Patents

Literature

66results about How to "Meet the bonding requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

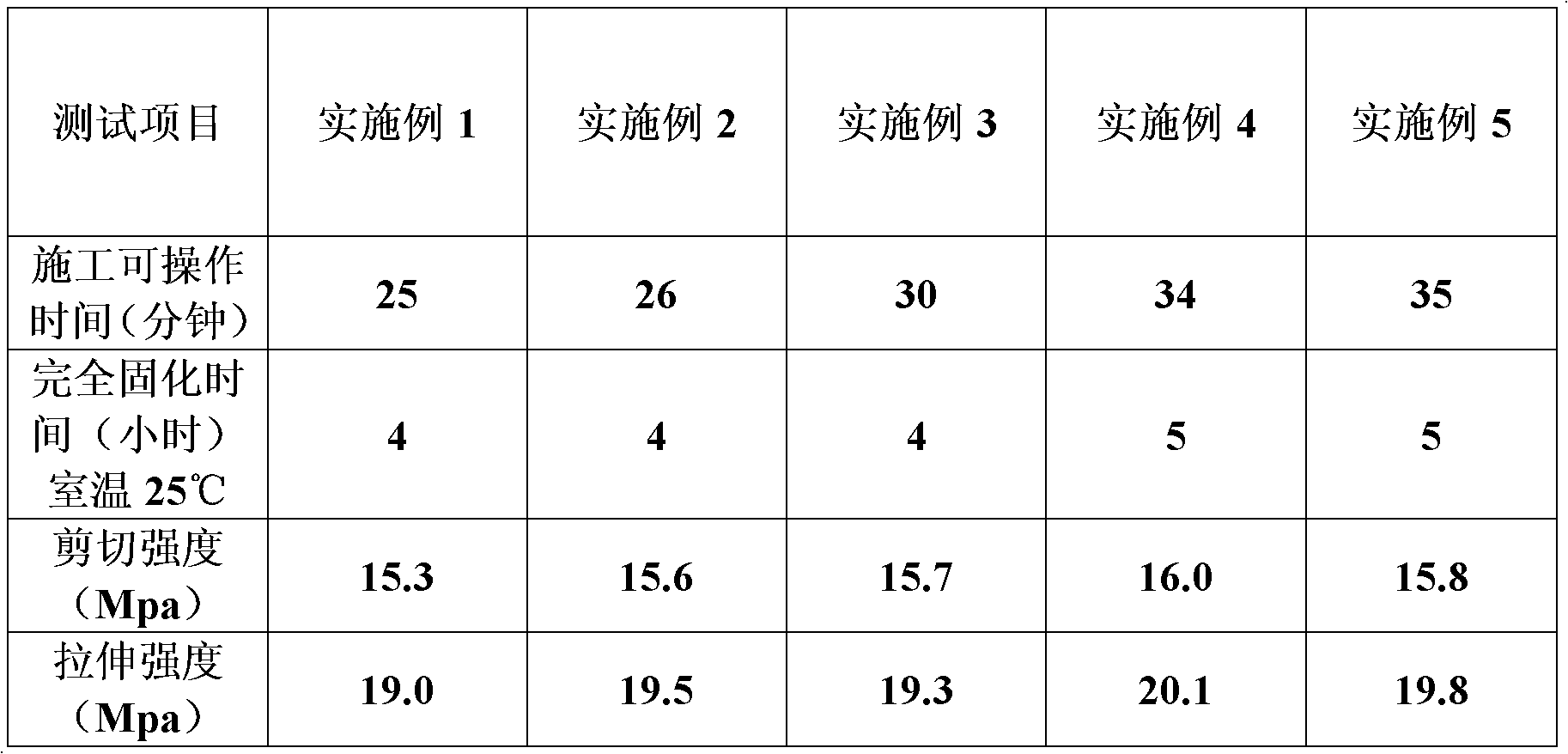

Single component room temperature curing epoxy construction glue

InactiveCN103131365AExtensive sources of raw materialsEasy to use in constructionNon-macromolecular adhesive additivesEpoxy resin adhesivesChemistryDiluent

The invention provides single component room temperature curing epoxy construction glue and belongs to the technical field of construction adhesive. The single component room temperature curing epoxy construction glue is formed by the following materials, by weight, 80-100 parts of epoxy resin, 5-25 parts of diluent, 10-20 parts of curing agent, 3.0-5.0 parts of coupling agent, 0.5-2.0 parts of accelerant, and 1.0-8.0 parts of filler. Compared with two-component epoxy adhesive in the prior art, the single component room temperature curing epoxy construction glue has the advantages that raw materials are wide in source and low in price; convenience is achieved in the process of construction and use, the phenomenon of waste like the two-component epoxy adhesive can not happen; and the single component room temperature curing epoxy construction glue can be cured at room temperature, and bonding requirements for stones, wood, concrete, metal, ceramics, glass and the like can be met.

Owner:常熟市辛庄镇前进五金厂

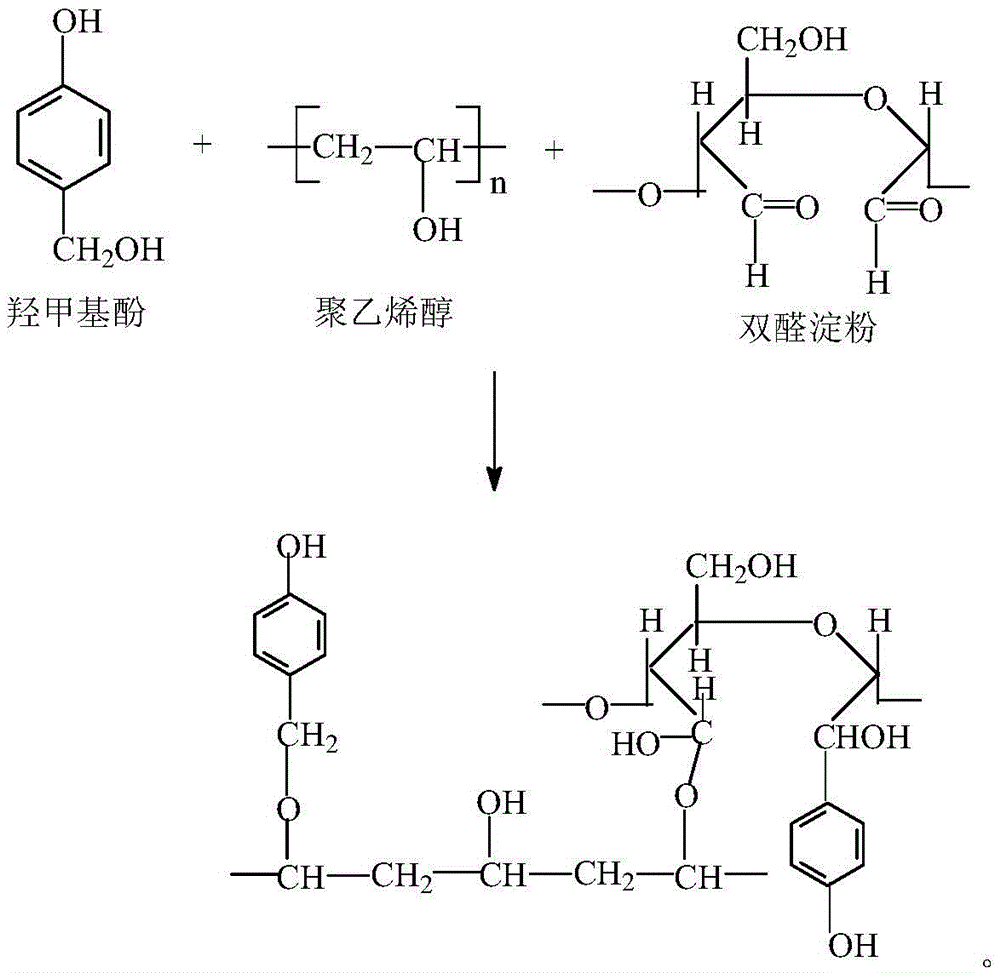

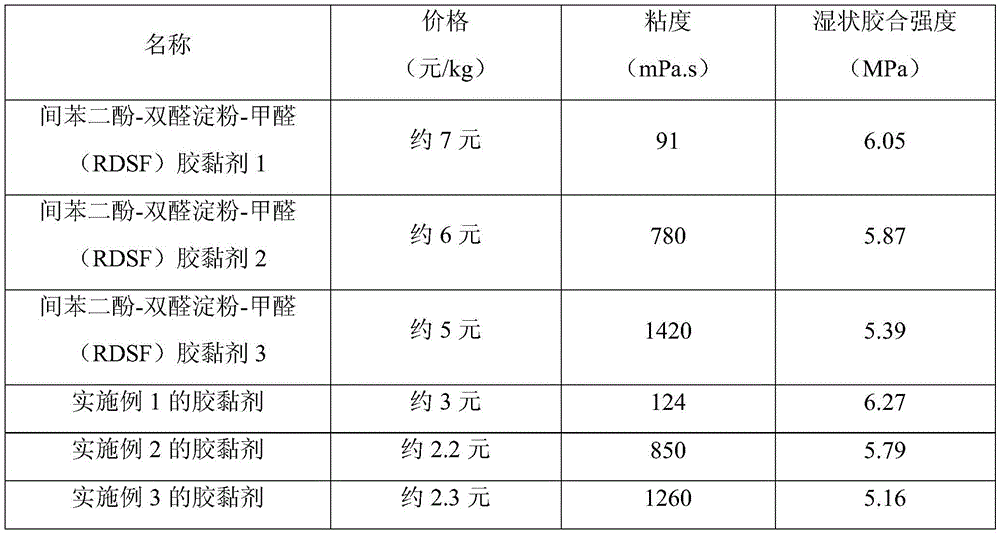

Phenol-dialdehyde starch-formaldehyde resin adhesive and preparation method thereof

ActiveCN105647449AReduce dependenceReduce manufacturing costAldehyde/ketone condensation polymer adhesivesPVA - Polyvinyl alcoholResin adhesive

The invention discloses a phenol-dialdehyde starch-formaldehyde resin adhesive. The adhesive comprises, by weight, 94.11 parts of phenol, 81.2-146.1 parts of formaldehyde solution, 8-100 parts of dialdehyde starch, 12-566.7 parts of water and 5-20 parts of polyvinyl alcohol. The dialdehyde starch which is a renewable degradable biomass resource is adopted to replace part of formaldehyde, and dependence, on petroleum resources, of a phenolic resin adhesive can be lowered; compared with an existing resorcinol-dialdehyde starch-formaldehyde resin adhesive, production cost is lowered remarkably; the phenol-dialdehyde starch-formaldehyde resin adhesive is high in adhesiveness, excellent in waterproofness, capable of meeting binding requirements of wood and bamboo and equivalent to the resorcinol-dialdehyde starch-formaldehyde resin adhesive in binding performance, so that performance-cost ratio is increased obviously, and the phenol-dialdehyde starch-formaldehyde resin adhesive can replace conventional phenolic resin adhesive and the existing resorcinol-dialdehyde starch-formaldehyde resin adhesive for use.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Formaldehyde-free aqueous timber glue and preparation method thereof

InactiveCN103834357AHigh bonding strengthLow costNon-macromolecular adhesive additivesProtein adhesivesFiberCalcium Chloride Hexahydrate

The invention relates to a flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board and a manufacturing method thereof. The flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board solves the problem that in the existing composite board manufacture, formaldehyde content of used glue exceeds the limit. The flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board has the functions of flame resistance, water resistance and phase-change energy storage. The flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board comprises a solid-wood layer and a flame-retardant waterproof phase-change energy-storage layer superposition-compounded to the solid-wood layer by pressure. The flame-retardant waterproof phase-change energy-storage layer comprises expanded perlite, a silica sol solution, plant fibers, calcium carbonate, a penetrant, a fire retardant, a waterproof agent, a pigment and any one of mirabilite, calcium chloride hexahydrate, n-caprylic acid and n-butyl stearate as phase-change materials. The preparation method comprises the following steps of stirring the ingredients to obtain a uniform mixture, paving the mixture, paving a non-woven fabric on the mixture, carrying out rolling by a rolling machine to obtain the flame-retardant waterproof phase-change energy-storage layer board, coating formaldehyde-free aqueous glue on the surface of the flame-retardant waterproof phase-change energy-storage layer, putting the solid-wood layer board on the flame-retardant waterproof phase-change energy-storage layer, putting the boards into a pre-pressing device, carrying out superposition pre-compression treatment on the solid-wood layer and the flame-retardant waterproof phase-change energy-storage layer so that the solid-wood layer tightly clings to the flame-retardant waterproof phase-change energy-storage layer, pushing the compounded board into a hot press, and carrying out hot pressing to obtain the flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board. The flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board solves the problem that in the existing composite board manufacture, formaldehyde content of used glue exceeds the limit, and has the advantages of energy saving, flame resistance and water resistance.

