Patents

Literature

101results about How to "Reduce assembly efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

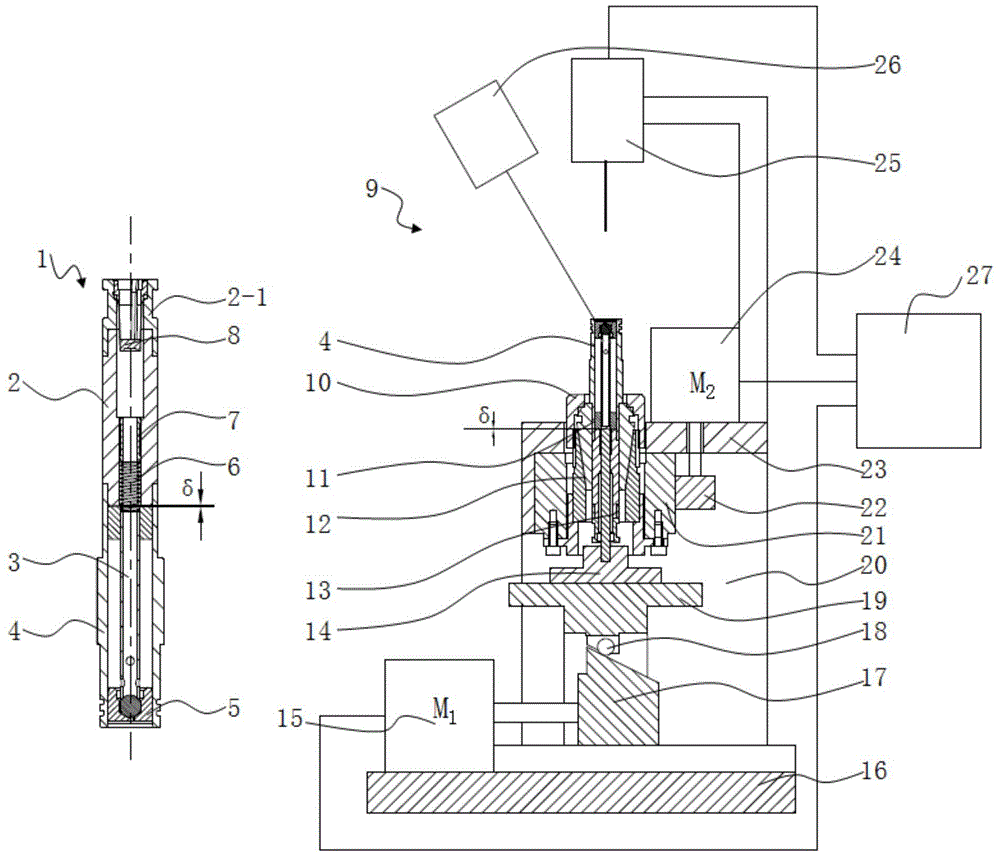

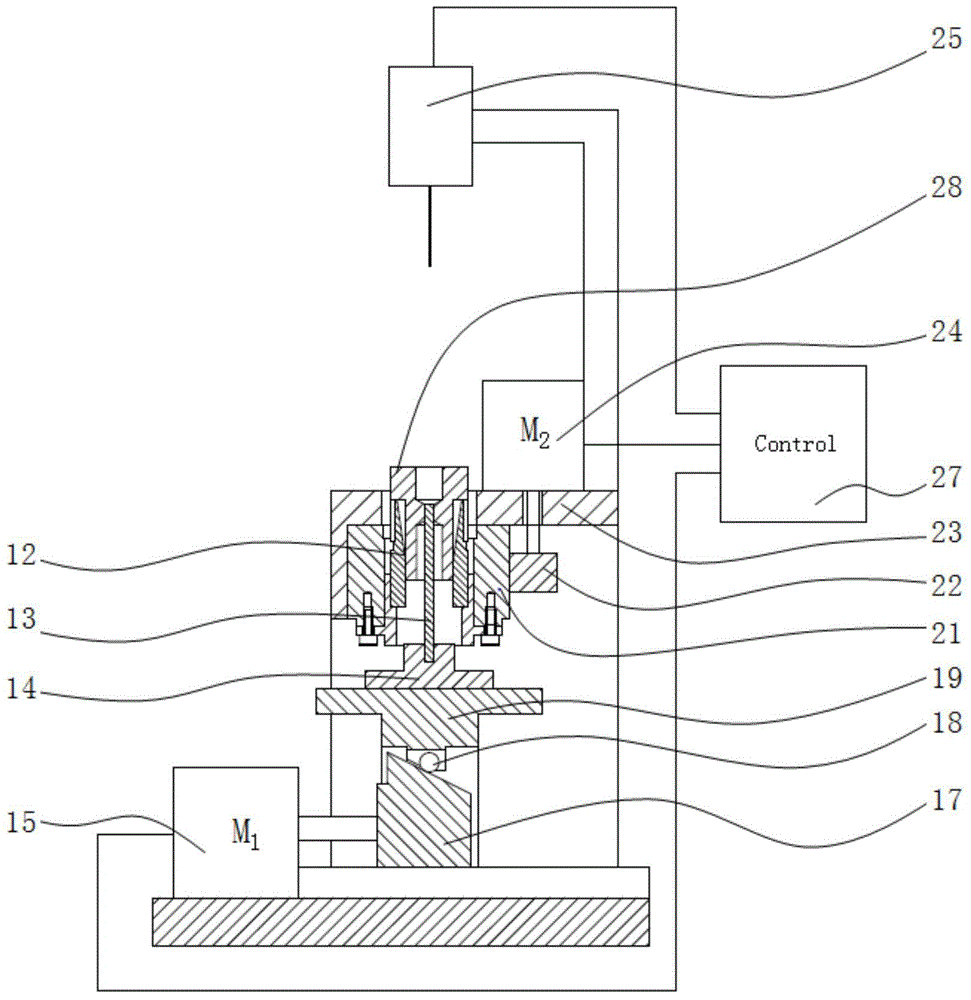

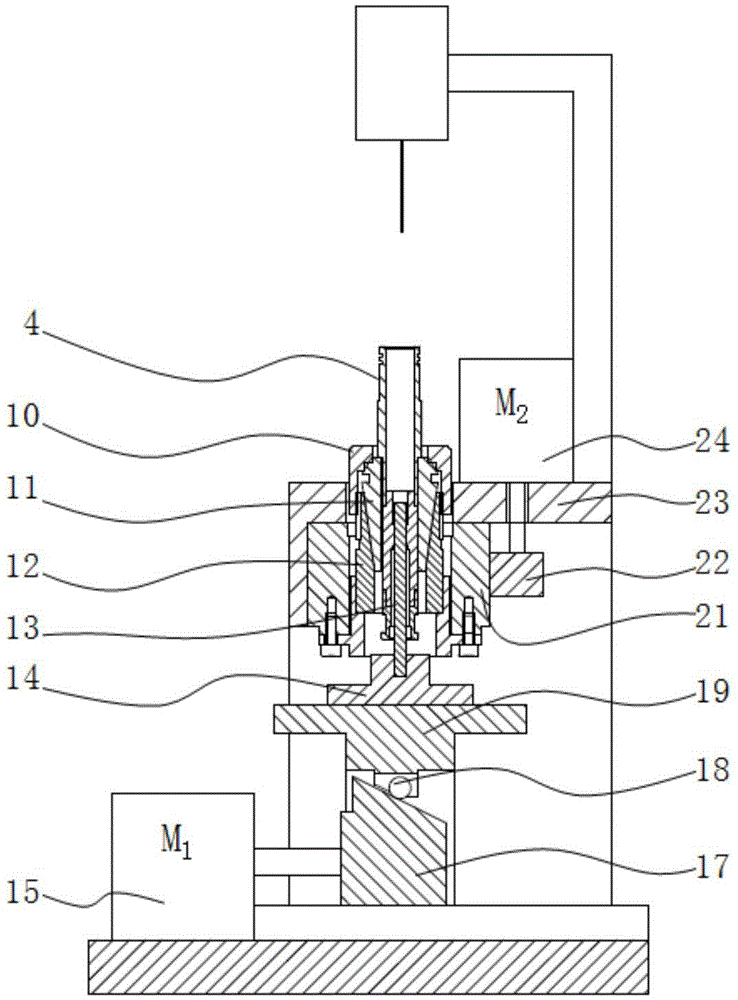

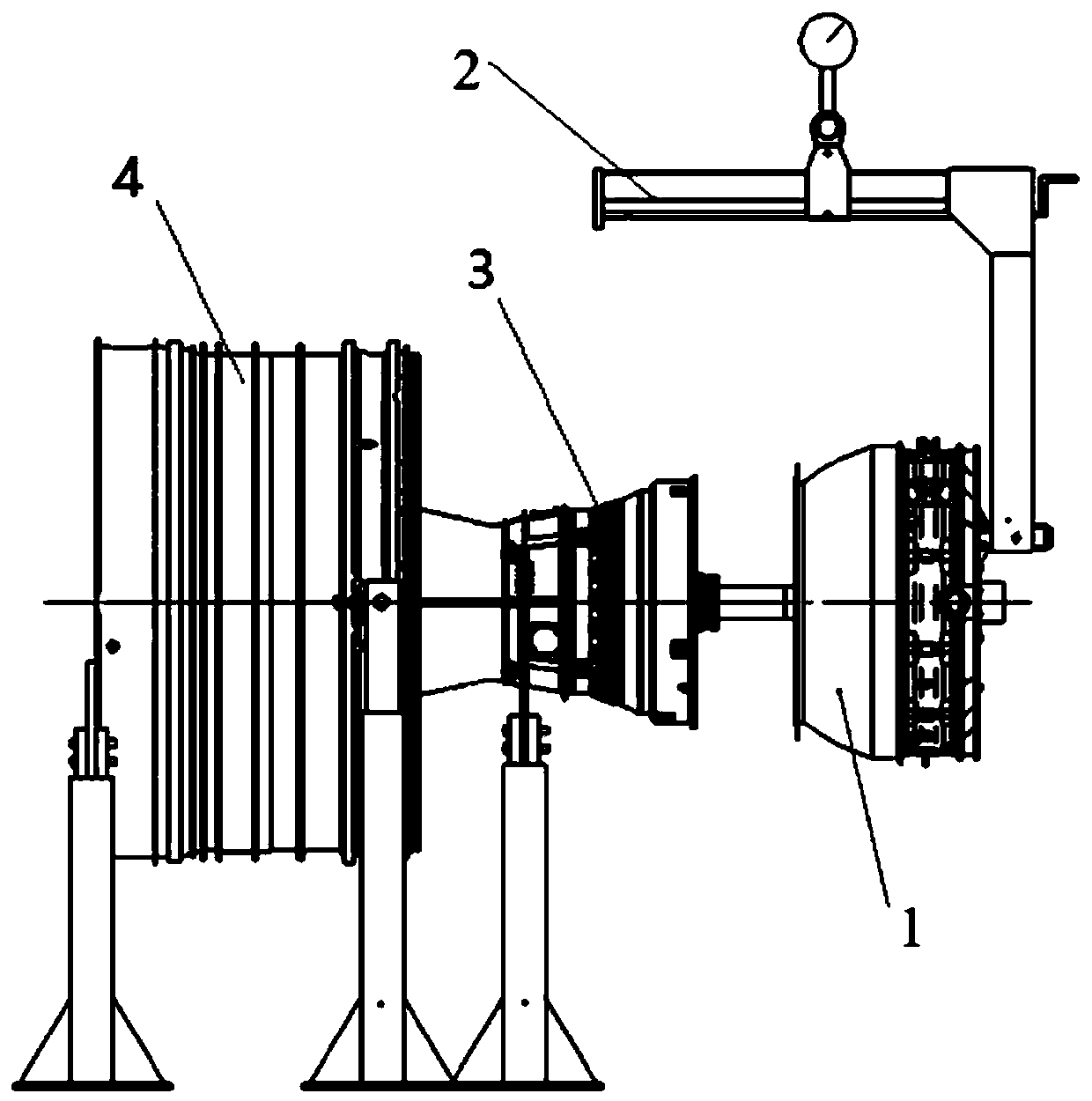

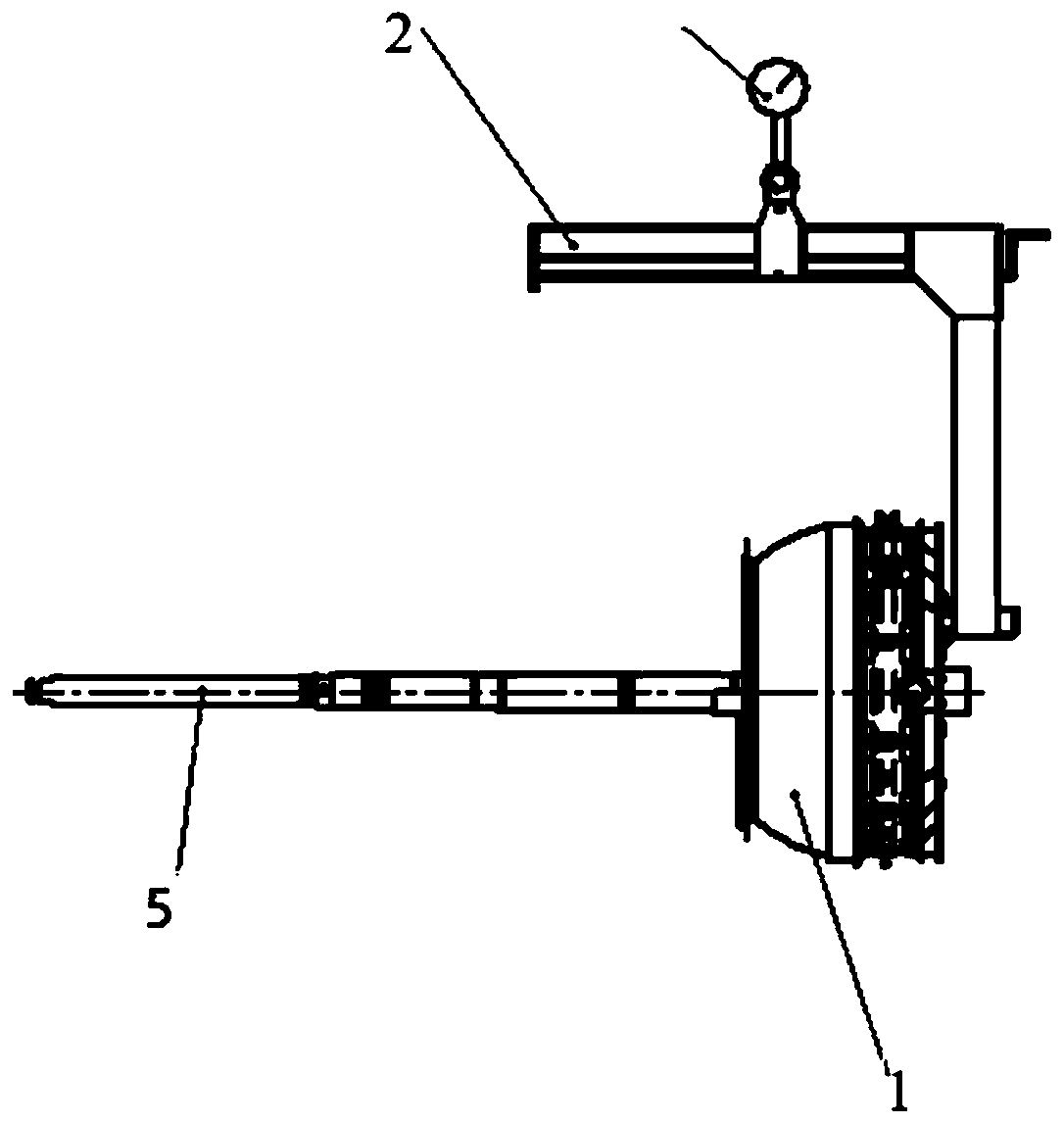

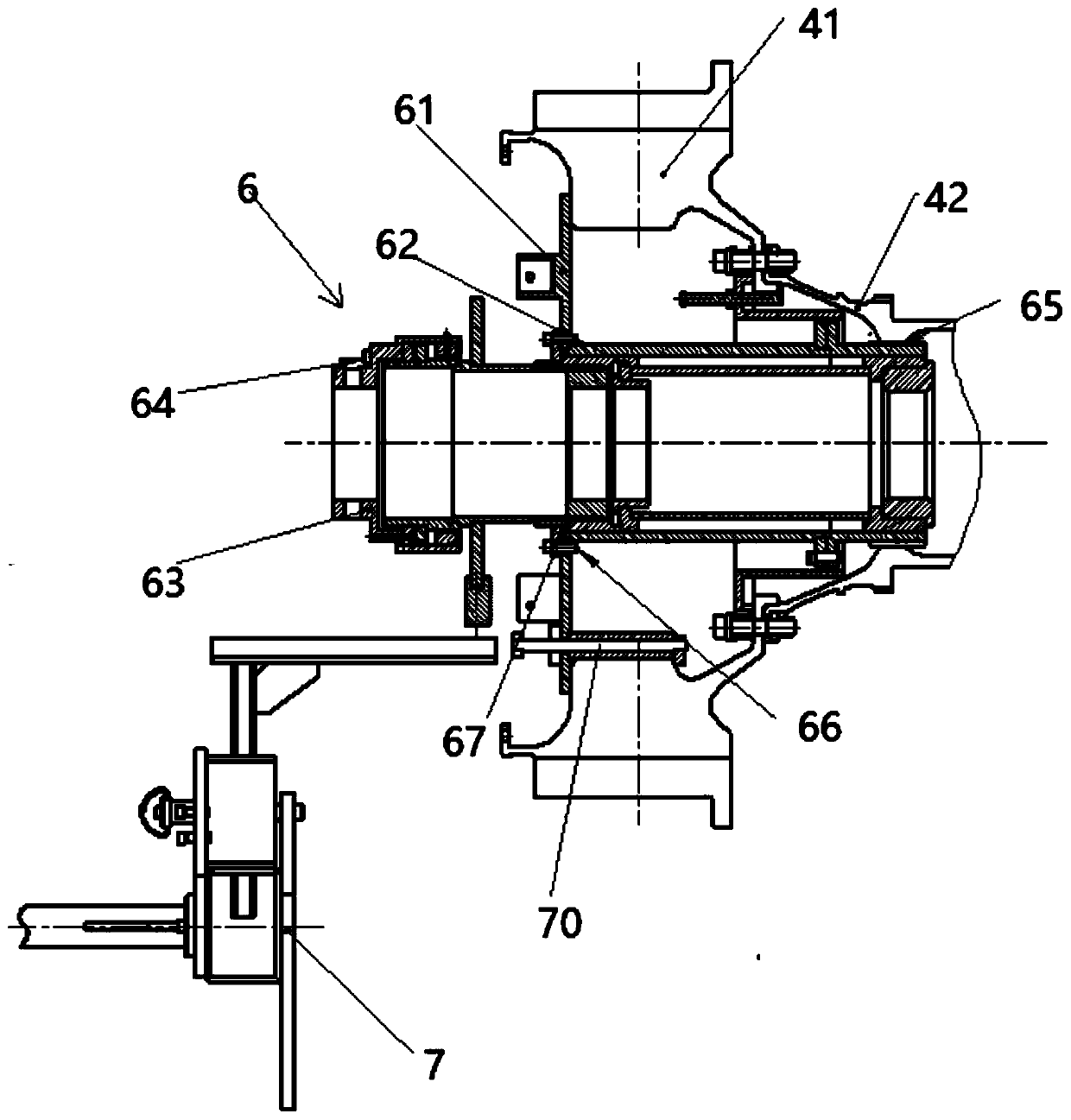

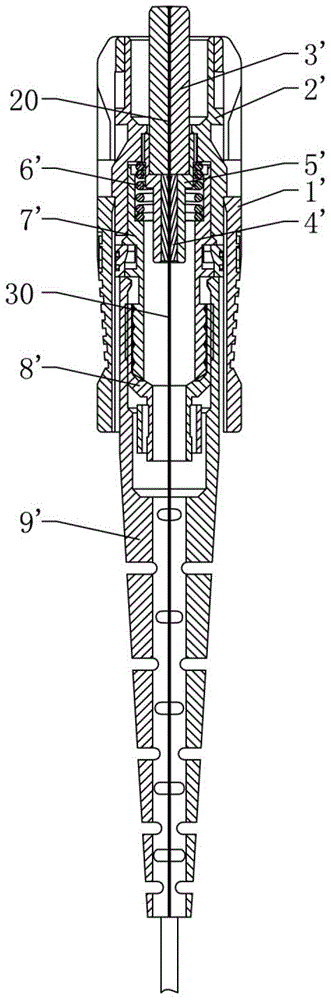

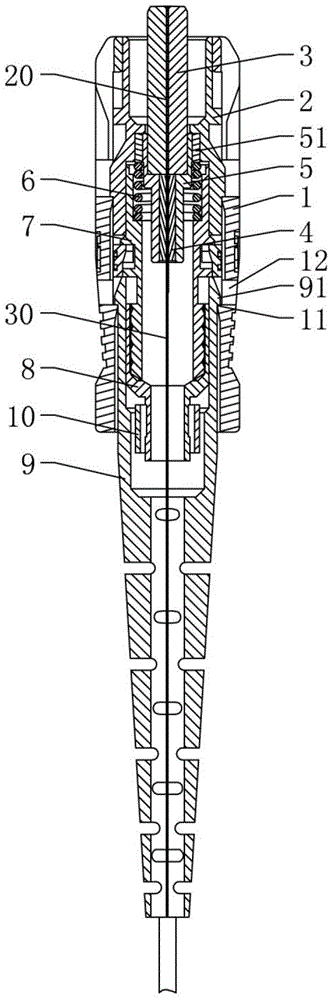

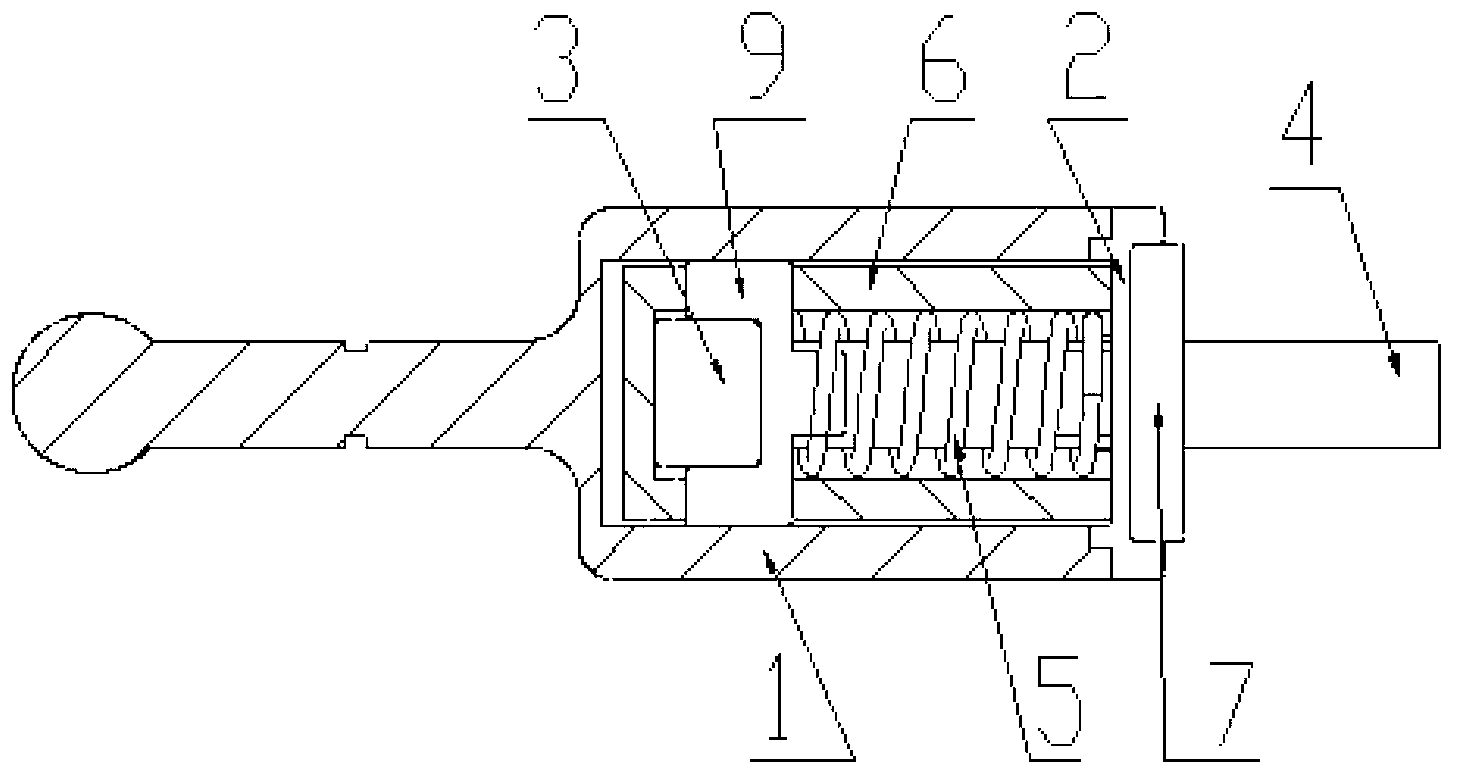

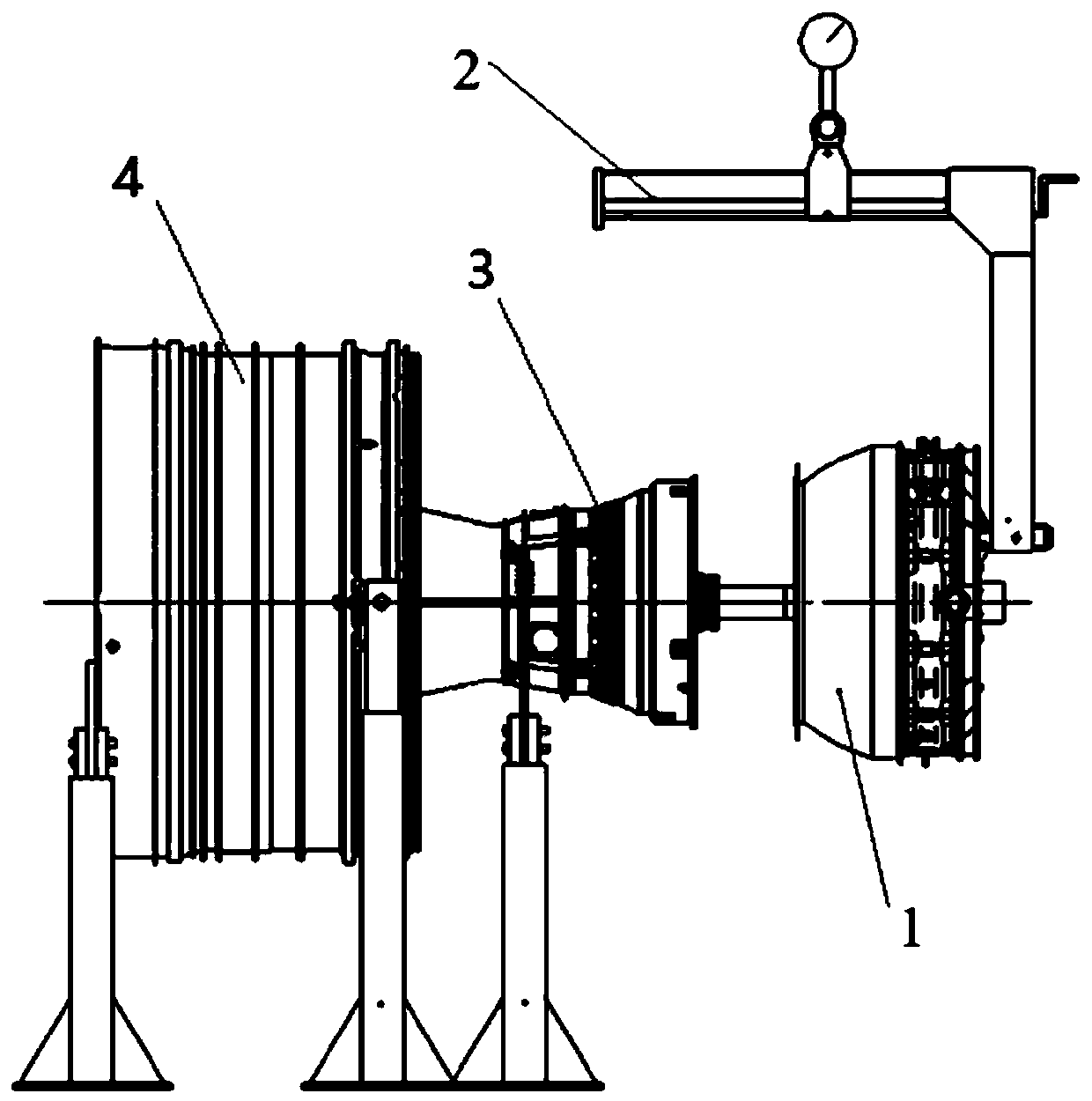

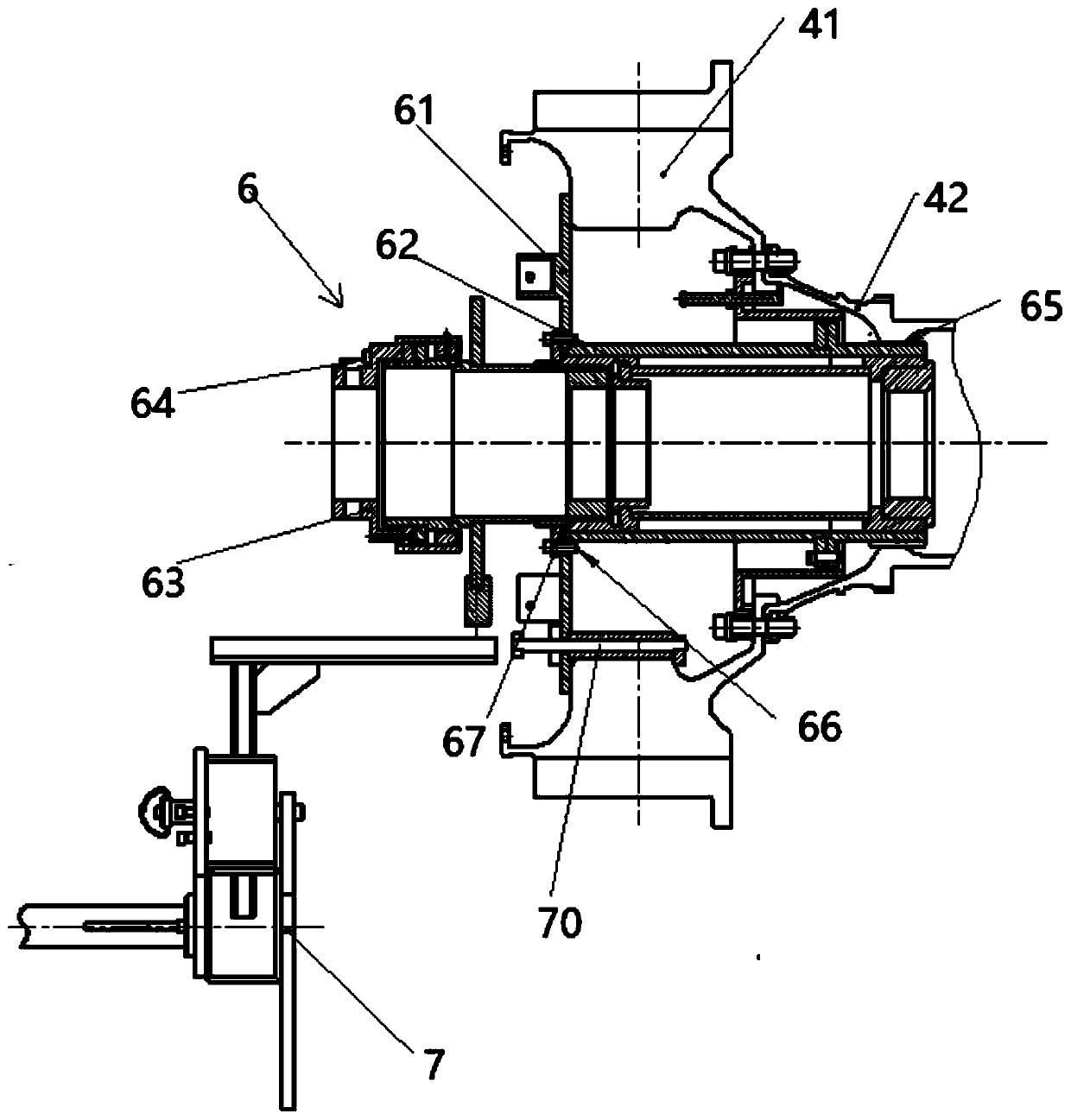

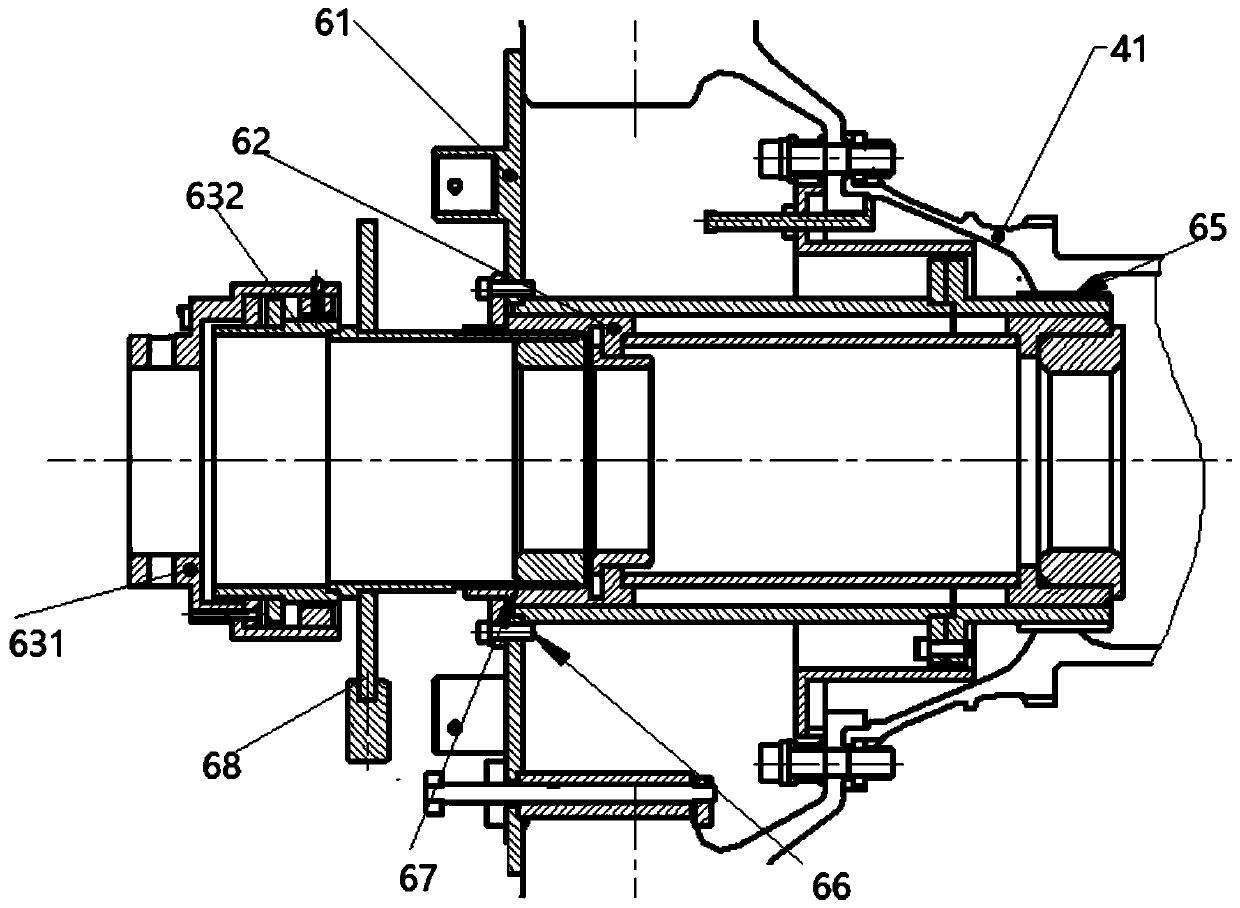

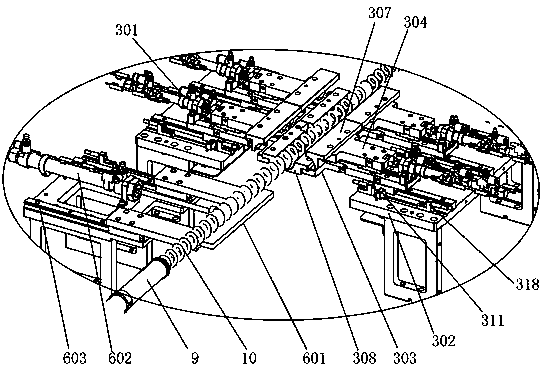

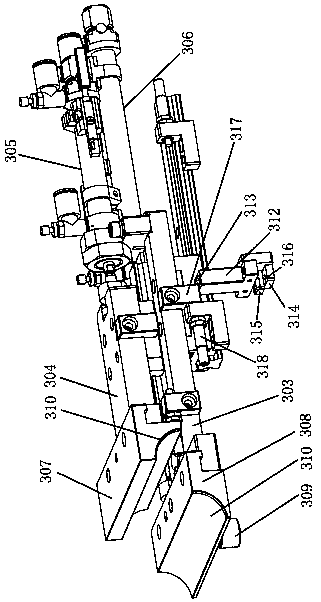

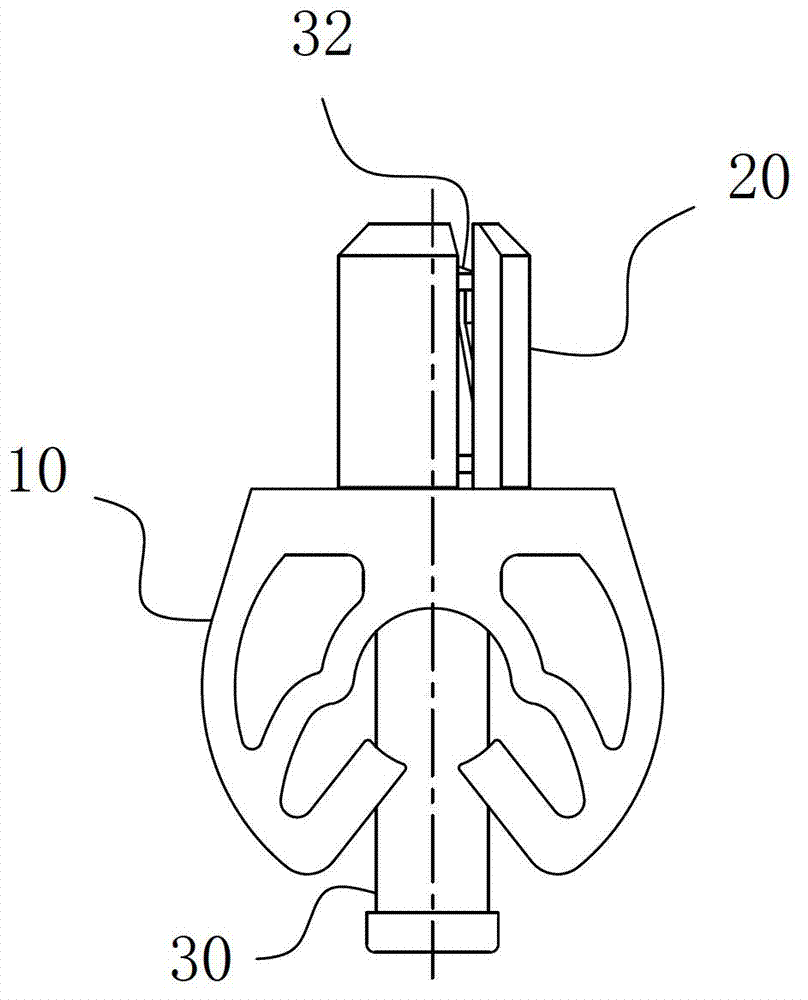

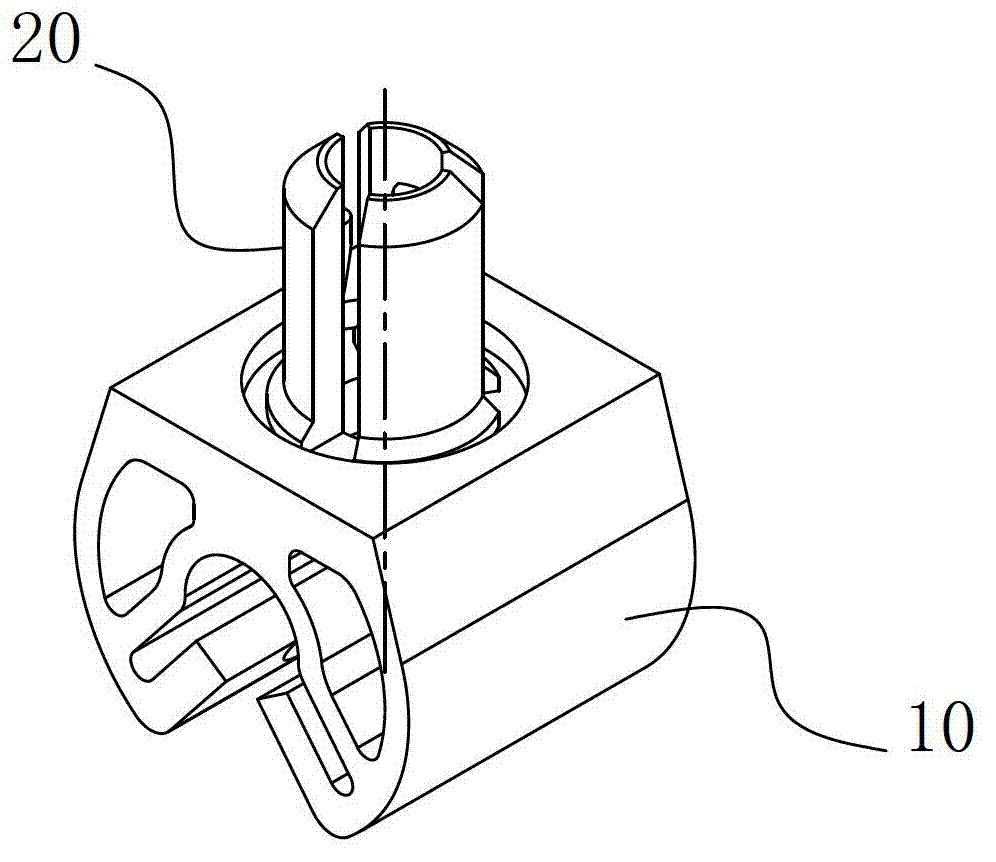

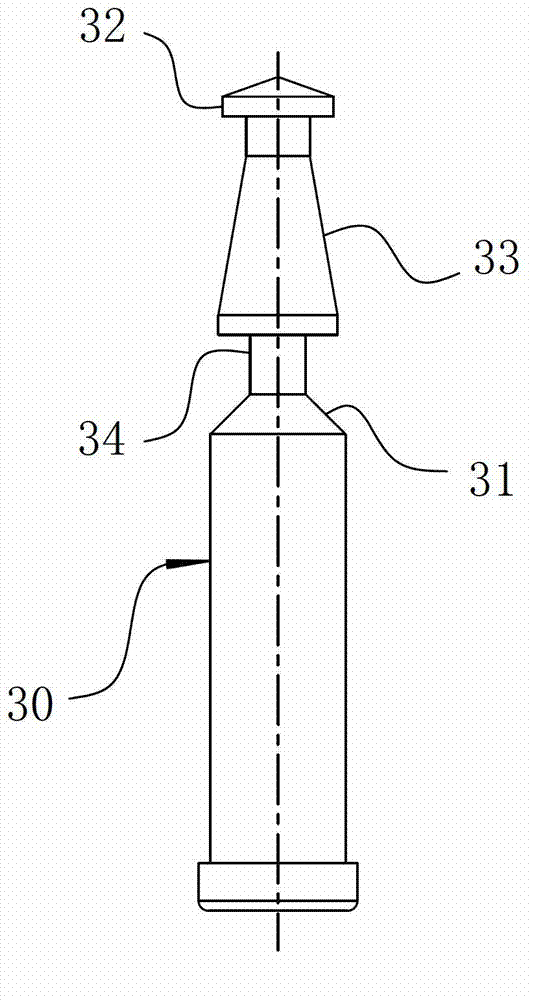

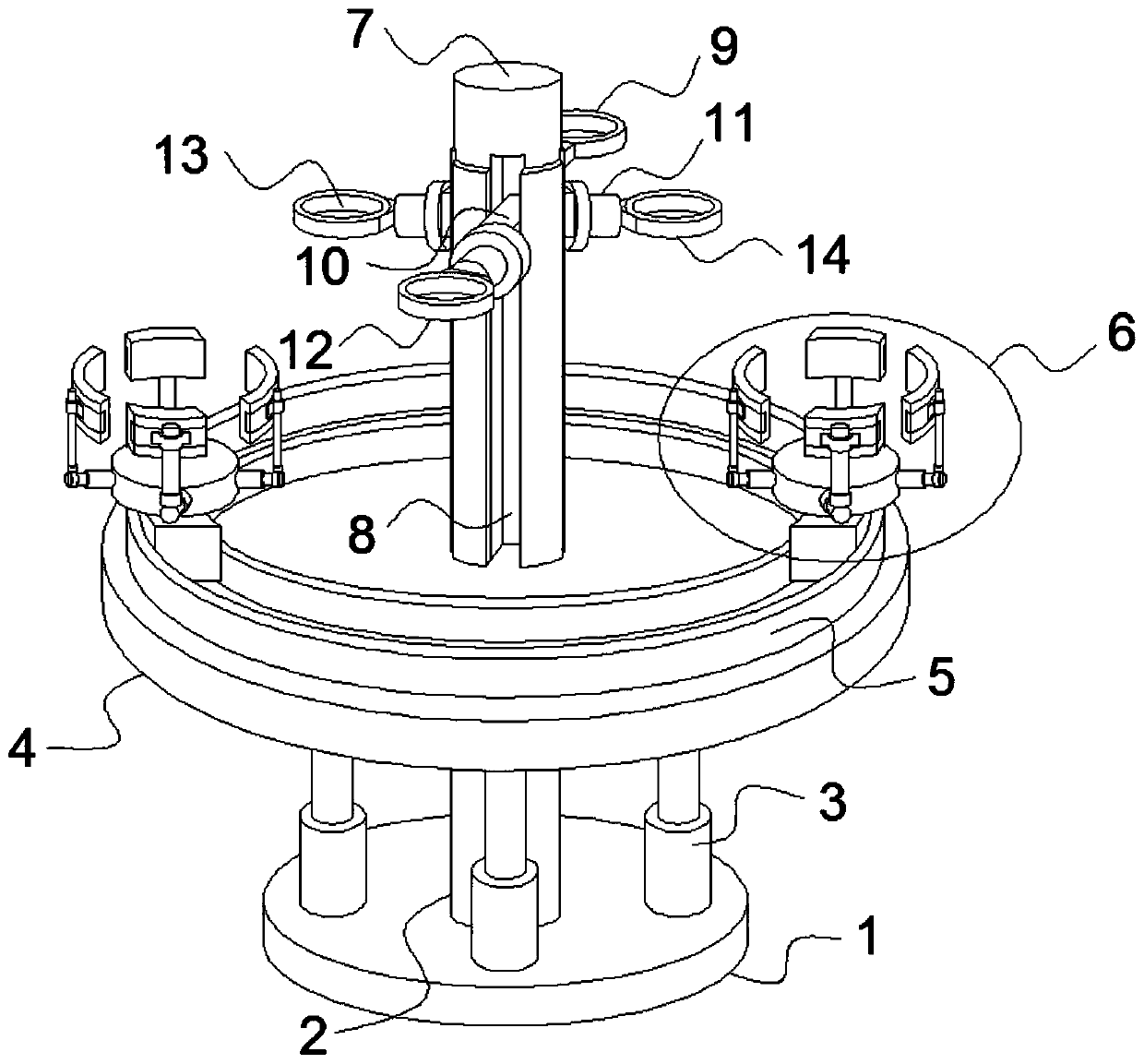

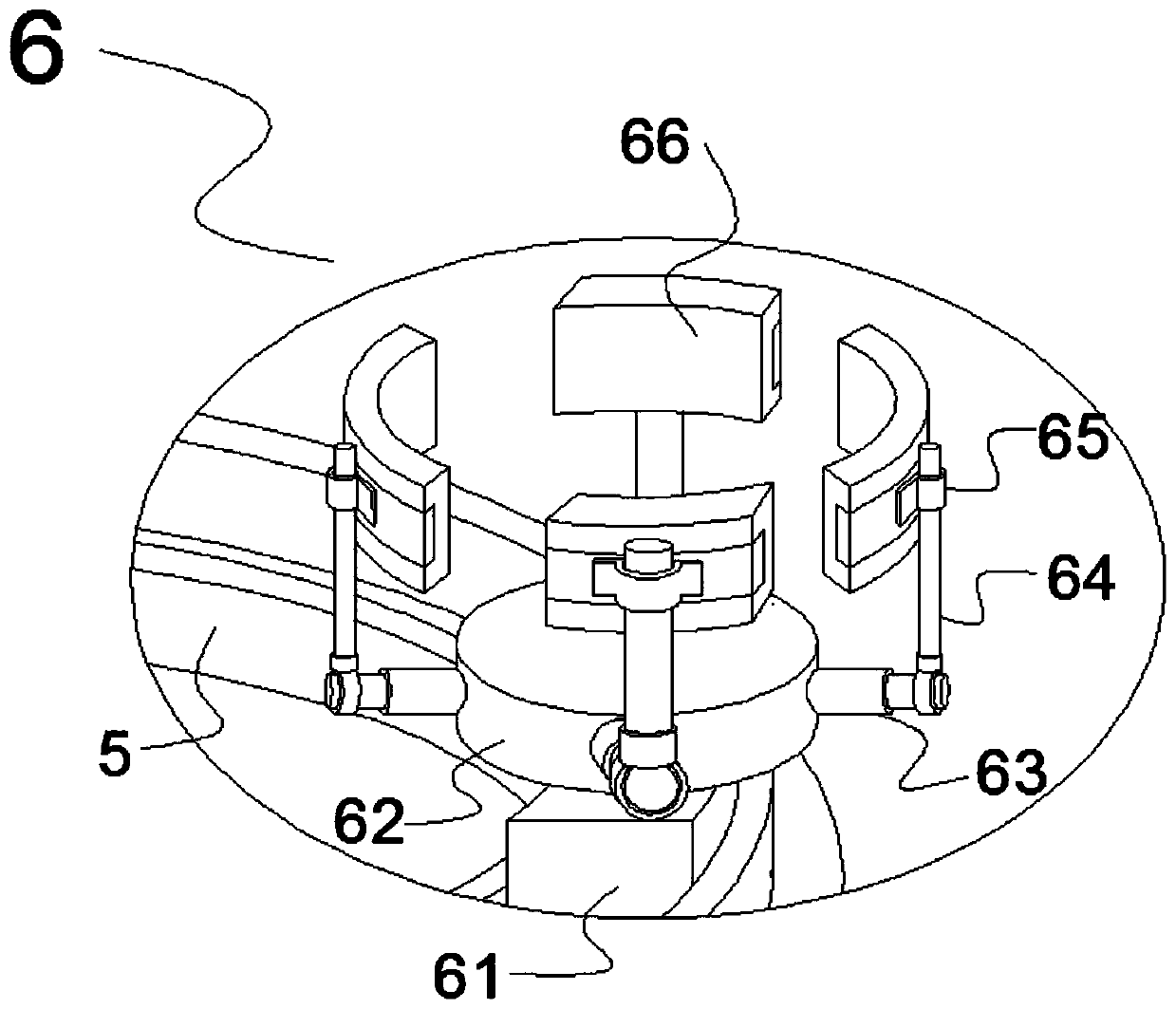

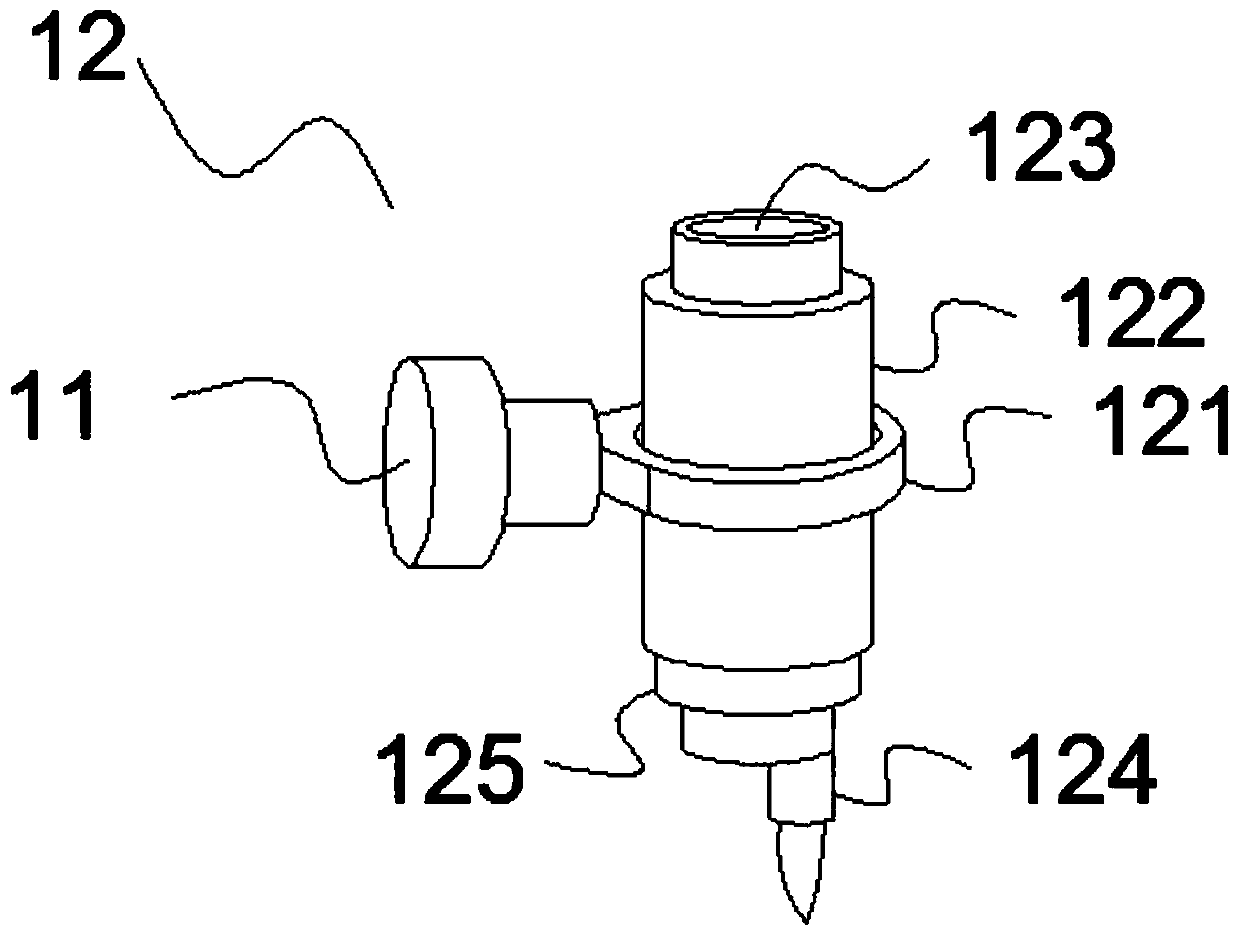

Assembly equipment and assembly method of fluid ejector

ActiveCN104858548AAvoid the problem of inaccurate lift adjustmentAvoid setpointLaser beam welding apparatusEngineeringDisplacement control

The invention discloses assembly equipment of a fluid ejector. The assembly equipment comprises a rack, a lifting mechanism, a clamping and rotating mechanism, a displacement sensor, a displacement controller and welding equipment, wherein the lifting mechanism is arranged at the lower part of the rack; the clamping and rotating mechanism is arranged above the lifting mechanism; the displacement sensor is arranged above the clamping and rotating mechanism; the welding equipment is arranged on one side of the clamping and rotating mechanism. The invention further discloses an assembly method of the fluid ejector. The assembly method comprises the following steps: firstly, pressing the other end, where an ejecting opening is formed, of a valve sleeve in the outer circumference at the top end of the a fixed iron core for welded fixing; secondly, adjusting the lifting range of a movable part through the displacement sensor and the displacement controller, and conducting welded fixing on a valve seat; finally, mounting the other parts. The assembly equipment and the assembly method have the advantages that the lifting range adjustment precision and the lifting range consistency of the movable part of the fluid ejector are obviously improved, so that the flow measurement precision and the responsiveness of the fluid ejector are guaranteed, and the assembly efficiency and quality are greatly improved; meanwhile, the allowable concentricity error ranges of armature and sealing parts can be widened, so that the difficulties of part processing and assembly are reduced.

