Patents

Literature

36results about How to "Simple cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of halohydrocarbon-free alpha-cyanoacrylate

ActiveCN102030681ANot easy to hydrolyzeEasy to controlCarboxylic acid nitrile preparationOrganic compound preparationHalohydrocarbonMethyl carbonate

The invention relates to a preparation method of halohydrocarbon-free alpha-cyanoacrylate, which comprises the following steps: mixing cyanoacetate and methyl carbonate in a reaction kettle, simultaneously mixing formaldehyde and a base catalyst in a charging hopper, then adding the mixture of the formaldehyde and the base catalyst to the reaction kettle at twice, performing a refluxing and condensation reaction at 78 DEG C under normal pressure, adding a dehydration solvent methyl carbonate to dehydrolyze after the condensation reaction is finished, adding an anionic polymerization inhibitor phosphorus pentoxide and a free radical polymerization inhibitor, and depolymerizing and distilling at 155-210 DEG C at a vacuum degree of 0.5-30 mmHg to obtain an alpha-cyanoacrylate coarse monomer; and rectifying the coarse monomer to obtain a high-purity alpha-cyanoacrylate refined monomer, wherein the yield of the alpha-cyanoacrylate refined monomer is more than 75%, and the purity of the alpha-cyanoacrylate refined monomer is 99%. The invention has the advantages of no pollution, energy conservation and high yield and high purity of the obtained product, and is stable in reaction, thereby being suitable for popularization and application.

Owner:山东禹王和天下新材料有限公司

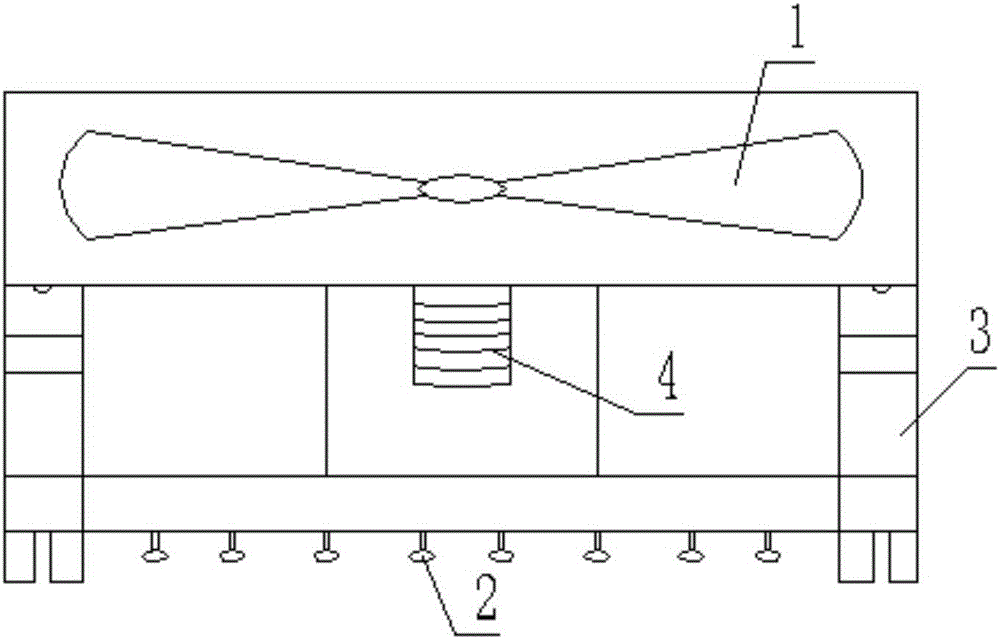

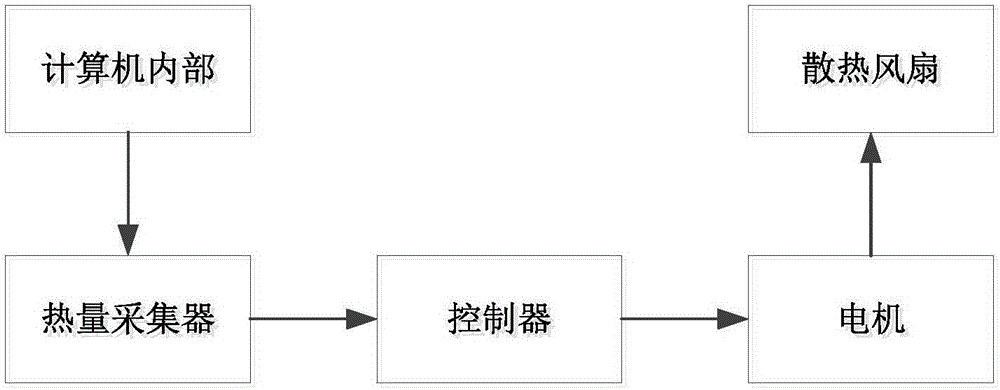

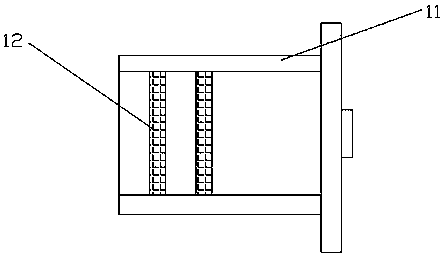

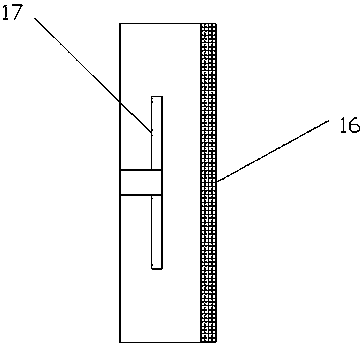

Cooling device of computer

InactiveCN106371533AAvoid the problem of noise affecting user experienceSimple coolingDigital data processing detailsElectric machineryCooling effect

The invention discloses a cooling device of a computer, and belongs to the technical field of computer-aided equipment. The cooling device comprises a cooling fan, a controller, a supporting frame and a minitype motor, wherein the supporting frame is installed in a computer case and is provided with a movable spindle; the fixing end of the movable spindle is fixed on the supporting frame to be stationary, the other end of the movable spindle is a movable end, the top of the movable end is provided with the cooling fan, and the movable end drives the cooling fan to rotate to regulate an airflow direction; the controller is connected to and control the motor, and the motor is connected with the moving end of the movable spindle. The movable spindle is arranged in the supporting frame, the cooling fan is installed on the movable end, the airflow direction of the cooling fan is regulated, so that the problems of concentrated airflow direction in the computer, no transformation and poor cooling effect are solved, the cooling device has the advantage of regulating the airflow direction according to temperature, is even in cooling and is favorable for cooling the inner side of the computer.

Owner:芜湖能盟信息技术有限公司

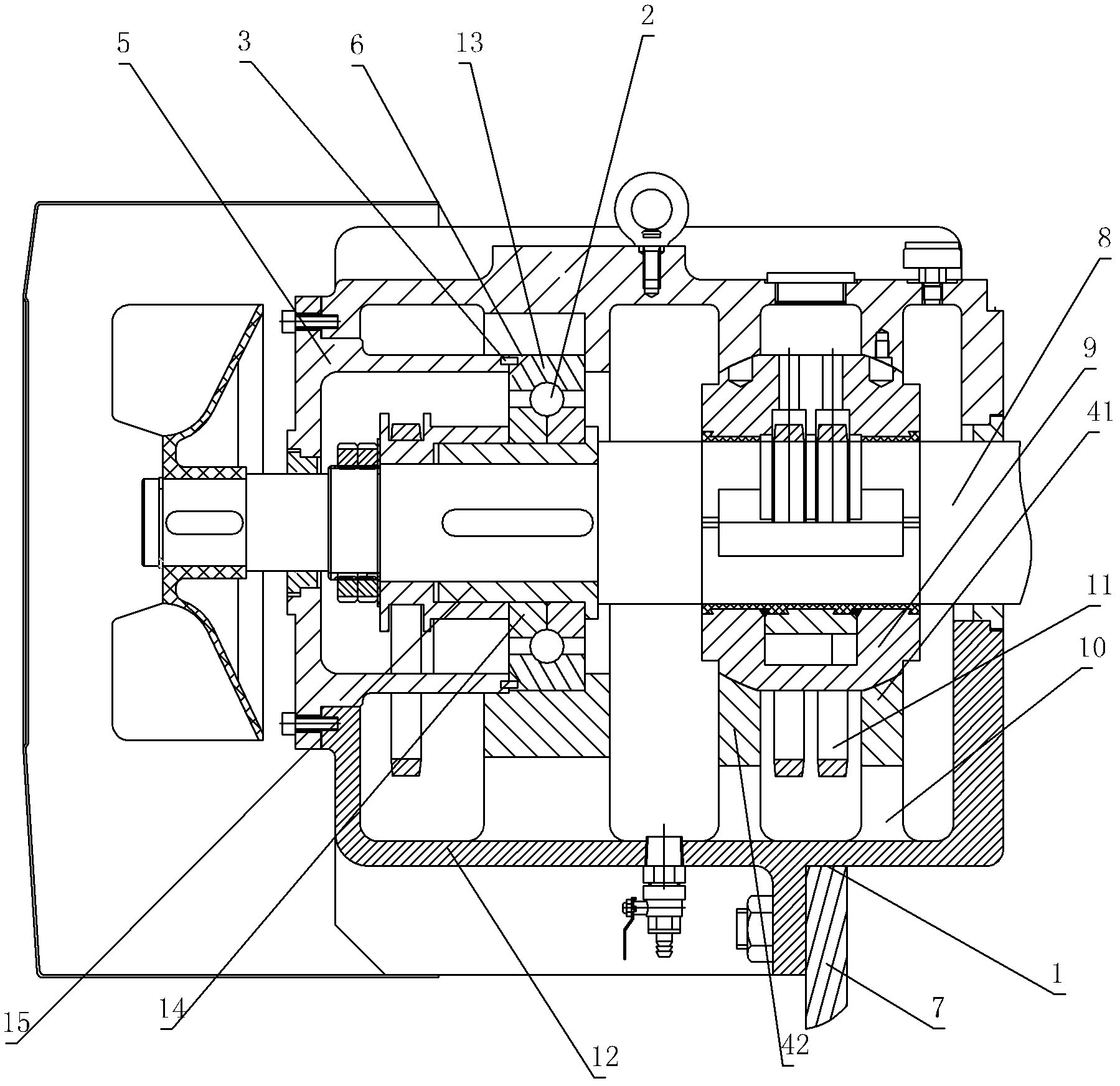

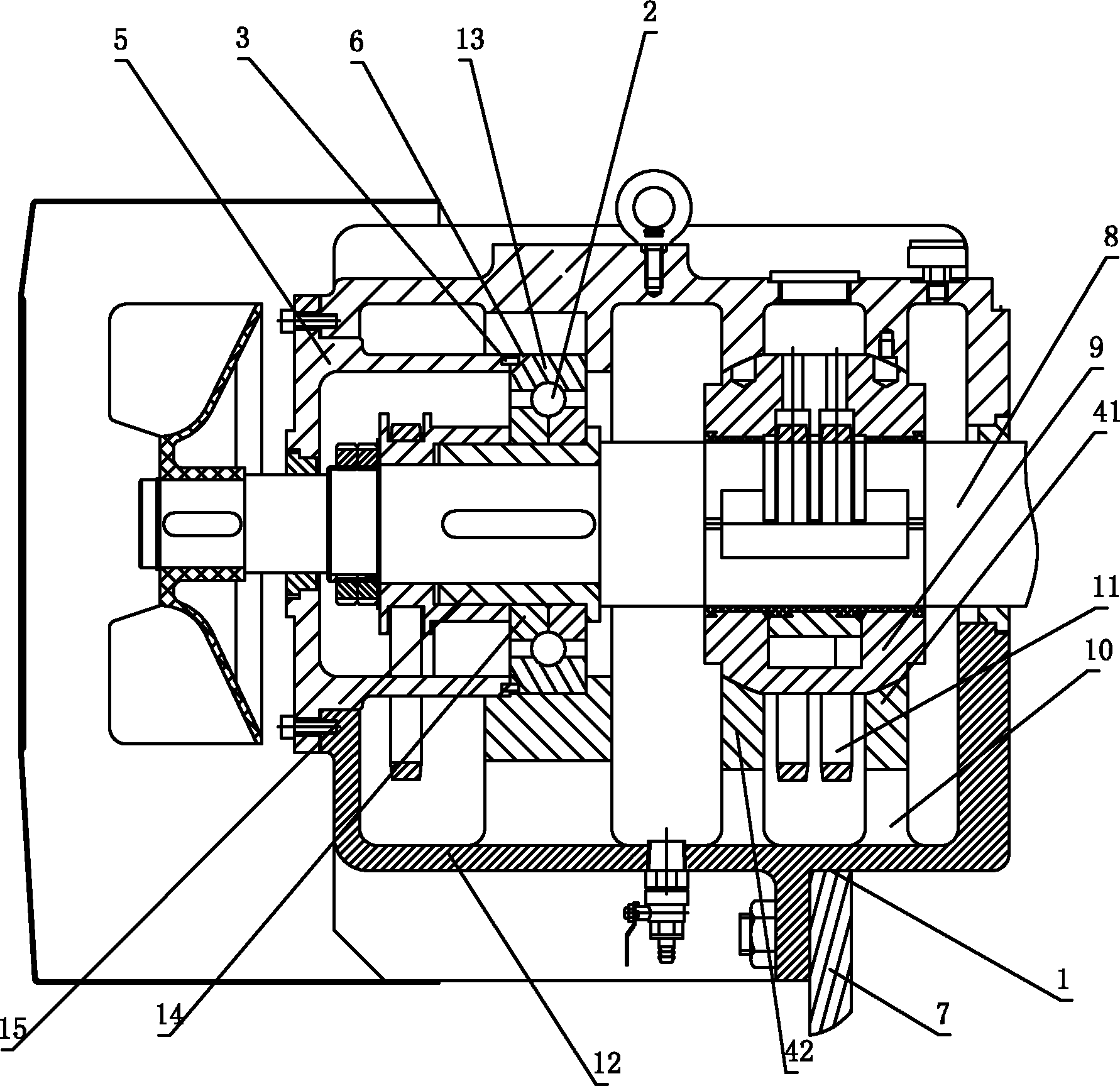

Split bearing bush seat type sliding bearing tank

InactiveCN102518680AEasy to installReduce bending momentBearing coolingBearing unit rigid supportBall bearingRolling-element bearing

The invention relates to a split bearing bush seat type sliding bearing tank, which comprises a tank body connected with a casing, a sliding bearing component and a rolling bearing component which are arranged in the tank body and used for supporting a shaft,; the sliding bearing component comprises a bearing bush, an oil ring and a bearing bush installation seat; the rolling bearing is a single four-point contact ball bearing; and a gravity support surface between the tank body and the casing is positioned at the lower part of the sliding bearing component. According to the invention, the technical problems of large volume, large weight and large bending moment of the current sliding bearing tank can be solved, the weight of the bearing tank can be reduced, the capacity of the lubricating oil can be raised, and the installation of the sliding bearing tank is more stable and reliable.

Owner:西安航天泵业有限公司

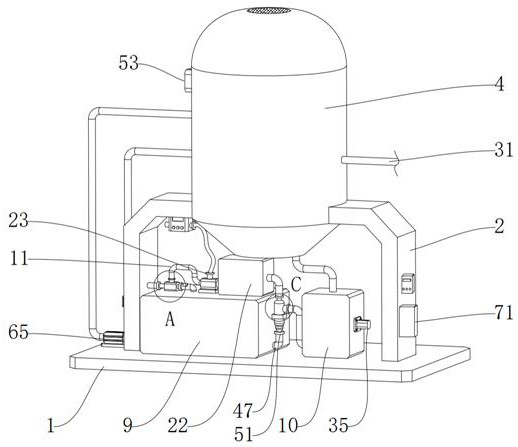

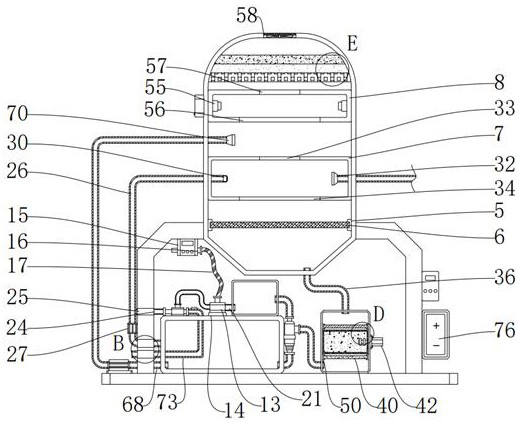

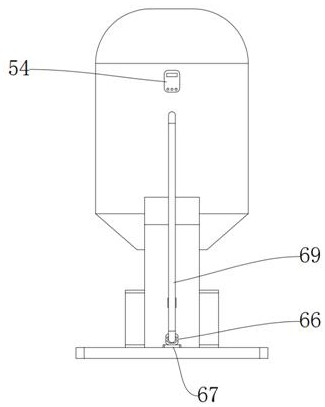

Impinging stream type ionization high-temperature waste gas harm removal, separation, degradation and circulation treatment device

ActiveCN113559686ASpeed up emissionsSolve recyclingCombination devicesFatty/oily/floating substances removal devicesWater storage tankHazardous substance

The invention discloses an impinging stream type ionization high-temperature waste gas harm removal, separation, degradation and circulation treatment device. The device comprises a separation bottom supporting seat, a separation tower supporting frame, a clash type negative pressure separation and degradation tower, an inertia type impinging stream mixing periodic swinging box, an adsorption type electrostatic state dust cleaning and storage box, a multifunctional integrated waste gas degradation water storage box, an ultrasonic waste water circulation purification and harm removal box, an impinging stream waste gas atomization cooling adsorption and degradation mechanism, a circulating cooling waste water ultrasonic purification mixing oil reduction mechanism, an all-dimensional electrostatic adsorption dust storage treatment mechanism, a negative pressure absorption waste gas filtering zero emission mechanism, a spraying covering cooling dust removal cooling mechanism and a temperature difference type power generation heat collection cooling emission mechanism. The invention belongs to the technical field of industrial waste gas treatment, and particularly provides an impinging stream type ionization high-temperature waste gas harm removal, separation, degradation and circulation treatment device which integrates separation and degradation of harmful substances contained in high-temperature waste gas and adsorbs and filters dust in all directions.

Owner:徐州众迈节能环保科技有限公司

Storage sofa

The invention discloses a storage sofa. The storage sofa comprises a backrest structure and a lying structure, wherein the backrest structure is arranged behind the lying structure; the backrest structure and the lying structure are connected through a detachable structure; movable drawers are arranged at the left and right sides of the lying structure; the movable drawers are in sliding connection with the lying structure; a movable door is arranged at the left side of the front surface of the lying structure; the movable door is rotatably connected with the lying structure through a rotatingshaft; a storage groove is formed in the right side of the rotating shaft; a stopping grid plate is arranged in the middle of the storage groove; a solid plate body is arranged at the right side of the storage groove; a cavity is formed in the right side of the solid plate body; the cavity is closed through a sliding door. By adopting the equipment, the movable drawers and the storage groove areadded, so that objects are convenient to gather and store; the storage sofa has relatively strong whole functionality and simple structure and is easy to realize.