Owner:HENAN LINGDIAN CONSTR CO LTD

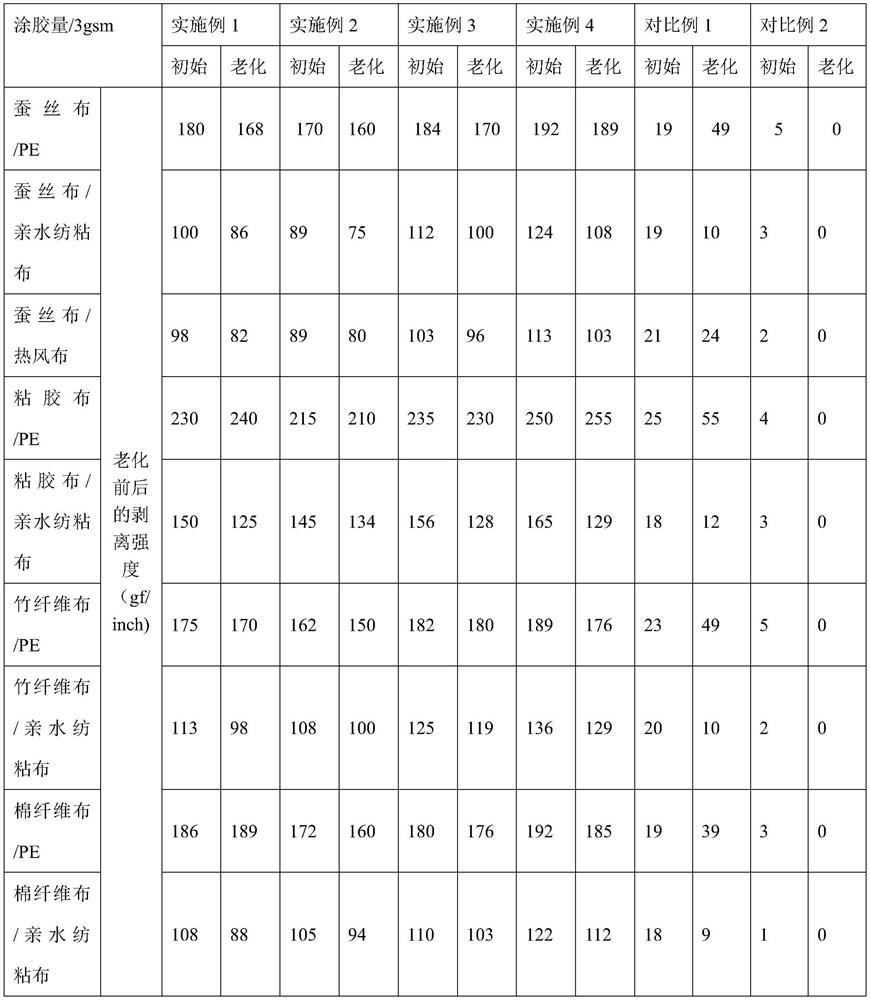

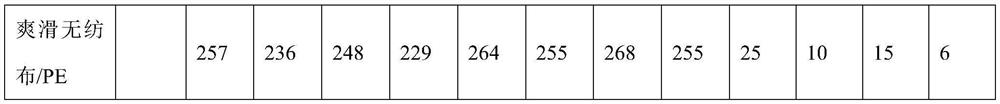

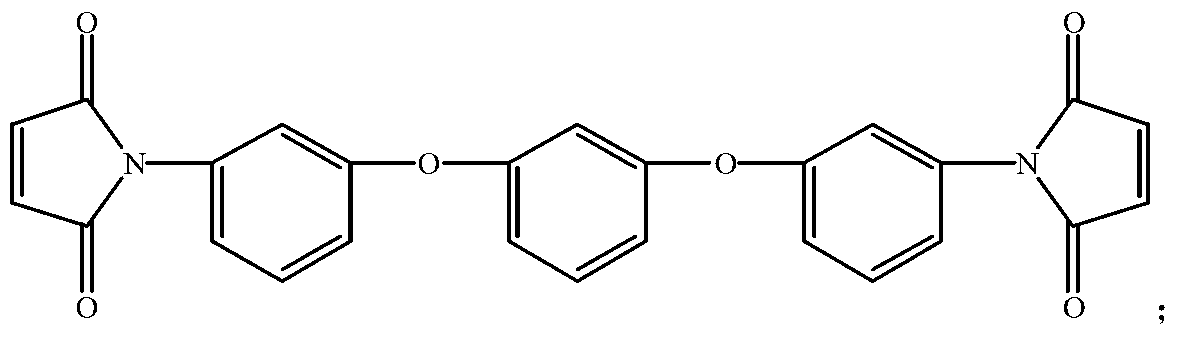

Hot melt adhesive for difficult-to-stick base material and preparation method thereof

ActiveCN111849397ASolve bonding problemsGood adhesionMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesElastomerPolymer science

The invention discloses a hot melt adhesive for a difficult-to-stick base material and a preparation method of the hot melt adhesive. The hot melt adhesive for the difficult-to-stick base material isprepared from the following components in parts by weight: 10 to 30 parts of naphthenic oil, 10 to 30 parts of styrene elastomer, 7 to 20 parts of solution polymerized styrene-butadiene rubber, 3 to 20 parts of polyolefin elastomer, 15 to 70 parts of tackifying resin, 0.35 to 3 parts of an antioxidant and 0.2 to 1 part of an ultraviolet light absorber. The hot melt adhesive disclosed by the invention can be used for well bonding difficult-to-adhere base materials so as to meet the adhesion requirements of different difficult-to-adhere fabrics, so manufacturers of sanitary material products such as paper diapers and sanitary towels can be provided with more options for high-quality fabrics, such as silk fabrics, hot through-air fabrics, smooth non-woven fabrics, cotton fiber fabrics, bamboofiber fabrics and viscose fabrics.

