Household electrical appliance product and bonding method thereof

A technology for home appliances and bonding methods, applied in bonding methods, adhesives, household heating, etc., can solve the problems of silicate glass plate and cover appearance defects, long curing cycle, waste of process equipment, etc. The effect of glue curing cycle, shortening bonding curing cycle, and accelerating assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

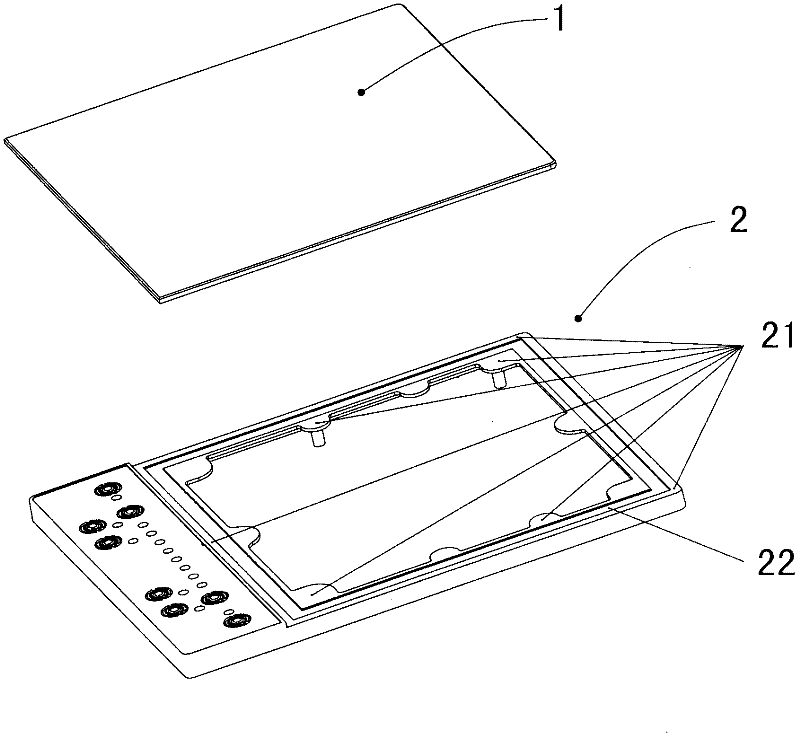

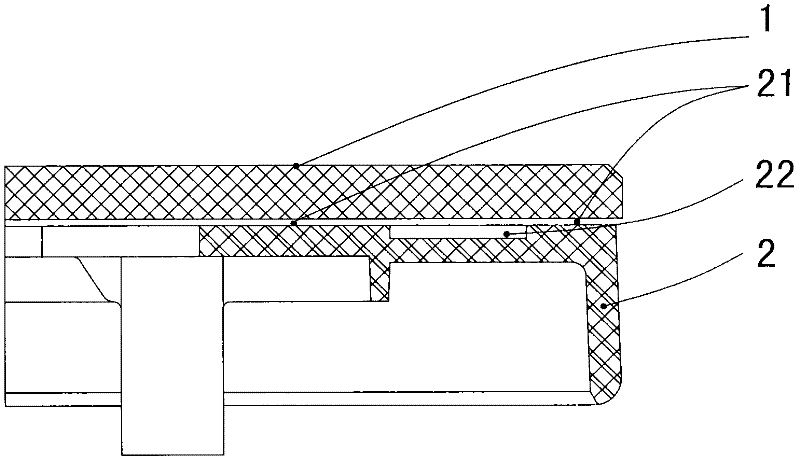

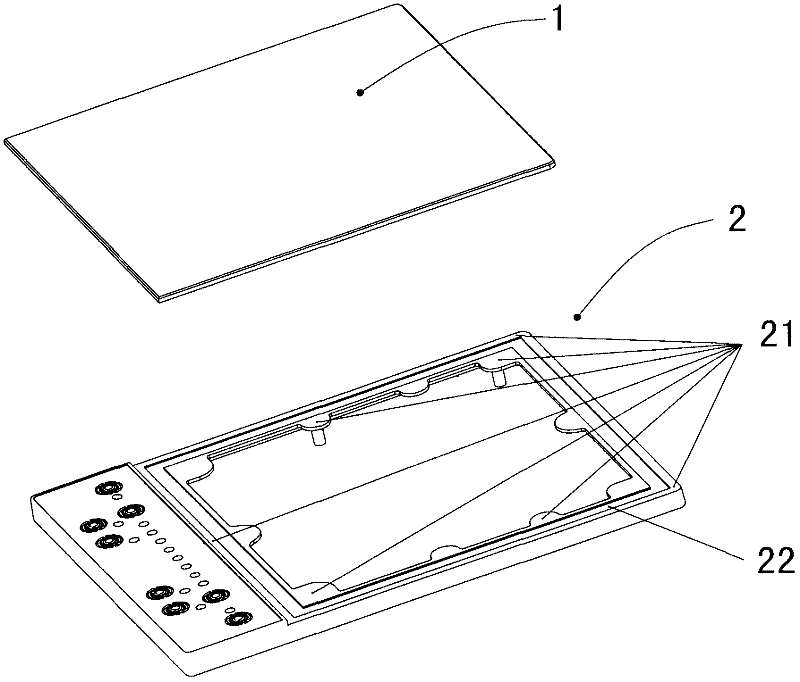

[0026] like figure 1 , 2 , the home appliance product is an induction cooker, the first part is a cover 2, the second part is a silicate glass plate 1, and the silicate glass plate 1 covers the outside of the cover 2; the cover 2 is set There is an adhesive surface consistent with the shape of the outer contour of the silicate glass plate, and the silicate glass plate 1 is placed on the adhesive surface; the periphery of the adhesive surface is provided with a slow-curing glue accommodation part and a quick-drying glue accommodation part.

[0027] The fast-drying glue containing portion of the cover 2 is the platform surface 21 outside the groove 22 on the adhesive surface, and the quick-drying glue layer is dotted on the platform surface 21 .

[0028] The quick-drying adhesive is a kind of hot-melt adhesive.

[0029] The slow curing glue containing part of the cover 2 is one or more grooves 22, and the slow curing glue layer is injected into the grooves 22.

[0030] The sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com