Owner:FOSHAN TIANLI TONGSE DECORATION MATERIAL CO LTD

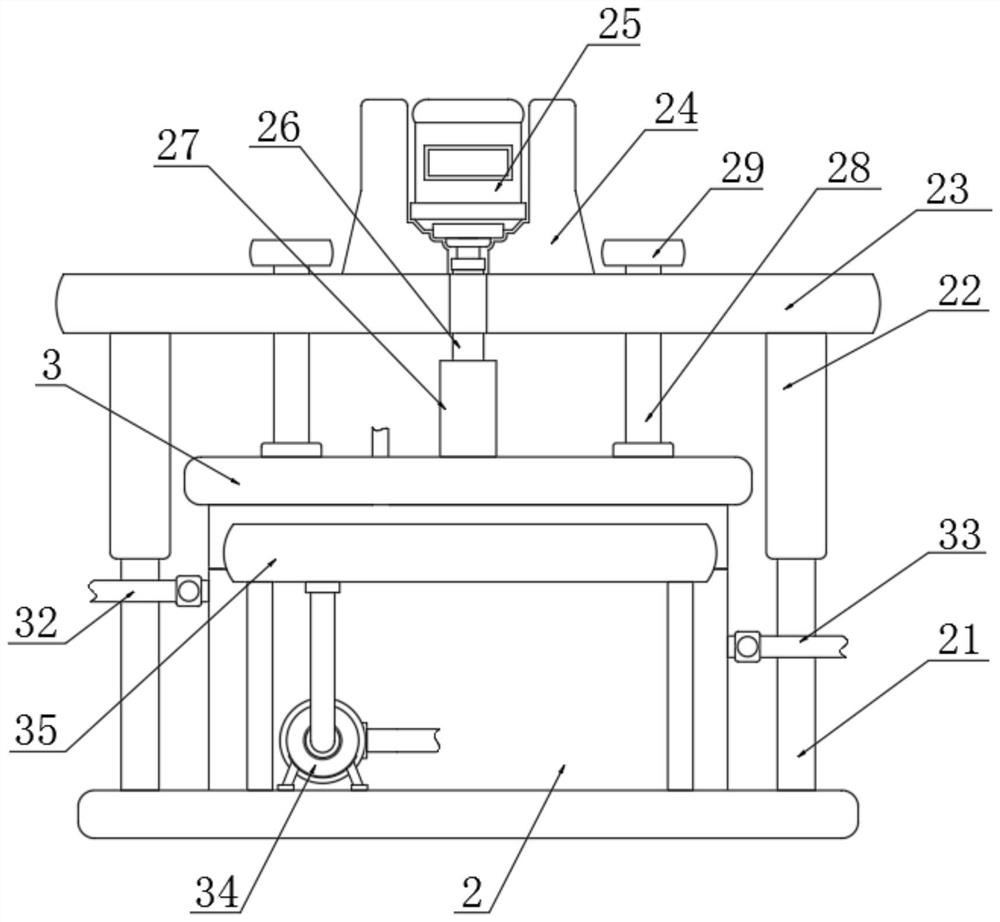

Rotary stripping type injection mold

Owner:广东伟力环保实业有限公司

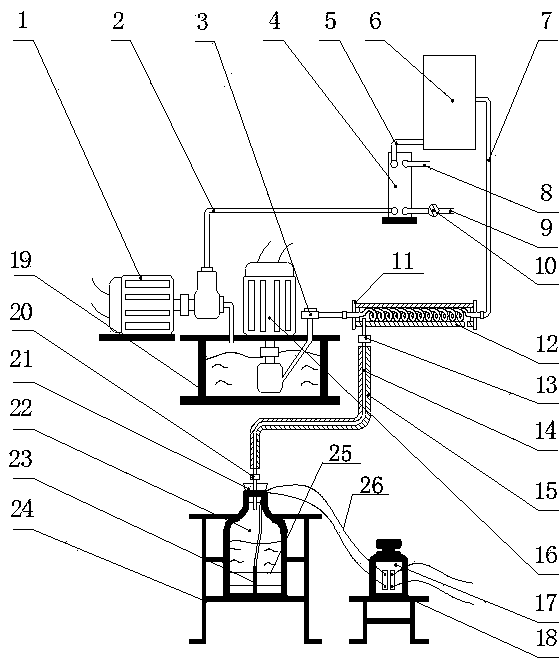

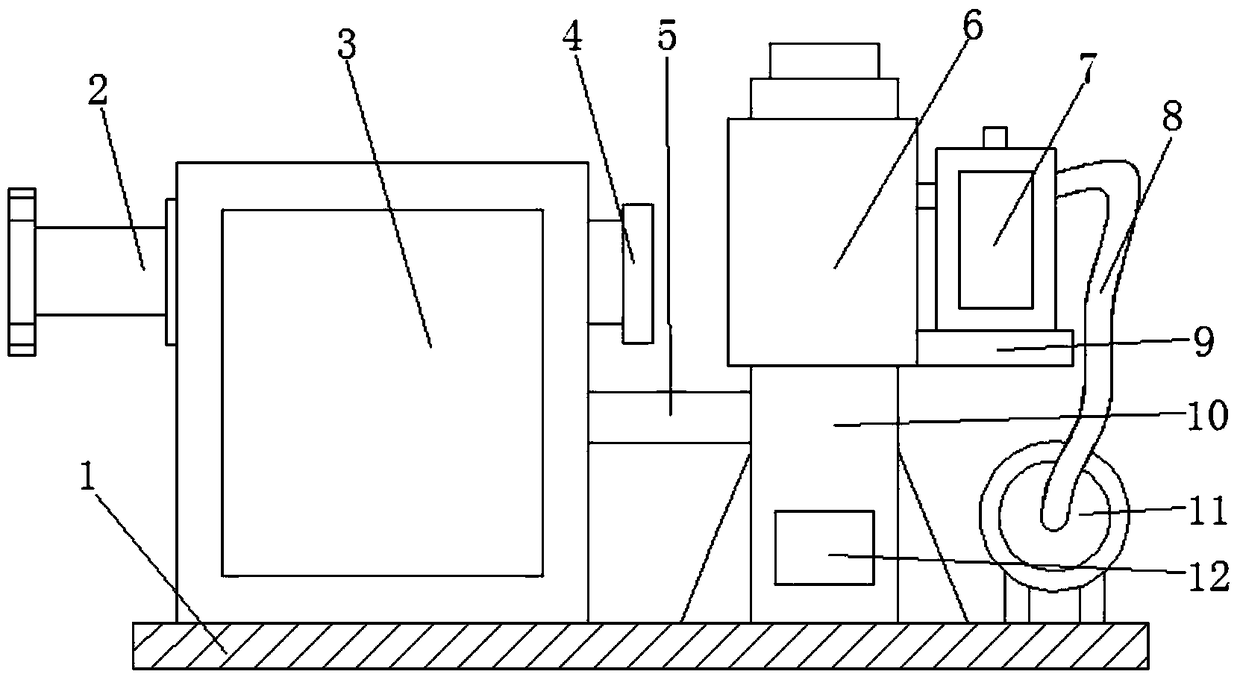

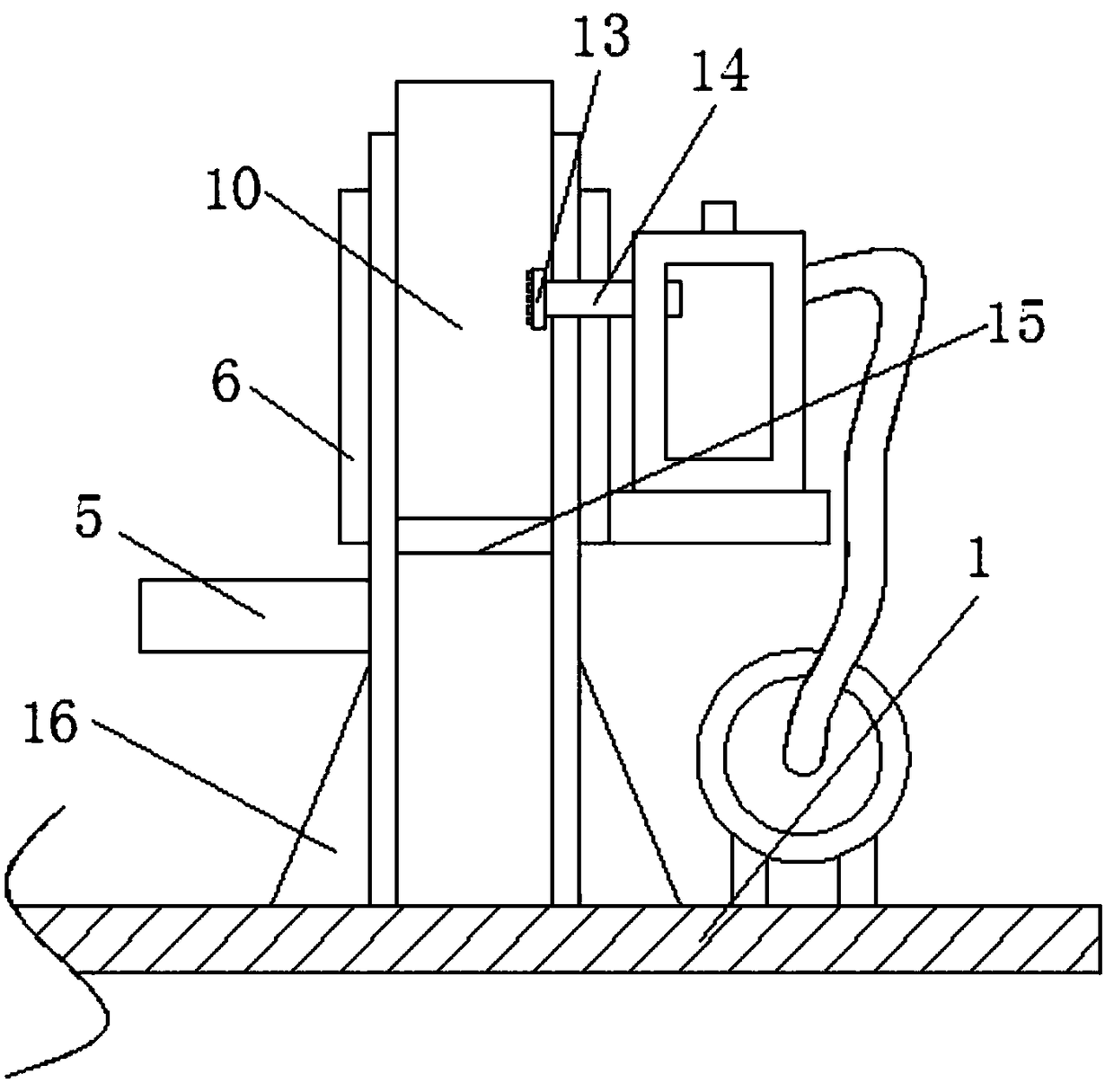

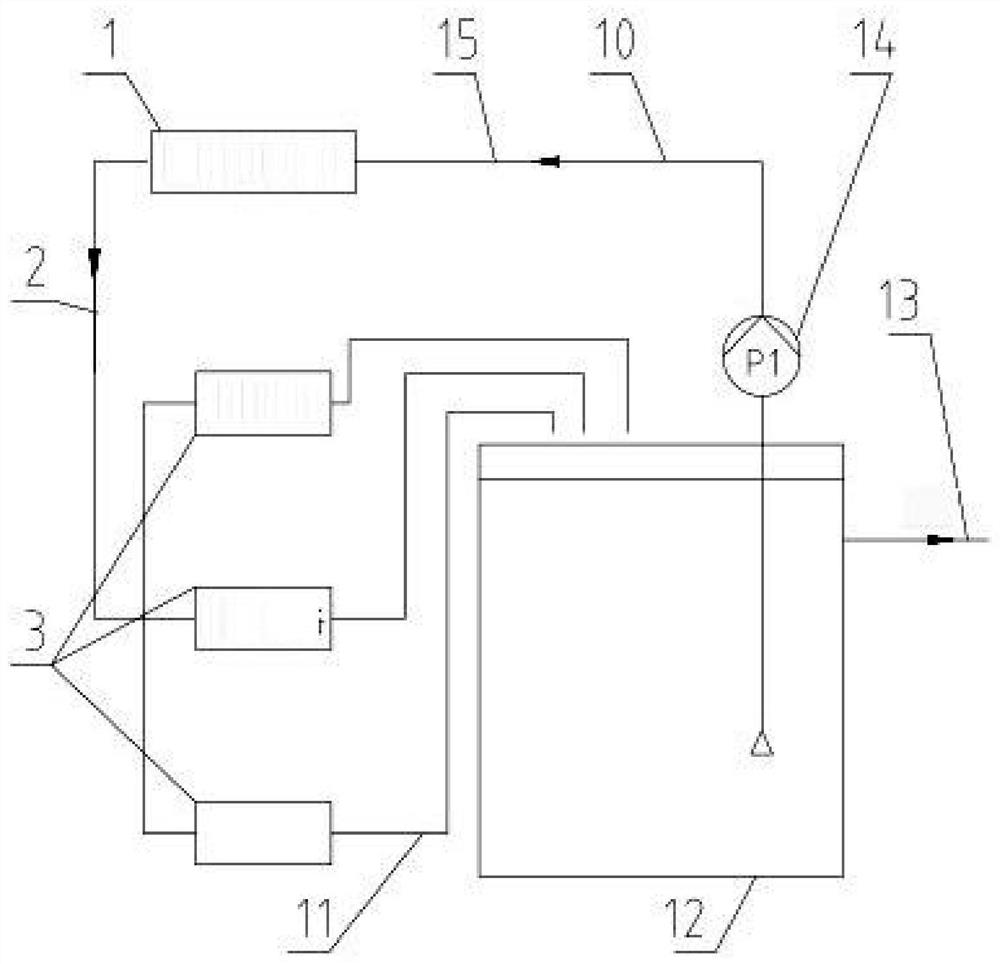

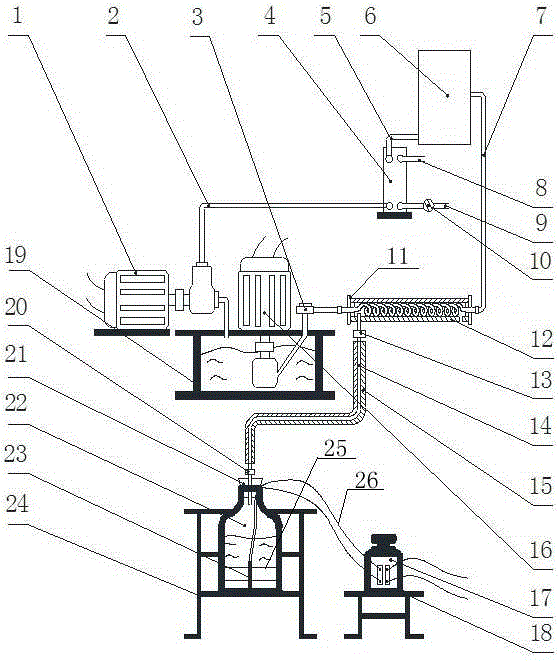

Small circulating lubrication system cooled by using liquid nitrogen

InactiveCN103822078AImprove leakageEasy to polluteLubrication elementsLiquid nitrogen coolingEngineering

A small circulating lubrication system cooled by using liquid nitrogen comprises a liquid nitrogen refrigerating system and a lubrication oil circulating system. The cooling speed of lubricating oil in an oil supply pipe of the lubrication system is increased; and moreover, the lubrication oil which is heated by using a plate radiator is recycled. The whole small circulating lubrication system is simple in structure and convenient to operate, and is economical and practical.

Owner:HENAN UNIV OF SCI & TECH

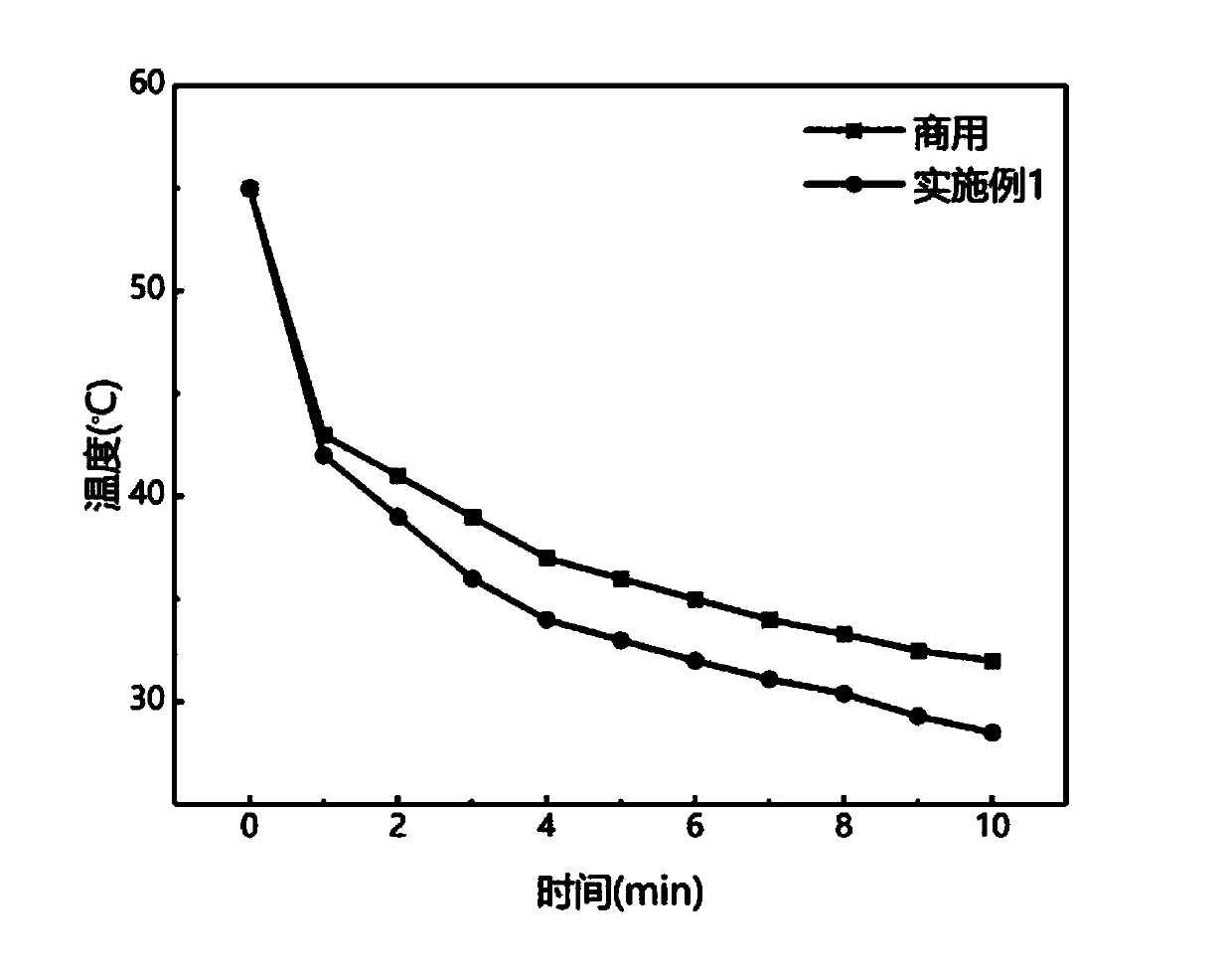

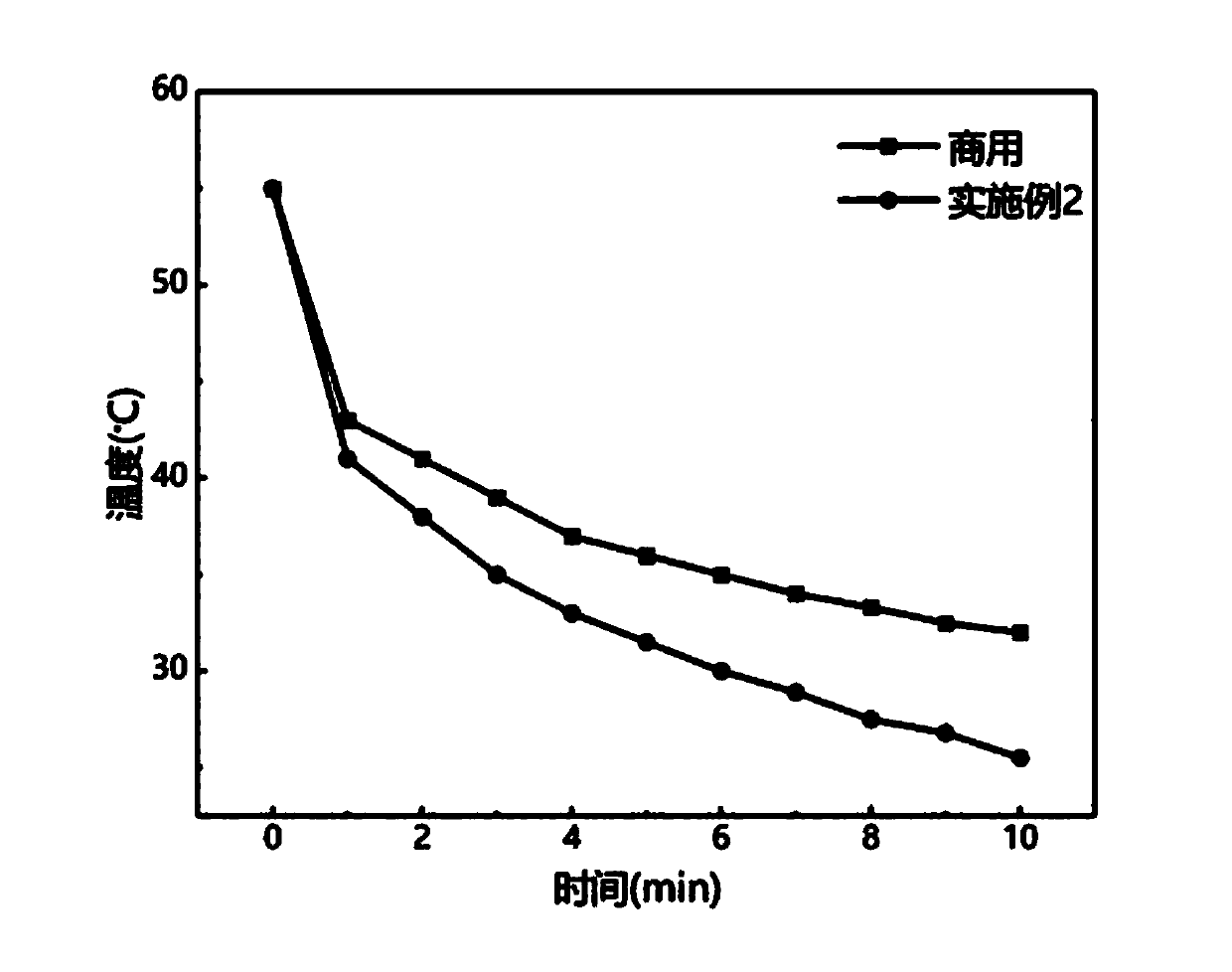

Novel graphite biomass fever cooling patch and preparation method thereof

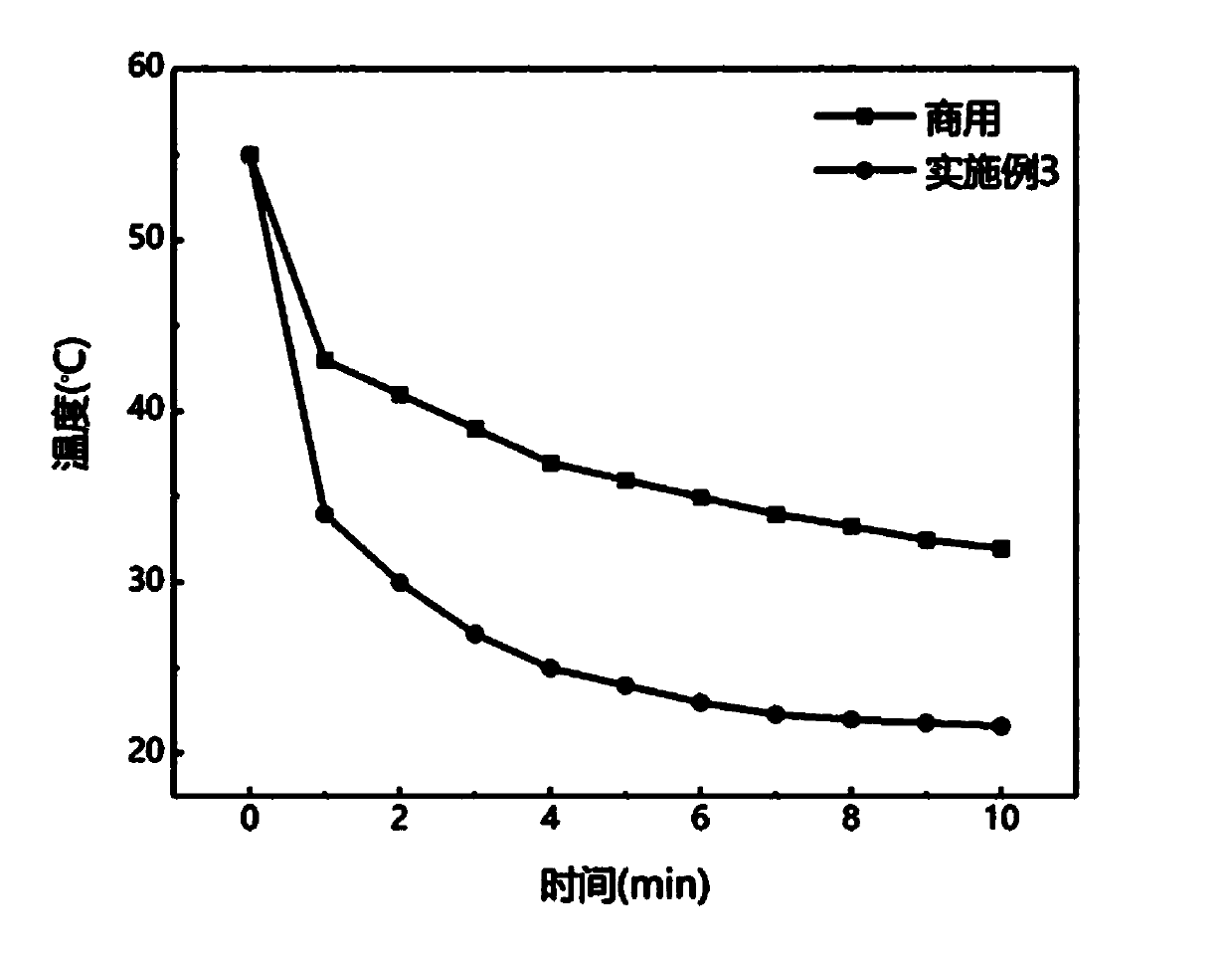

InactiveCN111228033APromote absorptionSimple coolingTherapeutic coolingTherapeutic heatingBenzoic acidMedicine

The invention discloses a novel graphite biomass fever cooling patch and a preparation method thereof and belongs to the technical field of medical care. The fever cooling patch comprises the following raw materials in parts by mass as follows: 6.75-28.4988 parts of starch, 60.5-72.2 parts of deionized water, 1-10 parts of graphite, 1-10 parts of alcohol and 0.0012-0.05 part of p-methoxybenzoic acid. Basic components in starch gel have more hydrogen bonds and can further contain more moisture than commercial fever cooling patch gel. Graphite contained in the gel is used as a heat conducting channel, so that heat can be absorbed by moisture more easily, and the purpose of cooling is achieved more easily.

Owner:JILIN UNIV

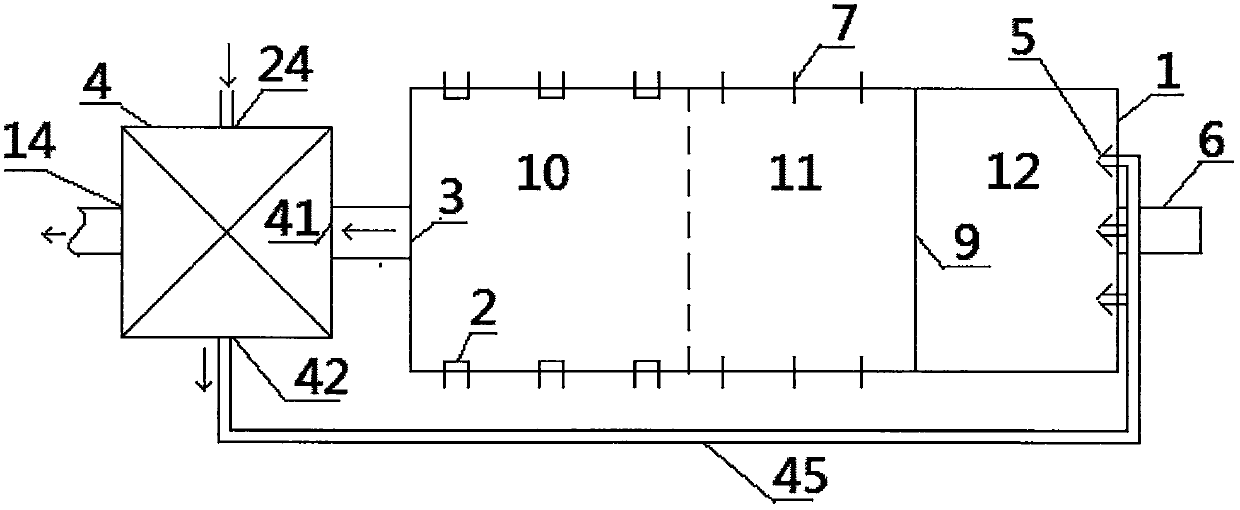

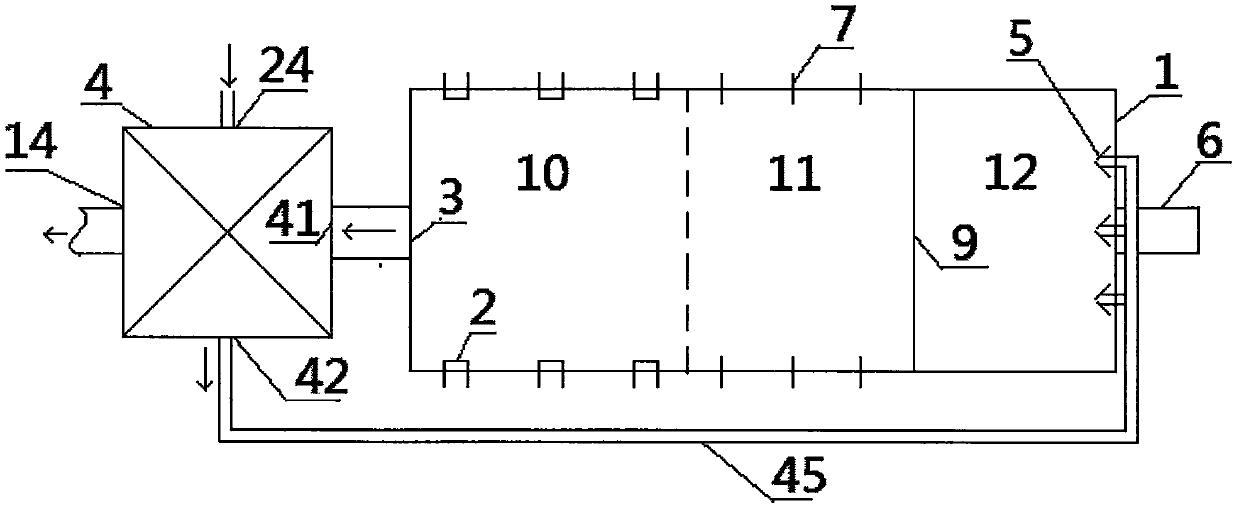

Environment-friendly, highly-efficient and heat-exchangeable glass melting furnace and production method

ActiveCN106698896ALower discharge temperatureWill not ablateGlass furnace apparatusGlass melting apparatusOxygenGlass melting

The invention relates to an environment-friendly, highly-efficient and heat-exchangeable glass melting furnace and a production method. The glass melting furnace is divided into 3 areas in a lengthwise direction: a first feeding and premelting area has the following functions: adding raw materials from any part of the area, absorbing the heat of a combustion product flowing from a second melting, homogenizing and clarifying area, premelting the raw materials, allowing the premelted raw materials to flow into the second area for melting, homogenizing and clarifying, and discharging a cooled combustion product to a heat exchanger at the exterior of the furnace from the end head of the melting furnace; the second area has the following functions: spraying a fuel from any part of the area, allowing the fuel to perpendicularly intersect with air or oxygen from a third cooling area of the furnace and carrying out mixed combustion, heating a glass liquid flowing from the first area to a temperature needed for homogenizing and clarifying, allowing the heated glass liquid to flow into the third area, and allowing a generated high-temperature combustion product to enter the first area; and the third area has the following functions: cooling the glass liquid flowing from the second area to a temperature needed for shape formation, allowing the cooled glass liquid to flow out of the furnace, wherein the glass liquid is cooled mainly by spraying air or oxygen of the heat exchanger from the terminal end of the area besides heat dissipation of a melt, and allowing heated air or oxygen to enter the second area for combustion supporting. The environment-friendly, highly-efficient and heat-exchangeable glass melting furnace provided by the invention has the advantages of low tail gas emission temperature, insusceptibility to ablating a furnace-gas heat-exchange device, easy cooling of the cooling area and high production efficiency.