Owner:佛山南宝高盛高新材料有限公司

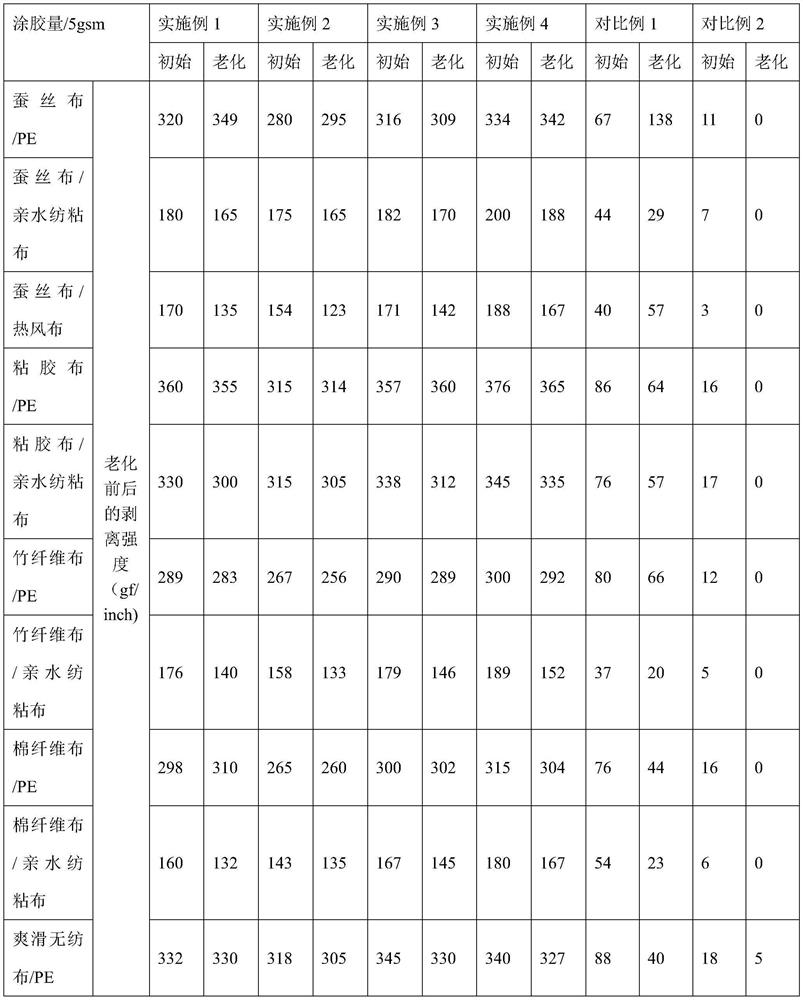

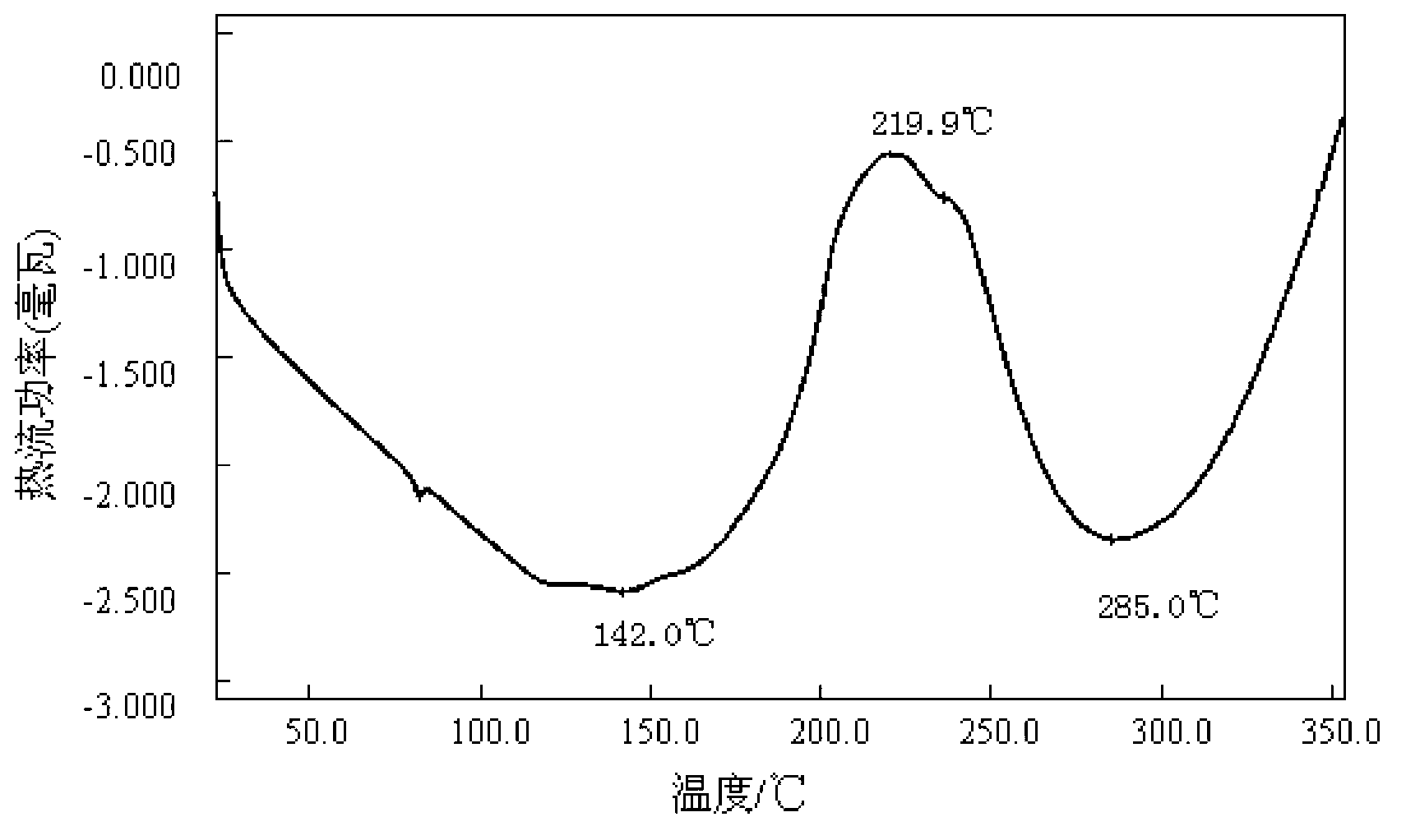

High-tenacity bismaleimide resin carrier structure adhesive film and preparation method thereof

The invention relates to a high-tenacity bismaleimide resin carrier structure adhesive film and a preparation method thereof. The invention aims at solving the problems of the existing bismaleimide adhesive that the tenacity is poor and the peel strength is low. The adhesive film is prepared from bismaleimide resin, a technical modifier, macromolecule blending alloy, a curing agent, a silane coupling agent and a carrier. The preparation method of the adhesive comprises the following steps of: firstly pre-polymerizing the bismaleimide resin and the copolymeric modifier so as to prepare bismaleimide resin prepolymer, then uniformly mixing the bismaleimide resin prepolymer, the macromolecule blending alloy, the silane coupling agent and the curing agent so as to prepare sizing material through a mechanical blending method, and taking braided fabric as the carrier and preparing the film adhesive through a dual-roller hot rolling manner. The adhesive has the characteristics of high strength, thermostability and high tenacity and can be used for cementing thermostability metal and resin-based compound material structural members in the field of aerospace.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

