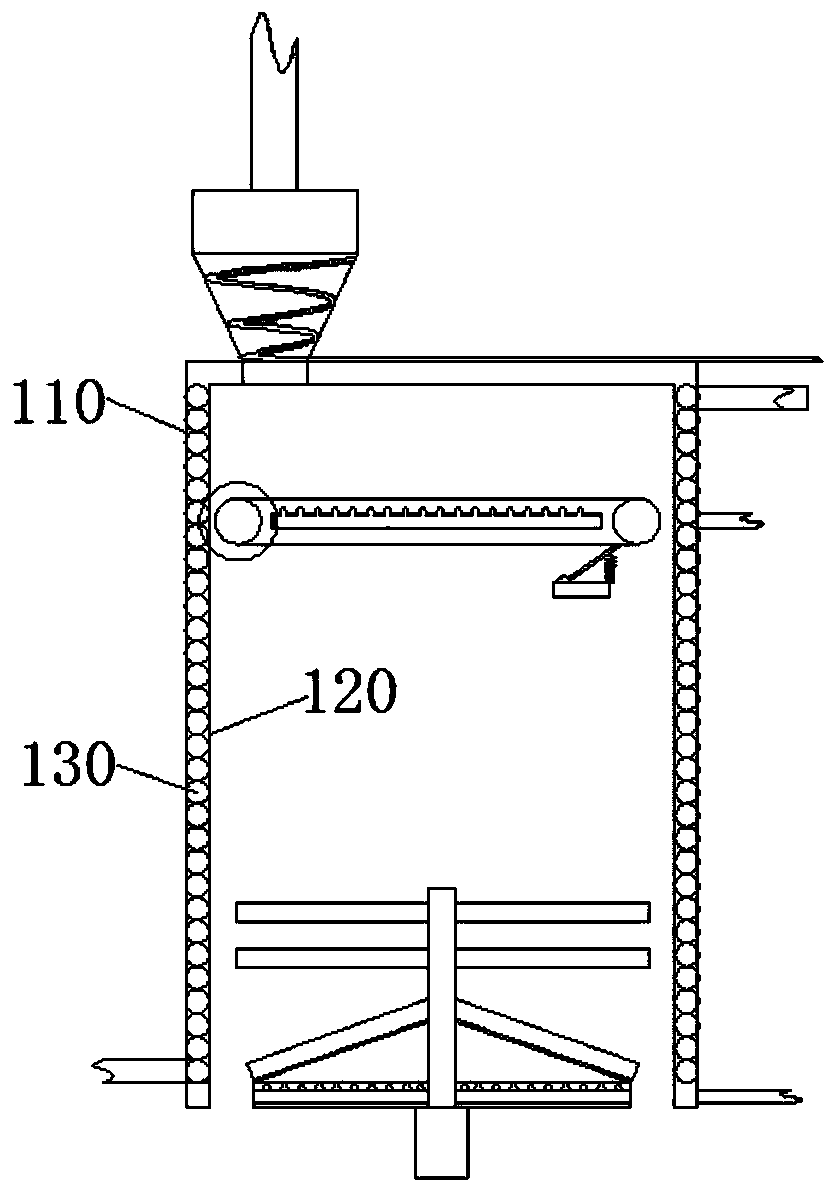

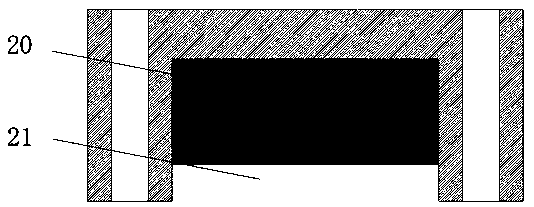

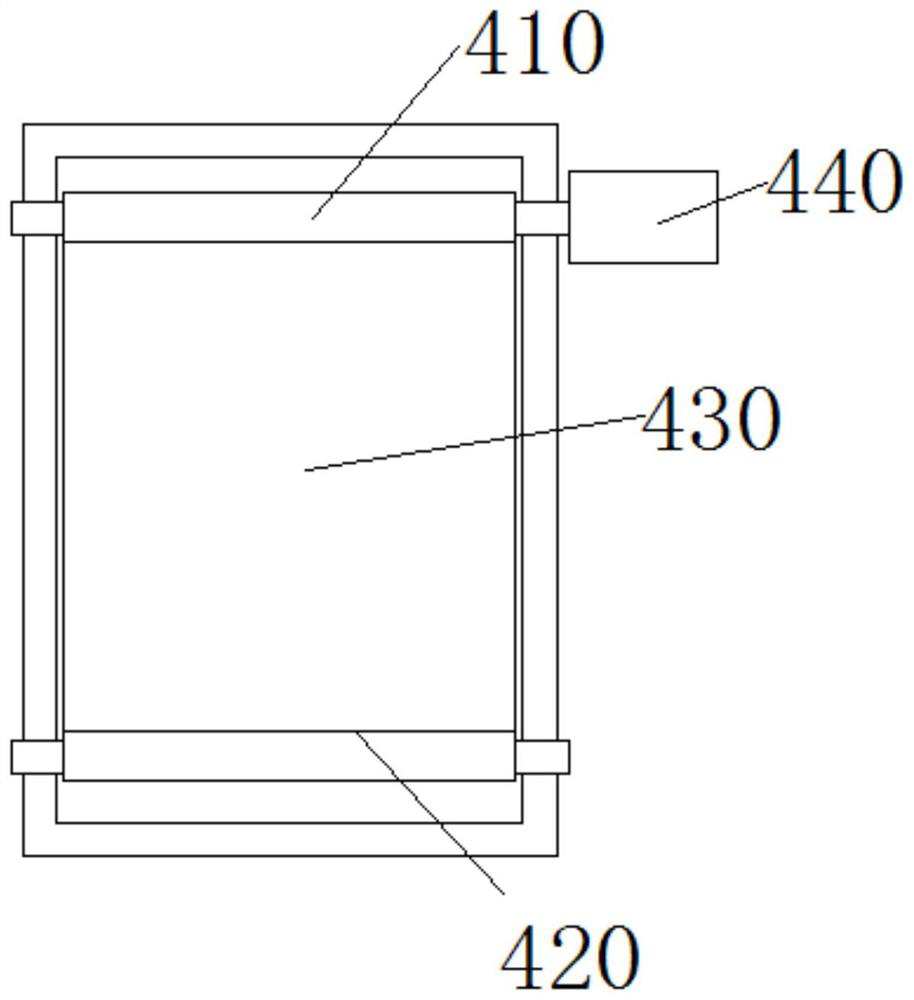

Rotary color master batch cooling device

The invention provides a rotary color master batch cooling device which comprises a cooling box, a cone-shaped feed inlet formed in one side of the upper part of the cooling box, a discharge port formed above the cone-shaped feed inlet, a conveying device arranged on the upper part of the inner side of the cooling box below the cone-shaped feed inlet, an exhaust structure arranged in the cooling box, a cooling device connected to the exhaust structure, a purging device arranged at the bottom of the cooling box and a plurality of discharge ports. By arranging a spiral air hose at the cone-shaped feed inlet, color master batch is cooled preliminarily conveniently. A coil pipe is arranged between the side walls of an outer box body and an inner box body, so that a low-temperature environmentin the box body is guaranteed. The conveying device is arranged in the box body, so that the time of the color master batch in the box body is prolonged, and meanwhile, a second exhaust plate is arranged between an upper conveyor belt and a lower conveyor belt, so that the cooling effect of the color master batch is improved greatly. A first exhaust plate is arranged between the outer box body andthe inner box body, so that the cooling effect of the color master batch is further improved. The purging device is arranged at the bottom of the box body, so that the sticky color master batch is separated conveniently.

Owner:TIANJIN YISANYOU MASTERBATCH CO LTD

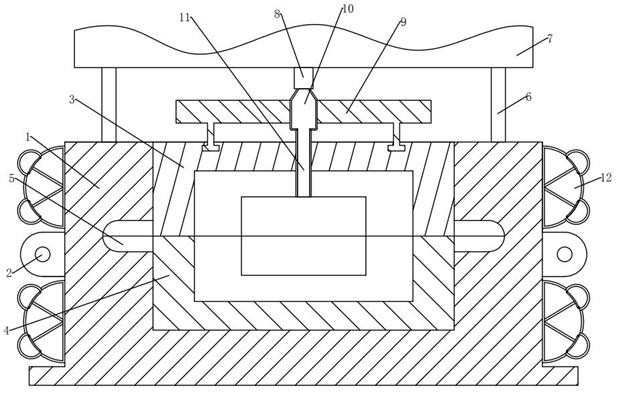

Mold with rapid cooling function and convenient mold taking for bearing machining

InactiveCN111016079AIncrease frictionEasy to combineDomestic articlesEngineeringMechanical engineering

The invention discloses a mold with a rapid cooling function and convenient mold taking for bearing machining, and relates to the technical field of bearing machining. The mold comprises a lower mold,a mold cavity and a cooling mechanism, wherein an upper mold is arranged above the lower mold, and a rubber attaching layer is arranged on the outer side of the joint of the upper mold and the lowermold; supporting columns are fixed on the two sides of the lower part of the lower mold, and an anti-skid bottom plate is arranged at the bottoms of the supporting columns; an ejection mechanism is arranged above the middle of the anti-skid bottom plate, and an ejection groove is formed in the middle of the lower part of the lower mold; and clamping blocks are fixed below the four corners of the upper mold, and clamping grooves are formed in the four corners of the lower mold. The mold has the beneficial effects that the ejection mechanism is arranged, so that a formed bearing can be conveniently ejected out to be loosened so as to be convenient to take; and an electric telescopic rod is arranged, so that a push plate and an ejection block can be conveniently driven to ascend and descend,and therefore the formed bearing can be conveniently ejected out, and the ejection block is of an annular structure and is matched with the shape of the mold cavity of the bearing.

Owner:东莞市史雷帝三维数控科技有限公司

Preparation process of diethyl zinc

A process for preparing diethyl zinc includes such steps as activating and drying Zn powder, adding it along with cuporous iodide and a quarter of the mixture of iodoethane and bromoethane into reactor, adding finished diethyl zinc as trigger, heating, adding rest of said mixture, heating, stirring while reacting, vacuum distilling and collecting product at a temp lower than -35 deg.C.

Owner:大连科利德半导体材料股份有限公司

Water tank-cooling and bird-preventing device for flowing pond water aquaculture

ActiveCN110063327AEasy to cool downSimple structurePisciculture and aquariaAnimal repellantsEngineeringSunlight

The invention discloses a water tank-cooling and bird-preventing device for flowing pond water aquaculture. The water tank-cooling and bird-preventing device comprises a supporting frame, wherein foursupporting columns are connected to four corners of the surface of the supporting frame in a welding manner; upper end supporting columns are connected to the upper ends of the left and right corresponding supporting columns in a welding manner; a protective net is connected between the two upper end supporting columns; through the protective net, the upper side of the water tank-cooling and bird-preventing device can be protected, and through the protective net, sunlight can be shaded; through an air sucking pump, air can be pumped into a condenser; through the condenser, the air can be cooled, and the cooled air enters an air diffusing main pipe; through the air diffusing main pipe, the air is guided into an air diffusing column; through the air diffusing column, the cooled air can be guided into water. The water tank-cooling and bird-preventing device for the flowing pond water aquaculture is simple in structure and convenient to mount, not only can prevent birds, but also can coolthe water, and provides convenience for people.