Owner:卢爱民

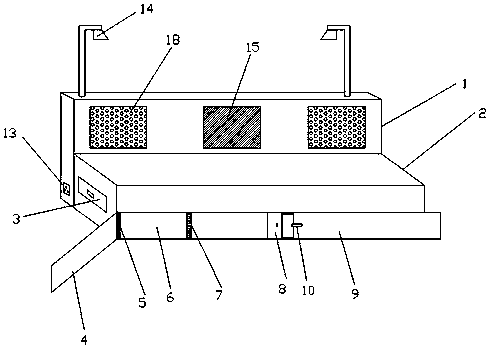

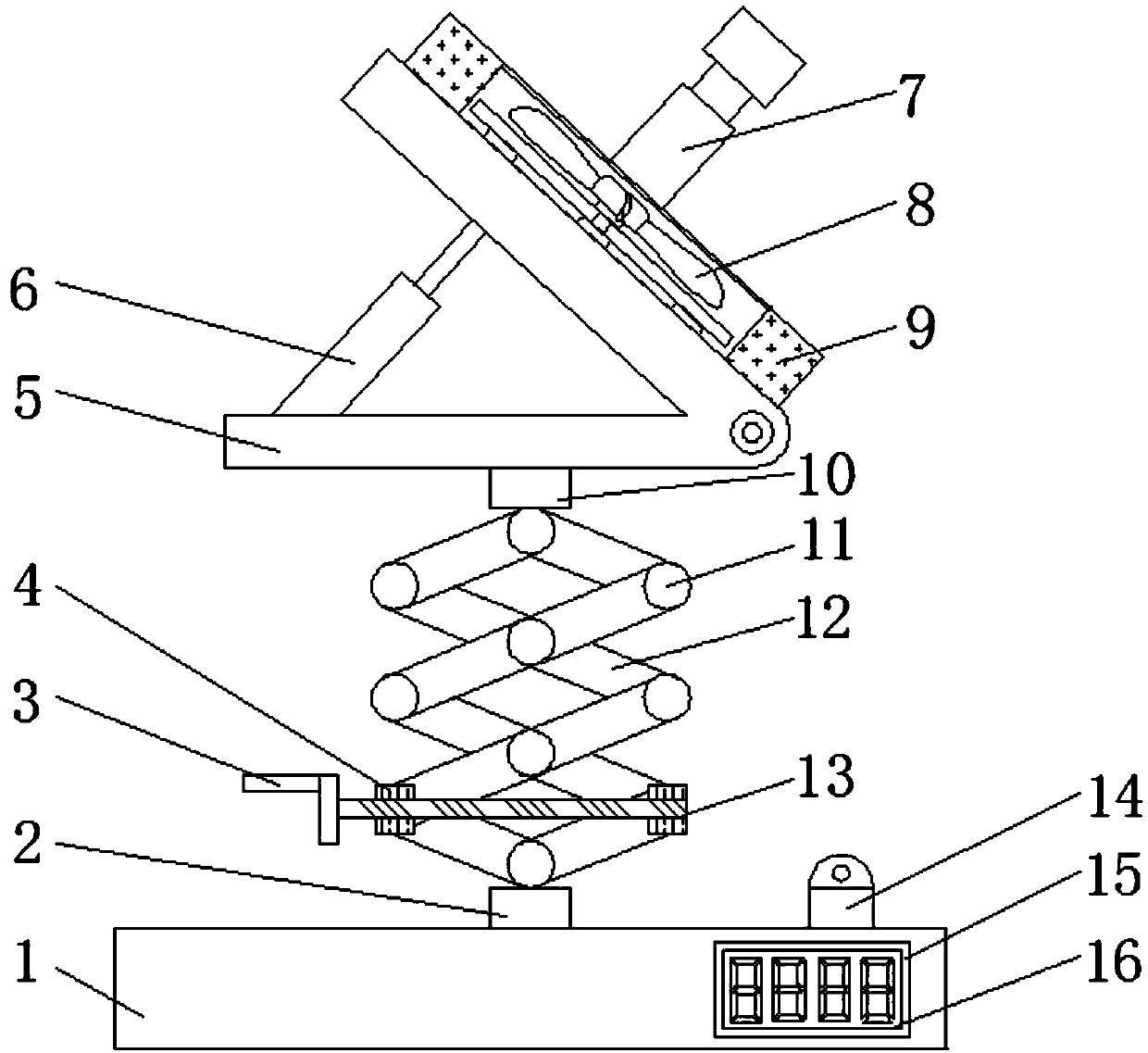

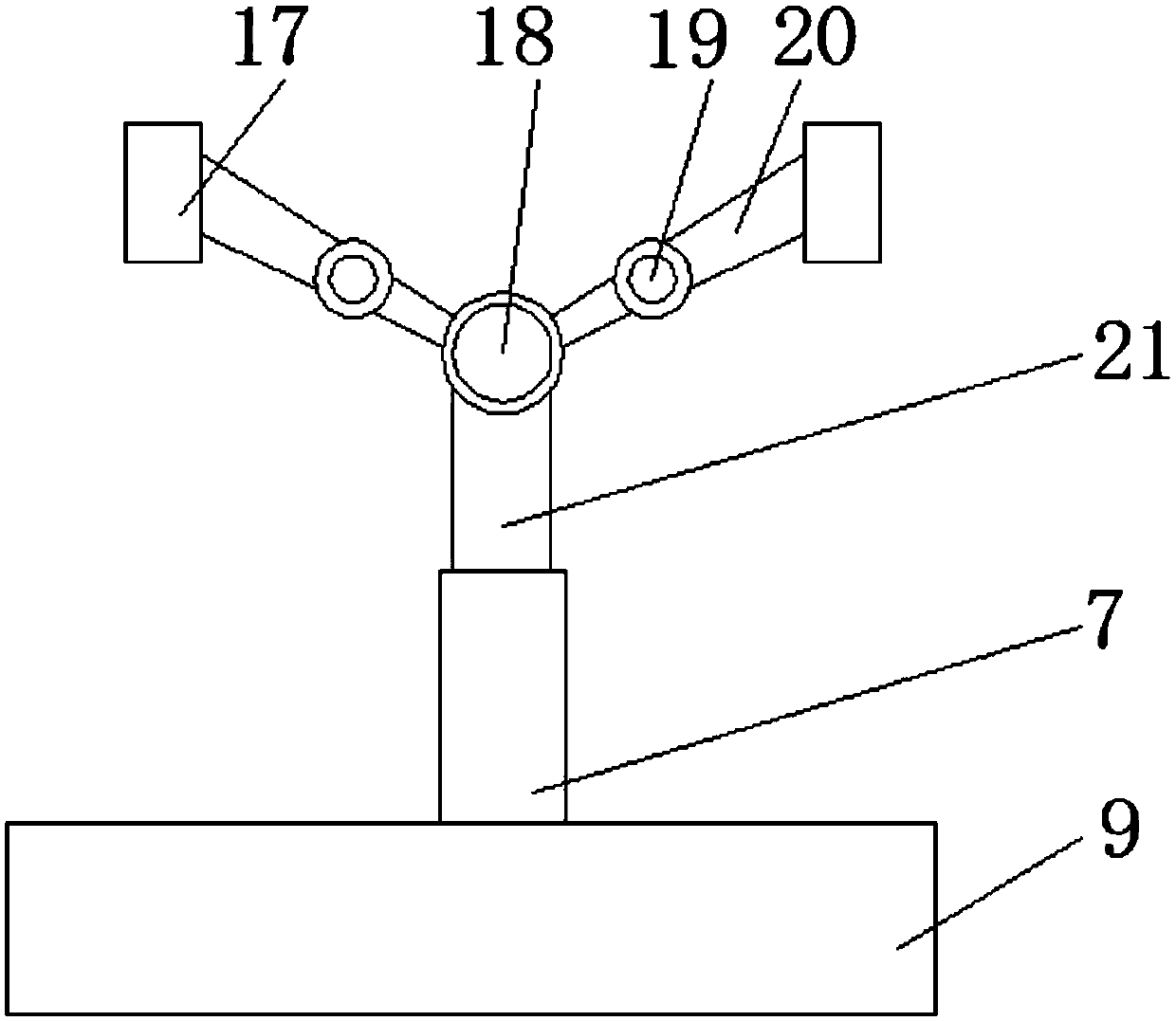

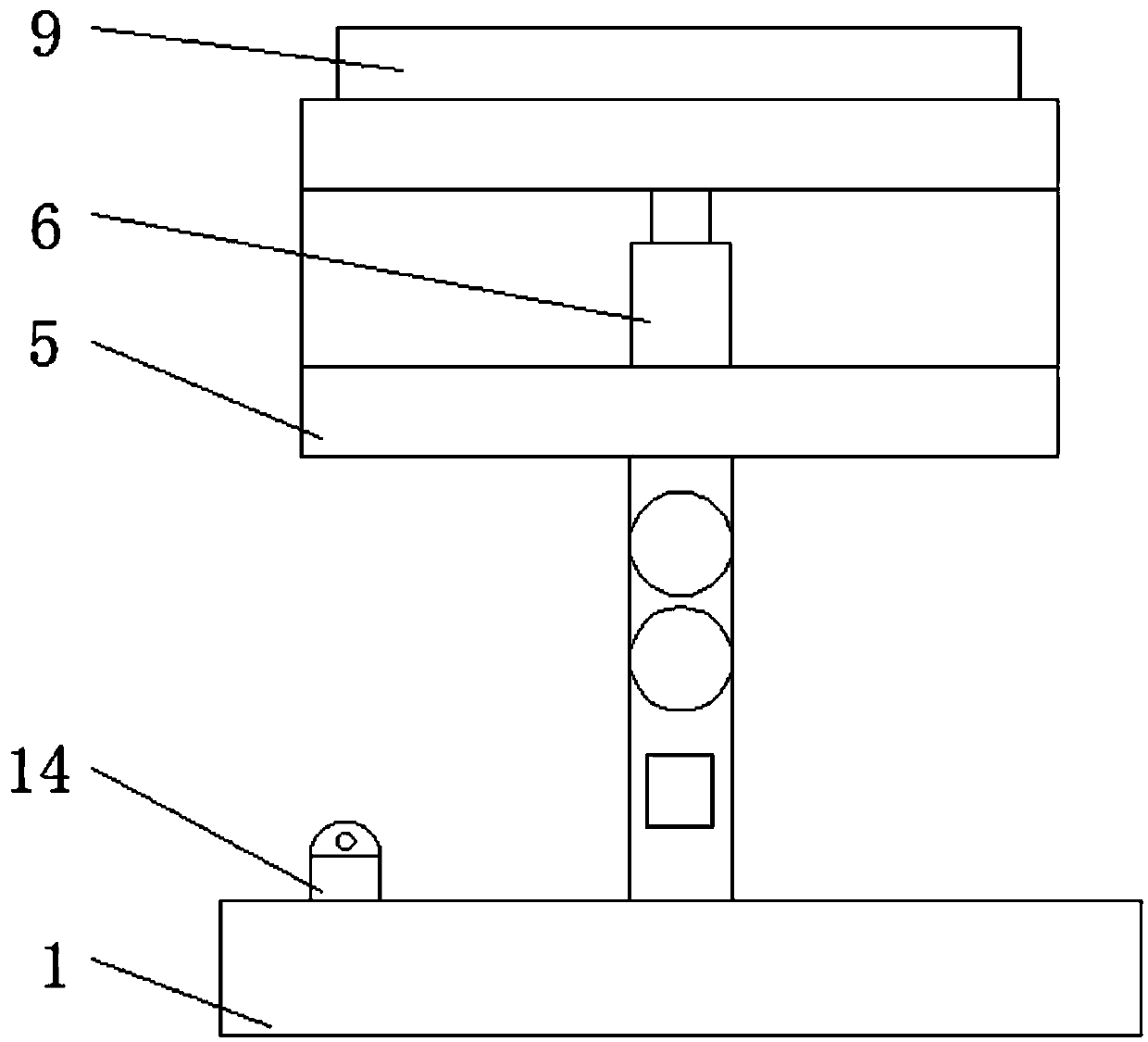

Electronic product support frame with heat dissipation function

InactiveCN108679410AReduce eye fatigueChange positionStands/trestlesPump installationsEngineeringEye Fatigue

The invention discloses an electronic product support frame with a heat dissipation function. The electronic product support frame comprises a base, a lower fixing block is welded to the middle of theouter wall of the top of the base, a telescopic bracket is fixed to the lower fixing block through a bolt, corners of the telescopic bracket are each provided with a connector, fixing clamps are welded to the outer walls of the two sides of the telescopic bracket, a same transmission rod is welded to the outer walls of the corresponding sides of the two fixing clamps, a handle is welded to the outer wall of one end of the transmission rod, and an upper fixing block is welded to the outer wall of the side, far away from the lower fixing block, of the telescopic bracket. According to the electronic product support frame with the heat dissipation function, the height and the inclination angle can be adjusted, a user can conveniently change the position of an electronic product, the using range of the device is widened, eye fatigue of the user is relieved, simple cooling is conducted on the electronic product, the condition that the user is scalded due to the fact that the electronic product is too hot is avoided, the electronic product can be prevented from being damaged due to the fact that the electronic product is too hot, and the service life of the electronic product is prolonged.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Watering cart sprayer

The invention discloses a watering cart sprayer. The watering cart sprayer comprises a sprayer base with a water inlet and a water outlet, a space porous water distributing network and a direct flow impact type water outlet channel are arranged in the sprayer base, the space porous water distributing network comprises a water inlet, a water storage pool, an ascending pipe, stair fractal pipes and a water outlet, and the ascending pipe is connected between the water storage pool and the stair pipes; and the stair fractal pipes are of a fractal structure and comprise at least two stages, and any stage of stair pipes are distributed in a circumferential arrayed manner and point to one circle center. According to the sprayer, the mist spraying liquid drops are large in density, the motion speed is high, the dust capturing efficiency is high, cooling through evaporation is easier, and therefore the aims of quick cooling and efficient dust removal of a watering cart are achieved.

Owner:SOUTHEAST UNIV

A rotary mold injection mold

The invention discloses a rotary mold release injection mold, comprising a base, the top of the base is fixedly connected with a lower mold base, the top of the lower mold base is movably connected with an upper mold base, and the inner cavity of the lower mold base is movable The lower mold cavity is connected, and the upper mold cavity is opened at the bottom of the upper mold base, and the inner wall of the lower mold base is rollingly connected with balls, and the surface of the ball penetrates the inner wall of the lower mold base and extends to the inner cavity of the lower mold base , The invention relates to the technical field of injection molds. The rotation of the mold release injection mold starts the first drive motor, and the lower mold cavity is driven to rotate through the first drive shaft, so that it is separated from the upper mold cavity, and then the top block is driven to collide with the surface of the injection molded part. At this time, the first drive is started. The drive motor drives the lower mold cavity to rotate through the drive shaft. At this time, the injection molded part is fixed by the top block, so that the lower mold cavity and the injection molded part can be demoulded, and the injection molded part can be demoulded quickly, which is very convenient to use.

Owner:广东伟力环保实业有限公司

Fast cooling system in cars, control method thereof and storage device therein

InactiveCN105082940AReduce the temperatureGood cooling helpAir-treating devicesVehicle heating/cooling devicesStored energyEngineering

A fast cooling system for a car includes an active or passive energy storage device, a temperature mixer and a control module. The energy storage device is located in the temperature mixer. The control module compares the temperatures of the energy storage device and an evaporator in the temperature mixer and the temperature in the car. Based on the result of the comparison, the control module controls the path of air that travels through the temperature mixer to guide the air flow to travel past the evaporator and / or the energy storage device. The air gets cool when it travels past the energy storage device in the form of a cold storage device. The cool air enters the car and rapidly reduces the temperature in the car.

Owner:苏峻苇

Combustion furnace with conveniently cooled smoke exhaust tube

InactiveCN108800184ASimple coolingGood cooling effectLighting and heating apparatusCombustion technology mitigationTransverse planeEngineering

The invention discloses a combustion furnace with a conveniently cooled smoke exhaust tube. The combustion furnace comprises a bottom plate. A boiler body is fixed to the outer wall of the top of thebottom plate through bolts, a smoke exhaust barrel is fixed to the outer wall of the top of the bottom plate through bolts, a heat conducting plate is fixed to the outer wall of one side of the smokeexhaust barrel through bolts, a stable rib plate is fixed to the outer wall of one side of the smoke exhaust barrel through bolts, the outer wall of one side of the stable rib plate is welded to the outer wall of the top of the bottom plate, a horizontally placed transverse plate is welded to the outer wall of one side of the smoke exhaust barrel, and a water tank is fixed to the outer wall of thetop of the transverse plate through bolts. The combustion furnace disclosed by the invention can cool the smoke exhaust barrel simply and effectively. The heat conducting plate exchanges heat with the outer side, and a water flow in the water tank is sprayed by means of a shower nozzle to absorb heat and be evaporated to take away part of heat, so that the cooling effect of the device is obviousin effect, and impurity particles of smoke passing a filter screen are filtered. Meanwhile, soot in the smoke is wet and falls in a humid environment in the smoke exhaust barrel, so that the blockagecondition is reduced.

