Device and method for returning circulating cooling water of continuous caster apparatus

A technology of circulating cooling water and return water device, which is applied in cooling fluid circulation device, household refrigeration device, lighting and heating equipment, etc. The effect of convenient judgment, cost reduction, and easy cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

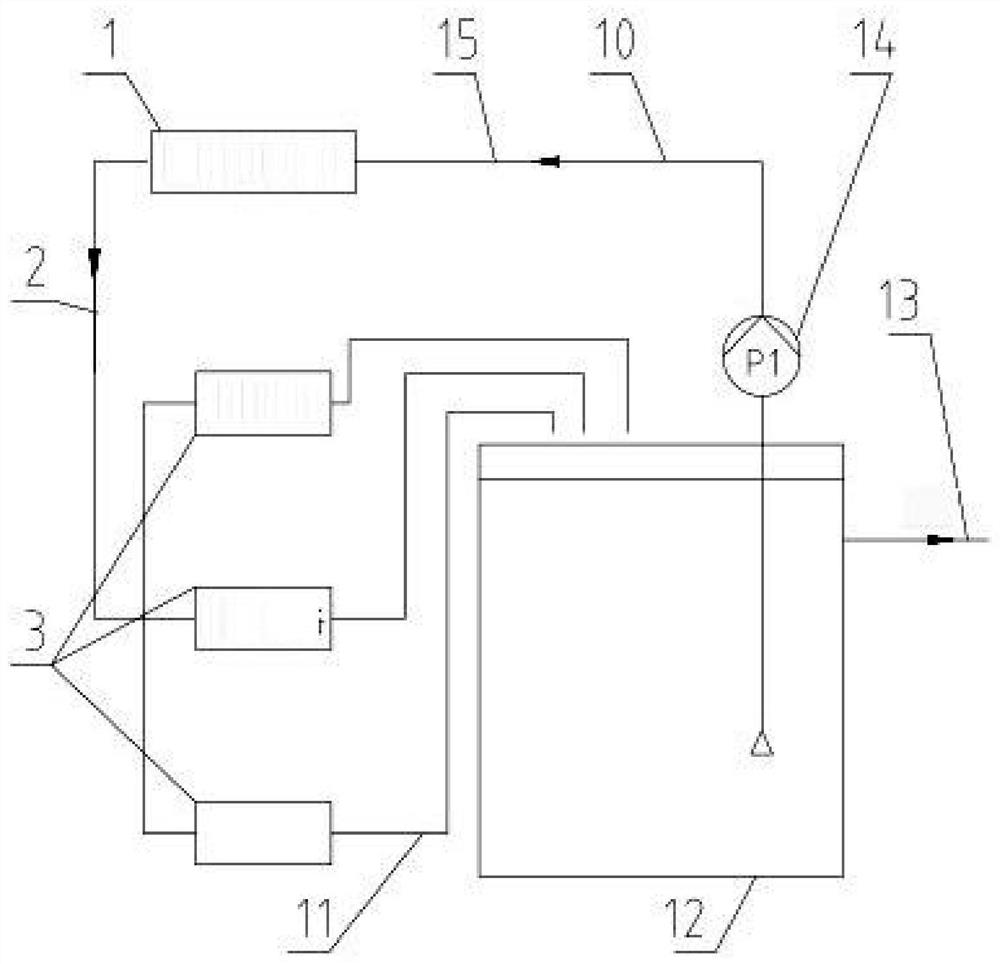

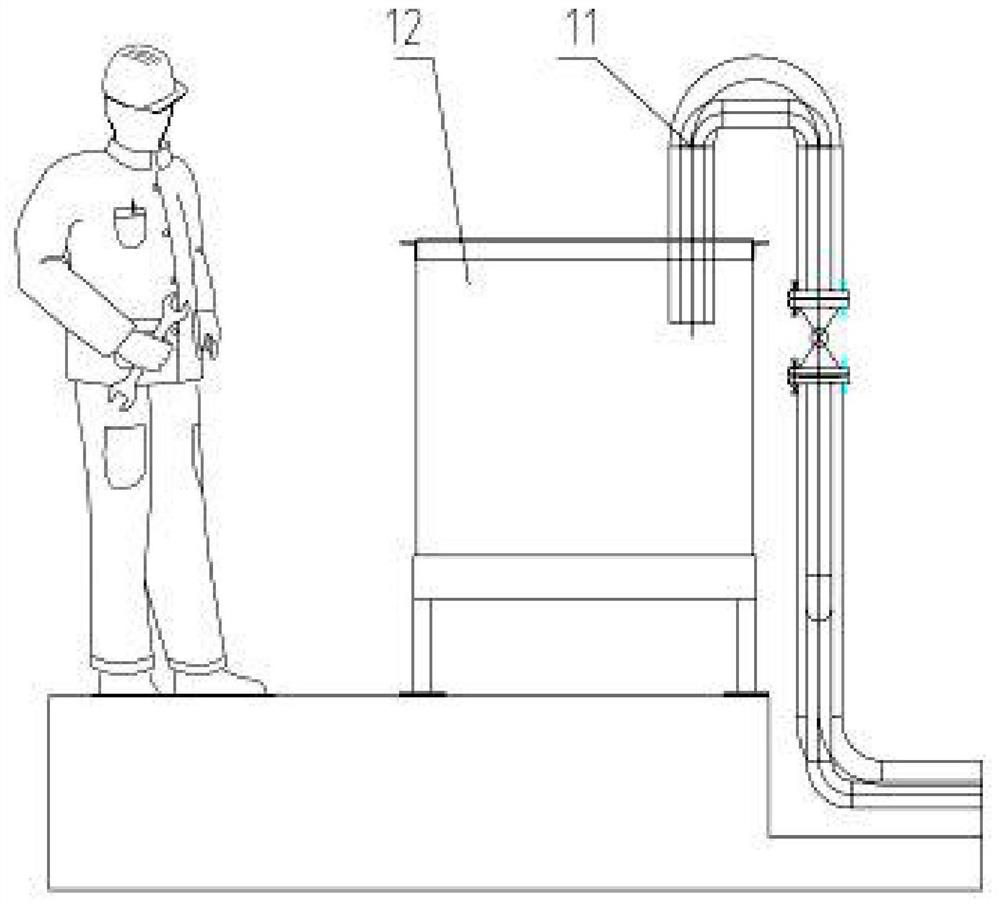

[0025] like Figure 1-2 As shown, a continuous casting machine equipment circulating cooling water return device includes a continuous casting machine water treatment center 1, a cooling water pipeline 2 and a plurality of continuous casting machine equipment 3, and the water outlet of the continuous casting machine water treatment center 1 is cooled The water pipeline 2 is connected to the water inlet of multiple continuous casting machine equipment 3, and also includes equipment cooling return water pipeline 11, pond 12, and cooling return water main pipe 10, and the water outlets of multiple continuous casting machine equipment 3 pass through the equipment cooling return water pipeline 11 is connected to the water inlet of the accumulated water pool 12, and the water outlet of the accumulated water pool 12 is connected to the water inlet of the continuous casting machine water treatment center 1 through the cooling return water main pipe 10.

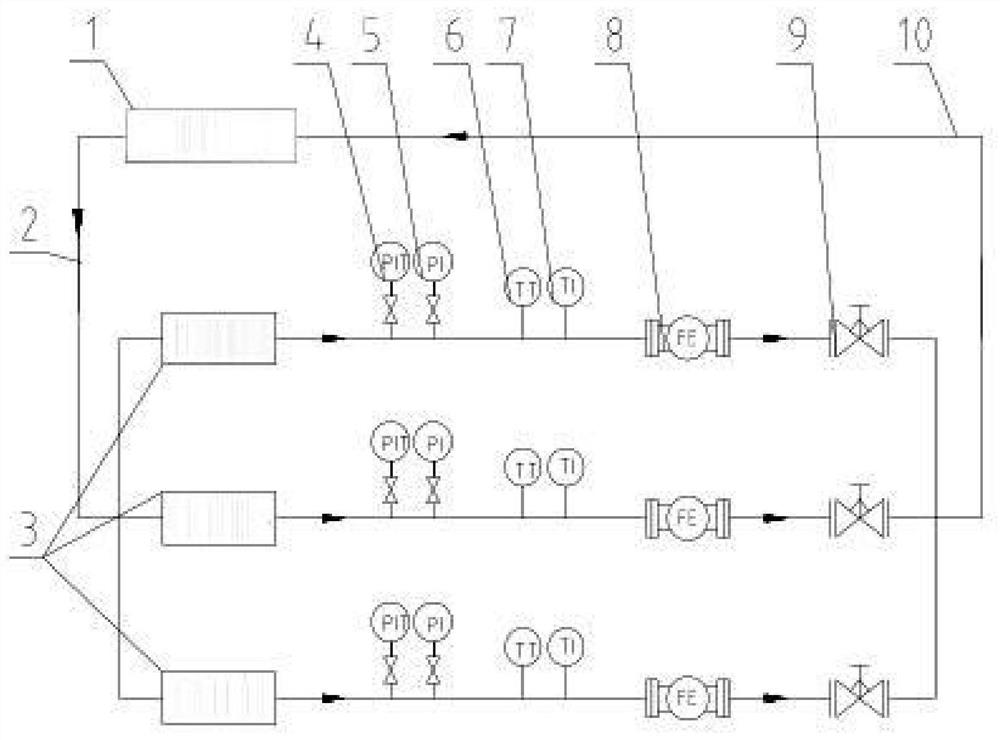

[0026] like image 3 As shown...

Embodiment 2

[0029] On the basis of Embodiment 1, a lifting device 14 is further included, and the water outlet of the accumulated water pool 12 is connected to the inlet port of the cooling return water main pipe 10 through the lifting device 14 .