Owner:CHINA FAW LIMITED WUXI FUEL INJECTIONEQUIP RES INST +2

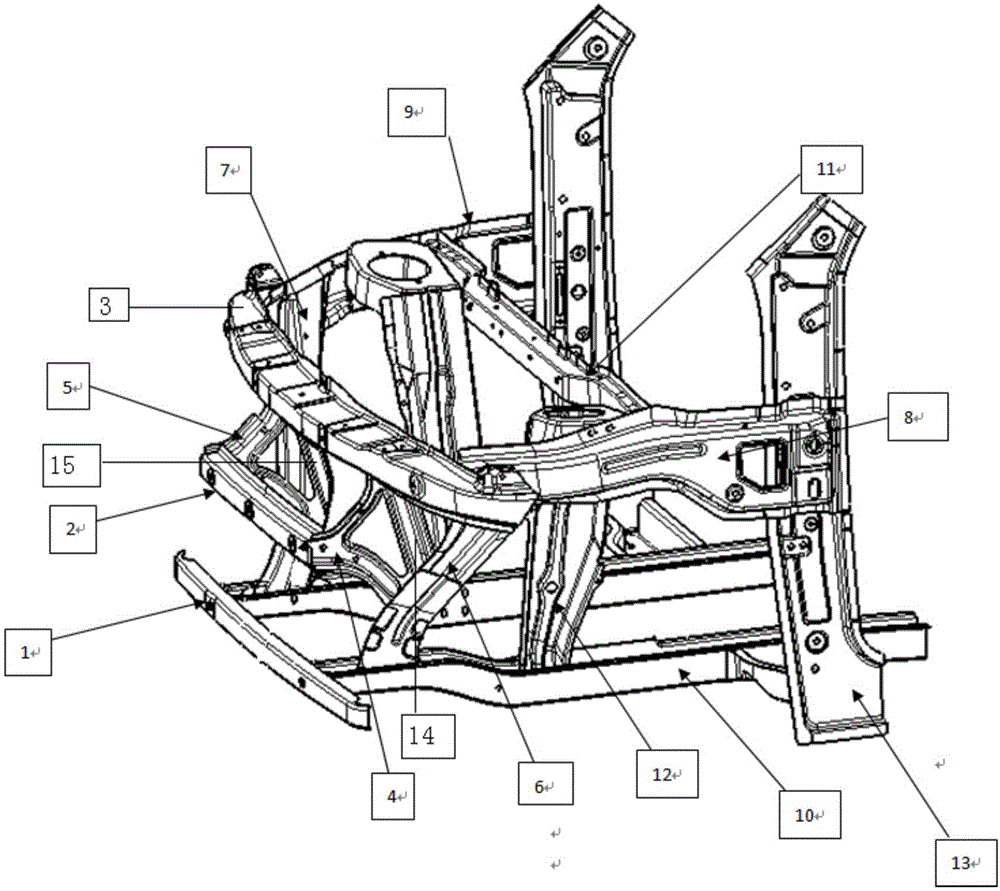

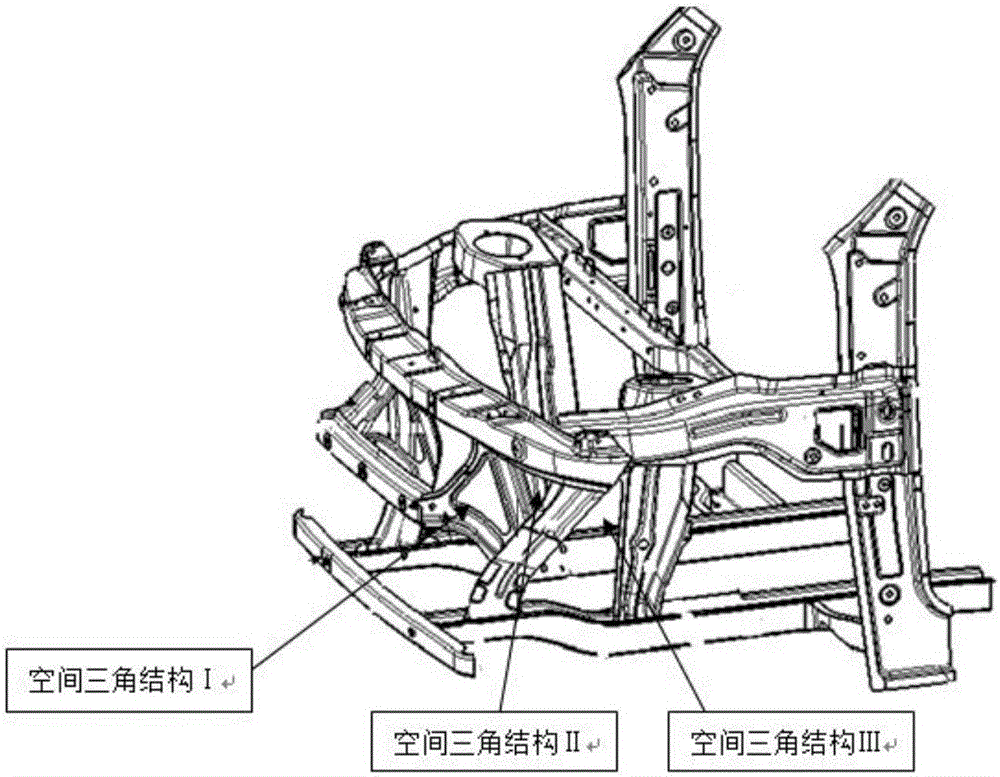

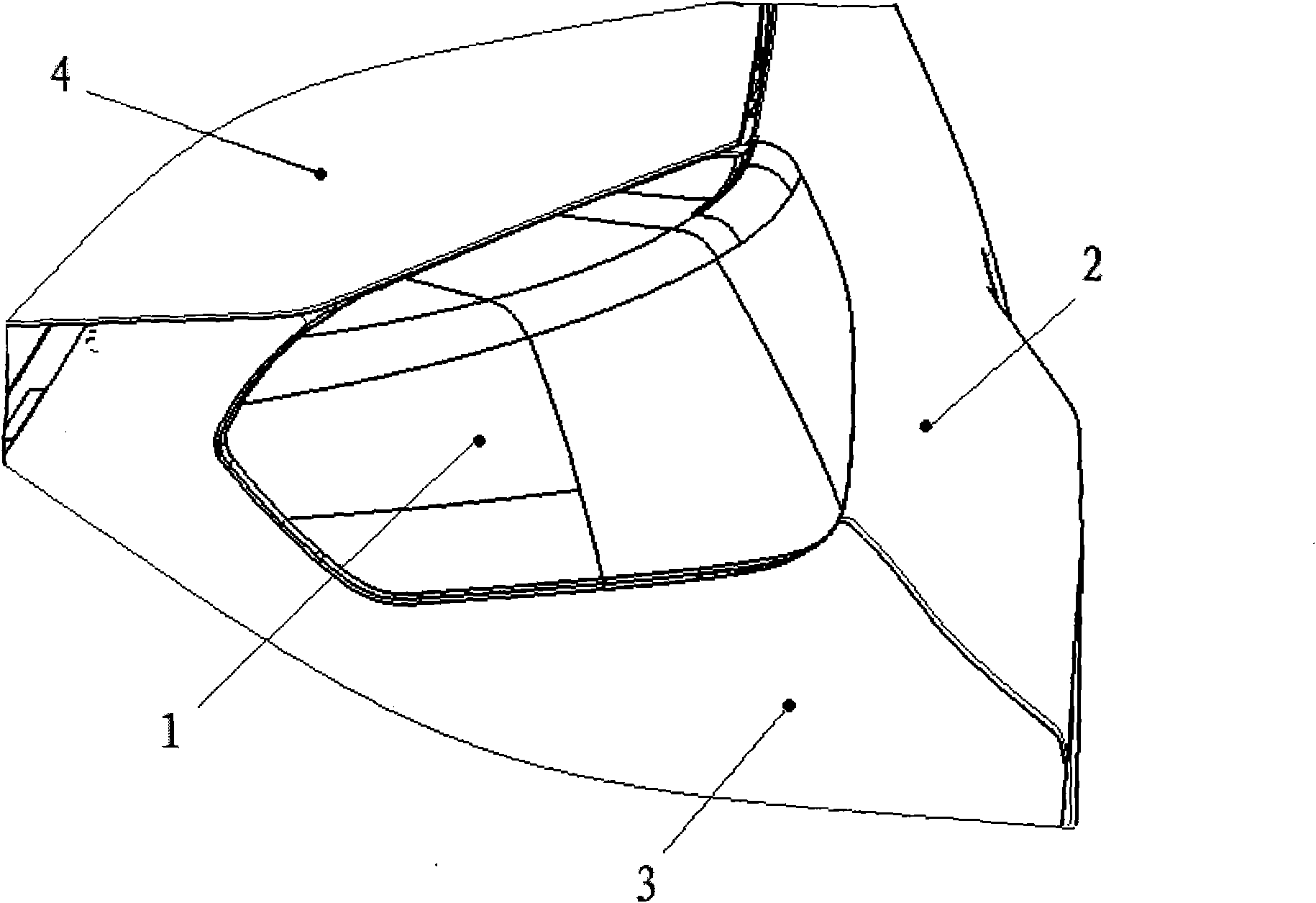

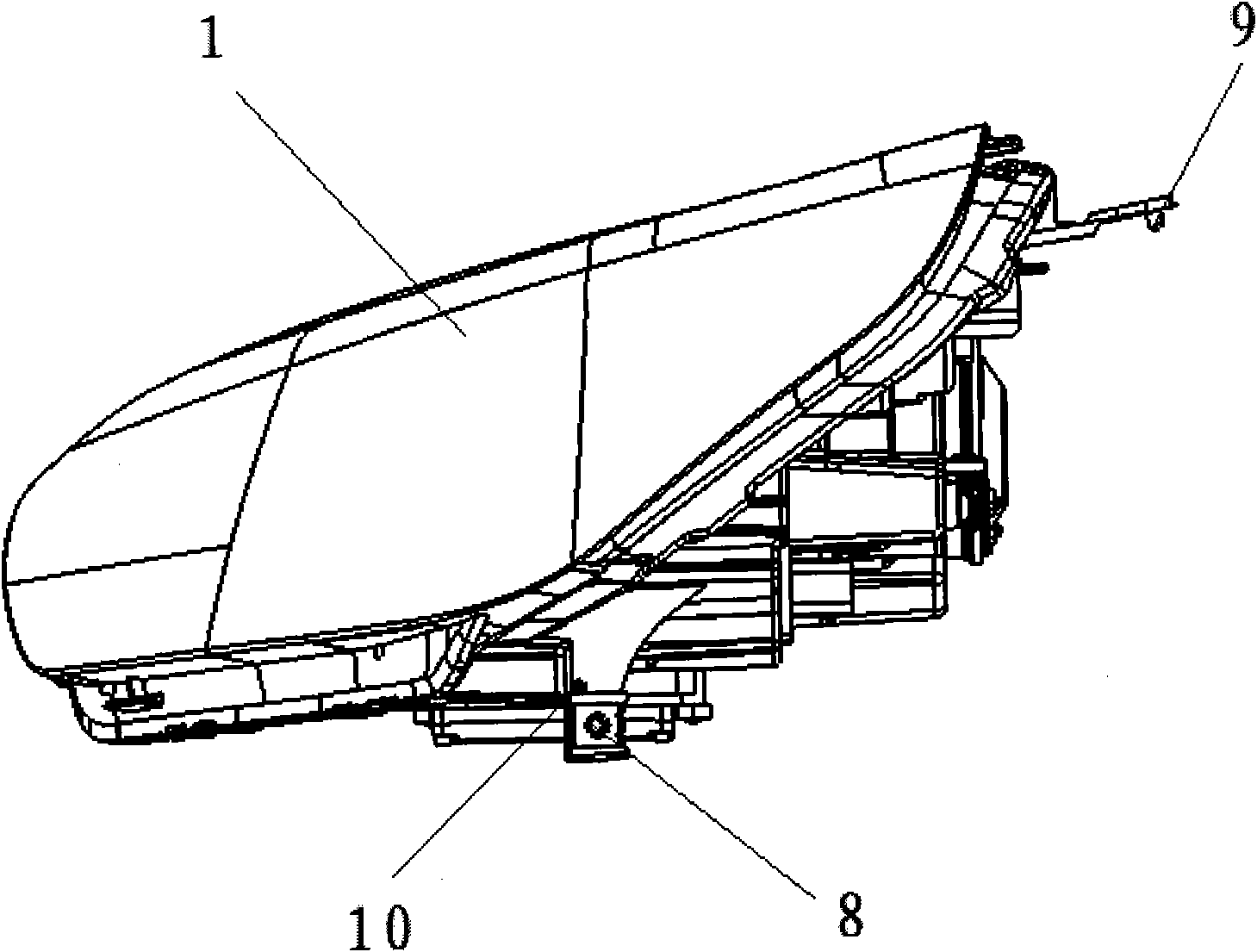

A front cab anti-collision structure of small electric vehicle

ActiveCN106240641AImprove protectionAnti-collision structure optimizationUnderstructuresVehicle frameElectric vehicle

The invention discloses a front cab anti-collision structure of a small electric vehicle. The anti-collision structure is composed of a lower anti-collision beam, a middle anti-collision beam, a front cab cross beam, anti-collision connecting pieces, oblique beams, front cab longitudinal beams, vehicle frame longitudinal beams, a front wall cross beam, shock absorption installation stand columns, connecting columns and the like in a welded mode. Three spatial triangular structures are formed, the collision energy is transferred to a vehicle body and a vehicle frame, the front impact is reduced, and pedestrian safety and passenger safety can be achieved more effectively.

Owner:HENAN HONGRUI SHIYING VEHICLE

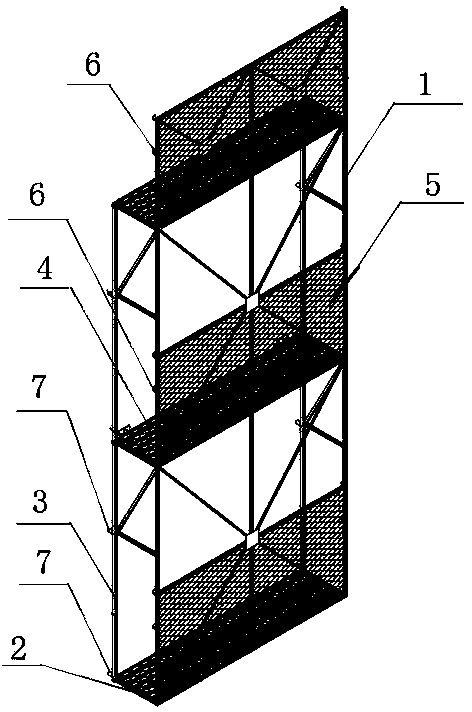

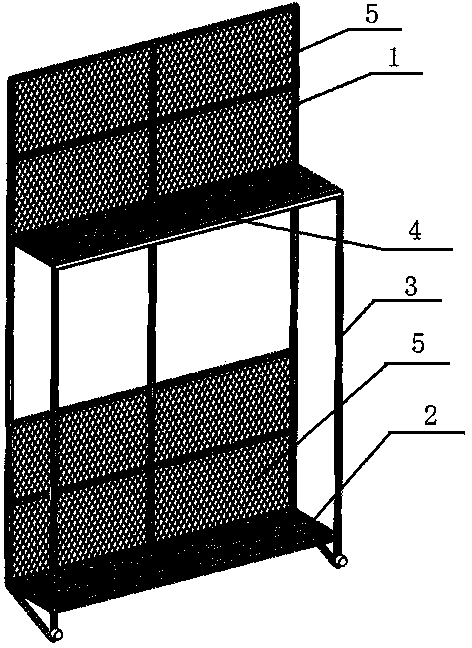

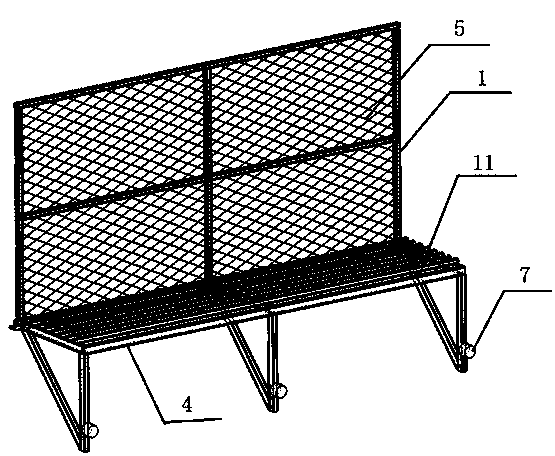

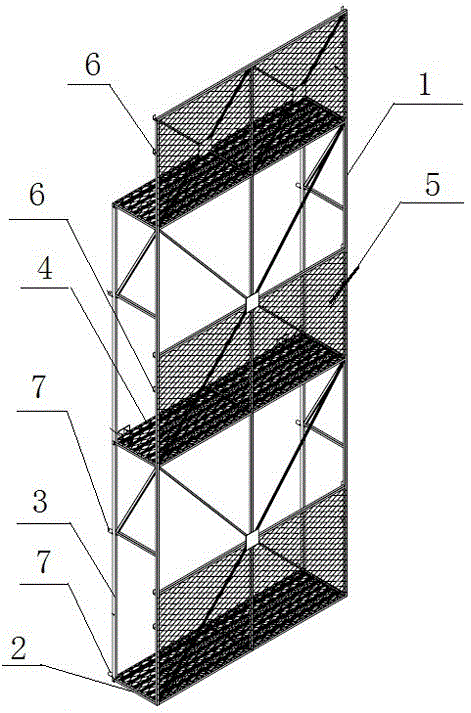

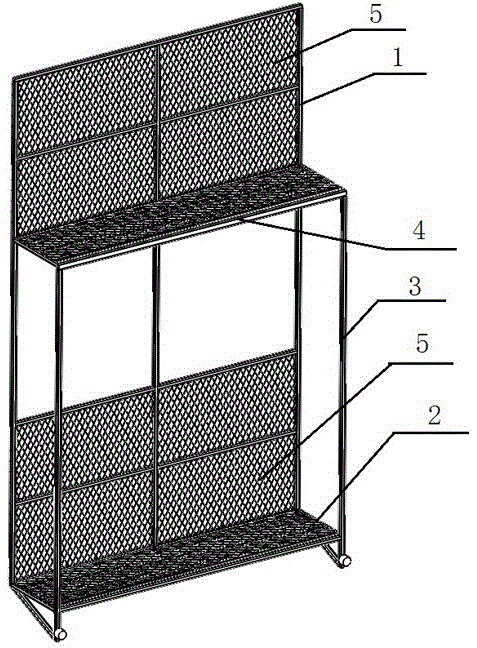

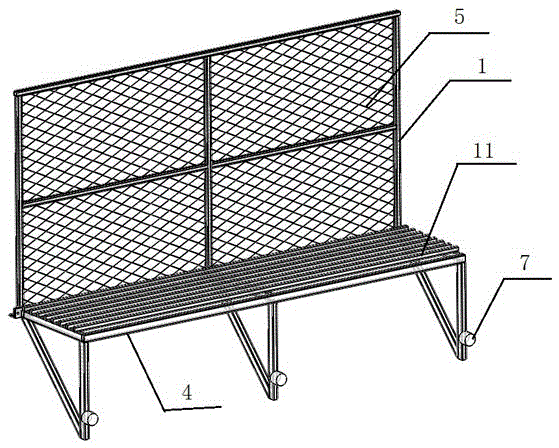

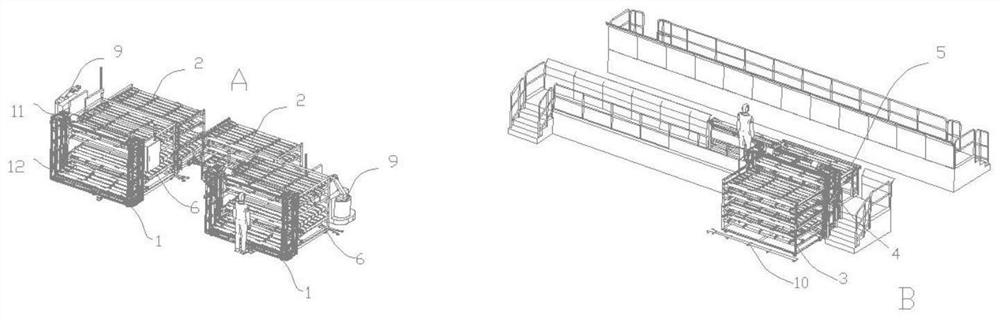

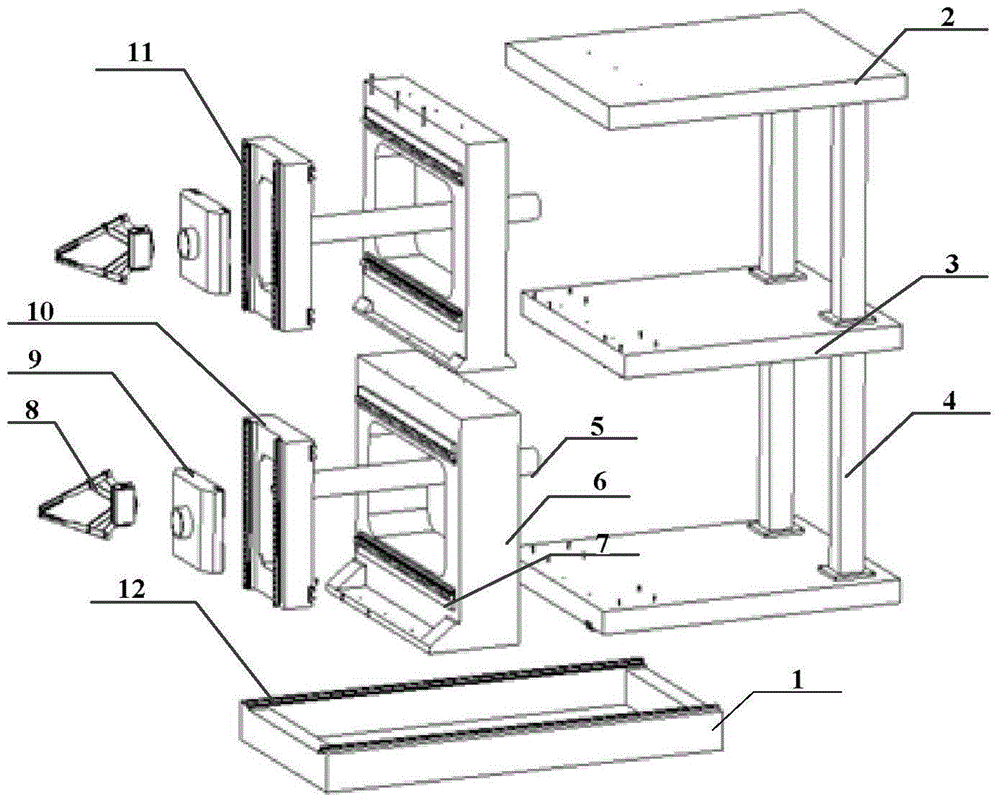

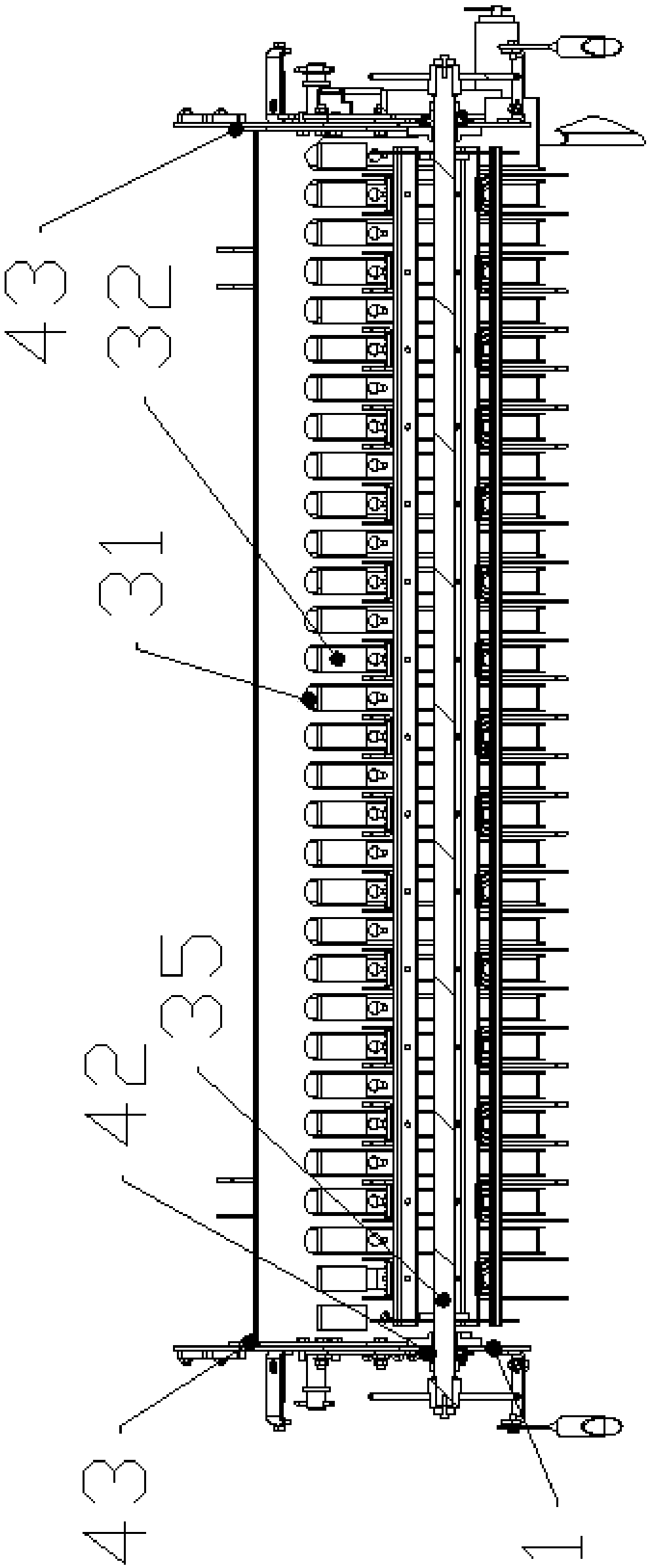

Externally-mounted work platform for fabricated building and method for operating externally-mounted work platform for fabricated building

ActiveCN104131688AImprove assembly efficiencyReduce assembly efficiencyBuilding material handlingScaffold accessoriesIndustrial engineeringTwo layer

The invention provides an externally-mounted work platform for a fabricated building. The externally-mounted work platform for the fabricated building comprises one or two or more work platform units which are horizontally arranged on the outer side of a prefabricated side fascia, multiple fastening devices which are pre-buried in the prefabricated side fascia, and multiple hook bases which are fixedly connected with the corresponding fastening devices through fastening pieces, wherein each work platform unit comprises a one-layer or two-layer or three-layer or multi-layer framework which is formed by hollow profiles through welding, protective screen or guardrails arranged on the outer sides of all layers of the framework and protective screens or pedals which are arranged on the bottoms of all layers of the framework, and the work platform units are hooked into the hook bases through the hollow profiles transversely arranged on the inner side of the framework to be fixedly arranged on the outer side of the prefabricated side fascia. According to the externally-mounted work platform for the fabricated building, safe and reliable work space is provided for workers for outer wall construction, construction is facilitated, the construction efficiency is improved, construction cost is reduced, objects falling from high altitudes and casualties are prevented, the structure is simple, the weight is low, and multiple functions are achieved. The invention further provides a method for operating the externally-mounted work platform.

Owner:HUNAN YUANDA CONSTR ENG CO LTD

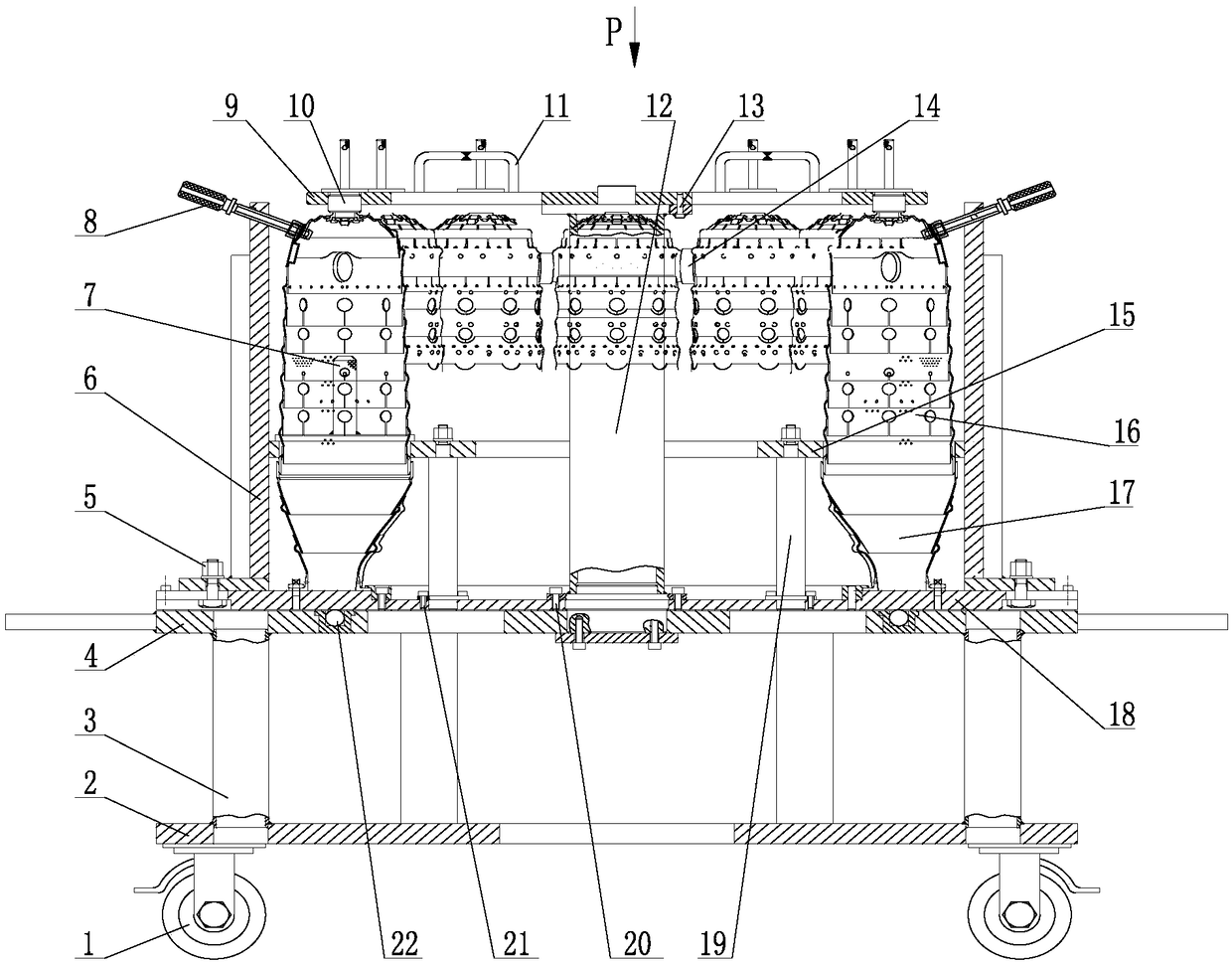

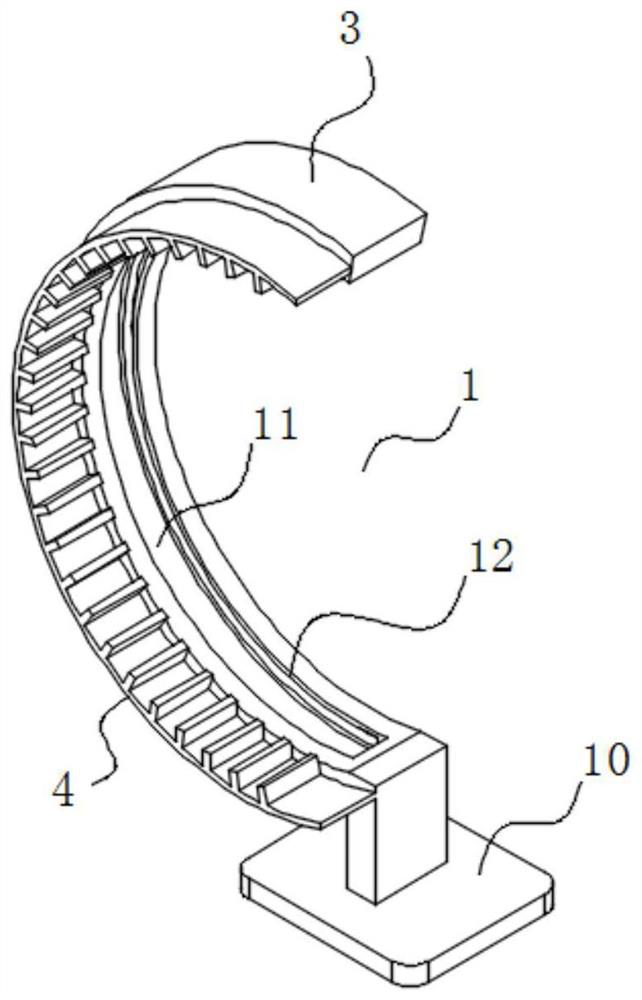

Assembly tool for low-pressure turbine of engine

ActiveCN111266861AHigh positioning accuracyEasy to install and disassembleAssembly machinesPhysicsEngineering

Owner:AECC AVIATION POWER CO LTD

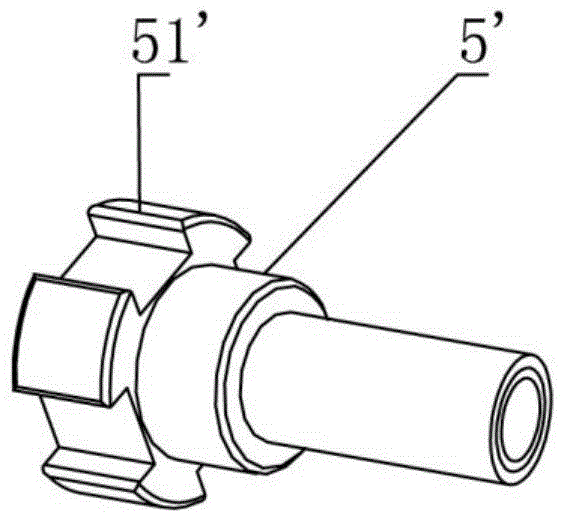

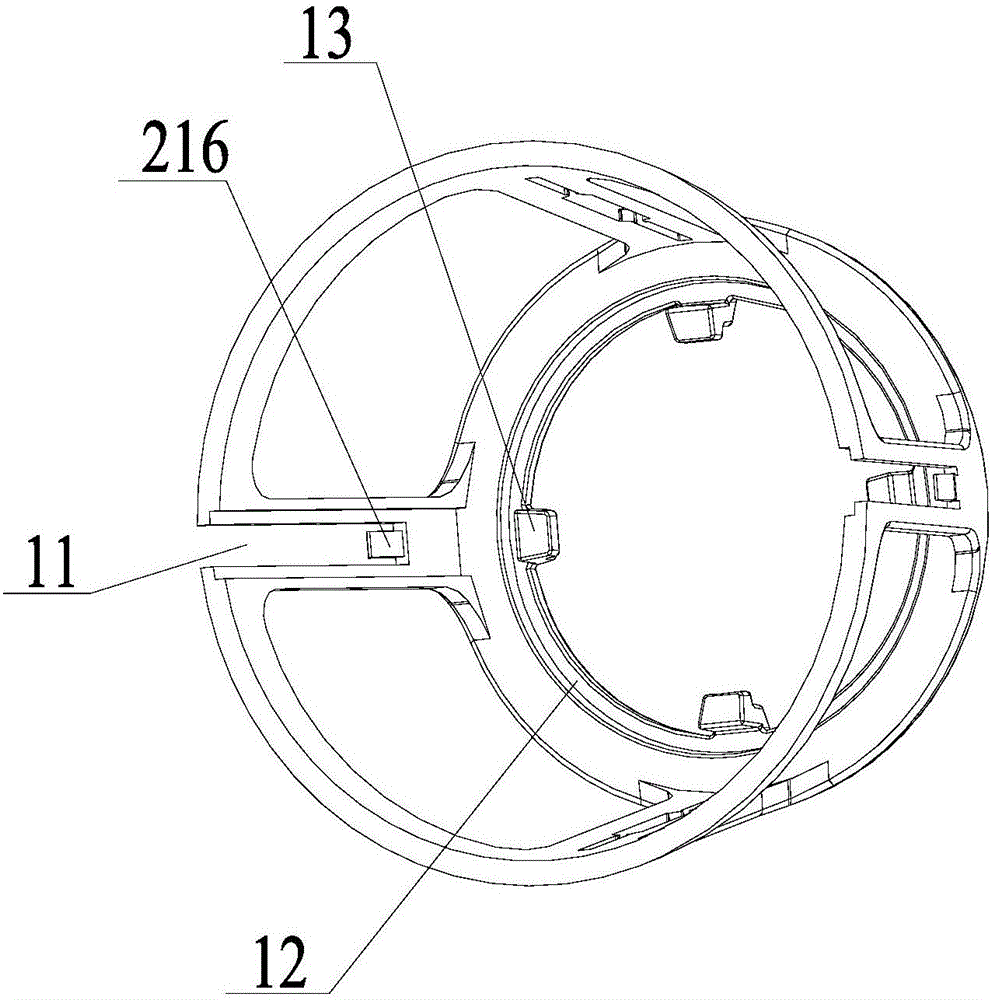

Novel optical fiber connector

ActiveCN104007515AEasy to disengageSimple structureCoupling light guidesEngineeringOptical fiber connector

The invention discloses a novel optical fiber connector comprising an outer packaging shell, a sleeve head base, a first insertion core, a second insertion core, a tail metal handle, a spring, a supporting base, a clamp screw cap and a rubber sleeve. The sleeve head base is sleeved with the outer packaging shell and matched with the outer packaging shell in a clamping mode. The end of the first insertion core and the end of the second insertion core are installed in the tail metal handle in an opposite insertion mode. The supporting base is sleeved with the outer packaging shell, the front end of the supporting base is matched with the sleeve head base in a clamping mode, and the tail end of the supporting base is sleeved with the clamp screw cap. A square groove is formed in the inner wall of the sleeve head base, a square block is arranged on the outer wall of the tail metal handle, a pair of clamping blocks is symmetrically arranged on the outer wall of the rubber sleeve, and buckles are arranged on the inner wall of the outer packaging shell and matched with the clamping blocks. Openings are formed in the walls of the outer packaging shell and communicated with the buckles. The novel optical fiber connector is simple and reasonable in structure, easy to machine, high in precision, convenient to install and position, low in manufacturing cost and high in assembly efficiency.