Owner:HUBEI AIFUWEI ENVIRONMENTAL ENERGY TECH CO LTD

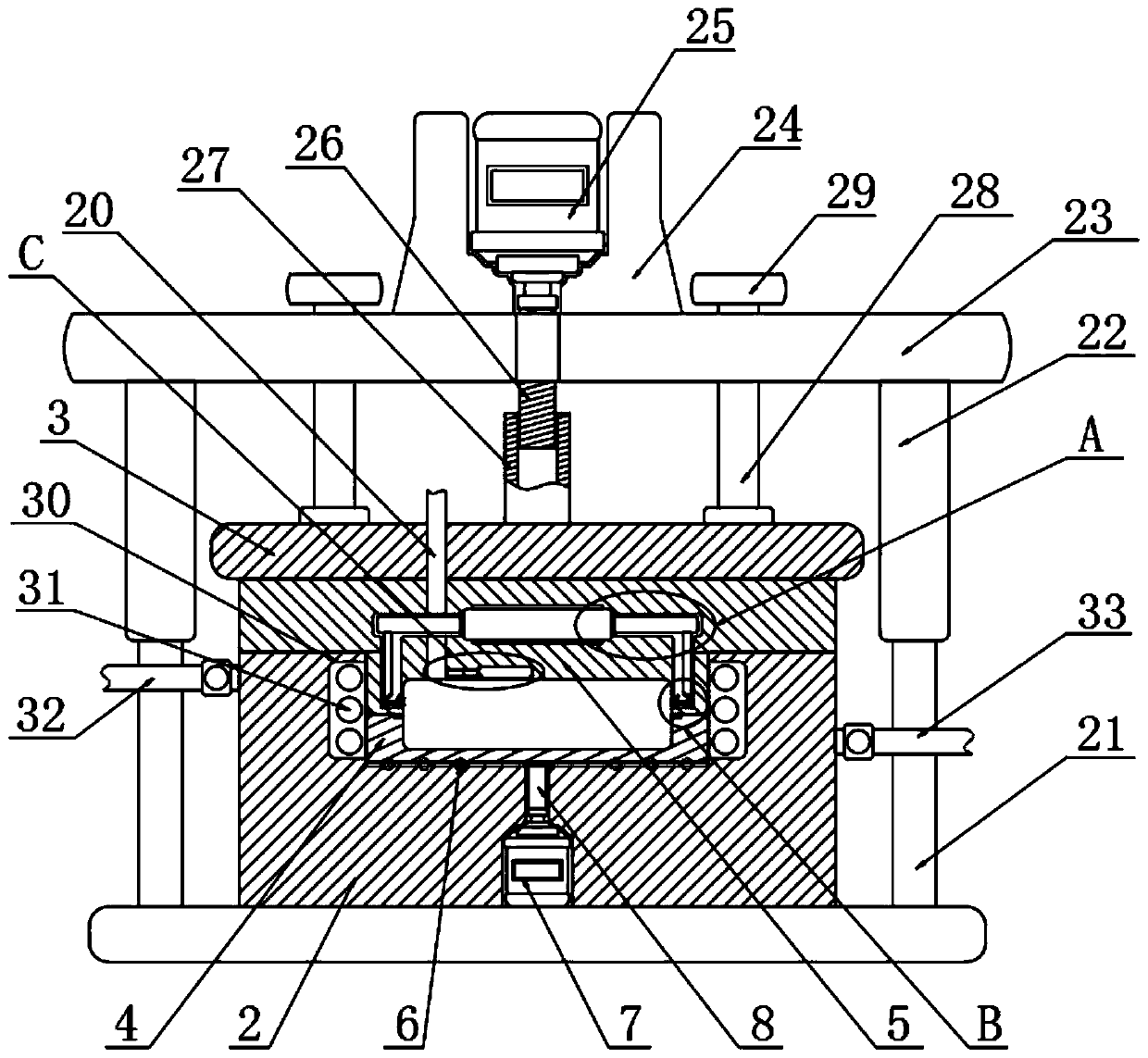

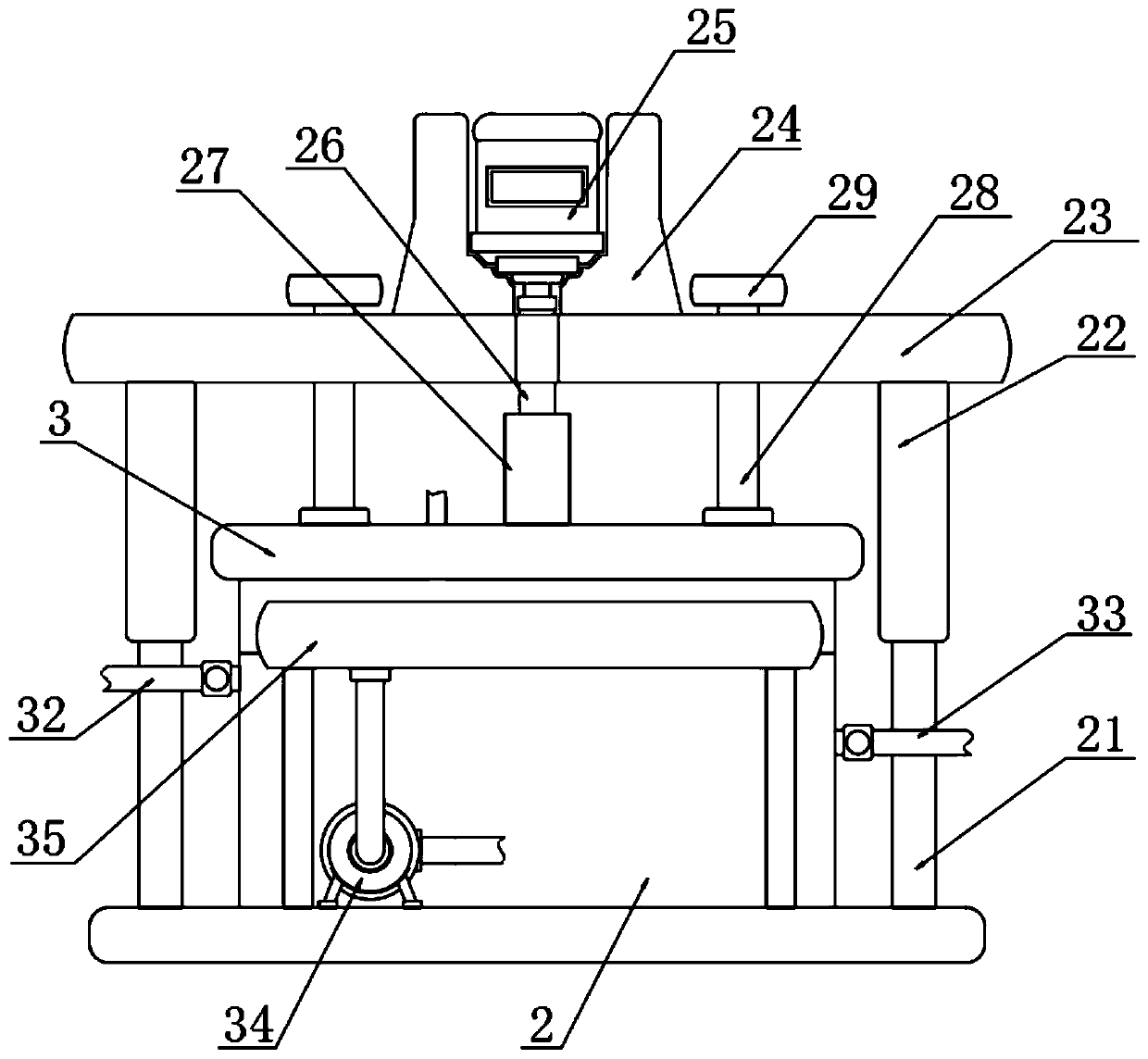

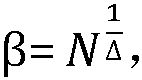

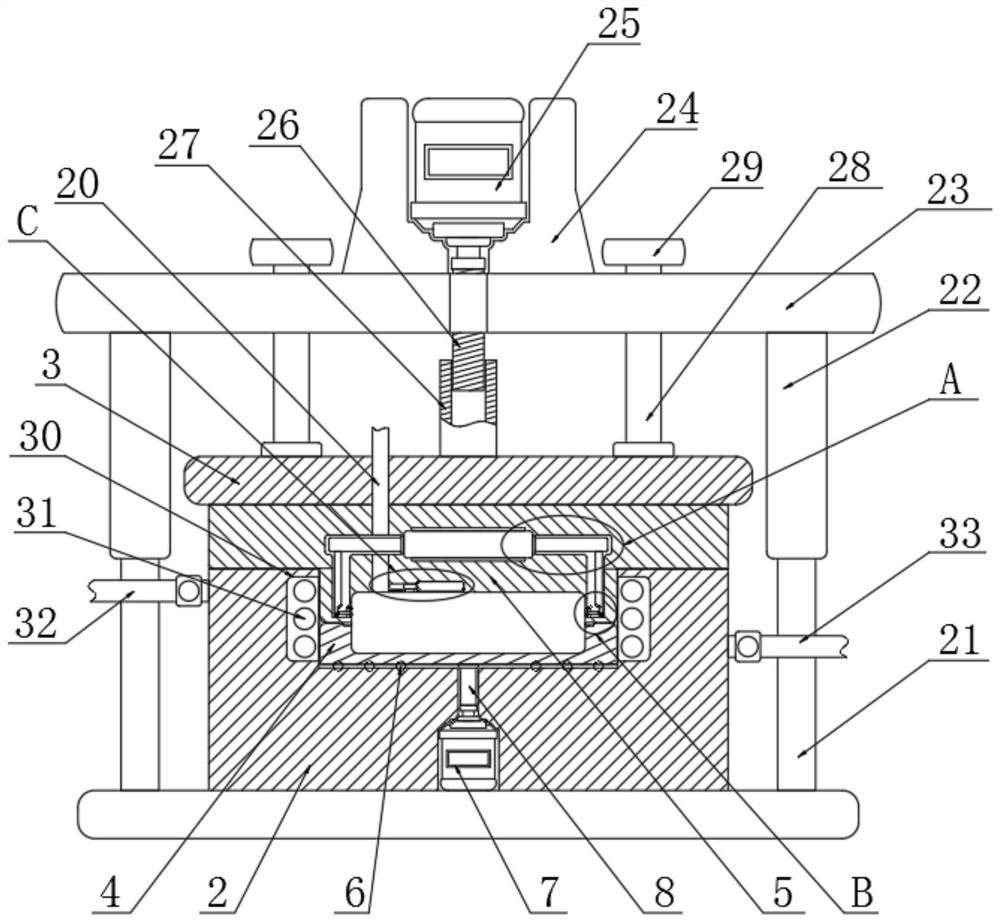

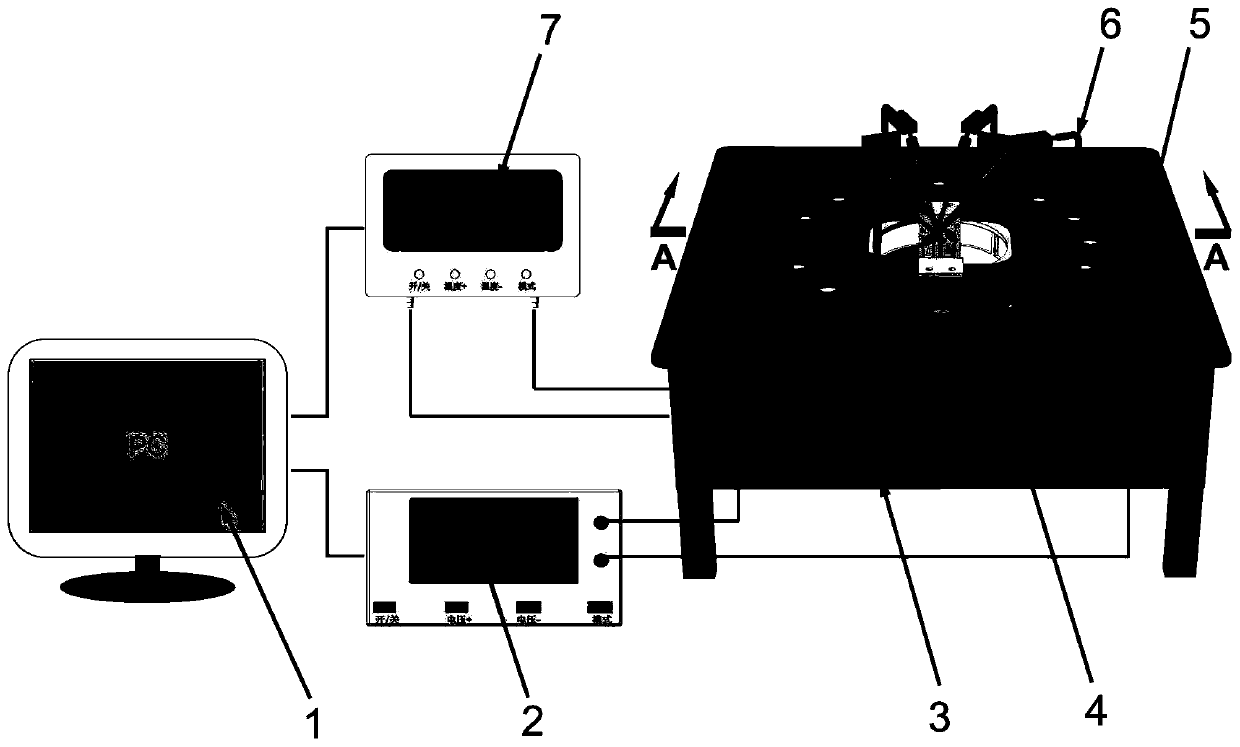

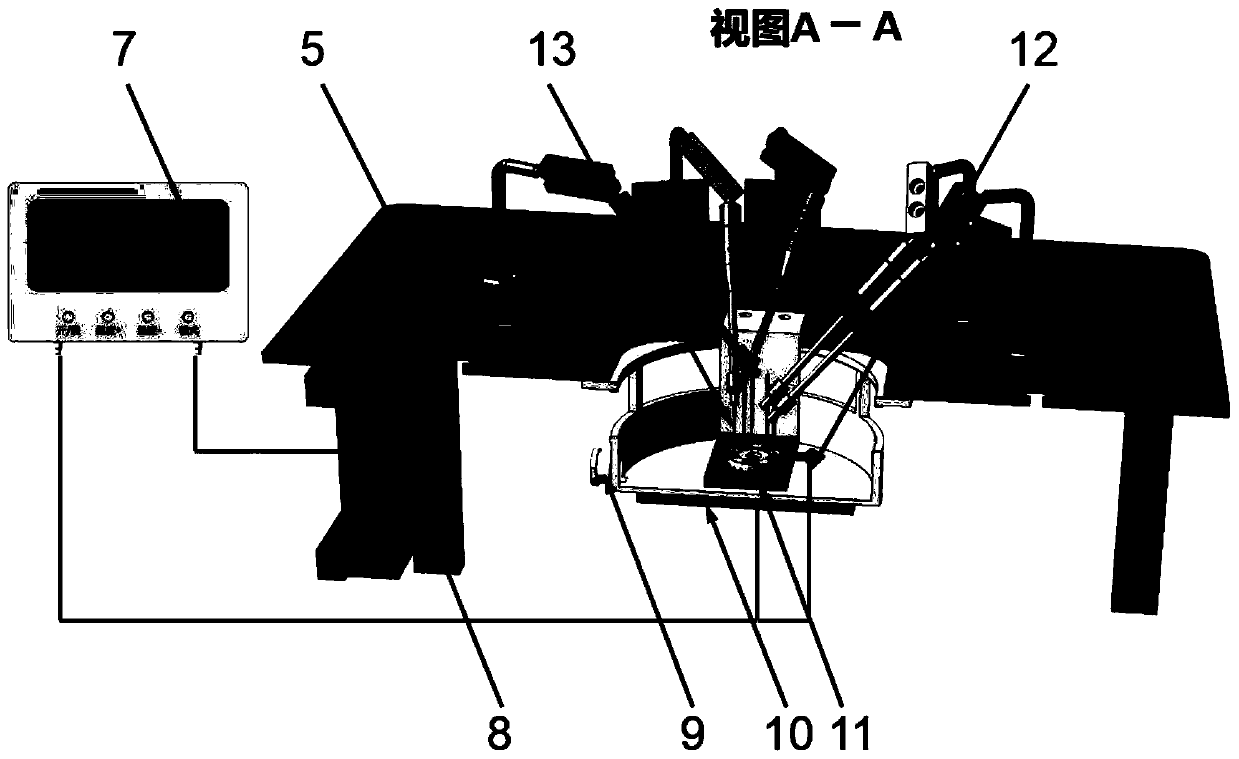

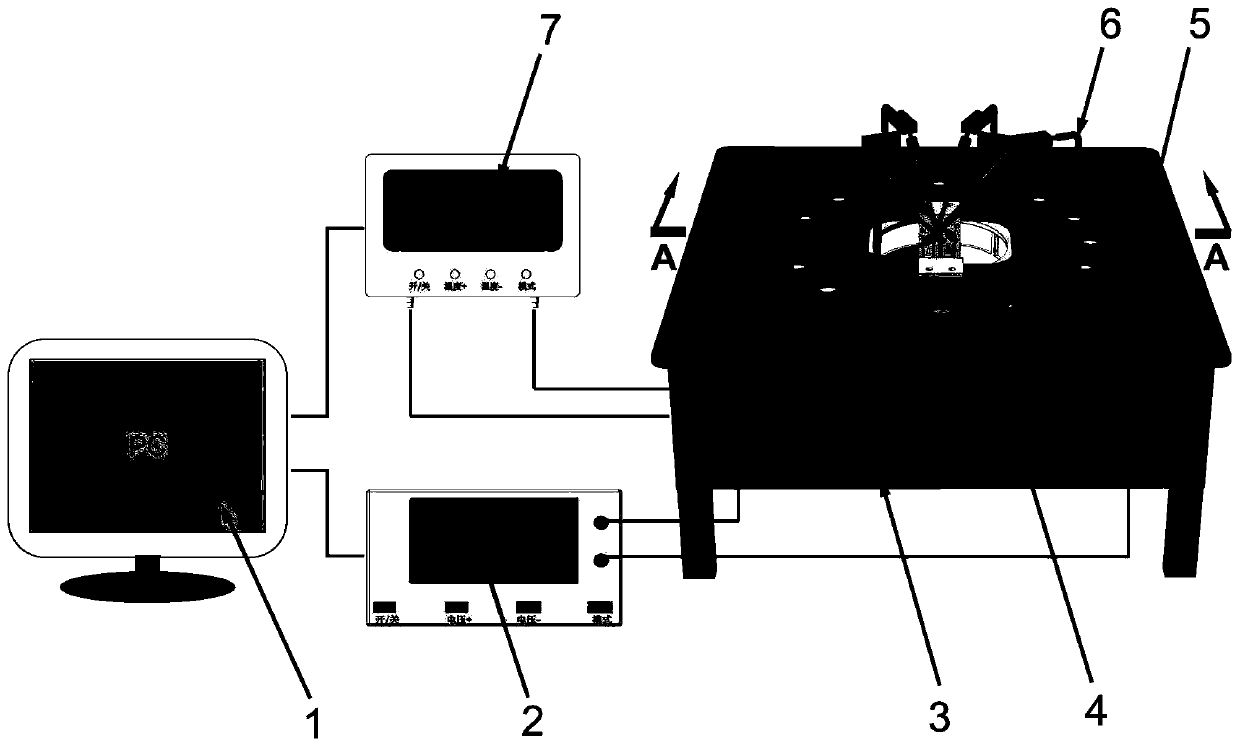

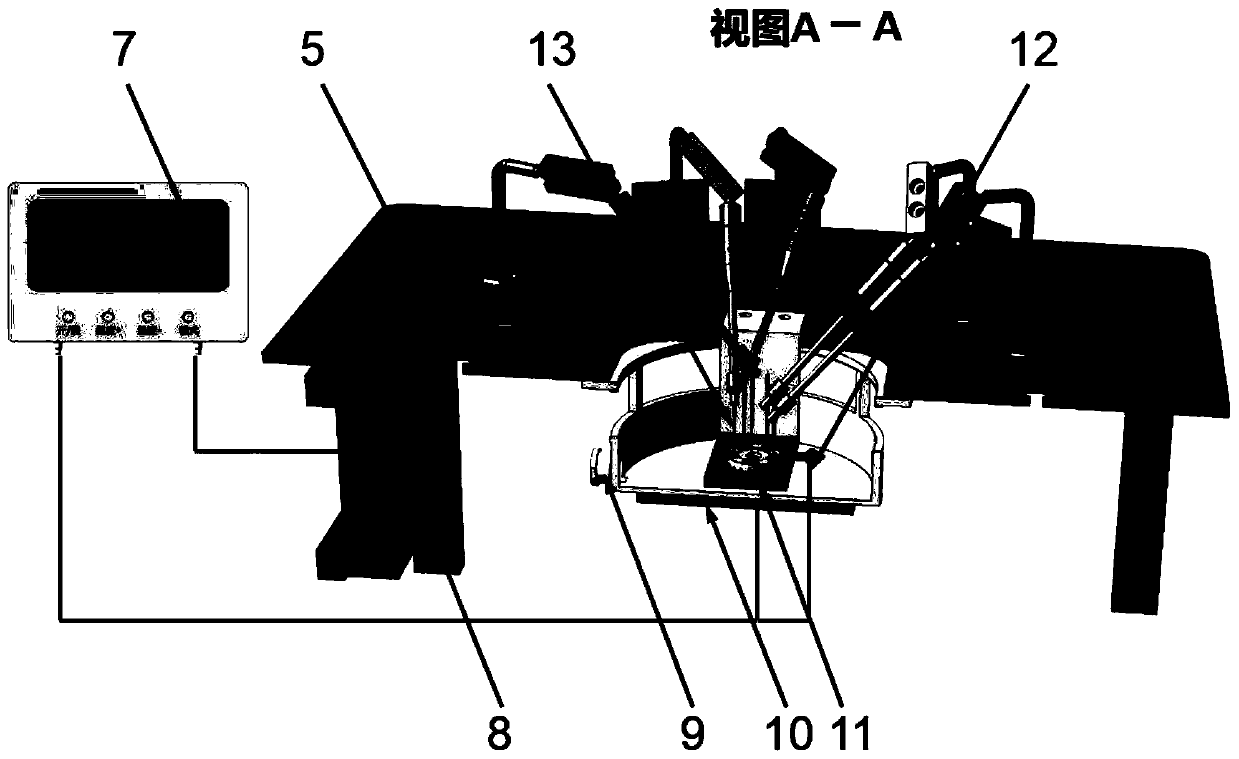

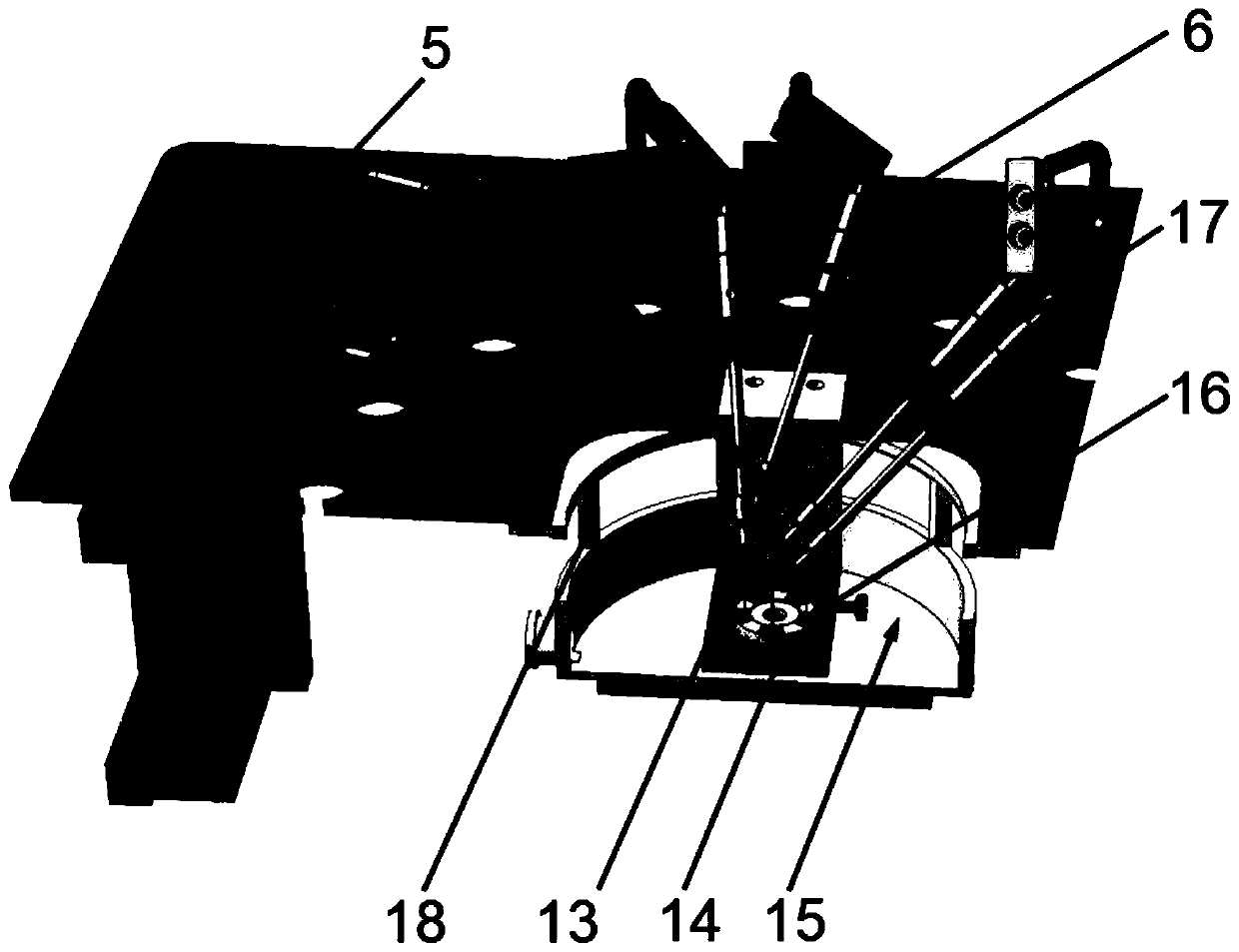

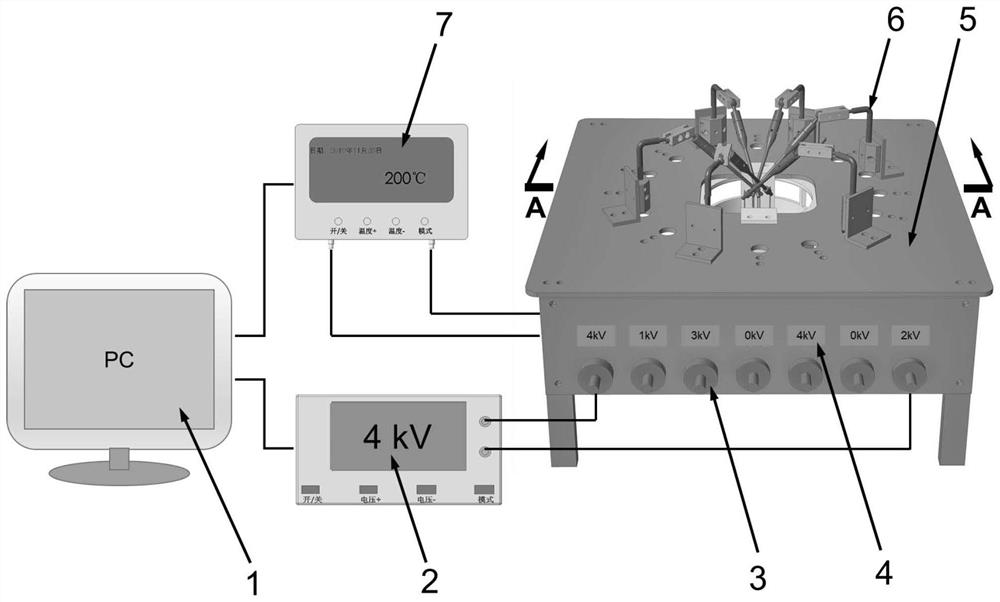

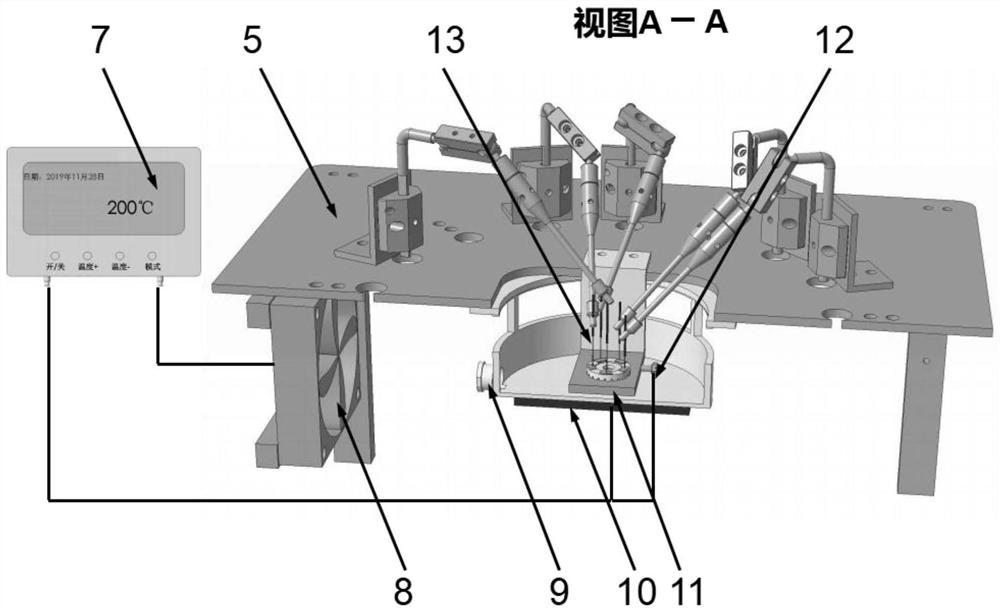

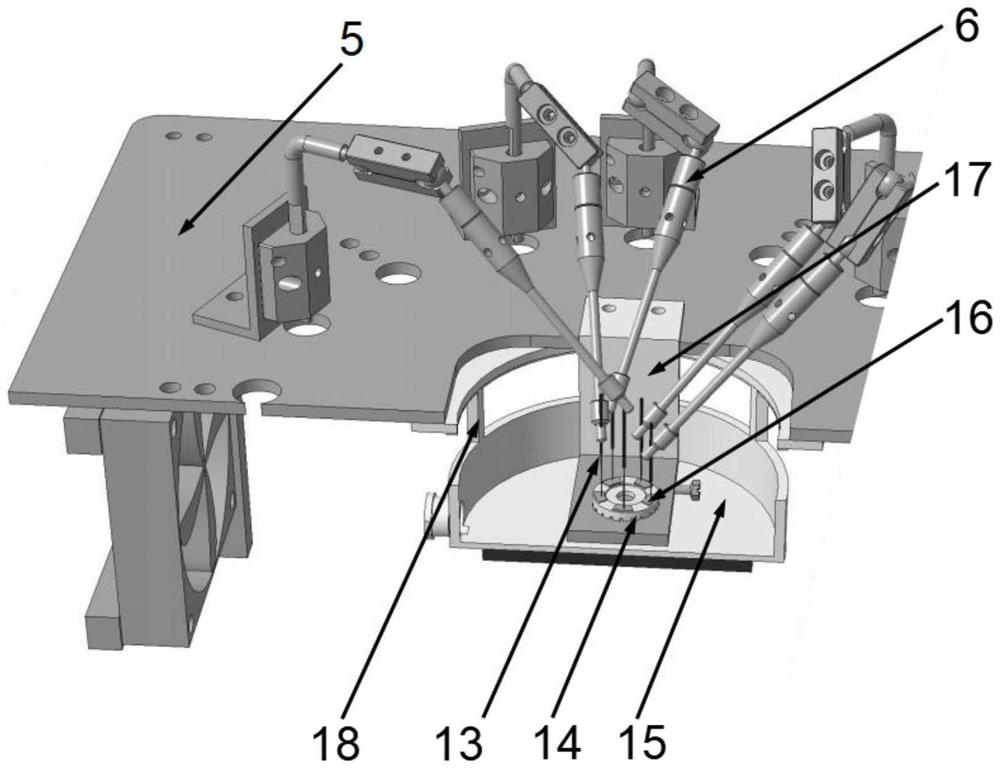

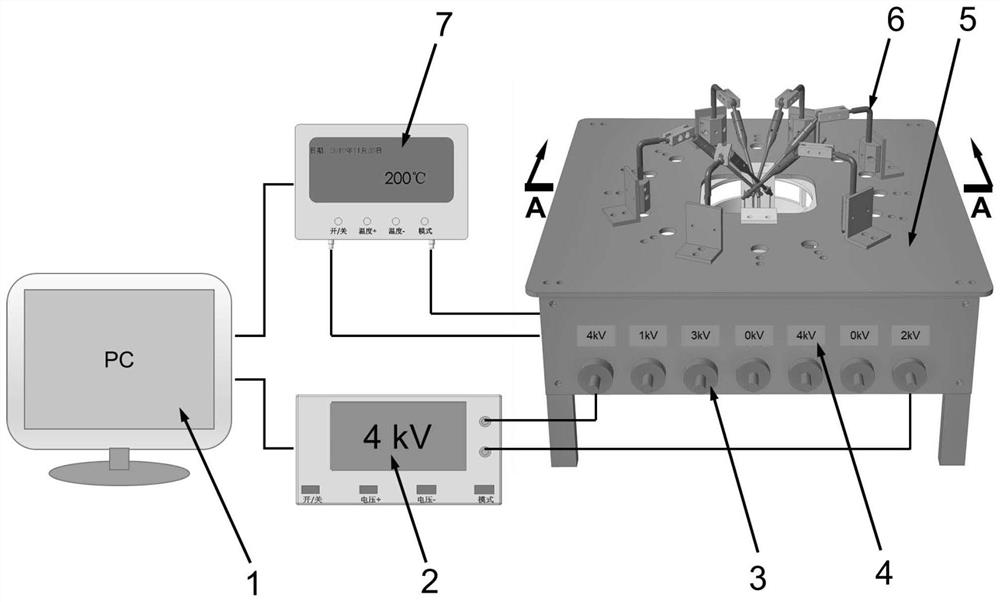

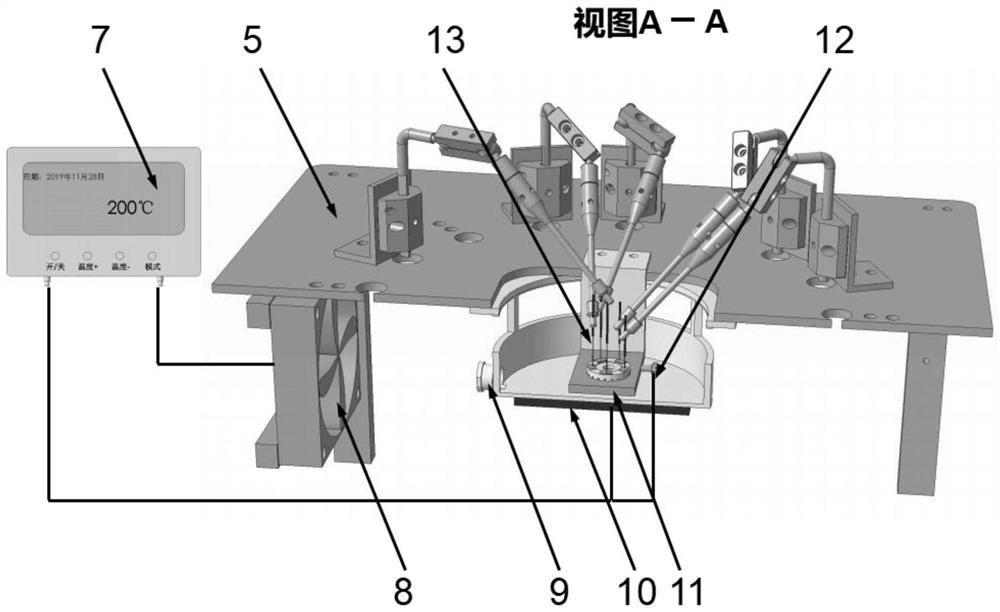

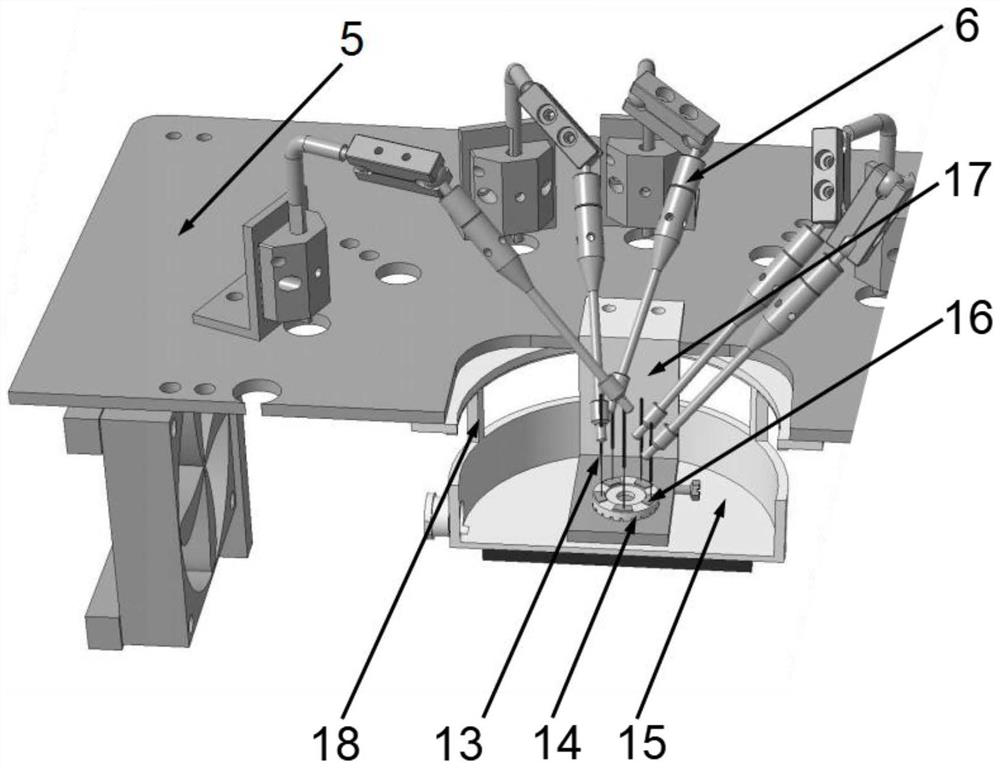

Piezoelectric element partition polarization device

ActiveCN111554803AAchieve independent controlSatisfy Polarization RequirementsPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringMechanical engineering

The invention discloses a piezoelectric element partition polarization device, and belongs to the technical field of polarization of materials with piezoelectric characteristics. The device comprisesa partition voltage adjusting module, a probe adjusting module and a polarization control module, the partition voltage adjusting module can adjust the polarization voltage of each subarea to realizeindependent control of the polarization subarea electric field; the probe adjusting module can realize accurate positioning and synchronous polarization of a plurality of hundred-micron micro electrodes by adopting a method of matching an elastic telescopic probe with a probe positioning bracket; and the polarization control module can control a time change curve of total voltage and polarizationtemperature required by polarization. According to the invention, independent control of the multi-partition polarization electric field is realized, the multi-partition piezoelectric element can be synchronously polarized at one time, and the problem of inconsistent thermal depolarization and partition polarization intensity of the piezoelectric element caused by repeated polarization is avoided;the problems of difficult operation, difficult positioning, single polarization area and the like in the traditional method are solved, and the polarization quality of the partitioned piezoelectric element is improved.