Owner:莫建华

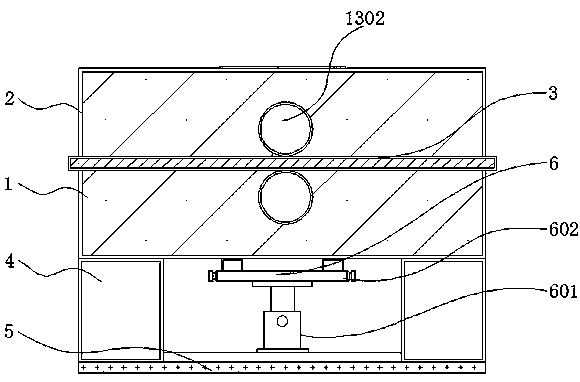

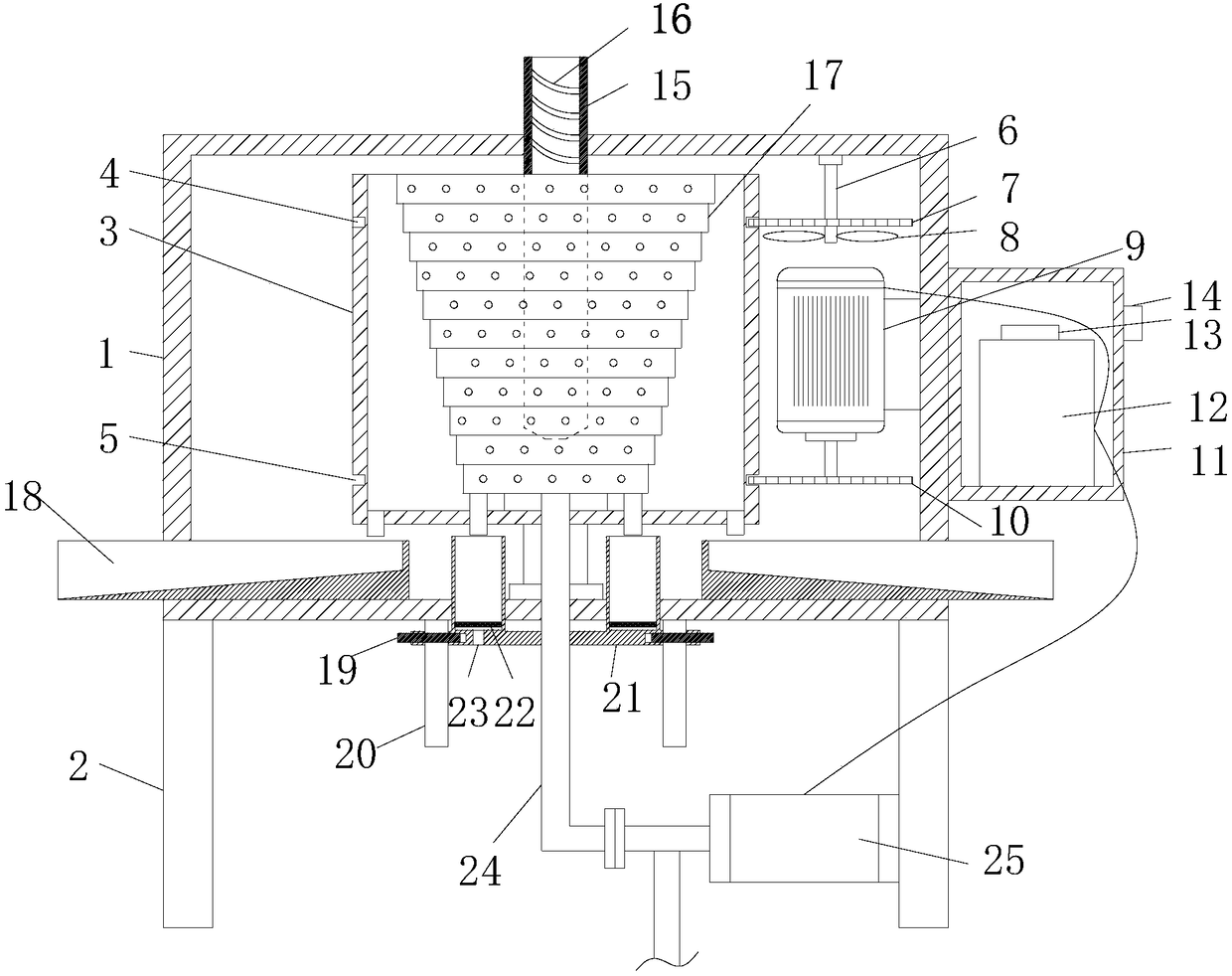

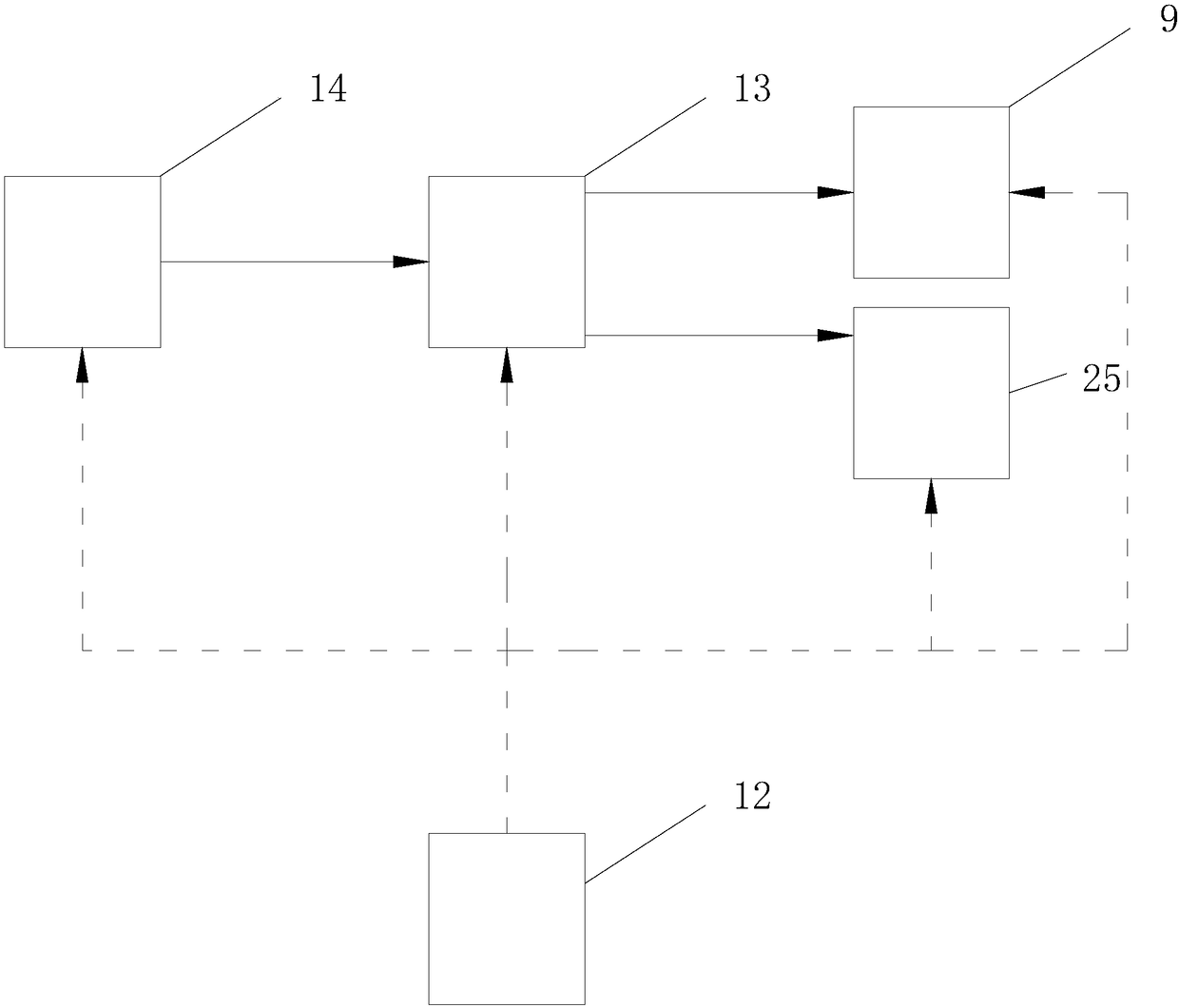

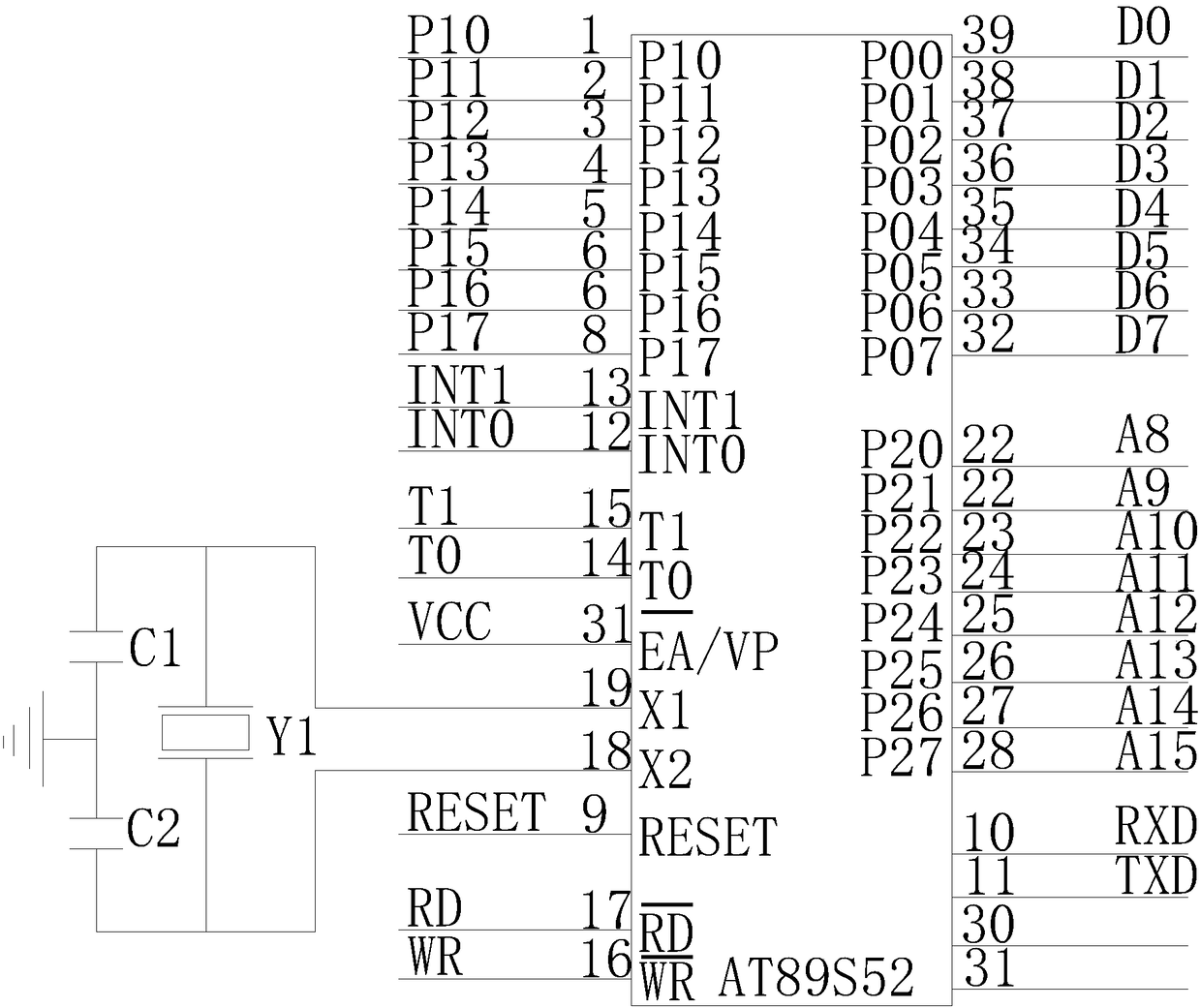

High-voltage switch contact temperature detection and control system

InactiveCN107894286AEasy to cool downAchieve coolingRadiation pyrometryContact temperatureHigh pressure

The invention relates to the field of power supply equipment detection and discloses a high-voltage switch contact temperature detection and control system. The high-voltage switch contact temperaturedetection and control system comprises a cooling mechanism, a control module, an infrared thermal imager and an image processing module. The infrared thermal imager is spaced from contacts (4) of a high-voltage switch and directed towards the contacts (4) of the high-voltage switch to convert the sensed temperature into image data. The image processing module is connected to the infrared thermalimager to convert the image data into a temperature value and output the temperature value to the control module. The control module is connected to the cooling mechanism to control the cooling mechanism to perform cooling when the temperature value is greater than a preset temperature. The high-voltage switch contact temperature detection and control system overcomes the problems of high heatingtemperature and high difficulty in installing a temperature sensor for accurate detection in the prior art, and solves the problem of difficulty in accurate detection of high-voltage switch contact temperature by the infrared non-contact temperature measurement technology.

