High-rotating-speed and high-power hydraulic coupler speed regulating device capable of achieving intelligent cooling

A technology of hydraulic coupler and speed control device, which is applied in clutches, clutches, rotary couplings, etc., which can solve the problems of inconvenient installation, poor cooling effect of hydraulic coupler speed control device, and influence on hydraulic coupler speed control device Cooling effect and other issues, to achieve the effect of easy cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

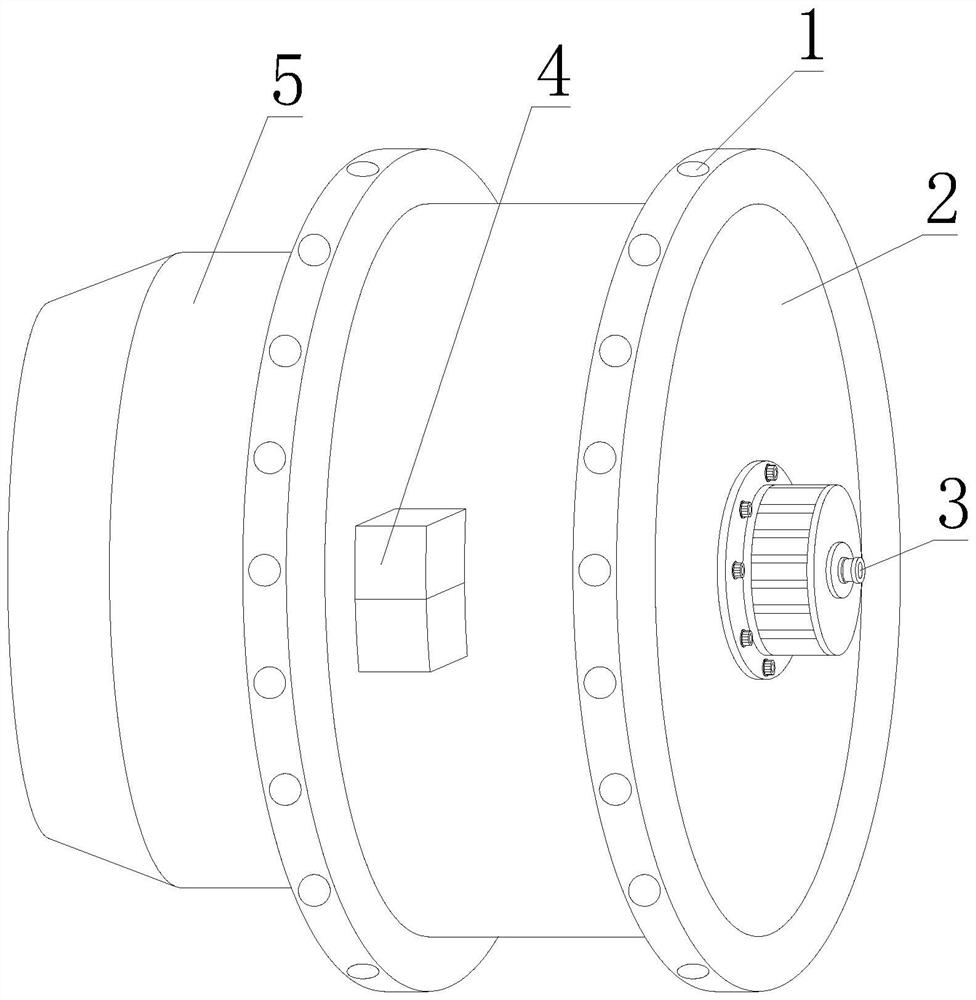

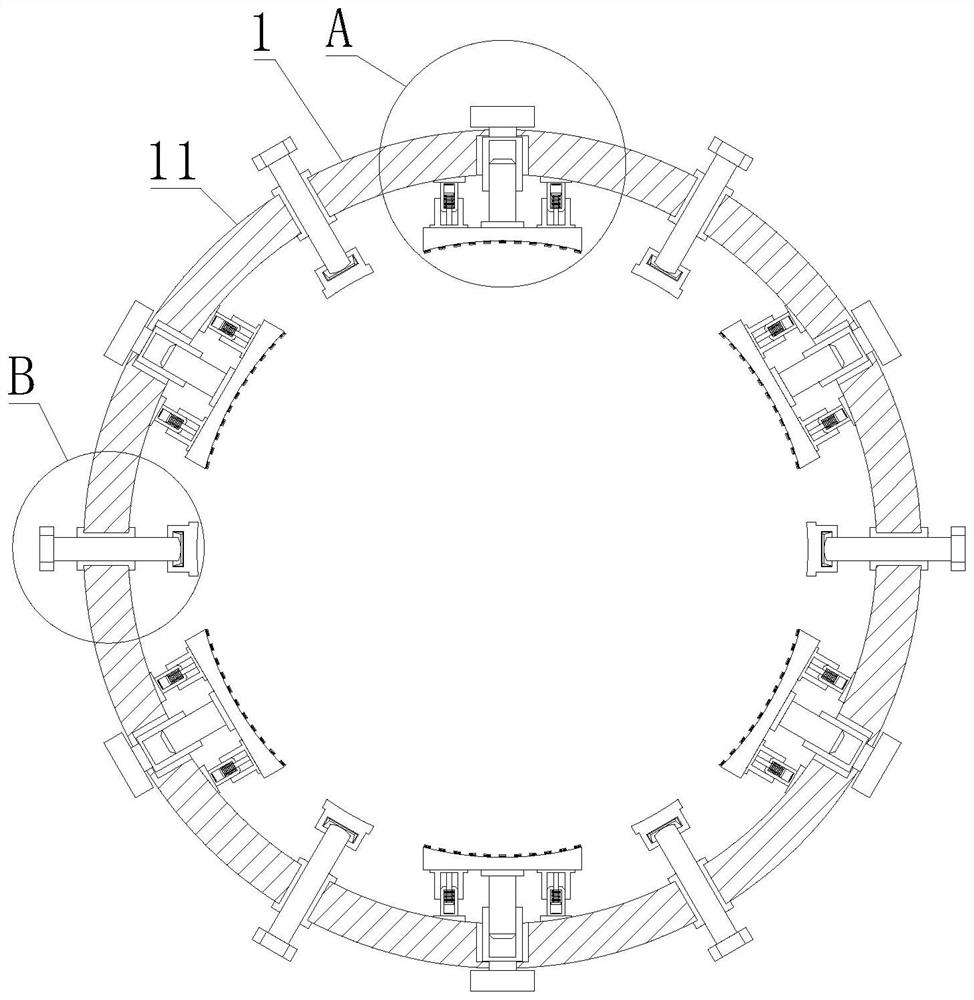

[0039] like Figure 1-7 As shown, the present invention provides a high-speed and high-power hydraulic coupler speed regulating device capable of intelligent cooling, comprising a cooling structure 2, an air supply pump 3 is fixedly installed at the right end of the cooling structure 2, and both ends of the cooling structure 2 are fixedly installed There is an annular fixed structure 1, a cooling device 4 is fixedly installed on the front of the outer wall of the cooling structure 2, and a hydraulic coupling speed regulating device body 5 is fixedly installed on the inner wall of the annular fixed structure 1. The annular fixed structure 1 includes a metal fixing ring 11, which is fixed by metal. One side of the ring 11 is fixedly installed with one end of the cooling structure 2, the outer wall of the metal fixing ring 11 is rotatably connected with an adjusting nut 12, the inner wall of the metal fixing ring 11 is fixedly installed with a guide column 15, and the front of the...