Owner:DALIAN UNIV OF TECH

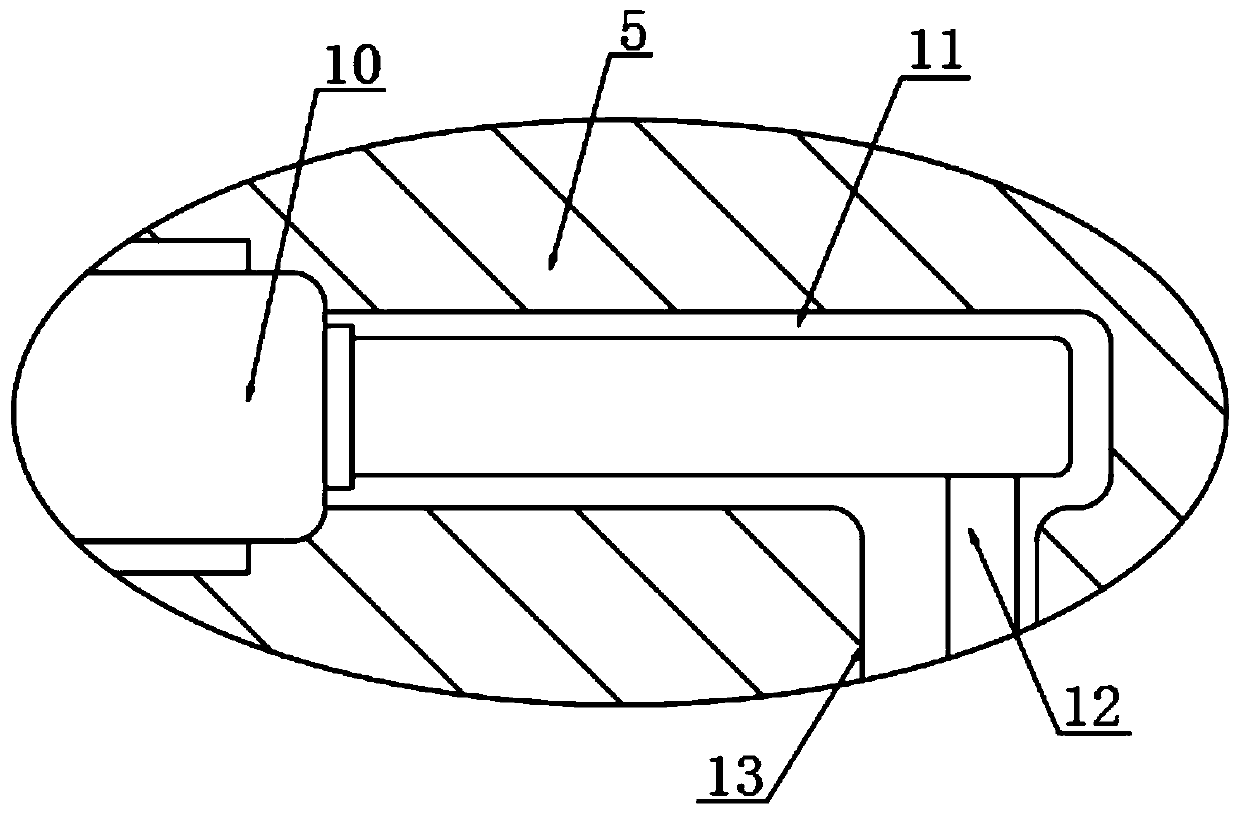

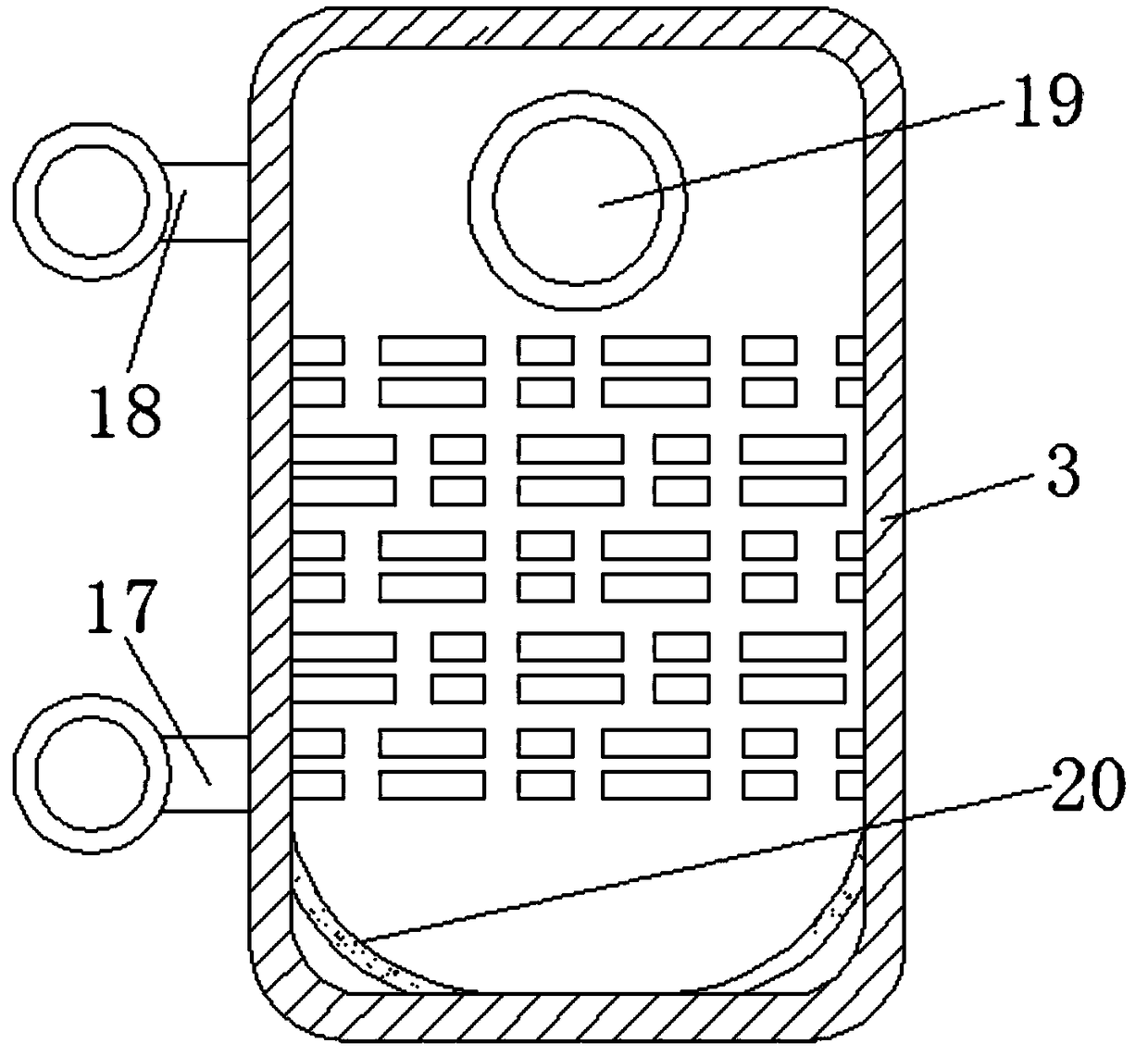

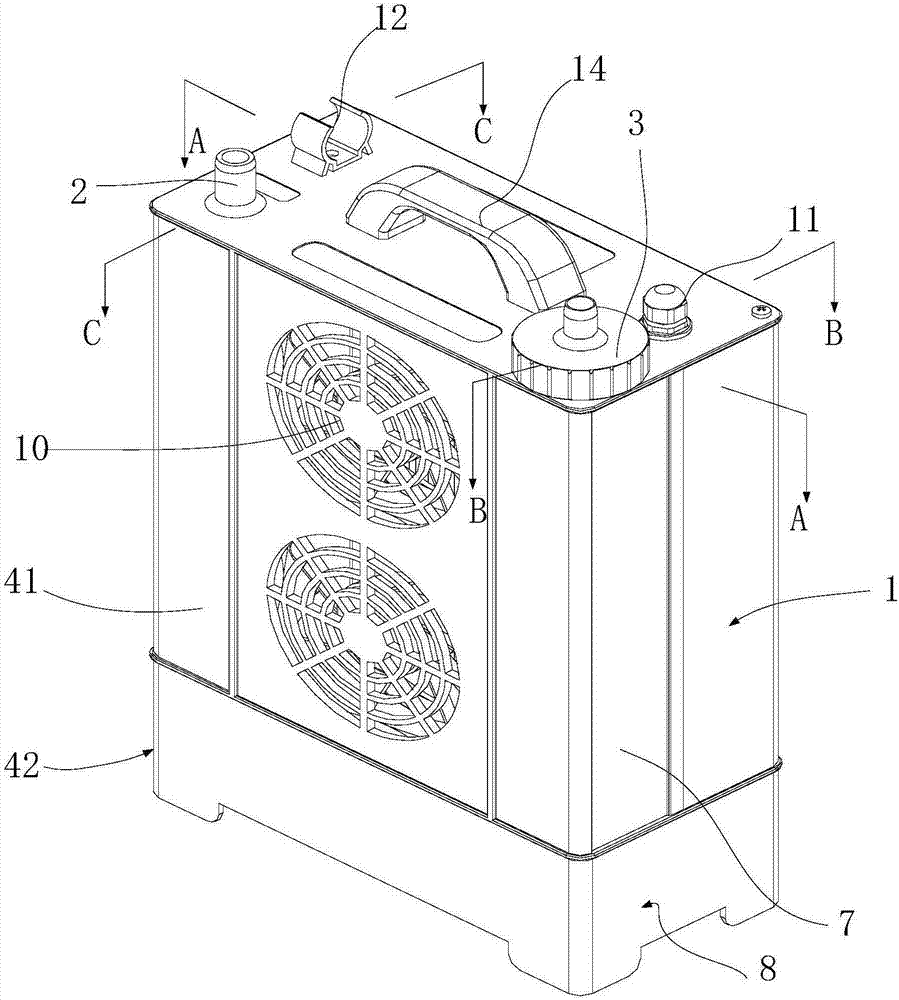

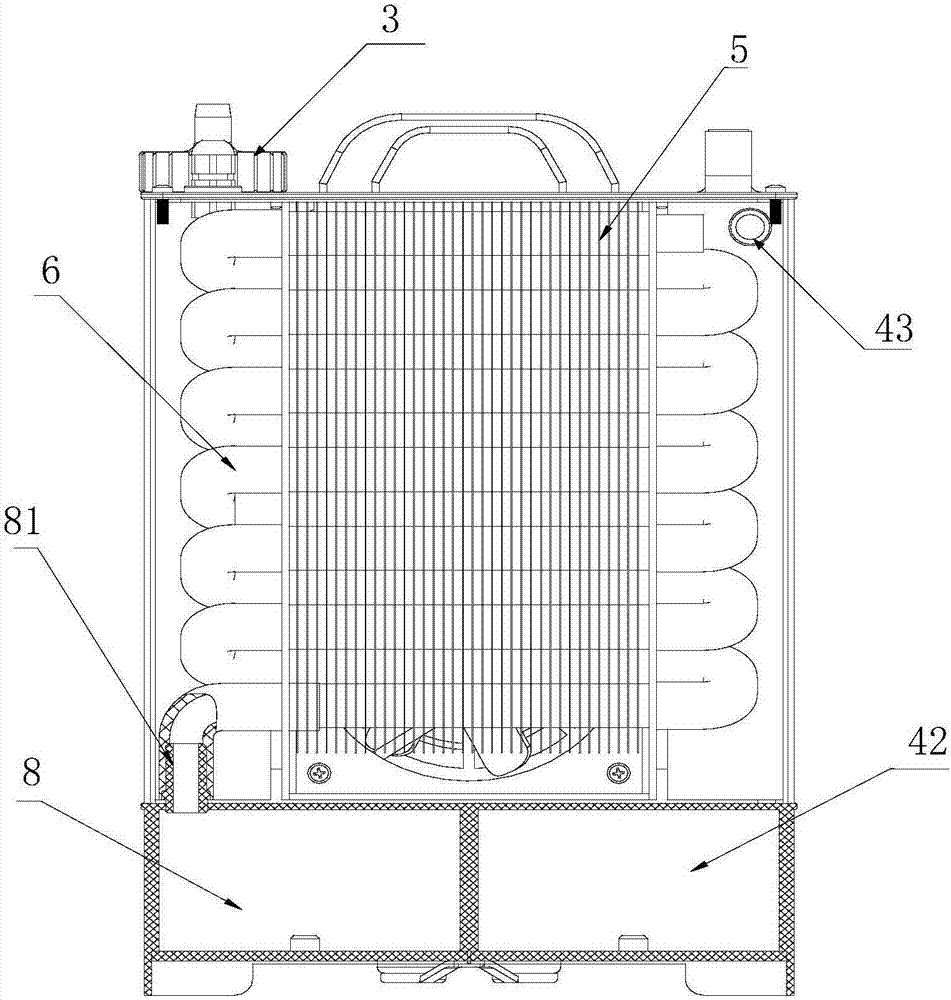

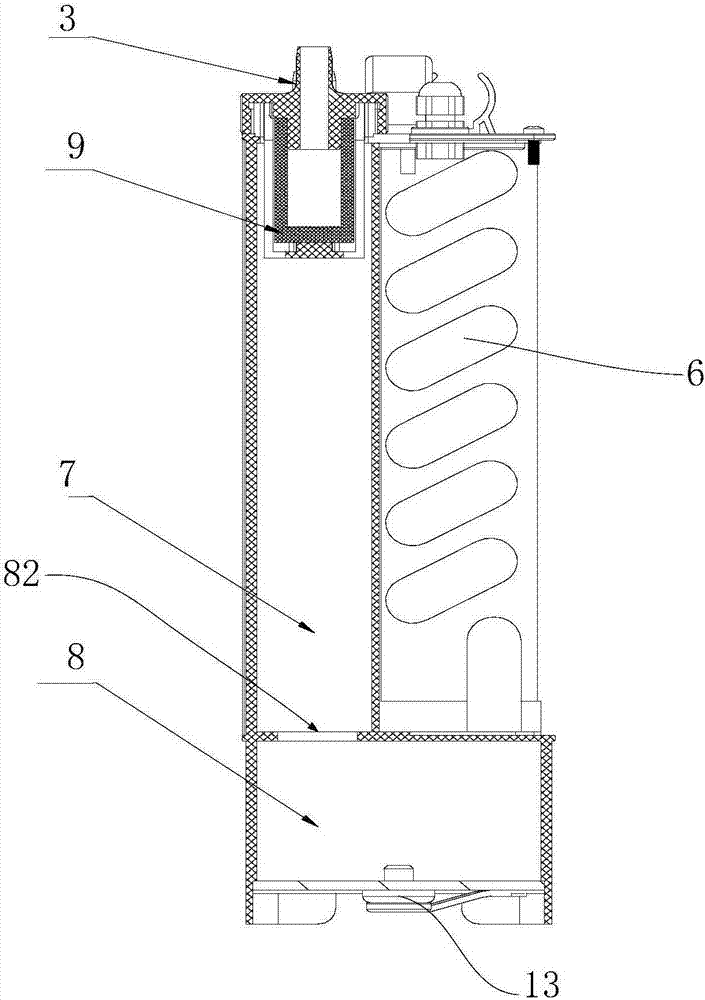

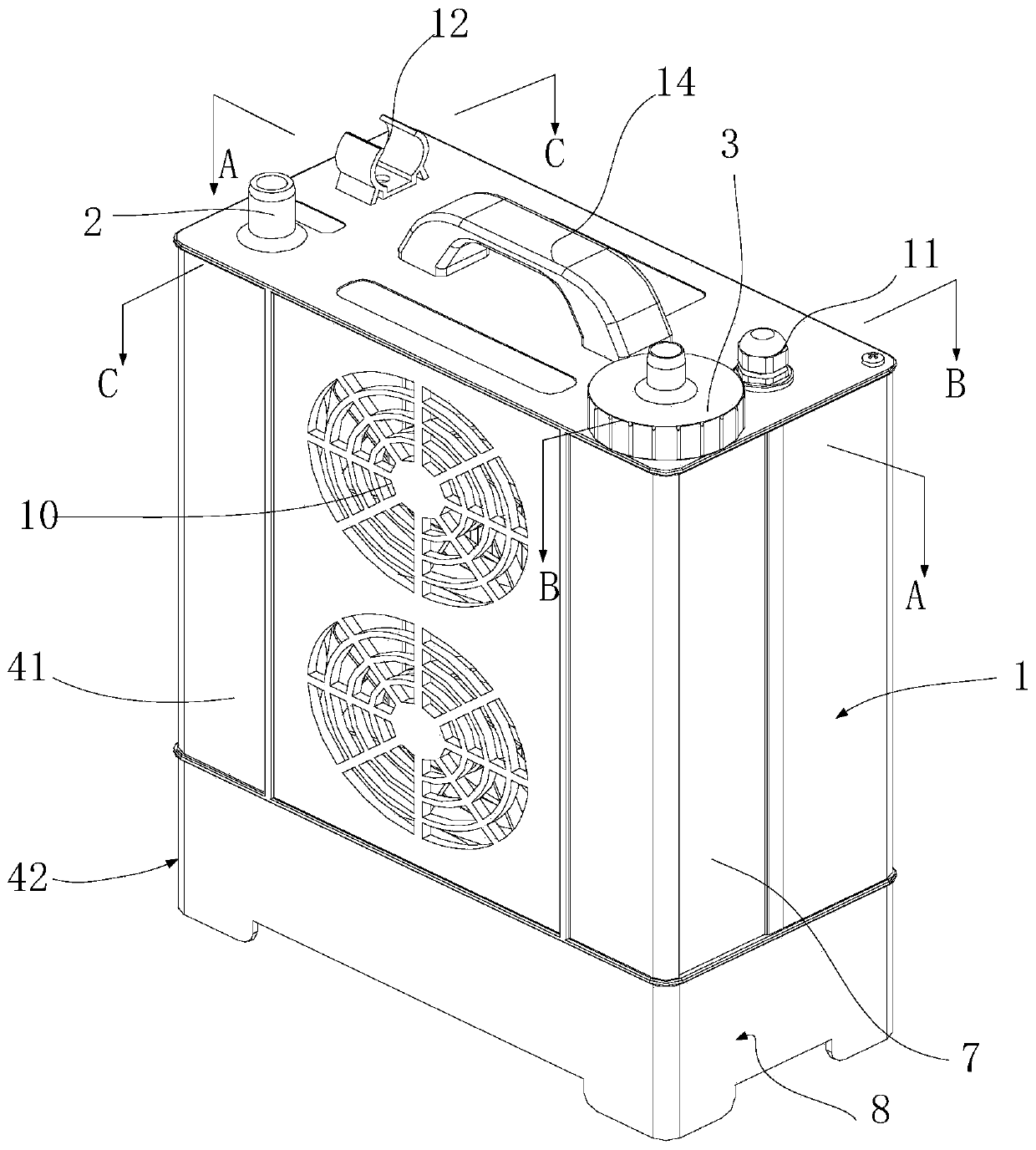

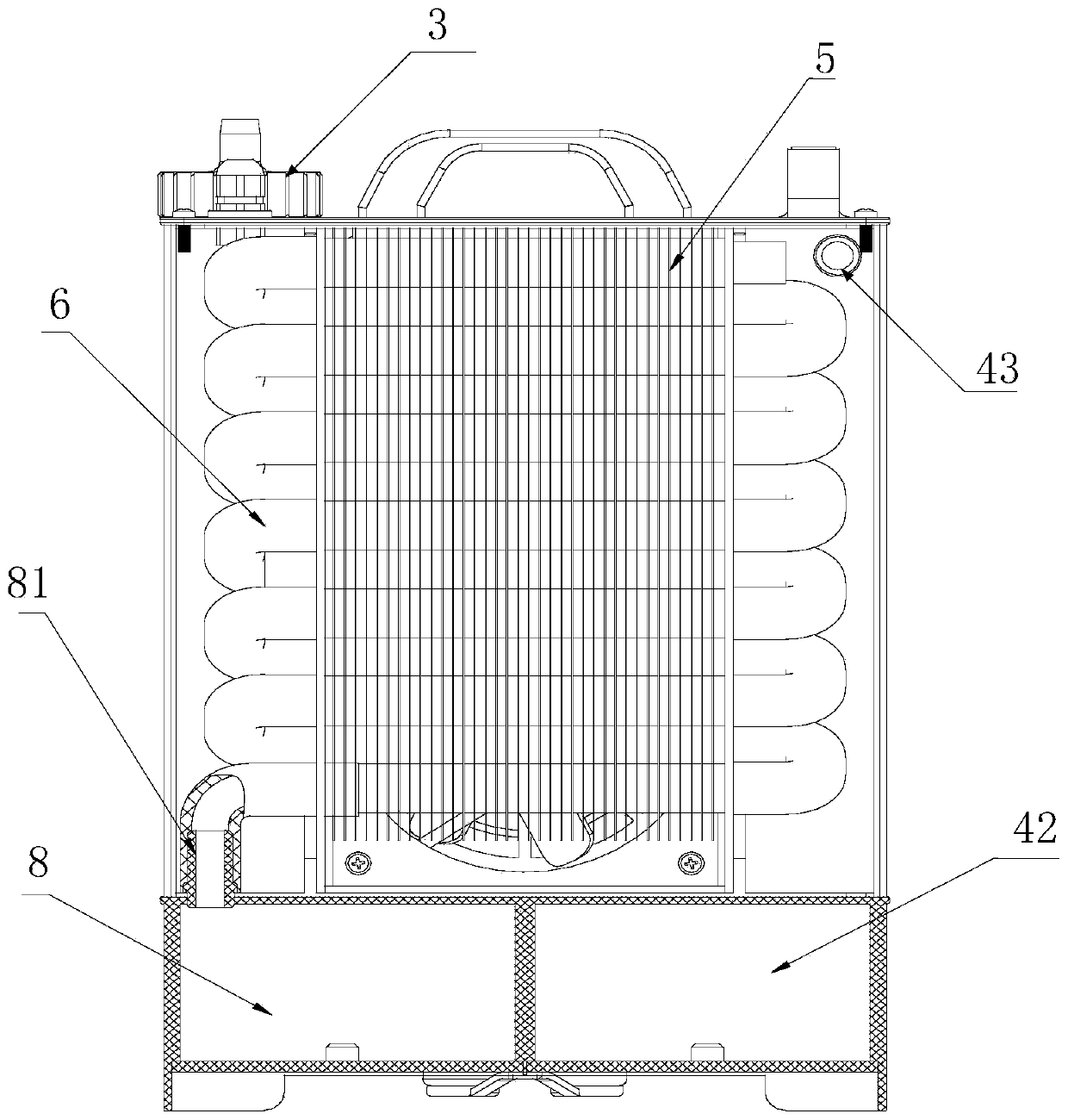

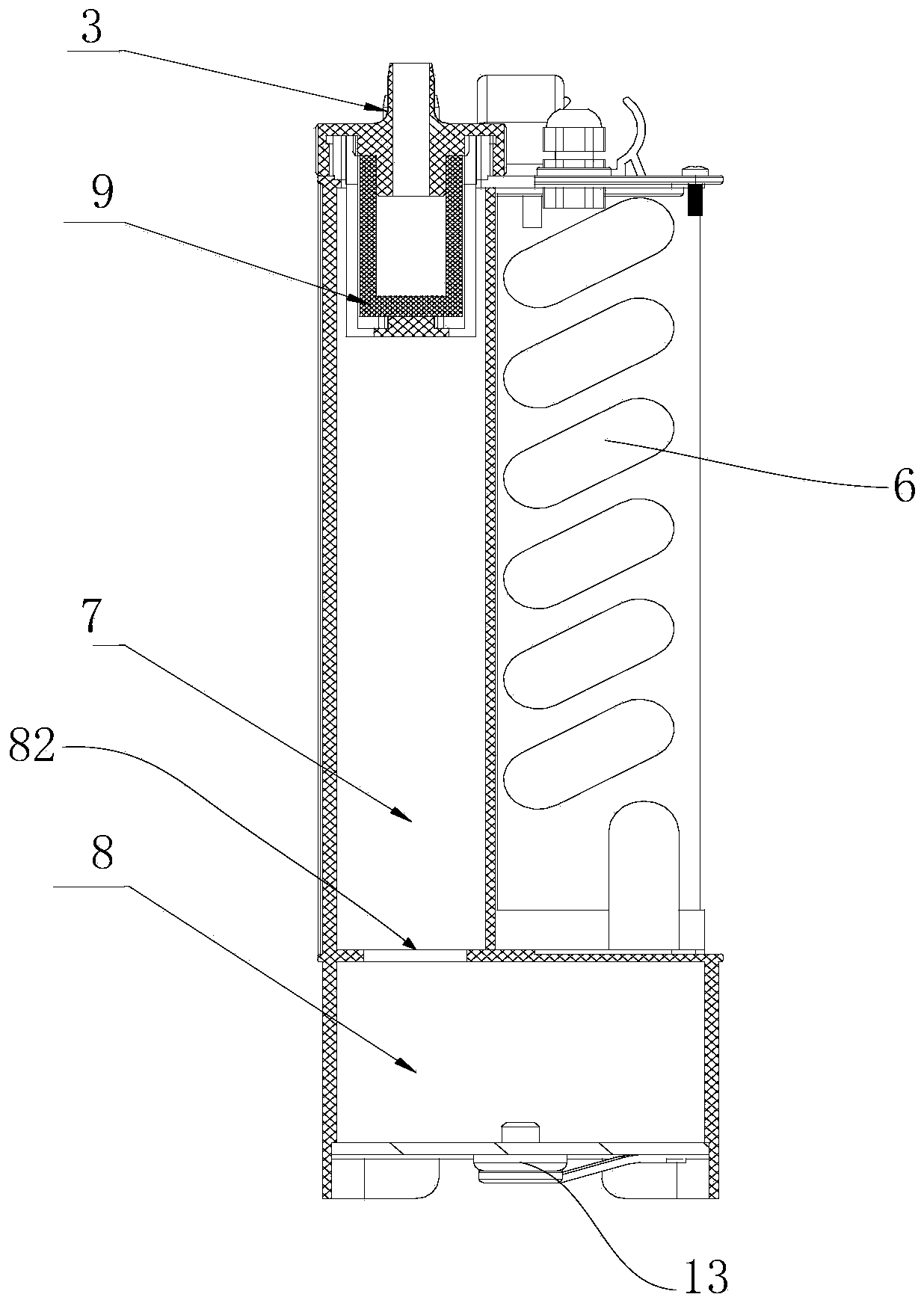

Smoke sampling dewatering device

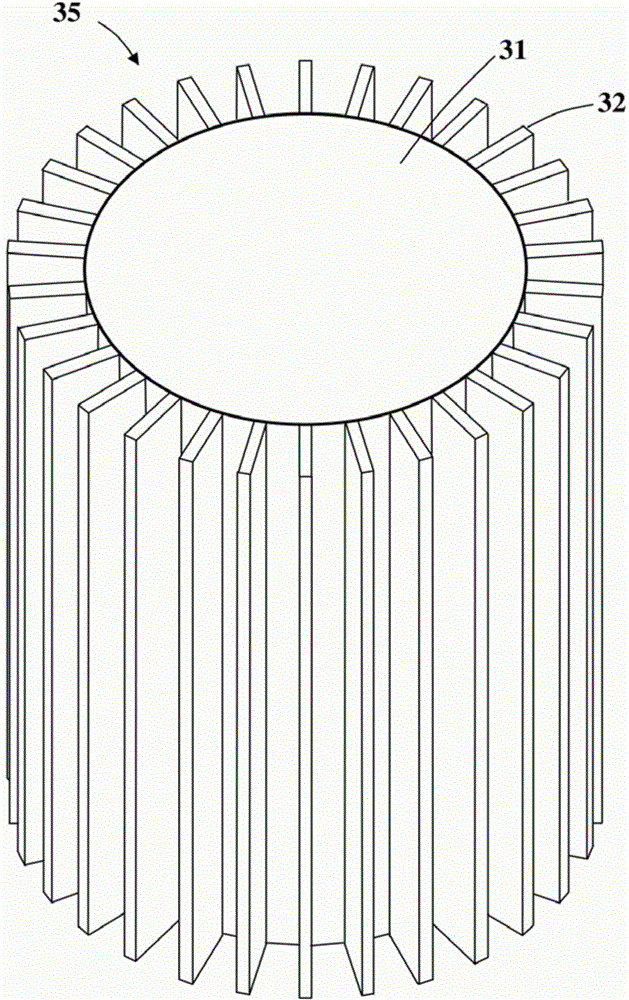

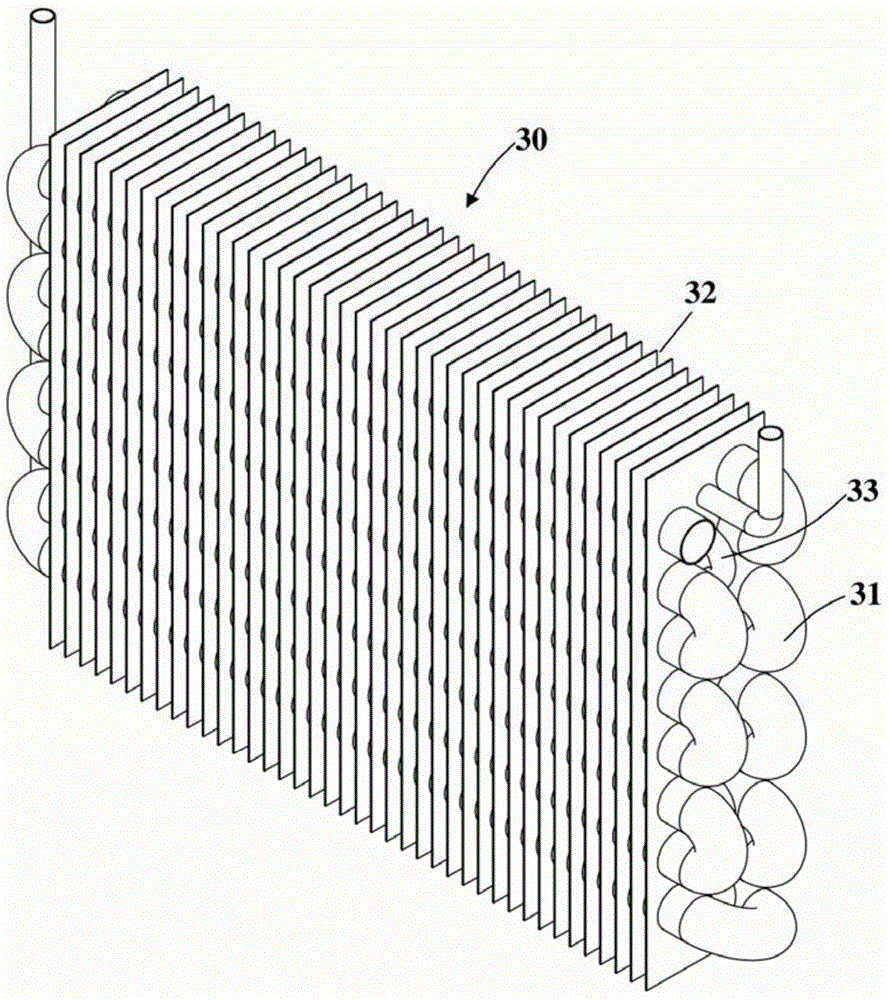

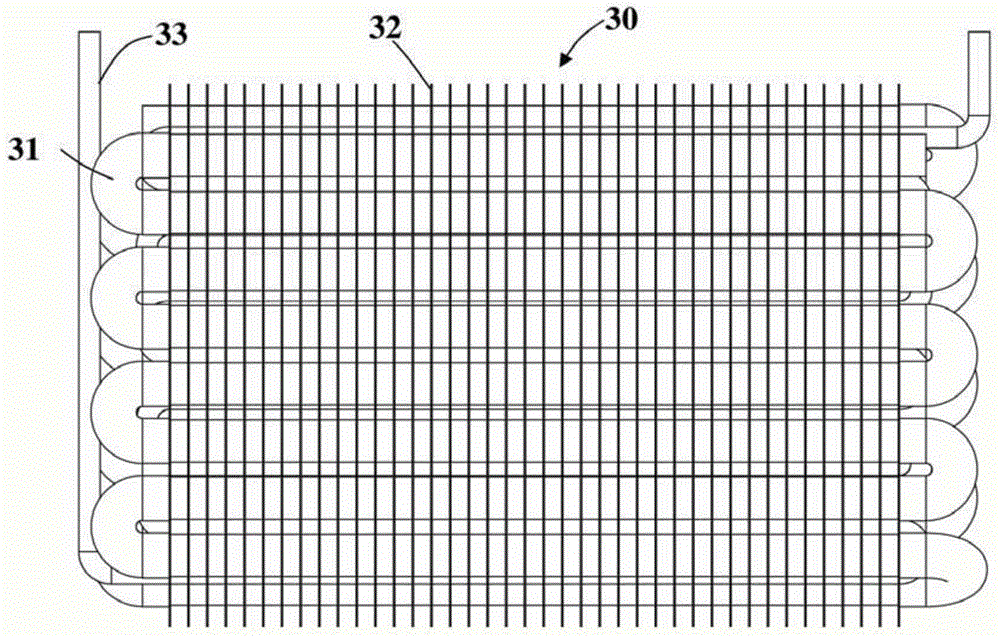

ActiveCN106896002AReduce usageImprove dehydration efficiencyWithdrawing sample devicesPreparing sample for investigationWater storageEngineering

The invention discloses a smoke sampling dewatering device which comprises a shell, a primary dewatering module, a secondary dewatering module and a tertiary dewatering module. The primary dewatering module comprises a first water storage cavity; the secondary dewatering module comprises a finned radiator and a multi-staged radiating pipeline, and a first water storage cavity gas outlet nozzle is communicated with a radiating pipeline gas inlet; the tertiary dewatering module comprises a drying chamber and a second water storage cavity, the multi-staged radiating pipeline is connected with a second water storage gas inlet nozzle, and the drying chamber is communicated with a smoke outlet nozzle. By the arrangement, other saturated gas enters the radiating pipeline gas inlet via the first water storage cavity gas outlet nozzle after passing through the primary dewatering module, quick cooling and dewatering are performed in the secondary dewatering module, condensed water is then stored in the second water storage cavity, and the gas is dried and filtered in the drying chamber prior to entering a host; the smoke sampling dewatering device is simple and reasonable in structural design, use amount of a drying agent can be reduced by three fourths, gas dewatering effect can reach more than 92%, and detection precision is obviously improved.

Owner:QINGDAO MINGHUA ELECTRONICS INSTR

Carbon dioxide absorbent and preparation method

ActiveCN100448513CHigh strengthReduce humidityDispersed particle separationAir quality improvementCalcium hydroxideLithium hydroxide

The invention discloses the carbon dioxide absorbent and the preparation method. The carbon dioxide absorbent includes the sodium hydroxide which is the added auxiliary absorbing agent of the lithium hydroxide, and the aluminium sesquioxide of the intensifier. The preparation method of the carbon dioxide absorbent is that the lithium hydroxide is crashed to the extent with the granularity larger than 80-screen mesh by a disintegrator, the sodium hydroxide and the aluminium sesquioxide are dried, and then are mixed evenly pro rata, the mixed materials are fed into a rotary tablet pressing machine for being pressed to tablet shapes, and then are put into the oven for drying. The carbon dioxide absorbent containing the lithium hydroxide is added with the sodium hydroxide and the aluminium sesquioxide, and the intensity is increased obviously. The percentage of the dust is less than or equal to zero point four percent, the phenomena of throat choking are obviously reduced, and the humidity of the exhaled gas is largely reduced, the gas is easy to be cooled after being inhaled, so people who wear the respirator containing the carbon dioxide absorbent will feel more comfortable. The preparation method is rather simple.

Owner:CCTEG SHENYANG RES INST

Synchronous polarization method for partitioned piezoelectric element

ActiveCN111554804AAvoid consistencyImprove polarization efficiencyPiezoelectric/electrostrictive/magnetostrictive devicesVoltage generatorTemperature control

The invention discloses a synchronous polarization method for a partitioned piezoelectric element, and belongs to the technical field of polarization of materials with piezoelectric characteristics. According to the invention, the plurality of elastic telescopic probes are adopted to press the subarea polarization electrodes on the piezoelectric element, and the polarization subareas are enabled to obtain polarization voltages with different magnitudes and directions by controlling the relative voltage difference, so that one-time synchronous polarization of the subarea piezoelectric element is completed. According to the invention, the polarization efficiency is improved, and the problem of inconsistent thermal depolarization and partition polarization intensity of the piezoelectric element caused by repeated polarization is avoided. Polarization of hundreds of microns of micro areas is realized, the elastic telescopic probe is in more sufficient contact with the micro electrode, thepolarization process is more stable, electrode surface damage caused by uneven stress is avoided, and the problems of difficult operation, difficult positioning and the like when a traditional polarization method polarizes the micro multi-partition piezoelectric element are solved. Meanwhile, the PC upper computer is used for controlling the high-voltage generator and the temperature control unit,the polarization process is simplified, and the polarization quality is improved.