Owner:WUHU ZHUOYA ELECTRIC

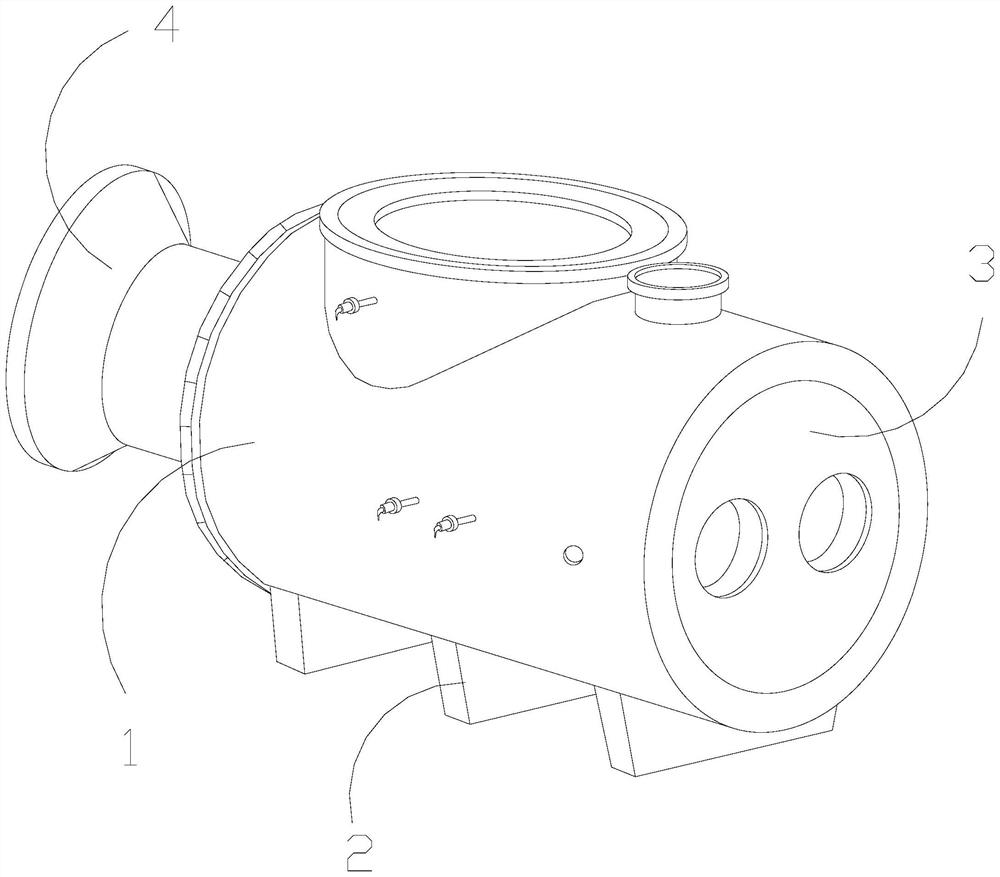

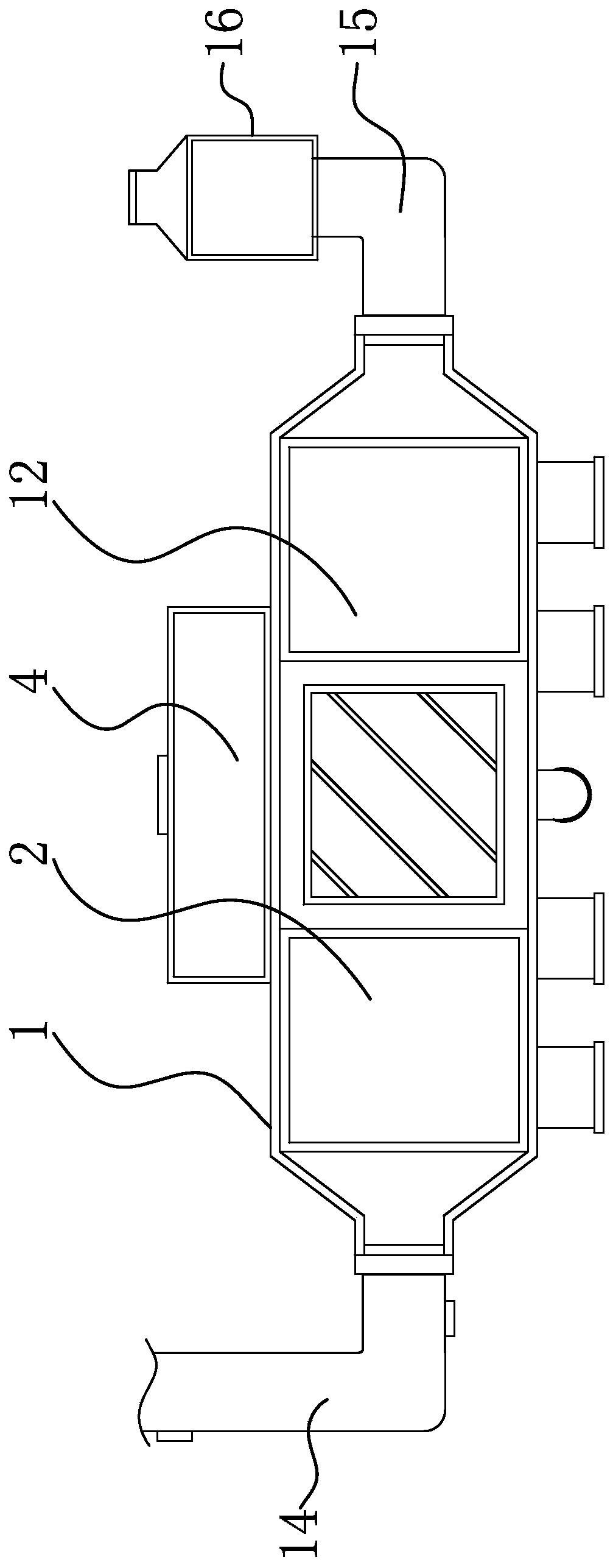

Novel centrifugal separator

InactiveCN108580059AEasy to cool downEasy to fix and removeRotary centrifugesCooling/ventillation arrangementCentrifugal separatorCentrifuge

The invention discloses a novel centrifugal separator. The novel centrifugal separator comprises a centrifugal machine body. The bottom end face of the centrifugal machine body is provided with supporting legs, and one side of the corresponding supporting leg is provided with a water pump. The centrifugal machine body is internally provided with a barrel body, the center of the bottom end face ofthe barrel body is connected with the top end of a fixing shaft in a welded manner, and the bottom end of the fixing shaft is installed on the inner wall of the centrifugal machine body through a bearing. The upper portion and the lower portion of the outer surface of the barrel body are provided with a first gear slot and a second gear slot. The left side of the top inner wall of the centrifugalmachine body is rotatably connected with the top end of a rotating shaft through a bearing, the bottom end of the rotating shaft is fixedly connected with a first gear in a welded manner, and the bottom end of the first gear is fixedly connected with fans in a welded manner. The right side wall inside the centrifugal machine body is provided with a motor through bolts, the bottom end of the motoris fixedly connected with a second gear in a welded manner, and the second gear and the second gear slot are in transmission connection through gear meshing. The centrifugal separator is compact in structure and convenient to use.

Owner:江西金石宝矿山机械制造有限公司

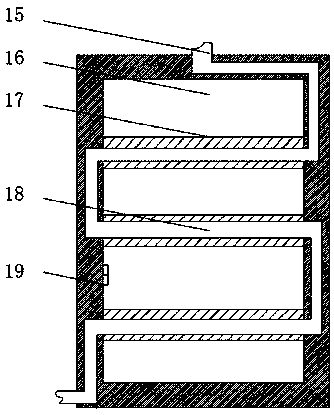

Microbial strain production workshop temperature automatic regulating device

InactiveCN111117876AEasy to cool downPrevent falling offBioreactor/fermenter combinationsBiological substance pretreatmentsMechanical engineeringBiotechnology