Embodiment 2

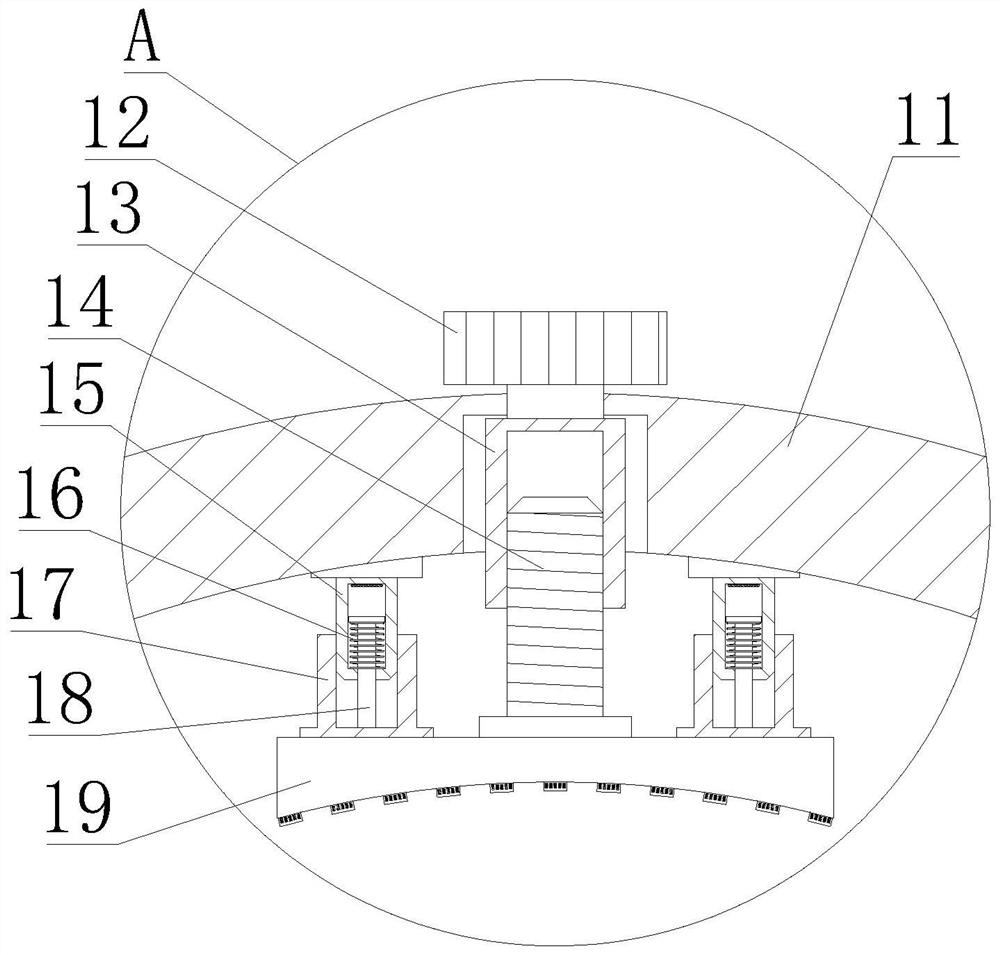

[0042] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a threaded adjusting sleeve 13 is fixedly installed at the bottom of the adjusting nut 12 and located on the front of the metal fixing ring 11, and the inner wall of the threaded adjusting sleeve 13 is threadedly connected There is a threaded push rod 14, the bottom of the threaded push rod 14 is fixedly installed with a pressure plate 19, the bottom of the outer wall of the guide column 15 is inserted with a guide sleeve seat 17, the bottom of the inner wall of the guide sleeve seat 17 is fixedly installed with a pull rod 18, and the top of the outer wall of the pull rod 18 is fixedly installed And a spring 16 is arranged on the front of the guide column 15, the bottom of the guide sleeve seat 17 is fixedly installed with the two ends of the top of the pressure plate 19, the inner wall of the threaded sleeve 110 is threadedly connected with a threade...

Embodiment 3

[0045] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the fixing block 22 includes a fixing plate 229, the bottom of the fixing plate 229 is fixedly installed with the inner wall of the metal ring sleeve 21, and the top of the fixing plate 229 is fixedly installed. A fixed screw sleeve 227 is fixedly installed, the inner wall of the fixed screw sleeve 227 is threadedly connected with a locking stud 226, the outer wall of the locking stud 226 is inserted with a pipe clip 225, and the top of the locking stud 226 is inserted with a fixed pressure plate 223 , the top of the fixed pressure plate 223 is fixedly installed with a fixed screw 222, the top of the fixed screw 222 and the top of the protective net 25 are threadedly connected with a compression nut 221, and the outer wall of the locking stud 226 is located between the fixed pressure plate 223 and the pipe clip 225. A first spring washer 224 is inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com