Owner:宁波宇达光电股份有限公司

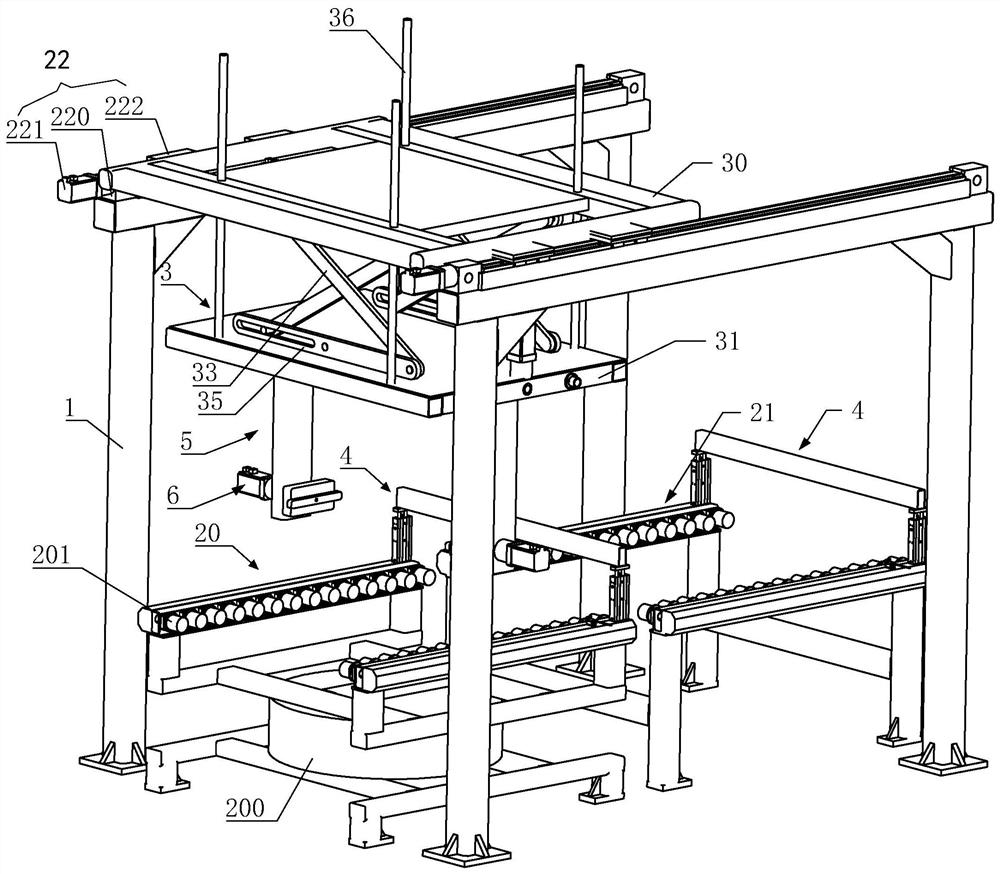

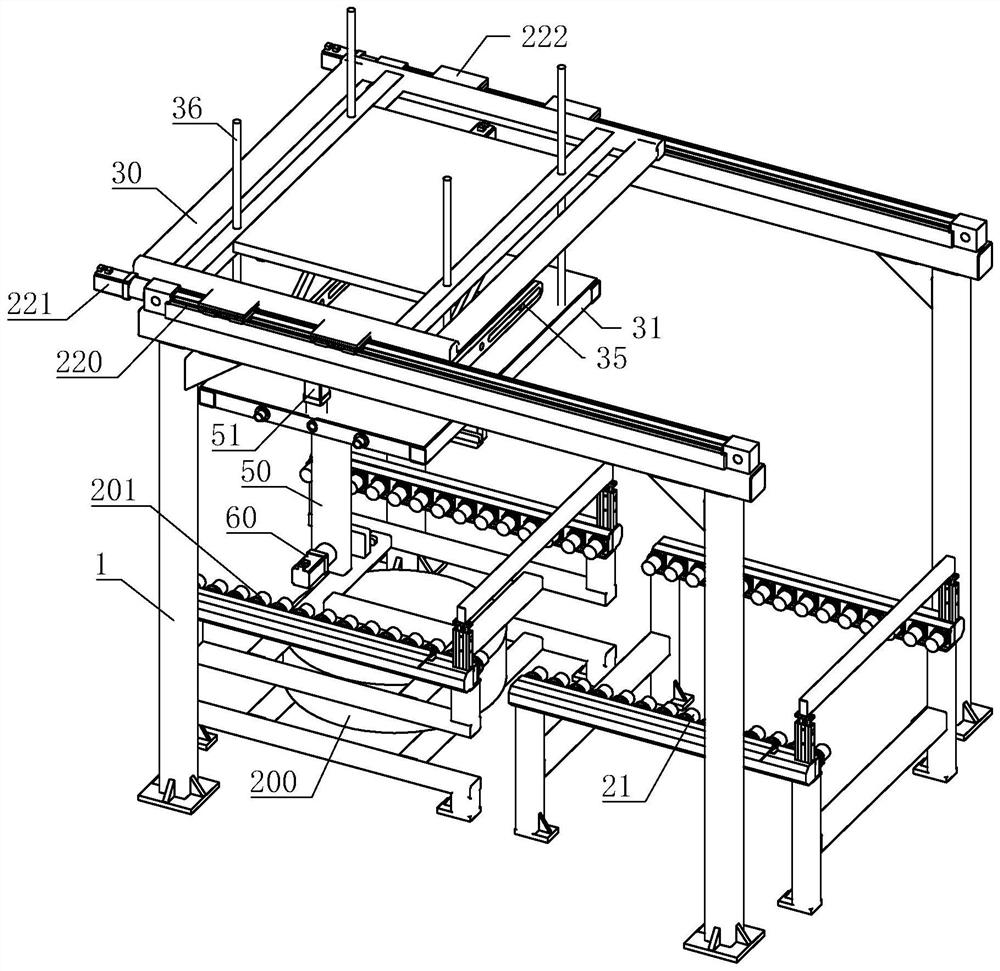

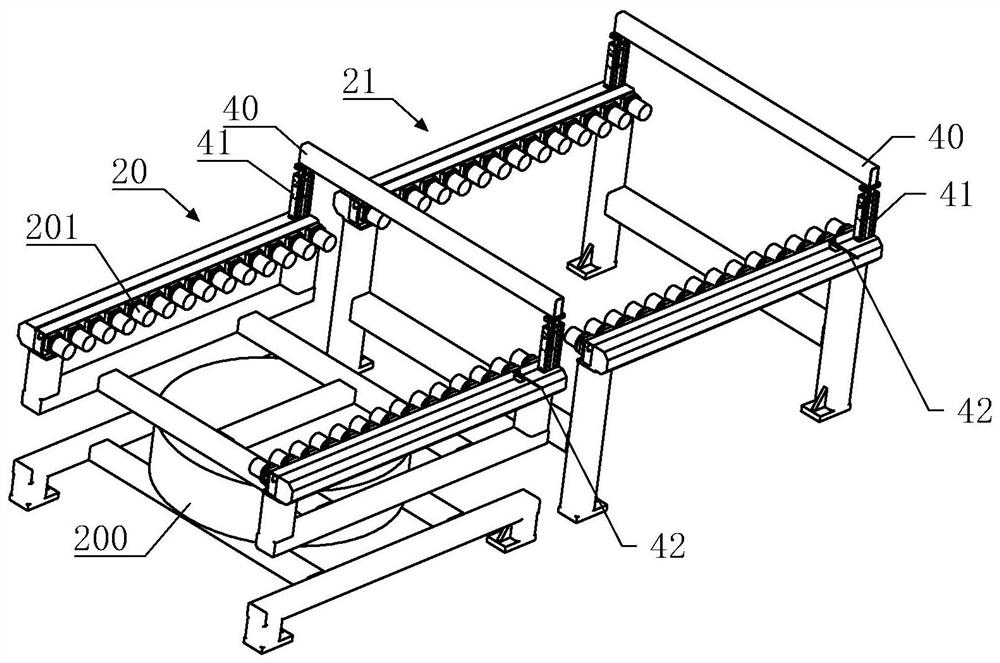

Sand mold assembly workbench suitable for dieless composite forming process

PendingCN113601462ARealize the fixtureAchieve transshipmentWork benchesThermodynamicsProcess engineering

The invention discloses a sand mold assembly workbench suitable for a dieless composite forming process. The sand mold assembly workbench comprises a clamping mechanism, a turnover mechanism, a lifting mechanism and a conveying mechanism, and the clamping mechanism and the turnover mechanism are arranged on the lifting mechanism; the conveying mechanism drives the lifting mechanism, the clamping mechanism and the turnover mechanism to move, and / or drives a sand mold to move; and the lifting mechanism is used for driving the clamping mechanism and the lifting mechanism to ascend and descend. After the sand mold is placed in place, the conveying mechanism drives the lifting mechanism, the clamping mechanism and the turnover mechanism to move to the position above the sand mold, the lifting mechanism drives the clamping mechanism and the turnover mechanism to descend, after the sand mold is placed in place, the clamping mechanism clamps the sand mold, the lifting mechanism ascends again, the conveying mechanism acts to drive the sand mold to move to an assembly station, and the turnover mechanism acts to drive the sand mold to turn over; and after overturning is completed, the lifting mechanism descends, the clamping mechanism loosens the sand mold, and the conveying mechanism can convey the sand mold. Therefore, the sand mold assembly workbench can realize overturning, clamping, transferring, assembling and the like of the sand mold, so that the process time is shortened, and the labor force is saved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

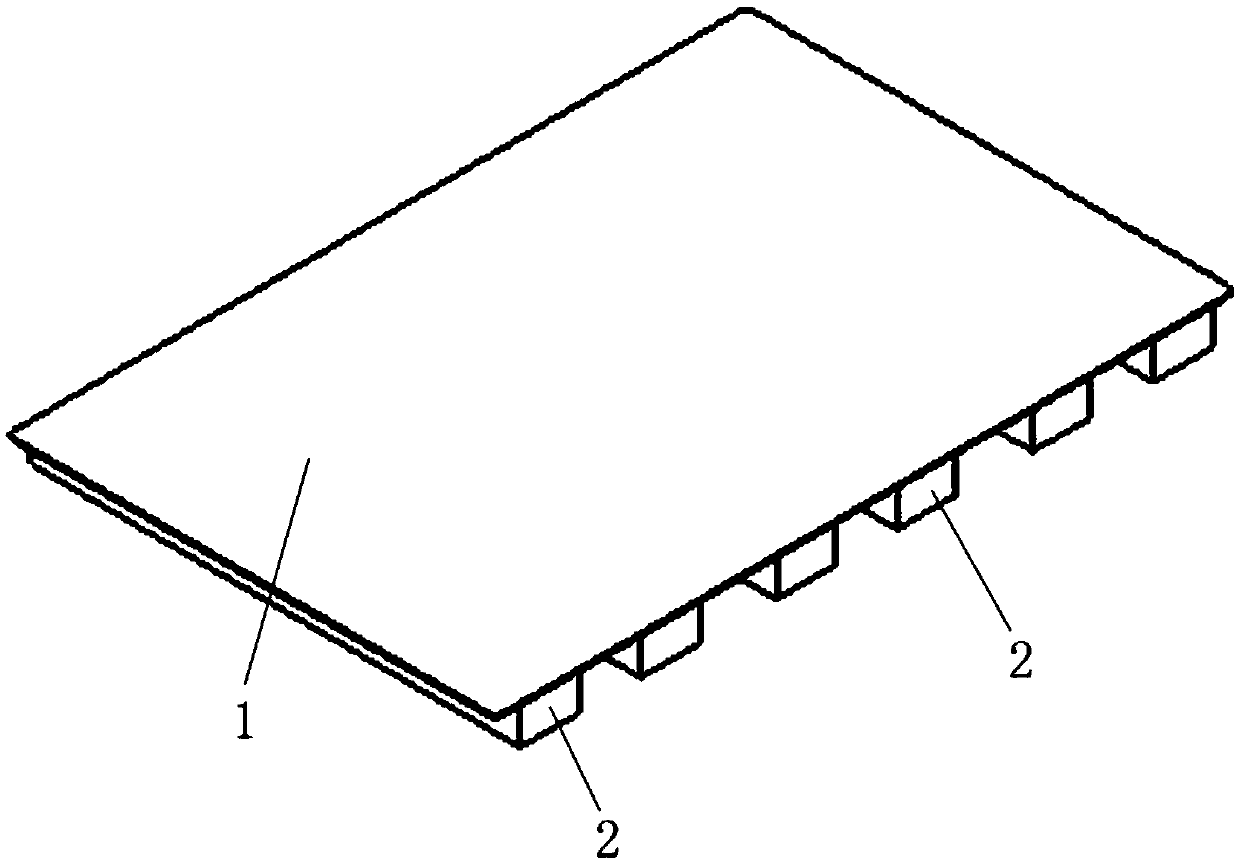

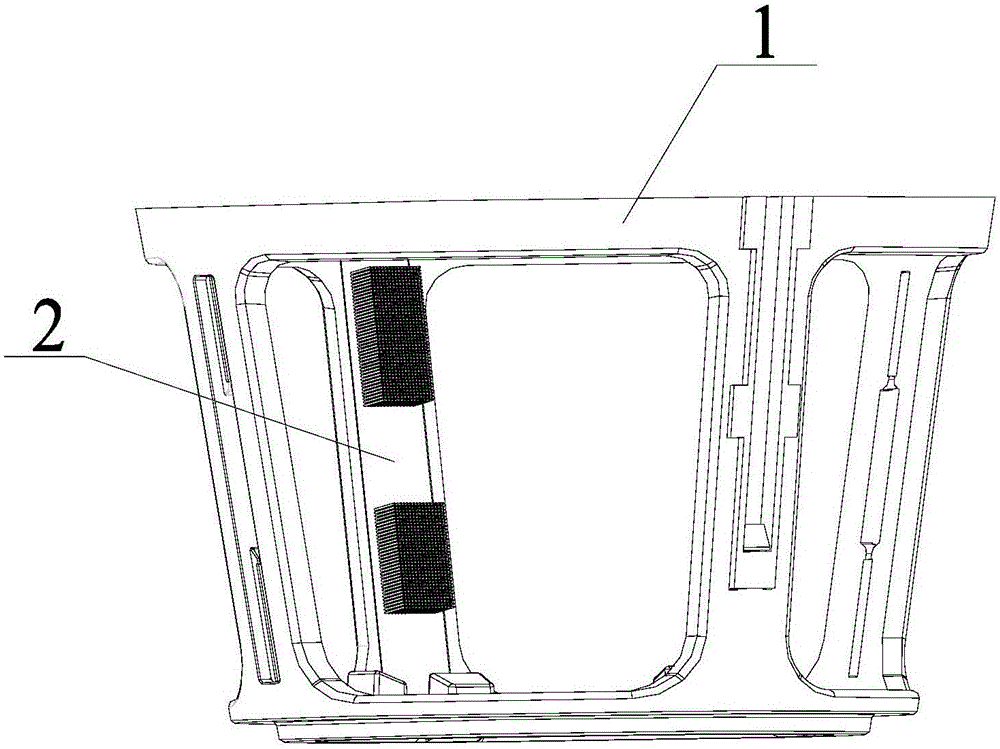

Battery module heating film, battery pack and lower housing thereof and battery pack assembling method

ActiveCN109585976AHeating fastImprove over temperature protectionFinal product manufactureSecondary cells manufactureAdhesive glueEngineering

The present invention relates to the field of vehicle battery packs, and discloses a battery module heating film, a battery pack and a lower housing thereof, and a battery pack assembling method. Thebattery module heating film comprises a film body, a battery module heating area configured to be in contact with the battery module is formed at least one part, facing the surface of one side of thebattery module, of the film body, the battery module heating area is covered with a heat conductive adhesive glue layer, the heat conductive adhesive glue layer is coated with a protection film capable of tearing, in the actual usage, the battery module heating film is arranged at a corresponding area in the lower housing of the battery pack as required, the protection film is teared down, the battery module is assembled at the corresponding area of the lower housing of the battery pack and is bonded at the battery module heating film of the corresponding area so as to improve the applying degree of the battery module and the battery module heating film, improve the heating of the battery module and the over-temperature protection of the battery module heating film and obviously reduce therejection rate and the protection cost of the battery module heating film.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Special external hanging operation platform for prefabricated buildings and its operation method

ActiveCN104131688BImprove assembly efficiencyReduce assembly efficiencyBuilding material handlingScaffold accessoriesIndustrial engineeringWorking space

The invention provides an externally-mounted work platform for a fabricated building. The externally-mounted work platform for the fabricated building comprises one or two or more work platform units which are horizontally arranged on the outer side of a prefabricated side fascia, multiple fastening devices which are pre-buried in the prefabricated side fascia, and multiple hook bases which are fixedly connected with the corresponding fastening devices through fastening pieces, wherein each work platform unit comprises a one-layer or two-layer or three-layer or multi-layer framework which is formed by hollow profiles through welding, protective screen or guardrails arranged on the outer sides of all layers of the framework and protective screens or pedals which are arranged on the bottoms of all layers of the framework, and the work platform units are hooked into the hook bases through the hollow profiles transversely arranged on the inner side of the framework to be fixedly arranged on the outer side of the prefabricated side fascia. According to the externally-mounted work platform for the fabricated building, safe and reliable work space is provided for workers for outer wall construction, construction is facilitated, the construction efficiency is improved, construction cost is reduced, objects falling from high altitudes and casualties are prevented, the structure is simple, the weight is low, and multiple functions are achieved. The invention further provides a method for operating the externally-mounted work platform.

Owner:HUNAN YUANDA CONSTR ENG CO LTD

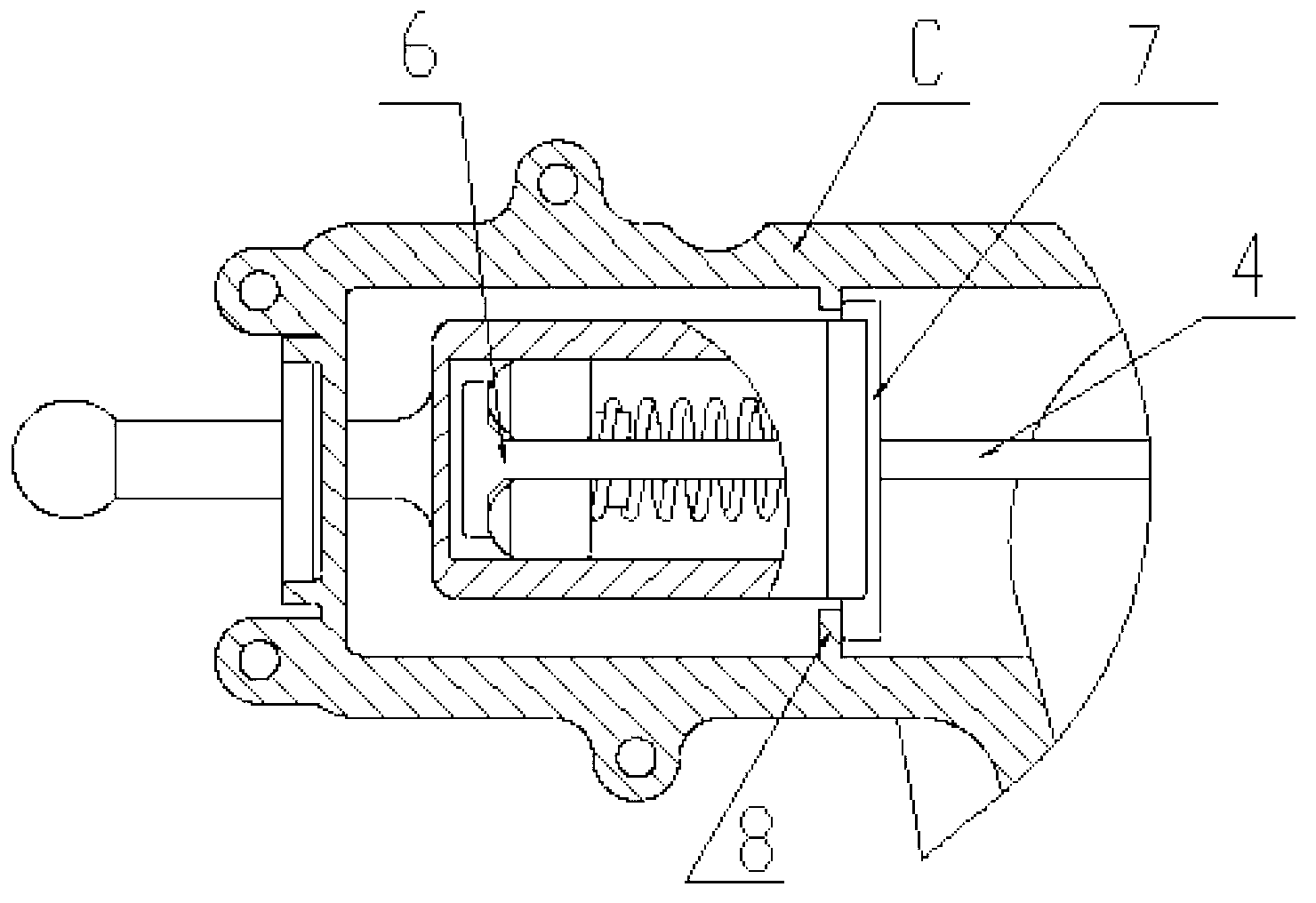

Automatic compensation device for clutch abrasion for locomotive

ActiveCN103062238ASimple and reasonable structureHigh control precisionFriction clutchesClutchPull force

The invention discloses an automatic compensation device for clutch abrasion for a locomotive. The automatic compensation device is arranged between a clutch separation bearing and a clutch execution mechanism. The automatic compensation device comprises a casing assembly, a self-locking device, a limit device and a pull rod. The self-locking device is arranged in the casing assembly and is a one-way self-locking device. The automatic compensation device achieves abrasion automatic compensation of a clutch under the effect of diaphragm spring piece and outputs certain pull force to provide preload force for the separation bearing. The execution mechanism achieves the automatic compensation function after the clutch is abraded. Simultaneously, preload force for separating a shifting fork and the separation bearing is provided. The automatic compensation device is simple and reasonable in structure, high in control accuracy, sensitive in reaction, stable in manipulation, low in cost and long in service life, has the function of automatic compensation of abrasion, avoids skidding of the clutch and can be widely applied to the locomotive.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

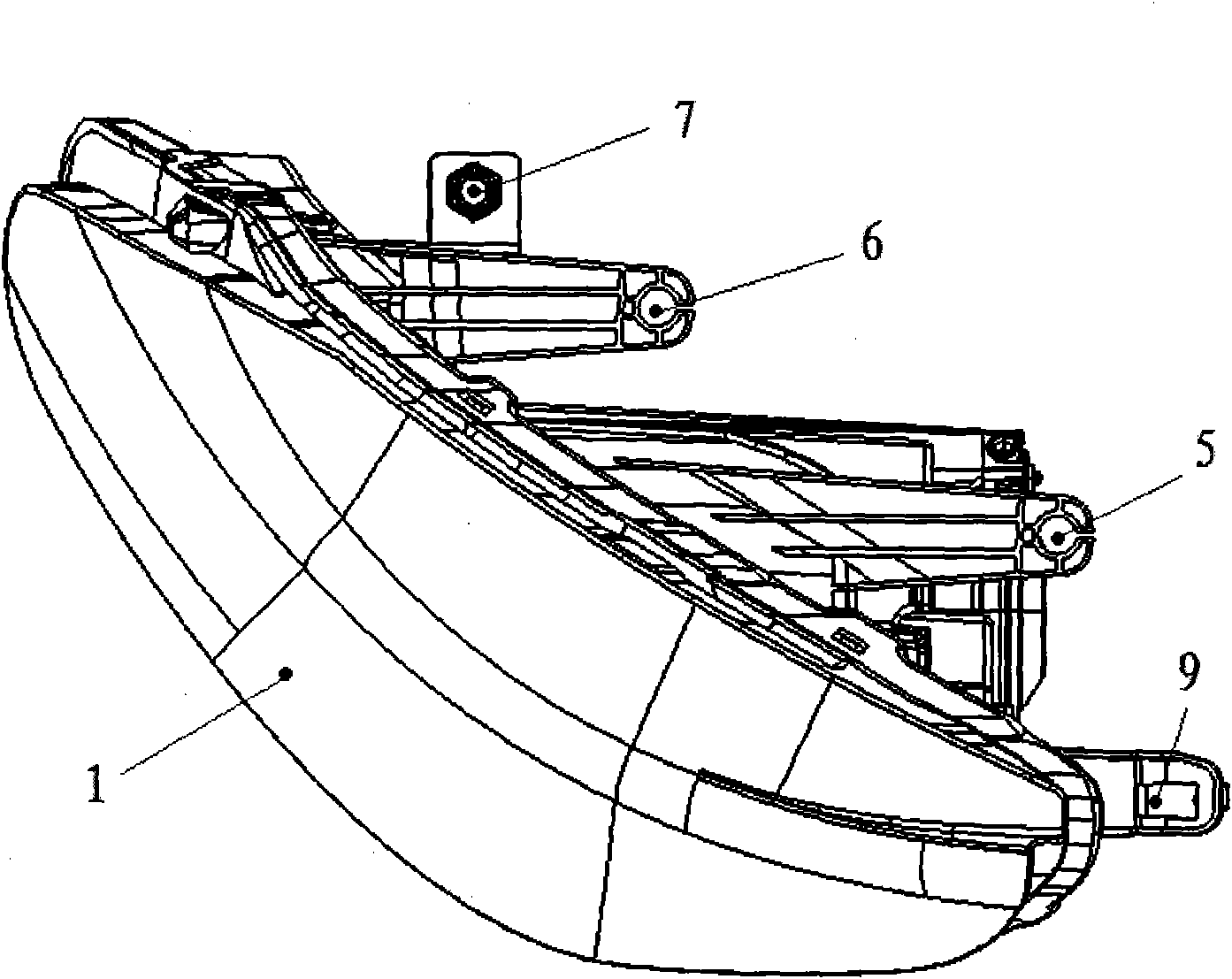

Traction tool for low-pressure turbine of engine

The invention provides a traction tool for a low-pressure turbine of an engine. The tool comprises a torque transmission bushing and a traction shaft sleeve, wherein in an assembly process, the traction end of a low-pressure turbine shaft sequentially passes through a core machine, the traction shaft sleeve and a connecting shaft sleeve and extends to the outside of a fan rotor, in an assembly process of a low-pressure turbine, torsion force is applied to a traction shaft outside, the traction shaft and the connecting shaft sleeve rotate synchronously, in the rotation process of the fan rotor,the traction shaft is driven to move axially through threads, so that the low-pressure turbine shaft has double acting force of rotation and axial movement, furthermore, a bearing cylindrical rolleron the low-pressure turbine shaft is gradually assembled into a bearing outer ring during rotation, thus solving the problem of mechanical collision between the cylindrical roller and the bearing outer ring in an existing assembly process.