Owner:JIANGSU UNISON BIOTECH DEV

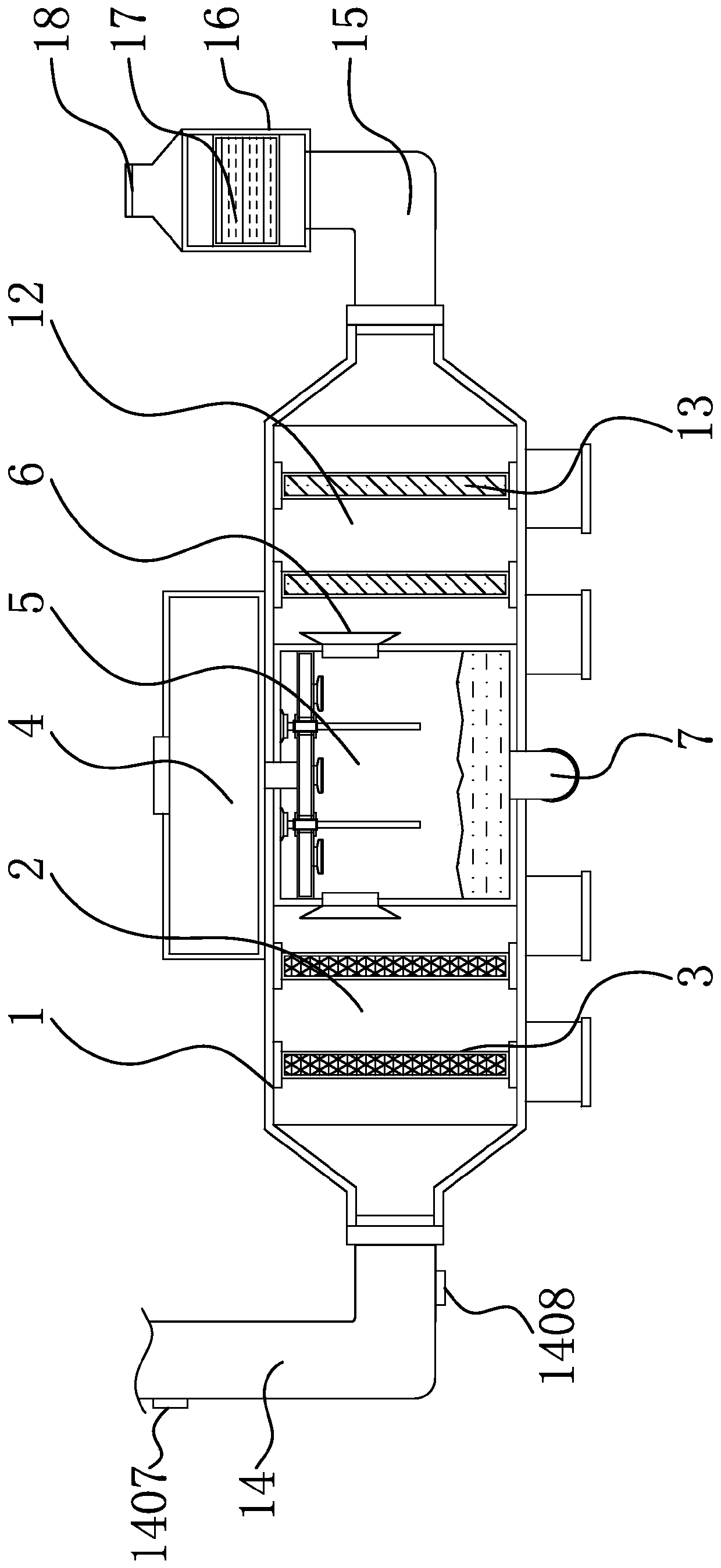

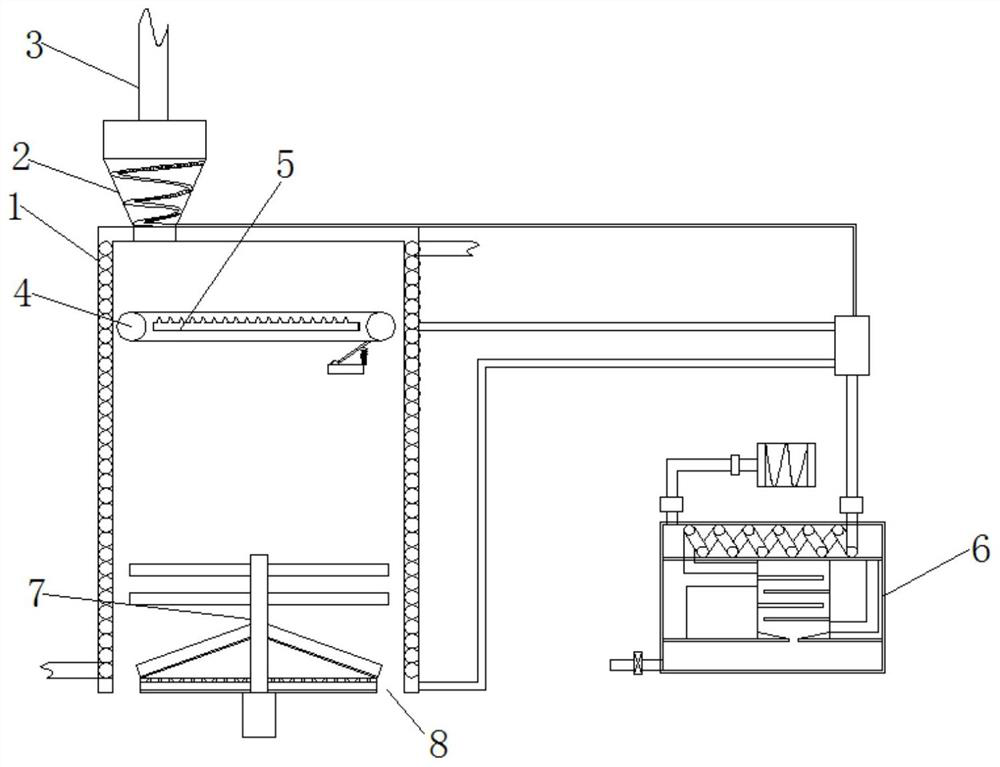

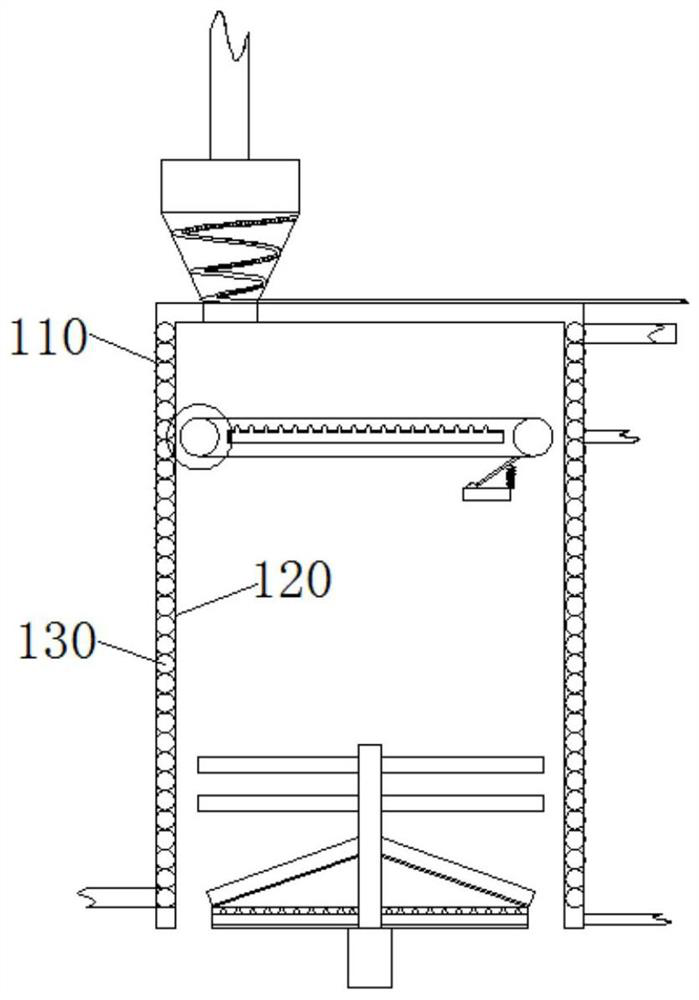

Waste gas treatment equipment for setting machine

InactiveCN111330397AImprove cooling effectEasy to spray dustCombination devicesEnvironmental engineeringDrainage tubes

The invention provides waste gas treatment equipment for a setting machine. The equipoment comprises a main body, a spraying pipe and an air inlet pipe mechanism, a first filtering chamber is arrangedon the left side in the main body; a filtering mechanism is mounted in the first filtering chamber; a water tank is fixed above the middle of the body, a washing chamber is mounted in the middle of the interior of the body, air duct openings are formed in the left side and the right side of the washing chamber, a drainage pipe is connected to the bottom of the washing chamber, a connecting pipe is fixed to the lower side of the middle of the water tank, and a spraying pipe is mounted below the connecting pipe and located above the interior of the washing chamber. The invention has the advantage of good use effect.

Owner:盛醒

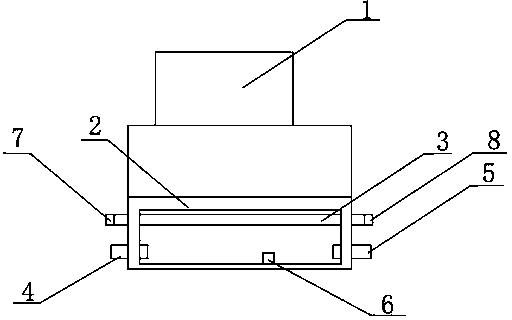

Cooling device of steel wire gauze knitter

InactiveCN103727377ASimple structureEasy to cool downWire networkLubrication elementsEngineeringEnvironmental geology

The invention provides a cooling device of a steel wire gauze knitter. The cooling device of the steel wire gauze knitter comprises a machine body and a water tank. The water tank is fixedly arranged on one side of the machine body through a screw, an oil pipe, a water inlet, a water outlet and a temperature sensor are arranged in the water tank, the oil pipe is inserted in the water tank, the two ends of the oil pipe are provided with an oil inlet and an oil outlet respectively, the water inlet is formed in the left side of the water tank, the water outlet is formed in the right side of the water tank, and the temperature sensor is arranged at the bottom of the water tank. The cooling device of the steel wire gauze knitter has the advantages of being simple in structure, convenient to cool and the like.

Owner:ANHUI KETAI IND TRADE

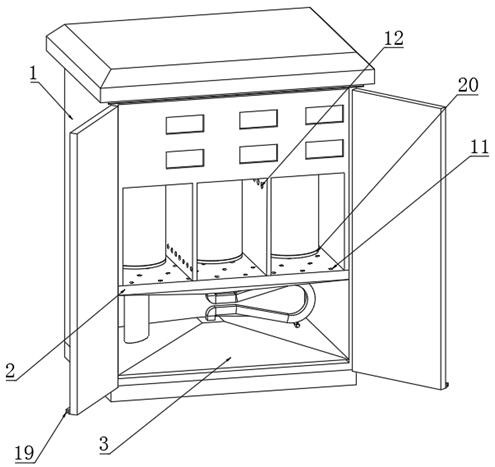

Power distribution box

PendingCN107809075AIncrease flow rateEasy to cool downLighting and heating apparatusSubstation/switching arrangement cooling/ventilationRefrigerantVertical filter

The invention discloses a power distribution box comprising a box body. The bottom part of the box body is provided with a ventilator which is internally provided with a refrigerator. The lower end ofthe ventilator is also provided with a dust collection tank. The lower end of the dust collection tank is provided with a slide rail. The two ends of the dust collection tank are provided with dust inlet holes. The ventilator comprises an air inlet and an air outlet. The air inlet is installed on the right side surface of the bottom part of the box body. The air outlet is installed on the left side surface of the top part of the box body. A vertical filter screen A is installed behind the air inlet. A vertical filter screen B is installed behind the air outlet. The lower end of the filter screen B is provided with a downwardly tilted baffle plate. The lower ends of the filter screen A and the filter screen B are provided with dust outlet holes which are communicated with the dust inlet holes. The advantages of the power distribution box are that the ventilation duct is installed on the bottom part of the box body so that the flow velocity of the air can be accelerated and cooling canbe facilitated; the refrigerator is installed on the bottom part so that the heat radiation function can be realized, the refrigerant can be recycled and thus the use amount of the refrigerant can besaved; and the filter screens and the dust collection tank are connected so that the dust in the filter screens can be processed in time.

