Synchronous polarization method for partitioned piezoelectric element

A piezoelectric element and electrode technology, which is applied in the field of synchronous polarization of partitioned piezoelectric elements, can solve problems such as the inability to control the polarization voltage intensity and polarization direction separately, difficulty in realizing the polarization of piezoelectric elements, and inconsistent polarization intensities of partitions. , to avoid electrode surface damage, avoid breakdown, and wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with technical solutions and accompanying drawings.

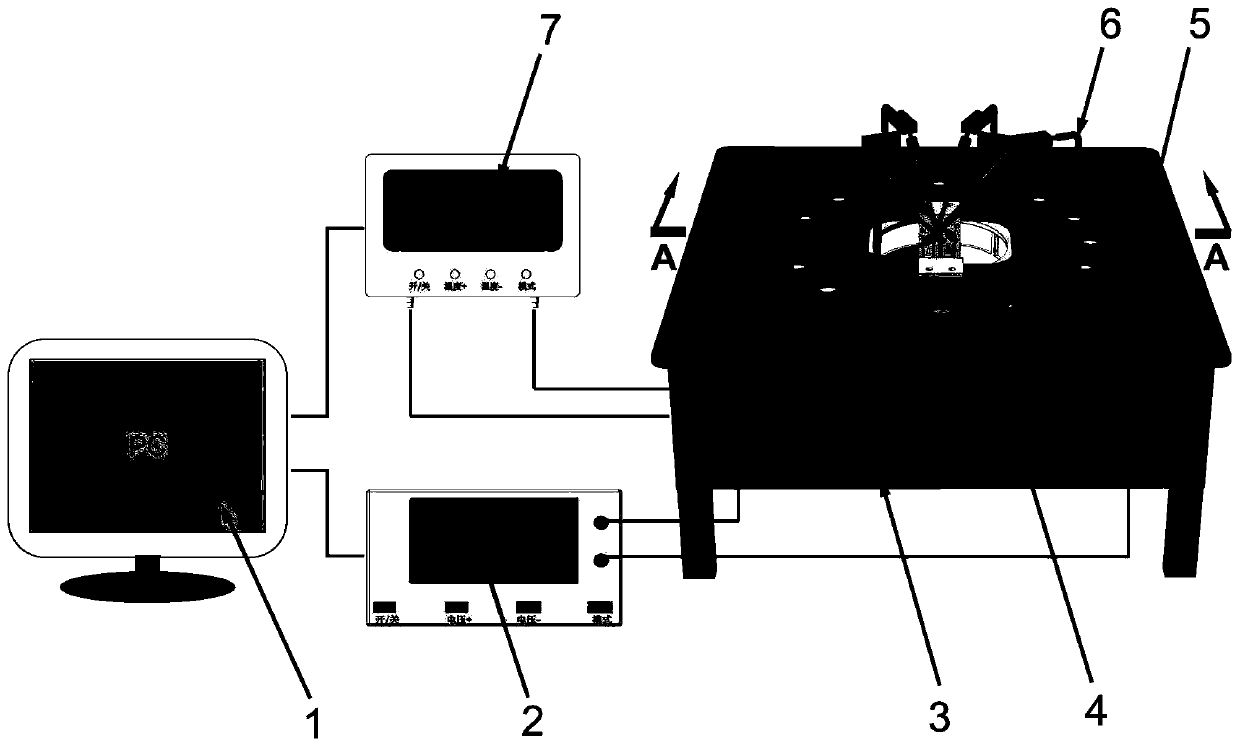

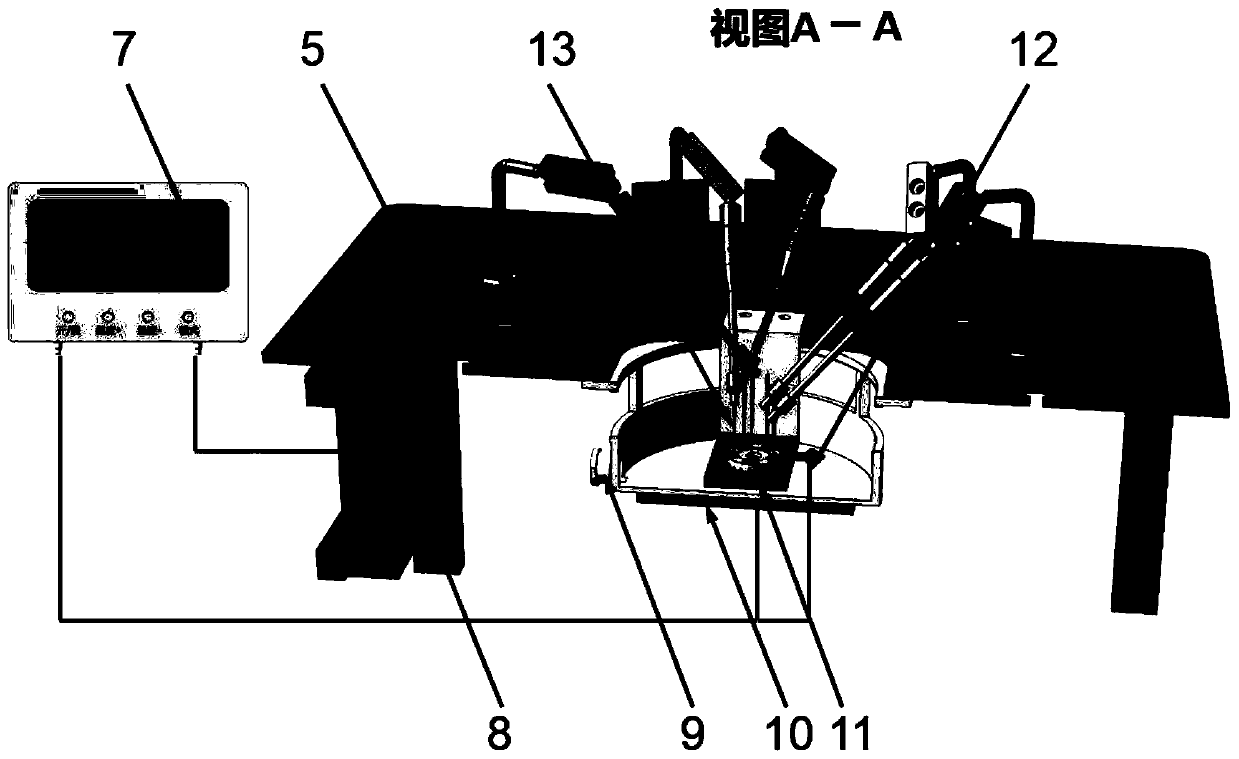

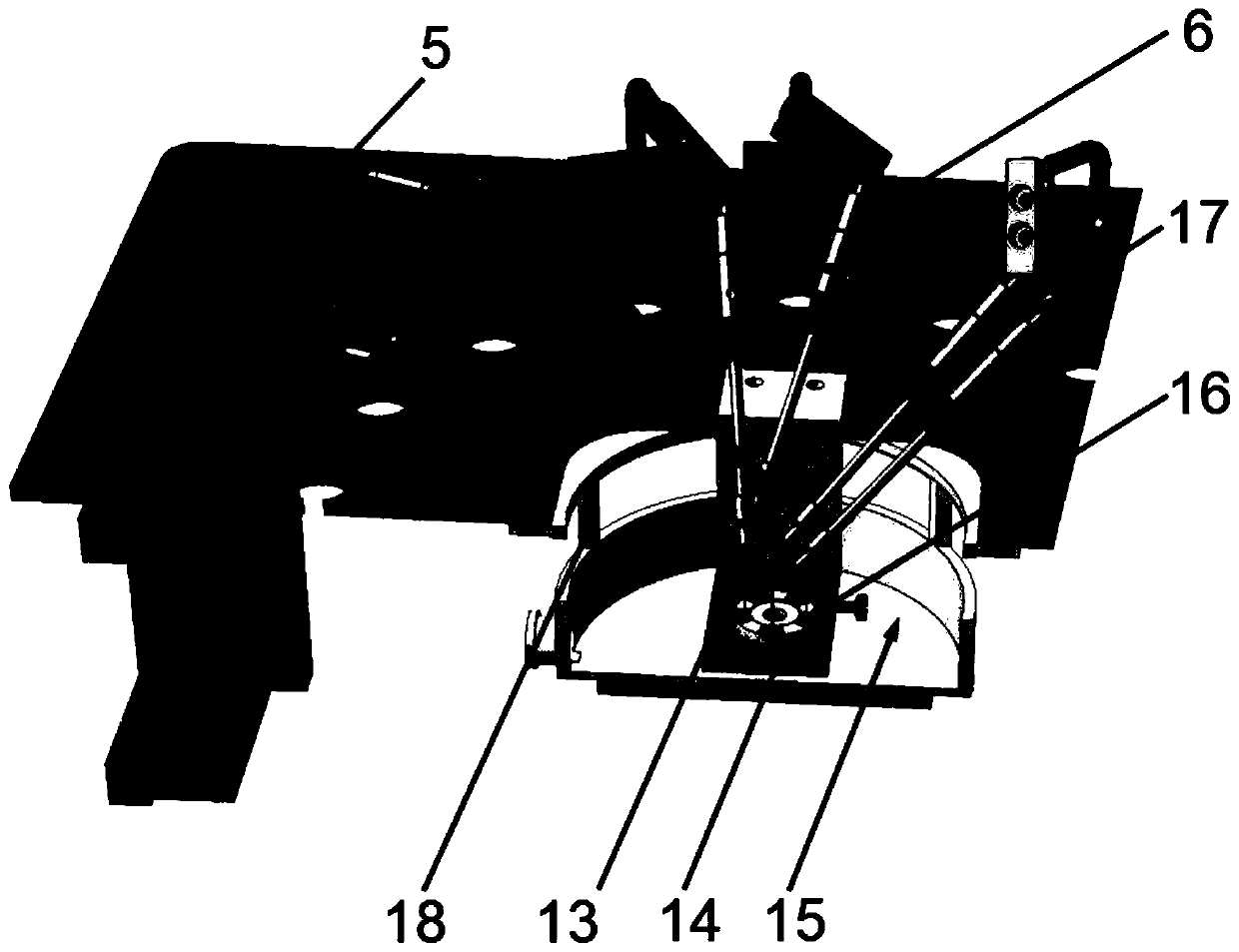

[0042] Such as Figure 1-Figure 4 As shown, the PC host computer 1 is connected to the high voltage generator 2 and the temperature control unit 7 to control the total output voltage of the high voltage generator 2 and the time variation curve of the polarization temperature. The high-voltage generator 2 is connected in parallel with the fixed end 19 of the voltage controller 3; the lower electrode connection plate 11 is connected with the sliding end 20 of one of the voltage controllers 3, and a high voltage is set to it; several elastic telescopic probes 13 are connected with the rest The sliding end 20 of the voltage controller 3 is connected, and the voltage output of the elastic telescopic probe 13 with different sizes is realized by adjusting the resistance of the voltage controller 3, and the output voltage acts on the required polarization t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com