Owner:AECC AVIATION POWER CO LTD

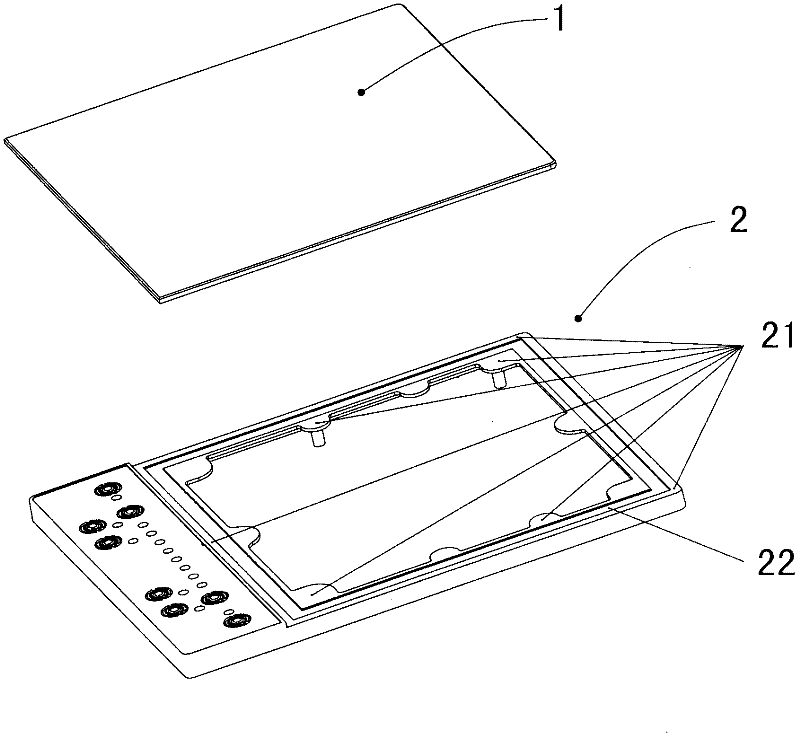

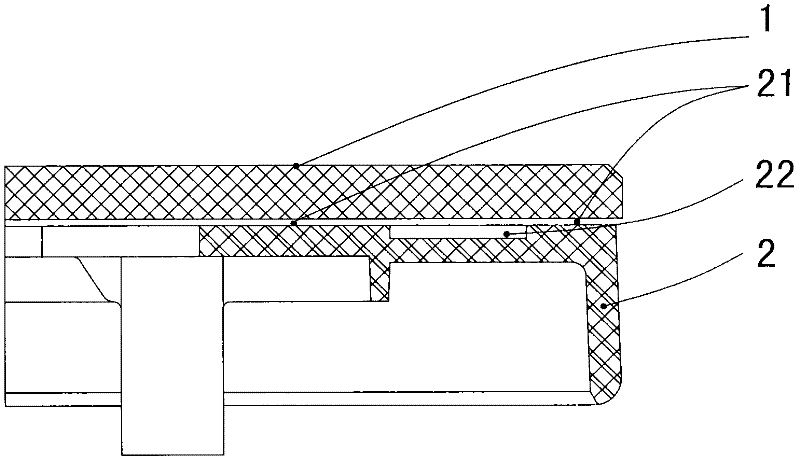

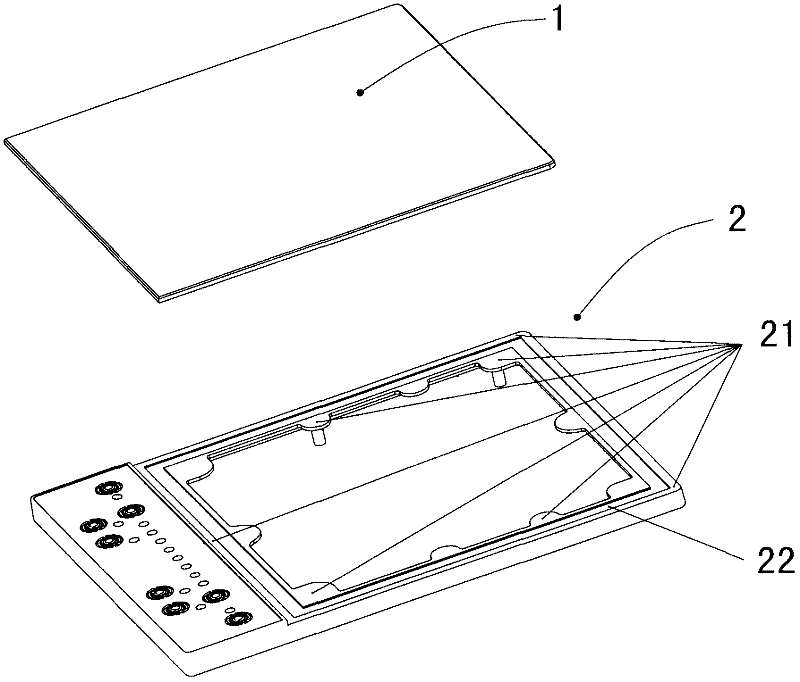

Household electrical appliance product and bonding method thereof

ActiveCN102538033AImprove curing cycleShorten curing cycleAdhesive processesDomestic stoves or rangesAdhesiveEngineering

The invention provides a household electrical appliance product and a bonding method thereof. Quick-drying adhesive and chronic curing adhesive are used jointly, complement each other's advantages and enable parts to be rapidly sealed, bonded and cured. Assembling efficiency is accelerated, reject ratio of process is eradicated, and workpieces do not need to be clamped by fixture and can be consigned or moved at any time. The household electrical appliance product comprises a first part and a second part which are connected in an adhesive mode. The first part is provided with a chronic curing adhesive containing portion and a quick-drying adhesive containing portion to be adhered to the second part, a chronic curing adhesive layer is arranged between the second part and the chronic curing adhesive containing portion, and a quick-drying adhesive layer is arranged between the second part and the quick-drying adhesive containing portion. The bonding method of the household electrical appliance product comprises the steps of filling chronic curing adhesive into the chronic curing adhesive containing portion of the first part, filling quick-drying adhesive into the quick-drying adhesive containing portion of the first part, aligning and bonding the first part and the second part and performing pressing and curing steps.

Owner:GREE ELECTRIC APPLIANCES INC +1

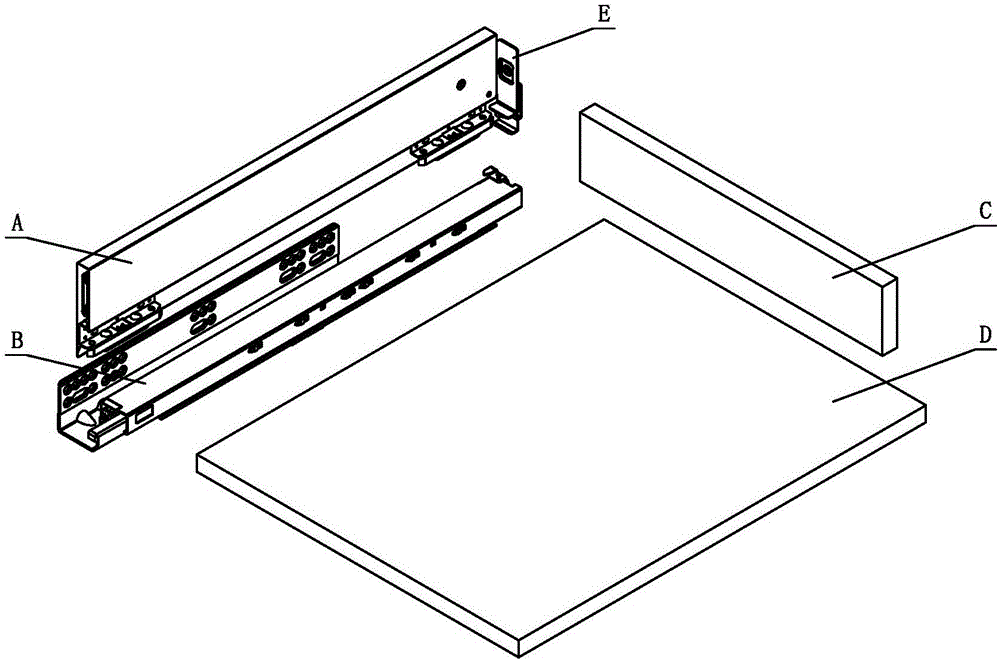

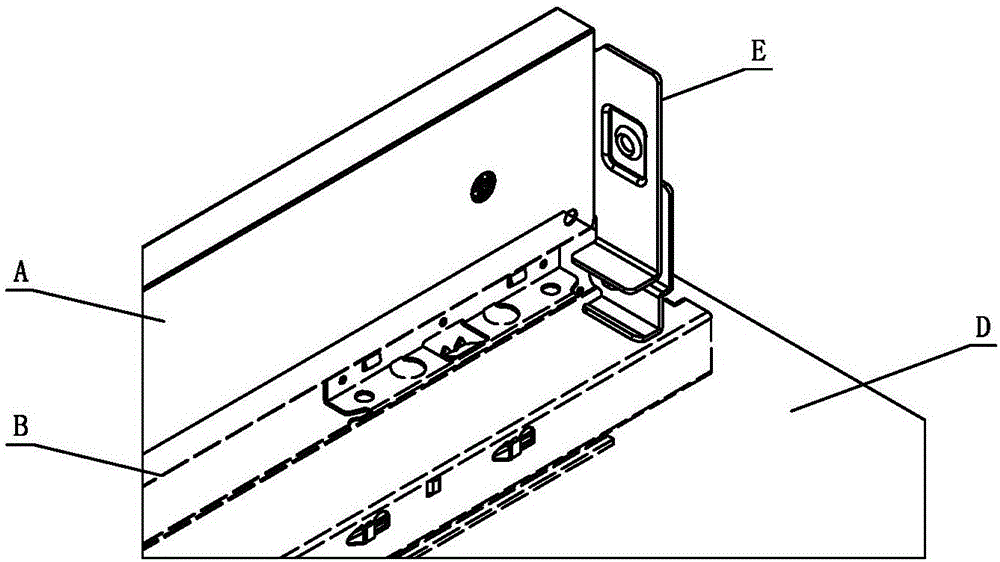

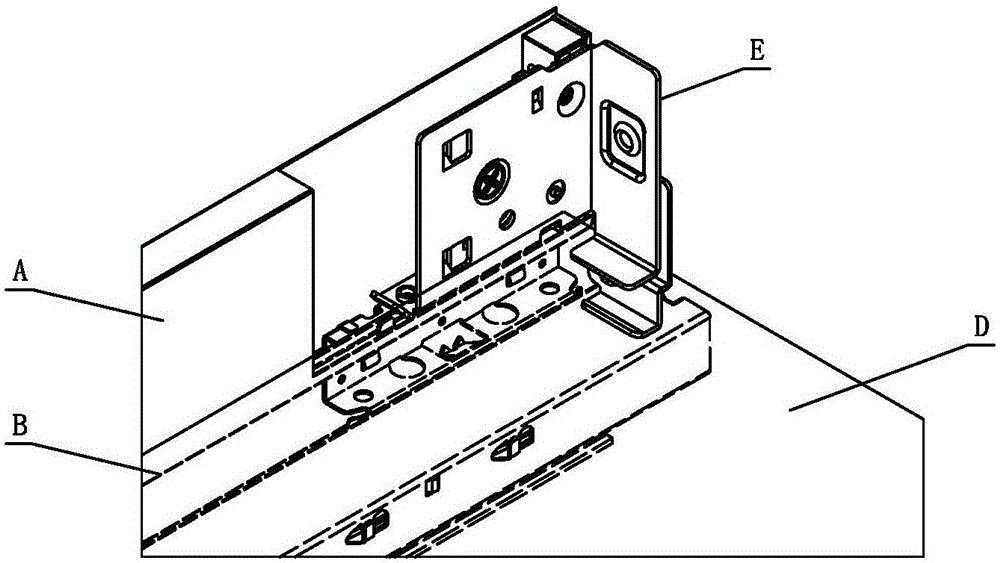

Regulating device for drawer tail

ActiveCN106175197ARealize sliding up and downImprove assembly efficiencyDrawersOrbitMechanical engineering

The invention discloses a regulating device for a drawer tail. The regulating device comprises side plates, sliding rail assemblies, a back plate, a bottom plate, and regulating assemblies arranged at the end parts of the side plates, wherein each regulating assembly comprises a height regulating piece, a regulating plate and a connecting plate; each height regulating piece is positioned on the corresponding plate in a rotating manner, and each regulating plate slides on the corresponding connecting plate up and down; each height regulating piece is provided with a spiral orbit, each regulating plate is provided with a concave boss, and each concave boss acts on the corresponding spiral orbit; the side plates and the back plate and / or the bottom plate are arranged on the connecting plates respectively, and the regulating plates are supported on movable rails of the sliding rail assemblies; the height regulating pieces are acted through manual operation or tools, the concave bosses slide on the spiral orbits relatively and interact with each other, so that the regulating plates move up and down relative to the connecting plates to realize height regulation for the drawer tail relative to the sliding rail assemblies. According to the regulating device, angle regulation for the drawer tail is realized by setting the regulating assemblies; the regulating device has the characteristics of simple and reasonable structure, simple and convenient regulation, reliable performance, low manufacturing cost, high stability and high assembling efficiency.

Owner:GUANGDONG TAIMING METAL PROD

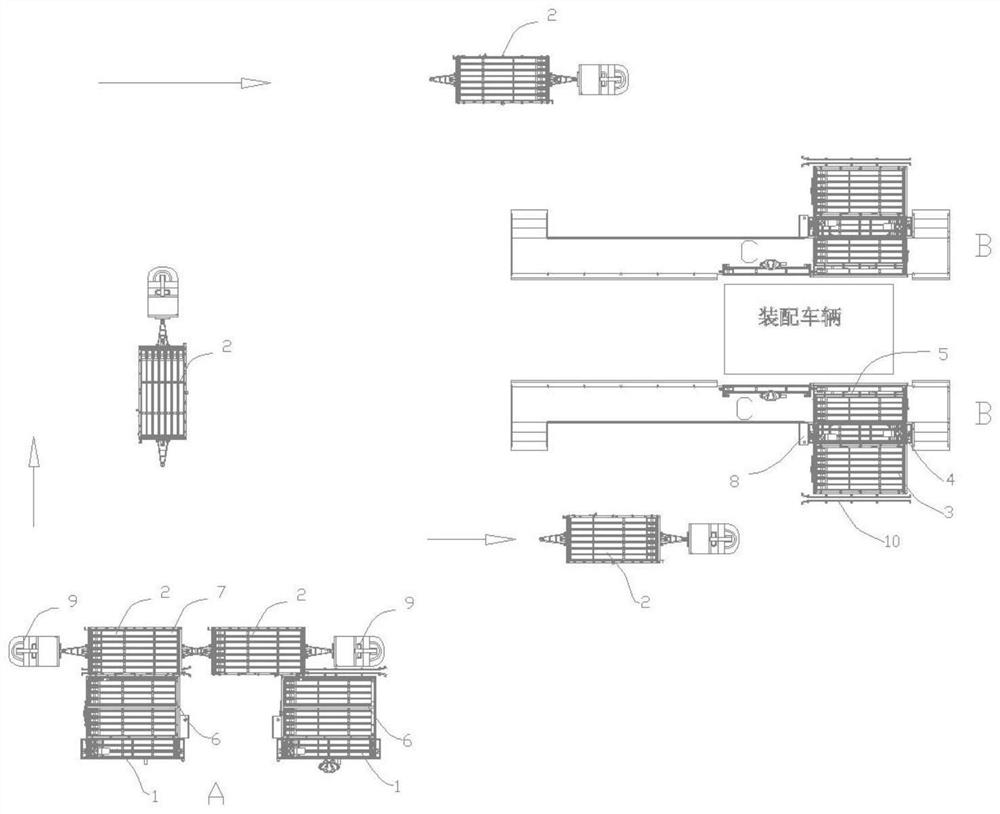

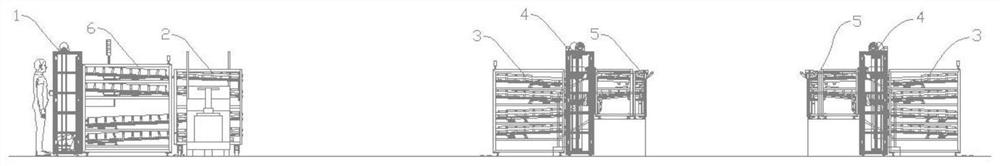

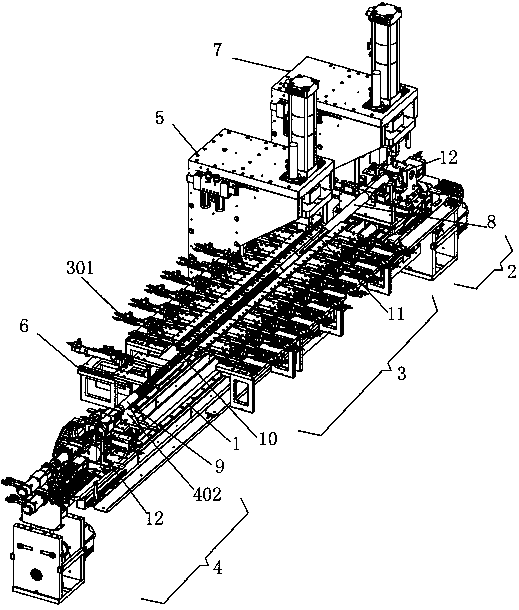

Automobile baggage holder and antenna base mixed sorting and automatic butt joint online and offline system

InactiveCN112009597AImprove the protective effectGuarantee quality requirementsVehiclesControl systemOnline and offline

The invention provides an automobile baggage holder and antenna base mixed sorting and automatic butt joint online and offline system which comprises a plurality of mixed sorting packaging boxes, a first lifting device, a material transfer trolley, a line edge butt joint storage device, a second lifting device, a transition material taking and recycling device and a control system, and the first lifting device is arranged in a sorting area; the material transfer trolley is used for transferring the mixed sorting packaging boxes from the sorting area to the material taking area; the line edge butt joint material storage device, the second lifting device and the transition material taking and recycling device are sequentially arranged in the material taking area in a butt joint mode. The transition material taking and recycling device is arranged at a material taking point, the second lifting device is arranged between the line edge butt joint material storage device and the transition material taking and recycling device, and the mixed sorting packaging boxes can be switched between the line edge butt joint material storage device and the transition material taking and recycling device along with ascending and descending of the second lifting device. All the devices in the sorting area and the material taking area can be automatically connected in a butt joint mode, the automation degree is high, and the distribution efficiency is high.

Owner:GAC FIAT CHRYSLER AUTOMOTIVE CO LTD

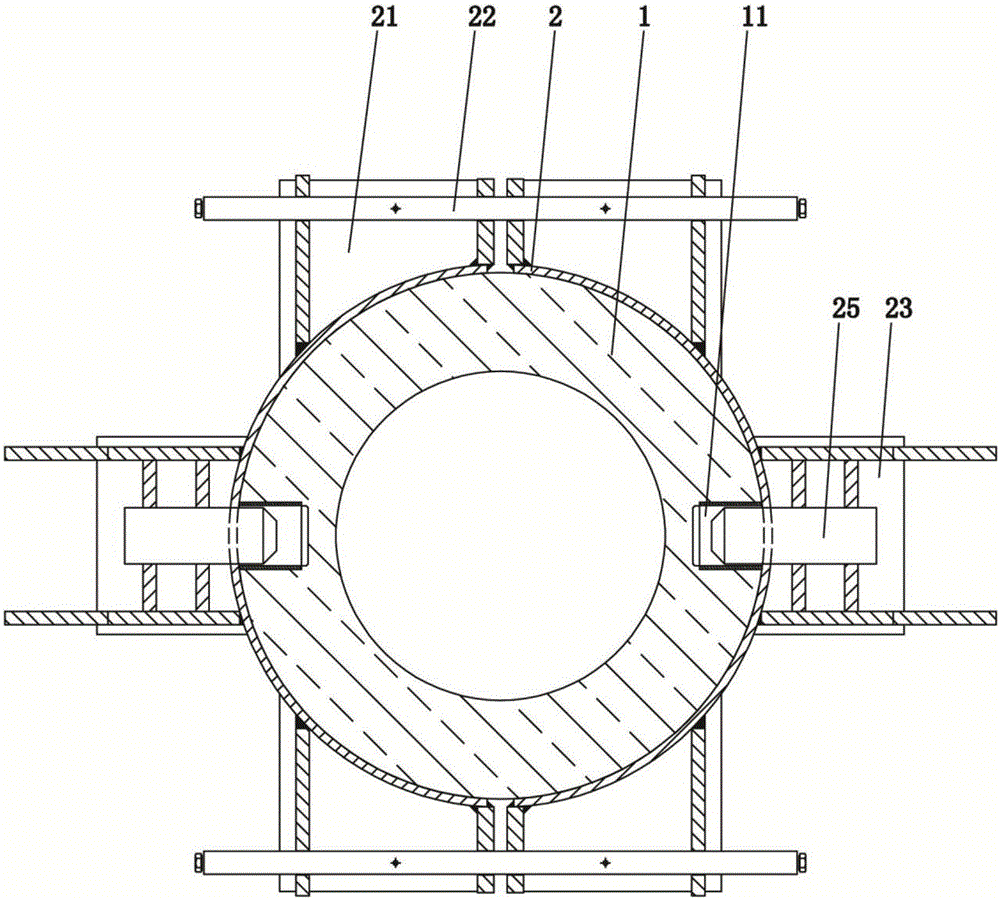

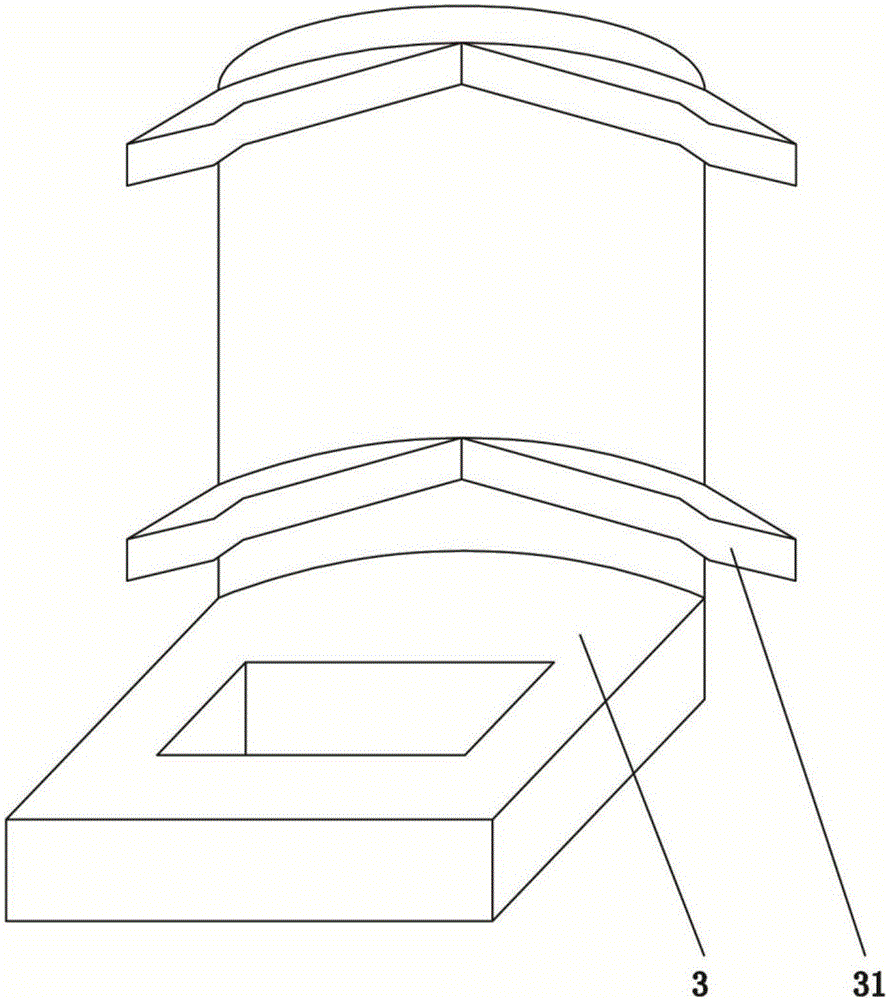

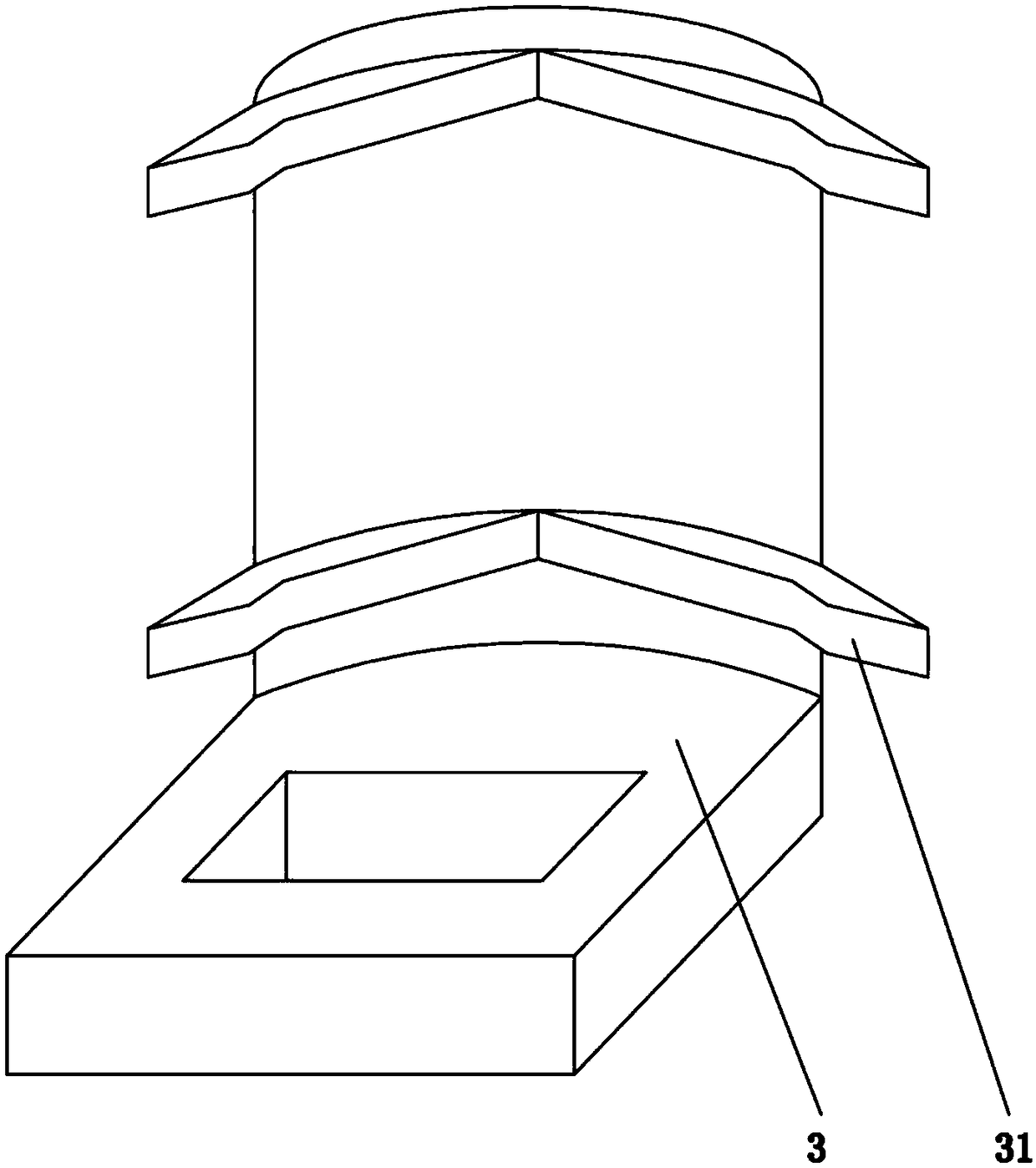

Prefabricated concrete octagonal column assembling device and assembling method thereof

ActiveCN106351400ASolve the problem that the hanging point cannot be embedded in advanceReduce usageStrutsBuilding material handlingPrecast concreteBuilding construction

The invention relates to the technical field of assembling a large prefabricated member, and particularly relates to a prefabricated concrete octagonal column assembling device and discloses an assembling method of a prefabricated concrete octagonal column. The assembling method comprises the following steps: a. setting up a measurement control frame at the outer periphery of an octagonal column embedded part; b. setting up a support frame connected with a scaffold; c. prefabricating the prefabricated concrete octagonal column; d. hoisting the prefabricated concrete octagonal column; and e. controlling the perpendicularity of the prefabricated concrete octagonal column. The problem that the centrifugal prefabricated concrete column cannot be embedded and hoisted can be effectively solved, and a clasp and foot pads can be repeatedly utilized; and the use amount of cranes can be saved, the site limiting problem for positioning cables can be avoided, the hoisting accuracy can be improved, the problem existing in traditional construction can be effectively solved, the assembling efficiency can be improved, the construction period can be shortened, and the construction cost can be saved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

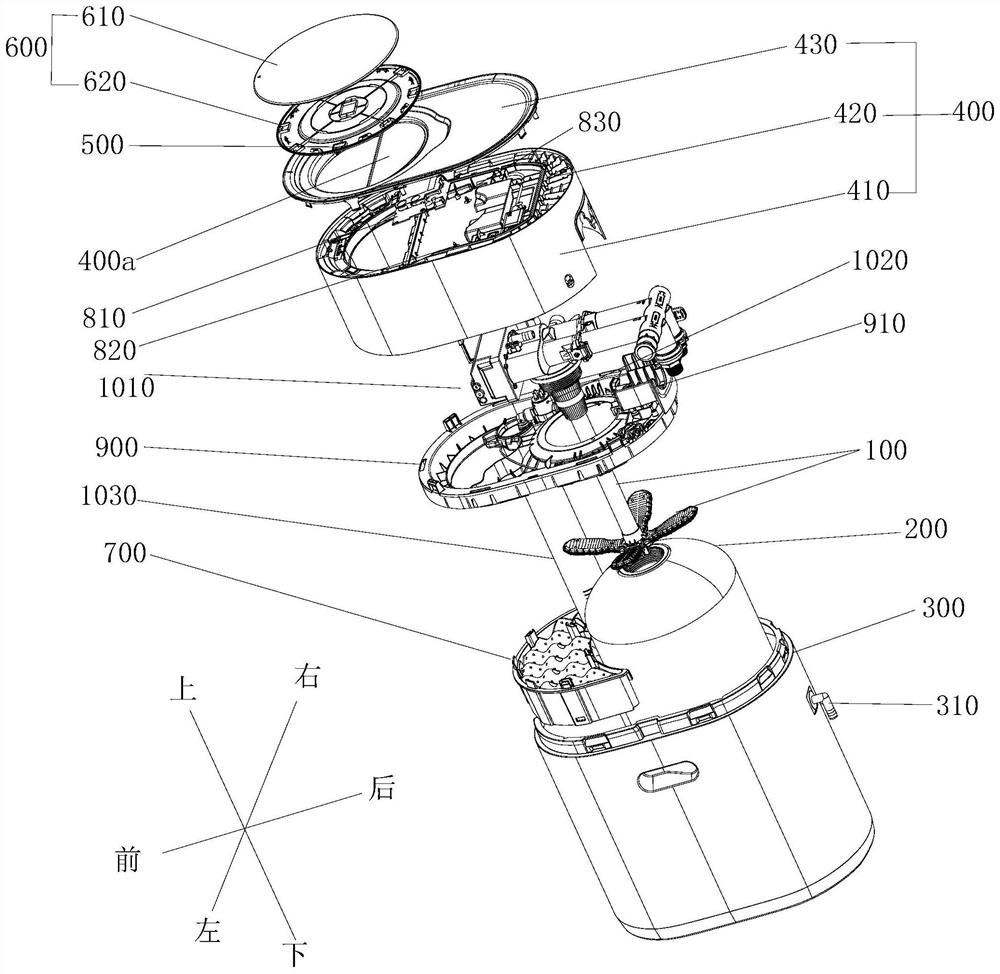

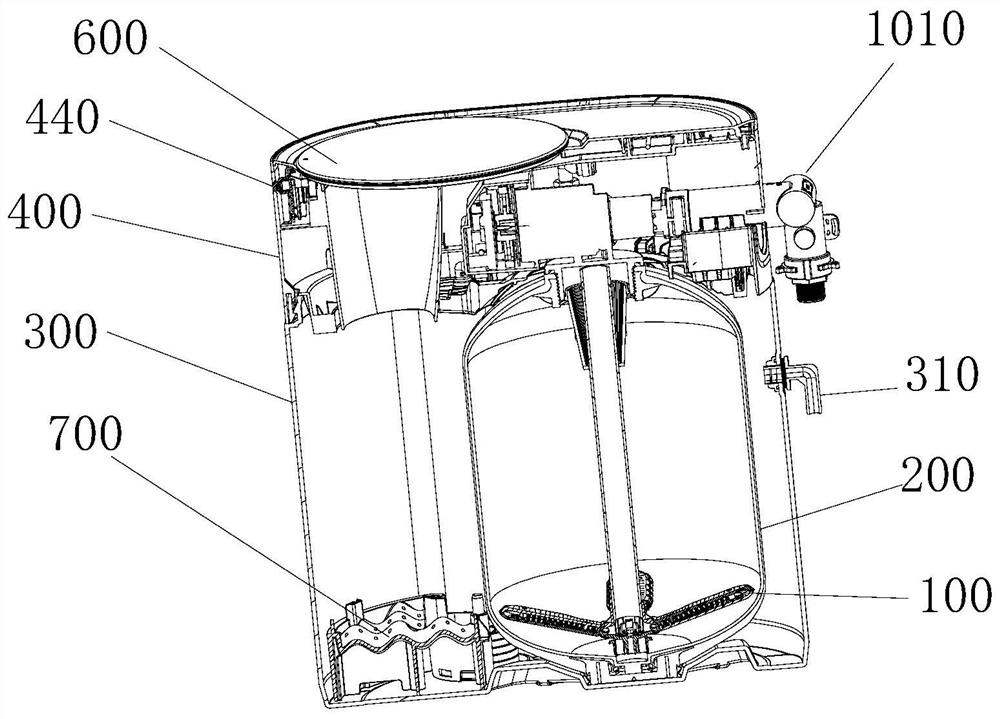

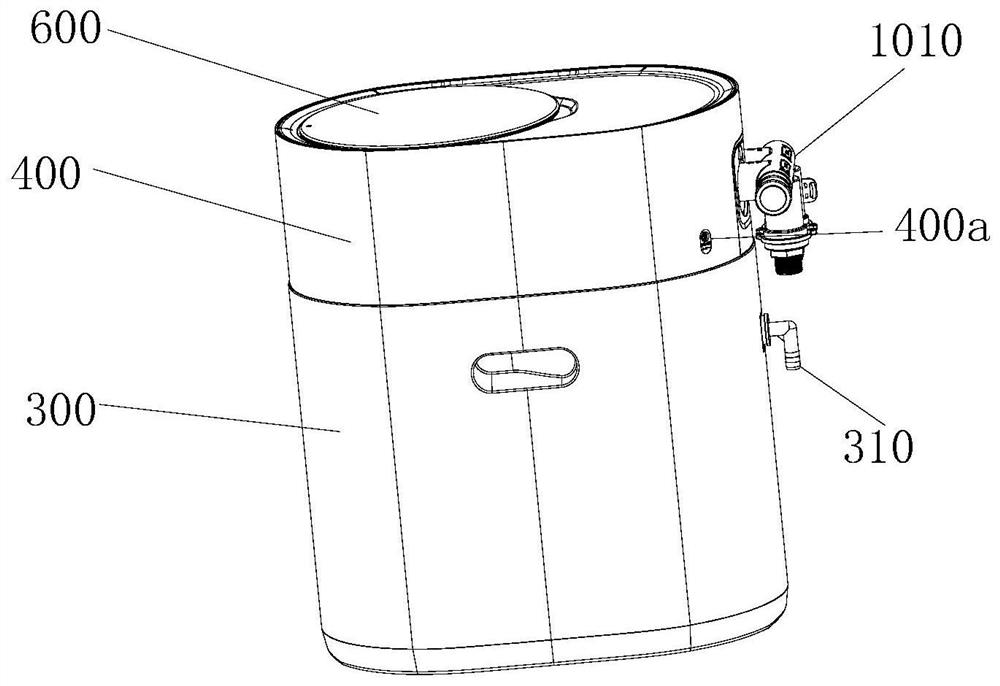

Water softener

PendingCN112374575AIncrease the angleIncrease spaceWater/sewage treatment by ion-exchangeWater/sewage treatment apparatusMechanical engineeringWater pipe

The invention relates to a water softener. The water softener comprises a salt box, an upper shell covering the salt box, a cover body assembly covering an operation window of the upper shell througha magnetic assembly, a resin tank arranged in the salt box and a water distributor arranged in the resin tank. The water distributor comprises a water pipe and a water distribution piece which is rotatably arranged on the water pipe through an adapter piece, the water distribution piece can be folded or unfolded by taking the water pipe as the center, and the water distribution piece can penetratethrough the tank opening of the resin tank in a folded state. According to the water softener, the magnetic assembly is arranged between the cover body assembly and the upper shell, and the water distribution piece of the water distributor is arranged to be of a structure capable of being folded or unfolded with the water pipe as the center, so that the water softener is convenient to assemble.