Owner:DALIAN UNIV OF TECH

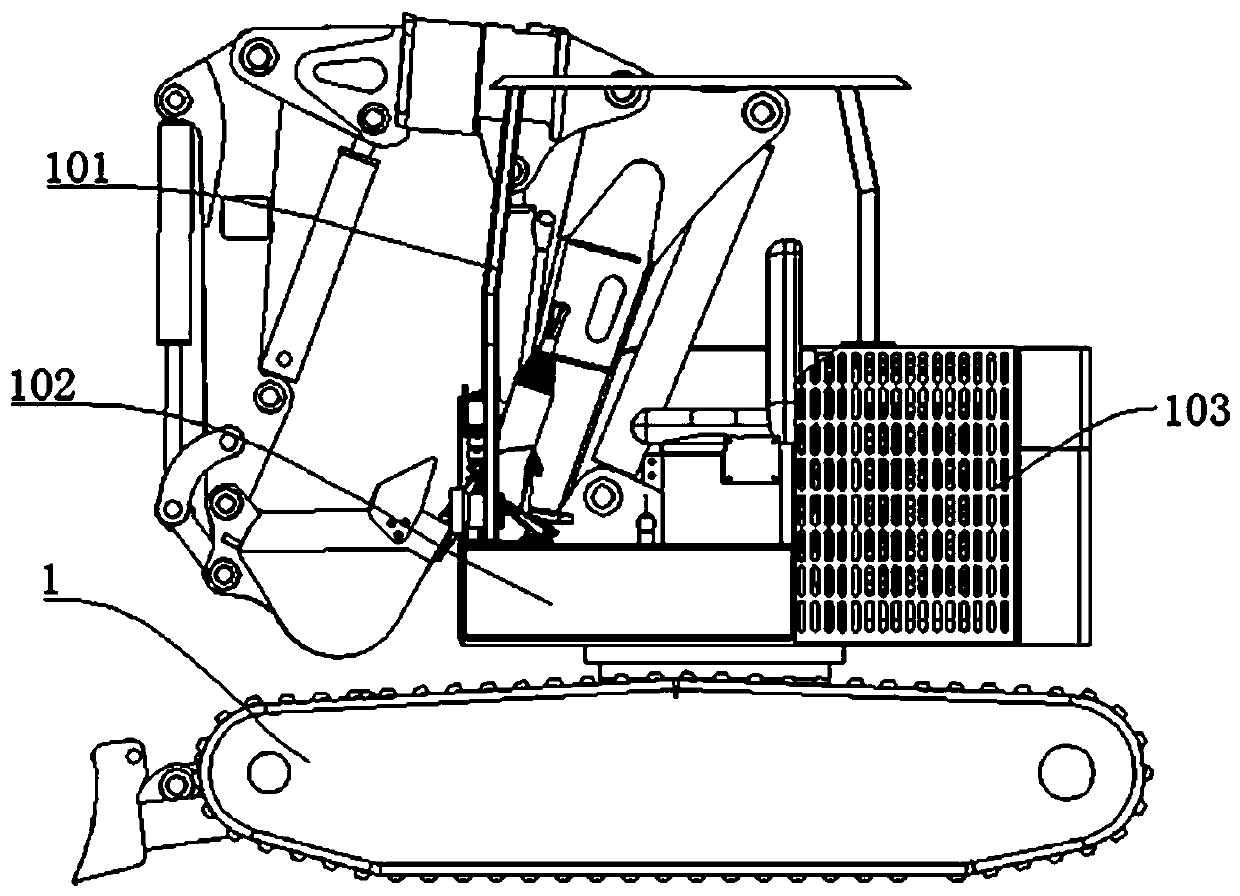

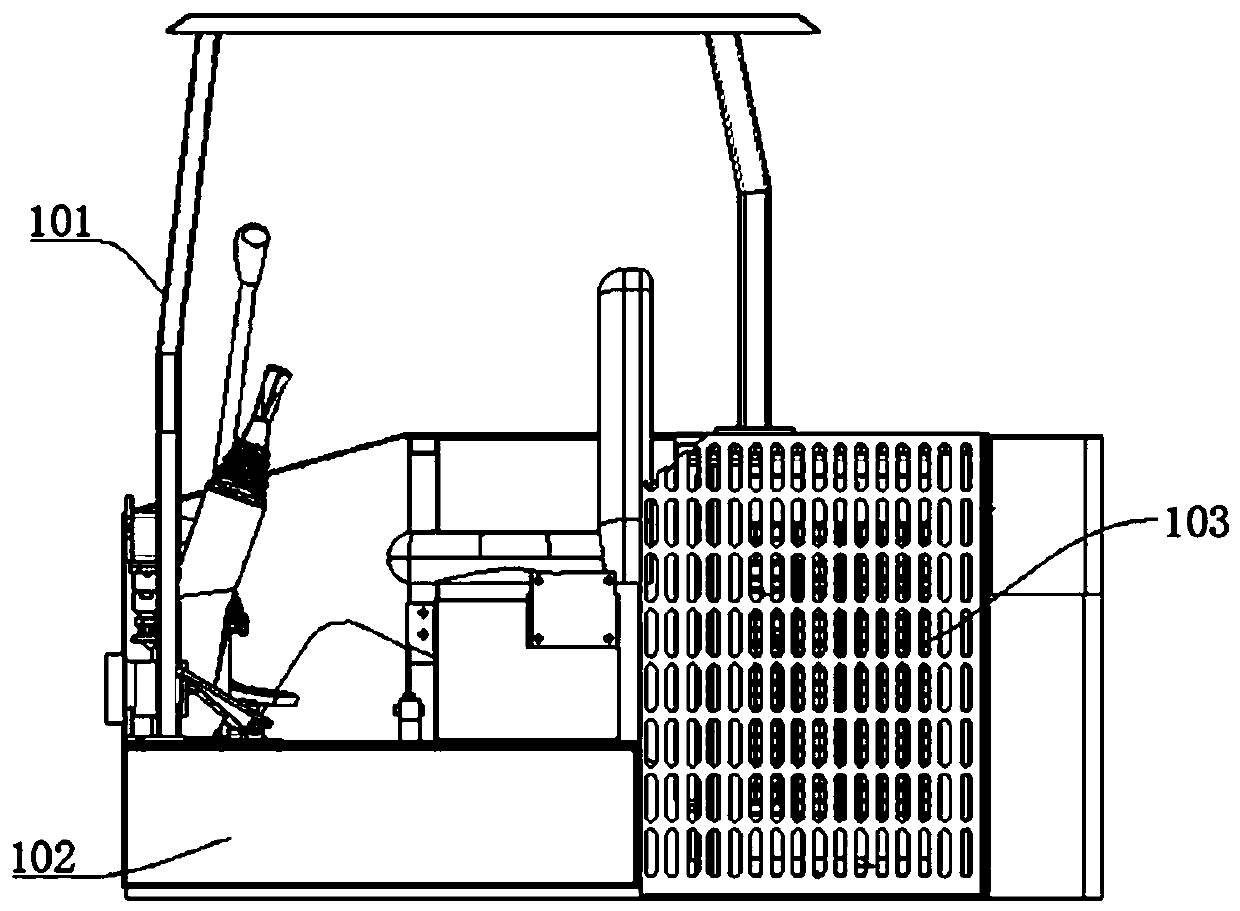

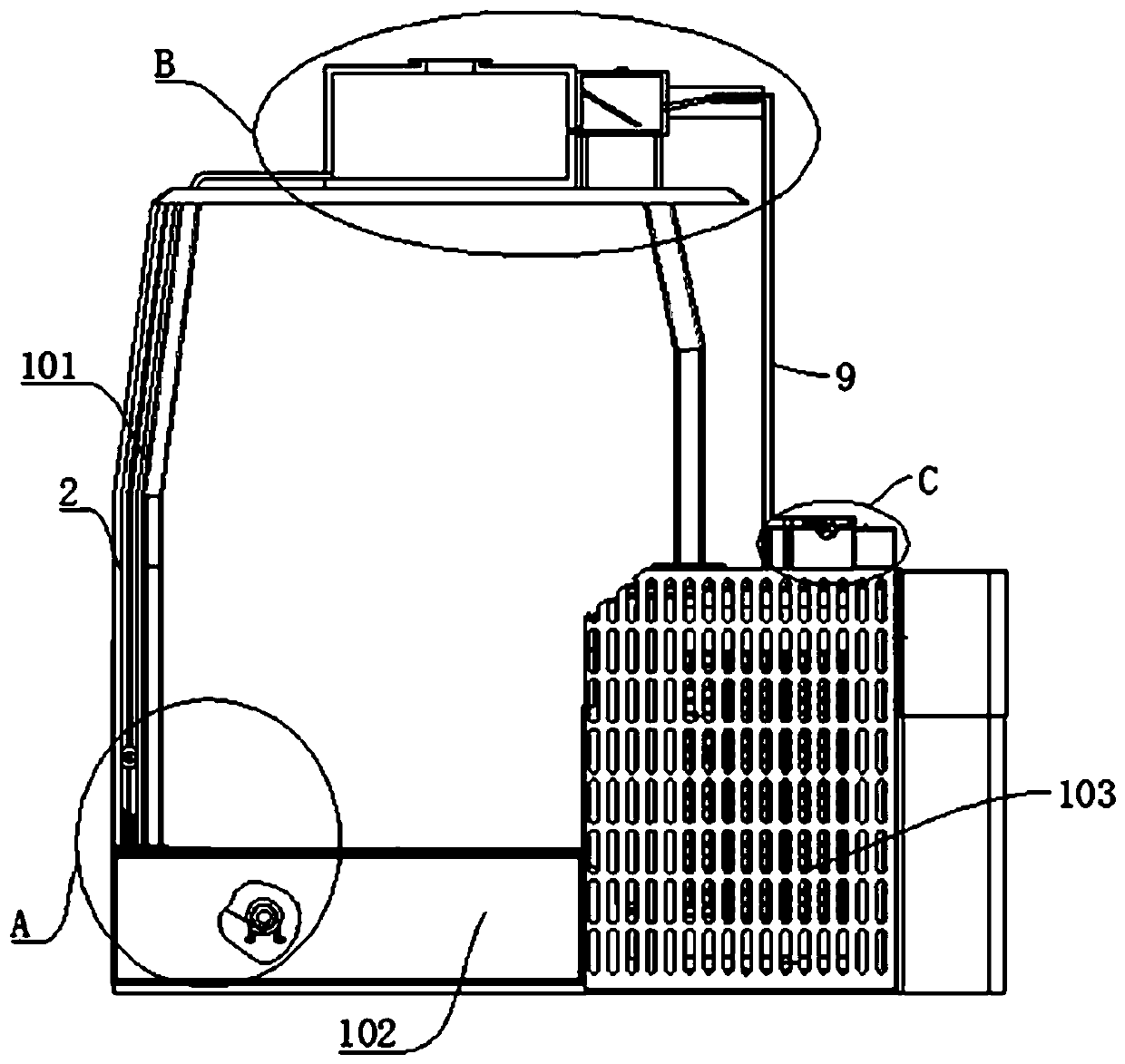

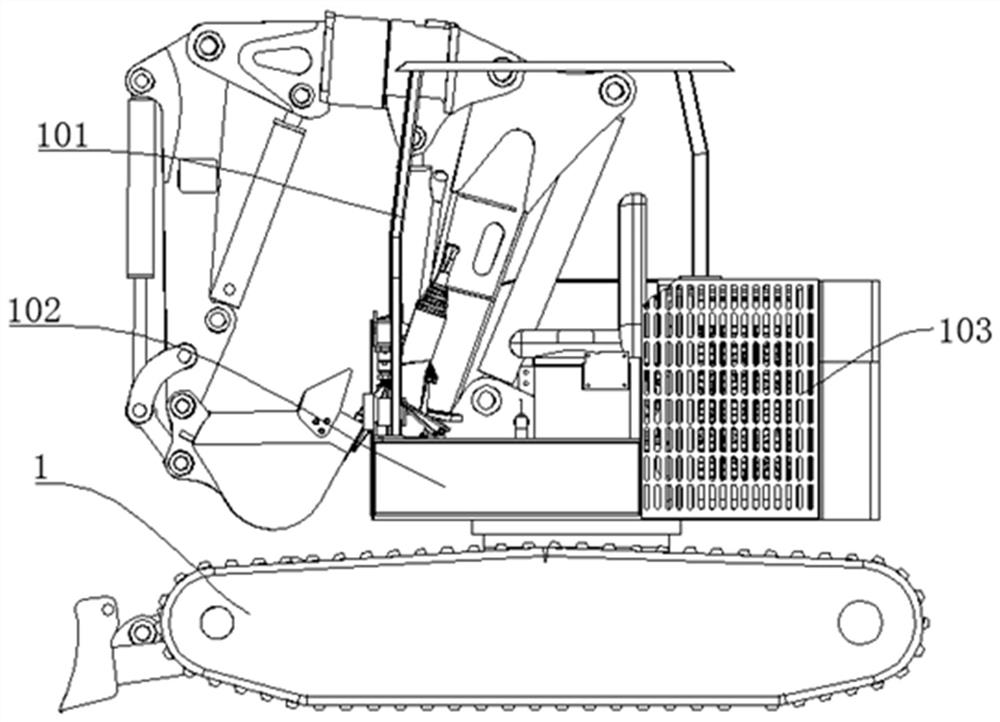

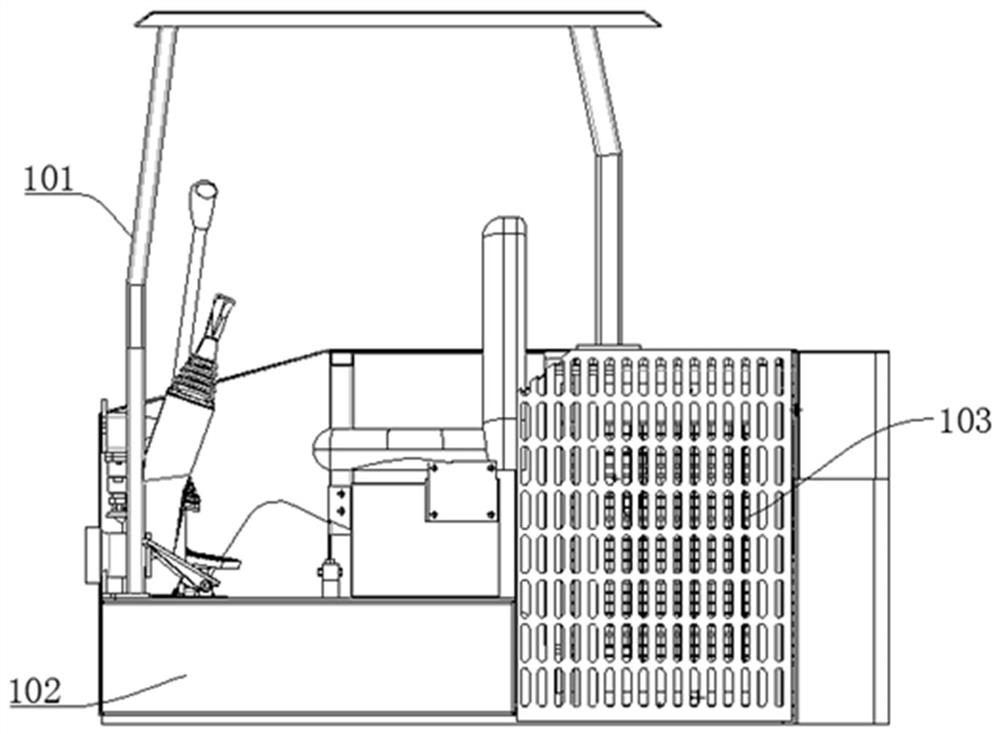

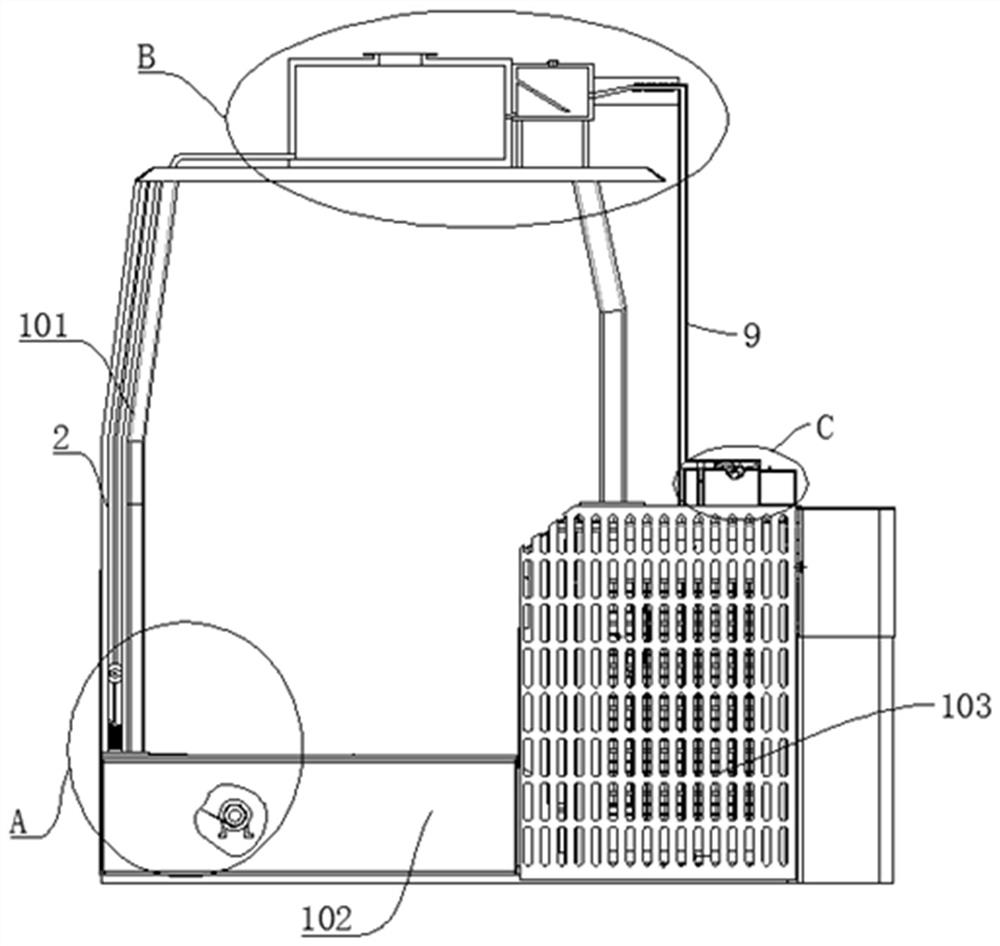

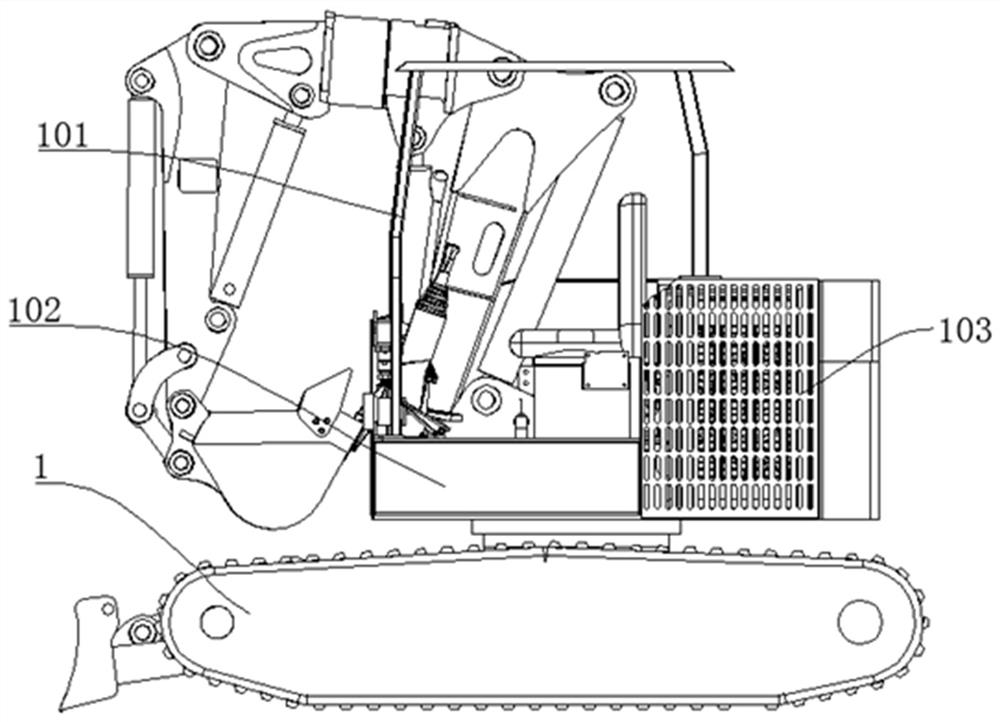

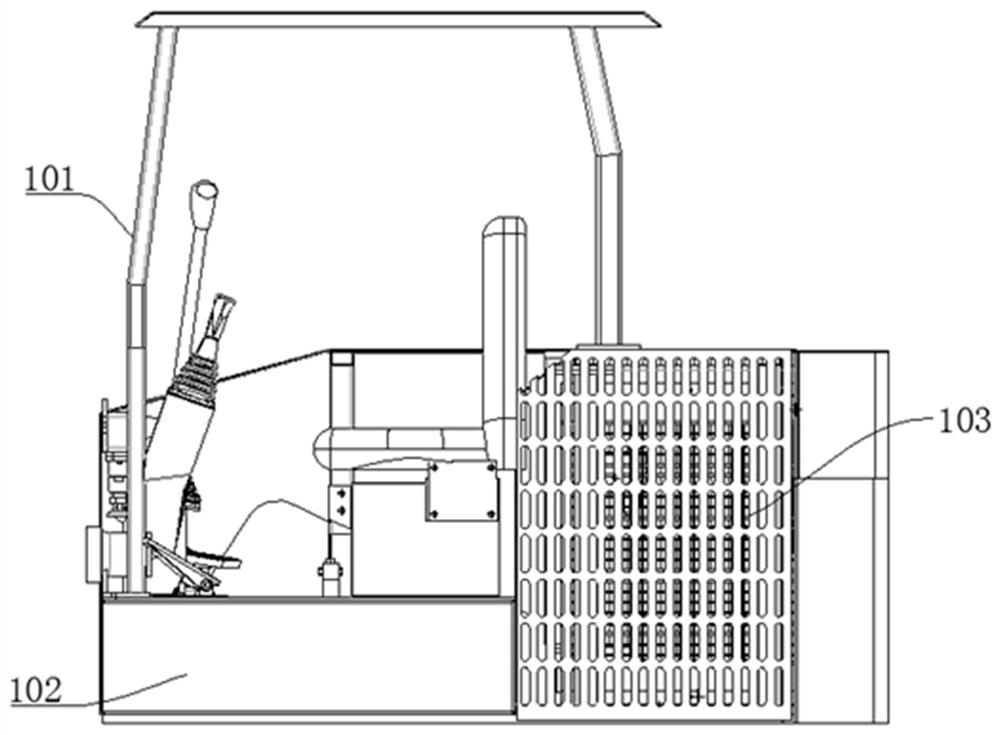

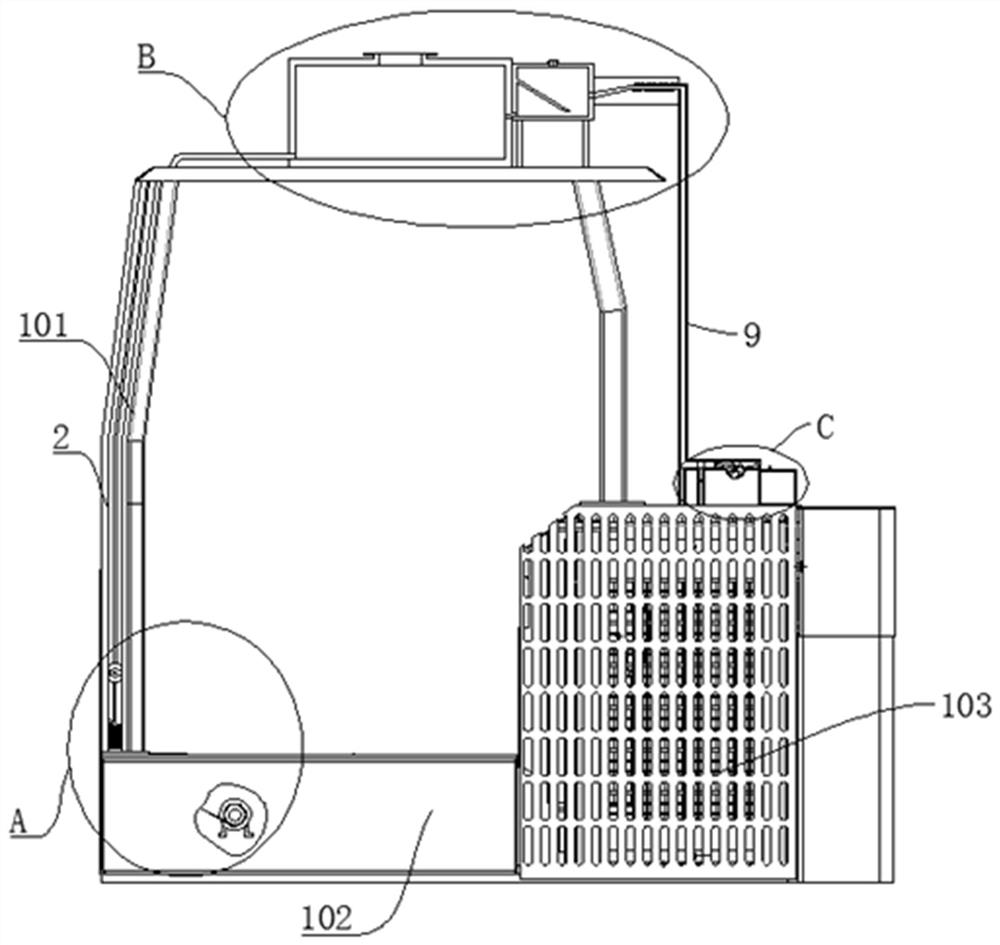

Heat dissipation device for underground caterpillar band type four-drive excavator

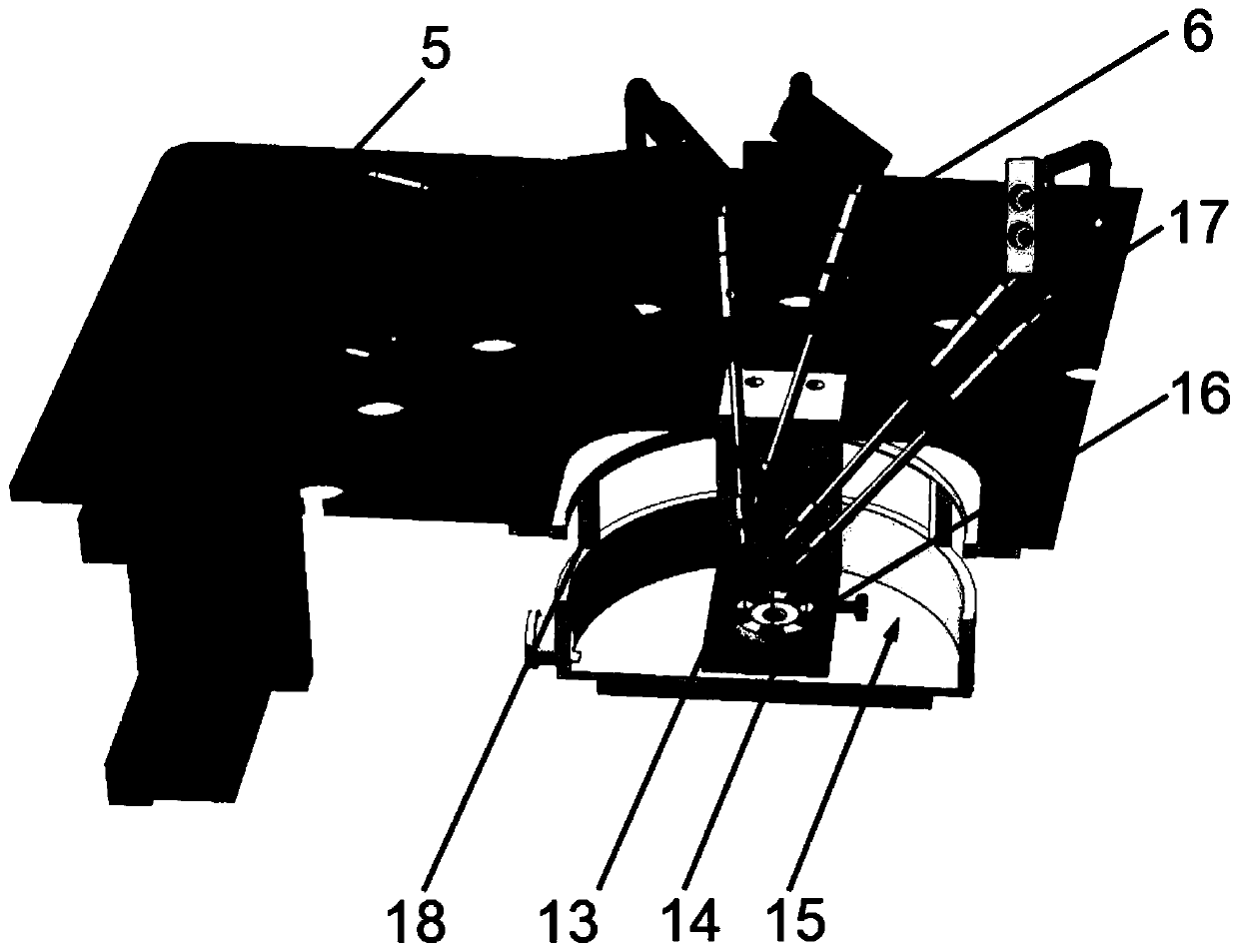

ActiveCN111456144AAchieve shock dropQuality improvementSoil-shifting machines/dredgersDrive shaftExcavator

The invention discloses a heat dissipation device for an underground caterpillar band type four-drive excavator, and belongs to the technical field of underground excavators. The heat dissipation device for the underground caterpillar band type four-drive excavator comprises an excavator group with a seat frame and a drive working box, and further comprises a gas inlet tube arranged on the drive working box, a gas inlet rotary shaft, a U-shaped tube, a water-absorbing soft block, a water-absorbing frame, a gas inlet driven shaft, a separating box and a cooling device. According to the heat dissipation device disclosed by the invention, a clearing plate can be arranged for clearing a transparent plate on the seat frame, a telescopic hose and a clearing collecting box are additionally arranged, so that dust adhered on the clearing plate is conveniently cleared, collected and filtered, and therefore, clearing effect is improved and a resource utilization rate is increased; the gas inlet tube, the water-absorbing soft block, the U-shaped tube and the cooling device can be arranged for filtering underground humid and dirty air; and meanwhile, the drive working box is simply cooled, thetelescopic hose further can be prevented from being blocked, and the clearing effect of the clearing plate is promoted.

Owner:扬州金洪车身零部件有限公司

A cooling device for an underground crawler-type four-wheel drive excavator

ActiveCN111456144BQuality improvementAccelerate evaporationSoil-shifting machines/dredgersDrive shaftEngineering

The invention discloses a cooling device for an underground crawler type four-wheel drive excavator, which belongs to the technical field of underground excavators. A cooling device for an underground crawler-type four-wheel drive excavator, including an excavator unit equipped with a seat frame and a driving working box, and also includes: an air intake pipe arranged on the driving working box; an air intake rotating shaft; a U-shaped pipe water absorption soft block; water absorption frame; air intake driven shaft; on the separation box; The setting of the collection box is convenient for cleaning, collecting and filtering the dust attached to the cleaning plate, improving the effect of cleaning and the utilization rate of resources, and the setting of the air intake pipe, water-absorbing soft block, U-shaped pipe, and cooling device can reduce the humidity in the well , Dirty air is filtered, and at the same time, the drive box is simply cooled, which can further prevent the telescopic hose from clogging and promote the cleaning effect of the cleaning plate.

Owner:扬州金洪车身零部件有限公司

Cup providing convenience for evenly dissolving milk powder and with good cooling function

InactiveCN108542262ANo precipitation will occurEvenly brewedBeverage vesselsWater storageEngineering

The invention discloses a cup providing convenience for evenly dissolving milk powder and with a good cooling function. The cup comprises a cup body, a base is fixed to the bottom wall of an inner cavity of the cup body, and a rotation groove is formed in the base; a rotation rod is movably inserted in the rotation groove, a rotation block is fixedly connected to the end, away from the base, of the rotation rod, and a milk powder groove is formed in the rotation block; a powder outlet is formed in the side wall in the milk powder groove, and a powder spraying pipe is fixedly connected to the powder outlet; a cover