Medium and high density board box making machine and box making method thereof

A high-density board and box-making machine technology, which is used in container manufacturing machinery, paper/cardboard containers, box-making operations, etc., can solve the problem of difficulty in applying medium and high-density boards to fully automatic box-making requirements, and achieve simple structure and ensure beautiful appearance. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] List specific embodiments below and further illustrate the specific implementation of the present invention in conjunction with accompanying drawing:

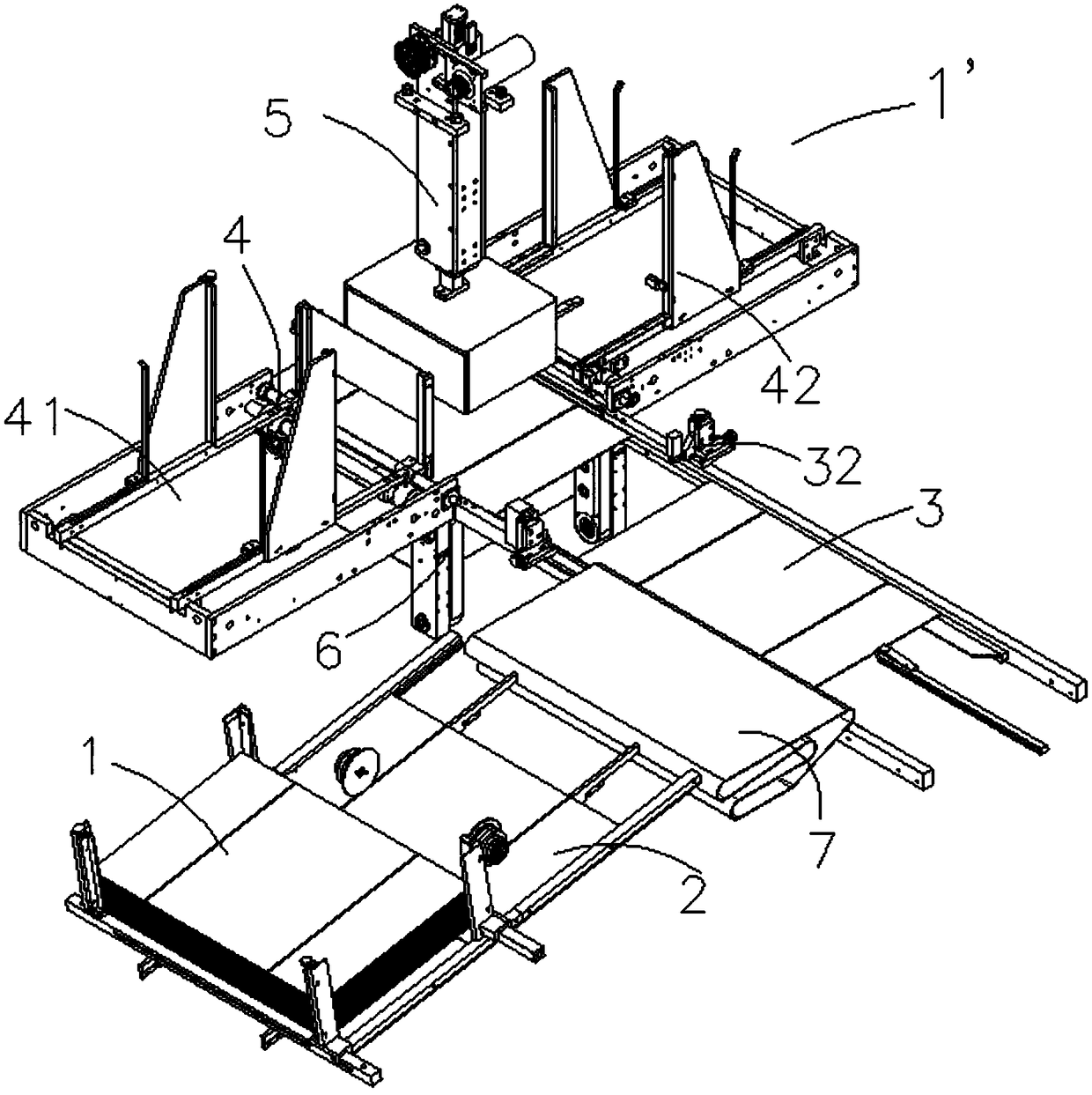

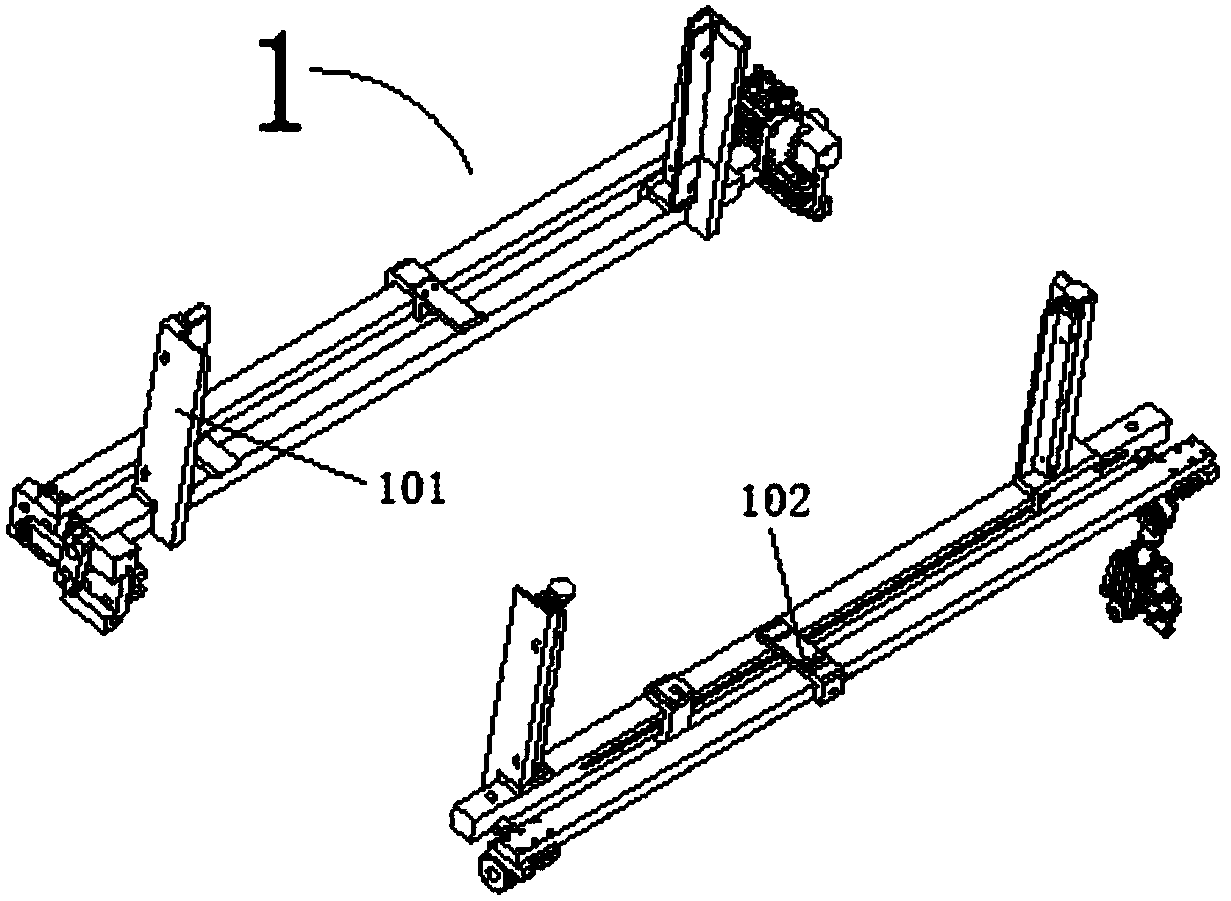

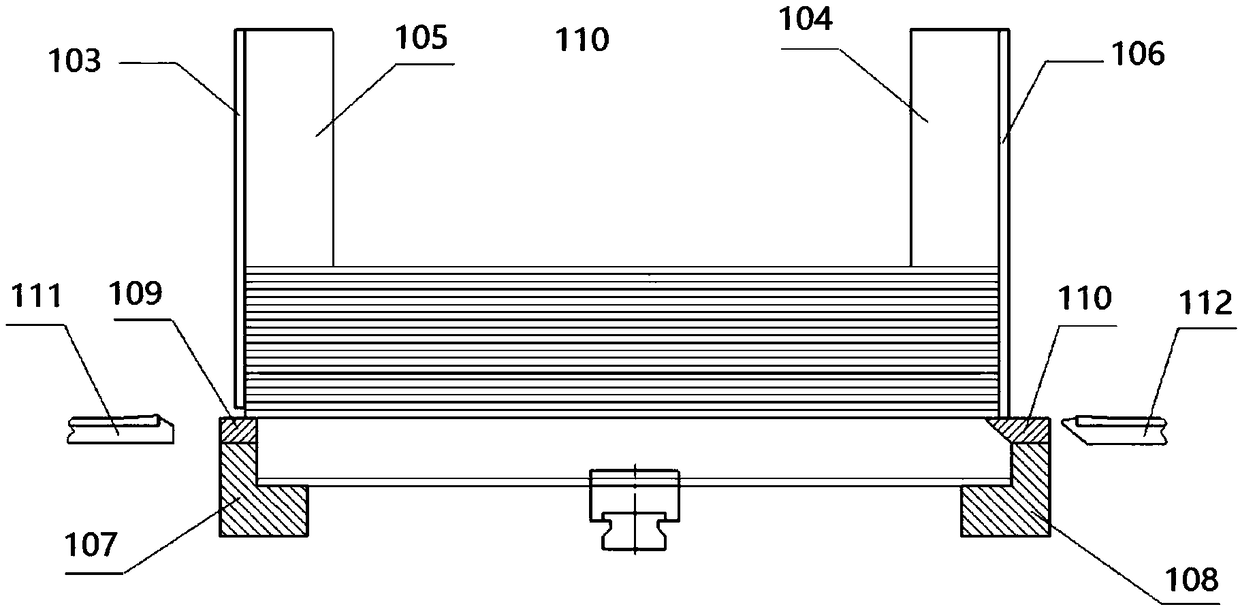

[0104] Such as figure 1 As shown, this embodiment provides a medium and high density board box making machine 1', including a silo discharge module 1, a groove glue module 2, a side glue module 3, a side plate discharge module 4, and a module pressing down module. Module 5 and cavity forming module 6. The output end of the silo discharge module 1 is connected to the input end of the groove lamination module 2, the output end of the groove lamination module 2 is connected to the input end of the side lamination module 3, and the output of the side lamination module 3 terminal is connected to the input end of the module pressing down module 5, and the side panel discharge module 4 comprises a left panel discharge module 41 and a right panel discharge module 42, a left panel discharge module 41 and a right panel discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com