Owner:YANCHENG POWER SUPPLY CO STATE GRID JIANGSU ELECTRIC POWER CO +4

A copper tungsten arc gouging device

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

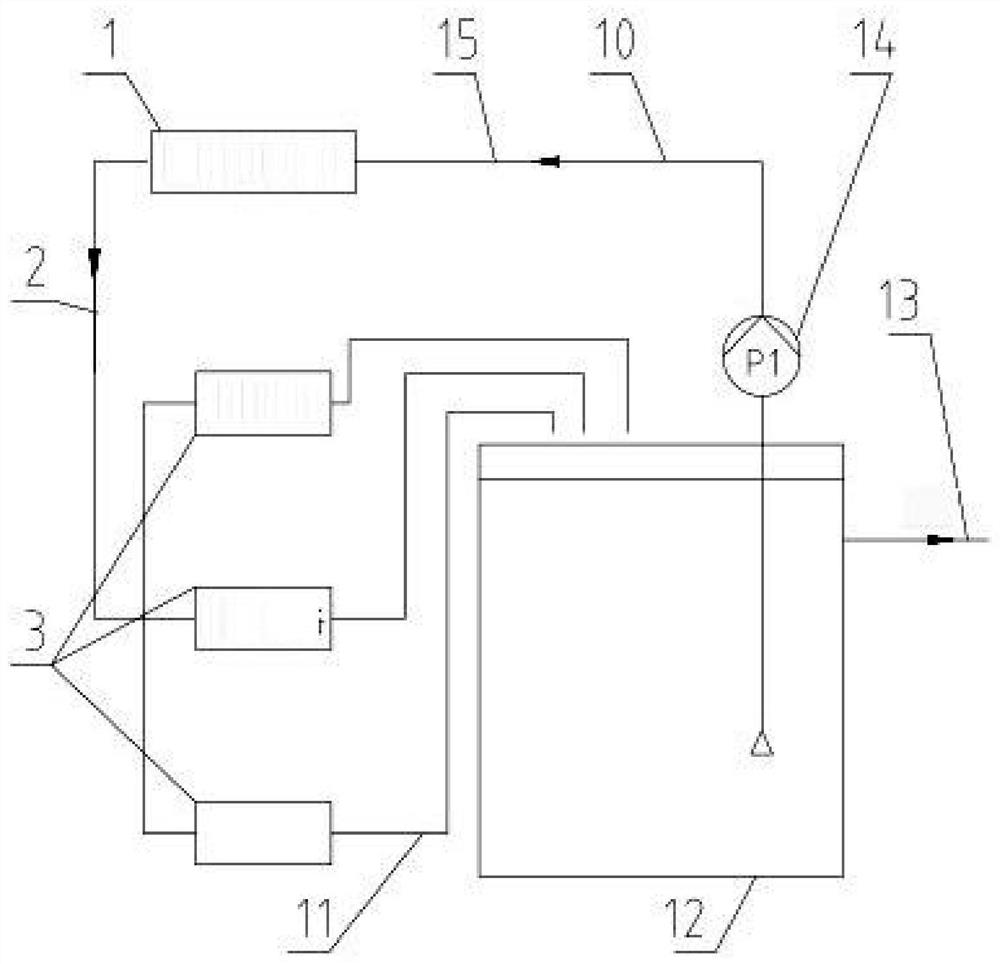

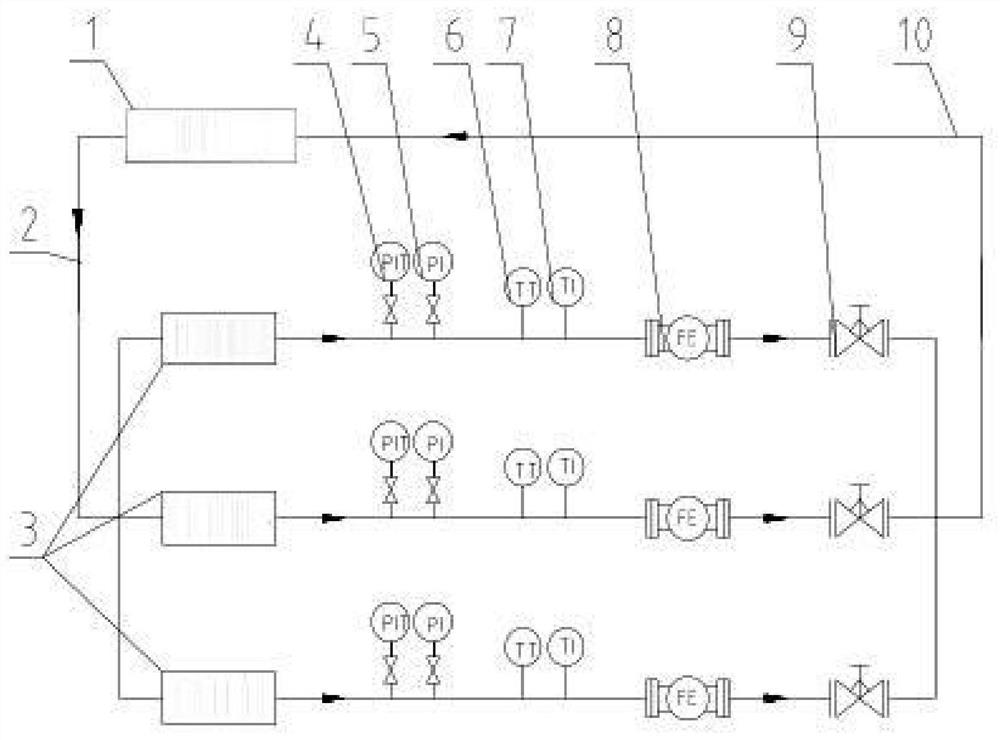

High-rotating-speed and high-power hydraulic coupler speed regulating device capable of achieving intelligent cooling

PendingCN114718962AEasy to cool downImprove cooling effectRotary clutchesGear lubrication/coolingPhysicsPush out

The invention discloses an intelligent-cooling high-rotating-speed high-power hydraulic coupler speed regulating device, and relates to the technical field of hydraulic couplers, the intelligent-cooling high-rotating-speed high-power hydraulic coupler speed regulating device comprises a cooling structure, an air supply pump is fixedly mounted at the right end of the cooling structure, and annular fixing structures are fixedly mounted at the two ends of the cooling structure; a refrigerating device is fixedly installed on the front face of the outer wall of the cooling structure, and a hydraulic coupler speed adjusting device body is fixedly installed on the inner wall of the annular fixing structure. According to the hydraulic coupler speed regulating device, the threaded adjusting sleeve rotates by rotating the adjusting nut, the threaded push rod is pushed out of the inner wall of the threaded adjusting sleeve, the inner wall of the pressing plate is in lap joint with the outer wall of the hydraulic coupler speed regulating device body, and therefore the annular fixing structure is fixed to the outer wall of the hydraulic coupler speed regulating device body; and a certain gap is formed between the outer wall of the hydraulic coupler speed regulation device body and the inner wall of the cooling structure, so that the hydraulic coupler speed regulation device body can be cooled conveniently.

Owner:陈振胜

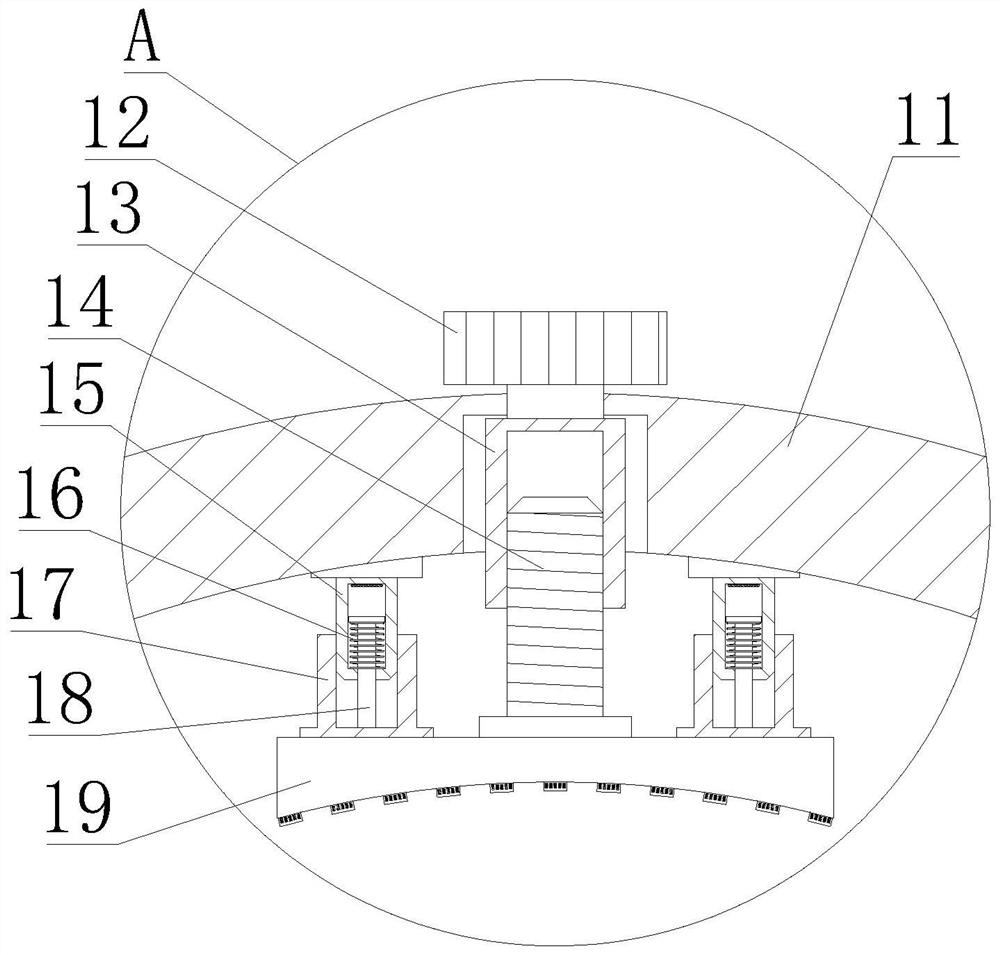

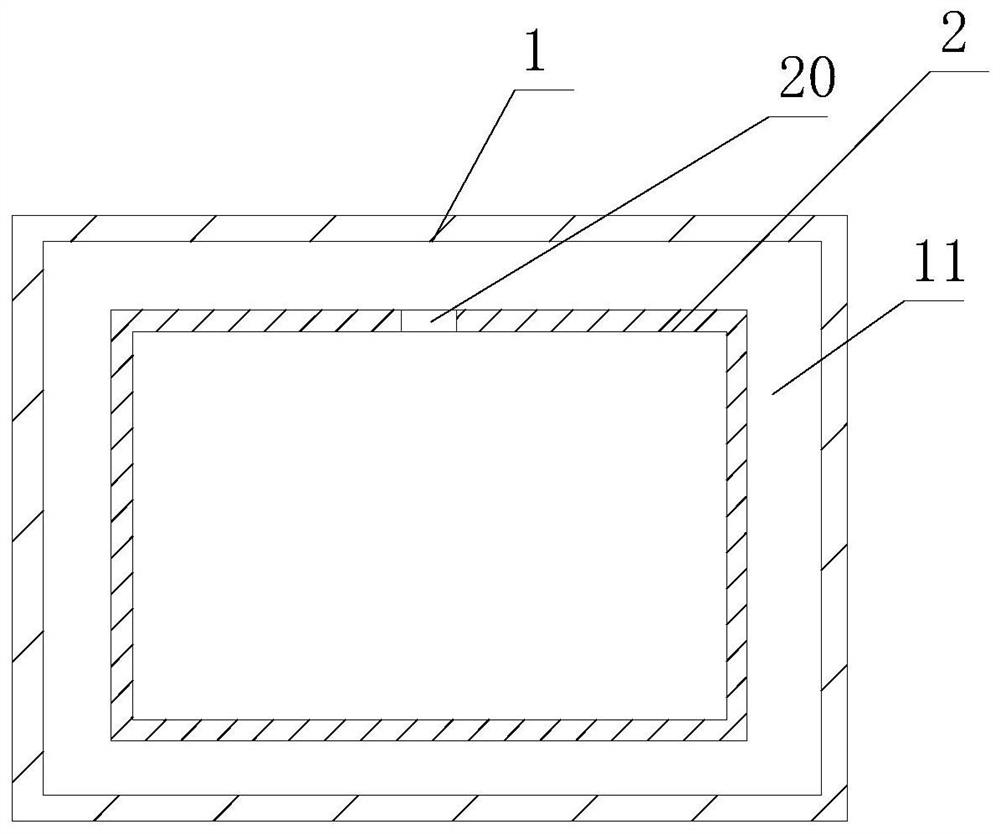

Tunnel ultrasonic wind speed and direction detector

PendingCN112415222AEasy to cool downGuaranteed detection accuracyIndication/recording movementFluid speed measurementPhysicsAir velocity

The invention discloses a tunnel ultrasonic wind speed and direction detector, which comprises an outer shell, an inner shell and an ultrasonic probe, and is characterized in that the ultrasonic probeis arranged on a top plate of the inner shell; the inner shell is provided with a mounting cavity and sleeved with the outer shell, a flowing cavity is formed between the outer shell and the inner shell, a first air hole is formed in one side face of the outer shell, a second air hole is formed in one side face of the inner shell, the first air hole and the second air hole are both communicated with the flowing cavity, the second air hole is communicated with the mounting cavity, and the air inlet direction of the first air holes is perpendicular to that of the second air holes. According tothe tunnel ultrasonic wind speed and direction detector provided by the invention, a gas circulation cavity is formed between the inner shell and the outer shell, so that external gas and gas in the inner shell can be exchanged conveniently, a circuit board in the mounting cavity can be cooled conveniently, and the detection precision is further ensured; and the air inlet directions of the first air holes and the second air holes are vertical, so that external rainwater is prevented from immersing into the mounting cavity in rainy days.

Owner:安徽曼德克环境科技有限公司

Industrial injection molding machine with protection mechanism

PendingCN114734607ARealize self-coolingEasy to cool downInjection molding machineMechanical engineering

The invention provides an industrial injection molding machine with a protection mechanism, which comprises: a plurality of self-cooling assemblies, which can automatically cool at high temperature, are fixedly mounted at the upper and lower ends of the outer surfaces of the left and right sides of an injection molding base in equal adjacent rows; the self-cooling assembly comprises a main shell, an upper auxiliary shell, a lower auxiliary shell, an upper discharging assembly and a lower discharging assembly, wherein the upper discharging assembly can guide out one kind of cooling materials at the high temperature, and the lower discharging assembly can guide out the other kind of cooling materials at the high temperature. A plurality of main shells are adjacently and fixedly mounted at the upper and lower ends of the outer surfaces of the left and right sides of the injection molding base; an upper auxiliary shell is fixedly installed in the upper through groove in a penetrating mode. According to the industrial injection molding machine with the protection mechanism, the outer side of the injection molding base can have a self-cooling function, when an injection molding head injects raw materials in a mold, even if heat is transferred out of the injection molding base, the heat can be timely cooled and dissipated, and the potential safety hazard that injection molding personnel are scalded when accidentally making contact with the injection molding base is eliminated.