plate is movably connected to the milk powder groove, a rotation motor is arranged at the side, away from the base, of the cover plate, and an electrode main shaft of the rotation motor is fixedly connected to the cover plate; a water storage block is arranged at the side, away from the cup body, of a cup cover. According to the cup, milk powder sprayed through rotation and dissolving water which flows along the wall are dissolved and mixed, the effect of keeping the milk powder even during dissolving is better achieved, in the flow process along the cup wall, the mixingwater can be better cooled, and the cup is very high in practicability and extremely worthy of popularization.

Owner:朱柏艳

Smoke sampling and dehydration device

ActiveCN106896002BSimple coolingGuaranteed accuracyWithdrawing sample devicesPreparing sample for investigationWater storageEngineering

The invention discloses a smoke sampling dewatering device which comprises a shell, a primary dewatering module, a secondary dewatering module and a tertiary dewatering module. The primary dewatering module comprises a first water storage cavity; the secondary dewatering module comprises a finned radiator and a multi-staged radiating pipeline, and a first water storage cavity gas outlet nozzle is communicated with a radiating pipeline gas inlet; the tertiary dewatering module comprises a drying chamber and a second water storage cavity, the multi-staged radiating pipeline is connected with a second water storage gas inlet nozzle, and the drying chamber is communicated with a smoke outlet nozzle. By the arrangement, other saturated gas enters the radiating pipeline gas inlet via the first water storage cavity gas outlet nozzle after passing through the primary dewatering module, quick cooling and dewatering are performed in the secondary dewatering module, condensed water is then stored in the second water storage cavity, and the gas is dried and filtered in the drying chamber prior to entering a host; the smoke sampling dewatering device is simple and reasonable in structural design, use amount of a drying agent can be reduced by three fourths, gas dewatering effect can reach more than 92%, and detection precision is obviously improved.

Owner:QINGDAO MINGHUA ELECTRONICS INSTR

A Synchronous Polarization Method for Partitioned Piezoelectric Elements

ActiveCN111554804BImprove polarization efficiencyAchieve independent controlPiezoelectric/electrostrictive/magnetostrictive devicesTemperature controlEngineering

The invention discloses a method for synchronous polarization of partitioned piezoelectric elements, which belongs to the technical field of polarization of materials with piezoelectric characteristics. In the present invention, several elastic stretchable probes are used to touch the partitioned polarized electrodes on the piezoelectric element, and each polarized partition can obtain polarization voltages of different sizes and directions by controlling the relative voltage difference. synchronized polarization. The invention improves the polarization efficiency and avoids the problems of thermal depolarization of the piezoelectric element and inconsistency of the divisional polarization intensity caused by repeated polarization. The invention realizes the polarization of the tiny area of hundreds of microns, the contact between the elastic stretchable probe and the tiny electrode is more sufficient, the polarization process is more stable, the electrode surface damage caused by uneven force is avoided, and the traditional polarization method is solved Difficulty in operation and positioning when polarizing tiny multi-section piezoelectric elements. At the same time, the PC host computer is used to control the high-voltage generator and the temperature control unit, which simplifies the polarization process and improves the polarization quality.

Owner:DALIAN UNIV OF TECH

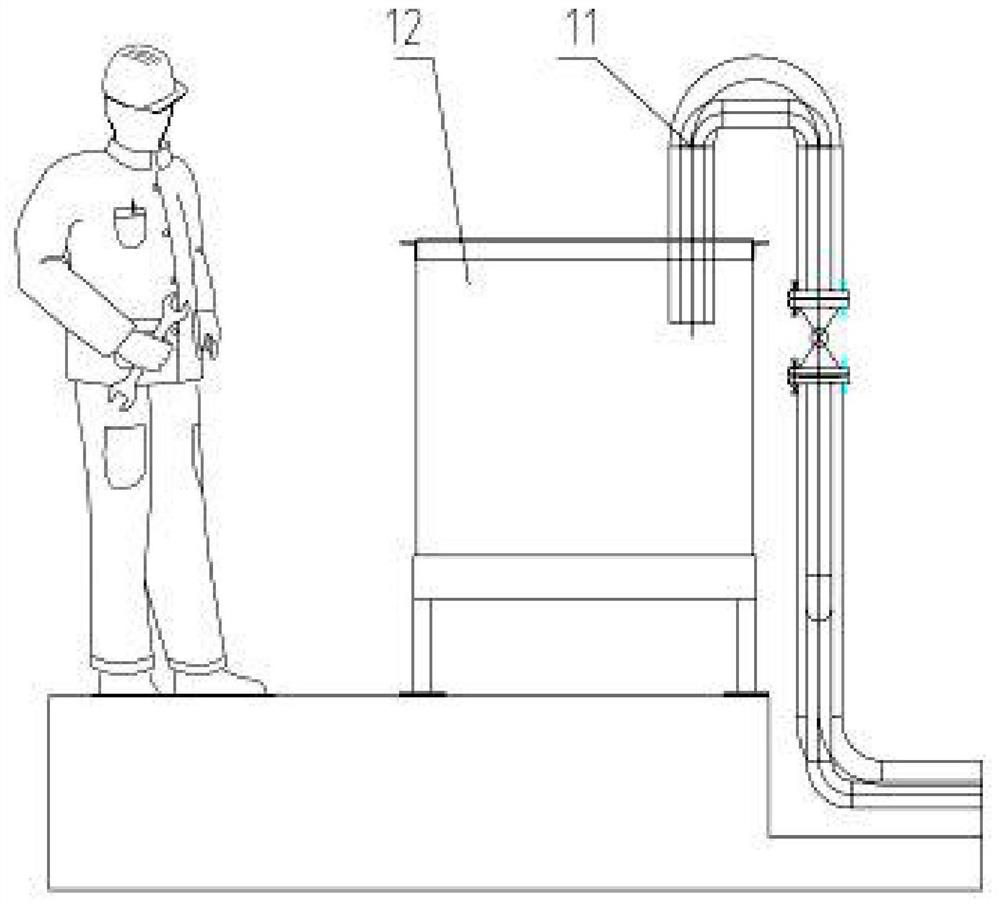

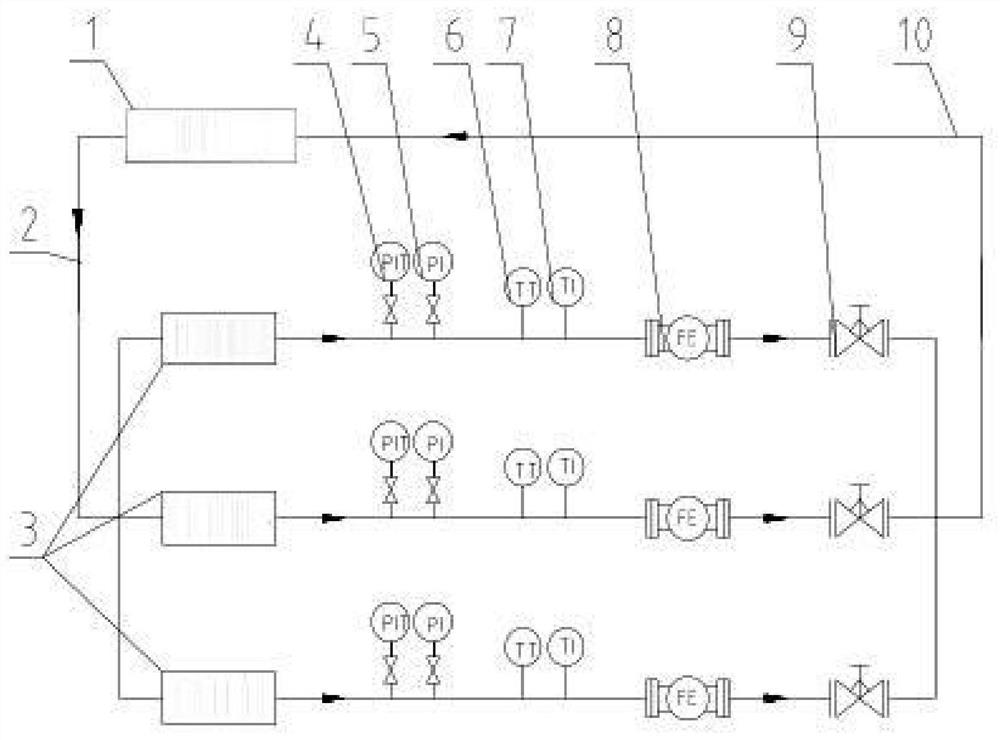

Device and method for returning circulating cooling water of continuous caster apparatus