Owner:GREE ELECTRIC APPLIANCES INC

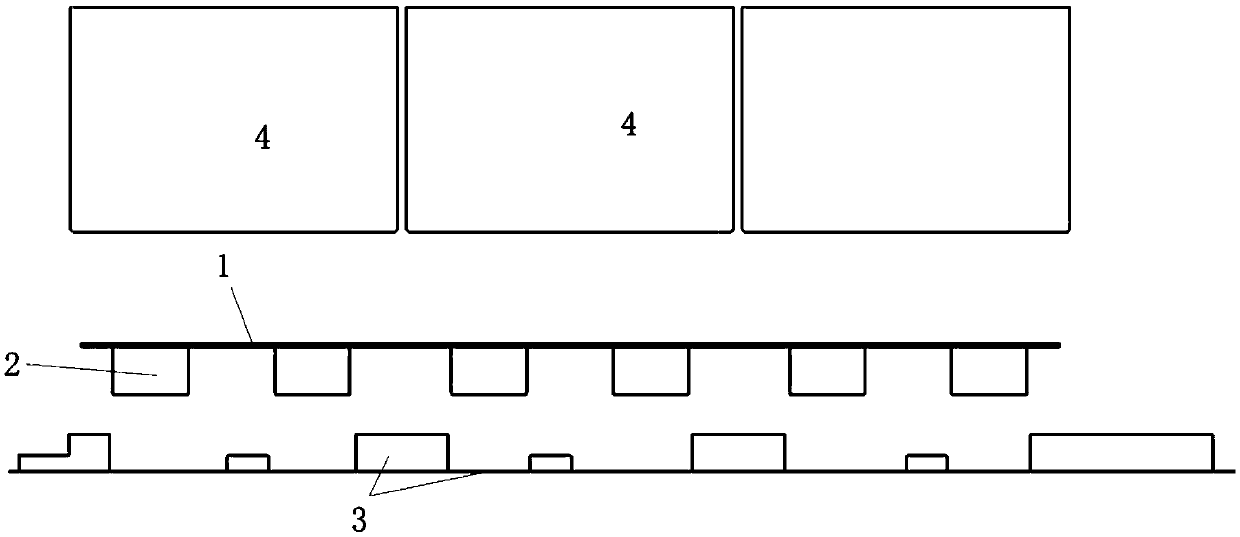

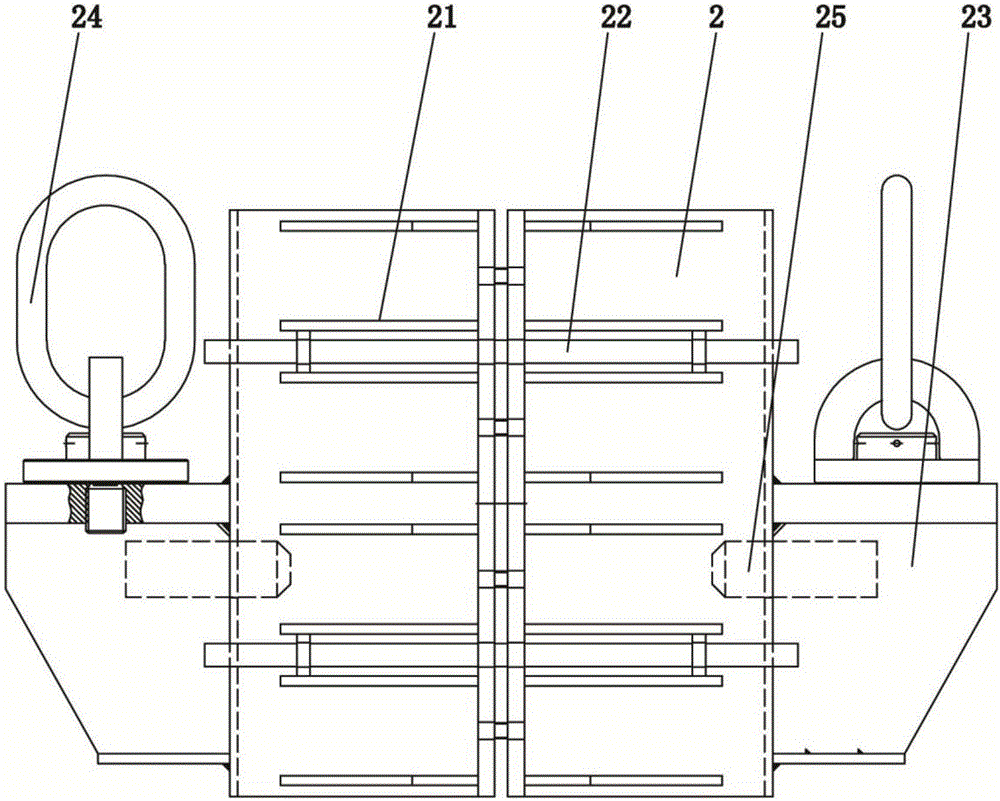

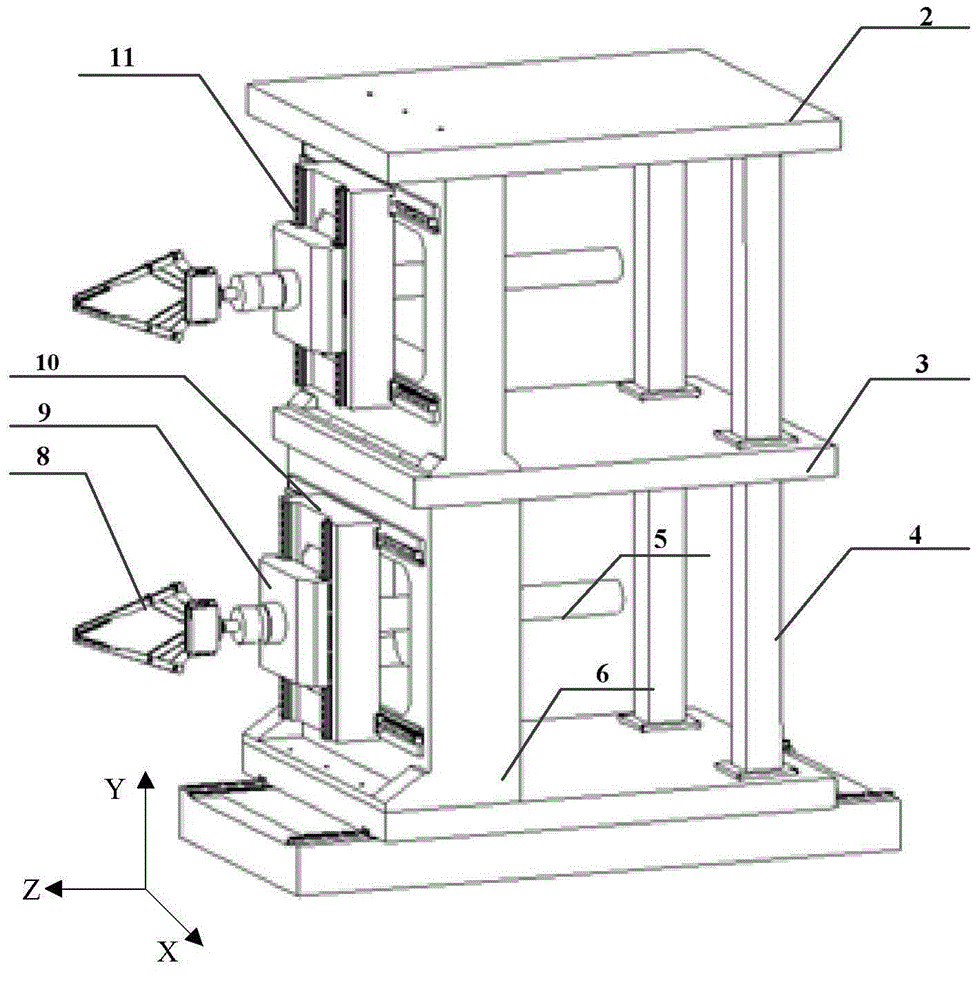

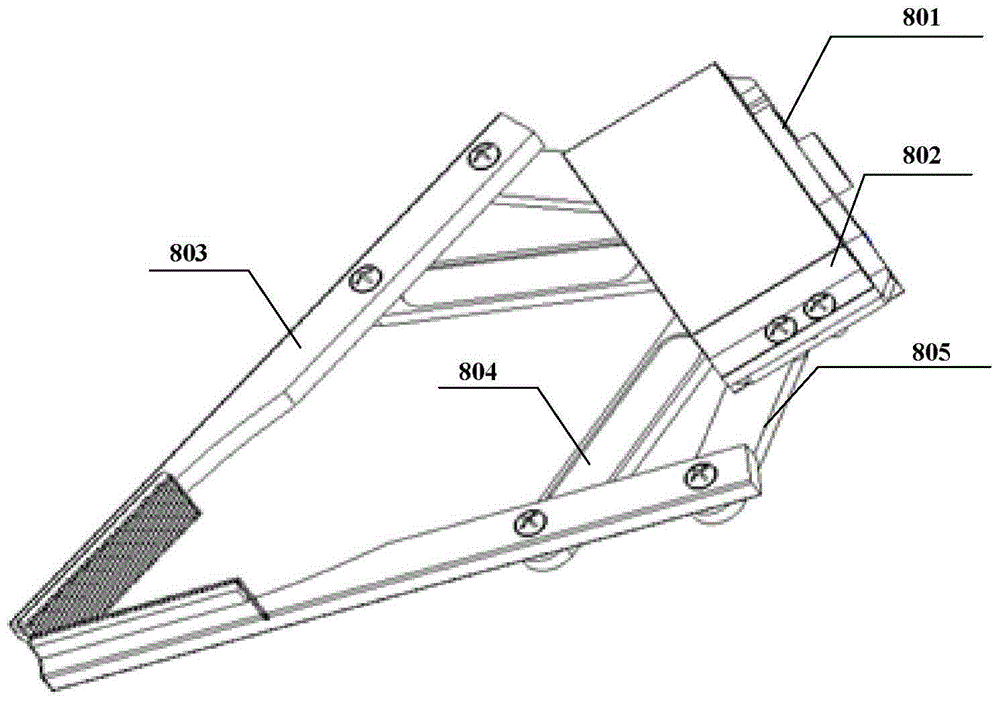

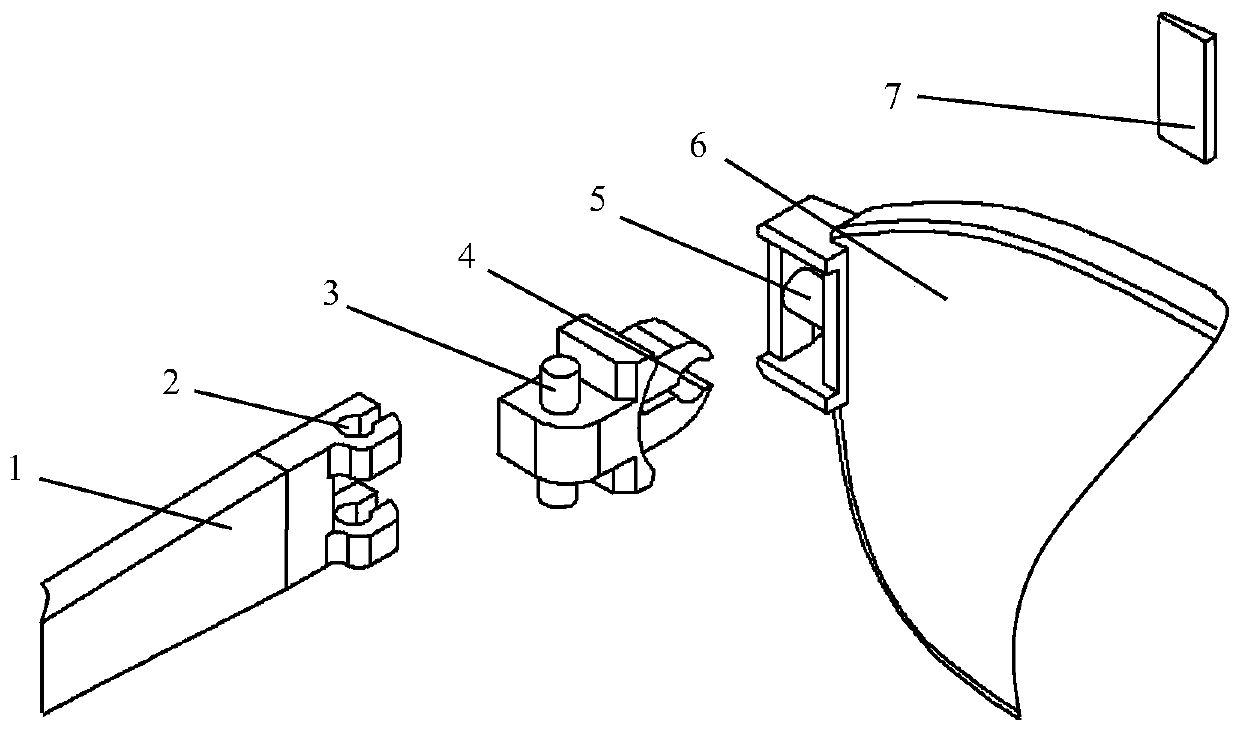

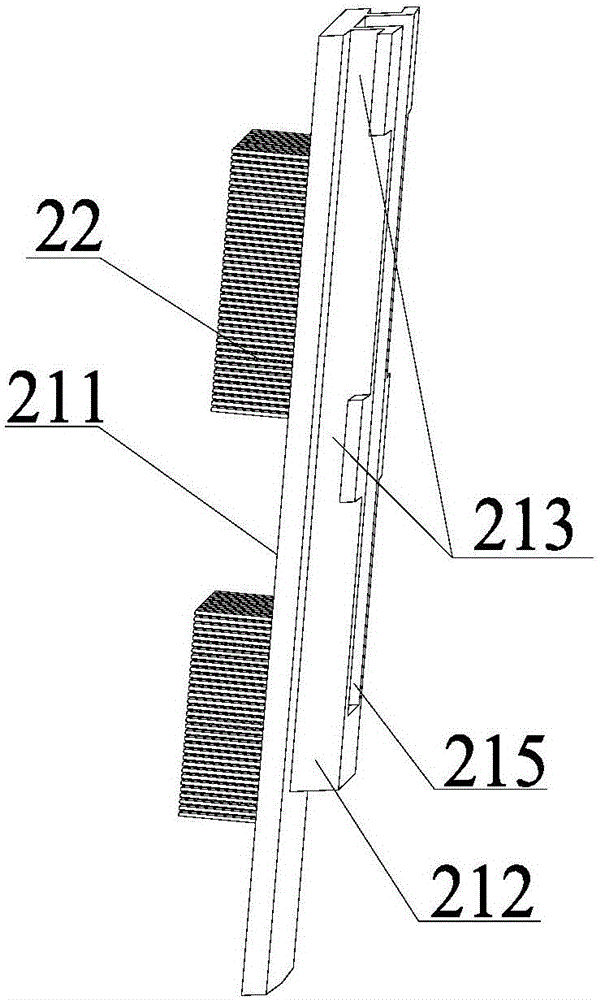

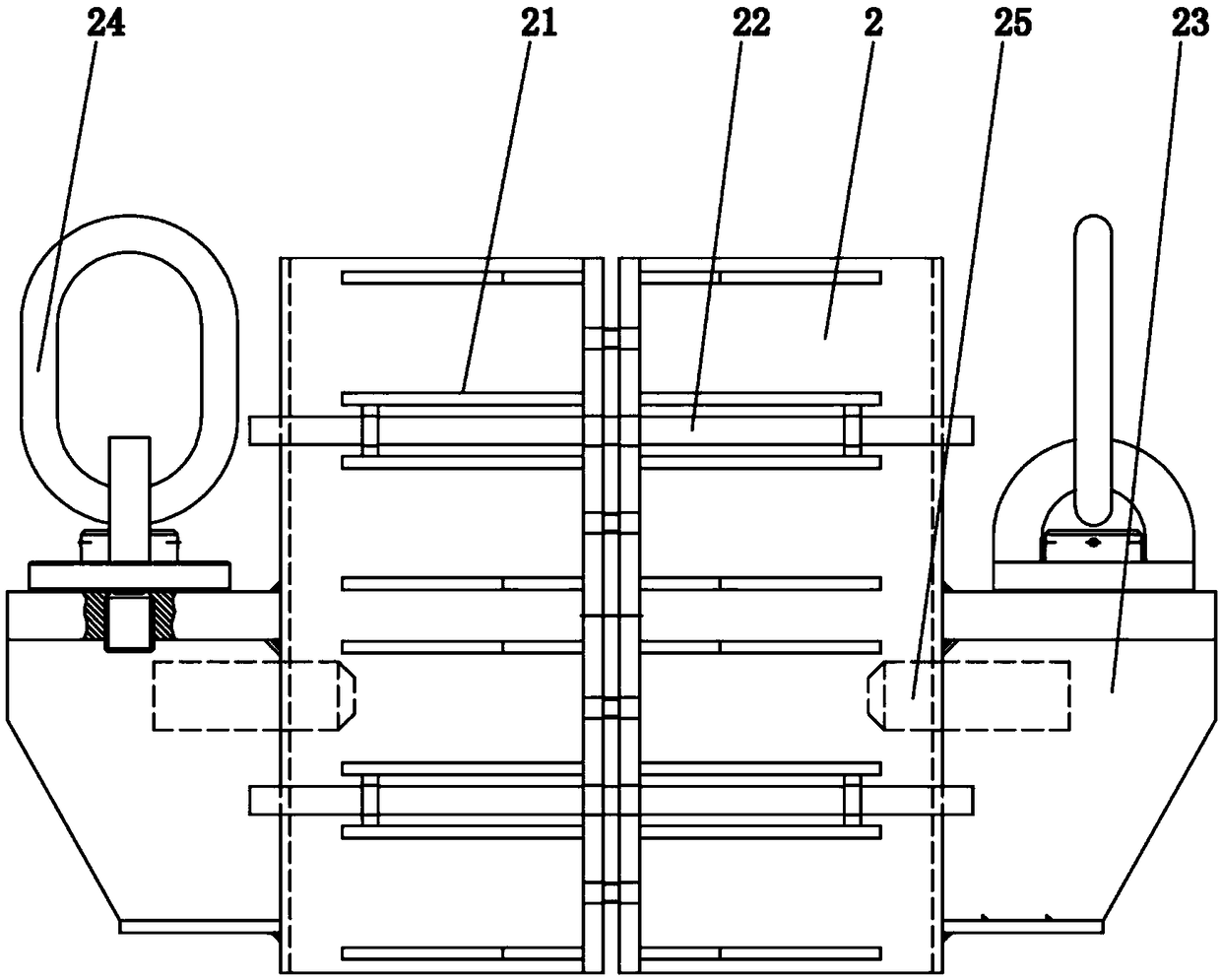

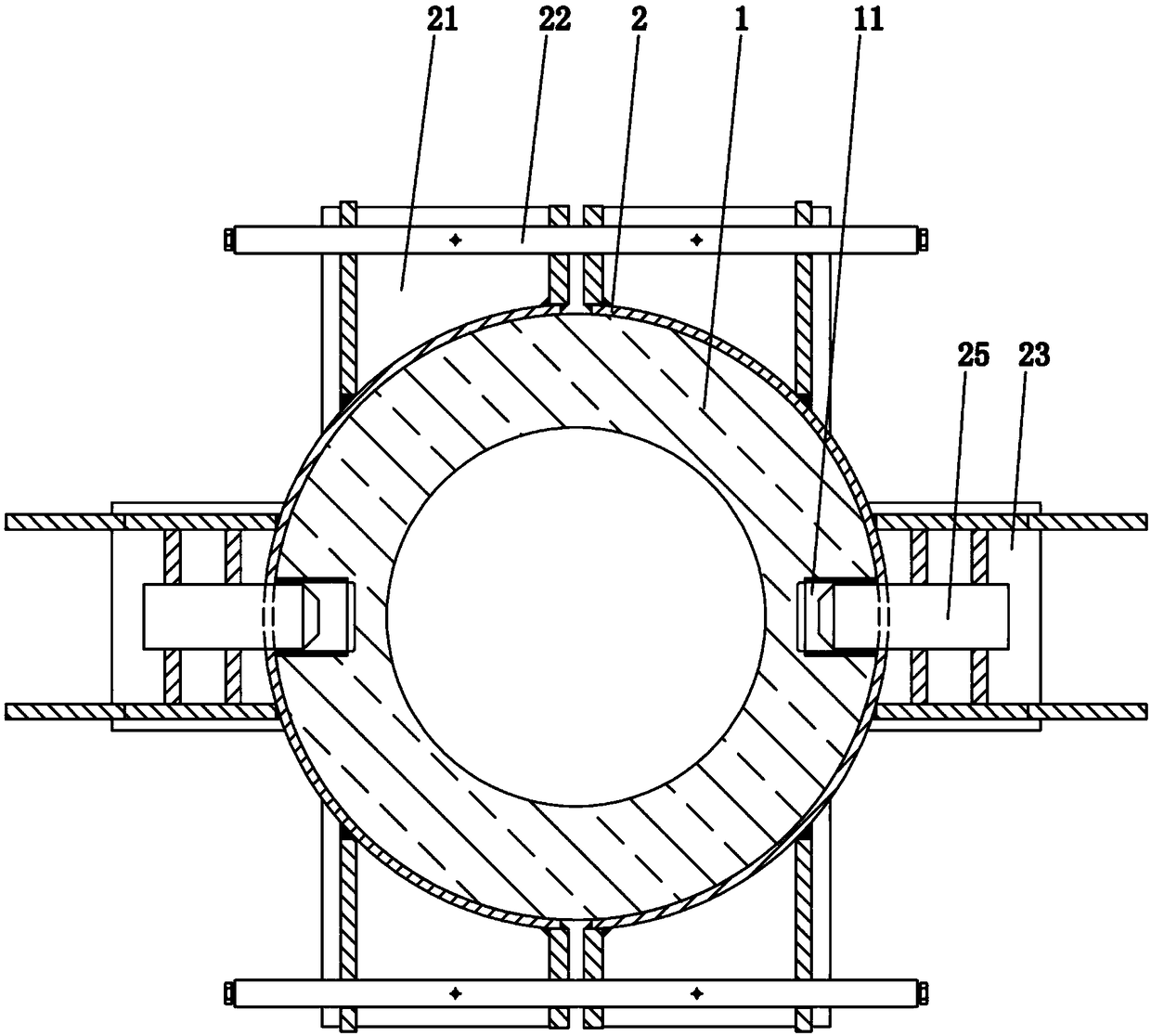

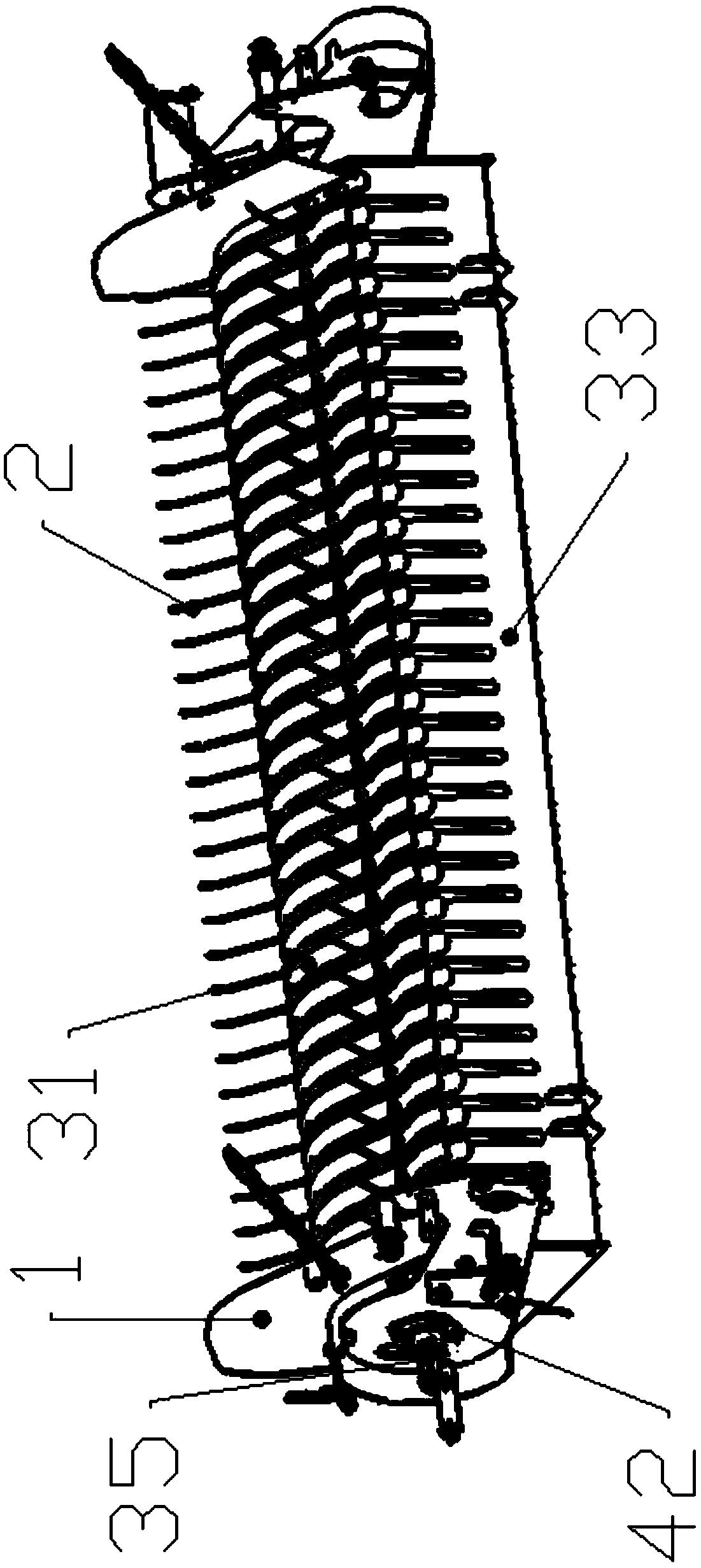

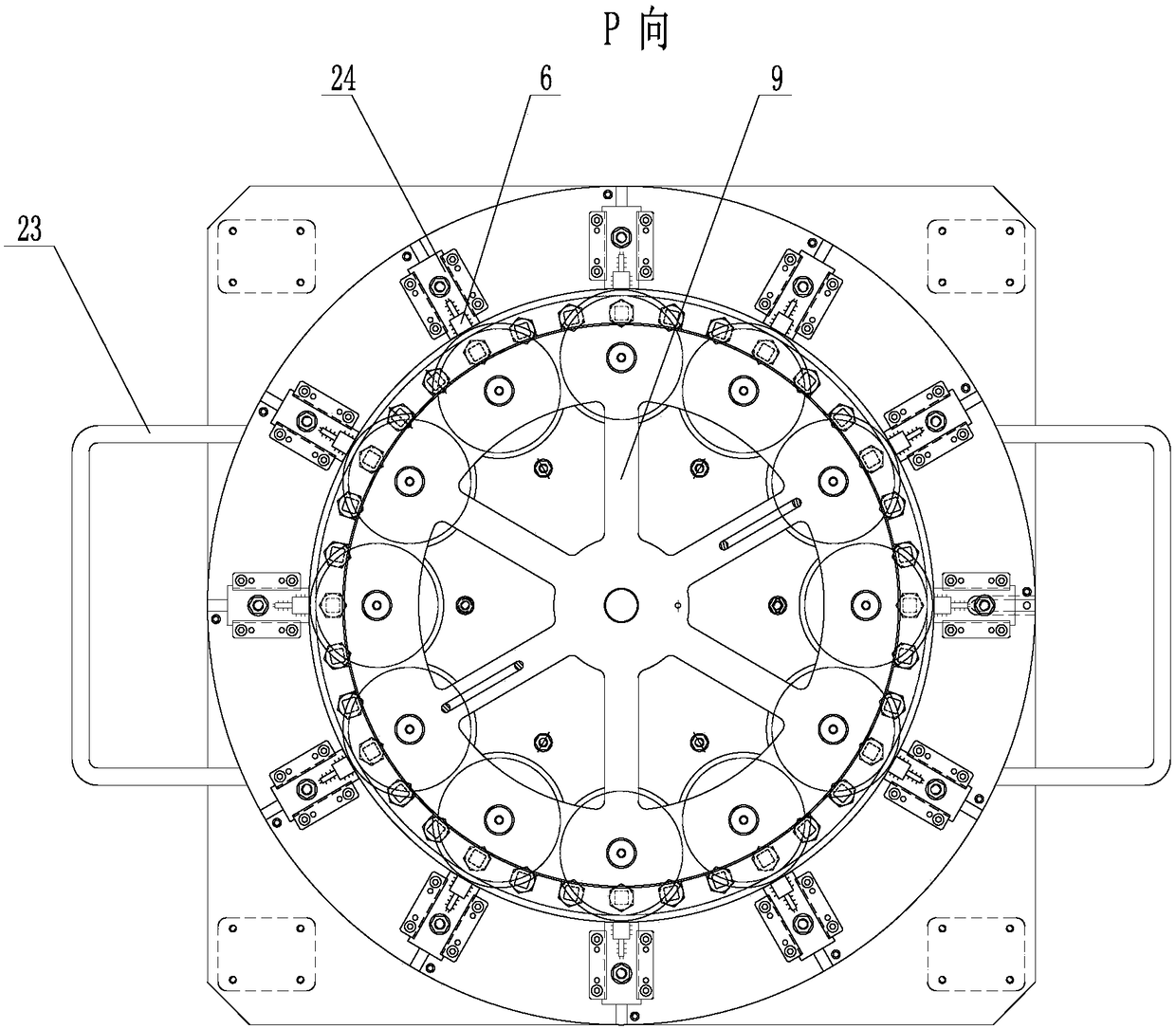

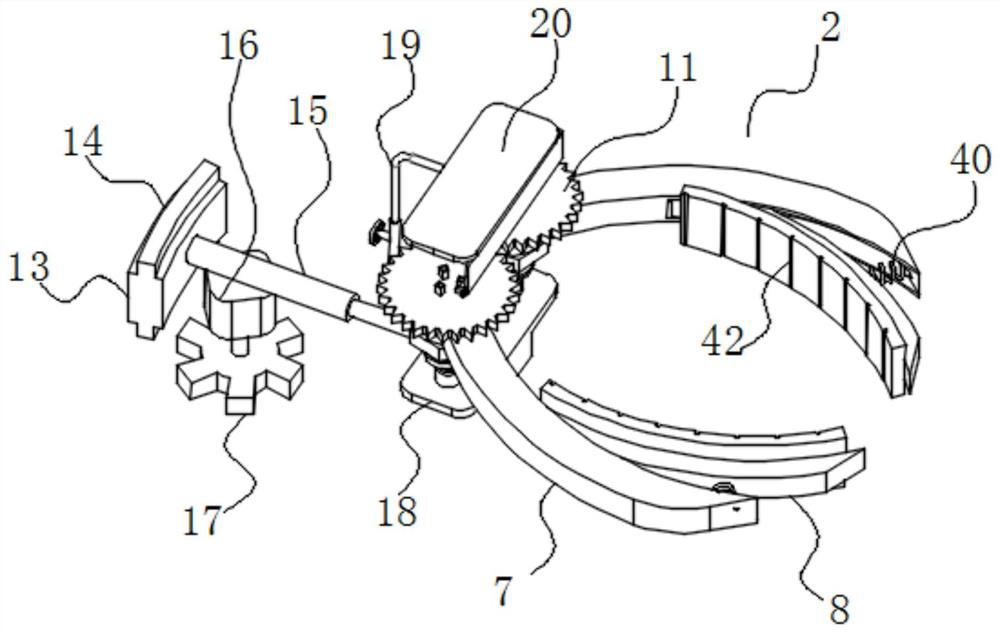

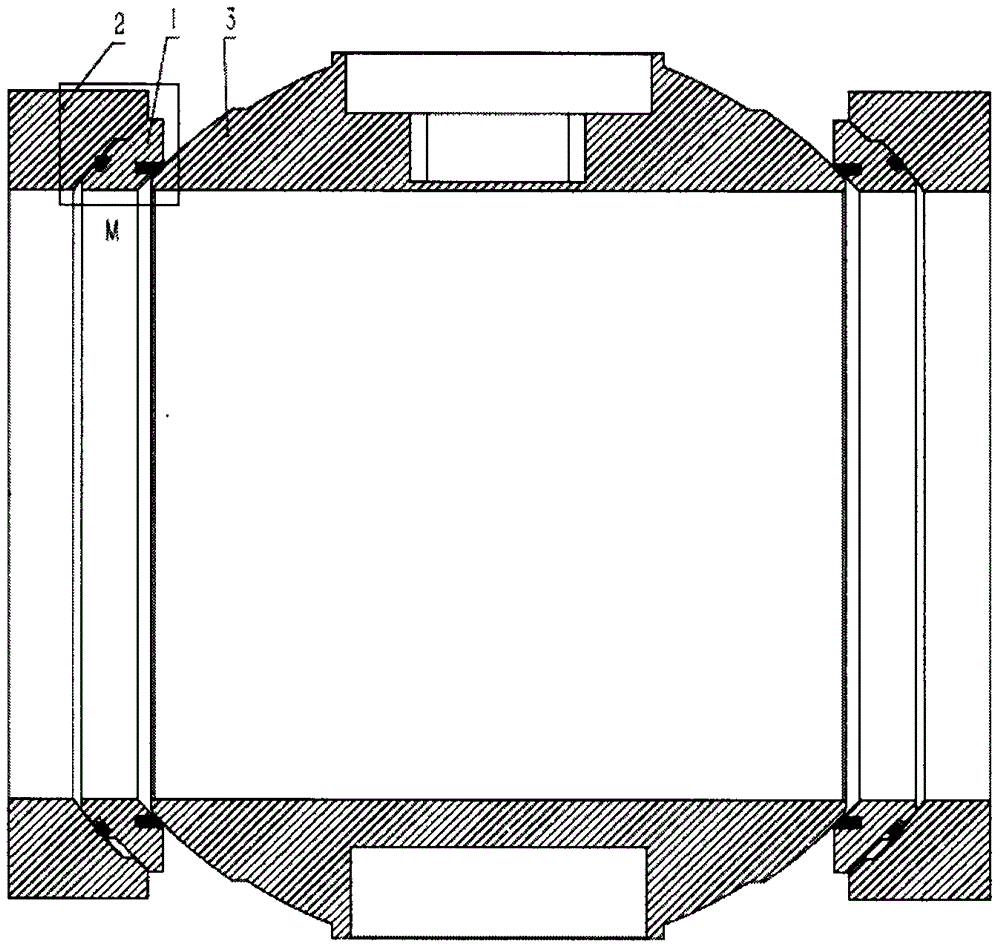

Flexible fixture device applied to assembly of antenna rib plates

InactiveCN104816266ATo overcome the poor recombination utilizationStrong reconfigurabilityWork holdersEngineeringMechanical engineering

The invention discloses a flexible fixture device applied to assembly of antenna rib plates. The flexible fixture device applied to assembly of antenna rib plates comprises a base, a support top plate, an upper-layer fixture structure unit and a lower-layer fixture structure unit. Each layer of the fixture structure unit comprises a support plate, a vertical column, a rotating shaft, a support body, two X-directional guide rails, a clamping module, a connector and a sliding rail seat, wherein the vertical column and the support body are fixedly connected to the top surface of the support plate, the two X-directional guide rails are fixedly connected one end surface of the support body, one end of the rotating shaft is matched with the connector and fixedly connected with the clamping module, one end surface of the sliding rail seat is slidingly connected with the X-directional guide rails through sliders, the other end surface of the sliding rail seat is provided with two Y-directional guide rails, and one end surface of the connector is slidingly connected with the Y-directional guide rails through sliders. The base is provided with a Z-directional guide rail, and the support plate of the lower-layer fixture structure unit is connected onto the Z-directional guide rail through a slider. The flexible fixture device applied to assembly of antenna rib plates solves the problem of poor reassembling usability, lower mechanism degree of freedom and lower assembling efficiency of antenna assembling fixtures.

Owner:SOUTHEAST UNIV

Spectacle hinge using large semicircular hinge hole structure

The invention relates to a spectacle hinge using a large semicircular hinge hole structure, when a spectacle leg is connected with a spectacle frame by using a single hinge, the spectacle hinge comprises a hinge shaft and a large semicircular hinge hole, the hinge shaft is installed from a notch position of the hole by the elasticity of the material of the large semicircular hinge hole and is positioned by the hinge hole to form the spectacle hinge, and the disassembly process is opposite to the assembly process; and when the spectacle leg is connected with the spectacle frame by using doublehinges, the spectacle hinge comprises a first hinge and a second hinge, each hinge is respectively composed of a first hinge shaft, a first large semicircular hinge hole, a second hinge shaft and a second large semicircular hinge hole, the hinge shaft is installed from the notch position of the hole by the elasticity of the material of the large semicircular hinge hole and is positioned by the hinge hole to form the spectacle hinge, and the disassembly process is opposite to the assembly process.

Owner:广州高增科技有限公司

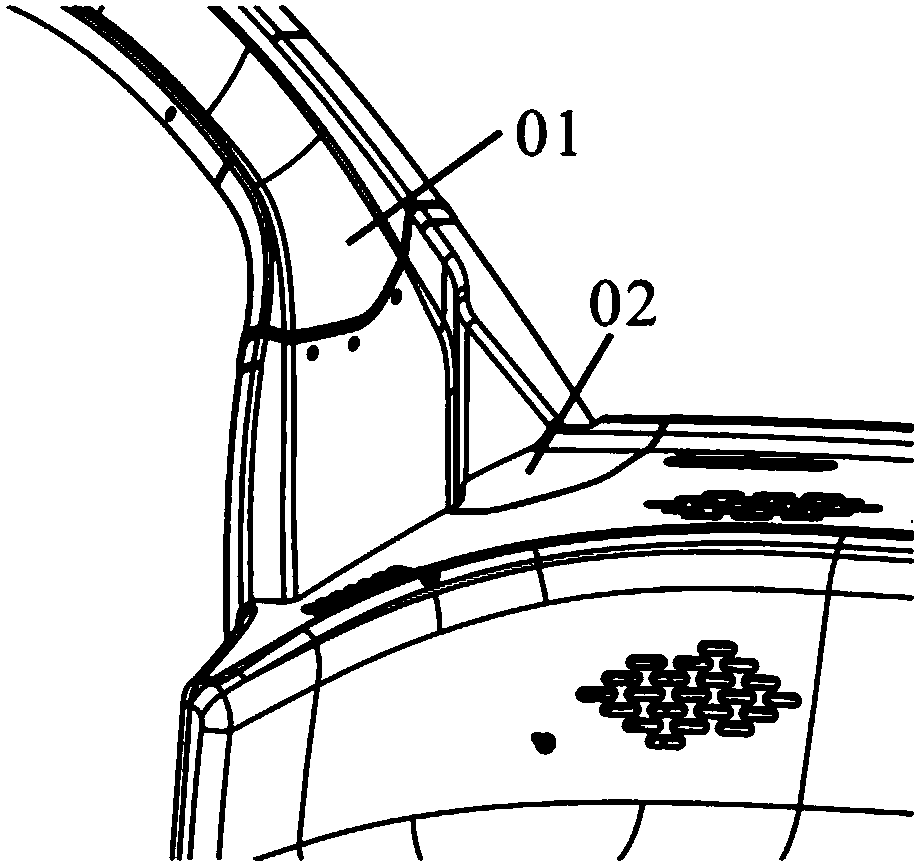

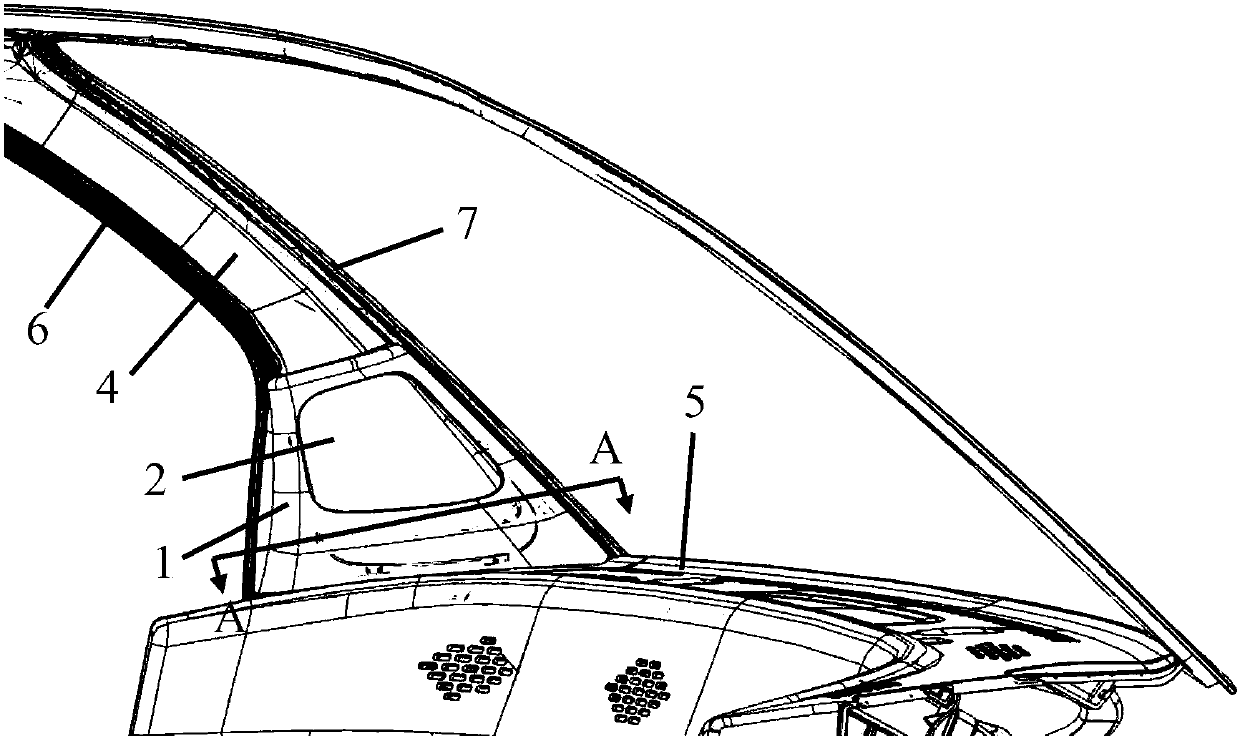

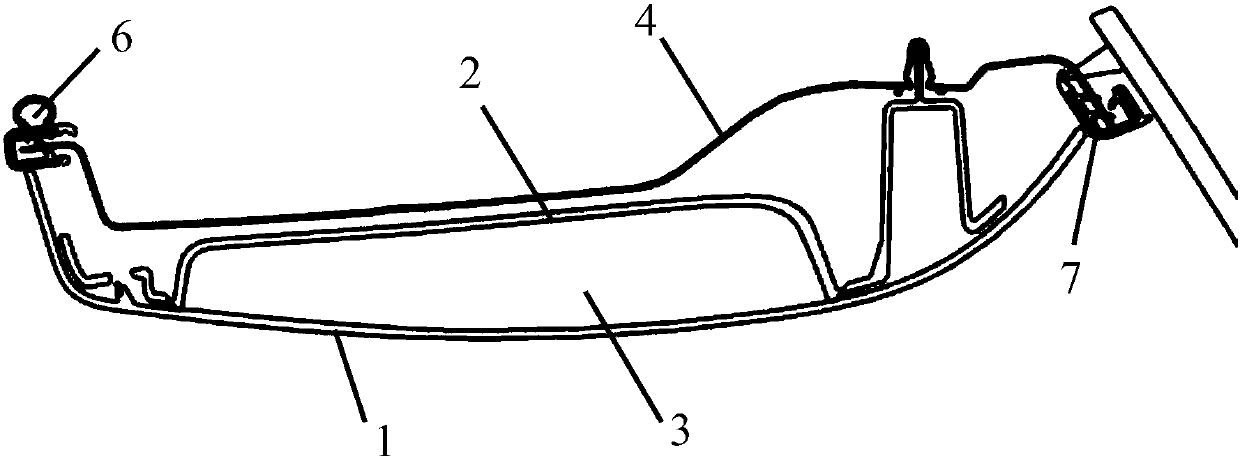

Automobile A-pillar decorative panel with storage function

PendingCN109955906AEasy to disassembleEasy to assemblePassenger spaceSuperstructure subunitsEngineering

The invention discloses an automobile A-pillar decorative panel with the storage function. The A-pillar trim panel comprises an A-pillar decorative panelouter plate and an A-pillar decorative panel inner plate. The A-pillar decorative panel outer plate is detachably fixed on the A-pillar decorative panel inner plate. The A-pillar decorative panel inner plate is detachably fixed on a A-pillar metalplate. The A-pillar decorative panel outer plate abuts against an instrument panel in a detachable mode, and a storage space is arranged between the A-pillar decorative panel outer plate and the A-pillar decorative panel inner plate. According to the automobile A-pillar decorative panel with the storage function, the welding spots of the A-pillar metal plate and the matched boundary of the instrument panel with the A-pillar metal plate are shielded. The automobile A-pillar decorative panel is easy to mount and dismount. The assembling efficiency is improved, and the storage space is increased.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

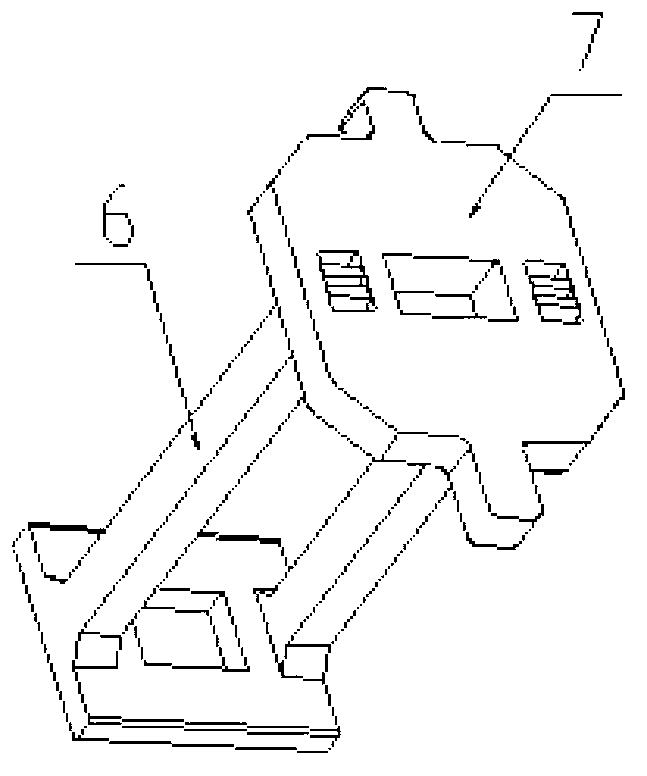

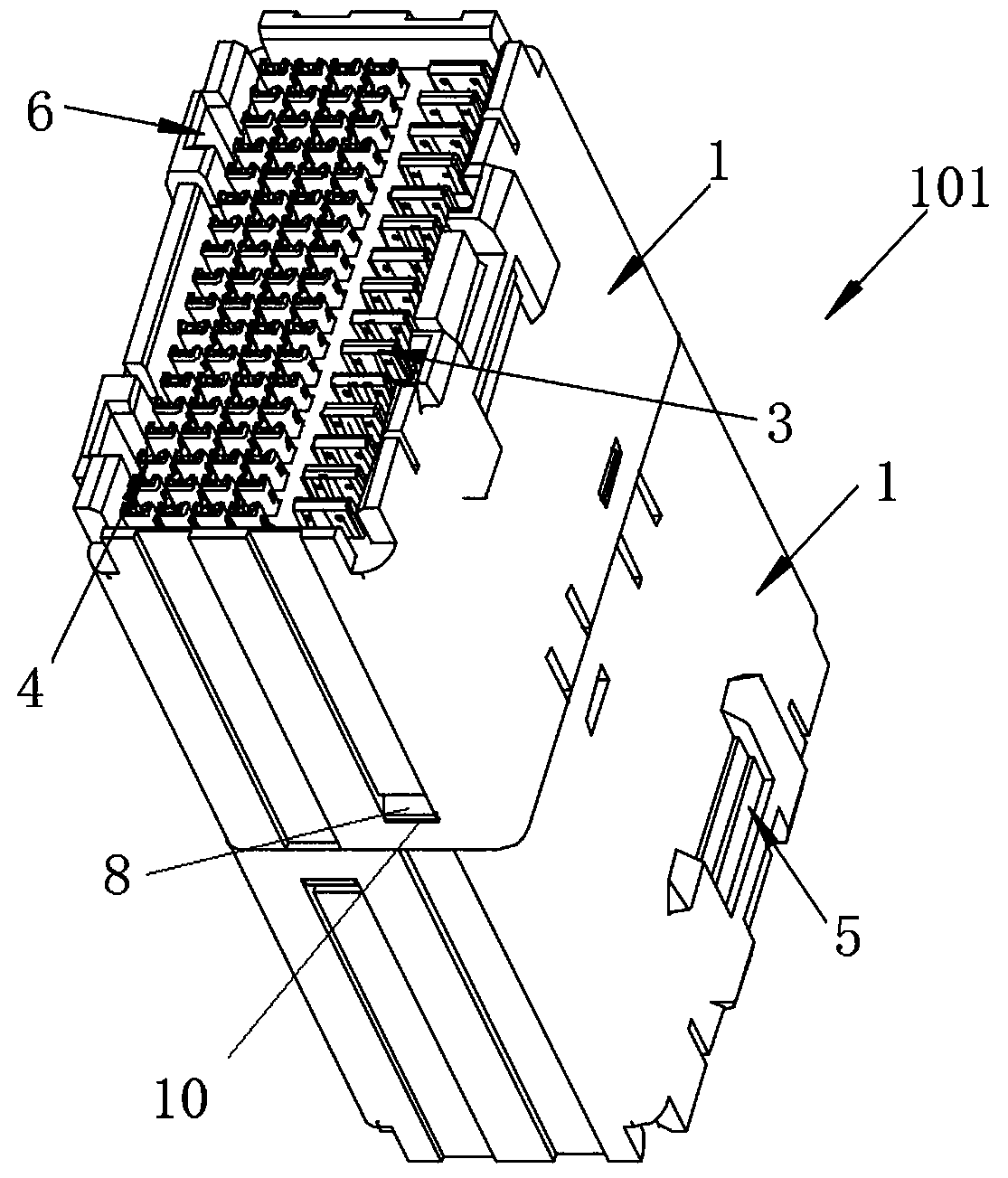