[0030] The existing conventional technology is to set a flow meter in the cooling water return pipeline of the equipment, and judge the cooling condition of the equipment by detecting whether there is flow in the pipeline; in fact, the cooling condition of the equipment is determined by whether there is cooling return water and the size of the return water. It is judged that in order to achieve this purpose, flow meters and valves are designed on the return water pipeline. Greatly increased the investment of continuous casting machine. In actual use, the cooling condition of the equipment does not require very high cooling water. As long as the pipeline is not blocked and the cooling water volume is not abnormally large, it can usually meet th...

Embodiment 3

[0037] On the basis of Example 2, a continuous casting machine equipment circulating cooling water return method includes the following steps: the continuous casting machine water treatment center 1 supplies cooling water to the continuous casting machine equipment 3, and the cooling water passes through the continuous casting machine equipment 3 After that, it enters the accumulated water tank 12 for storage, and the lifting device 14 lifts the water in the accumulated water tank 12 to the casting machine water treatment center 1 for processing.

[0038] In the present invention, since the return water first enters the accumulated water pool 12 next to the continuous casting machine equipment 3, the accumulated water pool 12 is conducive to the precipitation and cooling of the backwater, and only the lifting device 14 is required to lift and suppress the water in the accumulated water pool 12 to The water treatment center 1 of the continuous casting machine is reprocessed. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com