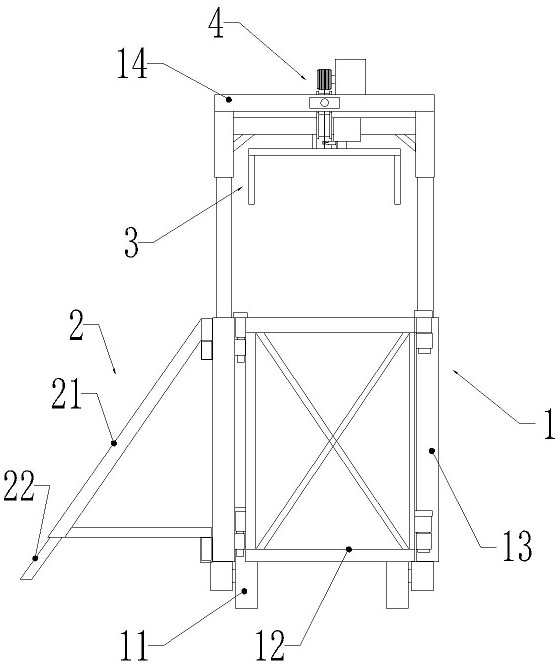

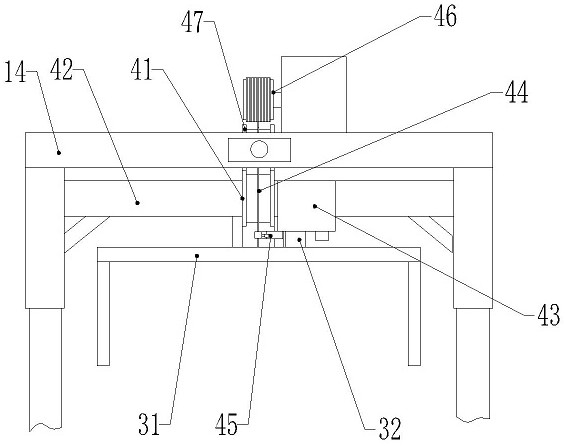

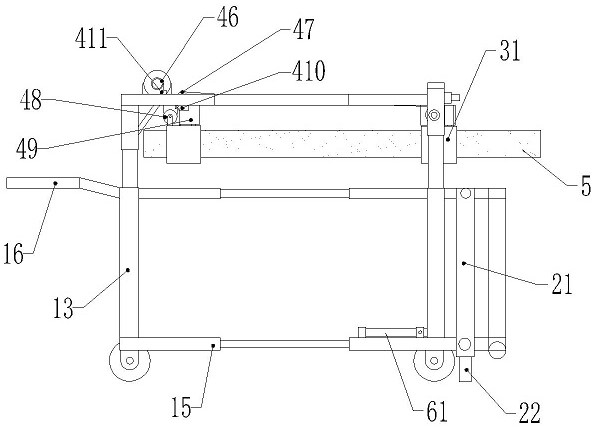

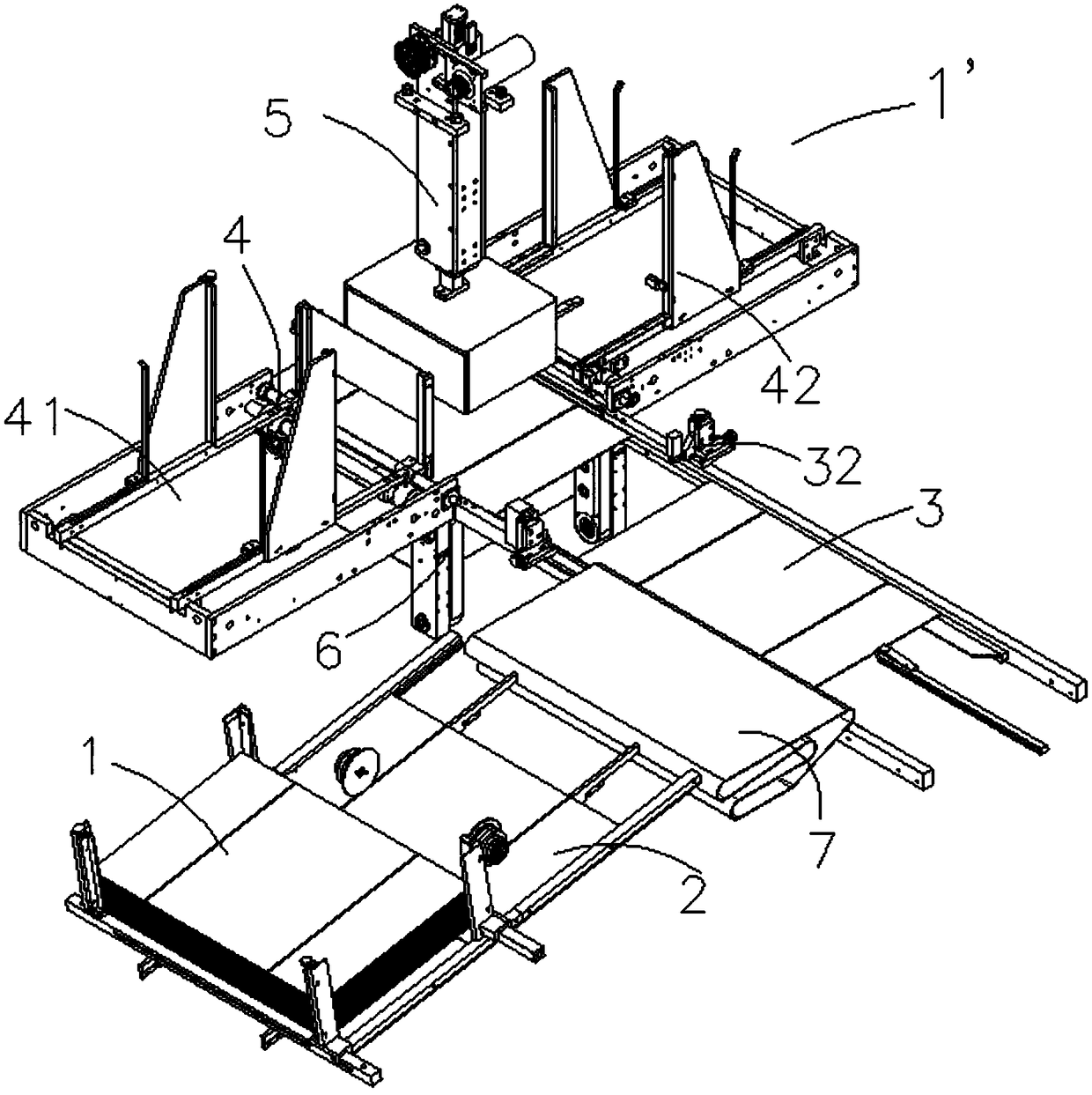

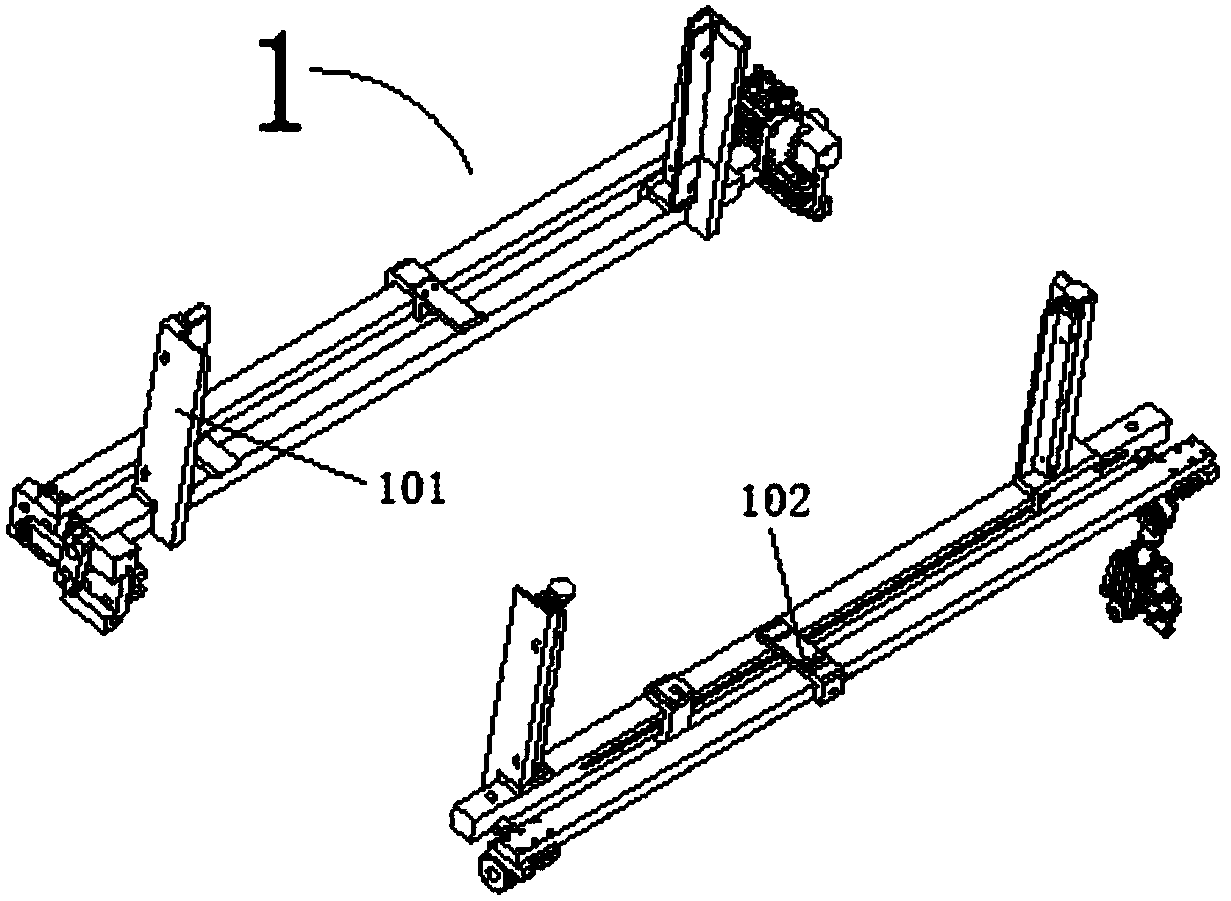

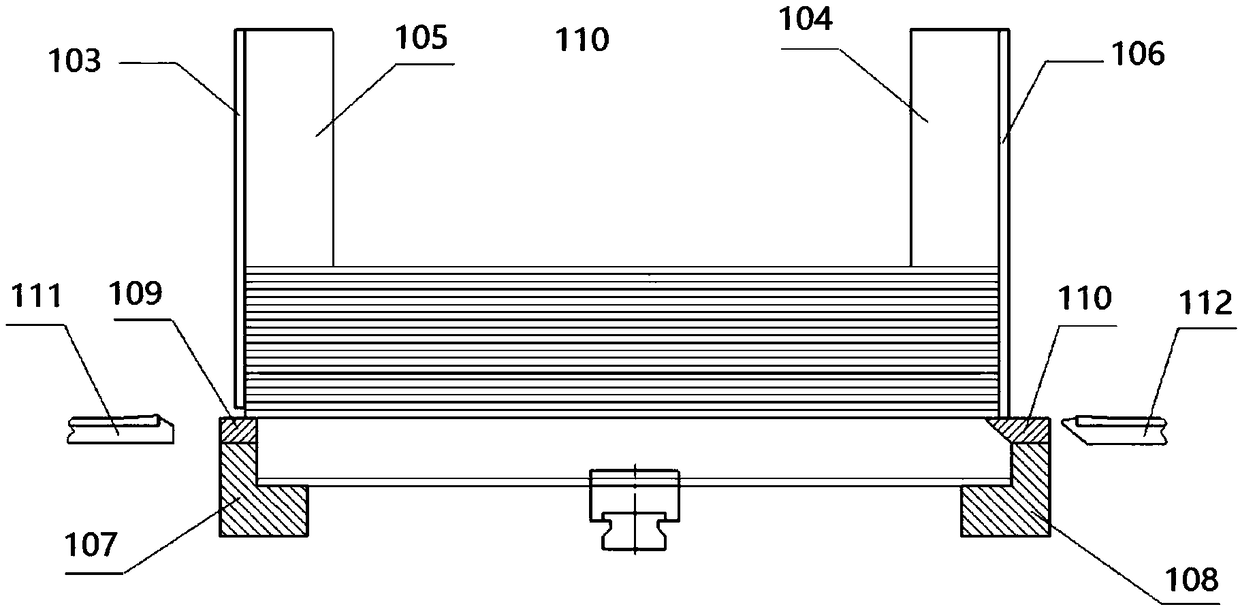

Equipment and method for carrying and in-place installation of vertical battens of a building infilled wall

PendingCN112850539AEasy to makeEasy to useLiquid surface applicatorsPortable liftingArchitectural engineeringEngineering

The invention relates to equipment and a method for carrying and in-place installation of vertical battens of a building infilled wall. The equipment for carrying and in-place installation of the vertical battens of the building infilled wall comprises a batten carrying system, a batten clamping system and a batten lifting and rotating system. The batten conveying system comprises a movable frame and a lifting support. The batten clamping system comprises two sets of mechanical clamping jaws, and the two sets of mechanical clamping jaws are located at the open end and the closed end of the movable frame correspondingly. The batten lifting and rotating system comprises a first pulley, a second pulley, a third pulley, a steel wire rope, steel wire rope winding equipment and a steel wire rope locking device. When a batten is overturned, a first steel wire rope non-return switch device locks the steel wire rope, the steel wire rope winding equipment releases the steel wire rope, and the end, close to the closed end of the movable frame, of the batten slowly descends until overturning of the batten is completed. The traditional method of carrying and mounting by multiple persons is changed, so that the labor intensity is reduced, the mounting time is shortened, and the manual carrying and mounting cost is greatly reduced.

Owner:李洪宾

Formaldehyde-free composite board special for flame retardant wooden house and preparing method of board

ActiveCN106514800AImprove bearing capacityTightly boundNon-macromolecular adhesive additivesStarch adhesivesPerliteParaffin oils

The invention relates to a formaldehyde-free composite board special for a flame retardant wooden house and a preparing method of the board. Plant fibers are adopted to be smashed, and the plant fibers and a phase change material are jointly machined into the board special for the wooden house. The board comprises a core layer with the flame retardant waterproof phase change energy storage function and a solid wood layer composited on the core layer through pressure; the core layer is prepared by raw materials including, by weight, 30 parts to 80 parts of expanded perlite or sepiolite, 30 parts to 40 parts of any phase change material in paraffin, n-octadecane, octadecanol, cetanol, tetradecyl alcohol, dodecanol, n-decanol, stearic acid, glyceryl stearate, palmitic acid, myristic acid, lauric acid, n-caprylic acid and stearic acid butyrin, 5 parts to 10 parts of Schiff alkaline gel factor, 10 parts to 20 parts of graphite, 20 parts to 40 parts of silica sol solutions, 20 parts to 40 parts of plant fibers, 10 parts to 20 parts of starch, 0.5 part to 5 parts of hydrogen peroxide, 5 parts to 10 parts of glass fibers, 2 parts to 10 parts of calcium carbonate, 0.5 part to 5 parts of a penetrating agent, 8 parts to 35 parts of a flame retardant agent, and 2 parts to 8 parts of a waterproof agent. The beneficial effects of saving a large amount of wood and adjusting the indoor temperature are achieved.

Owner:郑州一安水性高分子材料有限公司

Nano modified display shell position gum and preparing method thereof

ActiveCN101054503AGood stickinessGood flexibilityMineral oil hydrocarbon copolymer adhesivesFireworksEngineeringAdhesion strength

The invention relates to a nano-modified salute bomb location glue and method for preparing same. The glue uses SBS elastomer as the major material, addes with adhesion resin and nano-materials to reinforce the surface adhesive force and adhesion strength between the location glue and ignition pipe and the ball shells.

Owner:HUNAN SHENLI IND

Method for preparing maleic anhydride-containing polymer emulsion

The invention relates to a method for preparing maleic anhydride-containing polymer emulsion. The method comprises the following steps: adding toluene, butanone, ethyl acetate, methyl methacrylate, maleic anhydride and SBS rubber into a reaction kettle for stirring, and controlling the temperature to be 60-70 DEG C; introducing nitrogen, raising the temperature to 80-90 DEG C, adding benzoyl peroxide and an acrylic monomer solution for polymerizing for 3-5 hours by adopting a dripping mode, lowering the temperature to 50-60 DEG C, performing reduced pressure distillation to remove 50-80% of solvent, adding a neutralizer until the pH value of the system is 6.5-8.5, and reacting for 0.5-1 hour; gradually adding deionized water at high-speed stirring, and finally adding polyvinylpyrrolidone for uniformly stirring, and obtaining the maleic anhydride-containing polymer emulsion used for surface treatment of TPR sole materials. The maleic anhydride-containing polymer emulsion prepared by the method has an obvious adhesion promotion effect on the TPR material and is environment-friendly.

Owner:HANGZHOU DIANZI UNIV

Medium and high density board box making machine and box making method thereof

ActiveCN108582869AMeet the bonding requirementsImprove practicalityBox making operationsPaper-makingHigh densityEngineering

The invention provides a medium and high density board box making machine which comprises a material bin discharging module, a groove lamination module, a side edge lamination module, a side plate discharging module, a die pressing module and a mold cavity forming module. The output end of the material bin discharging module is connected with the input end of the groove lamination module, the output end of the groove lamination module is connected with the input end of the side edge lamination module, the output end of the side plate discharging module and the output end of the side edge lamination module serve as the input end of the die pressing module at the same time, and the output end of the die pressing module is connected with the input end of the mold cavity forming module. The invention further provides a box making method of the medium and high density board box making machine. A groove of a base plate can be subject to lamination, meanwhile, side edges of the base plate aresubject to lamination, the good bonding effect can be achieved, the attractiveness of boxes can be guaranteed, and the production efficiency and practicability are high.