Owner:袁成婕

Ring main unit with constant-temperature dehumidification function

PendingCN112751279AEasy to cool downExtended service lifeHeat storage plantsSubstation/switching arrangement cooling/ventilationPhysicsActivated carbon

The invention discloses a ring main unit with a constant-temperature dehumidification function. The ring main unit comprises a cabinet body, cabinet doors are hinged to two side parts of the front surface of the cabinet body, a partition plate is fixedly mounted at the bottom end of the inner wall of the cabinet body, a conical cover is welded to the bottom end of the inner wall of the cabinet body, and a filter plate is fixedly mounted at the bottom end of the inner wall of the conical cover. A constant-temperature heating tube is installed in the middle of the bottom end of the filter plate, and a curved glass tube is connected to the top edge of the conical cover. The ring main unit is scientific and reasonable in structure and safe and convenient to use, the conical cover, the filter plate, the constant-temperature heating pipe, the arc-shaped glass pipe, activated carbon filter cotton, a drainage valve, a conical body, an exhaust outlet, a partition plate, a flow guide opening, a fan and an air pipe are arranged, the interior of the cabinet body can be conveniently heated, meanwhile, moisture in the cabinet body can be reduced, gas in the cabinet body can be conveniently exchanged, so that the interior of the cabinet body can be conveniently cooled, meanwhile, the interior of the cabinet body can be uniformly heated, and the interior of the cabinet body is kept in a constant-temperature state.