InactiveCN113091395AEasy to cool downRelieve pressureLighting and heating apparatusCooling fluid circulationProcess engineeringWater pipe

The invention belongs to the technical field of continuous casting in the metallurgical industry, and particularly provides a device and a method for returning circulating cooling water of a continuous caster apparatus, wherein the device comprises a continuous caster water treatment center, a cooling water pipeline and a plurality of continuous caster apparatuses; a water outlet of the continuous caster water treatment center is connected with water inlets of the plurality of continuous caster apparatuses through the cooling water pipeline; the device further comprises an apparatus cooling water return pipeline, a water accumulation pool and a cooling water return main pipe; water outlets of the plurality of continuous caster apparatuses are connected with a water inlet of the water accumulation pool through the apparatus cooling water return pipeline; a water outlet of the water accumulation pool is connected with a water inlet of the continuous caster water treatment center through the cooling water return main pipe; and a continuous caster has the problems about a high water supply pressure level and a high equipment investment. The device provided by the invention avoids the use of detection components in the cooling water return pipeline, reduces a pressure of the overall water return pipeline and lowers the cost.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

A Small Circulating Lubrication System Using Liquid Nitrogen Cooling

InactiveCN103822078BImprove leakageEasy to polluteLubrication elementsLiquid nitrogen coolingLubrication

Owner:HENAN UNIV OF SCI & TECH

Nuclear power plant master control heat dissipation chamber

PendingCN108091406AOvercome the problems of low heat storage capacity and low heat storageIncrease contact areaNuclear energy generationCooling arrangementNuclear engineeringMetallic materials

The invention provides a nuclear power plant master control heat dissipation chamber, which comprises a wall and an interlayer that is disposed in the wall to conduct heat. Specifically, the wall is made of a metal material, and the interlayer is made of a phase change heat storage material within certain melting point range. The nuclear power plant master control heat dissipation chamber providedby the invention can overcome the problems of low heat storage capacity, and little heat storage and the like of concrete in the prior art, and is suitable for marine environment.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Cleaning device for underground crawler four-wheel drive excavator

ActiveCN111452757BPrevent proliferationIncrease elasticityDispersed particle filtrationMechanical machines/dredgersWater storageProcess engineering

The invention discloses a cleaning device for an underground crawler type four-wheel drive excavator, which belongs to the technical field of underground excavators. A cleaning device for an underground crawler-type four-wheel drive excavator, including an excavating unit provided with a seat frame and a seat base, and also includes: cleaning guide rails; cleaning sliders; cleaning plates; cleaning water storage tanks; driving mechanisms; reset elastic ropes ; cleaning collection box; telescopic hose parts; telescopic spring; in the present invention, through the setting of the cleaning plate, the transparent plate on the seat frame can be cleaned, and the setting of the telescopic hose and the cleaning collection box are added, which is convenient for cleaning The dust attached to the board is cleaned, collected and filtered to improve the cleaning effect and the utilization rate of resources, and through the air intake pipe, water absorption soft block, U-shaped pipe, and cooling device, the humid and dirty air underground can be filtered, and at the same time Simple cooling of the driving working box can further prevent the telescopic hose from clogging and promote the cleaning effect of the cleaning plate.

Owner:义乌市倩飞科技有限公司

Partitioned polarization device for piezoelectric element

ActiveCN111554803BAchieve independent controlSatisfy Polarization RequirementsPiezoelectric/electrostrictive/magnetostrictive devicesEngineeringMechanical engineering

The invention discloses a partitioned polarization device for a piezoelectric element, which belongs to the technical field of polarization of materials with piezoelectric characteristics. The device includes a partition voltage regulation module, a probe regulation module and a polarization control module; the partition voltage regulation module can adjust the polarization voltage of each partition to realize independent control of the polarization partition electric field; the probe regulation module adopts The method of elastically stretching the probe with the probe positioning bracket can realize the precise positioning and synchronous polarization of multiple hundreds of micron-scale tiny electrodes; the polarization control module can control the time change of the total voltage required for polarization and the polarization temperature curve. The present invention realizes the independent control of multi-partition polarization electric field, can simultaneously polarize multi-partition piezoelectric elements at one time, and avoids the problem of thermal depolarization of piezoelectric elements caused by repeated multiple polarizations and inconsistency of partition polarization intensity; solves the problem of The problems of difficult operation, difficult positioning, and single polarization area in the traditional method are solved, and the polarization quality of the partitioned piezoelectric element is improved.

Owner:DALIAN UNIV OF TECH

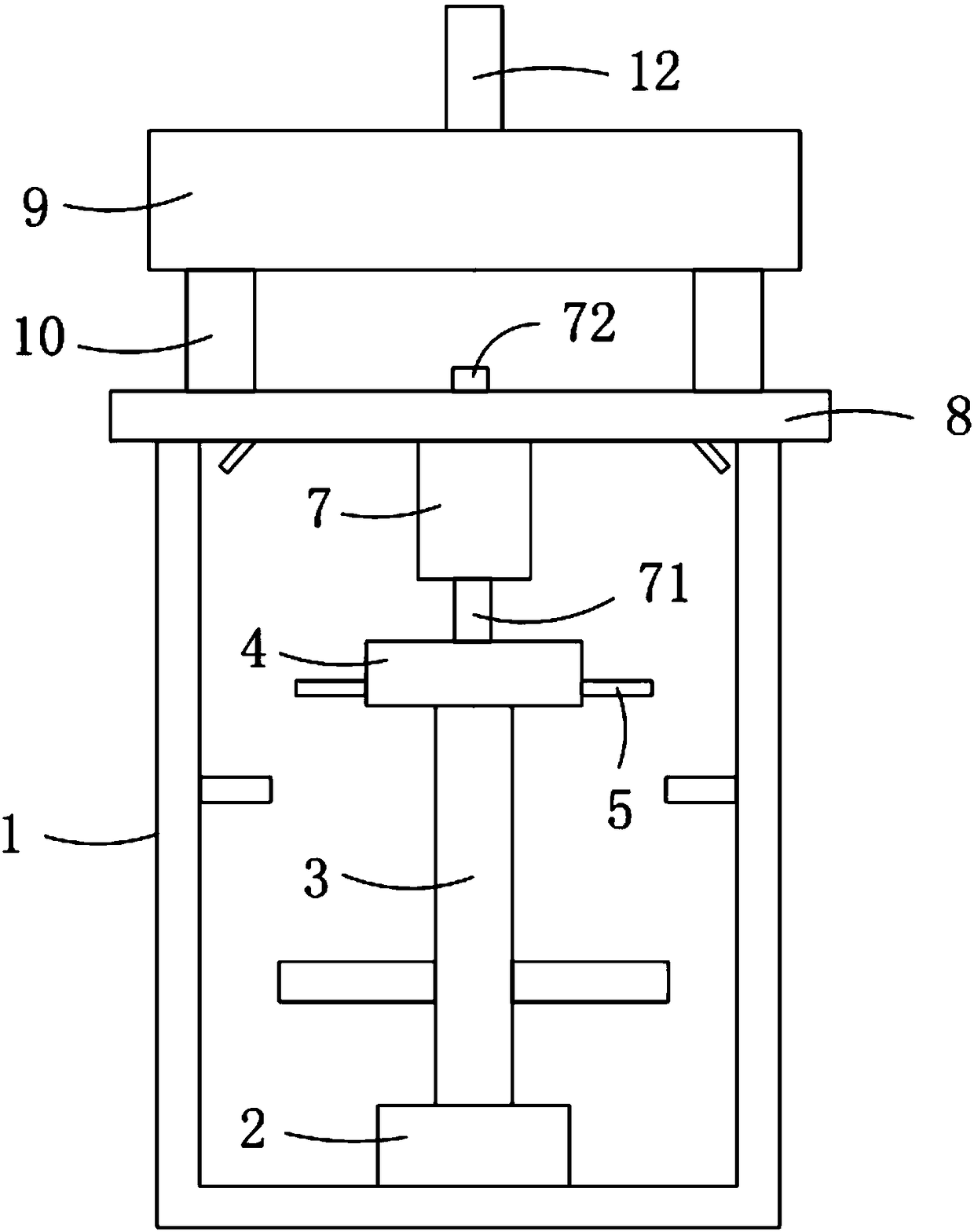

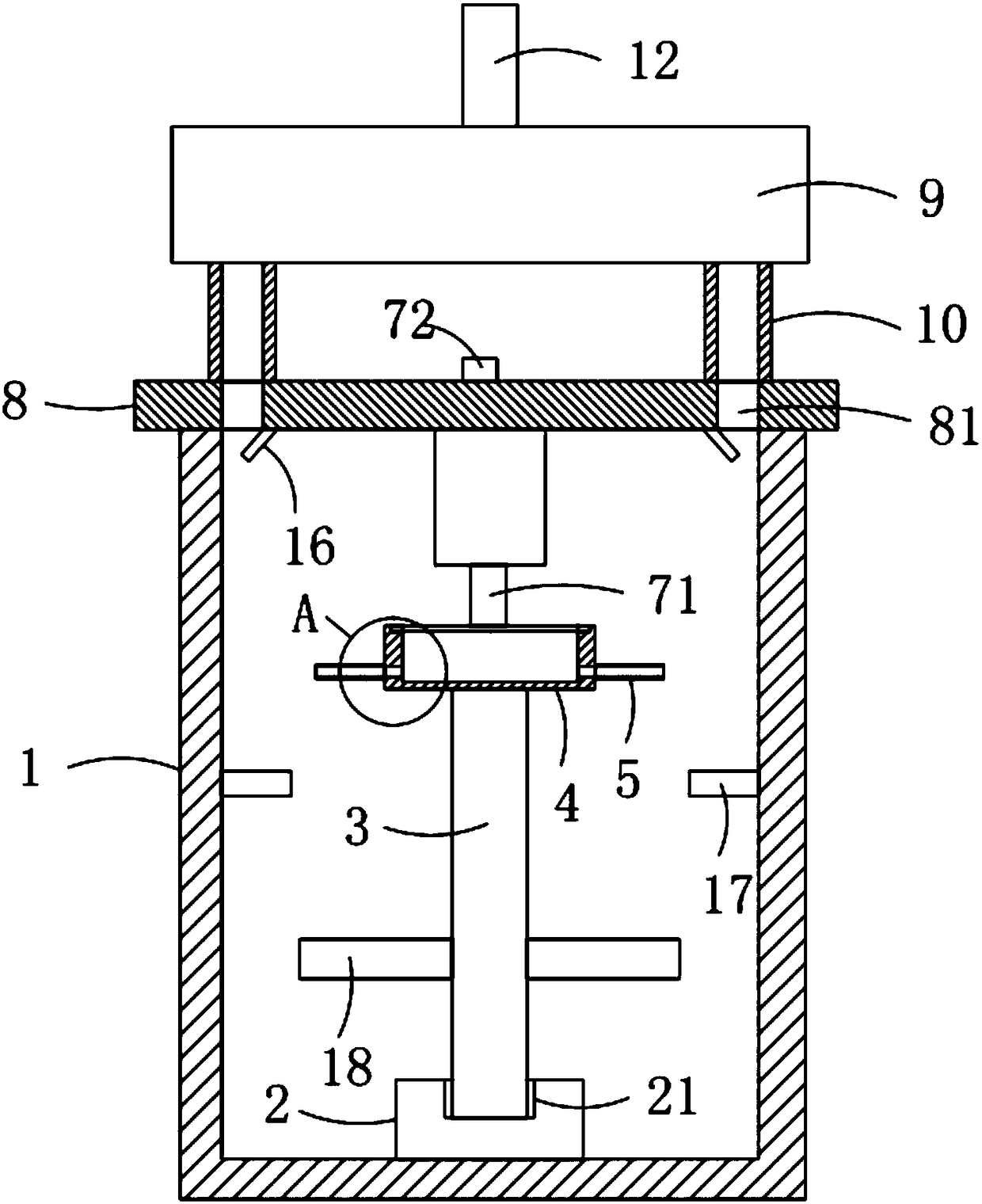

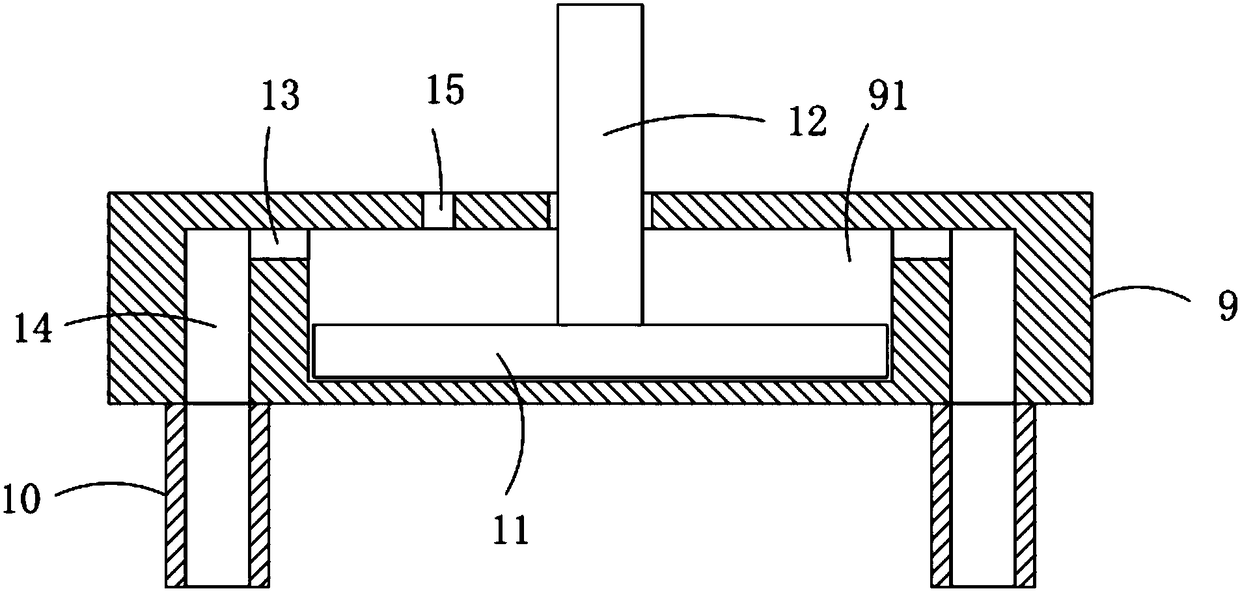

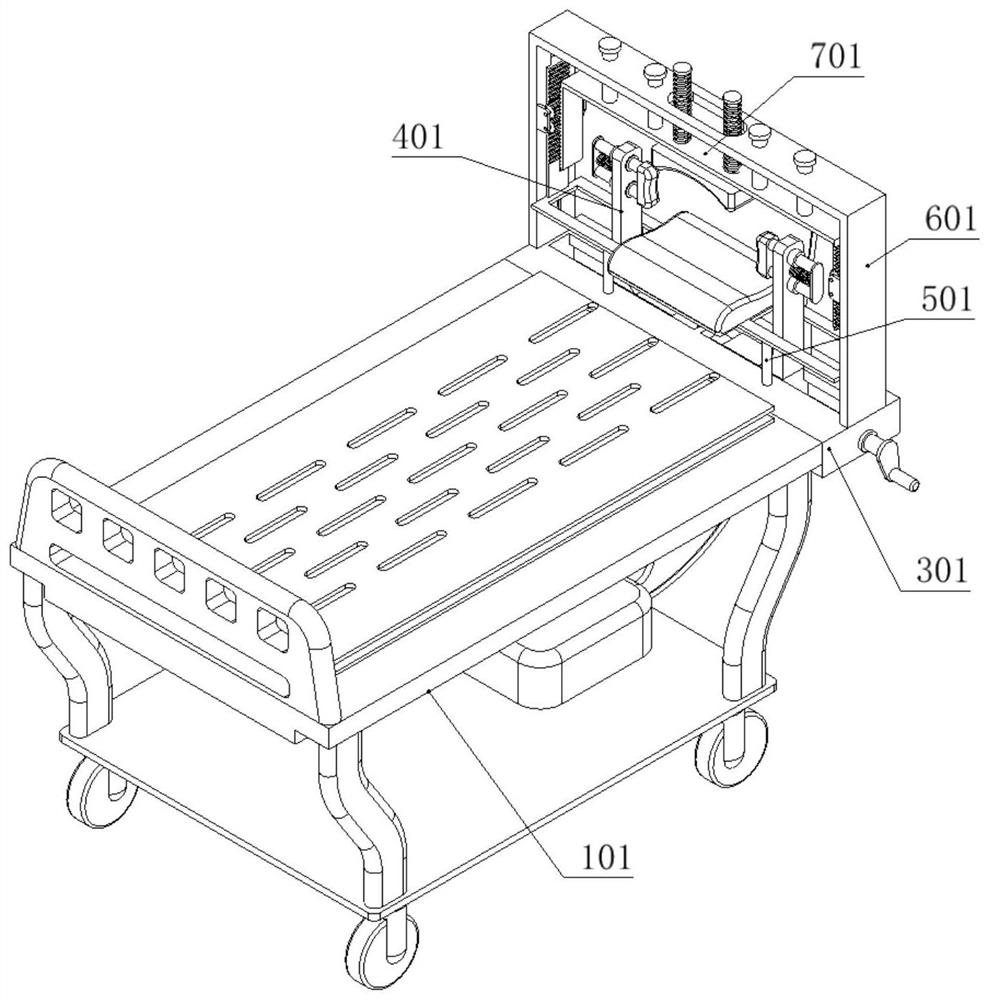

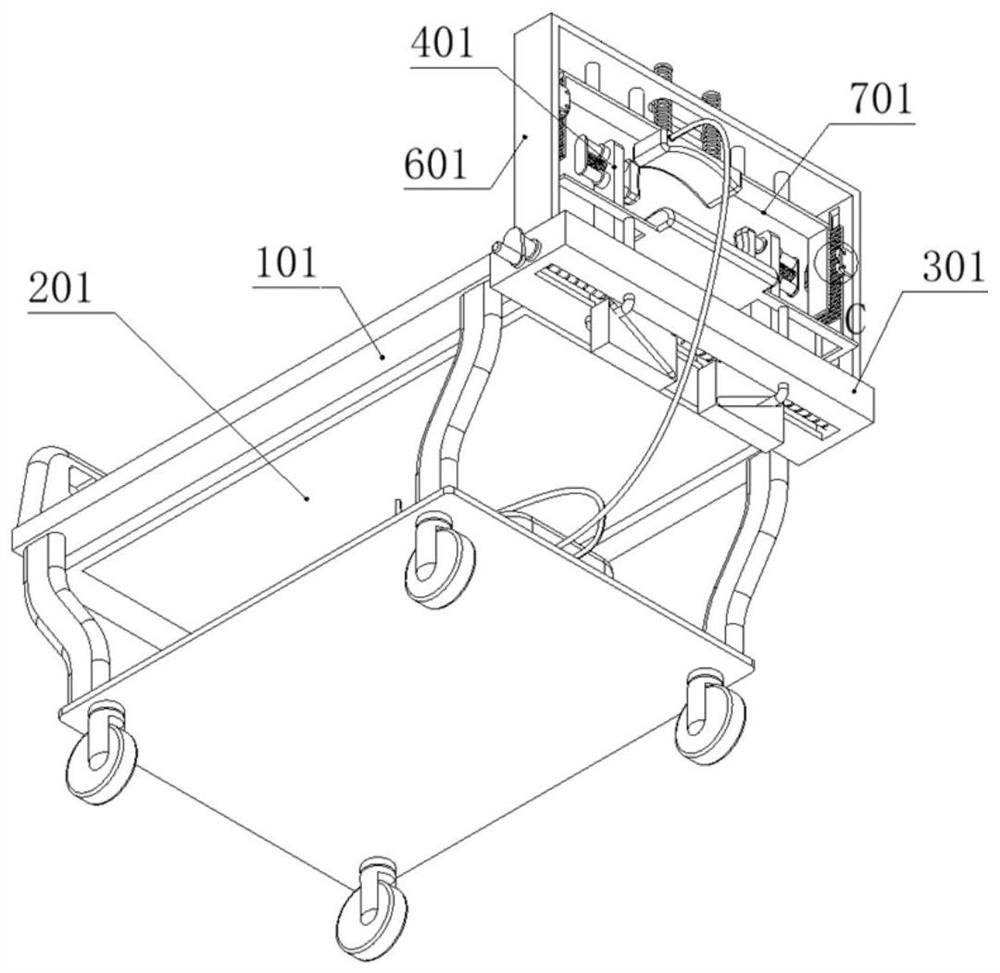

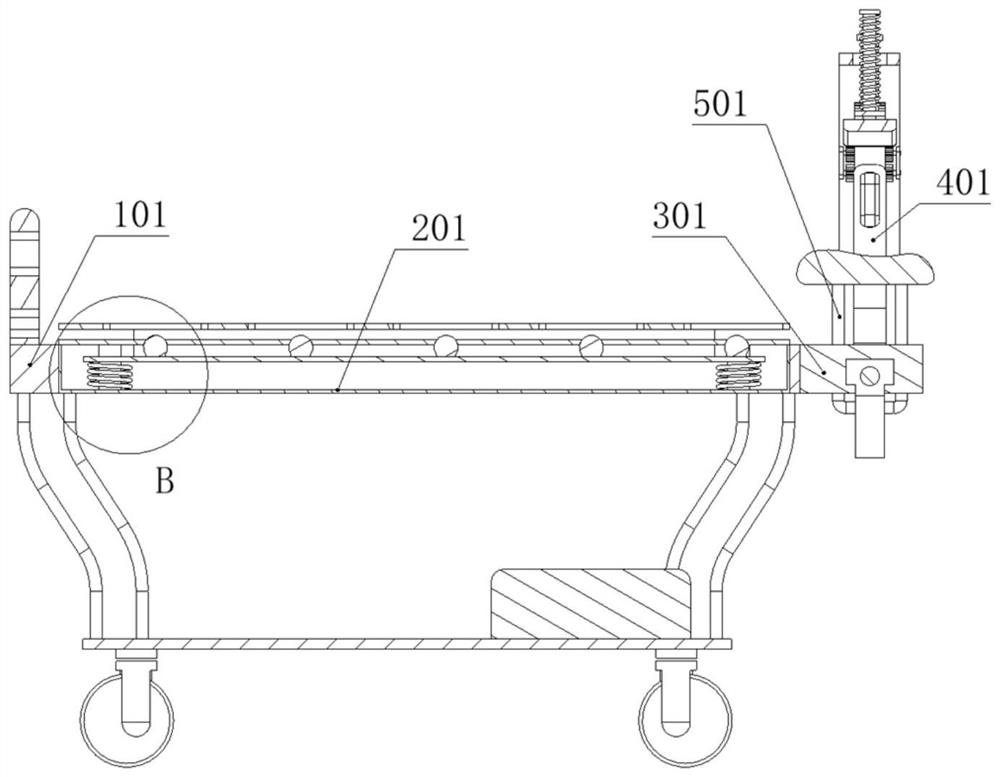

Rapid cooling device applied to nursing in intensive care medicine department

InactiveCN114404130ACool down directlyRapid coolingOperating tablesDiagnosticsCritical care medicine specialtyWhole body

The invention provides a rapid cooling device applied to nursing in the intensive care department, and relates to the technical field of medical instruments. The supporting device is fixedly connected with a sedimentation part; the supporting device is fixedly connected with a driving part; the driving part is fixedly connected with two positioning devices; the driving part is slidably connected with a lifting device; the driving part is fixedly connected with a reverse linkage part; a cooling device is installed on the reverse linkage part, cooling is more direct, meanwhile, the whole body of a patient can be rapidly cooled in a targeted mode, the protection performance on the patient is better, meanwhile, the device can be applied to patients with different head circumferences, the labor intensity of medical workers is better reduced, and the problems that an existing cooling device is low in cooling efficiency, not comprehensive in cooling and poor in cooling effect are solved. And meanwhile, a positioning device for the head of the patient is not arranged, so that the patient is easily bumped in the using process, linkage fitting cannot be quickly realized, and the patient cannot use the device conveniently.

Owner:ZHUJIANG HOSPITAL SOUTHERN MEDICAL UNIV

Preparation method of halohydrocarbon-free alpha-cyanoacrylate

ActiveCN102030681BNot easy to hydrolyzeEasy to controlCarboxylic acid nitrile preparationOrganic compound preparationHalohydrocarbonMethyl carbonate

The invention relates to a preparation method of halohydrocarbon-free alpha-cyanoacrylate, which comprises the following steps: mixing cyanoacetate and methyl carbonate in a reaction kettle, simultaneously mixing formaldehyde and a base catalyst in a charging hopper, then adding the mixture of the formaldehyde and the base catalyst to the reaction kettle at twice, performing a refluxing and condensation reaction at 78 DEG C under normal pressure, adding a dehydration solvent methyl carbonate to dehydrolyze after the condensation reaction is finished, adding an anionic polymerization inhibitor phosphorus pentoxide and a free radical polymerization inhibitor, and depolymerizing and distilling at 155-210 DEG C at a vacuum degree of 0.5-30 mmHg to obtain an alpha-cyanoacrylate coarse monomer; and rectifying the coarse monomer to obtain a high-purity alpha-cyanoacrylate refined monomer, wherein the yield of the alpha-cyanoacrylate refined monomer is more than 75%, and the purity of the alpha-cyanoacrylate refined monomer is 99%. The invention has the advantages of no pollution, energy conservation and high yield and high purity of the obtained product, and is stable in reaction, thereby being suitable for popularization and application.

Owner:山东禹王和天下新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com