Owner:WENZHOU GAOSHENG MACHINERY CO LTD

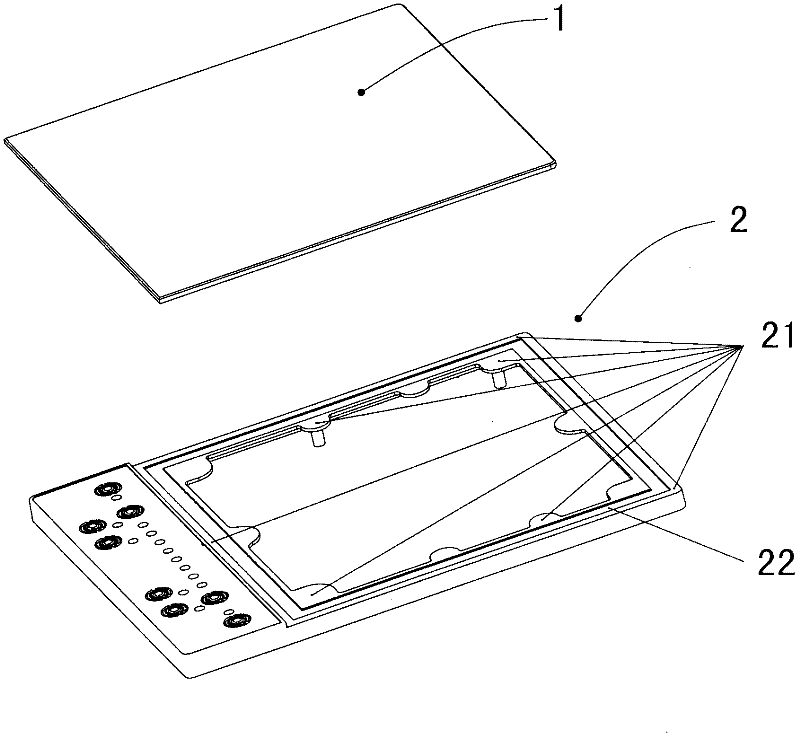

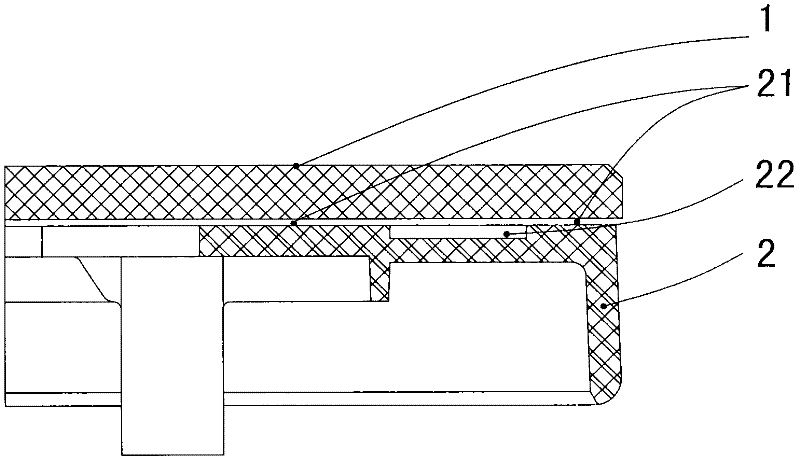

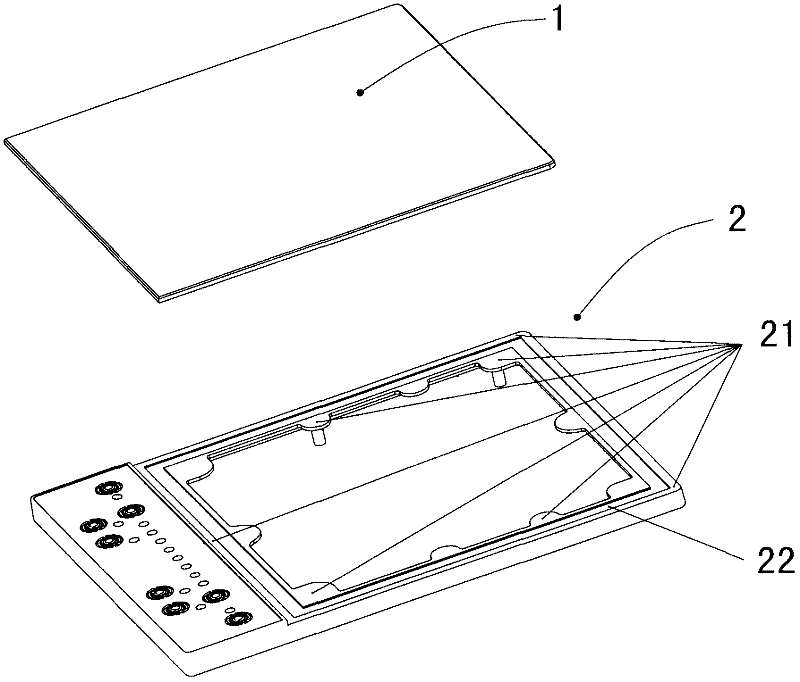

Household electrical appliance product and bonding method thereof

ActiveCN102538033AImprove curing cycleShorten curing cycleAdhesive processesDomestic stoves or rangesAdhesiveEngineering

The invention provides a household electrical appliance product and a bonding method thereof. Quick-drying adhesive and chronic curing adhesive are used jointly, complement each other's advantages and enable parts to be rapidly sealed, bonded and cured. Assembling efficiency is accelerated, reject ratio of process is eradicated, and workpieces do not need to be clamped by fixture and can be consigned or moved at any time. The household electrical appliance product comprises a first part and a second part which are connected in an adhesive mode. The first part is provided with a chronic curing adhesive containing portion and a quick-drying adhesive containing portion to be adhered to the second part, a chronic curing adhesive layer is arranged between the second part and the chronic curing adhesive containing portion, and a quick-drying adhesive layer is arranged between the second part and the quick-drying adhesive containing portion. The bonding method of the household electrical appliance product comprises the steps of filling chronic curing adhesive into the chronic curing adhesive containing portion of the first part, filling quick-drying adhesive into the quick-drying adhesive containing portion of the first part, aligning and bonding the first part and the second part and performing pressing and curing steps.

Owner:GREE ELECTRIC APPLIANCES INC +1

Caking agent

The invention relates to an adhesive, which consists of, by weight percentage, polypropylene-random 27 to 33 percent, heat-resistant polyethylene 17 to 23 percent, diisopropylbenzene peroxide 0.04 to 0.06 percent, viscosity regulator 39 to 41 percent, tackifying resin 8.5 to 9.5 percent and maleic anhydride 0.75 to 1.15 percent. The adhesive has the advantages that the adhesive can meet the adhesion requirement for PP-R / AL / PE-RT as well as the adhesion requirement for PP-R / AL / PP-R tubes.

Owner:SHANGHAI SHANGFENG GROUP

Waterproof anti-corrosion adhesive and preparation method thereof

ActiveCN108707441AImprove corrosion resistanceGood mechanical properties and aging resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCeramic tilesAdhesive

The invention provides a waterproof anti-corrosion adhesive and belongs to the technical field of adhesives. The waterproof anti-corrosion adhesive is prepared from the following raw materials in parts by weight: 40-48 parts of trichloropropane, 25-30 parts of modified acrylic resin, 7-10 parts of waterproof agent, 12-16 parts of anti-corrosion agent, 5-8 parts of filler and 6-8 parts of auxiliaries. According to the waterproof anti-corrosion adhesive provided by the invention, the acrylic resin is modified and has a remarkable synergistic effect with the waterproof agent, the anti-corrosion agent, the filler and the auxiliaries; through organic combination of the materials, an adhesive for ceramic materials is prepared, which can improve the corrosion resistance and water resistance of the materials and has good mechanical property and aging resistance; with excellent comprehensive performance, the adhesive meets the bonding requirements of the ceramic materials such as glass and ceramic tiles, and has good bonding property and can be applied to a tough environment for long.

Owner:ZHENGZHOU INST OF TECH

Preparation method of SBS (styrene-butadiene-styrene) rubber graft polymer emulsion

The invention relates to a preparation method of an SBS (styrene-butadiene-styrene) rubber graft polymer emulsion. The preparation method comprises the steps of adding butanone, acetic ether, methyl methacrylate and SBS rubber into a reaction kettle, stirring, and controlling the temperature to be 60-70 DEG C; introducing nitrogen, then heating to 80-90 DEG C, adding a mixed solution of benzoyl peroxide and an acrylic monomer, and performing polymerization for 3-4 hours; cooling to 50-60 DEG C, performing reduced pressure distillation to remove 50-80% of a solvent, then adding a neutralizing agent until the pH value of the system is 6.5-8.5, and performing salt forming reaction for 0.5-1 hour; and gradually adding deionized water under high-speed stirring, adding polyvinylpyrrolidone at last, and uniformly stirring. According to the method, SBS rubber is grafted with acrylic acid and an ester monomer to form the graft polymer emulsion; the graft polymer emulsion is used for performing surface treatment on a TPR (thermal plastic rubber) sole material during cold bonding shoemaking, is good in treatment effect, can meet bonding requirements for shoemaking industries, and accords with requirements on environmental protection.

Owner:HANGZHOU DIANZI UNIV

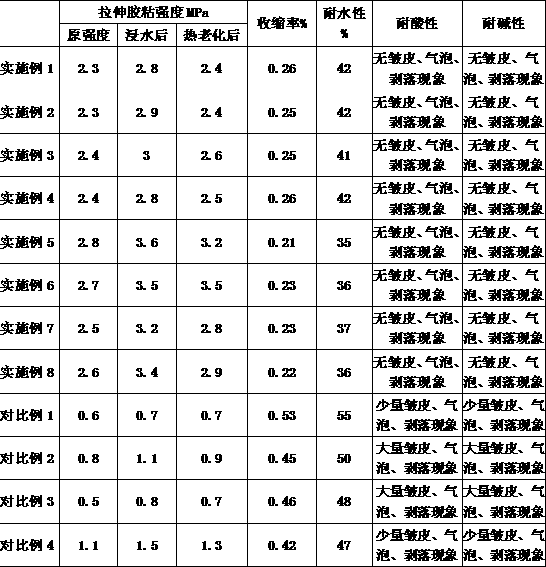

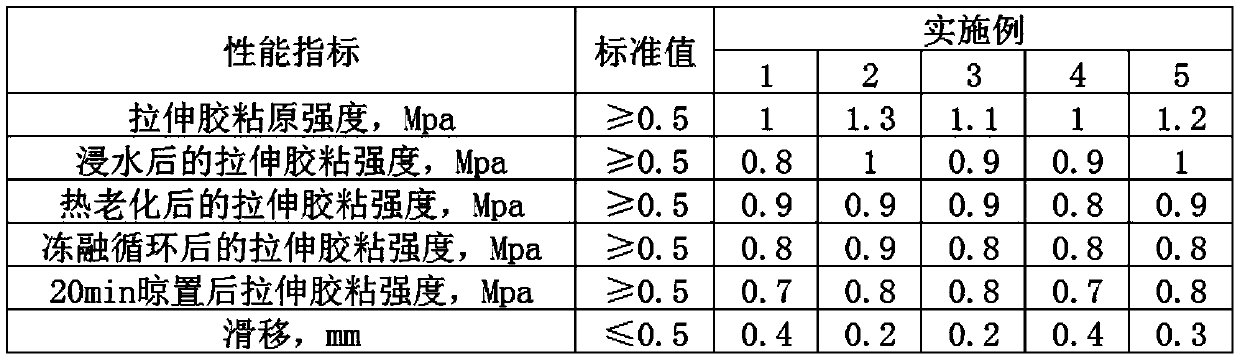

One-component adhesive for vitrified tiles

ActiveCN106916554BGood flexibilityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyBrick

The invention discloses a single component vitrified brick back glue, which comprises the following components in parts by weight: 20 to 50 parts of emulsion, 5 to 25 parts of aqueous epoxy resin, 0.5 to 3 parts of sodium silicate, 0.5 to 2 parts of auxiliary agent, 0.5 to 2 parts of modifier, 50 to 70 parts of slag micro powder, 0.1 to 0.8 part of antiseptic, and 0.1 to 1 part of dispersant, wherein the emulsion comprises 15 to 35 parts of acrylic acid emulsion and 5 to 15 parts of VAE emulsion, the auxiliary agent is fumed silica, and the modifier is a silane coupling agent. The provided single component vitrified brick back glue has the advantages of good flexibility, high bonding strength, and good weatherability, the compatibility between the back glue and a cement based adhesive material is good, and the bonding requirements of vitrified bricks can be met completely. Aqueous epoxy resin has the characteristics of good adhesive force, excellent operability, good anticorrosion performance, and acid / alkali resistance. Through the back glue, vitrified bricks can be adhered on different base materials, the construction is simple, and the problems such as hollowing, bubbling, falling, and the like, in vitrified brick pasting are solved.