Owner:厦门锦瓯网络科技有限公司

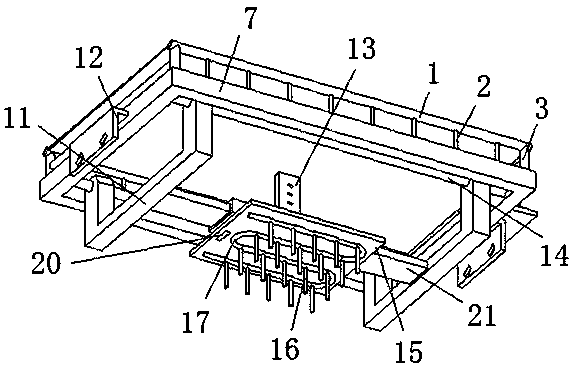

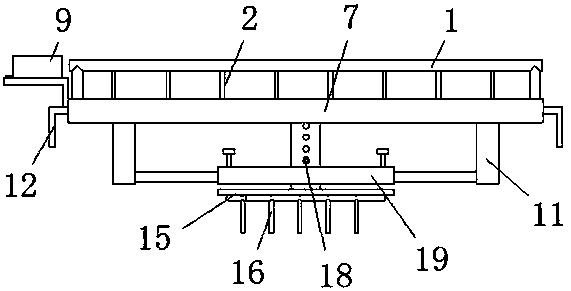

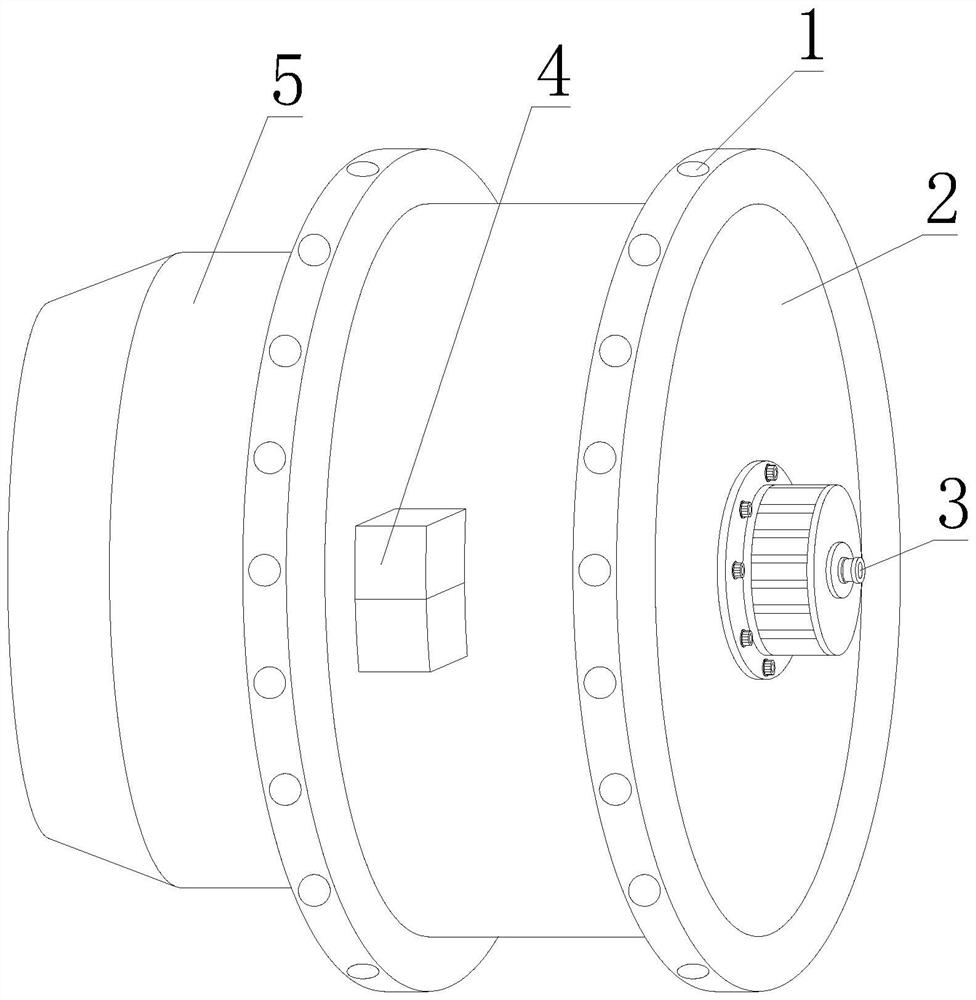

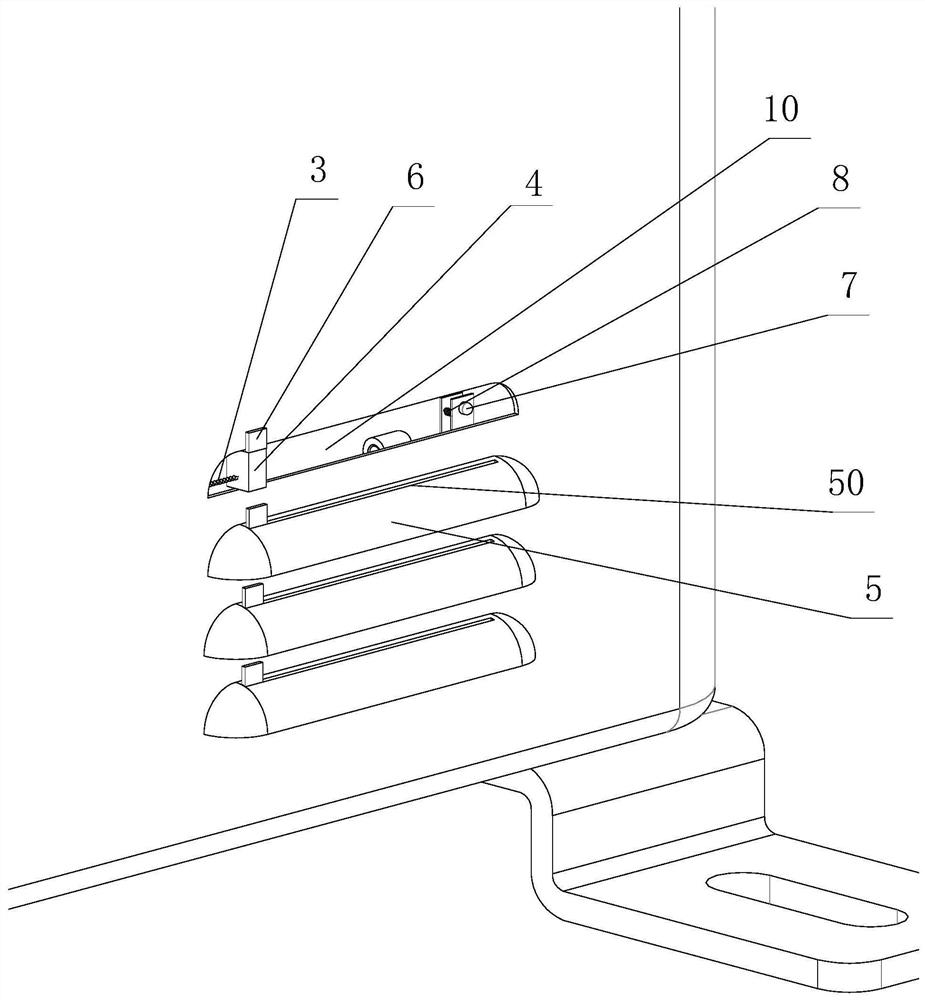

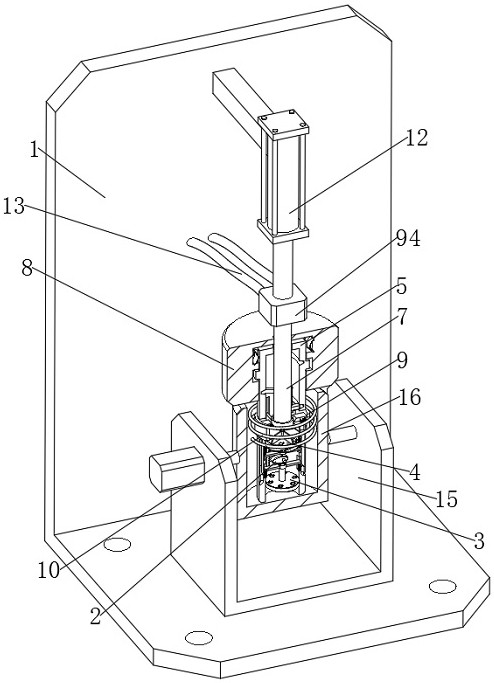

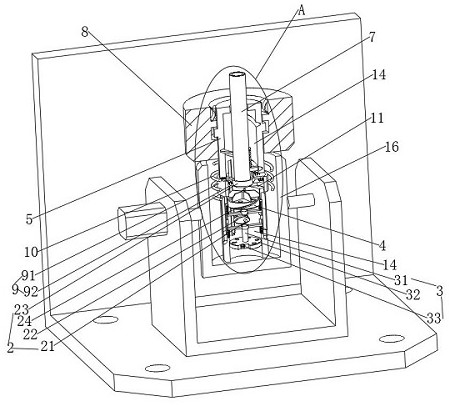

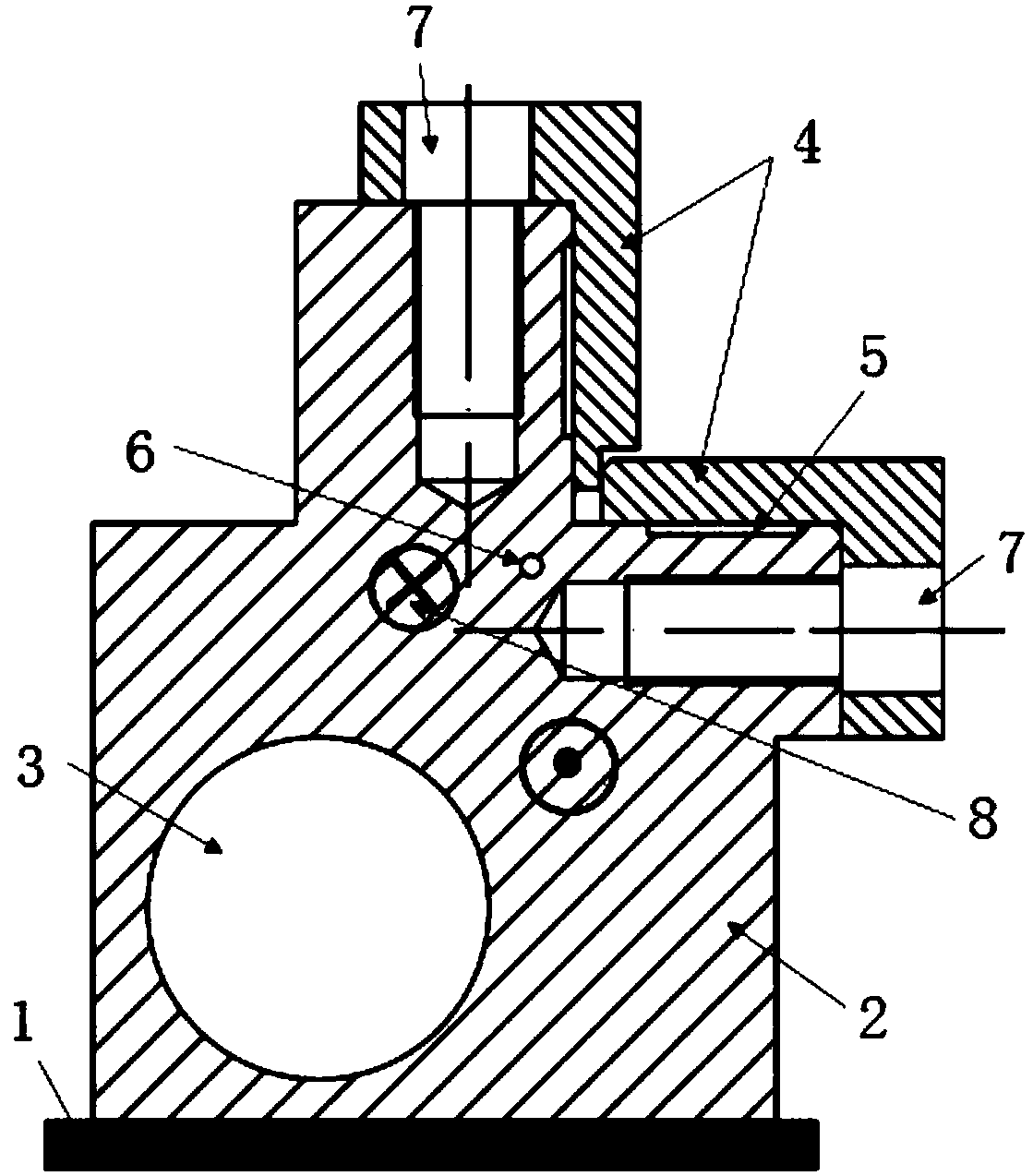

Automatic resistance wire burying equipment for PE pipe fitting and wiring method of automatic resistance wire burying equipment

The invention relates to the technical field of PE pipe fitting machining, and discloses an automatic resistance wire burying device for a PE pipe fitting and a wiring method.The automatic resistance wire burying device for the PE pipe fitting comprises a base and a supporting frame on the base, a mold is rotationally connected to the supporting frame, and a mold core is slidably connected to the interior of the mold; a supporting device is connected to the mold core in a sliding mode, a resistance wire is arranged on the outer surface of the supporting device, the supporting device is used for supporting the resistance wire, an adjusting rod is further installed in the mold core and used for abutting against the supporting device, a containing groove is formed in the mold core, and the supporting device is connected to the interior of the containing groove in a sliding mode. The supporting device comprises an arc-shaped plate which is slidably connected to the interior of the storage groove. Heat is taken away through water circularly flowing into the adjusting rod, hot air is cooled, cold air is discharged to the PE pipe fitting through the second piston, cooling of the PE pipe fitting is further accelerated, and a mold core is conveniently pulled out.

Owner:ZHEJIANG XINDA PLASTIC PIPE

A single-sided soldering copper pad device with water cooling and backside protection and a corresponding soldering method

ActiveCN109865966BCompact structureReduce weightWelding/cutting auxillary devicesAuxillary welding devicesShielding gasWeld seam

The invention belongs to the technical field of welding, and particularly relates to a single-sided welding copper liner device with water cooling and back protection and a corresponding welding method. By circulating cooling water and shielding gas inside a copper liner, the good welding forming effect of workpieces to be welded is ensured, many beneficial effects of reducing welding deformation,prolonging the service life of the liner, preventing oxidation inclusion on the back of a weld seam, refining weld seam grains, improving the tensile strength of the weld seam and the like are realized, and the single-sided welding copper liner device is suitable for various electric-arc welding methods.

Owner:WUHAN UNIV OF TECH +1

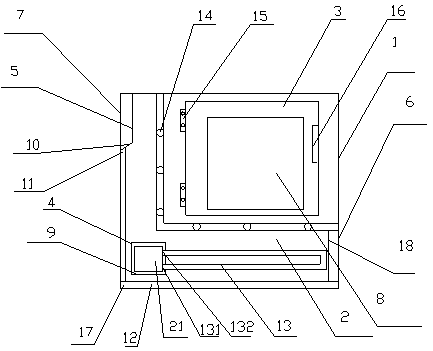

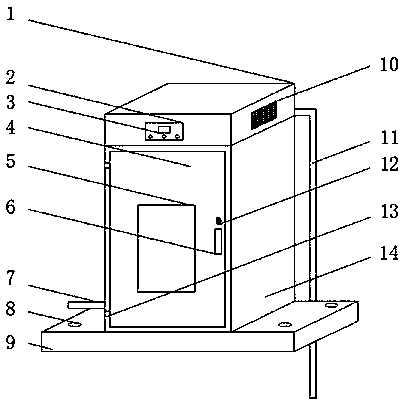

A water-cooled power distribution cabinet suitable for a water surface

InactiveCN109103793AImprove cooling effectReduce labor intensitySubstation/switching arrangement cooling/ventilationSurface mountingPump chamber

A water-cooled power distribution cabinet suitable for a water surface is provided. A pump chamber is installed on the upper surface of the cabinet body, and the pump chamber and the cabinet are cuboid, the head end of the pump chamber is provided with the control panel, and a display screen is arranged on the control panel, the head end of the cabinet body is provided with a box door, and the boxdoor and the cabinet body are connected with each other through the hinge, a tempered glass window is arranged on that box door, and the right end of the tempered glass window is provided with the handle, and the handle is mounted on the box door, the lower surface of the cabinet body is mounted on the upper surface of the base, and the four corners of the upper surface of the base are provided with the holes, the left side of the cabinet body is provided with the drain port, the pump chamber is provided with the water inlet pipe, the upper surface of the cabinet body is provided with the water inlet port, and the water inlet port is connected with the pipeline. The invention has the function of automatically adjusting the height of the electric cabinet according to the water level change.

Owner:李冬梅

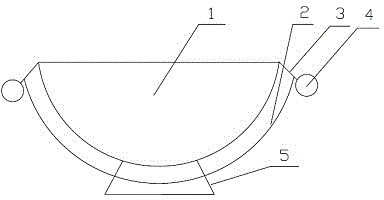

Multi-purpose bowl

Owner:QINGDAO XINYIFA IND & TRADE

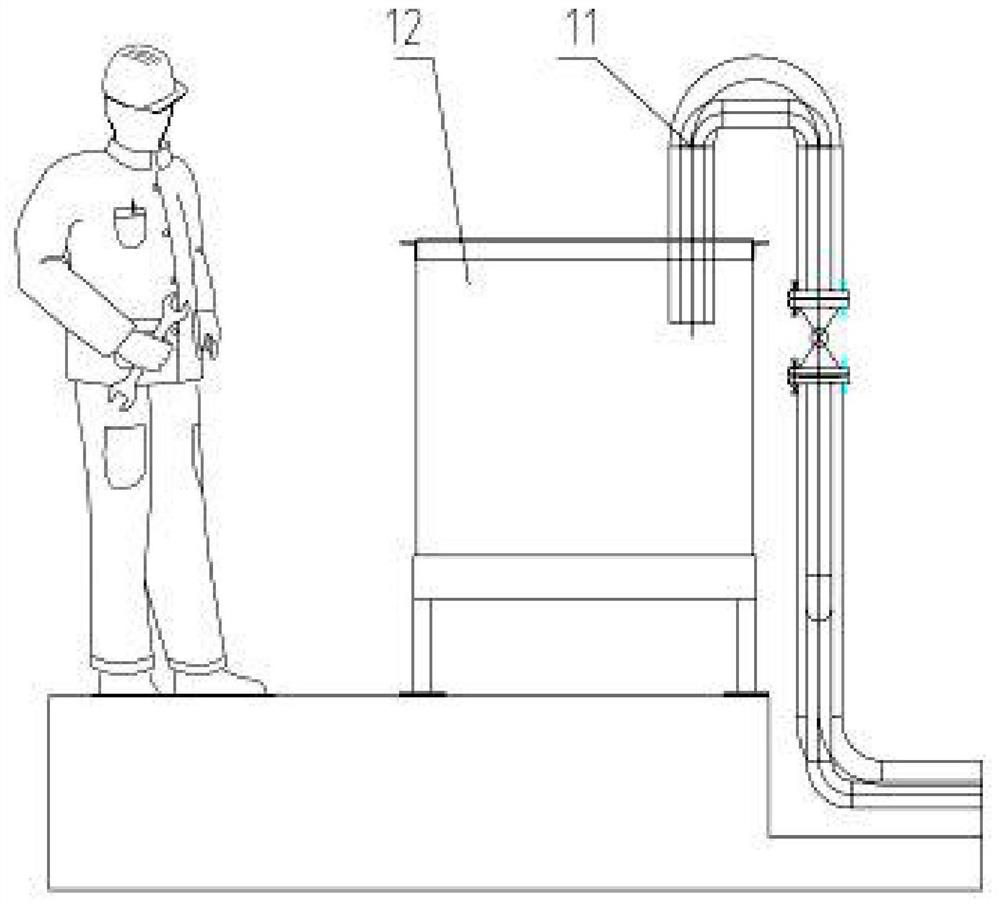

Device and method for returning circulating cooling water of continuous caster apparatus

InactiveCN113091395AEasy to cool downRelieve pressureLighting and heating apparatusCooling fluid circulationProcess engineeringWater pipe

The invention belongs to the technical field of continuous casting in the metallurgical industry, and particularly provides a device and a method for returning circulating cooling water of a continuous caster apparatus, wherein the device comprises a continuous caster water treatment center, a cooling water pipeline and a plurality of continuous caster apparatuses; a water outlet of the continuous caster water treatment center is connected with water inlets of the plurality of continuous caster apparatuses through the cooling water pipeline; the device further comprises an apparatus cooling water return pipeline, a water accumulation pool and a cooling water return main pipe; water outlets of the plurality of continuous caster apparatuses are connected with a water inlet of the water accumulation pool through the apparatus cooling water return pipeline; a water outlet of the water accumulation pool is connected with a water inlet of the continuous caster water treatment center through the cooling water return main pipe; and a continuous caster has the problems about a high water supply pressure level and a high equipment investment. The device provided by the invention avoids the use of detection components in the cooling water return pipeline, reduces a pressure of the overall water return pipeline and lowers the cost.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

