Assembly equipment and assembly method of fluid ejector

A fluid injector and assembly equipment technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of injector responsiveness, excessive travel of movable parts, affecting injector performance and other problems, to achieve the effect of improving assembly efficiency and quality, relaxing the tolerance range of concentricity error, and avoiding inconsistent adjustment values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

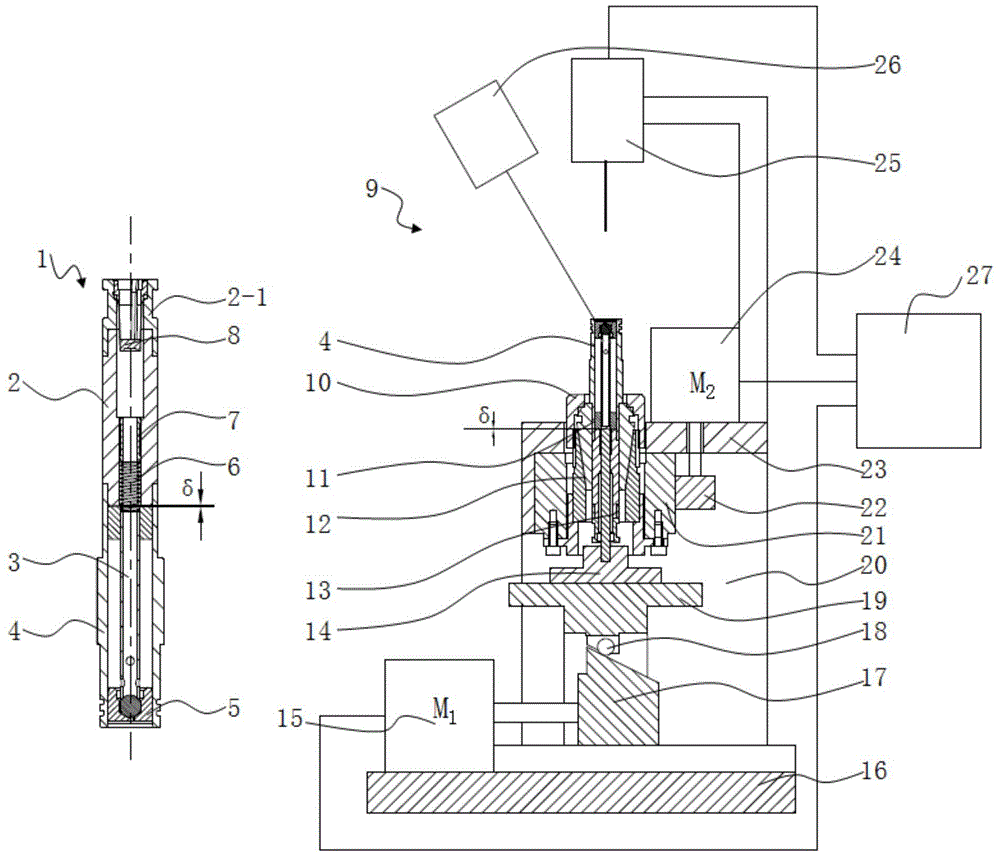

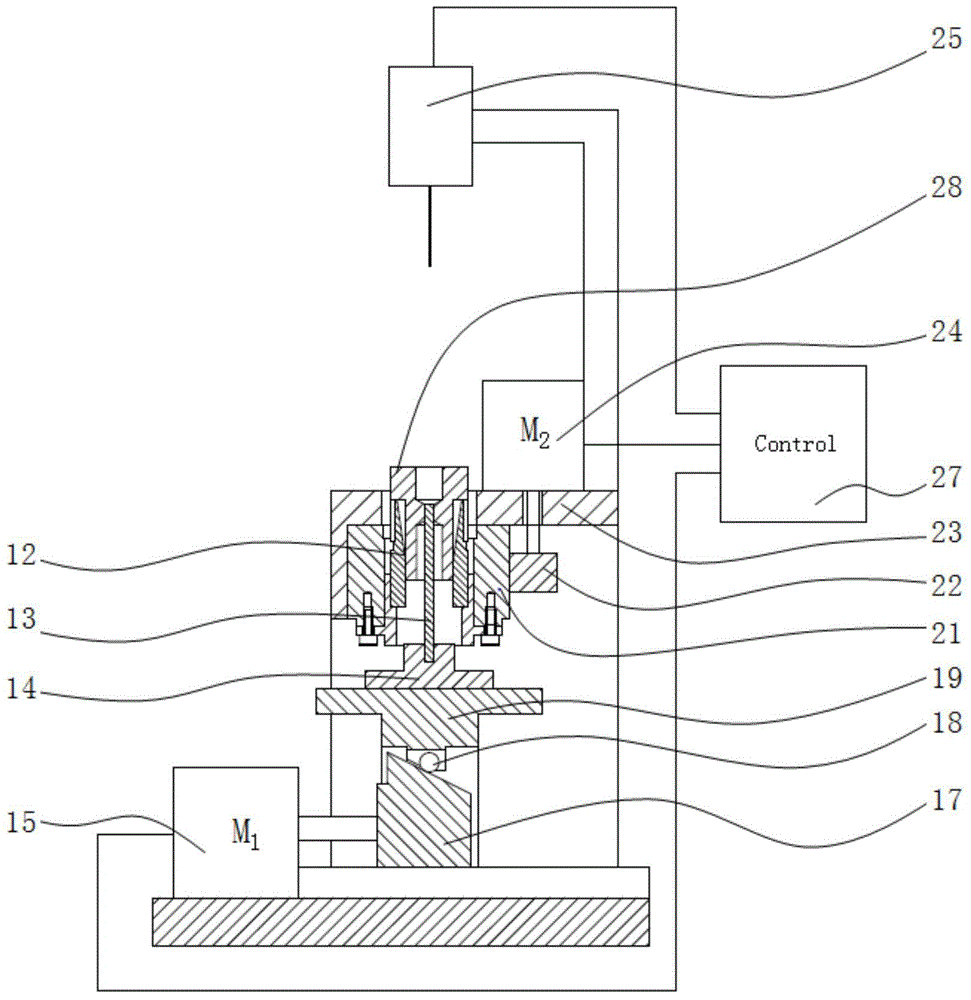

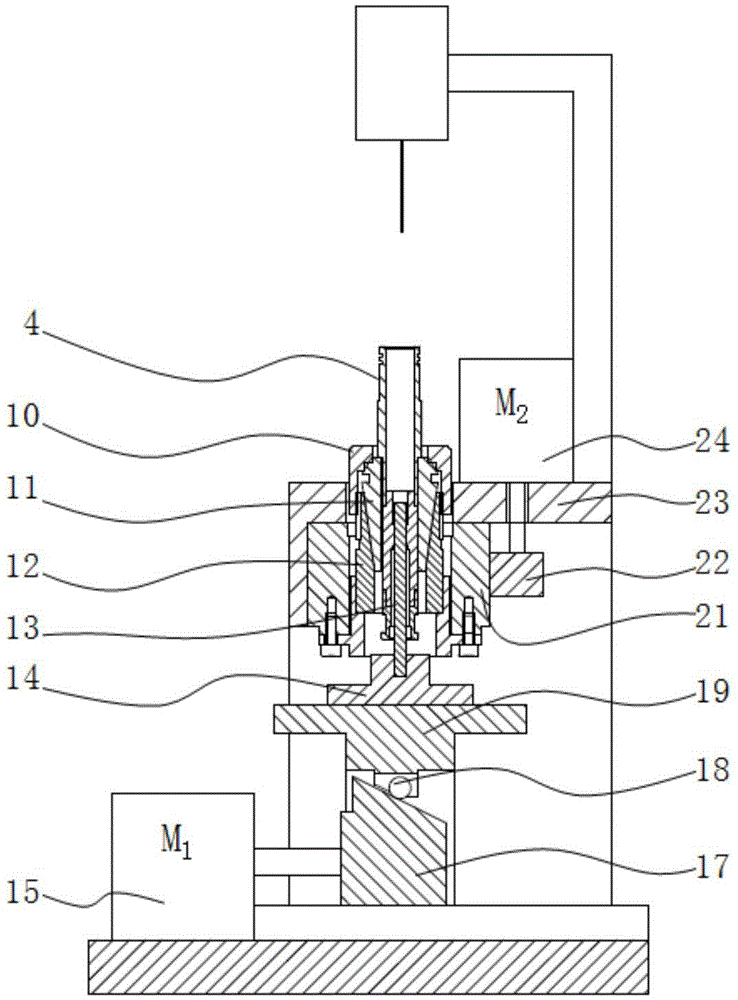

[0036] Such as figure 1 , 4 , The fluid injector shown in 5, 6, and 7 includes components such as a fixed iron core 2, a movable part 3, a valve sleeve 4, a valve seat 5, a spring 6, an elastic cylindrical pin 7, and a filter 8.

[0037] Such as figure 1 , 2 , 3, 5, and 6 show the assembly equipment (9), including the ejector rod 13, the ejector rod seat 14, the lifting motor 15, the lifting displacement platform 19, the rotating motor 24, the displacement sensor 25, the displacement controller 27, etc., the described Lifting motor 15 drives the stroke of lifting displacement platform 19 to be greater than the distance between the lower end surface of movable part 3 and the top surface of push rod 13 when the zero point of displacement sensor 25 is set and the sum of the set lift of movable part 3.

[0038] The position of the top surface of the push rod 13 is lower than the lower end surface of the movable part 3 before the zero position of the displacement sensor 25 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com