Owner:湖北碱克新材料有限公司

Preparation method of maleic anhydride containing TPR (Thermal Plastic Rubber) surface treating agent

The invention relates to a preparation method of a maleic anhydride containing TPR (Thermal Plastic Rubber) surface treating agent. The method comprises the following steps of: preparing SBS (Styrene Butadiene Styrene) grafted maleic anhydride copolymer emulsion and chlorinated polypropylene grafted copolymer emulsion; uniformly agitating 100 parts by weight of SBS grafted maleic anhydride copolymer emulsion, 20 to 80 parts by weight of chlorinated polypropylene grafted copolymer emulsion, and 10 to 15 parts by weight of polyvinylpyrrolidone, so as to obtain the water-based surface treating agent for the TPR sole material. According to the preparation method, the SBS grafted maleic anhydride copolymer emulsion and chlorinated polypropylene grafted copolymer emulsion are compounded, and the obtained water-based surface treating agent shows high compatibility with the TPR material because of maleic anhydride and chlorinated polypropylene, also shows a good effect on surface treating of the TPR material, meets the adhering requirements of the shoes manufacturing industry, and also realizes the requirements on green and environmental protection.

Owner:HANGZHOU DIANZI UNIV

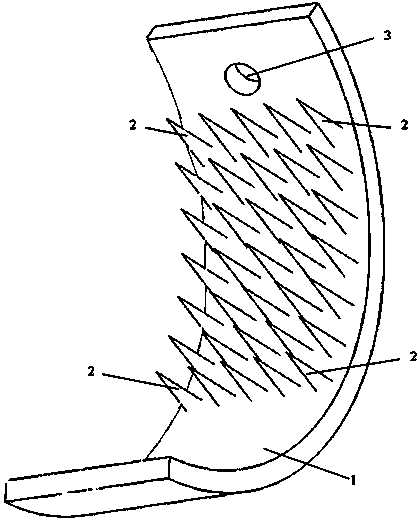

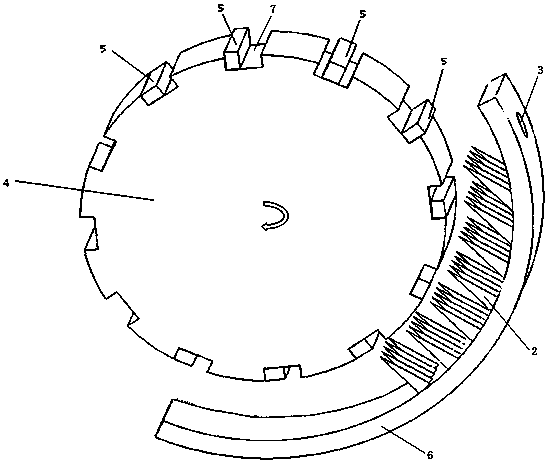

Method for aligning and adhering oil duct struts

InactiveCN108335896AAvoid manual identificationMeet the bonding requirementsTransformers/inductances coolingInductances/transformers/magnets manufacturePulp and paper industryMechanization

The invention discloses a method for aligning and adhering oil duct struts. The method comprises the following specific steps: (1) grooving, namely forming roller grooves used for placing oil duct struts in outer side faces of rollers at intervals, and mounting the oil duct struts in the roller grooves in a roller rotating process; (2) turning, namely axially turning the oil duct struts of which thick sides are inconsistent with the radial directions of the rollers in the roller grooves; (3) adhering, namely enabling oil duct struts that do not need to turn and the turned oil duct struts to separate from the roller grooves along with rotation of the rollers under the gravity action when the oil duct struts rotates to the lower sides of the rollers, and enabling the oil duct struts to droponto moving dispensing paper, wherein the thick sides of the oil duct struts are perpendicular to the paper surface of the dispensing paper during separation, and the contact surface of the oil duct struts and the dispensing paper is one of two surfaces composed of lengths and widths of the oil duct struts. According to the method for aligning the oil duct struts, provided by the invention, the oil duct struts that do not need to turn and the turned oil duct struts keep in right postures so as to reach the dispensing paper, and adhering mechanization of the oil duct struts is realized.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

High-rigidity high-bonding-strength nylon reinforcing material and preparation method thereof

The invention discloses a high-rigidity high-bonding-strength nylon reinforcing material and a preparation method thereof. The high-rigidity high-bonding-strength nylon reinforcing material is prepared from the following components in percentage by weight: 38-59% of PA; 40-60 percent of alkali-free chopped glass fiber; 0.3-1% of an adhesion promoter; and 0.5-1.5% of other auxiliary agents. The high-rigidity high-bonding-strength nylon reinforced material has good mechanical properties and good surface adhesion, and has a wide application prospect in 3C electronic products such as mobile phonesand tablet personal computers.

Owner:DONGGUAN HONOUR E P

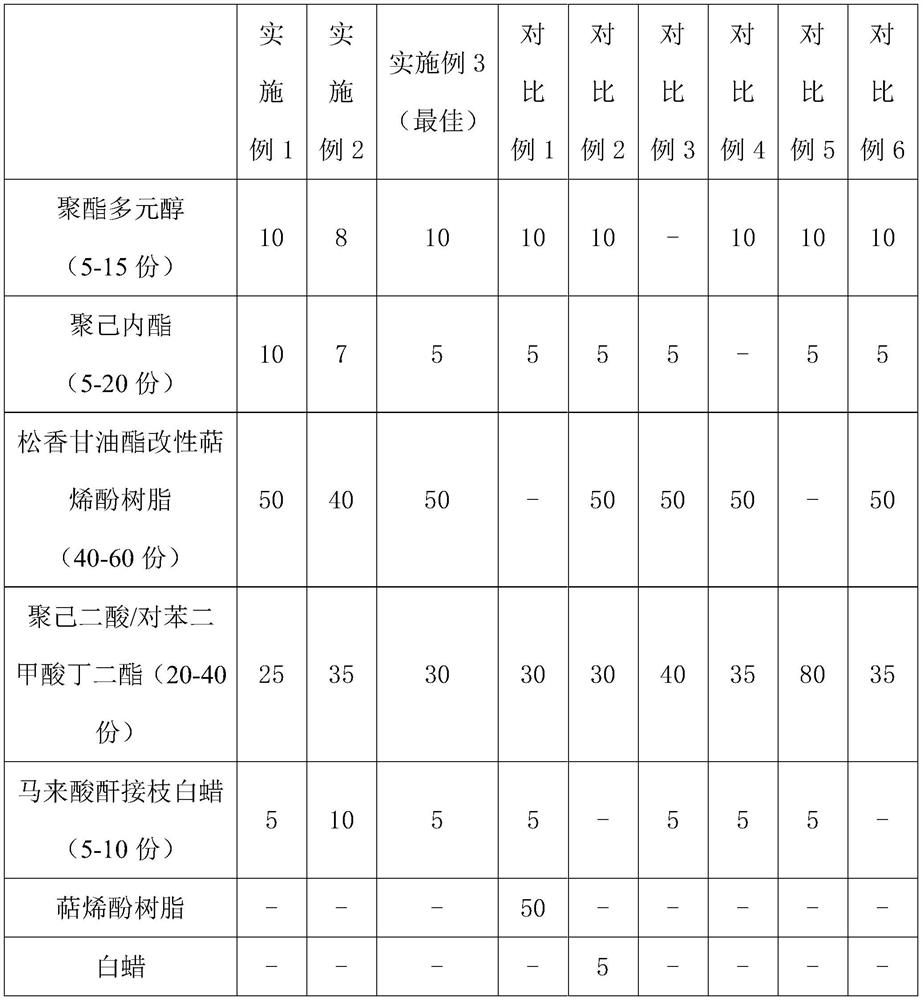

Low-temperature biodegradable paper bag hot melt adhesive and preparation method thereof

ActiveCN114395349AImprove conversion rateMeet the bonding requirementsBio-packagingGraft polymer adhesivesPolyesterPolymer science

The invention discloses a low-temperature biodegradable paper bag hot melt adhesive and a preparation method thereof. The biodegradable paper bag hot melt adhesive used at low temperature is prepared from the following components in parts by weight: 5 to 15 parts of polyester polyol, 5 to 20 parts of polycaprolactone, 40 to 60 parts of rosin glyceride modified terpene-phenolic resin, 20 to 40 parts of poly (butylene adipate-co-terephthalate) and 5 to 10 parts of maleic anhydride grafted white wax. By adding the polyester polyol, the polycaprolactone PCL, the rosin glyceride modified terpene-phenolic resin, the maleic anhydride grafted white wax and other components and adjusting the use amount of the components, the prepared hot melt adhesive is applied to the bonding part of a paper bag, and the bonding requirements of the bonding part of a paper carrying rope and the paper bag and the sealing part of the paper bag can be met. Meanwhile, the hot melt adhesive prepared by the invention has the greatest advantage that the colloid part of the paper bag can be completely degraded by aerobic composting, while the common EVA type hot melt adhesive cannot be degraded by aerobic composting.

Owner:佛山南宝高盛高新材料有限公司

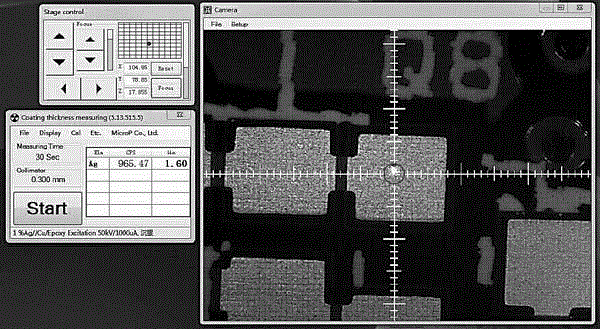

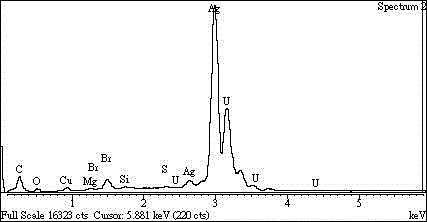

Method and composition for high-speed chemically depositing thick silver

ActiveCN105986254AEnvironmentally friendlyProcess stabilityLiquid/solution decomposition chemical coatingEtchingEnvironmental chemistry

The invention discloses a method and a composition for high-speed chemically depositing thick silver. The method includes the steps of acidic chemical oil removal, three steps of water washing, chemical micro-etching, three steps of water washing, pre-impregnation, preparation of the chemical silver deposition composition, chemical silver deposition, three steps of water washing, air drying, inspection on appearance, and package. The method can deposit a silver layer with the thickness being at least more than 1 [mu]m on the surface of a copper substrate within 1-3 min, satisfies a bonding requirement, can replace the gold and silver plating technologies using highly toxic cyanides in the prior art, is environment-friendly and is stable, and is simple in operations and low in cost. A product with the silver deposited, compared with a product with the gold deposited, has good luminance, and compared with framework connection of electronic-plated silver, the silver plate layer in the invention has good heat dissipation effect.

Owner:广东德瑞勤科技有限公司

Novel vitrified brick gum

InactiveCN107033821AHigh bonding strengthMeet the bonding requirementsNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyEmulsion

The invention discloses a novel vitrified brick gum. The novel vitrified brick gum comprises slurry and powder. The weight percentage ratio of the slurry to the powder is 1: 3.5-4.5. The slurry comprises the following components in parts by weight: emulsion 15-55 parts, silicon modified aqueous epoxy resin 18.5-53 parts, a preservative 0.5-3.5 parts and cellulose 0.5-2 parts. The powder comprises the following components in parts by weight: titanium dioxide 1-8 parts and an inorganic filler 15-35 parts. The silicon modified aqueous epoxy resin comprises the following components in parts by weight: aqueous epoxy resins 8-20 parts, an auxiliary agent 5-15 parts, a modifying agent 5-15 parts and catalyst 0.5-3 parts. The slurry and the powder are organically combined according to a certain ratio, the adhesion strength of the vitrified brick gum is improved, adhesion requirements of vitrified bricks can be met completely, the vitrified bricks can be adhered to different base materials, the novel vitrified brick gum is simple to construct, and the problems of hollowing, breaking, dropping and the like during adhesion of the vitrified bricks are solved effectively.