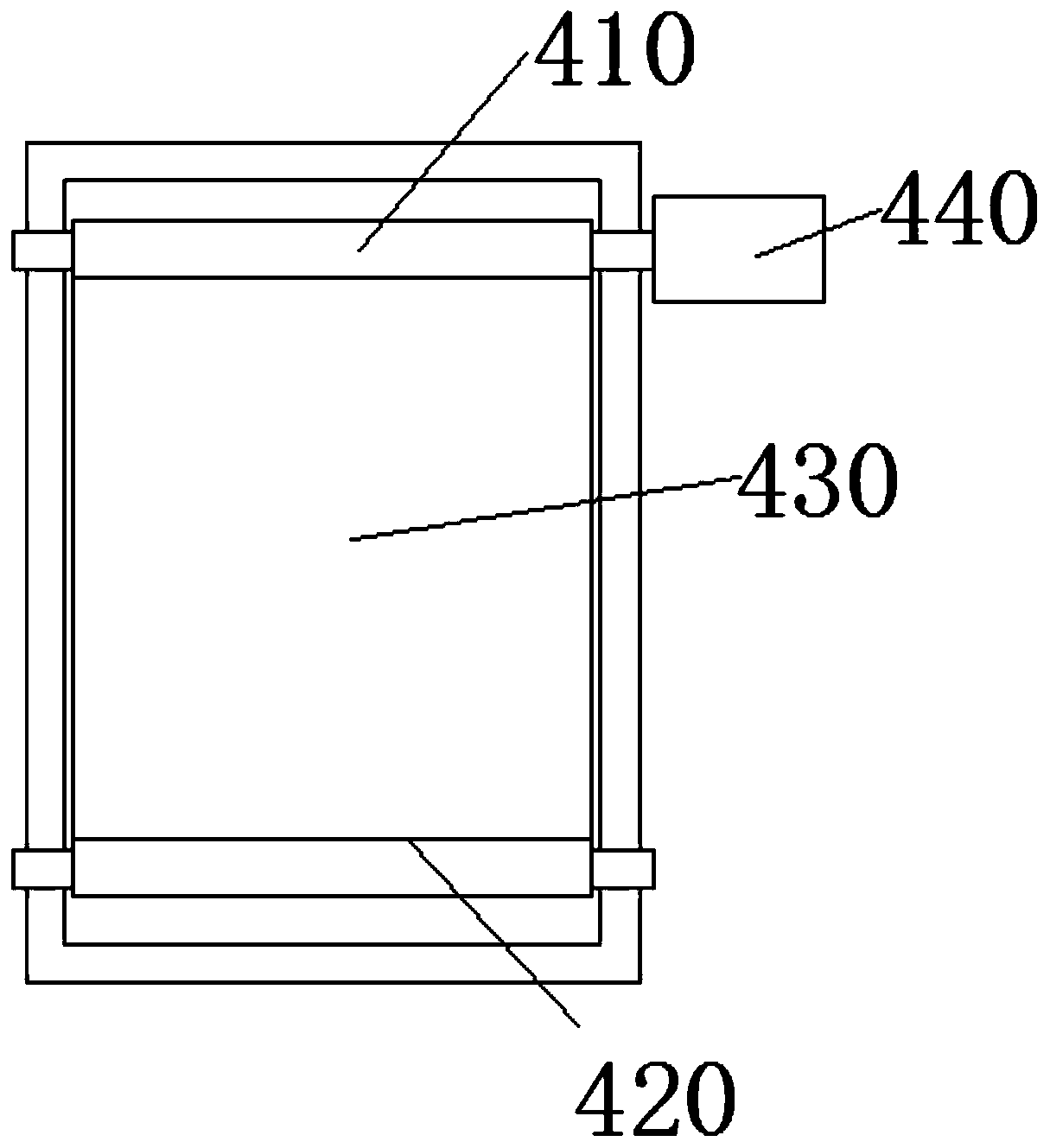

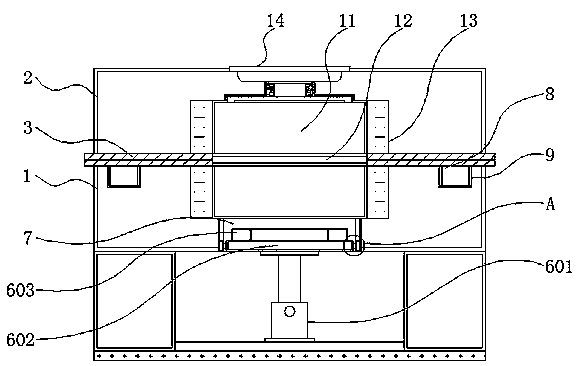

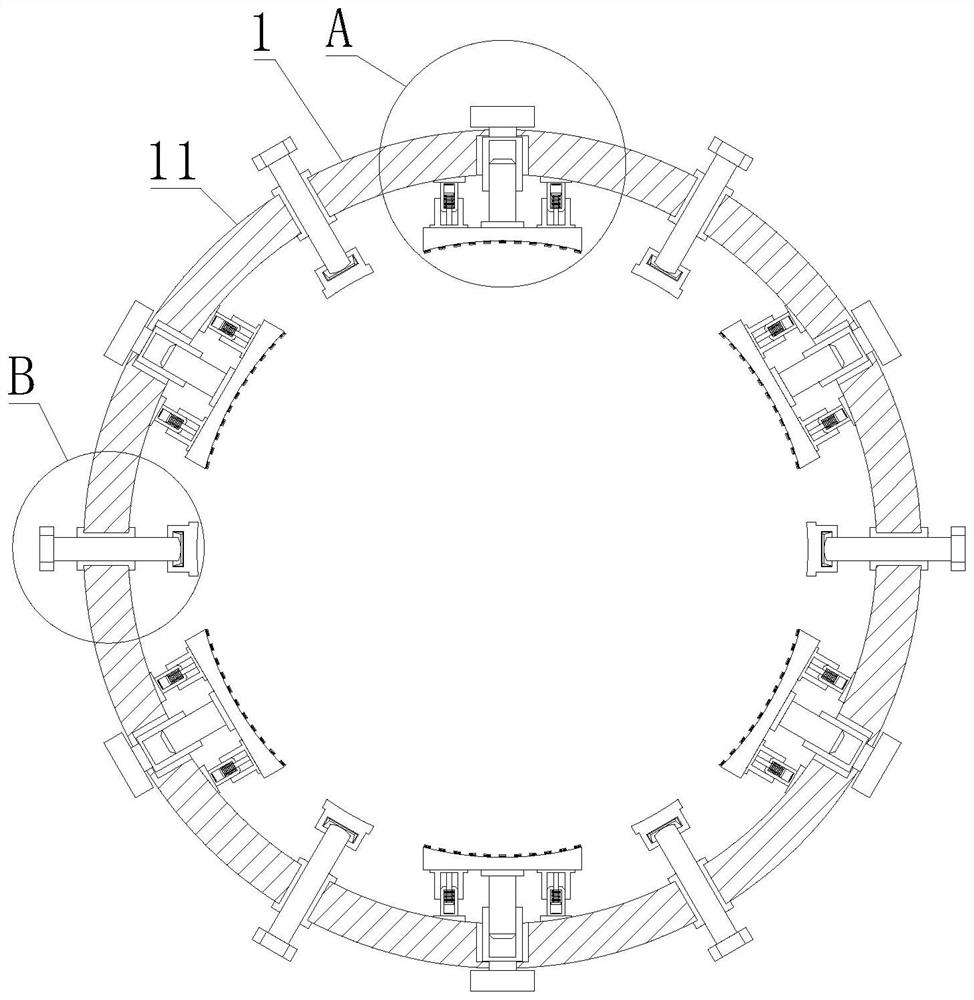

A welding device and method for superconducting joints inside nbti/cu superconducting coils

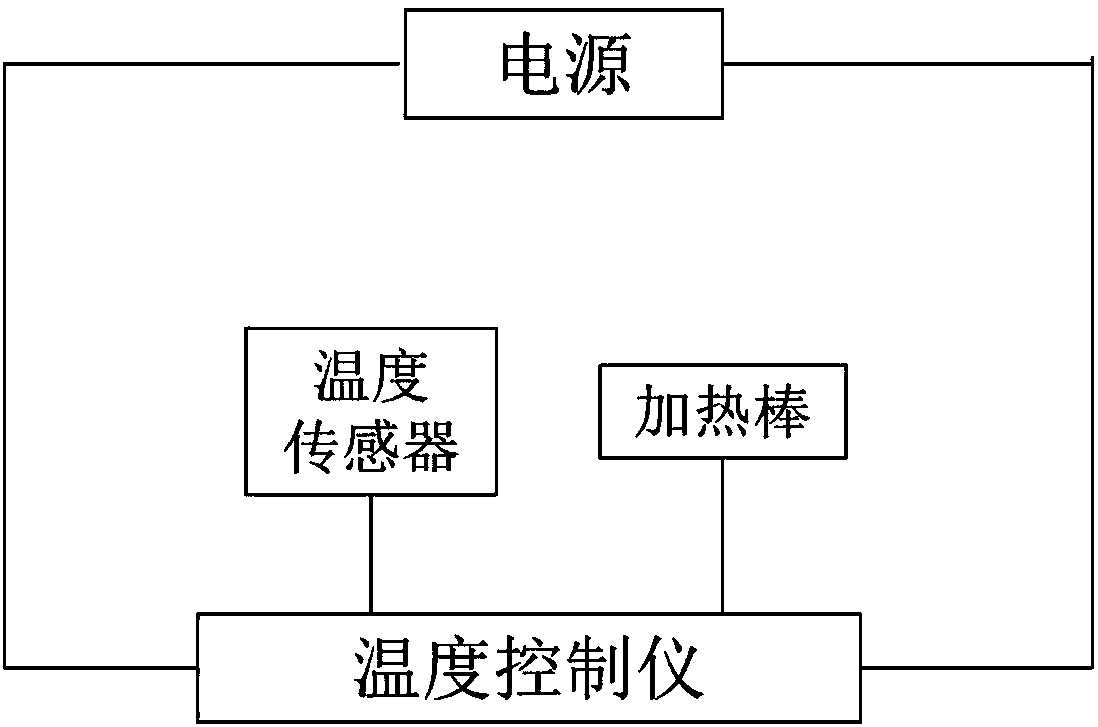

ActiveCN106825834BGuaranteed sizeImprove stabilityLine/current collector detailsHeating appliancesTemperature controlChinese characters

The invention discloses a welding device applied to an internal superconductive connector in NbTi / Cu superconductive coil and method thereof. The device comprises a temperature control unit, a welding main platen, a welding size pressing unit and a thermal insulation unit, wherein the temperature control unit comprises a heating rod, a temperature sensor and a temperature control instrument; a power is connected with the heating rod and the temperature sensor through the temperature control instrument, the heating rod is distributed on the welding main platen, the temperature sensor is distributed at the position adjacent to a welding face of the welding main platen, the welding main platen is in a shape like a Chinese character Tu, superconductive wire connectors are tightly pressed on the welding main bench board through the welding size pressing unit, the welding size pressing unit is composed of two sets of pressing strips, the two sets of the pressing strips are both fixed to the upper end and the lateral side of the welding main bench board through screws, and the superconductive wire connectors are arranged at the corners of the pressing strips and the welding main platen. According to the device disclosed by the invention, the internal connector of the coil can be welded through the adjustable welding device, and the connector size can meet a requirement.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

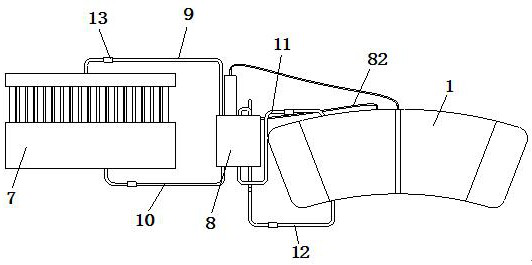

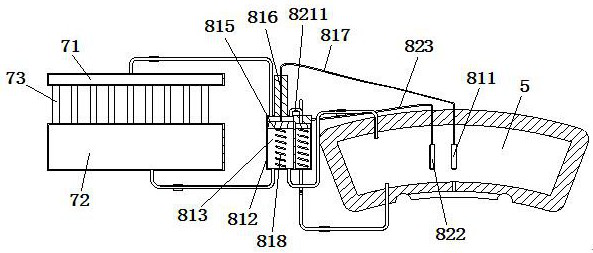

Motor vehicle brake pads with good heat dissipation performance

ActiveCN111503192BIncrease stressAvoid situations that affect braking effectivenessOperating means/releasing devices for valvesBraking elementsThermodynamicsEngineering

The invention discloses a motor vehicle brake pad with good heat dissipation performance, relates to the technical field of brake pads, and comprises sequentially connected friction pads, a heat insulation layer, a back plate and a sound-absorbing sheet, and one side of the heat insulation layer is provided with a cooling groove for cooling The notch of the groove is provided with a heat conducting sheet, the side of the back plate is provided with a cooling water tank, a driving mechanism is provided between the back plate and the cooling water tank, the driving mechanism includes a driving component and a control component, and a A first connecting pipe and a second connecting pipe, a first connecting pipe is provided between the driving assembly and the cooling tank, a second connecting pipe is provided between the control assembly and the cooling tank, the first connecting pipe, the second connecting pipe The pipe, the first communication pipe and the second communication pipe are all provided with a first one-way valve. The invention lowers the temperature of the friction plate through self-circulation, so that the temperature can be maintained within an acceptable range to work normally, avoiding the situation that the friction coefficient decreases due to excessive temperature of the friction plate, and does not need to be driven by external energy, which is energy-saving and environmentally friendly.

Owner:莱州恒宇刹车制品有限公司

A rotary cooling device for color masterbatch

Owner:TIANJIN YISANYOU MASTERBATCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com