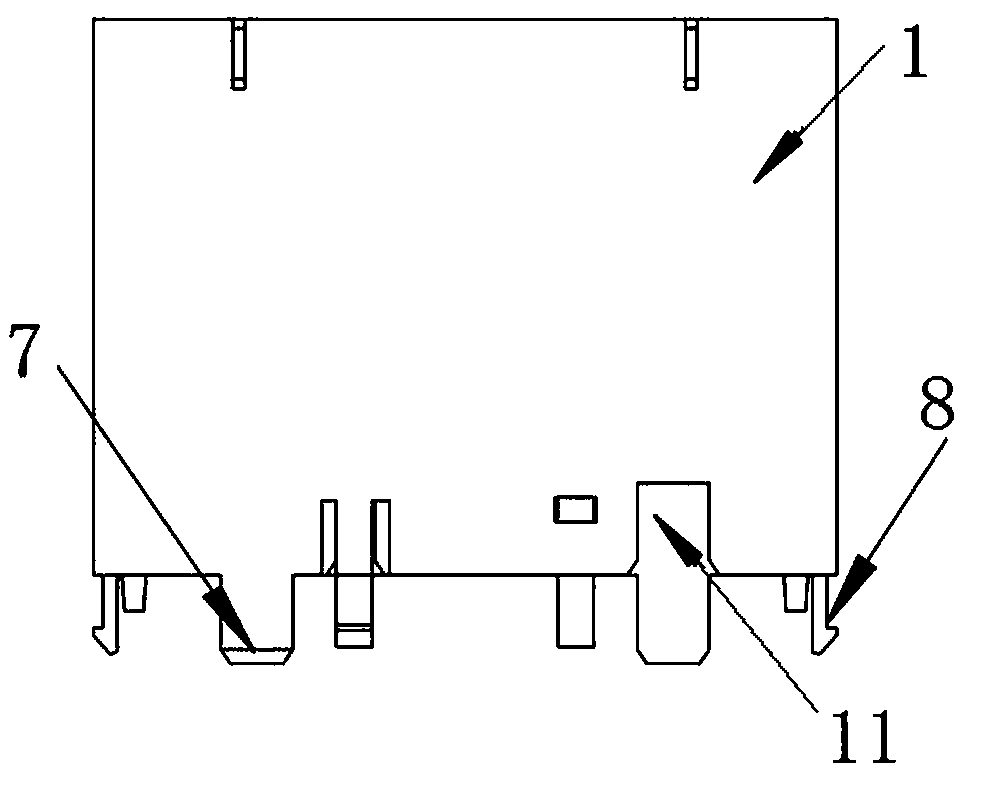

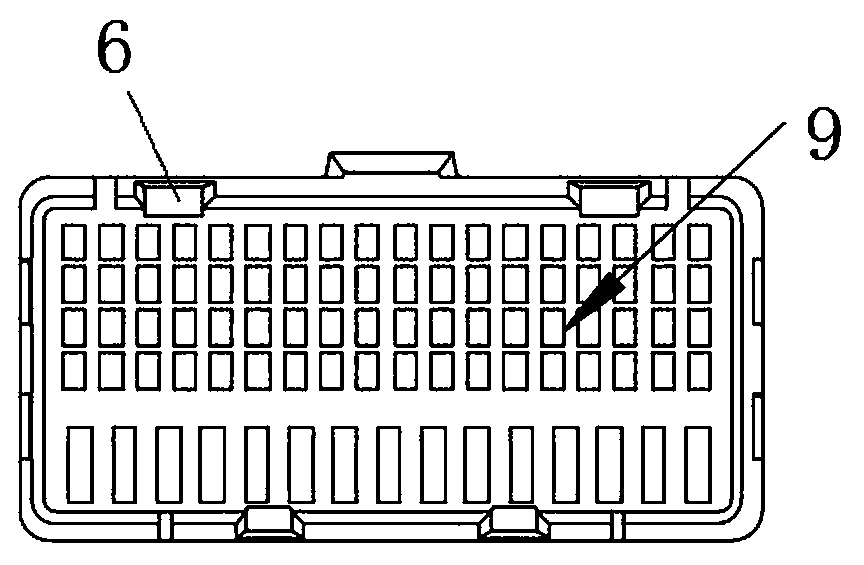

Adapter connector housing and adapter connector

ActiveCN109659755AImprove signal transmission performanceEasy to assembleSecuring/insulating coupling contact membersComputer moduleEngineering

The invention relates to an adapter connector housing and an adapter connector. The adapter connector housing comprises two housing units which are oppositely arranged and identical in structure. Theconnection end of each housing unit is provided with at least one set of hooks and necks, and the same set of hooks and necks are symmetrically arranged, each housing unit is internally provided witha through hole configured to hold a signal transmission module, and a limiting structure configured to be in stop limiting fit with the signal transmission module in the insertion direction of the adapter connector to prevent the signal transmission module from taking off from the corresponding opposite end is integrally formed at the opposite end of each housing unit. The adapter connector housing is formed by buckling of the hooks and the necks of the two housing units having the same structures to facilitate assembling of the signal transmission module in the adapter connector housing so asto reduce the assembly efficiency, and the structures of the two housing units are identical, a housing unit is only produced to achieve connection of the two housing units so as to reduce the mold preparation and reduce the cost.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD +1

A strut spring assembly equipment

The invention discloses a supporting rod spring assembling device and belongs to the field of supporting rod spring assembling equipment. The supporting rod spring assembling device comprises a slide rail line, an outer sleeve positioning part, spring keeping parts and a spring compressing part, wherein the outer sleeve positioning part, the spring keeping parts and the spring compressing part are sequentially arranged along the slide rail line from front to back, and the spring compressing part and the outer sleeve positioning part are both arranged on the slide rail line in a sliding manner; the outer sleeve positioning part comprises a positioning sliding plate and an outer sleeve clamping base arranged on the positioning sliding plate; the spring keeping parts are sequentially arranged along the slide rail line, and two keeping mechanisms of each spring keeping part are arranged above the slide rail line relative to the mirror image of the slide rail line; and the spring compressing part comprises a driving sliding plate, a shifting plate and a spring sleeve clamping base, and the shifting plate and the spring sleeve clamping base are sequentially arranged on the driving sliding plate from front to back. It is guaranteed that no deformation is generated in the spring assembling process, friction collision between the spring and other parts is avoided, the assembling time is shortened, the assembling efficiency is improved, the automation degree is high, and the supporting rod spring assembling device can adapt to supporting rods in different length specifications.

Owner:CHENGDU TIANCHUANG PRECISION MOLD

Cleaning rotating brush and normal juice machine

ActiveCN106388238AWill not cause accumulationReduce noiseBrush bodiesBristle carriersBristleDrive motor

The invention relates to the technical field of normal juice machines, and especially relates to a cleaning rotating brush and a normal juice machine. The cleaning rotating brush comprises a rotating brush rack, the rotating brush rack is provided with a rotating brush main body, the rotating brush main body comprises a connection board, the connection board is provided with a hairbrush layer, the connection board is connected with the rotating brush rack in a detachable manner, and the hairbrush layer is arranged at the inner side of the rotating brush rack. The normal juice machine comprises a front body, a cylindrical filter screen is arranged in the front body, a feed screw is arranged in the filter screen, the feed screw is connected with a driving motor, the outer side of the filter screen is provided with the cleaning rotating brush, and the bottom of the feed screw is connected with the bottom of the rotating brush rack. The cleaning rotating brush can clean the metal filter screen, residues are not accumulated on the hairbrush layer and the metal filter screen, and the hairbrush layer and the metal filter screen do not need to be cleaned individually, the cleaning rotating brush can be used more safely and reliably, noise generated between the bristles and the metal filter screen is low, and the cleaning rotating brush can be used more comfortably. The normal juice machine has a better metal filter screen cleaning effect and a better muting effect.