Owner:湖北碱克新材料有限公司

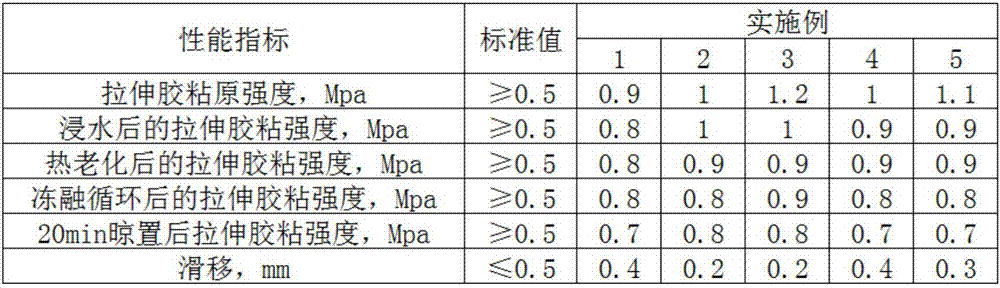

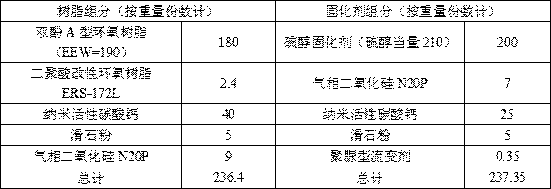

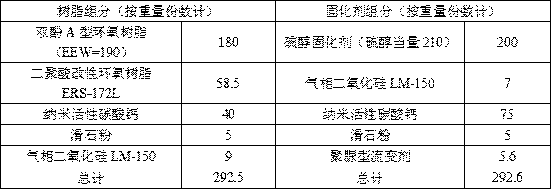

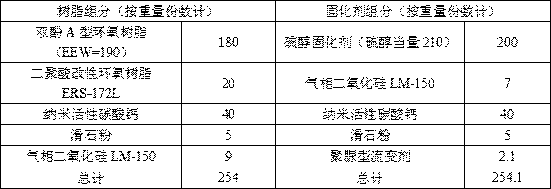

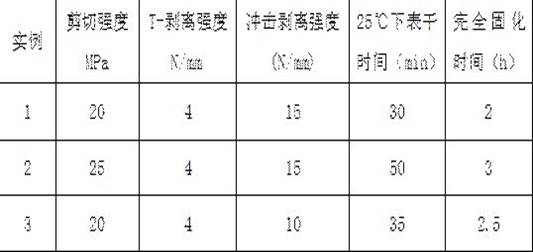

Epoxy adhesive for LED lamp tube plug and LED lamp tube adhesive

InactiveCN109021901AMeet the bonding requirementsEasy extrusionNon-macromolecular adhesive additivesMacromolecular adhesive additivesBonding processRoom temperature

The invention provides an epoxy adhesive for an LED lamp tube plug, wherein the epoxy adhesive comprises a resin component and a curing agent component with the ratio of 1:1. The resin component comprises, in parts by weight, 160-200 parts of epoxy resin, 1-50 parts of epoxy resin modified by dimeric acid, 35-50 parts of a filler and 7-12 parts of a thixotropic agent. The curing agent component comprises, in parts by weight, 180-220 parts of a mercaptan curing agent, 10-100 parts of a filler, 6-9 parts of a thixotropic agent and 5-80 parts of a polyurea rheological agent. The epoxy adhesive does not need refrigeration, does not need to be back to warm for waiting before use, can be cured at room temperature, does not need heating, and has simple and easy bonding process.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Glue for increasing adhesion property of shoe sole

InactiveCN107446511AGood adhesionMeet the bonding requirementsNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveAntioxidant

The invention discloses glue for increasing the adhesion property of a shoe sole. The glue is prepared from the following raw materials in parts by weight: 30 to 40 parts of a grafted adhesive, 15 to 20 parts of bone glue, 15 to 20 parts of pectin, 15 to 20 parts of latex, 5 to 8 parts of fiber powder, 4 to 10 parts of composite resin, 3 to 5 parts of ethylene, 0.5 to 1 part of oxidation water, 0.6 to 1.2 parts of a water repellent, 6 to 10 parts of a viscosity enhancer, 2 to 5 parts of a nylon treating agent, 3 to 4.5 parts of an antioxidant and 30 to 50 parts of water. The glue for increasing the adhesion property of the shoe sole, disclosed by the invention, has very strong adhesion property after curing, is particularly suitable for adhesion between cloth and leather, and is capable of meeting the adhesion requirements of shoe uppers and soles; meanwhile, the glue has certain elasticity after curing and is easy to smooth, so that the using comfort of shoes is increased, good waterproof and dampproof functions are obtained, the glue is not easy to age, oxidation cannot be caused, the service life is long, the performance is stable, the glue contains no formaldehyde, and the using safety of leather shoes and the like can be effectively increased.

Owner:成都卡美奇鞋业有限公司

Reactive polyurethane hot melt adhesive and preparation method thereof

PendingCN113980631AHigh densityIncrease crosslink densityPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a reactive polyurethane hot melt adhesive, which comprises the following components: 10-40% of polyester polyol, 10-30% of polyether polyol, 0.5-8% of polycarbonate polyol, 1-10% of micromolecule polyol, 0-10% of petroleum resin, 10-30% of isocyanate, 0.1-1% of a silane coupling agent, 0-1% of an auxiliary agent and 0.1-0.5% of a catalyst. The invention also provides a preparation method of the reactive polyurethane hot melt adhesive. The reactive polyurethane hot melt adhesive which is good in high-temperature resistance and small in strength attenuation in a high-temperature environment can be prepared, and is resistant to oleic acid etching.

Owner:YANTAI DARBOND TECH

Double-component epoxy structural adhesive

InactiveCN112358838AMeet strength requirementsLong storage periodNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePlasticizer

The invention discloses a double-component epoxy structural adhesive which comprises the following raw material components in percentage by mass: a component A, the component A comprising the following components in percentage by mass: 40-60% of epoxy resin, 5-10% of a plasticizer, 20-40% of a flexibilizer and 10-20% of a filler; a component B, prepared from the following components in percentageby mass: 20-35 percent of an epoxy curing agent, 1020 percent of an auxiliary agent, 1025 percent of a plasticizer and 3545 percent of filler; wherein the mass ratio of the component A to the component B is 3: 1. The double-component epoxy structural adhesive is low in curing temperature, simple to operate and long in storage life, and can meet the bonding requirements of conventional mechanical structural parts such as airplanes and automobiles.

Owner:三友(天津)高分子技术有限公司

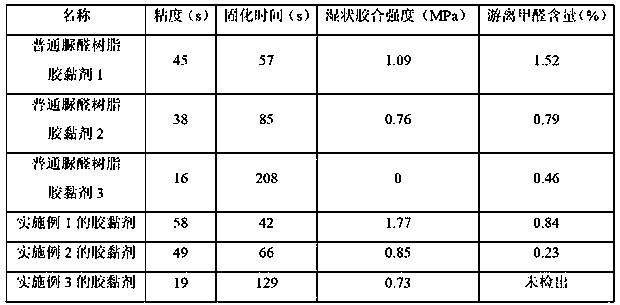

Urea-dialdehyde starch-formaldehyde copolycondensed resin adhesive and preparation method therefor

ActiveCN109609068AGood adhesionImprove water resistanceAldehyde/ketone condensation polymer adhesivesFiberMelamine

The invention discloses a urea-dialdehyde starch-formaldehyde copolycondensed resin adhesive and a preparation method therefor. The preparation method comprises the steps: (1) gelatinizing dialdehydestarch; (2) adjusting a pH value of the gelatinized starch, adding urea, heating the temperature of the mixture to 85 DEG C to 95 DEG C, carrying out a reaction for 0.5 to 1.5 hours while carrying outheat preservation, and then, cooling the temperature of the reacted substance to 35 DEG C to 45 DEG C; (3) adjusting a pH value of the mixture obtained in the step (2), adding formaldehyde and melamine, then, heating the temperature of the mixture to 85 DEG C to 95 DEG C, and carrying out a reaction for 0.5 to 1 hour while carrying out heat preservation; (4) adjusting a pH value of the mixture obtained in the step (3), and carrying out a reaction until the viscosity of the mixture is 20s to 60s; and (5) adjusting a pH value of the mixture obtained in the step (4), adding the urea, cooling thetemperature of the mixture to 80 DEG C to 85 DEG C, carrying out a reaction for 0.5 to 1 hour while carrying out heat preservation, and then, carrying out cooling and discharging. The adhesive prepared by the method is excellent in adhesion and water resistance, can meet the requirements of wood, bamboo and straws on bonding and can be applied to the production and manufacturing of veneers, shaving boards, fiber boards, lumber core plywood and furniture.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

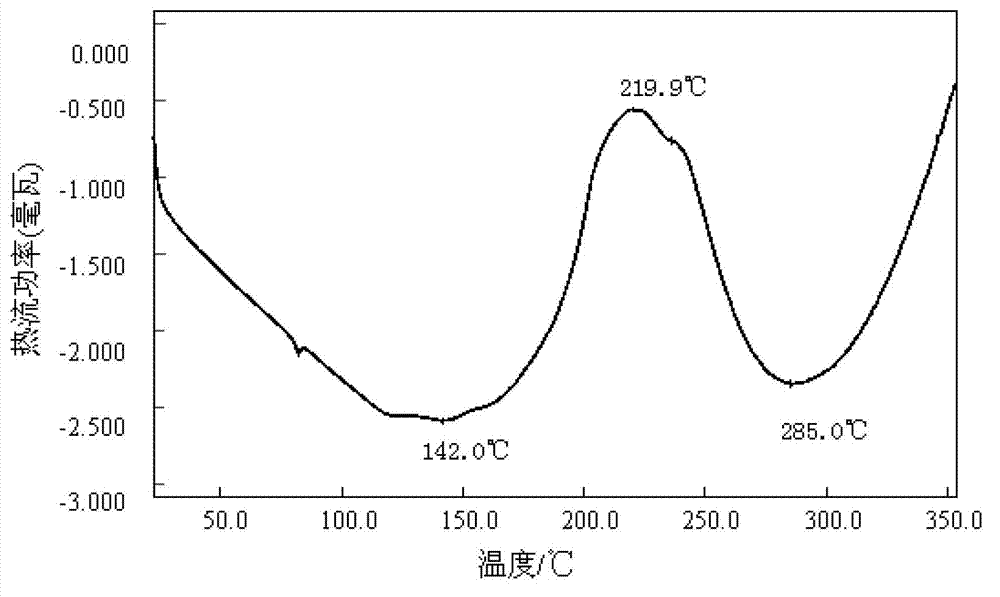

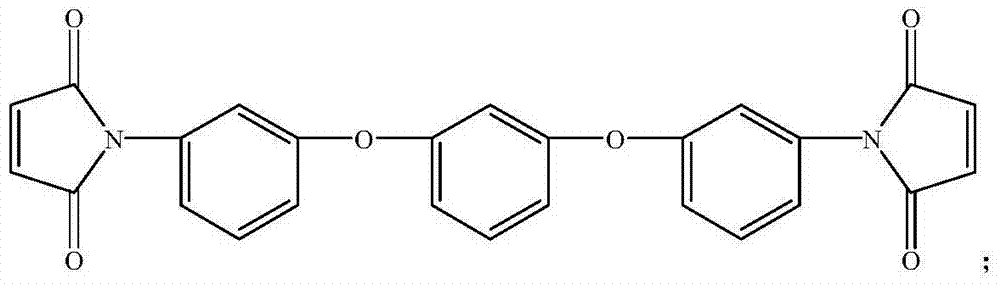

High-tenacity bismaleimide resin carrier structure adhesive film and preparation method thereof

