A copper tungsten arc gouging device

A technology of arc gouging and copper tungsten, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of unstable arc formed by carbon rod electrodes, high technical requirements, and deteriorating working conditions, etc. Loss, easy to use, strong connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

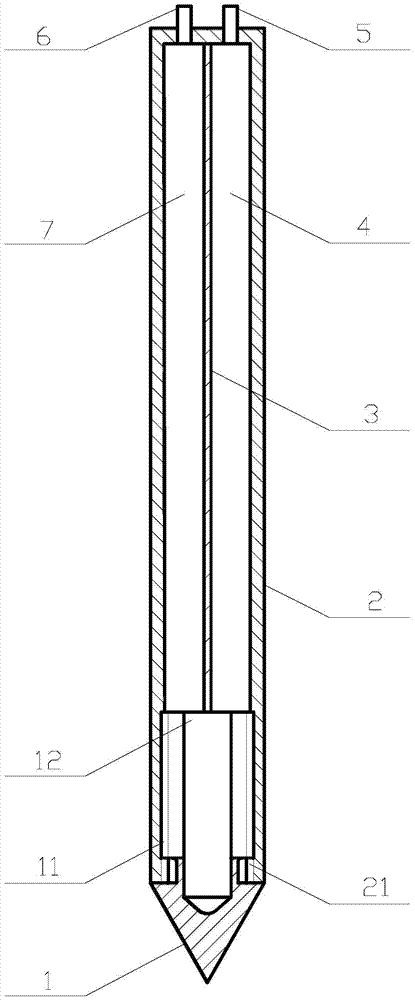

[0018] Such as figure 1 As shown, the copper-tungsten arc gouging device includes: tungsten electrode head 1, copper pipe body 2, partition 3, water inlet pipe 5, and water outlet pipe 6;

[0019] The lower end of the tungsten electrode tip 1 is a cone, and the upper end is a cylinder, and the lower end of the cone can be connected to the workpiece ( figure 1 (not shown in ) to form a stable arc; the outside of the cylinder is provided with an external thread 11, and the tungsten electrode tip 1 is provided with an inner hole 12 of the tungsten electrode tip along the axial direction.

[0020] The copper pipe body 2 is a cylindrical shell with a closed upper end and an open lower end. The lower end of the copper pipe body 2 is provided with an internal thread 21, and the internal thread 21 of the copper pipe body 2 is matched with the external thread 11 of the tungsten electrode head 1; 2 forms a thread-tight connection with the external thread 11 of the tungsten electrode he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com