Owner:GREE ELECTRIC APPLIANCES INC

A prefabricated concrete octagonal column assembly device and its installation method

ActiveCN106351400BSolve the problem that the hanging point cannot be embedded in advanceReduce usageStrutsBuilding material handlingEngineeringPrecast concrete

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

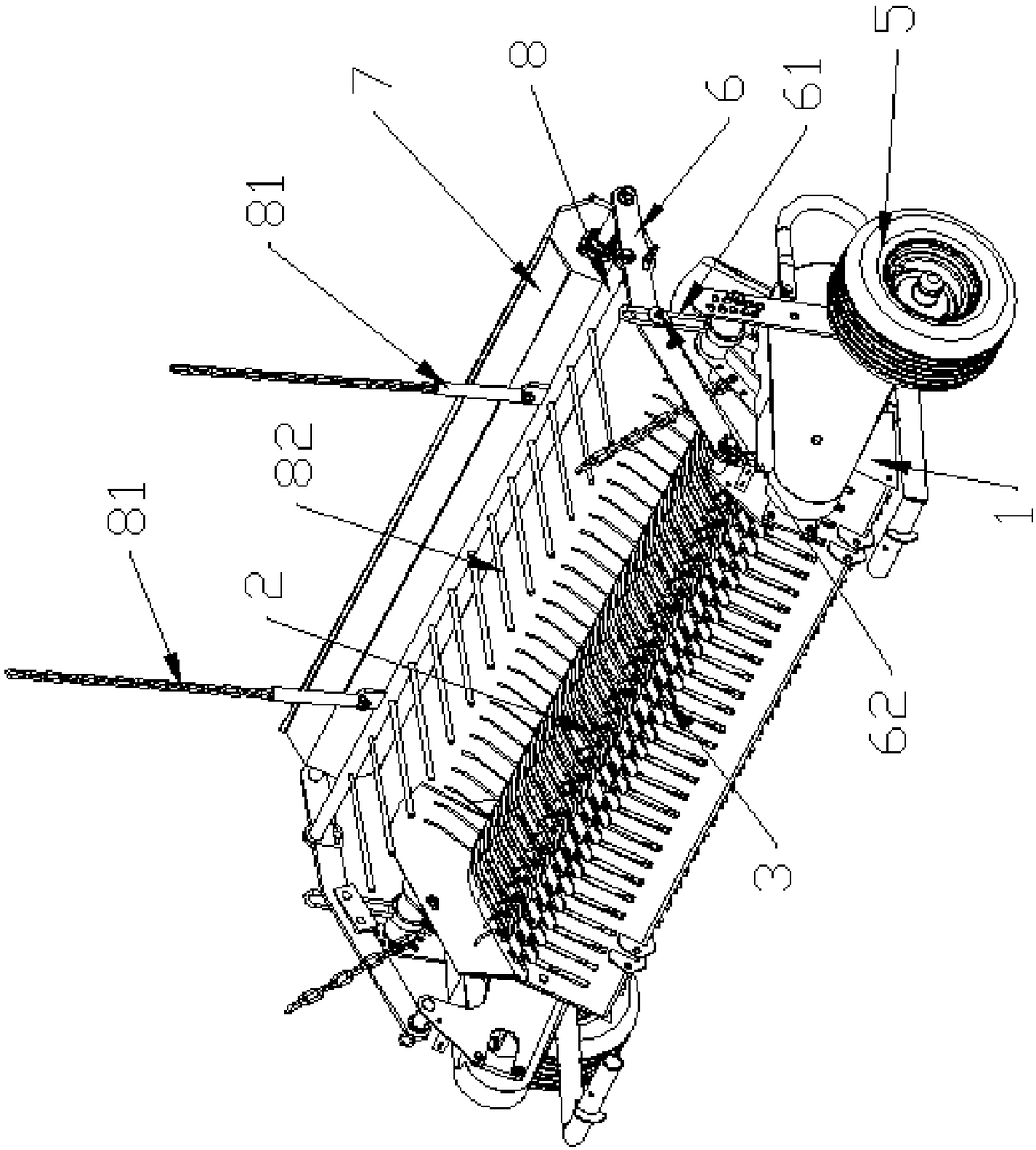

Pickup device for straw baler

PendingCN109328660APrevent upward scatterImprove work efficiencyLoadersEngineeringMechanical engineering

The invention provides a pickup device for a straw baler, and belongs to the field of agricultural baler devices. The pickup device comprises a machine frame, a rotating assembly, retainer assembliesand elastic claw assemblies. The rotating assembly is erected on the machine frame and rotationally connected with the machine frame. The elastic claw assemblies are fixedly arranged on the rotating assembly. The retainer assemblies are arranged on the outer ring of the rotating assembly. The retainer assemblies are arranged between every two adjacent elastic claw assemblies. A follower wheel assembly is arranged at the lower end of the machine frame. Supporting force arms are symmetrically arranged at the upper end of the machine frame. One end of each supporting force arm is hinged to the machine frame. The other end of each supporting force arm is provided with a floating wheel. A floating roller is erected on the symmetrical supporting force arms and rotationally connected with the supporting force arms. A positioning rod is arranged on each supporting force arm and provided with a plurality of comb teeth. The upper end of each positioning rod is provided with a limiting chain connected with a fixing piece. The pickup device is simple in structure, low in cost, high in carding efficiency, not prone to getting stuck, low in failure rate and stable in performance.

Owner:天津威猛机械制造有限公司

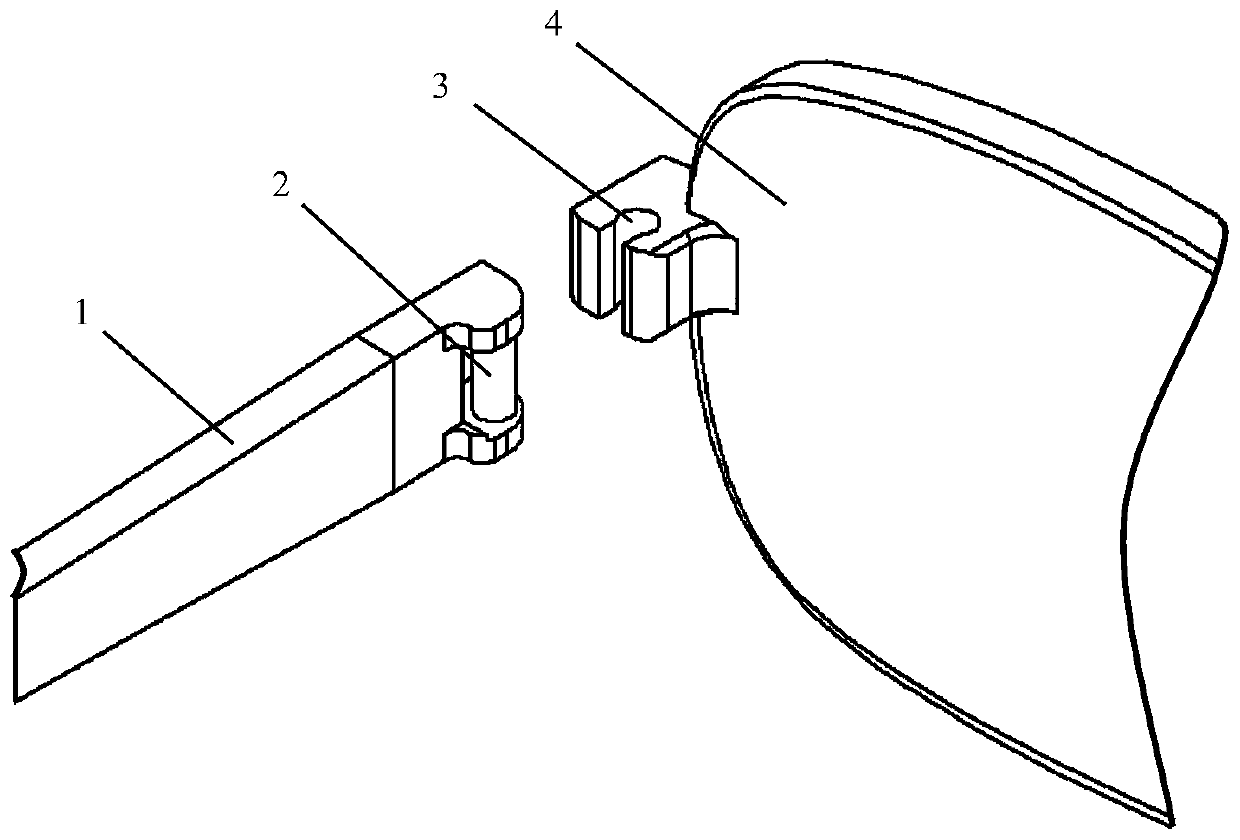

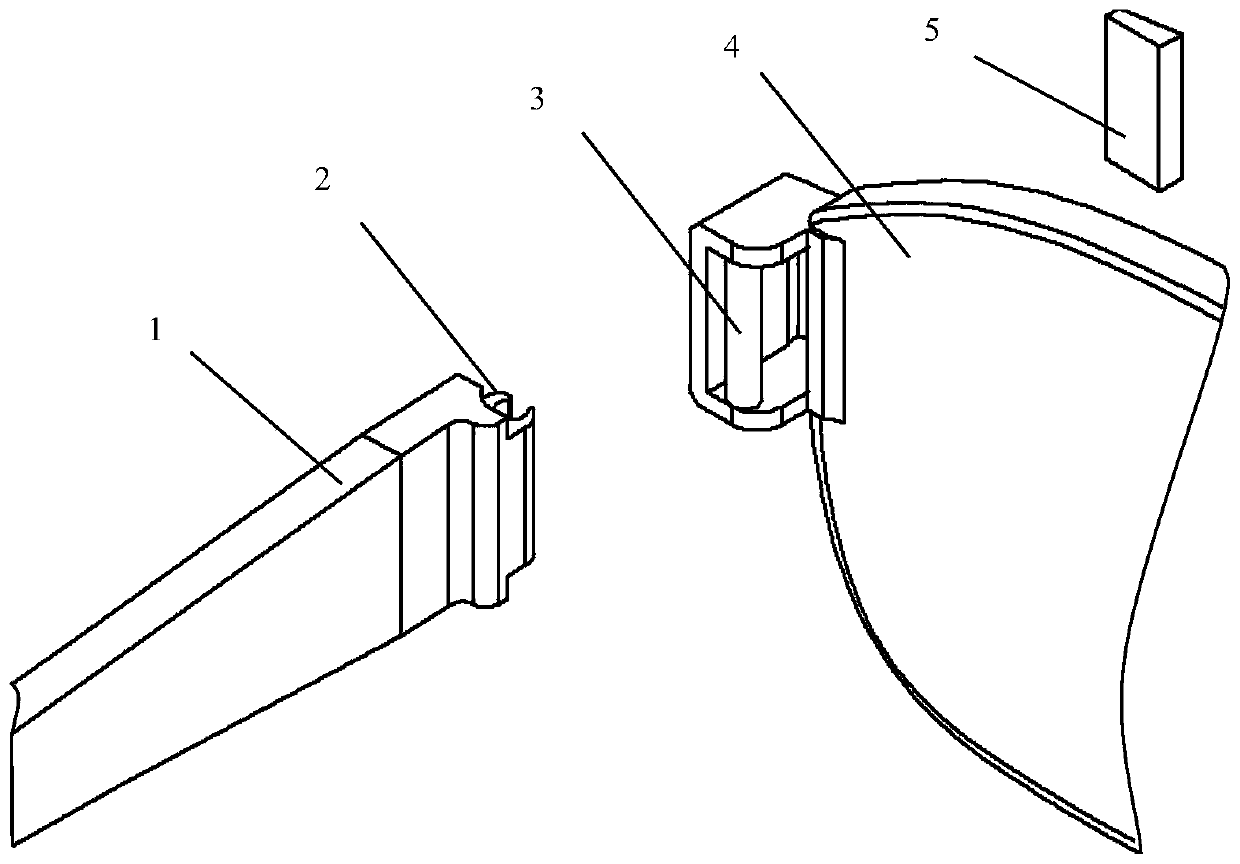

Anti-stripping pipe clamp

ActiveCN102808828AAvoid pre-expansionReduce assembly efficiencyPipe supportsDowelsPipe fittingEngineering

The invention belongs to the field of automobile connecting pieces, specifically relates to an anti-stripping pipe clamp. The anti-stripping pipe clamp comprises a nip used for clamping pipe fittings. The other side of the nip relative to a clamping interface used for clamping pipe fittings is reversely provided with inserting columns orderly. Each inserting column is distributed with right tapered through holes penetrating the inserting column. The through holes form a hollow expansive sleeve structure of the inserting column, and the inserting columns and automobile fixing pieces form an inserting type expansive nail match. The pipe clamp also comprises expansive pins used for forming an inserting match with the inserting columns which are in a shape of an expansive sleeve. The inserting ends of the expansive pins are forwardly provided with sheltering sections orderly along the axes. The sheltering sections and the top ends of the inserting columns form a unidirectional sheltering match. The separation distances of the sheltering sections on the expansive pins and the inserting ends are greater than or equal to the lengths of the through holes. The unidirectional stop performance is realized after the expansive pins are inserted in the inserting columns by arranging the sheltering sections at the inserting ends of the expansive pins, so that the storage and transportation cost of the pipe clamp is obviously reduced, and meanwhile the self-working performance of the pipe clamp is maintained.

Owner:黄山市必利精密塑业科技有限公司

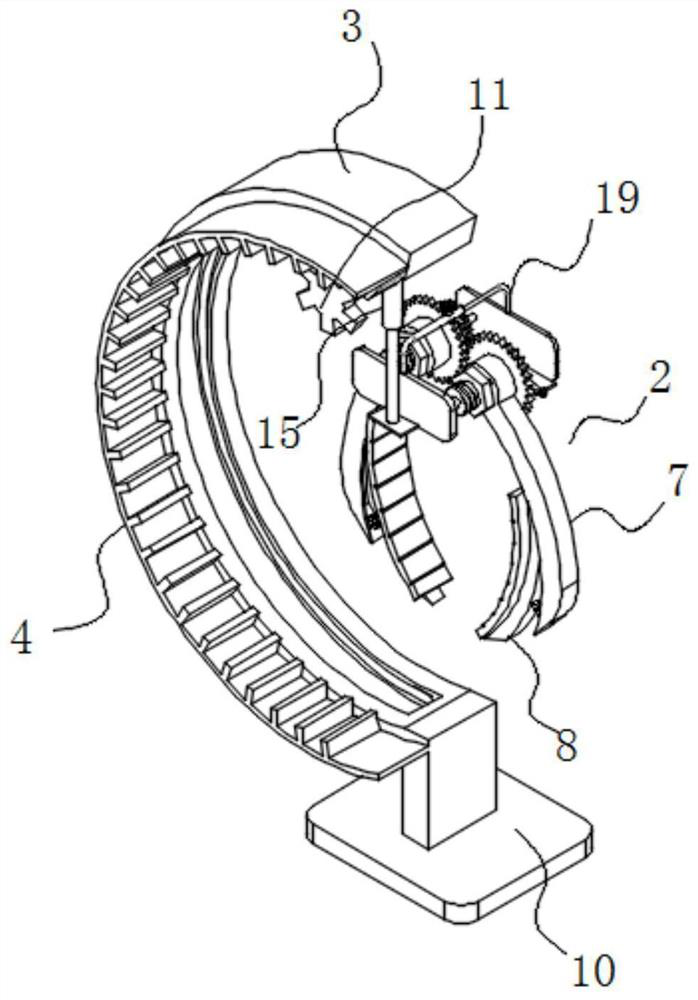

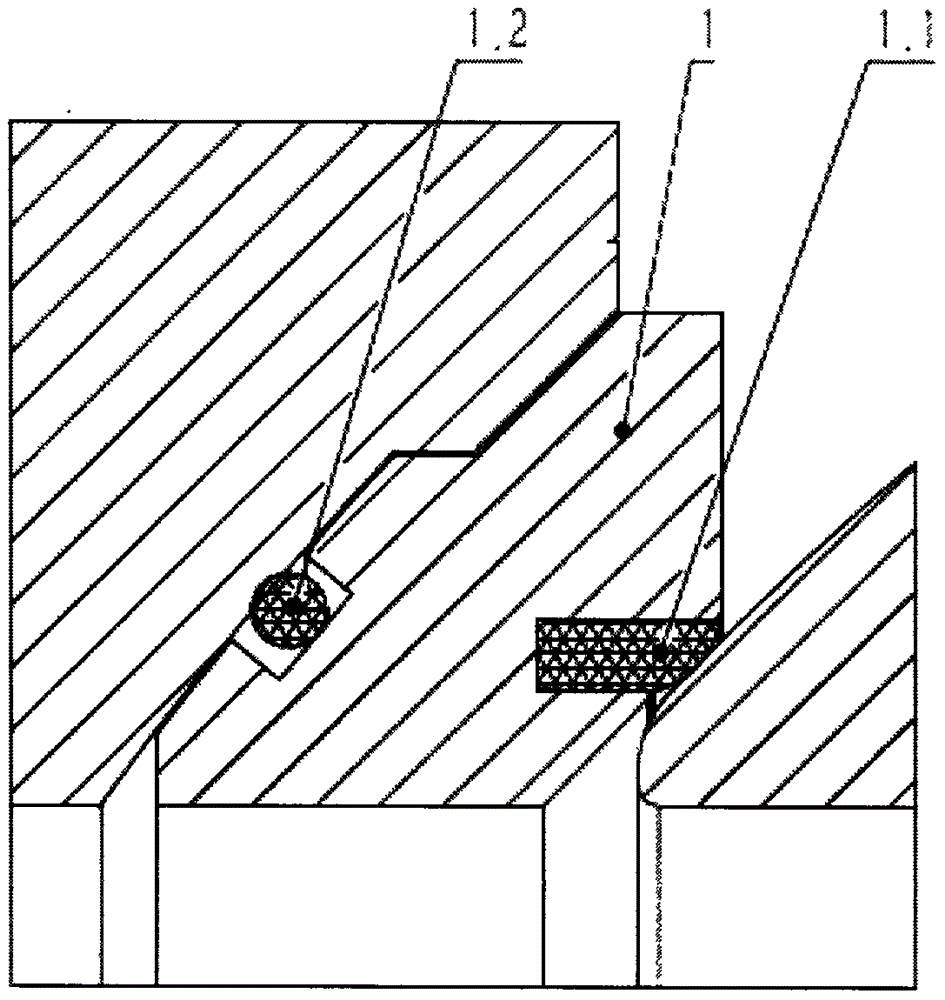

Intelligent assembly equipment for front cover of new energy motor

ActiveCN110868030AReduce assembly efficiencyReduce vibrationManufacturing dynamo-electric machinesElectric machineNew energy

The invention relates to the technical field of motor assembly, in particular to intelligent assembly equipment for a front cover of a new energy motor. The intelligent assembly equipment comprises abase, a strut is arranged in the center of the top of the base, an operating panel is fixedly connected to the top of the strut, damping shock absorbers are circumferentially and uniformly arranged between the bottom of the operating panel and the top of the base at intervals, a first annular sliding rail surrounds the top of the operation panel in the circumferential direction, a motor fixing mechanism is slidably connected to an inner cavity of the first annular sliding rail, a stand column is fixedly connected to the center of the top of the operating panel, four sets of straight sliding rails are evenly arranged on the lower portion of the outer wall of the stand column in the circumferential direction at intervals, electric sliding blocks are slidably clamped in inner cavities of thestraight sliding rails in a matched mode, and an electro-hydraulic push rod is fixed at the front end of each electric sliding block. The defects that in the prior art, a traditional new energy motorfront cover is assembled through a single process and single equipment, the assembling efficiency is low, and the occupied production space is large can be effectively overcome.

Owner:JIAMUSI ELECTRIC MACHINE

The device used for the pre-assembly of the aero-engine combustor flame tube

The invention discloses a device for preassembly of a matching table of a flame tube of a combustor of an aero-engine. The components of the device comprise a base, a bearing shaft, a turntable, a dierectifying plate, a plug pin assembly, a cover plate, a first verifying pin and a second verifying pin. The bearing shaft is arranged in the center position of the base, the turntable is arranged outside the bearing shaft in a sleeved mode and rotatably arranged on the base and used for mounting a matching table component of a collector. The die verifying pin is fixedly arranged above the turntable, and the plug pin assembly is used for conducting angular positioning on the flame tube. The cover plate is mounted at the top end of the bearing shaft through a fastening piece and used for limiting and fastening a matching table component of the flame tube. The first verifying pin is used for verifying connection coordination of the matching component of the collector and the flame tube, andthe second verifying pin is used for verifying the coordination of the outer end of the flame tube. The device is adopted to conduct preassembly of the matching table of the flame tube of the combustor of the aero-engine, the assembly efficiency and the assembly continuity of the aero-engine and the coordination and the stability of the assembly position of the matching table can be improved greatly, the probability that engine components are damaged due to bumping or scratching can be lowered, and the product quality is improved.

Owner:AECC AERO SCI & TECH CO LTD

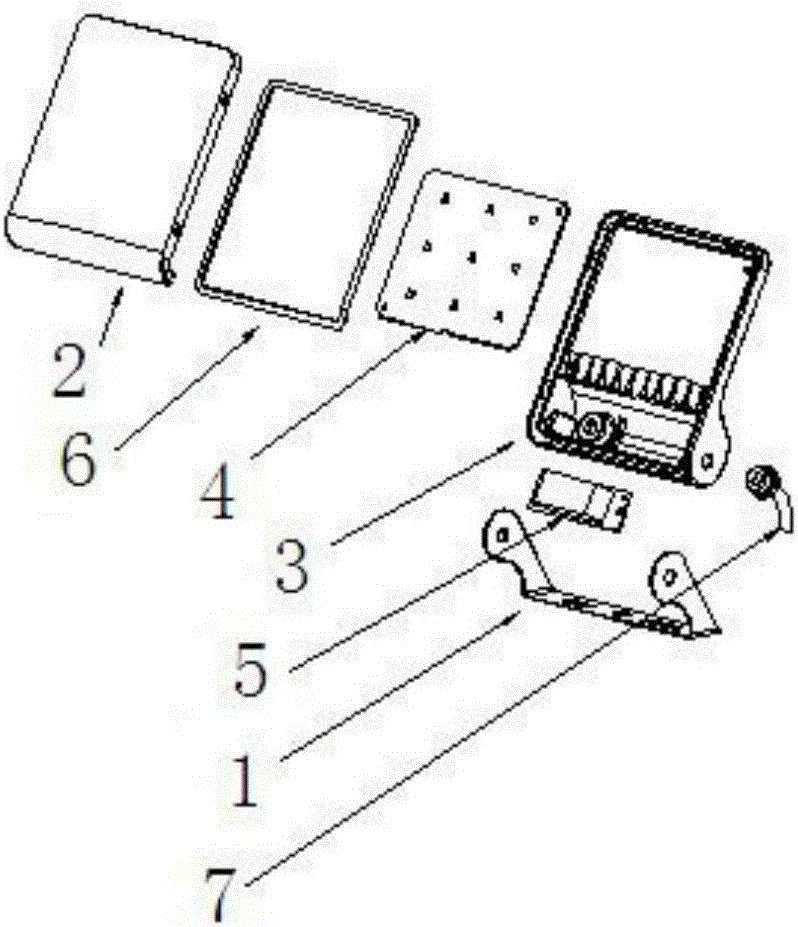

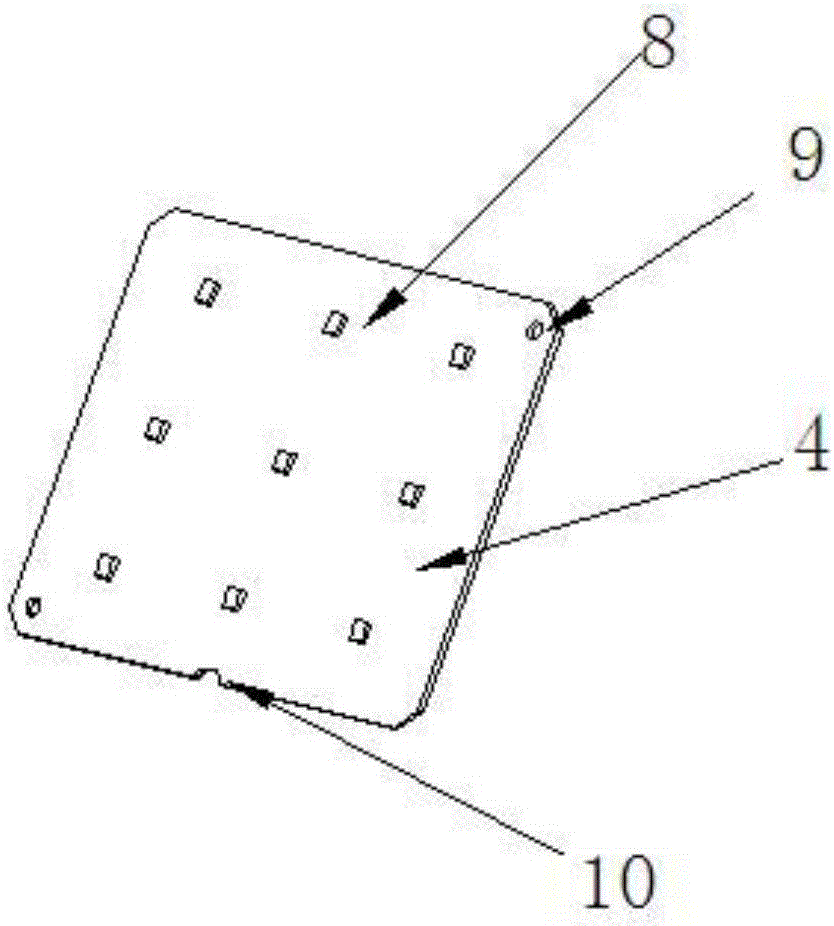

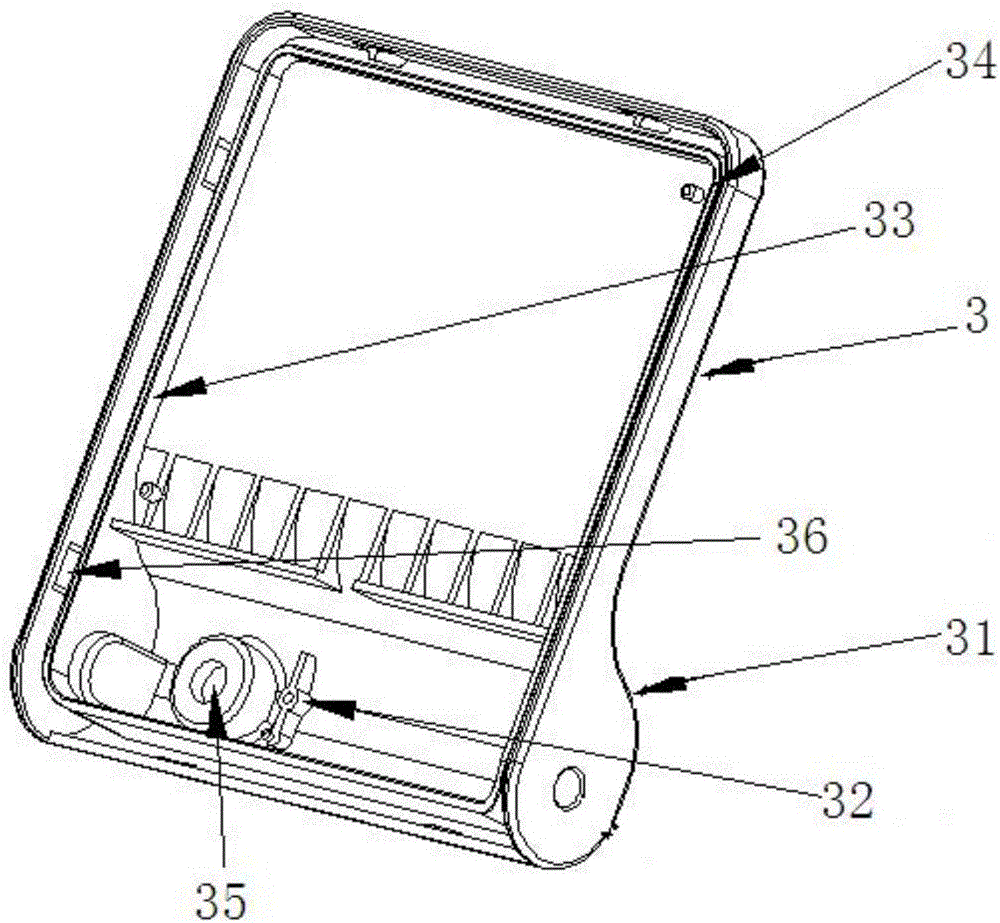

LED projection lamp

InactiveCN106287432ALightweightRealize thinner and lighterPlanar light sourcesLighting support devicesDie castingEngineering

The invention discloses an LED projection lamp. The LED projection lamp comprises a support, a panel and a shell with the front face open. The support is connected with the shell. The panel covers the position of the opening of the shell. A light source board and a PCB are arranged in the shell. The panel is a transparent panel made of PC materials. The panel and the opening edge of the opening of the shell are sealed through a silicone rubber ring. The light source board is a high heat conduction plane aluminum substrate. A plurality of LED lamp beads are arranged on the light source board at equal intervals. Corresponding convex lenses are arranged on the panel opposite to the LED lamp beads. The shell is formed through high heat conduction aviation aluminum in a die casting manner. The LED projection lamp is attractive in appearance, few components are adopted, the assembling efficiency is high, and the structure is light and thin.

Owner:HANGZHOU XUGUANG LIGHTING ELECTRICAL APPLIANCES

Part grabbing device for automatic production workshop

PendingCN113602793ASolve damage, problems affecting production qualityAvoid damageMetal working apparatusConveyor partsGear wheelMachining

The invention provides a part grabbing device for an automatic production workshop, and belongs to the technical field of machining equipment. The problems that when an existing grabbing device grabs parts, the parts cannot be protected, the parts are prone to being damaged, and the production quality is affected are solved. The part grabbing device comprises a supporting frame and a grabbing assembly, the grabbing assembly is connected with the supporting frame in a sliding fit mode, the supporting frame comprises an arc-shaped connecting plate, the side face of the arc-shaped connecting plate is fixedly connected with an arc-shaped gear strip, and the grabbing assembly comprises a sliding frame, a rotating component, a first clamping jaw and a second clamping jaw. One end of the rotating component is connected with the sliding frame in a rotating fit mode, the other end of the rotating component is connected with the sliding frame in a clamping fit mode, the first clamping jaw is connected with the rotating component in a clamping fit mode, the first clamping jaw is connected with the second clamping jaw in a rotating fit mode, and the inner side face of the rotating component is connected with the gear strip in a sliding fit mode. The part grabbing device for the automatic production workshop is mainly used for grabbing parts.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Vehicle headlight installation assembly and installation method thereof

The invention discloses a vehicle headlight installation assembly and an installation method thereof, belonging to the field of automobiles. The installation method comprises the following steps: positioning a vehicle headlight and a front fender with positioning components, fixedly connecting the vehicle headlight and a vehicle bracket and a crossbeam with fasteners, fixedly connecting a front bumper installation seat, the vehicle headlight and the front fender with connectors, and installing a front bumper on the front bumper installation seat. Therefore, the invention solves the problems of difficult assembly, high labor intensity and low assembly efficiency during manual installation of the headlight and surrounding components and high cost during installation with assembly aids without increasing the equipment and the labor intensity, and has the advantages of low cost, easy assembly and adjustment, high assembly efficiency and no increase in the labor intensity. When in use, the invention can improve the site production speed and avoid the quality problem.

Owner:CHERY AUTOMOBILE CO LTD

Ball valve seat

The invention discloses a ball valve seat, and particularly relates to the ball valve seat capable of being fast assembled and disassembled. A sealed closed structure is formed by arranging sealing parts between a valve seat body and a valve body as well as between the valve seat body and a ball body respectively; the valve seat body and the valve body are respectively provided with an arc-shaped surface, a rectangular boss is arranged in the vertical direction of the valve body, a rectangular groove is formed in the vertical direction of the valve seat body, the valve seat body can rotate around the arc surface and move vertically along a sliding groove, an opening between the two ends of the valve seat body is greater than the width of the ball body when the valve seat body moves to the lower end, then the ball body can be fast installed into the valve body, the valve seat body is pulled back to the installation position by a tool, is fixed by a locating device and then reaches the installation position, and finally sealing is realized. When the ball valve seat needs to be fast disassembled, users just need to take down the locating device, push the valve seat body to the lower end through the tool and take out the ball body, then the valve seat body can be fast taken out, and disassembly can be realized. The ball valve seat can be fast assembled and disassembled and is low in machining cost and high in installation efficiency.

Owner:ZHONGYU VALVE COMPONENTS SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com