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

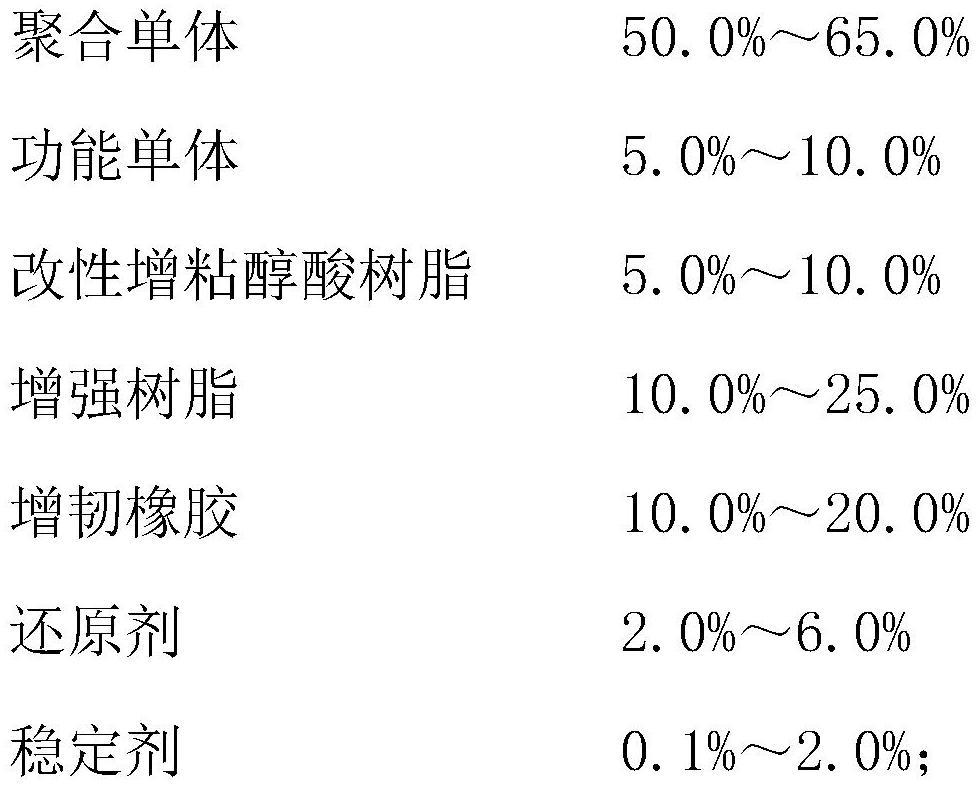

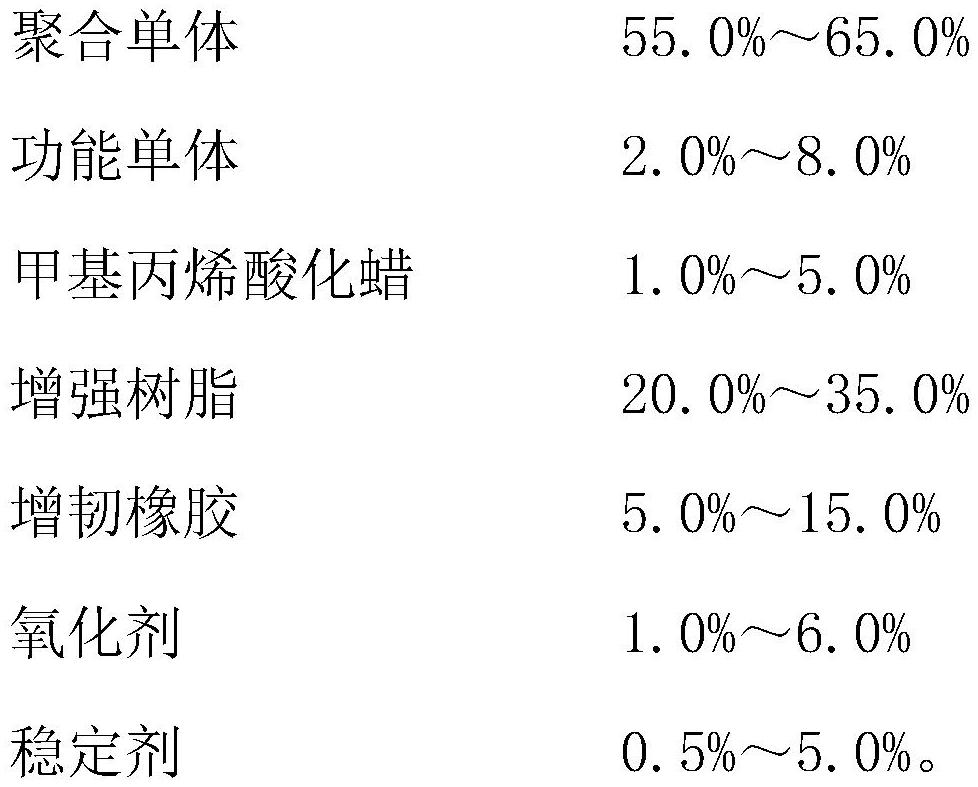

Hybrid acrylate AB glue and preparation method thereof

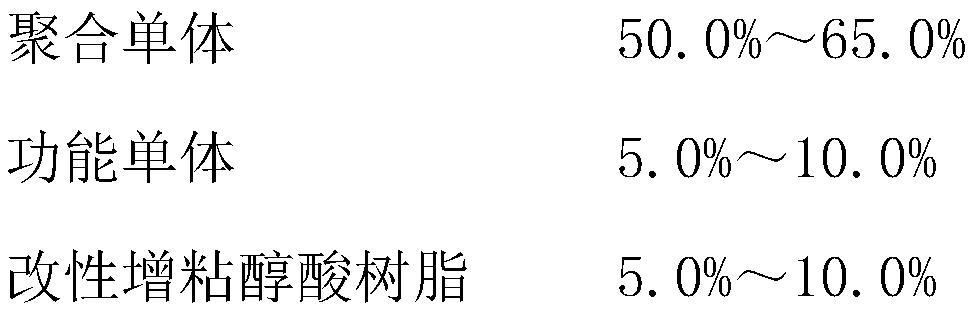

ActiveCN114634779AIncrease polaritySmall smellWax adhesivesConjugated diene hydrocarbon adhesivesPolymer scienceFunctional monomer

The invention discloses a hybrid acrylate AB adhesive which comprises the following components in percentage by mass: a component A: 50.0%-65.0% of a polymeric monomer, 5.0%-10.0% of a functional monomer, 5.0%-10.0% of modified tackified alkyd resin, 10.0%-25.0% of reinforced resin, 10.0%-20.0% of toughened rubber, 2.0%-6.0% of a reducing agent and 0.1%-2.0% of a stabilizer; and the component B comprises the following components in percentage by weight: 55.0%-65.0% of a polymeric monomer, 2.0%-8.0% of a functional monomer, 1.0%-5.0% of methacrylic acid wax, 20.0%-35.0% of reinforced resin, 5.0%-15.0% of toughened rubber, 1.0%-6.0% of an oxidant and 0.5%-5.0% of a stabilizer. The invention also discloses a preparation method of the hybrid acrylate AB adhesive. Through compounding of the raw materials, the prepared hybrid acrylate AB glue has excellent adhesion to engineering plastics such as ABS, ASA and the like, has the characteristics of low odor, good curing debonding property, strong adhesive force, high toughness, fatigue resistance, creep resistance, good heat resistance, good weather resistance and wide range of bonding materials, and can meet the bonding requirements of new energy automobile body materials.

Owner:GLEIHOW NEW MATERIALS CO LTD

A kind of natural environmental protection type modified casein glue and its preparation process

InactiveCN104531059BEasy to processHigh viscosityNon-macromolecular adhesive additivesProtein adhesivesSolubilityMonoglyceride

The invention discloses a natural environment-friendly modified casein glue and a preparation process thereof, aiming to provide a modified preparation using succinic anhydride as a raw material, starch and urea as auxiliary materials, and a trace amount of monoglyceride , calcium chloride, and sodium benzoate are natural environment-friendly modified casein glue prepared as auxiliary agents and a preparation method thereof; the modified preparation succinic anhydride used in the present invention has little side effects and remarkable modification effect, and succinylated casein carboxyl The content is significantly increased, and its solubility and other processing characteristics are significantly improved; acylated casein is used as raw material to prepare adhesives, avoiding the addition of chemical additives, significantly improving the environmental performance of casein adhesives, and satisfying people's health requirements for adhesives. Environmental protection requirements; the prepared casein adhesive has high viscosity and low stringiness, which can meet the industrial requirements for adhesive bonding; the preparation conditions of the modified casein adhesive are mild, the preparation process is simple, and the preparation process is easy to control. Industrialized production and promotion.

Owner:GANSU AGRI UNIV

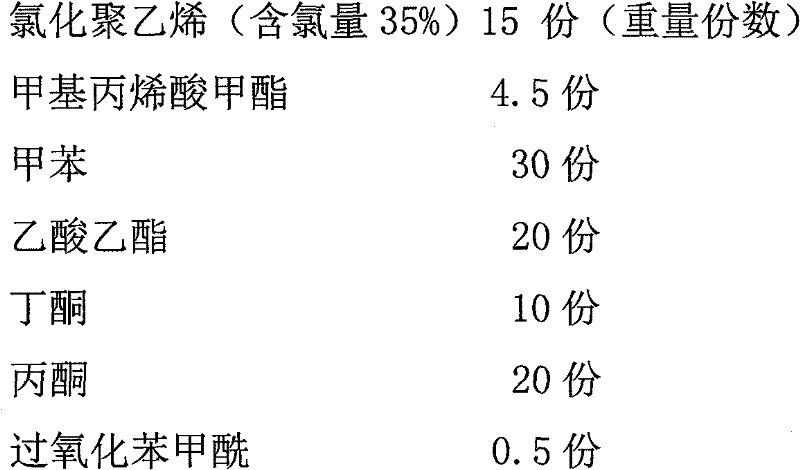

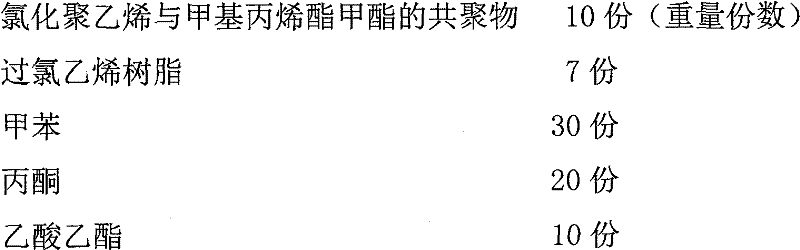

A kind of preparation method of PVC plastic sole surface treatment agent

InactiveCN101503600BMeet the bonding requirementsEasy to handleSolesAdhesive processes with surface pretreatmentCyclohexanoneShoe industry

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com